Patents

Literature

38results about How to "Degree of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

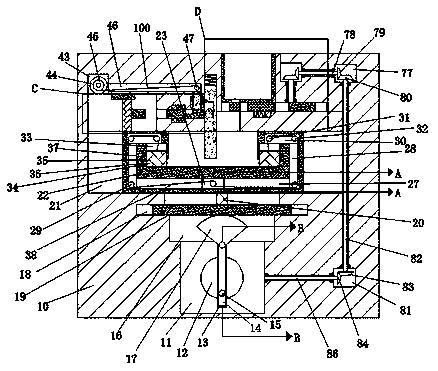

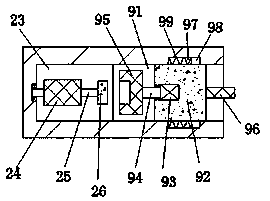

Environment multivariable control breeding test chamber

PendingCN107410048AEasy to operateEasy to controlAnimal housingOther apparatusGreenhouse gasDomestic animal

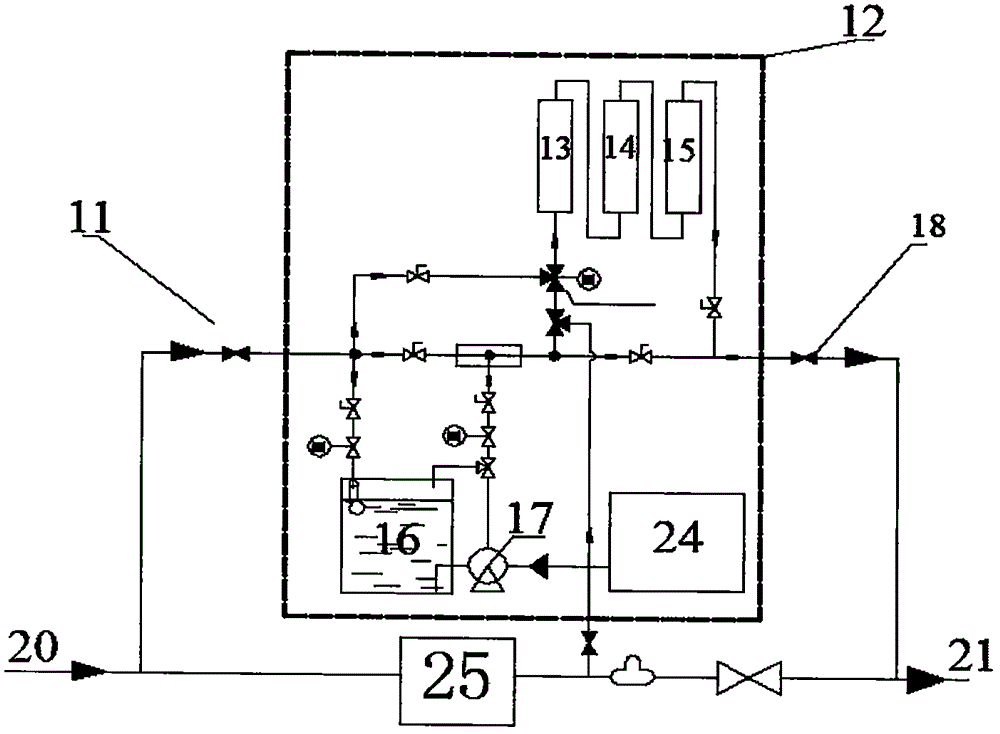

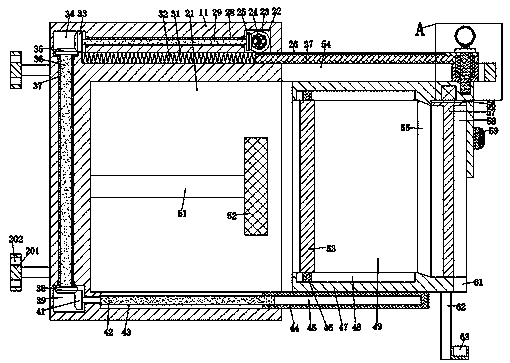

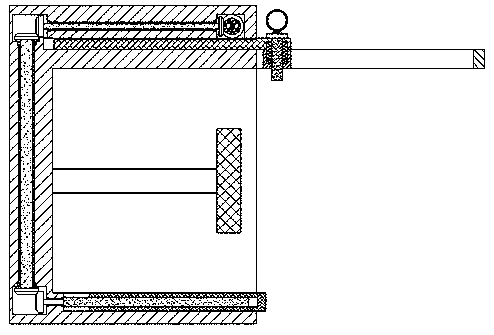

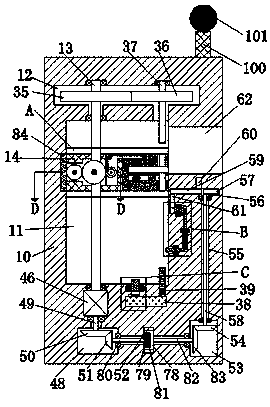

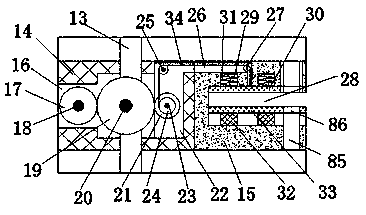

The invention discloses an environment multivariable control breeding test chamber. The test chamber comprises a breeding box body and an air circulating pipeline system; the interior of the breeding box body is provided with an LED light board, a breeding box gas detection module group, and a breeding box differential pressure transducer; and the air circulating pipeline system comprises an air premixing box, a refrigeration compressor, breeding box exhaust fans, a breeding box wind outlet gas detection module group, a breeding box wind outlet valve, a vent valve, a premixing box new wind inlet valve, premixing box exhaust fans, and a breeding box wind inlet gas detection module group. The test chamber can realize automatic and accurate control of a breeding microenvironment, monitors and controls warm, humidity, harmful gases, greenhouse gases and motes in the test chamber in real time, is suitable for breeding tests of livestock for a long period, and provides accurate and effective guidance for intensive livestock breeding.

Owner:HUAZHONG AGRI UNIV

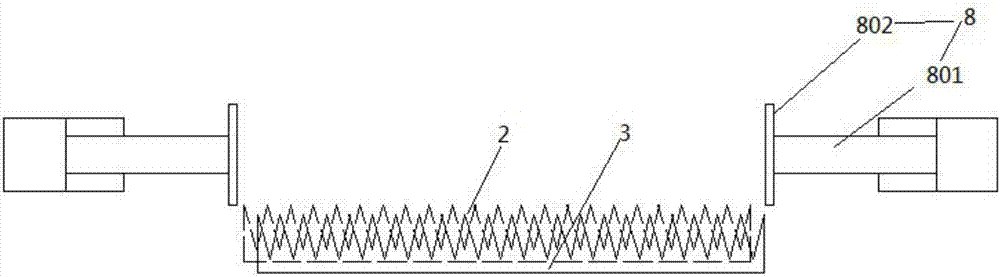

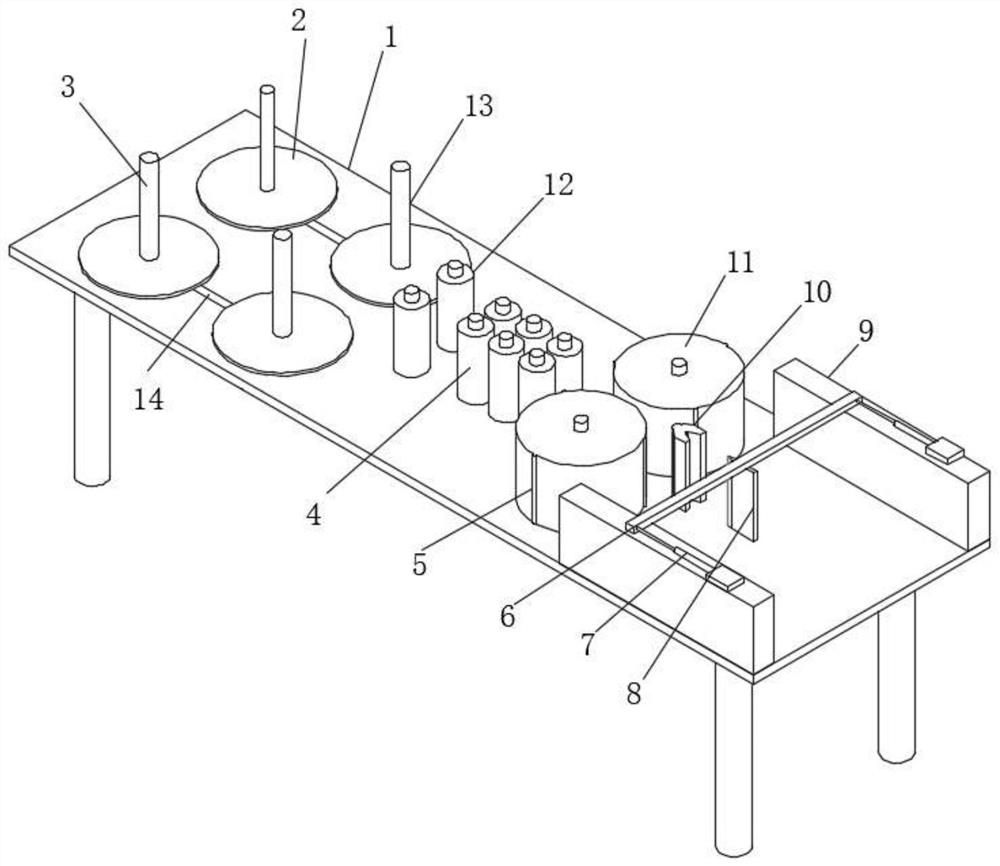

Novel degradable fiber straw and manufacturing method thereof

ActiveCN111231040ASimple processing technologyDegree of automationBio-packagingWood compressionFiberSingle plate

The invention relates to a novel degradable fiber straw and a manufacturing method thereof. The method includes the steps of processing single plates, bending the single plates into half-cylinders, coating edges with glue, gluing together the edges, and performing cutting and post processing of the straw. The single plates pass through two large and small matched round rollers, a half-cylinder protruding body on the small roller presses the single plates into parallel concave die cavities in the large roller, glue is applied to the portions, reserved outside the die cavities, of the single plates, the two concave die cavities in the large roller correspond to the edges correspondingly, the glue applying part on the surface of the roller performs pressing and gluing, the edges of the singleplates are cut in the direction parallel to the central line of the straw, and the edges are ground, sterilized again and packaged, so that the novel fiber straw is obtained, and in this way, the straw can be continuously and automatically produced. The novel degradable fiber straw has the advantages that the bamboo and wood single plates are used for preparing the novel fiber straw different from paper and plastic straws after being processed, the processing process is simple, the automation degree is high, cost is low, the straw is naturally degraded after being used and can also be used asfuel for combustion, and the straw has no influences on the environment and embodies the sustainable circular economy.

Owner:NANJING FORESTRY UNIV

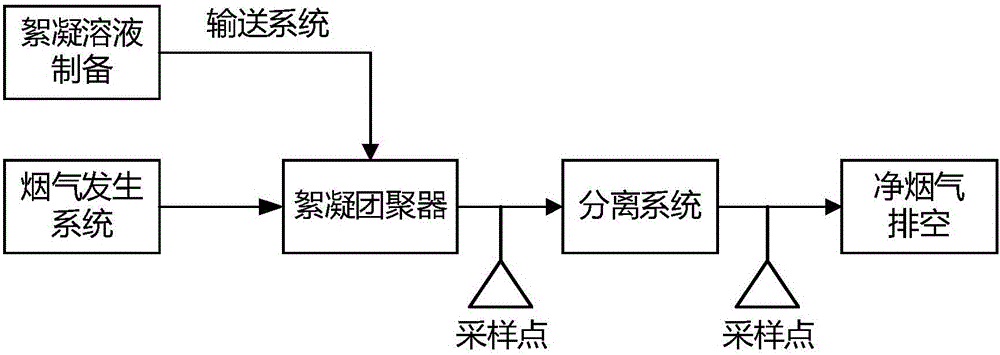

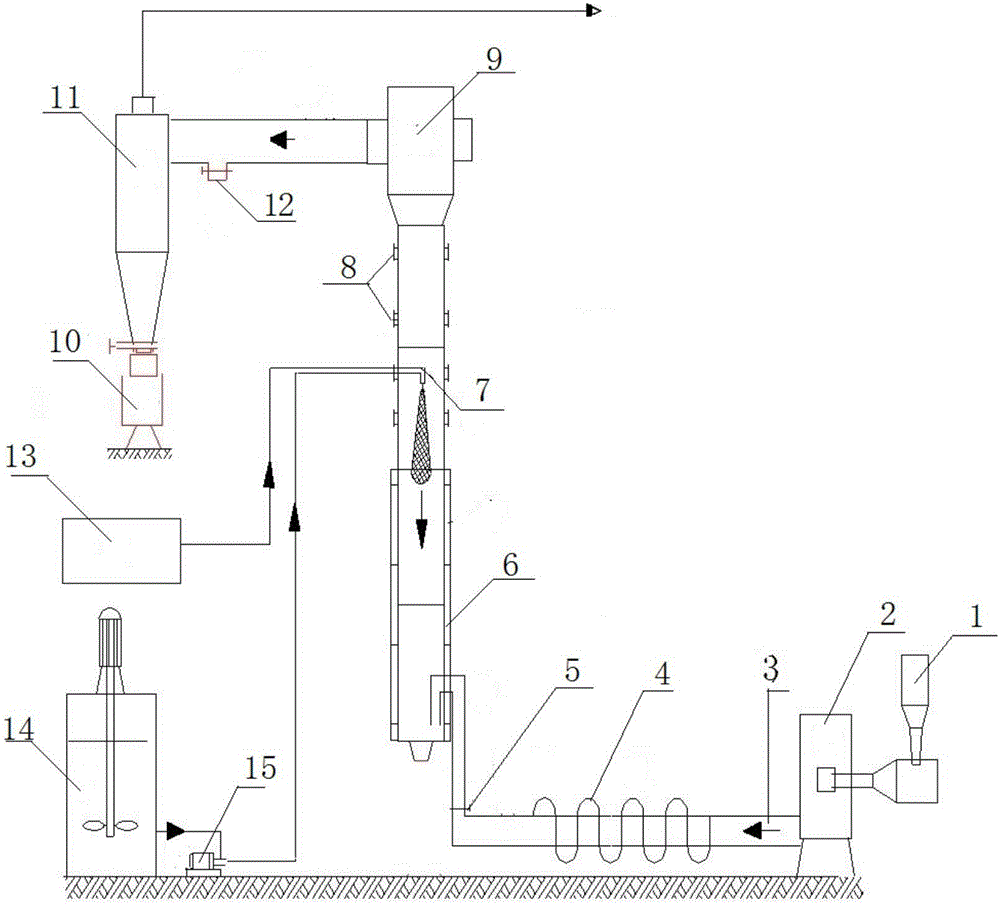

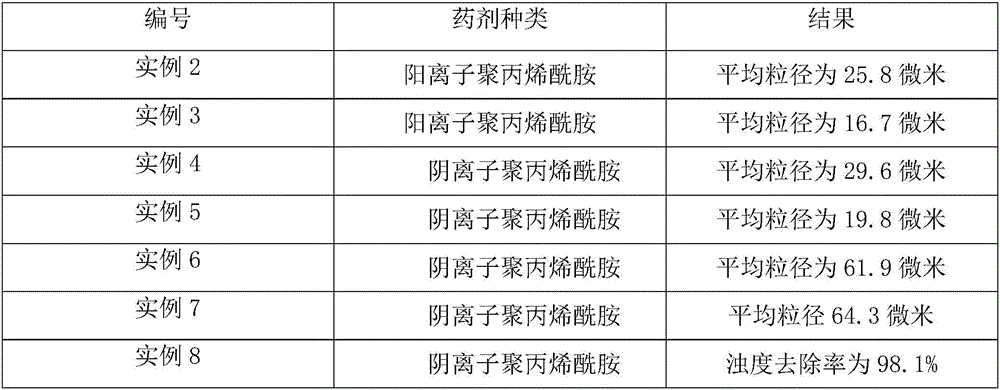

System for removing fine particulate matters in gas-phase mixture

The invention relates to a system for removing fine particulate matters in gas-phase mixture. The system comprises a flue gas generation system, a flocculation reunion device, a flue gas particulate separation system and a flocculation solution preparation and delivery system. The flue gas generation system is connected with the flocculation reunion device, the flocculation solution preparation and delivery system and the flue gas particulate separation system are connected with the flocculation reunion device, and the flue gas particulate separation system is further connected with an emptying pipeline. Chemical substances are added into the gas-phase mixture through the flocculation solution preparation and delivery system to enable the fine particulate matters to gather in the flocculation reunion device, particle size or mass of the fine particulate matters is increased, and then the fine particulate matters after flocculation are removed through the flue gas particulate separation system. The system has the advantages that the fine particulate matters are treated by means of the chemical agglomeration principle to enable the size or mass of the fine particulate matters to be increased, convenience is brought to follow-up conventional dust removal equipment for removal, and the system is simple in process flow, high in efficiency, low in cost and easy for wide popularization.

