Output control method for welding power source

A welding power source and output control technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problem of unstable state of the first arc 31

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

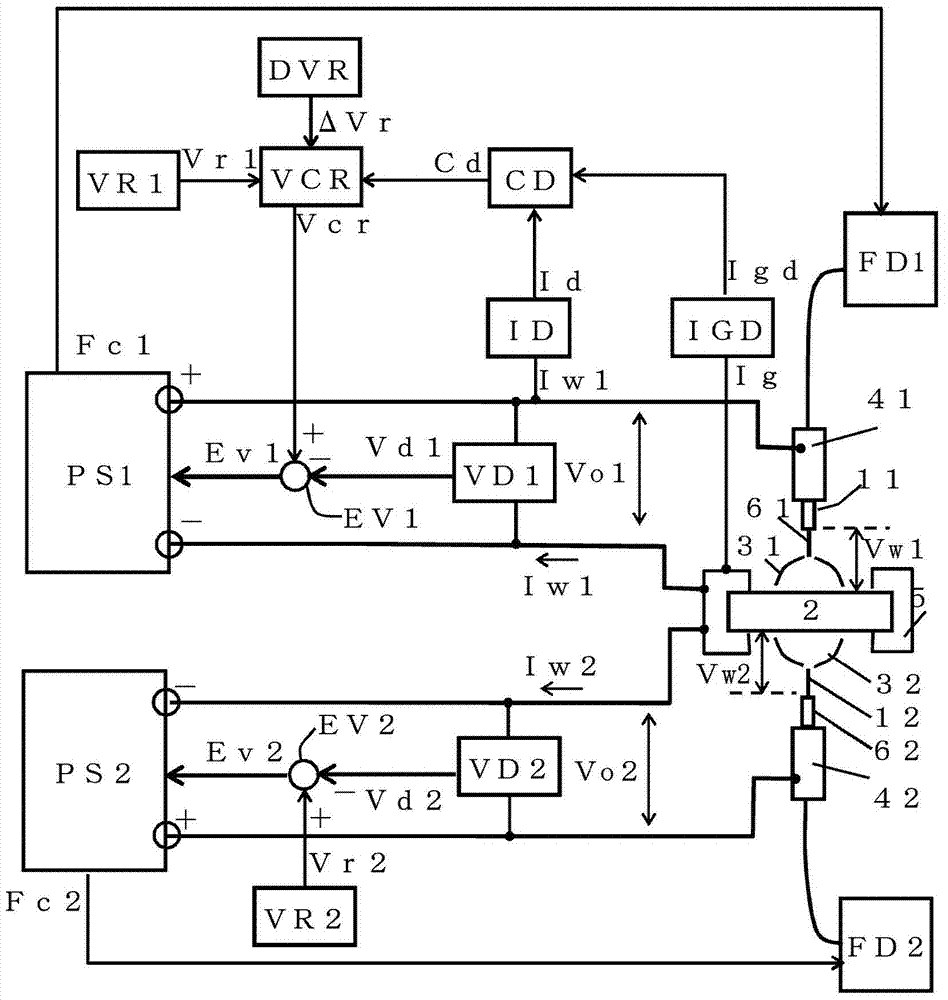

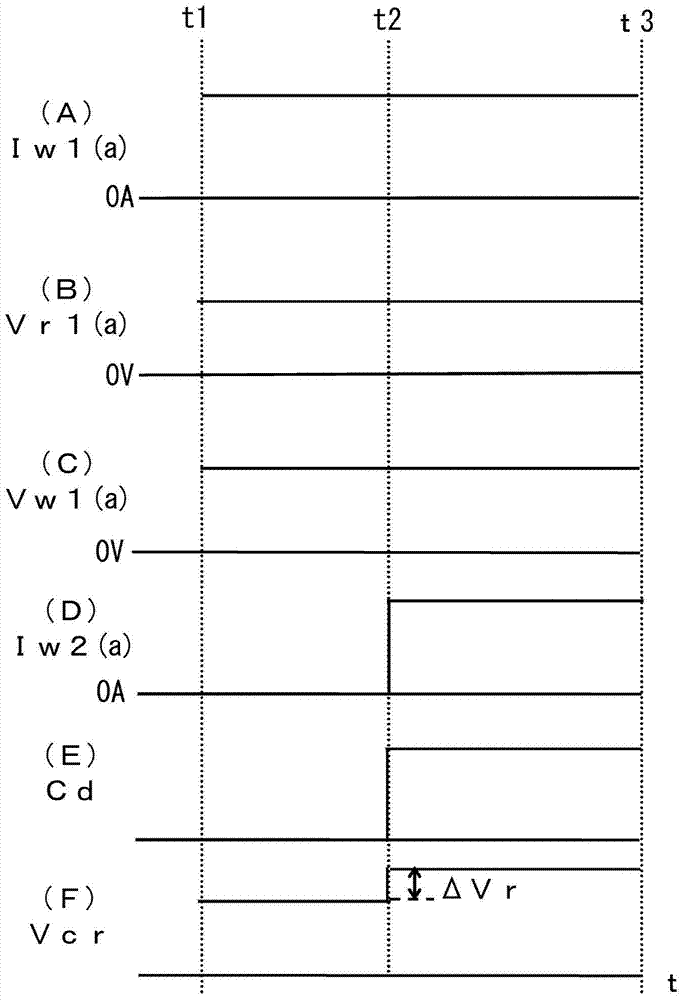

[0040] figure 1 It is a configuration diagram of a welding apparatus for simultaneously welding two welding locations of one workpiece using two welding power sources according to Embodiment 1 of the present invention. figure 1 with the above Figure 5 Correspondingly, the same symbols are assigned to the same components, and these descriptions are not repeated. exist figure 1 Among them, in order to simplify description, the invention of Embodiment 1 is implemented only about 1st welding power source PS1. Therefore, the 2nd welding power source PS2 is the same welding power source as the prior art. figure 1 exist Figure 5 A total welding current detection circuit IGD, a welding current detection circuit ID, a current energization discrimination circuit CD, a voltage increase value setting circuit DVR, and a voltage control setting circuit VCR are added. Below, refer to figure 1 , to illustrate these constituents.