Owner:GUODIAN NEW ENERGY TECH INST

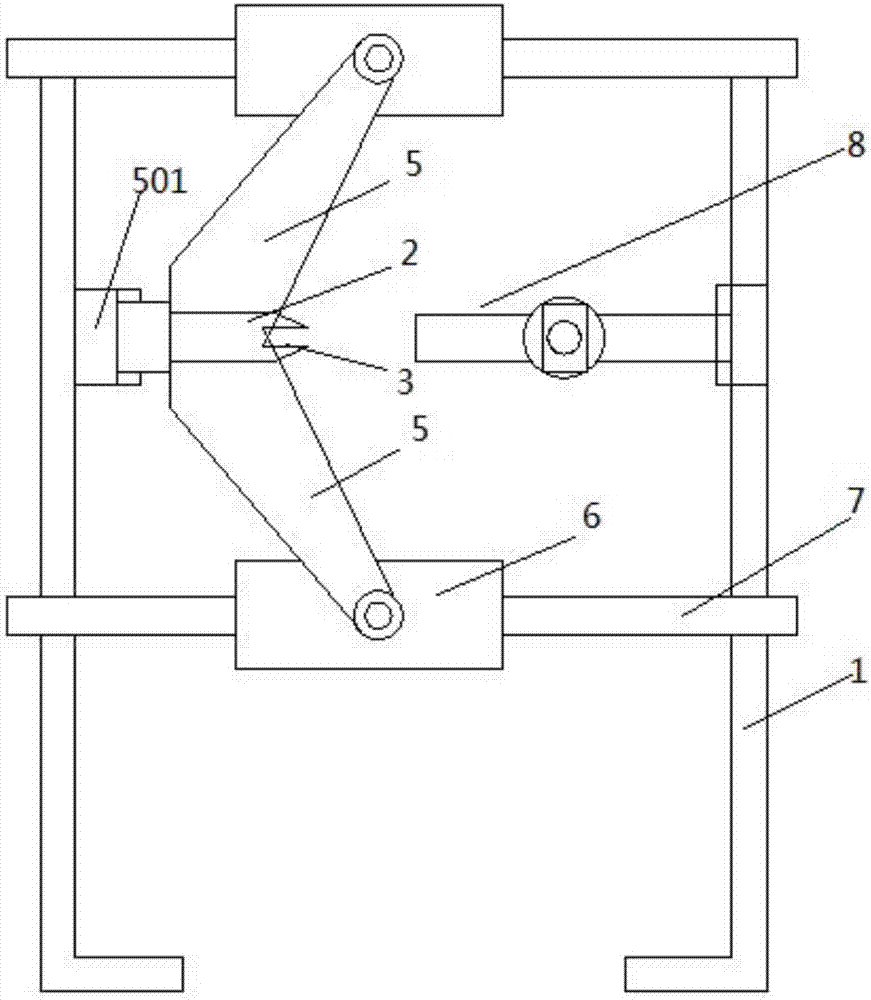

Welding equipment for improving efficiency

InactiveCN108311773ADegree of automationEasy to useShielding gas supply/evacuation devicesWelding/cutting auxillary devicesPneumatic pressureAutomation

The invention discloses welding equipment for improving the efficiency. The welding equipment comprises a bottom plate, motor storehouses, a mounting storehouse, a mounting shell and an air box. A first mounting plate is mounted at one end of the upper portion of the bottom plate. A second mounting plate is mounted at the other end of the upper portion of the bottom plate. The motor storehouses are arranged on the lower portions of the outer sides of the first mounting plate and the second mounting plate correspondingly. Rotating motors are mounted in the motor storehouses correspondingly. Rotating shafts are mounted at the output ends of the rotating motors. U-shaped clamping plates are mounted at the ends, away from the rotating motors, of the rotating shafts. According to the welding equipment, an iron plate can be clamped through the U-shaped clamping plates, welding surfaces are rotated and adjusted through the rotating motors, and thus welding of the iron plate can be more comprehensive; a welding part of the welding device can move on an electromagnetic sliding rail through a mounting rod, so that an electric welding machine is moved, and the welding position is adjusted; and the welding device can adjust the height of the electric welding machine through an air cylinder, the automation degree is high, and using is convenient.

Owner:钟丽菊

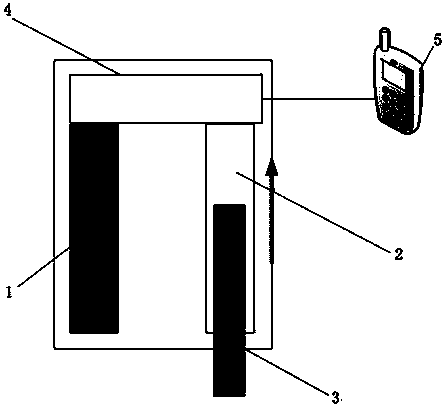

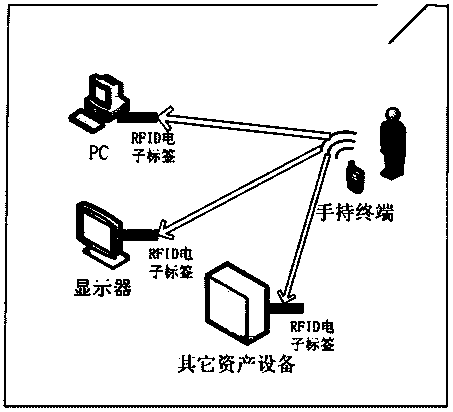

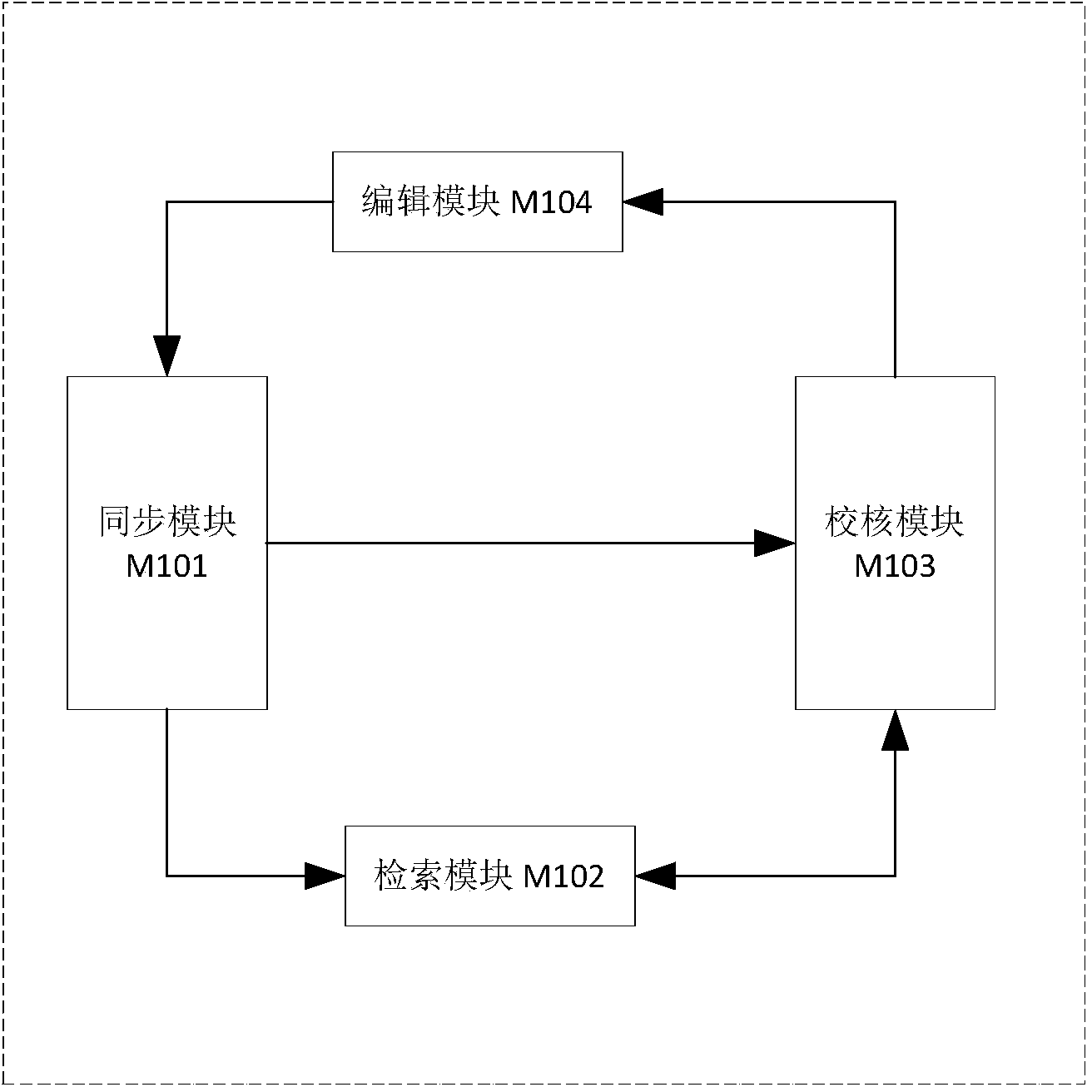

Double-RFID label-controlled power grid information asset management system and implementation method thereof

ActiveCN104166891AStrong randomnessError-proneCo-operative working arrangementsResourcesControl powerPower grid

A double-RFID label-controlled power grid information asset management system and an implementation method thereof. The double-RFID label-controlled power grid information asset management system includes an RFID label device and a handheld information verification terminal, wherein the RFID label device includes two external RFID labels and a label locking device, and the two external RFID labels are an asset information label and a human resource information label. In the implementation method in the invention, control of equipment is performed by adopting double RFID labels, i.e., one of the RFID labels is used for storing equipment asset information, and the other RFID label is used for storing human resource information of users, and in the using process of the users, the RFID label that stores human resource information is inserted in a control device to form binding to the asset information RFID label. Data in the information verification terminal and the bound human resource information RFID label are compared, and control of asset use is performed through a method of turning on or turning off information assets according to comparison results.

Owner:STATE GRID CORP OF CHINA +2

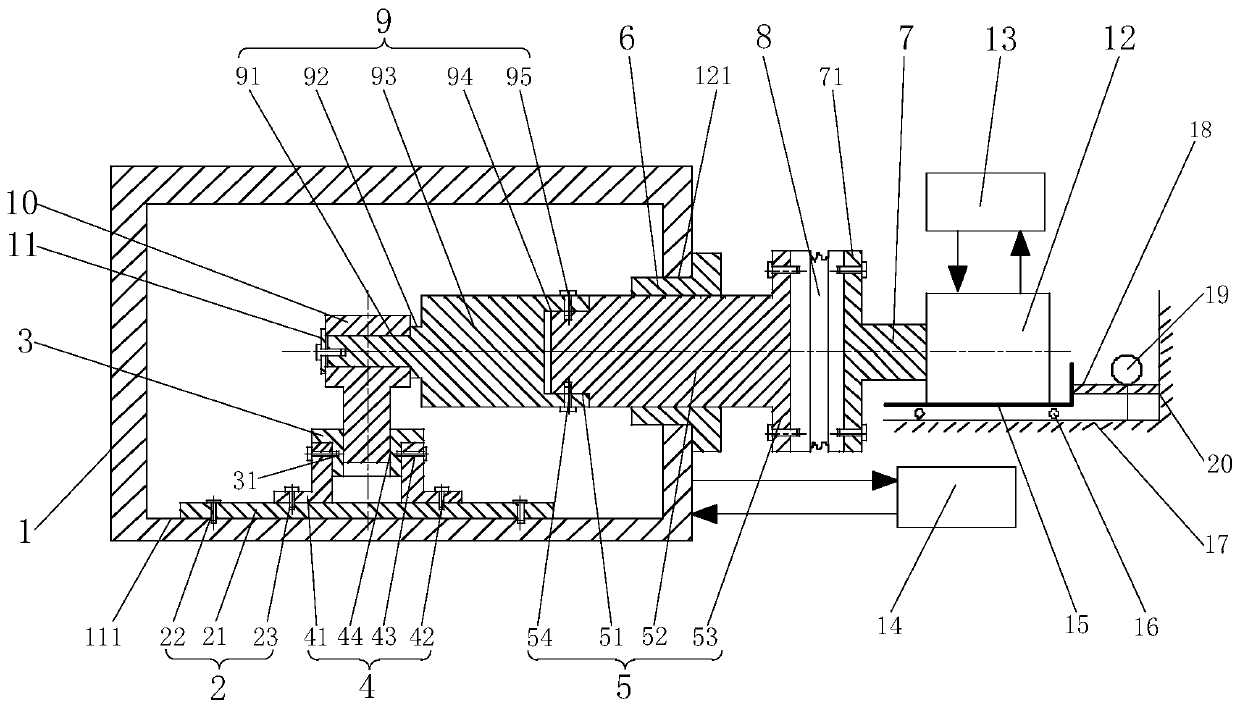

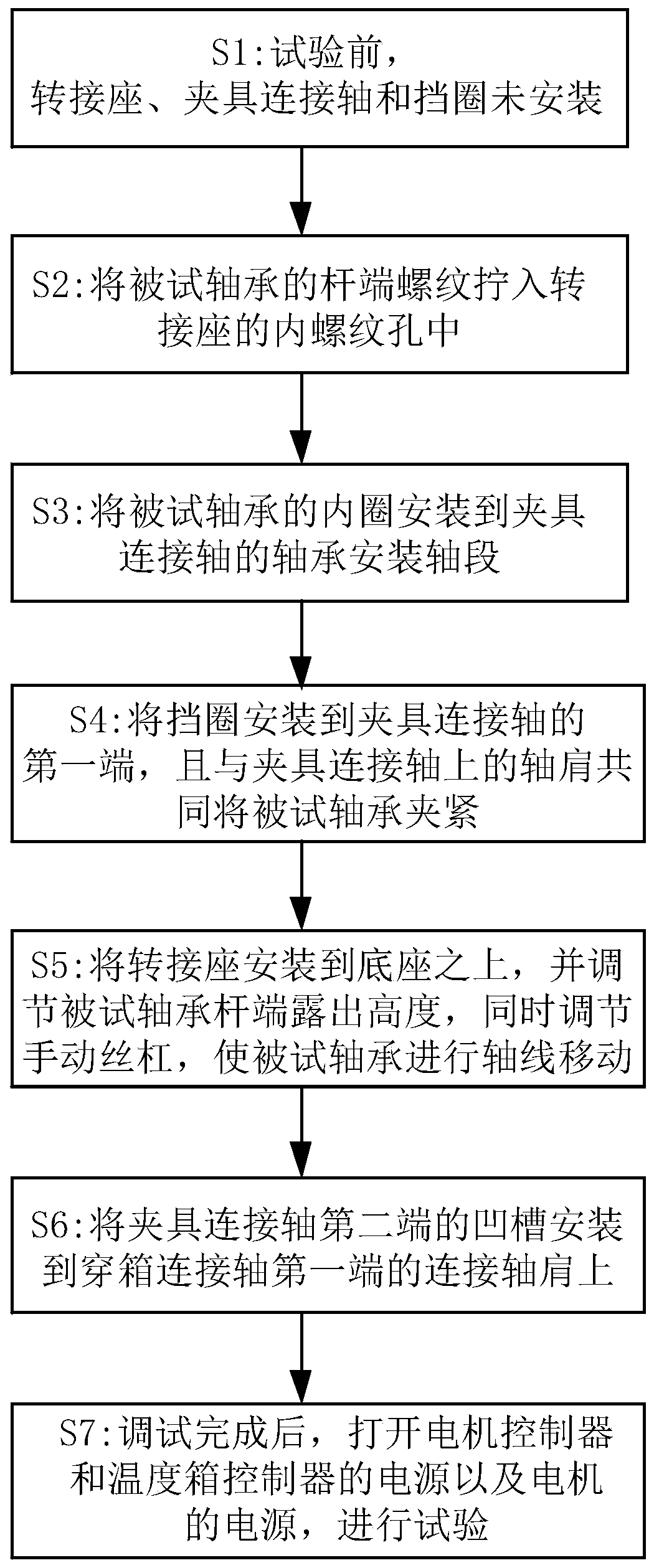

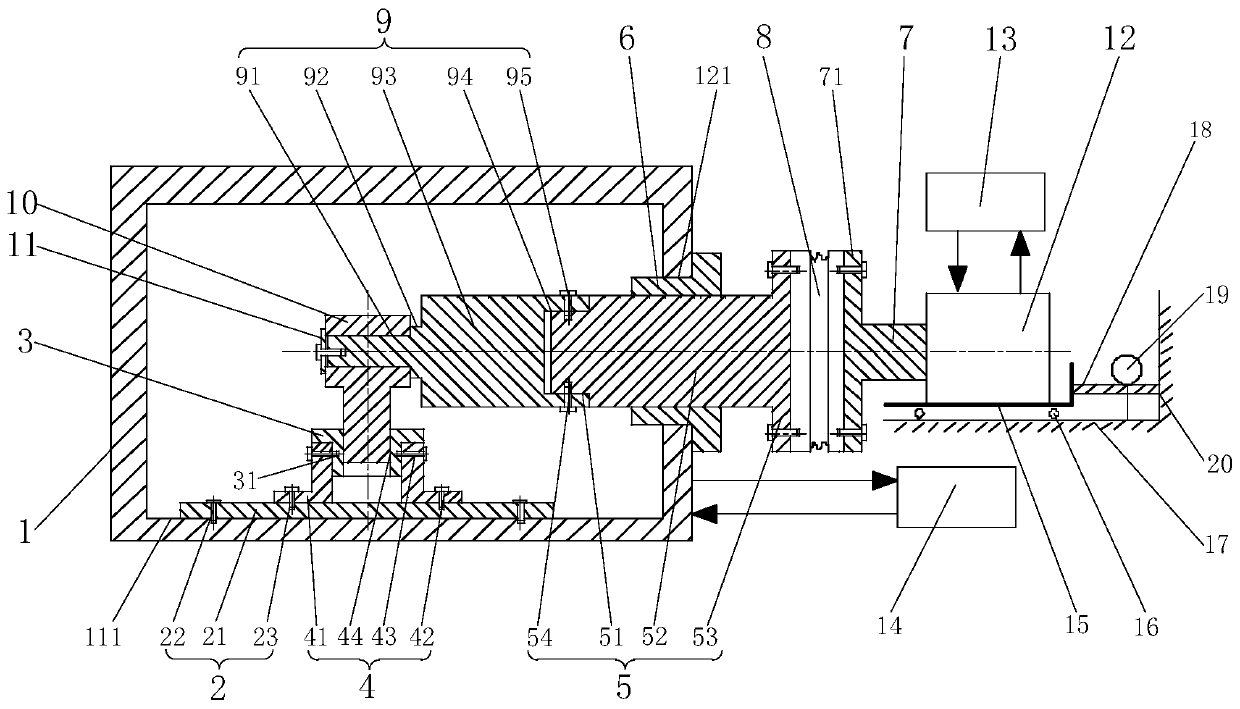

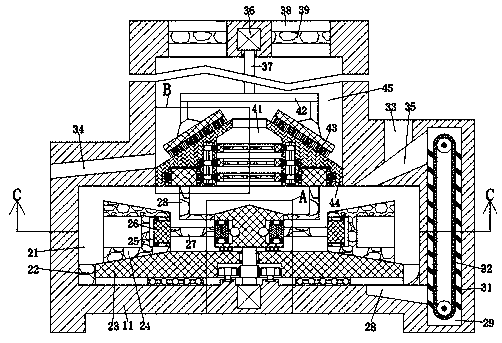

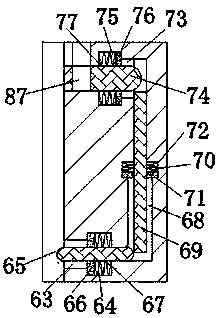

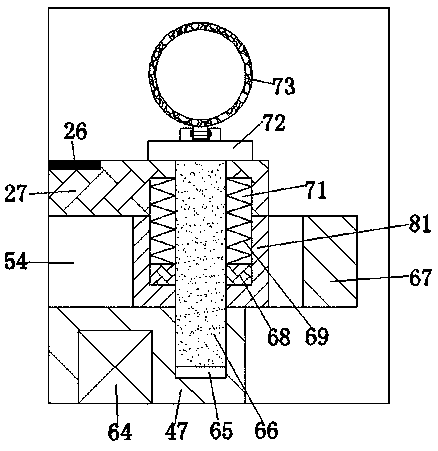

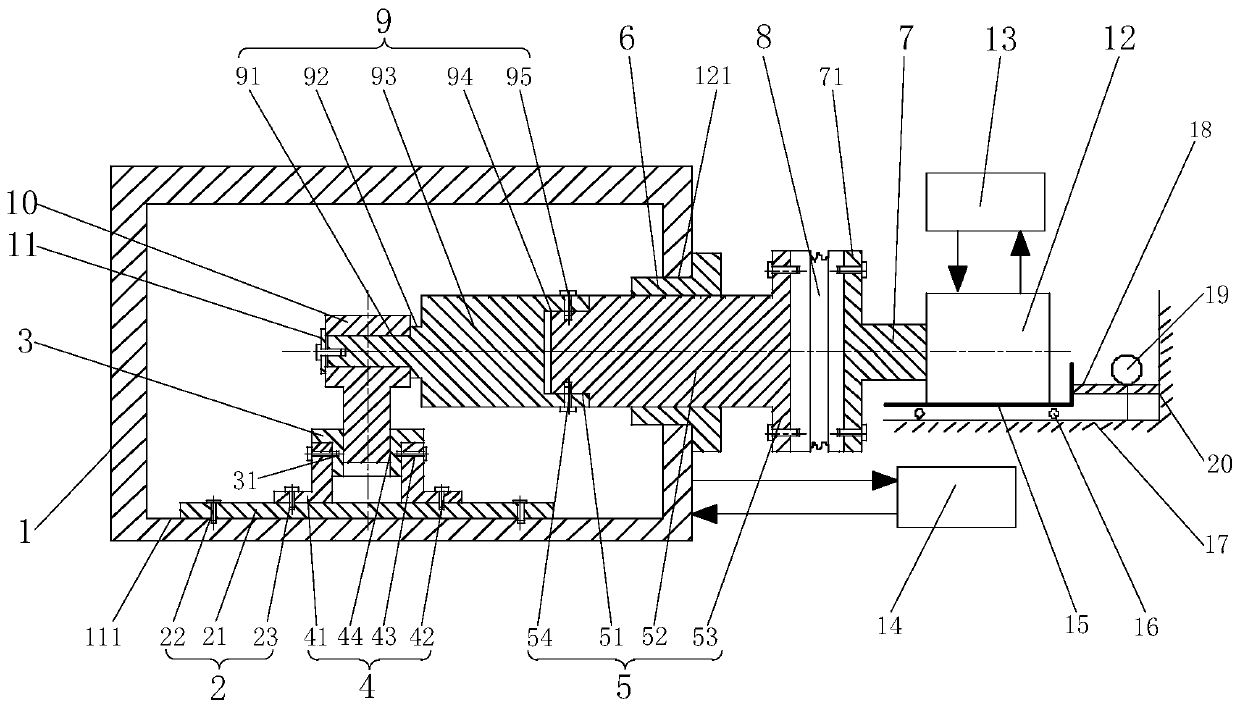

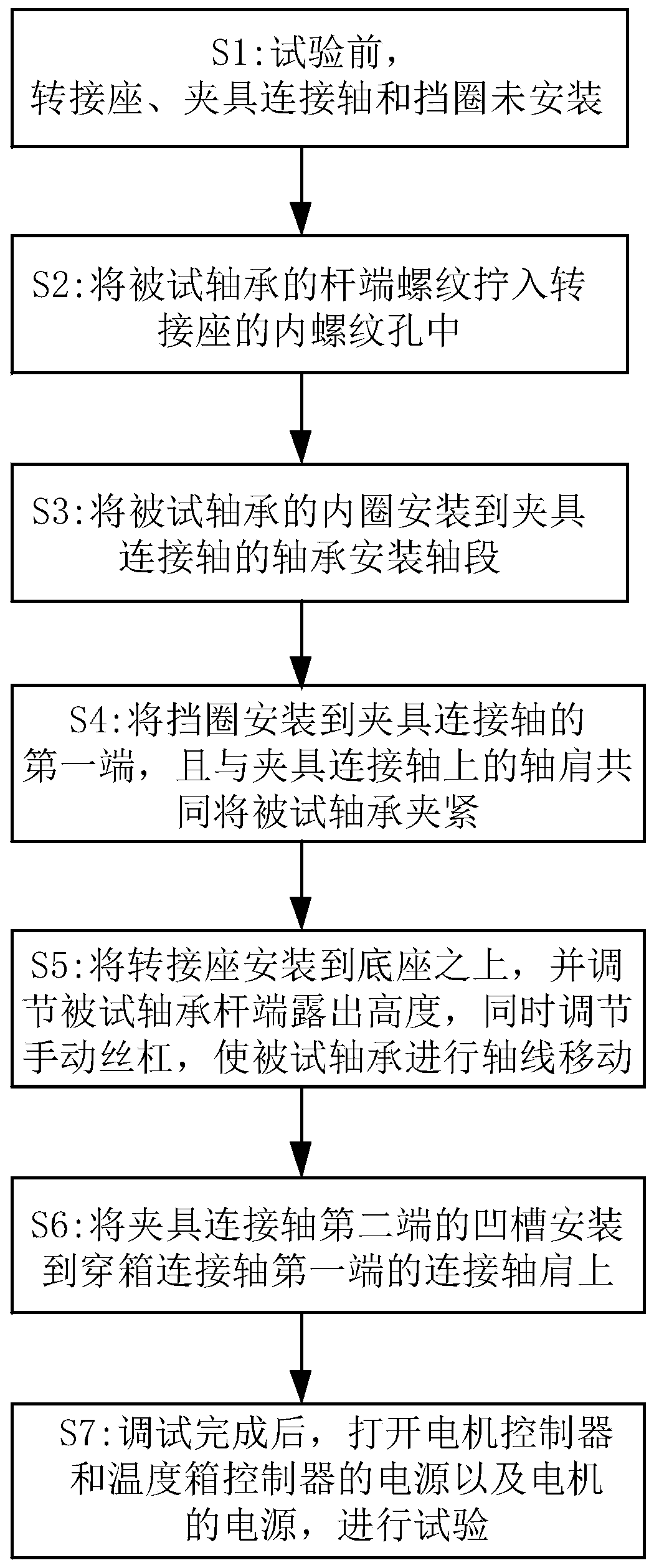

Rod end bearing limit temperature test fixture and test method thereof

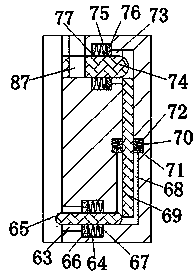

ActiveCN109839273ASave storage spaceImprove general performanceMachine bearings testingCouplingEngineering

The invention relates to a rod end bearing limit temperature test fixture and a test method thereof. The rod end bearing limit temperature test fixture comprises a fixing table, an adapter seat, a base, a box passing connection shaft, a plastic sleeve, a motor shaft, a coupling, a fixture connection shaft and a retaining ring, wherein the adapter seat is mounted on the base; the base is mounted onthe fixing table; during the test, a tested bearing is connected to the inner threaded hole of the adapter seat through the outer thread of the rod end, and the outer diameter of the adapter seat ismatched with the inner hole of the base, a screw passing through the retaining ring is clamped to the fixture connection shaft, and the shaft is driven by the motor to realize the radial rotation of the inner ring of the tested bearing; and the fixture connection shaft is provided with a groove, the box passing connection shaft is provided with a connection shoulder, the box passing connection shaft passes through the temperature test box to be connected with the motor through the coupling, and the box passing connection shaft passes through the temperature test box through the plastic sleeve.The fixture has a simple structure, disassembly is facilitated, the mounting preparation time is shortened, and the device use efficiency is improved.

Owner:CHINA AERO POLYTECH ESTAB

Mineral powder and impurity separation device

The invention discloses a mineral powder and impurity separation device which comprises a main device body and a mineral powder production device arranged in the main device body, wherein the mineralpowder production device comprises a first cavity formed in the main device body, and a first motor is fixedly arranged in the inner wall of the lower side of the first cavity; a first grinding blockis rotatably arranged in the first cavity, and a second cavity with a downward opening is formed in the first grinding block; the upper end of the first motor is connected with a first rotating shaftin a mode of power fit, and the first rotating shaft extends upward through the second cavity and extends out of the end face of the upper side of the first grinding block; and a first gear which canrotate in the second cavity is fixedly connected on the first rotating shaft. The invention aims to design the device which can directly separate the particles of qualified ground mineral powder during ore grinding and further accelerates the processing efficiency.