[0041] The total welding current detection circuit...

Embodiment approach 2

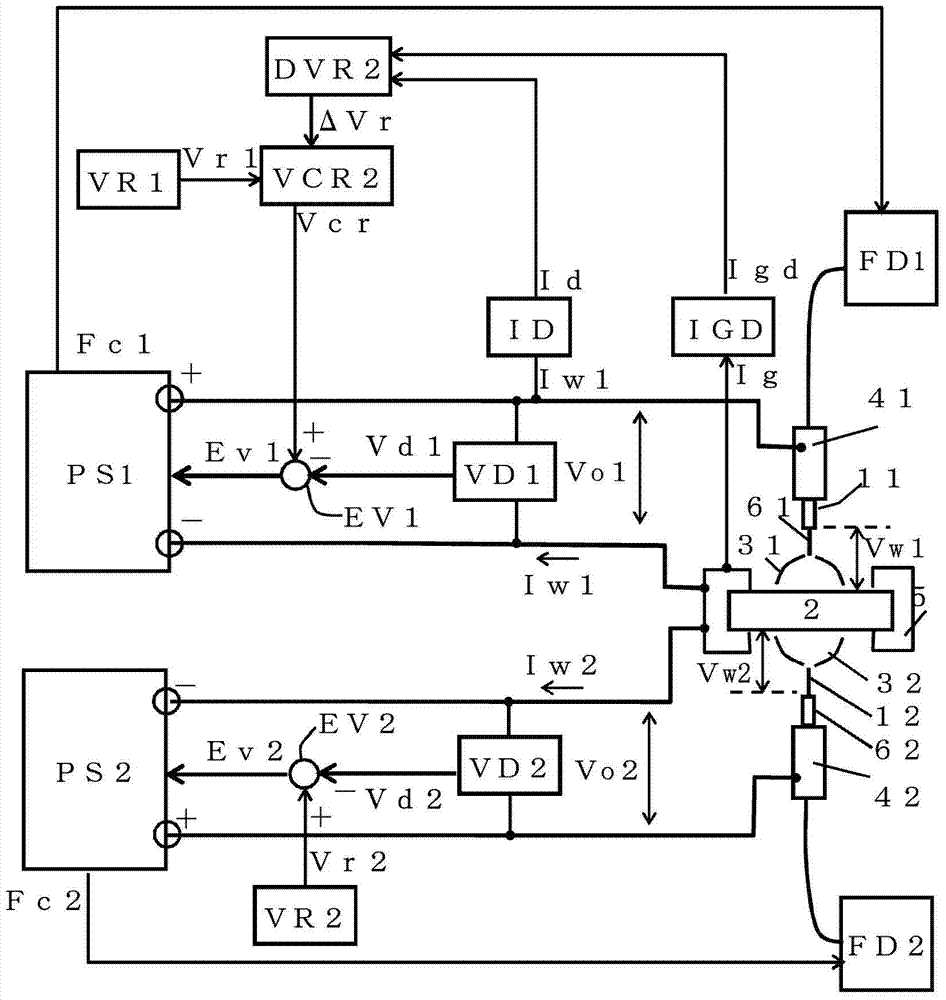

[0060] In the invention of Embodiment 1 described above, the voltage increase value is set in advance. On the other hand, in the invention of Embodiment 2, the voltage increase value is automatically set every time during welding to a value obtained by multiplying the average value of the total value of welding current energized from other welding power sources by the common resistance value. .

[0061] image 3 It is a configuration diagram of a welding apparatus for simultaneously welding two welding locations of one workpiece using two welding power sources according to Embodiment 2 of the present invention. image 3 with the above figure 1 Correspondingly, the same symbols are attached to the same components, and their descriptions are not repeated. exist image 3 Among them, in order to simplify description, the invention of Embodiment 2 is implemented only with respect to 1st welding power supply PS1. Therefore, the 2nd welding power source PS2 is the same welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com