Owner:杨明华

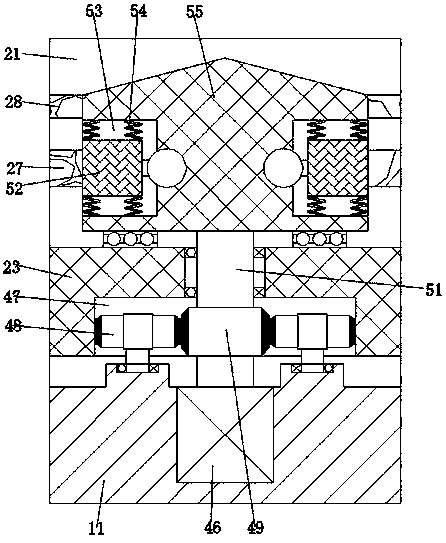

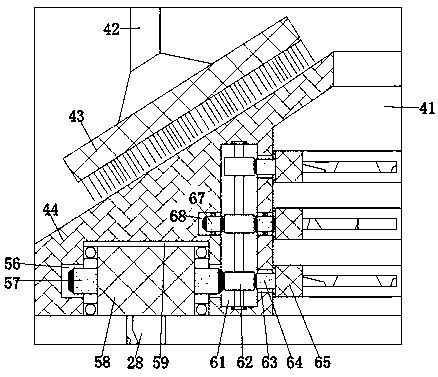

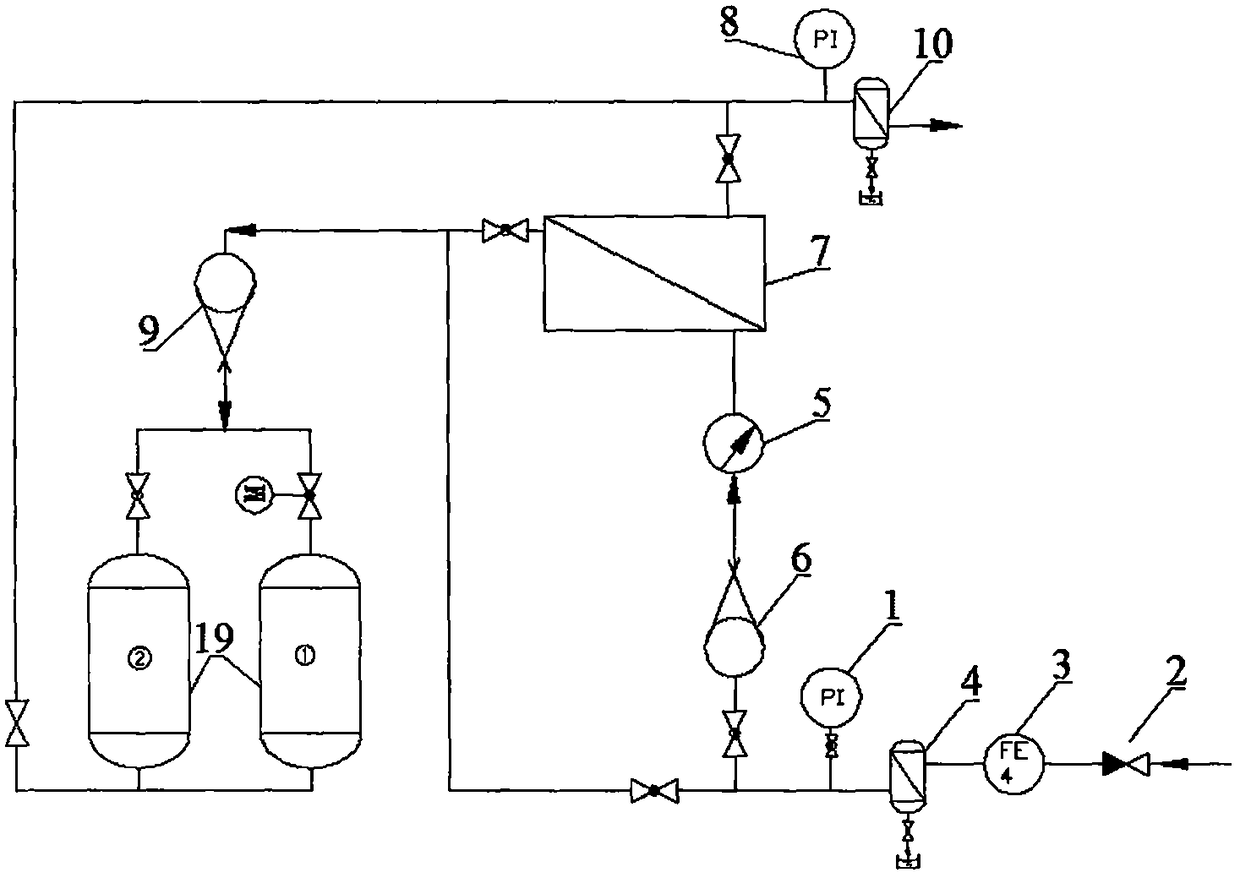

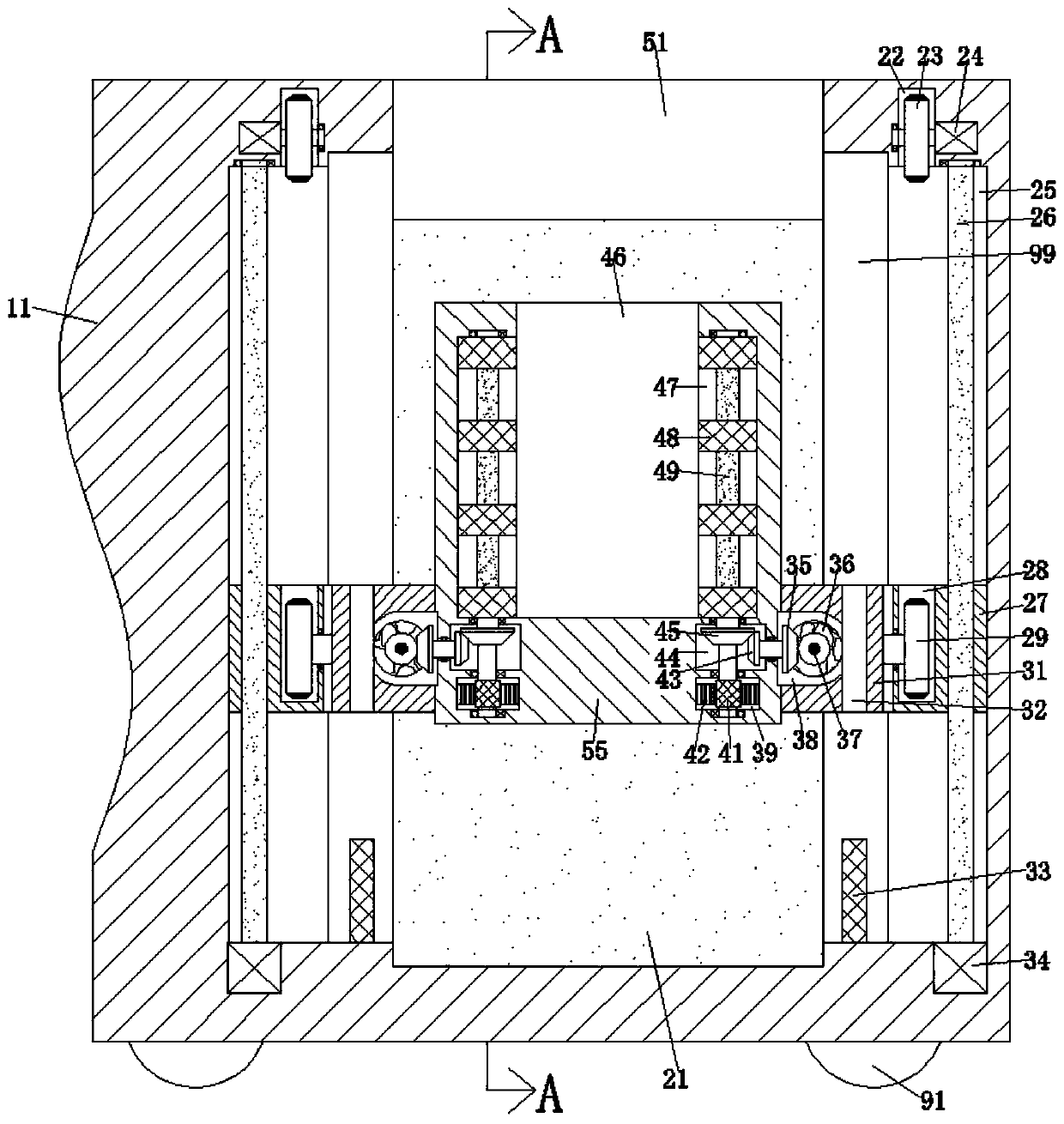

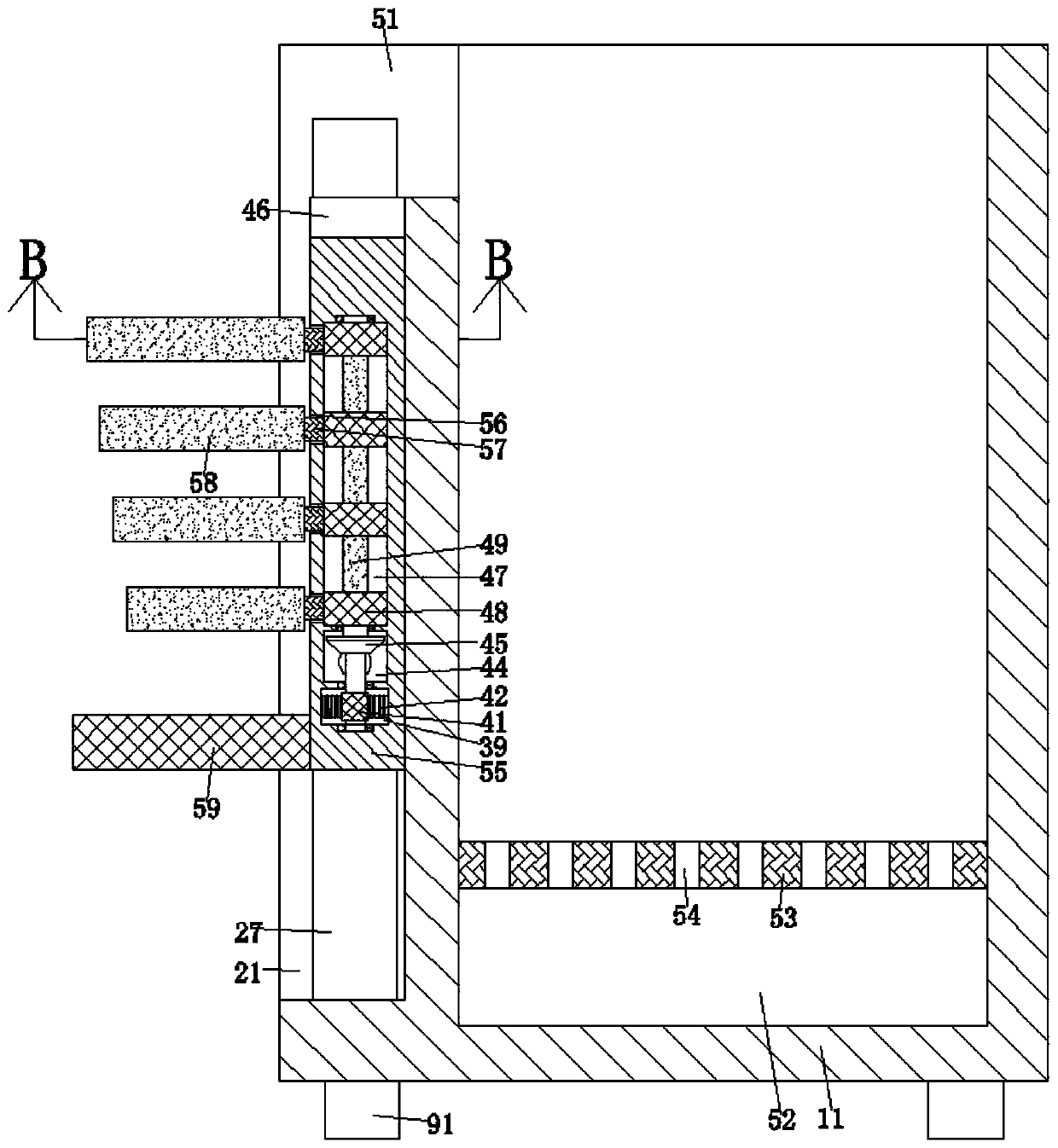

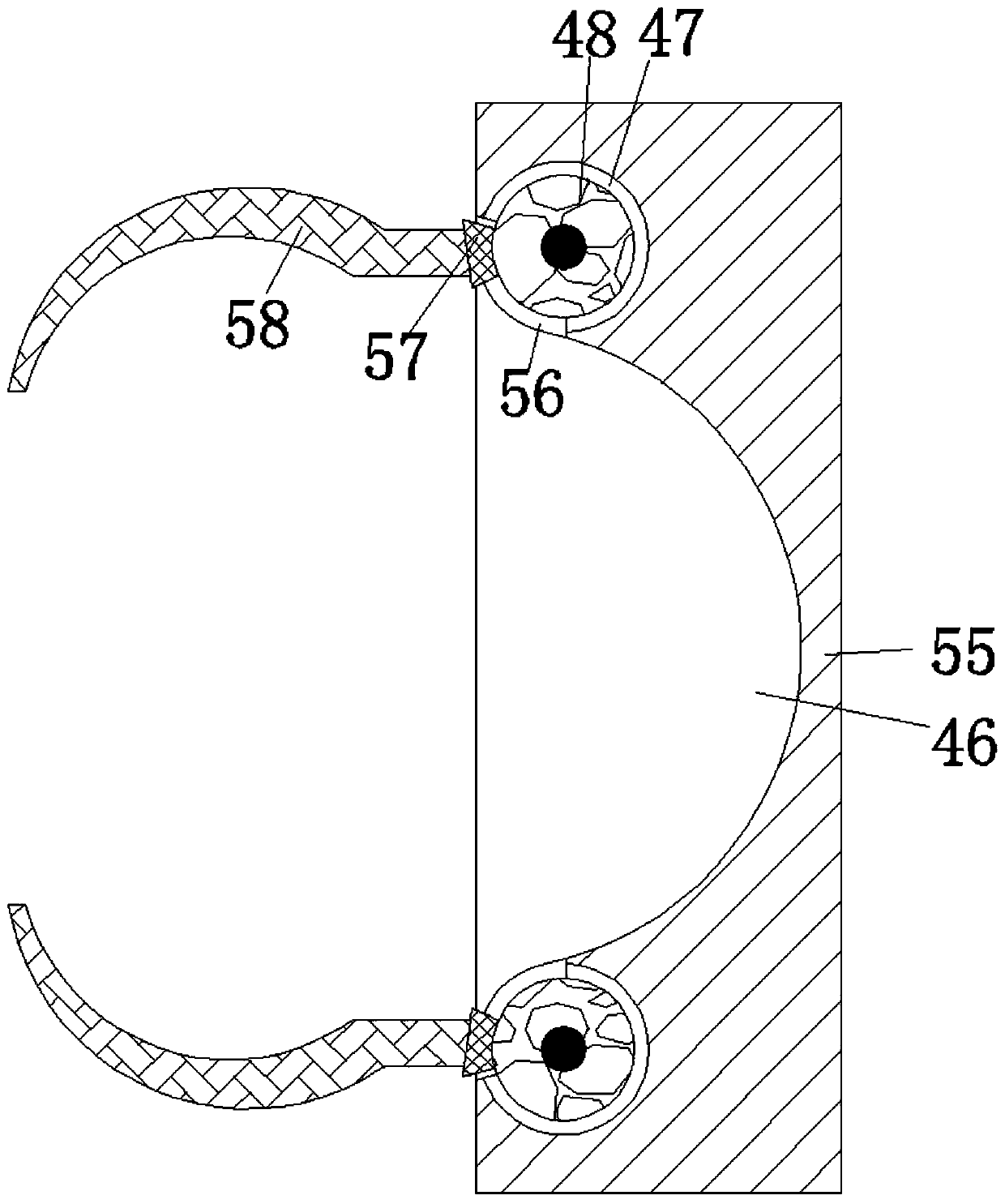

Membrane purification and alkalization control processing device for generator internal cooling water

ActiveCN105948330AReduce conductivityRaise the pHWater treatment parameter controlWater/sewage treatment by ion-exchangeHydrogenEnvironmental engineering

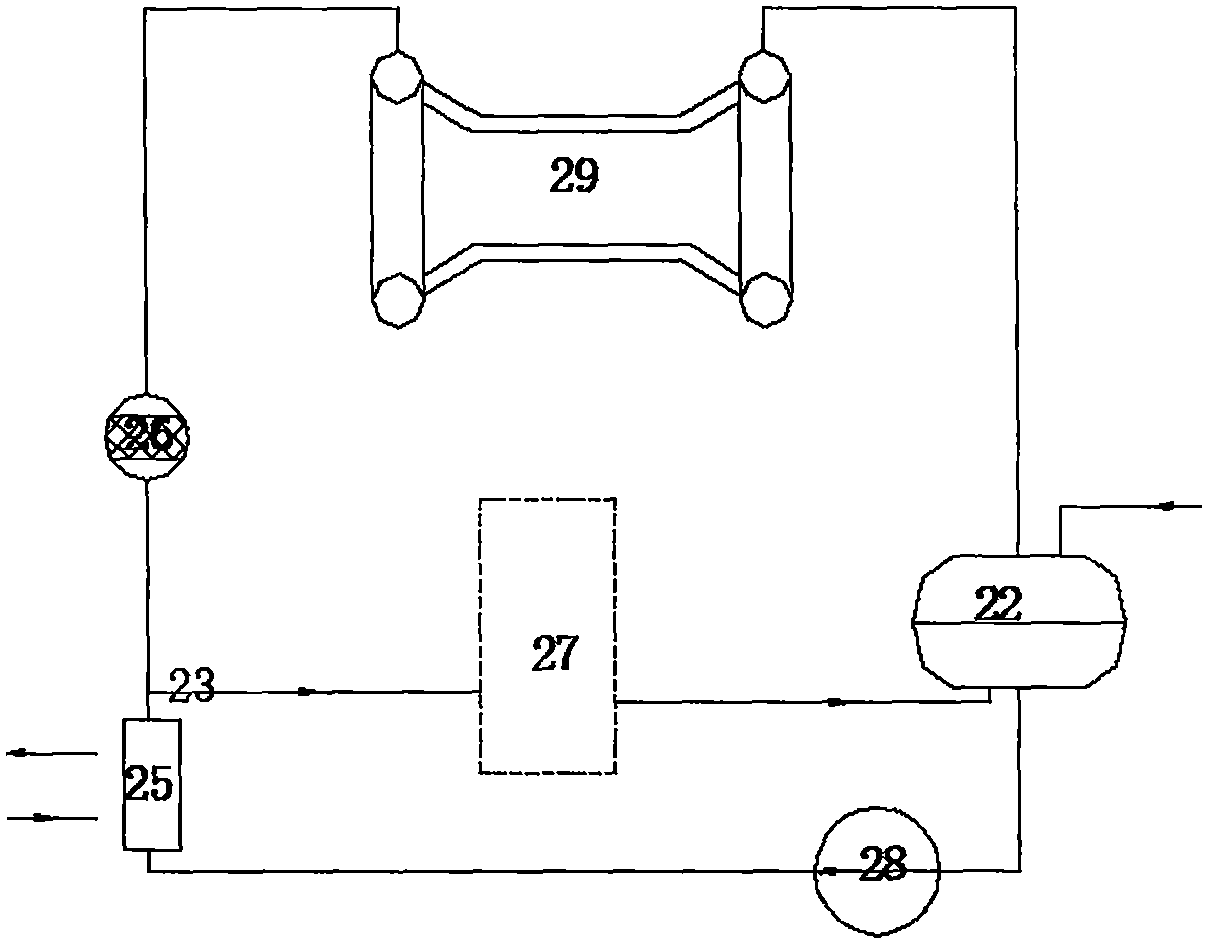

The invention relates to a membrane purification and alkalization control processing device for generator internal cooling water. A water inlet pipe (20) of the device is connected with a generator internal cooling water bypass (23); a water outlet of the device is directly returned to a generator internal cooling water tank (22); the pressure of inlet water, which enters the device, of the internal cooling water is detected by an onsite pressure gauge (1) which is mounted on an inlet pipeline; after entering the device, the generator internal cooling water enters an ion removing part. The device provided by the invention has advantages that the structure is simple, the cost is low, the conductivity of the internal cooling water is the lowest, a pH (potential of hydrogen) value is moderate, the content of copper ions is the lowest, the insulativity of a generator is furthest improved, and the running period is long. A method provided by the invention has advantages of being simple in technique, being convenient to operate and having a certain degree of automation.

Owner:哈尔滨安泰利达科技开发有限公司

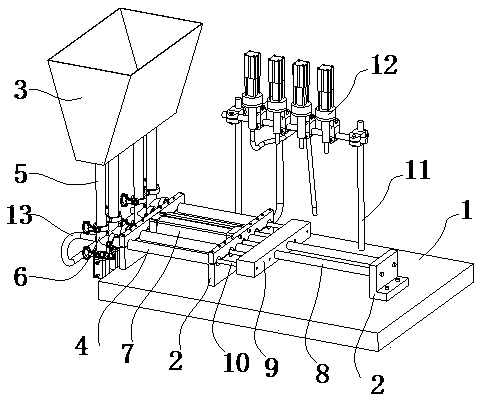

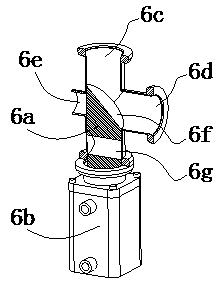

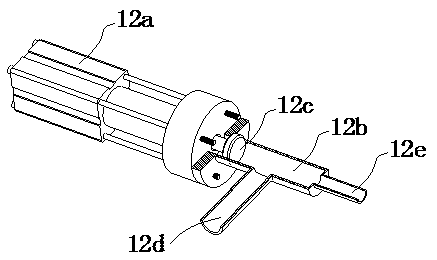

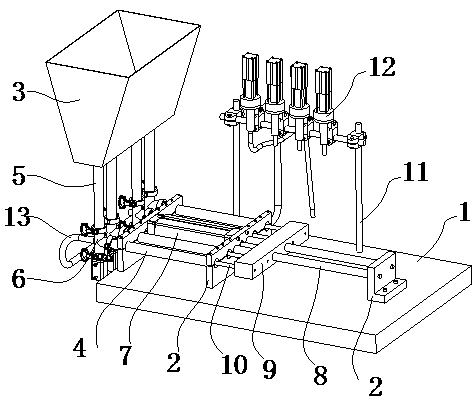

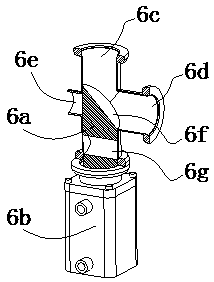

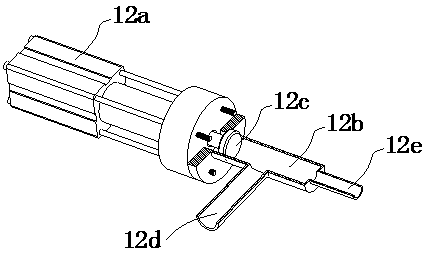

Automatic unguent base tray-loading equipment

InactiveCN105366085AAvoid uneven thicknessImprove work efficiencyLiquid materialEngineeringControl valves

The invention relates to the field of automatic unguent tray-loading equipment, in particular to automatic unguent base tray-loading equipment. The automatic unguent base tray-loading equipment comprises a base, a pneumatic feeding device and a pneumatic discharging device, wherein the pneumatic feeding device is fixed to the base through a support and provided with a hopper and a pushing pipe; a discharging pipe communicated with the pushing pipe is arranged at the bottom of the hopper; a control valve is mounted in the connecting position of the pushing pipe and the discharging pipe. A pushing rod is driven by a feeding air cylinder in the pneumatic feeding device to move in the pushing pipe, materials are sucked into the pushing pipe from the hopper and are conveyed into the pneumatic discharging device by the pushing pipe via a feeding hose, the pneumatic discharging device is used for feeding the materials onto a tray quantitatively, the situation that the thickness of bases is not even due to manual filling is avoided, the traditional manual filling work is replaced, the degree of automation is high, and the filling work efficiency is improved.

Owner:嘉兴实新企业服务有限公司

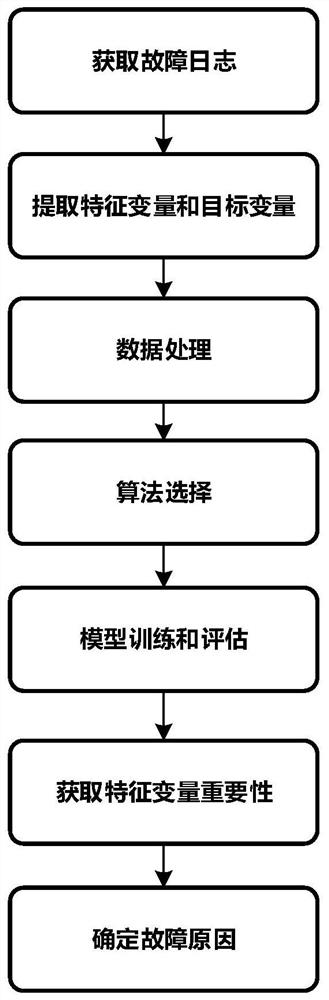

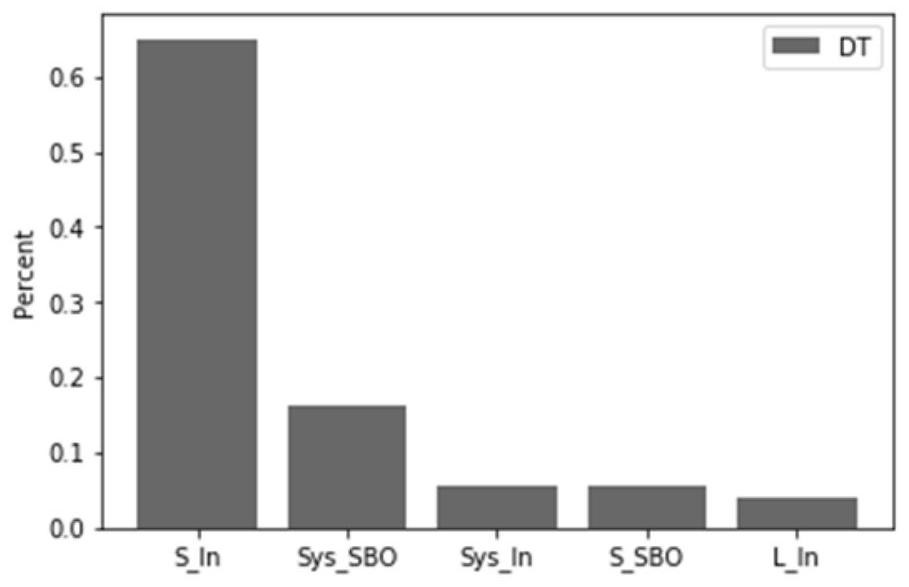

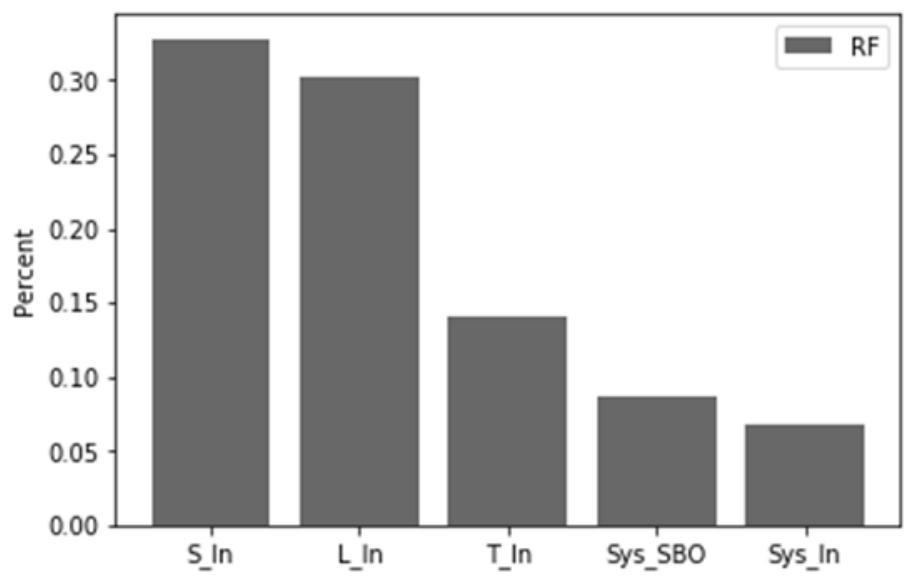

Interlocking system fault positioning method based on data mining algorithm

PendingCN111858270AHigh precisionReduce workloadHardware monitoringCharacter and pattern recognitionAlgorithmAlgorithm Selection

The invention relates to an interlocking system fault positioning method based on a data mining algorithm. The method comprises the following steps: step 1) fault log acquisition; (2) feature variableand target variable extraction, (3) data processing, (4) algorithm selection, (5) model training and evaluation, (6) feature variable importance acquisition, and (7) fault reason determination. Compared with the prior art, the invention has the advantages that the workload of engineers is greatly reduced, the working efficiency is improved, and the like.

Owner:CASCO SIGNAL

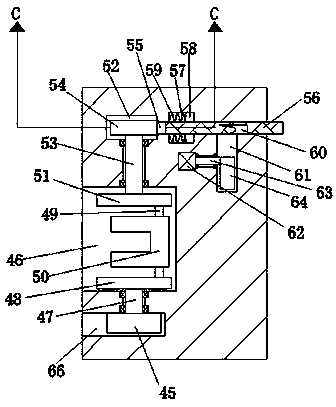

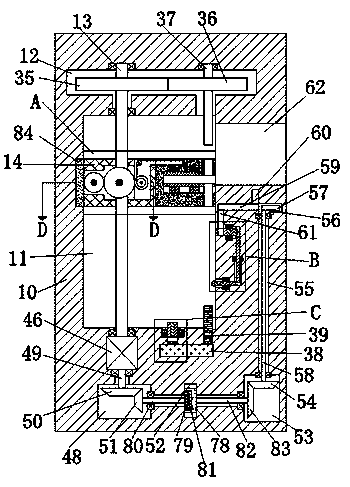

Door opening-closing device and using method thereof

InactiveCN108915487ASimple structureEasy to operateWing fastenersPower-operated mechanismRemote controlAutomation

The invention discloses a door opening-closing device and a using method thereof. The door opening-closing device comprises a device body, an opening-closing device and a locking device, wherein the opening-closing device is arranged in the device body; the locking device is arranged in the device body; the opening-closing device comprises a first wire rotating cavity arranged in the device body;and a first motor is fixedly arranged in the inner wall of the upper side of the first wire rotating cavity. Currently, a lot of automatic doors are sold in the furniture market; most of the automaticdoors can only be locked through remote control or buttons after being closed, cannot be always kept in the open state, and are relatively troublesome to use; in order to overcome the defects, the door opening-closing device which is capable of automatically locking a door once the door is closed, is capable of always keeping the door in the open state when the door is pulled to the greatest extent, has the relative degree of automation, and is capable of automatically closing the door just through remote control is designed; and the using method of the door opening-closing device is furtherdesigned.

Owner:石力峰

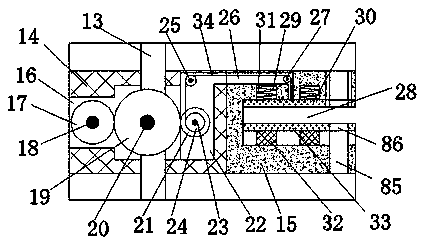

Fully-automatic bookbinding machine

The invention discloses a fully-automatic bookbinding machine. The fully-automatic bookbinding machine comprises a device main body, a bookbinding device arranged in the device main body and a conveying device arranged in the device main body, wherein the bookbinding device comprises a first cavity arranged in the device main body; a first motor is fixedly arranged in the device main body; and a second cavity is arranged in the inner wall of the upper side of the first cavity in a communication mode. In daily office work and learning, the bookbinding machine needs to be used frequently; a common bookbinding machine needs to use labor to bind paper through stitching needles; and as a result of volume limit of a manual bookbinding machine, a thick pad of paper cannot be bound, so that trouble is caused. The invention aims to design the fully-automatic bookbinding machine which can automatically fill a plastic willow tube and binds paper through a heat fusion method.

Owner:毛岳生

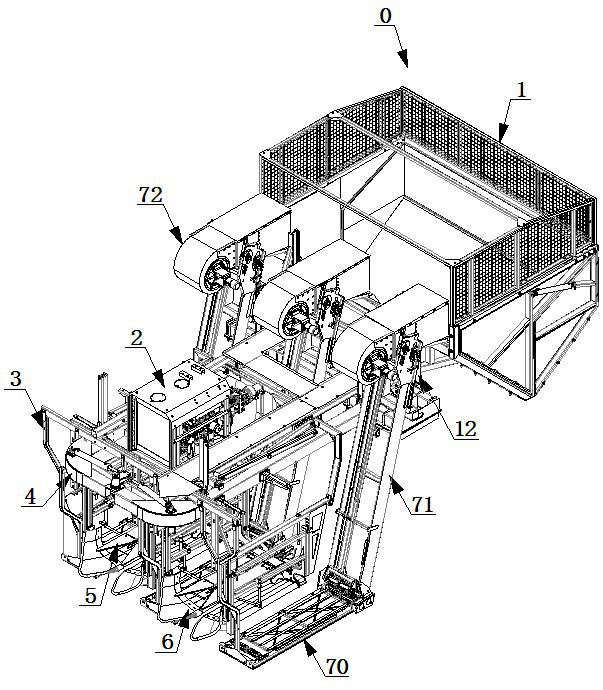

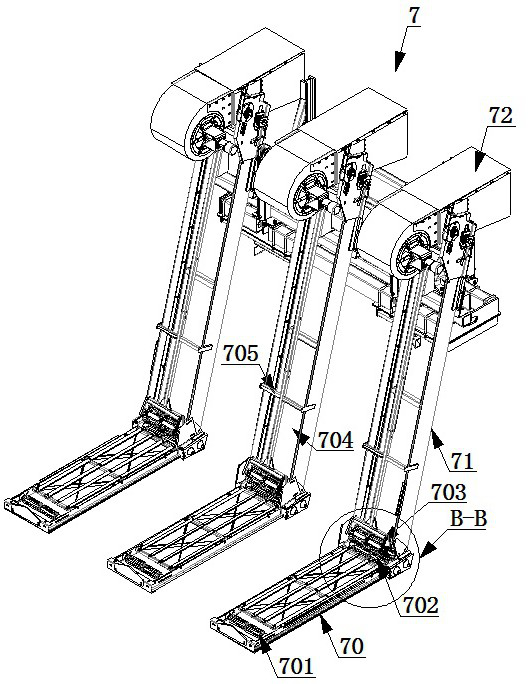

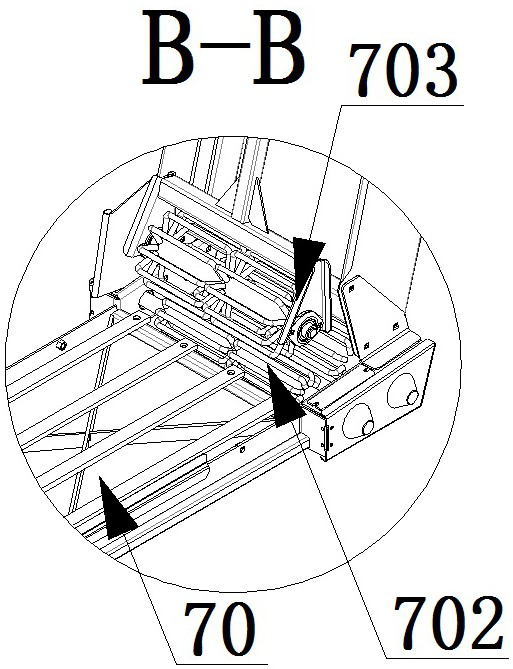

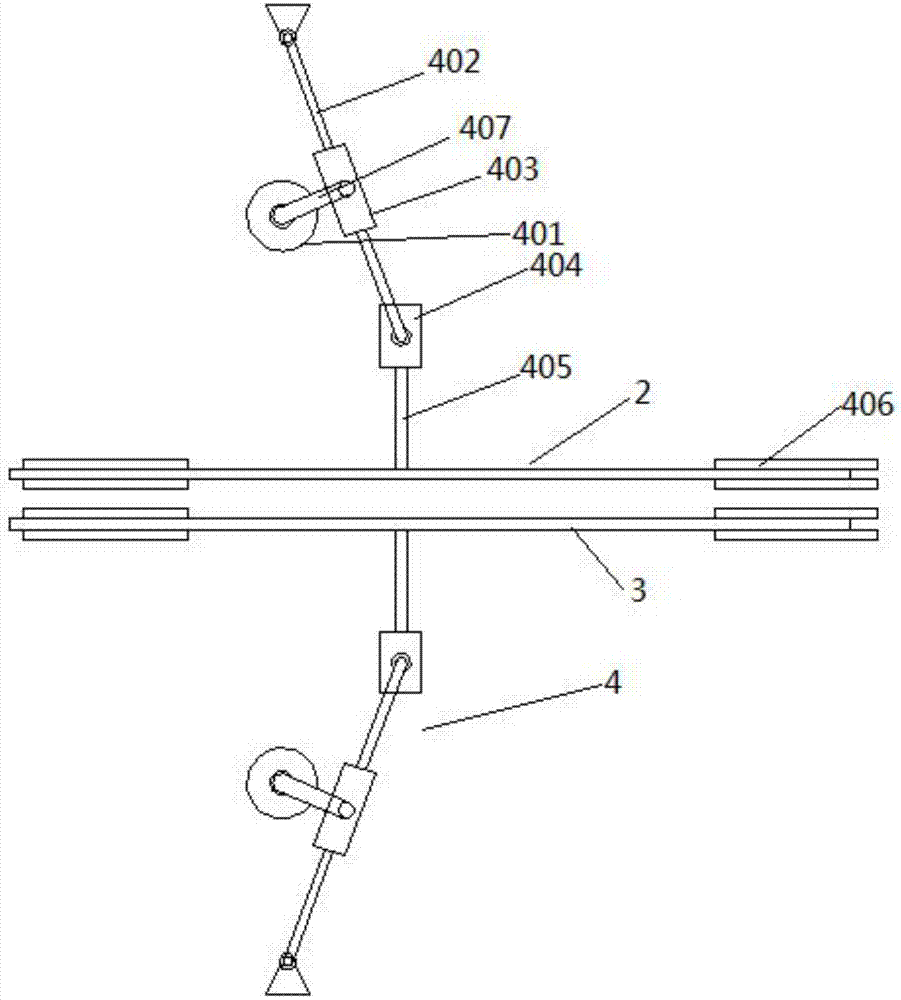

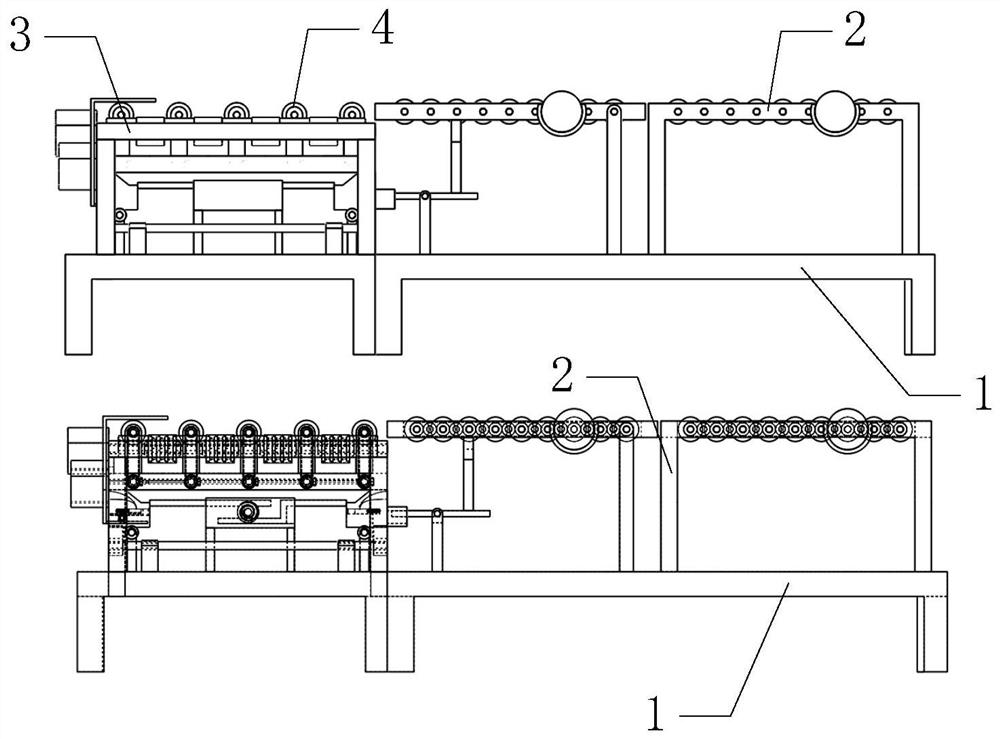

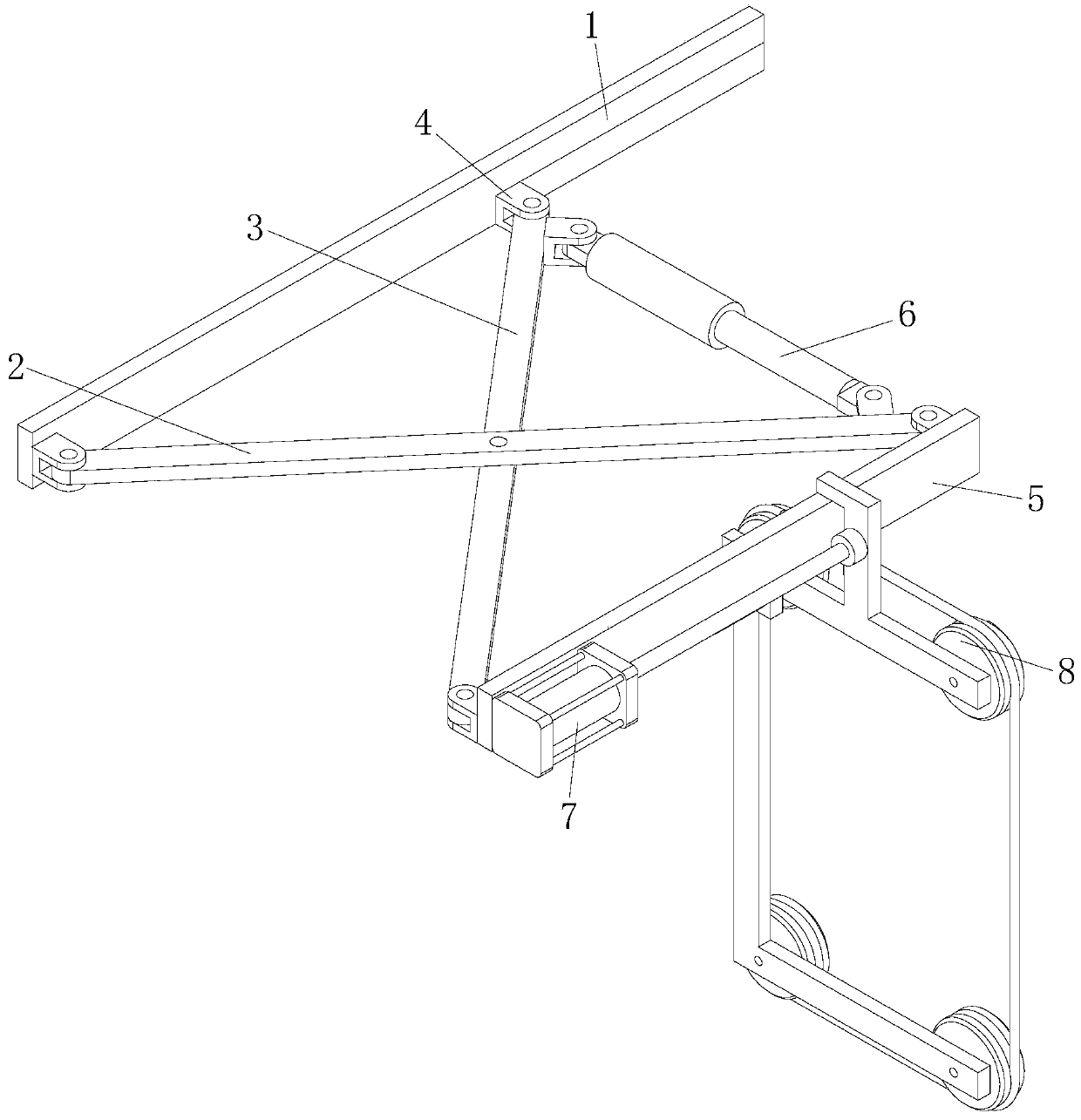

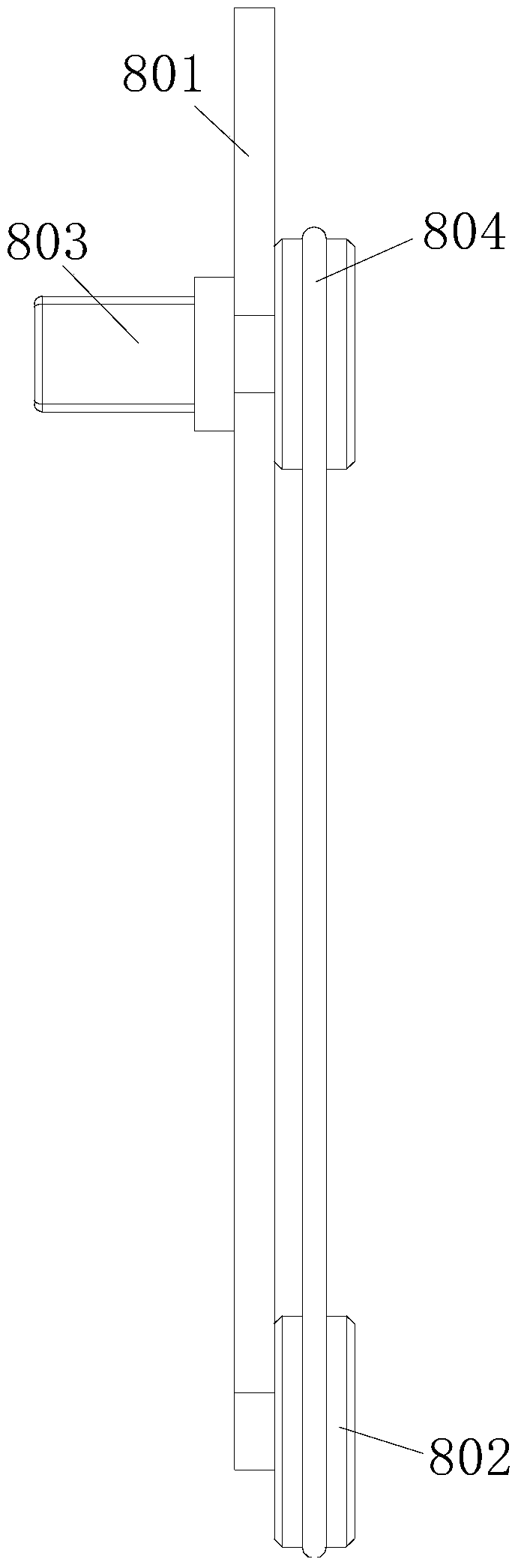

Conveying mechanism suitable for tobacco leaf picking machine

PendingCN112715151ADegree of automationSave manpower and material resourcesMowersAgricultural undercarriagesAgricultural engineeringFixed Slide

The invention relates to a conveying mechanism suitable for a tobacco leaf picking machine. The conveying mechanism for the tobacco leaf picking machine is characterized in that a rack assembly is located at the upper middle part of a conveying mechanism body, an upper cross beam at the front end of a two-layer frame mechanism assembly is fixed to the upper end of the front end of the rack assembly, an upper cross beam at the rear end of the two-layer frame mechanism assembly is fixed to the upper end of the rear middle part of the rack assembly, the outer side wall of the bottom of the front end of a tobacco leaf conveying assembly is fixed to the two-layer frame mechanism assembly, the bottom of a fixing mechanism at the rear end of the tobacco leaf conveying assembly is fixed to the rear end of the rack assembly, a tobacco leaf collecting frame is located at the rear end of the tobacco leaf conveying assembly and is connected with a sliding rail assembly arranged at the rear end of the rack assembly in a matched mode through a fixing sliding piece, front and rear vertical beams of a tobacco leaf picking and conveying assembly are fixed to the upper ends of the front ends of left and right longitudinal beams of the rack assembly and the inner side wall of a cross beam at the front end of the two-layer frame mechanism assembly, and the bottom of an engine assembly mechanism is fixed to the upper end of a middle cross beam at the front half part of the rack assembly. In conclusion, the conveying mechanism has the advantages of being simple in structure, convenient to operate, high in automation degree and capable of saving manpower and cost.

Owner:ZHENGZHOU RONGDA TECH CO LTD

Integrated toothpick box

The invention discloses an integrated toothpick box. The integrated toothpick box comprises a device body, a fixing device arranged in the device body, and a toothpick box device matched with the fixing device. The fixing device comprises a first fixing block fixedly connected to the upper end of the right end face of the device body, and a first sliding groove running through the upper and lowerportions is formed in the first fixing block; a first cavity with a rightward opening is formed in the device body, a second cavity with a rightward opening is formed in the inner wall of the upper side of the first cavity, and a first sliding block is slidably arranged in the second cavity. Many people need to use toothpicks after dining in restaurants, and the toothpicks are always placed in various toothpick boxes which are always plastic tanks serving as containers; when the toothpicks are taken from the containers, a plurality of toothpicks are often poured out at a time, and waste is caused; meanwhile, the containers cannot be sealed, and bacteria easily enter the containers. The integrated toothpick box can only pop up one toothpick at a time.

Owner:周一戈

Bristle flat cutting device

The invention provides a bristle flat cutting device which comprises a fixing frame and scissor plates including the upper scissor plate and the lower scissor plate. The upper scissor and the lower scissor are each connected with a reciprocating motion mechanism, the reciprocating motion mechanisms are arranged on a fixing plate, the fixing plate is movably installed on a sliding block through a hinge linkage piece, the sliding block is arranged on a fixing rod in a sliding mode, the fixing rod is arranged on the fixing frame, clamping devices are arranged at the front ends of the upper and lower scissor plates, and the upper and lower scissor plates are arranged in a stacked mode. Due to the fact that the two scissor plates are vertically arranged in the stacked mode, a plurality of continuously-distributed scissor teeth are arranged on the two scissor plates for performing relative motion, bristles are directly cut to be flat, the automatic degree is high, the clamping devices are arranged at the front end of the flat cutting device, the bristles can be clamped and fixed, and flat cutting is achieved conveniently.

Owner:安徽三和刷业股份有限公司

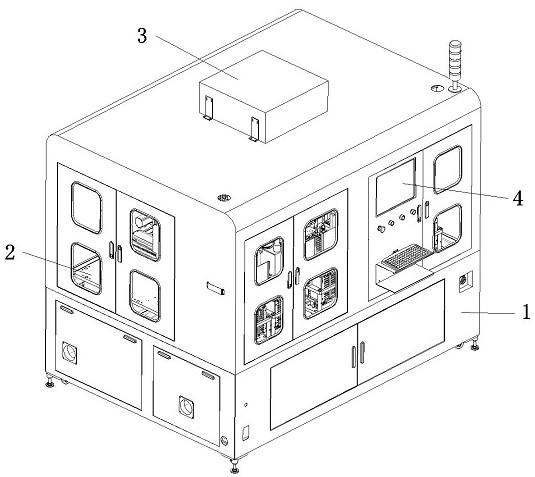

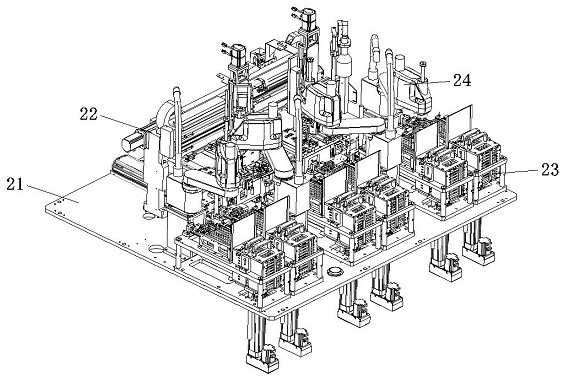

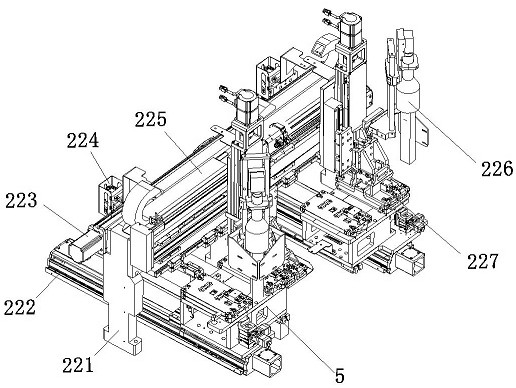

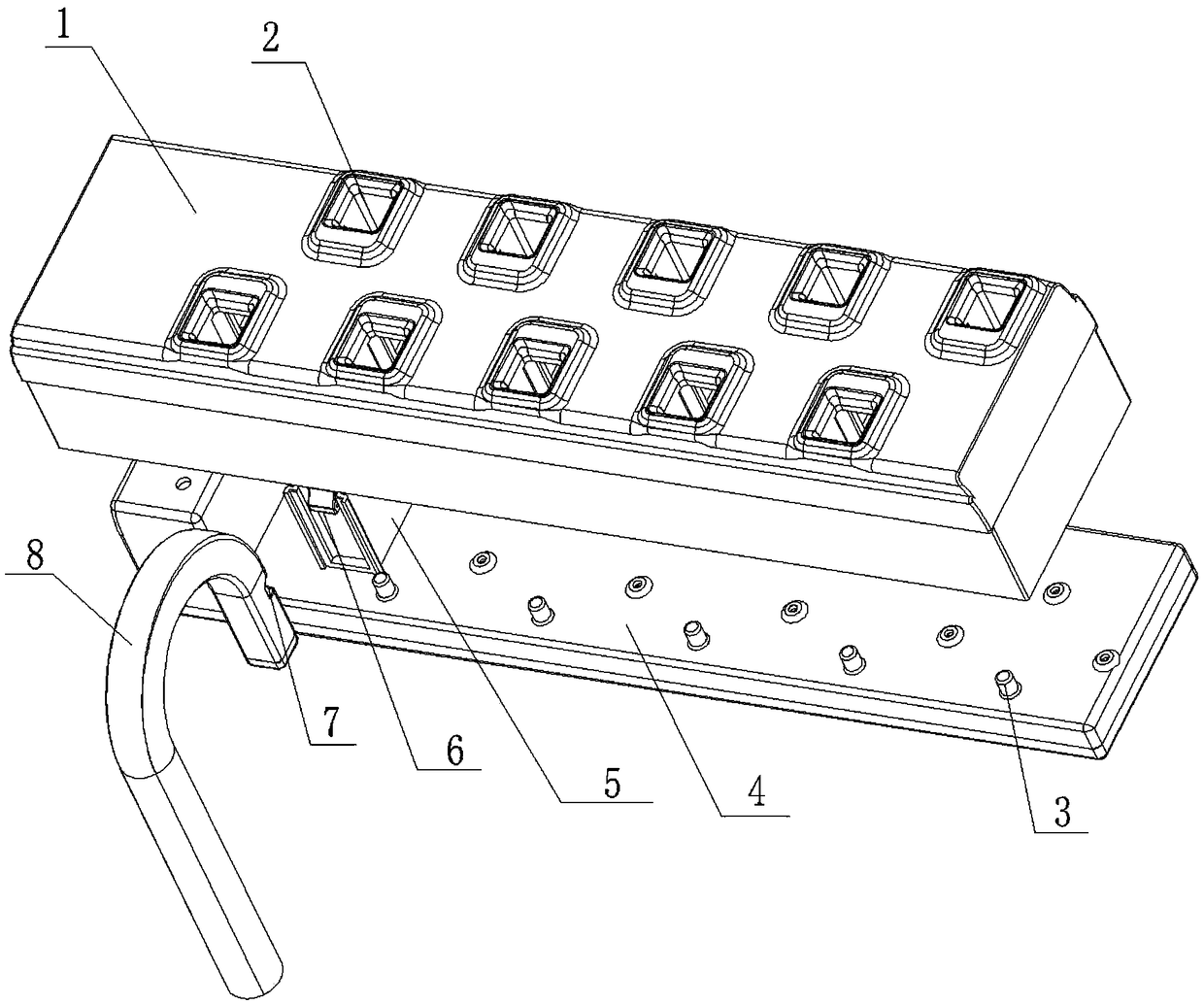

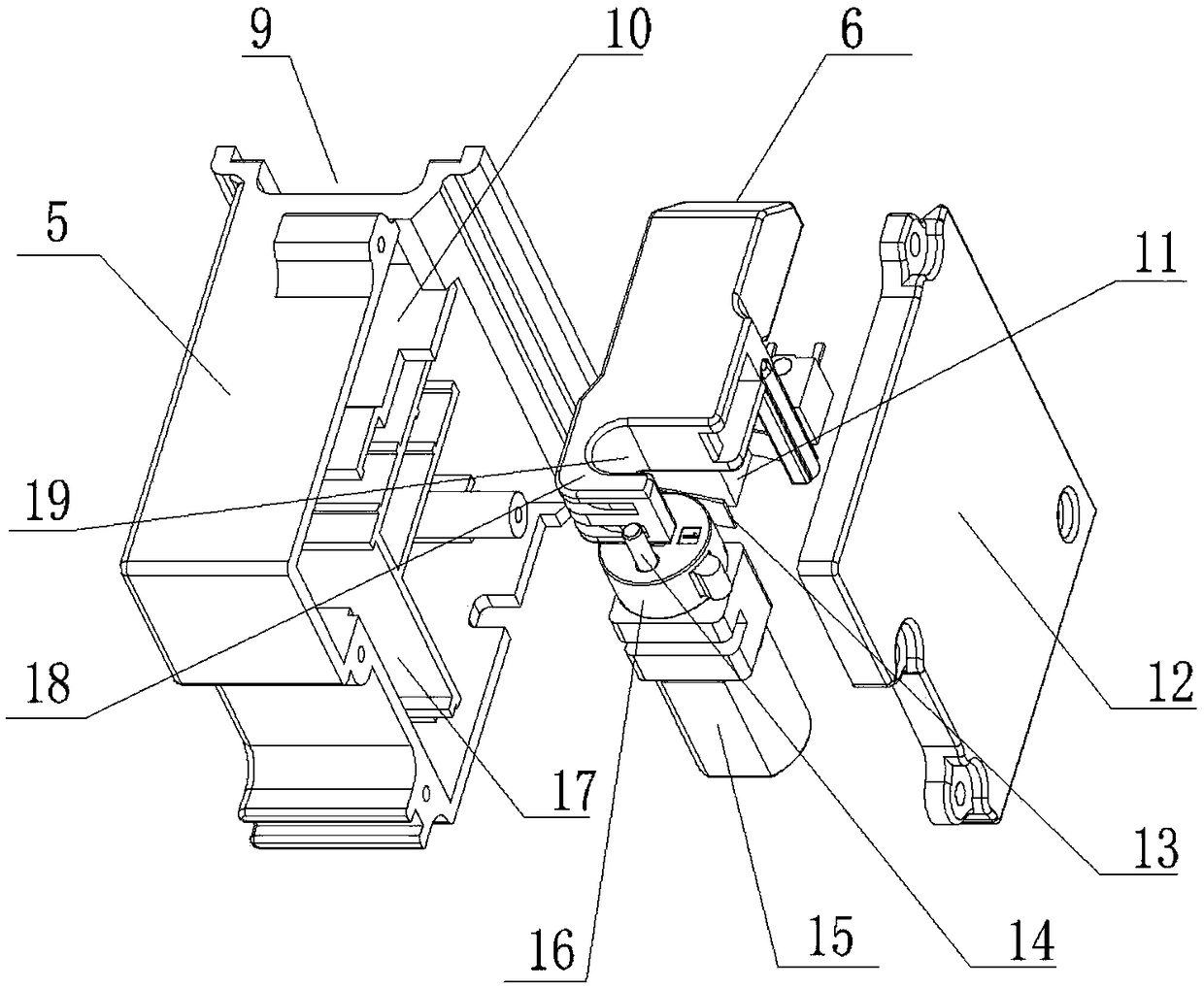

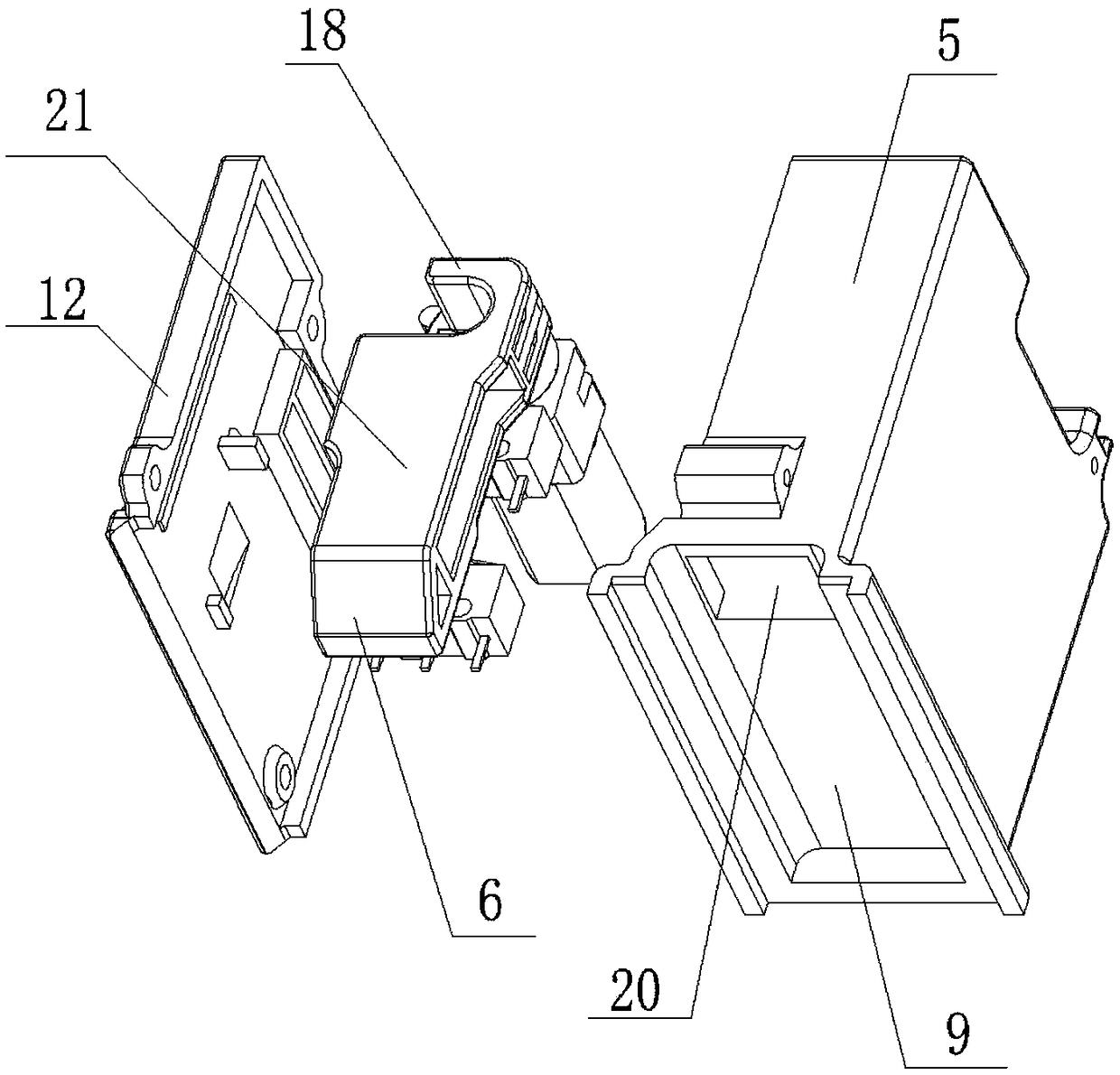

A kind of assembly equipment and its assembly process

ActiveCN113020975BImprove installation accuracyImprove processing qualityAssembly machinesProduction lineMobile phone

The invention discloses an assembly device, comprising: a shell, an assembly mechanism, a plasma purifier and a PLC controller; the assembly mechanism is installed at the bottom of the inner cavity of the shell; the plasma purifier is arranged at the top opening of the inner cavity of the shell place; the PLC controller is arranged on the front side of the shell. The assembly equipment and its assembly process, for the lack of an assembly equipment in the current mobile phone assembly production line of the prior art to automatically assemble and trim the gasket, the first decorative material plate and the second decorative material plate in the jig, resulting in the existing The gasket, the first decorative material plate and the second decorative material plate have poor installation accuracy and low degree of automation, which affect the processing quality and production efficiency. It can be solved for the gasket, the first decorative material plate and the second decorative material plate in the jig The boards are automatically assembled and trimmed, and the CCD positioning is performed multiple times to improve the installation accuracy of the gasket, the first decorative material board and the second decorative material board after automatic installation, and improve the processing quality.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

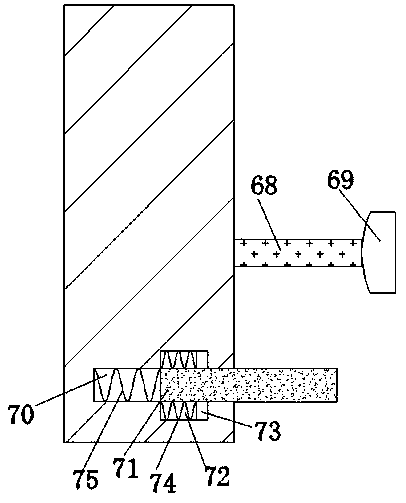

Shared umbrella device and usage method thereof

InactiveCN109360344ADegree of automationThe equipment is convenient and efficientApparatus for meter-controlled dispensingPush outEmbedded system

The invention discloses a shared umbrella device and a usage method thereof. The device comprises a housing and an inner cover, and further comprises a control unit, a communication unit, a lock box,a lock box control device, a mounting block, a plastic bin, and a plastic bin cover. The plastic bin is arranged on an inner lid. The outer side of the plastic bin is provided with a lock slot adaptedto the shape of the handle of the shared umbrella. A through hole communicating with the interior of the plastic bin is provided in the lock slot. The lock box control device can control the lock boxto be pushed out from the through hole or pulled to the through hole. The lock cooperates with the inner wall of the housing to form a lock hole. The plastic bin cover and the plastic bin are interlocked, and the communication unit can realize information interaction with an external signal source. According to the device and the method, the automatic locking and unlocking functions are realized,and the structure is simple and convenient to use.

Owner:江西大地走红伞业有限公司

High-precision full-automatic binding machine

InactiveCN109016931ASimple structureEasy to operateSheet bindingElectric machineryPulp and paper industry

The invention discloses a high-precision full-automatic binding machine. The high-precision full-automatic binding machine comprises a device body, a binding device arranged in the device body, a conveying device arranged in the device body and a lighting device arranged at the upper end of the device body. The binding device comprises a first cavity formed in the device body, a first motor is fixedly arranged in the device body, and a second cavity is formed in the upper inner wall of the first cavity in a communicating mode. Binding machines are frequently used during daily office work and study, however, as for a common binding machine, paper sheets need to be bound manually through staples, meanwhile, a very thick stack of paper sheets cannot be bound due to size limitation of a manualbinding machine, operation is quite troublesome. The high-precision full-automatic binding machine can achieve automatic filling of riveting pipes and can also bind the paper sheets through a hot melting method.

Owner:毛岳生

Generator internal cooling water membrane purification and alkalization control treatment device

ActiveCN105948330BKnow what's actually going onReduce conductivityWater treatment parameter controlWater/sewage treatment by ion-exchangeHydrogenEnvironmental engineering

The invention relates to a membrane purification and alkalization control processing device for generator internal cooling water. A water inlet pipe (20) of the device is connected with a generator internal cooling water bypass (23); a water outlet of the device is directly returned to a generator internal cooling water tank (22); the pressure of inlet water, which enters the device, of the internal cooling water is detected by an onsite pressure gauge (1) which is mounted on an inlet pipeline; after entering the device, the generator internal cooling water enters an ion removing part. The device provided by the invention has advantages that the structure is simple, the cost is low, the conductivity of the internal cooling water is the lowest, a pH (potential of hydrogen) value is moderate, the content of copper ions is the lowest, the insulativity of a generator is furthest improved, and the running period is long. A method provided by the invention has advantages of being simple in technique, being convenient to operate and having a certain degree of automation.

Owner:哈尔滨安泰利达科技开发有限公司

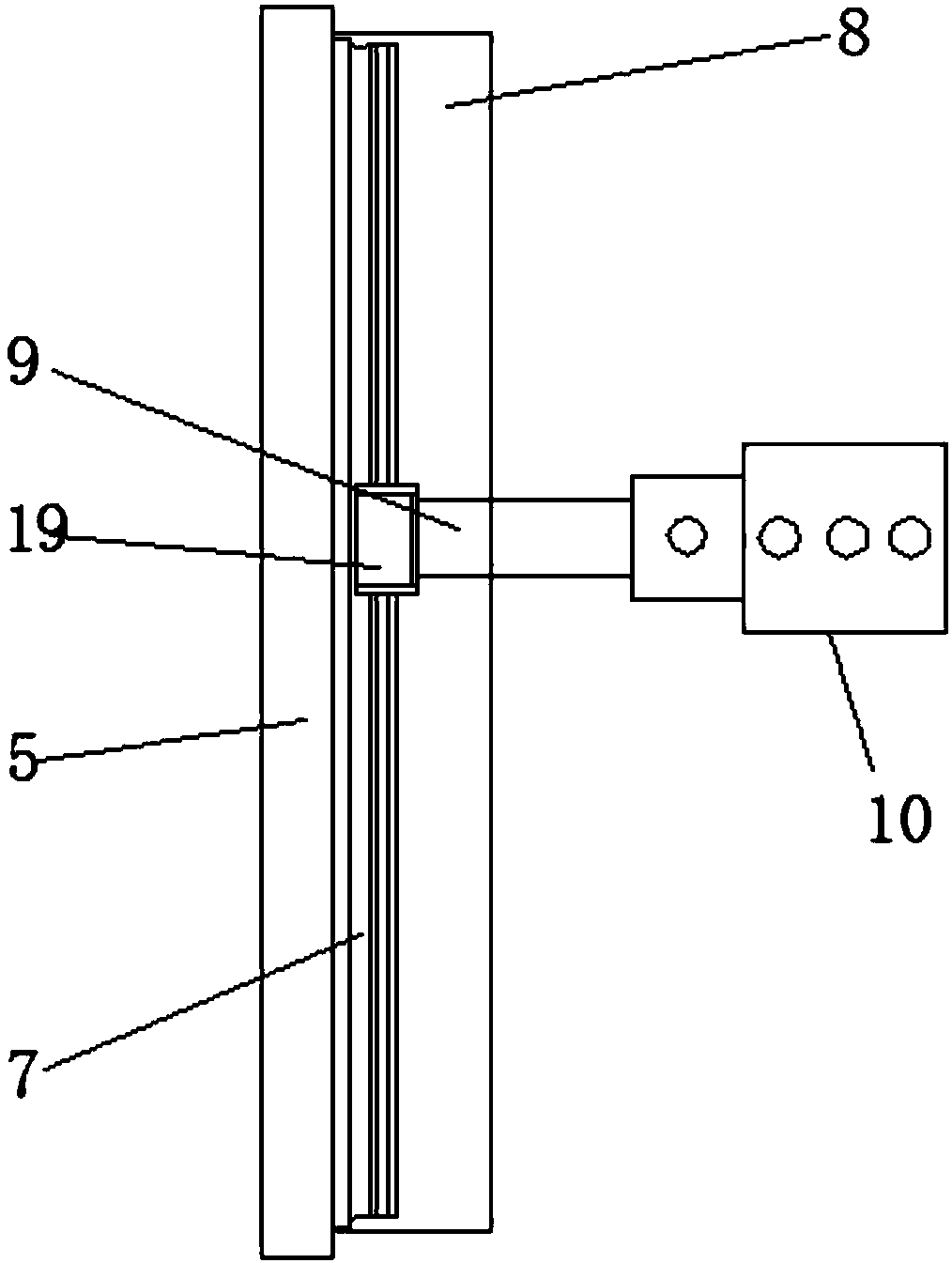

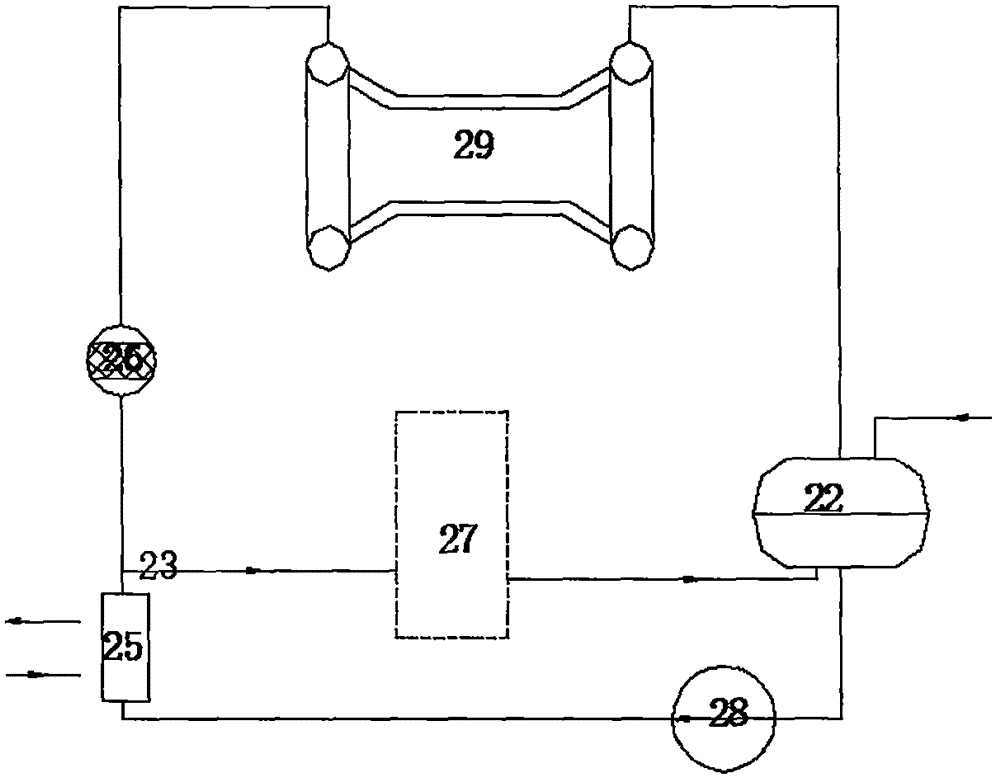

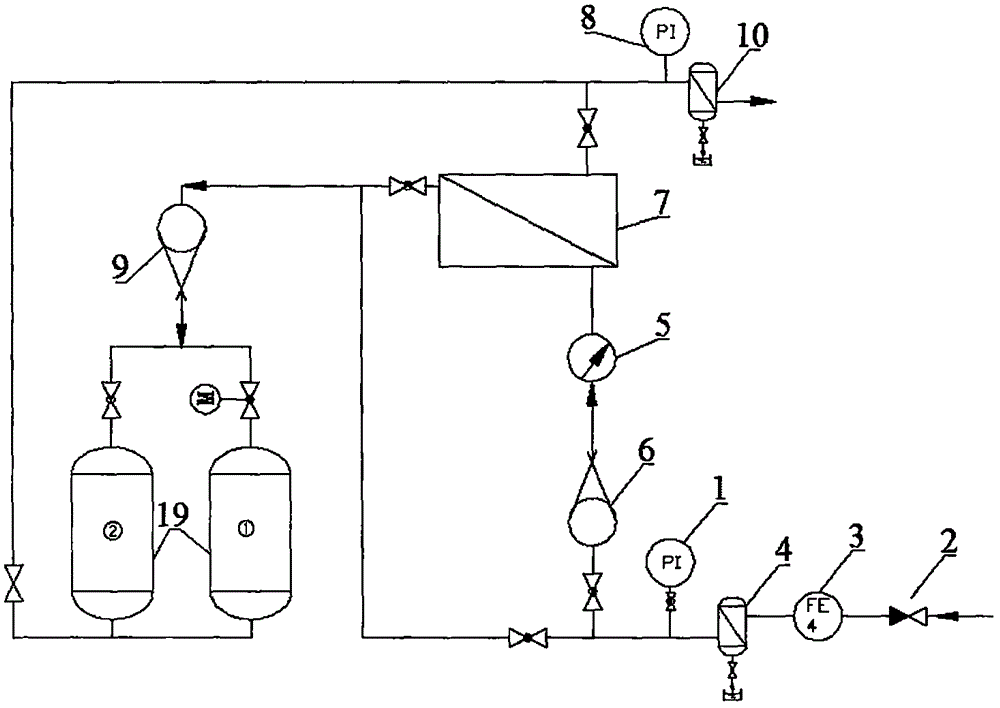

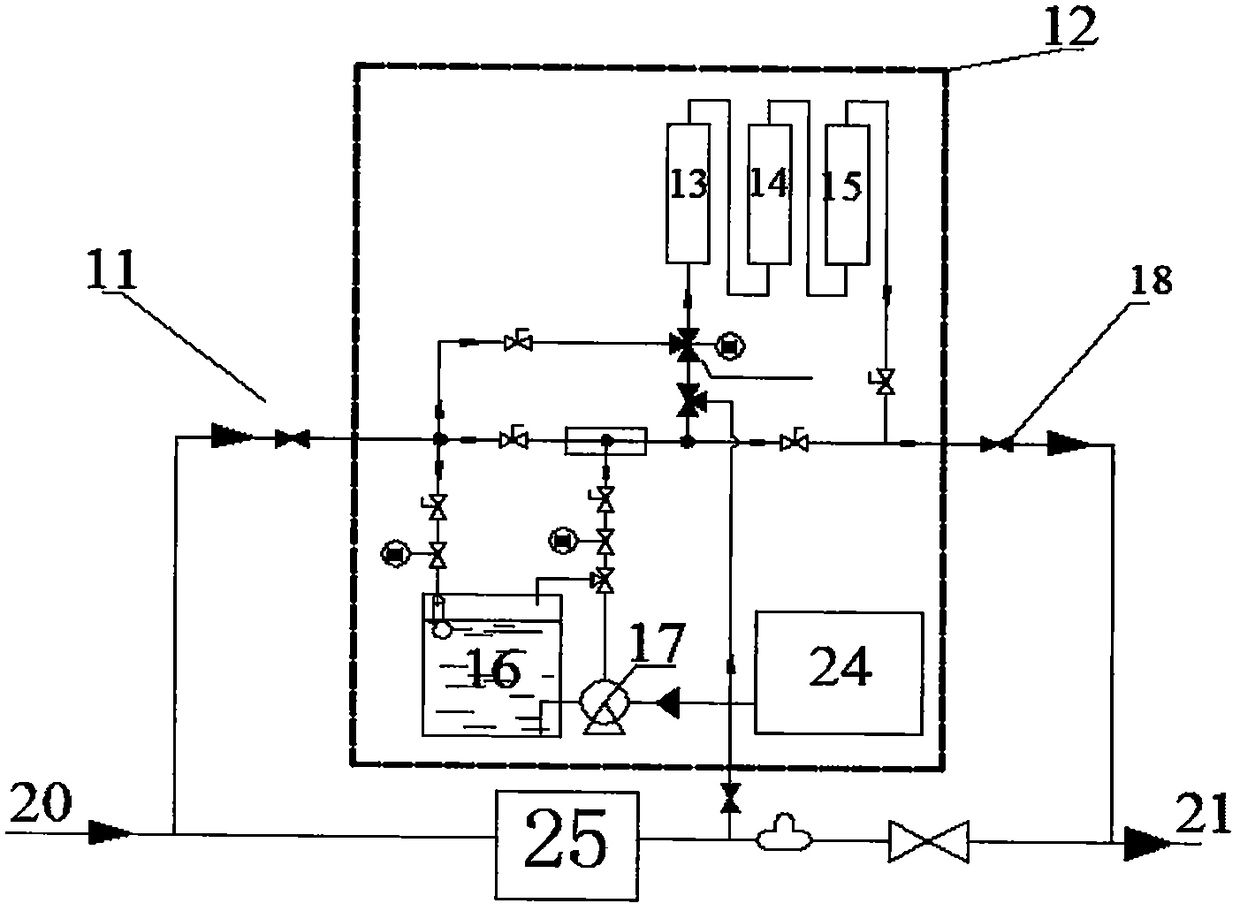

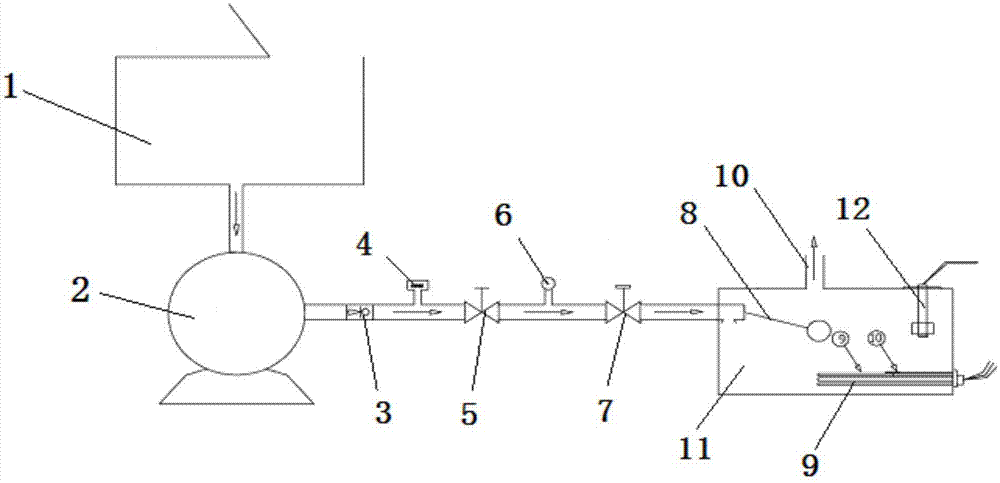

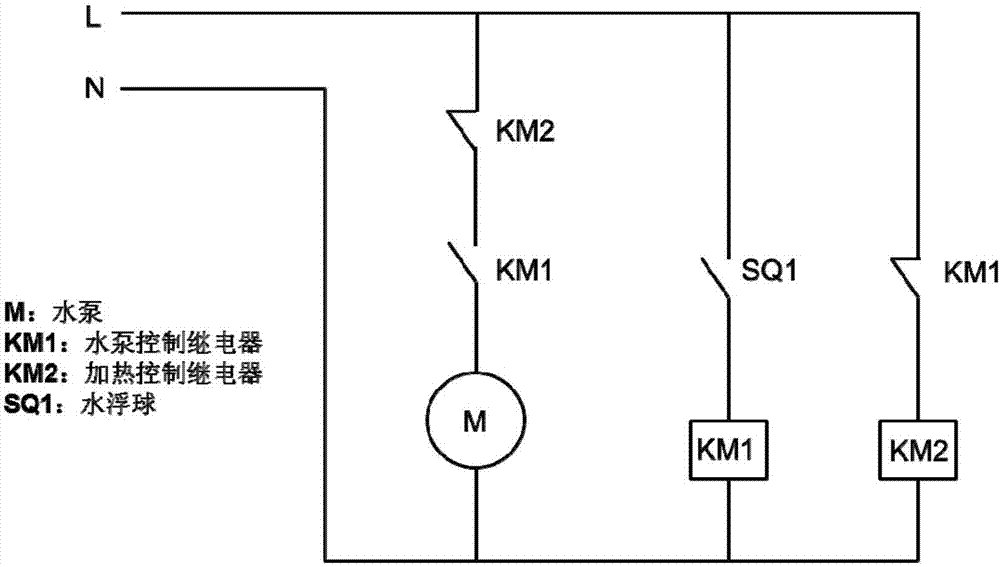

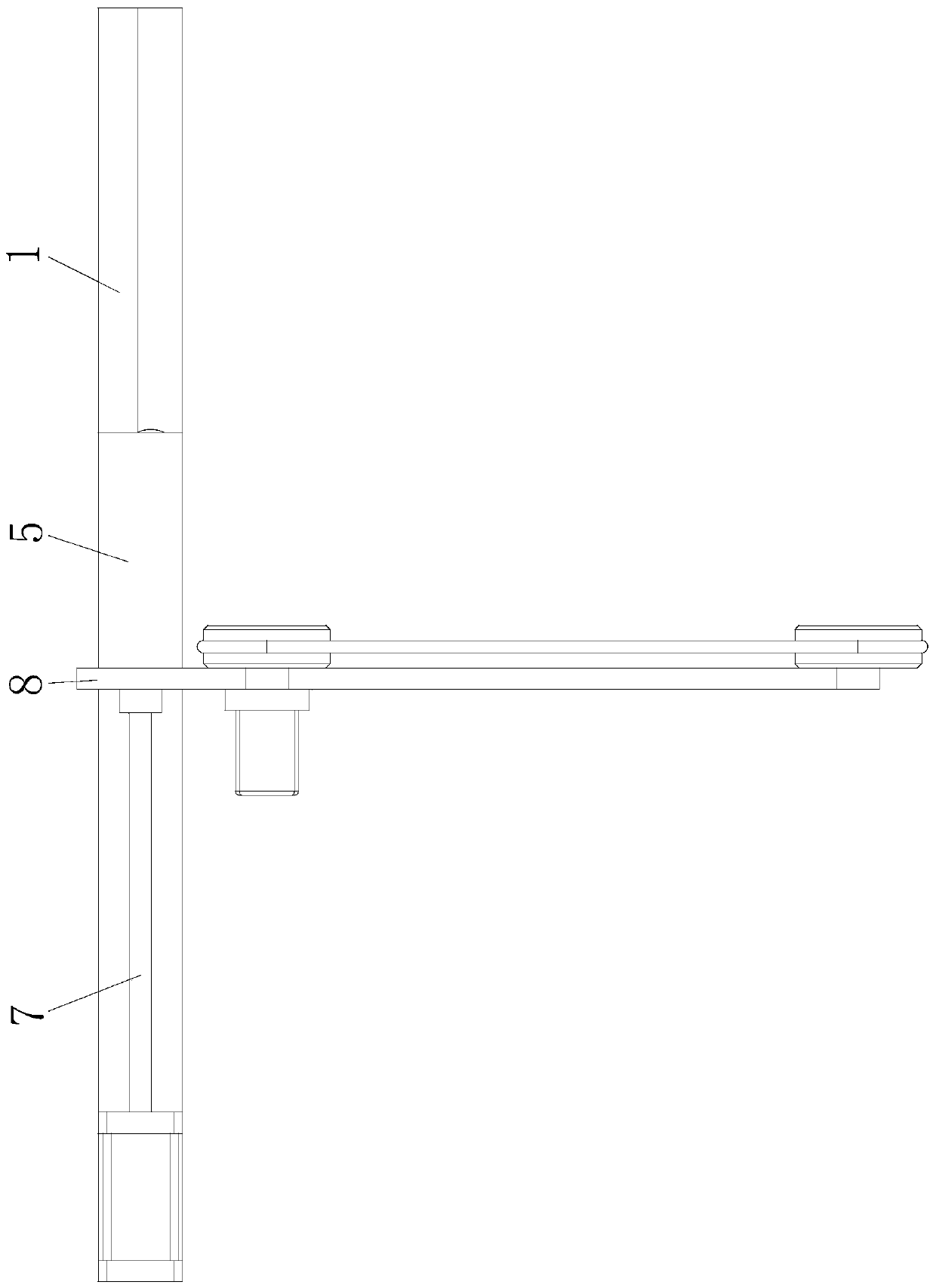

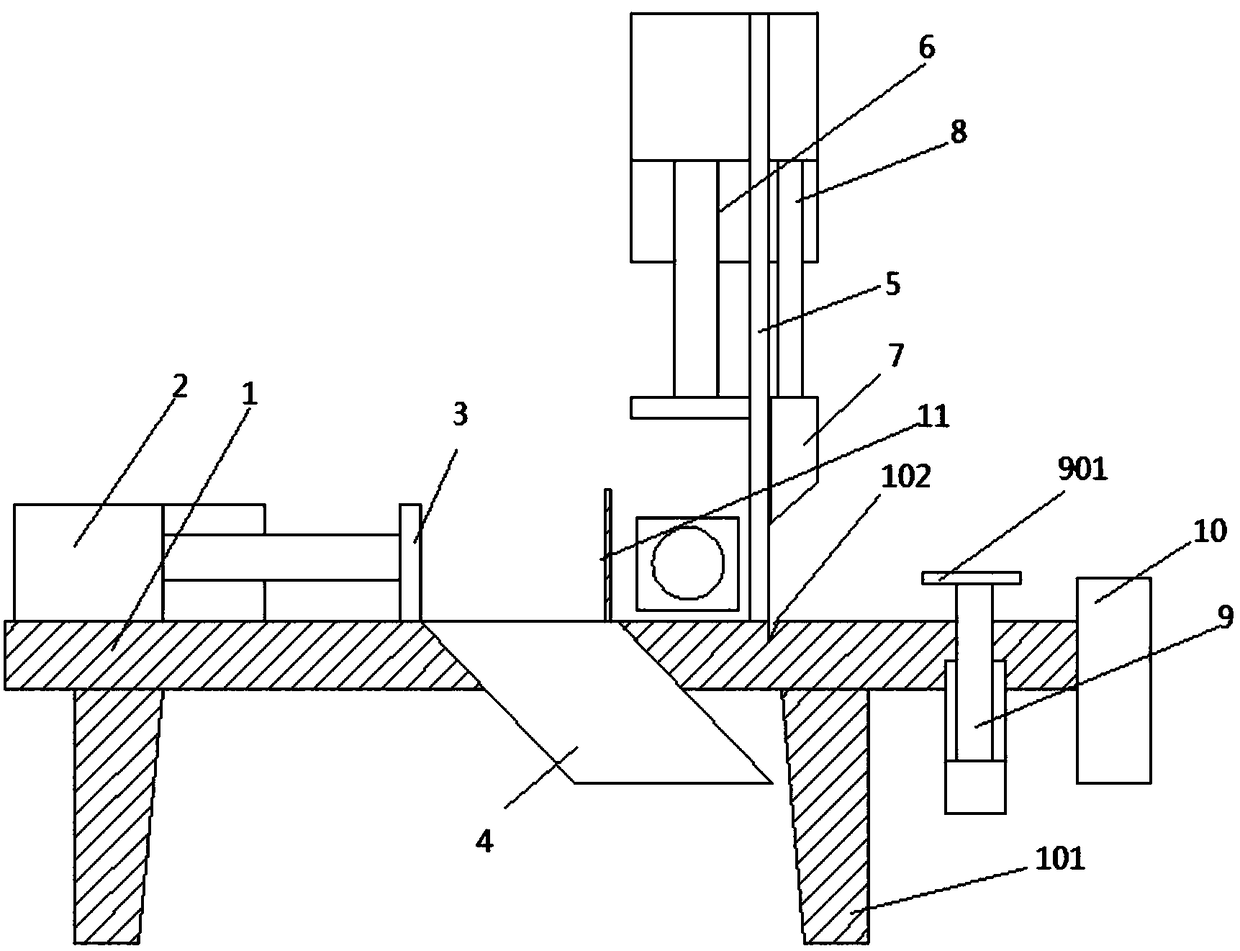

Automatic waterway circulation device

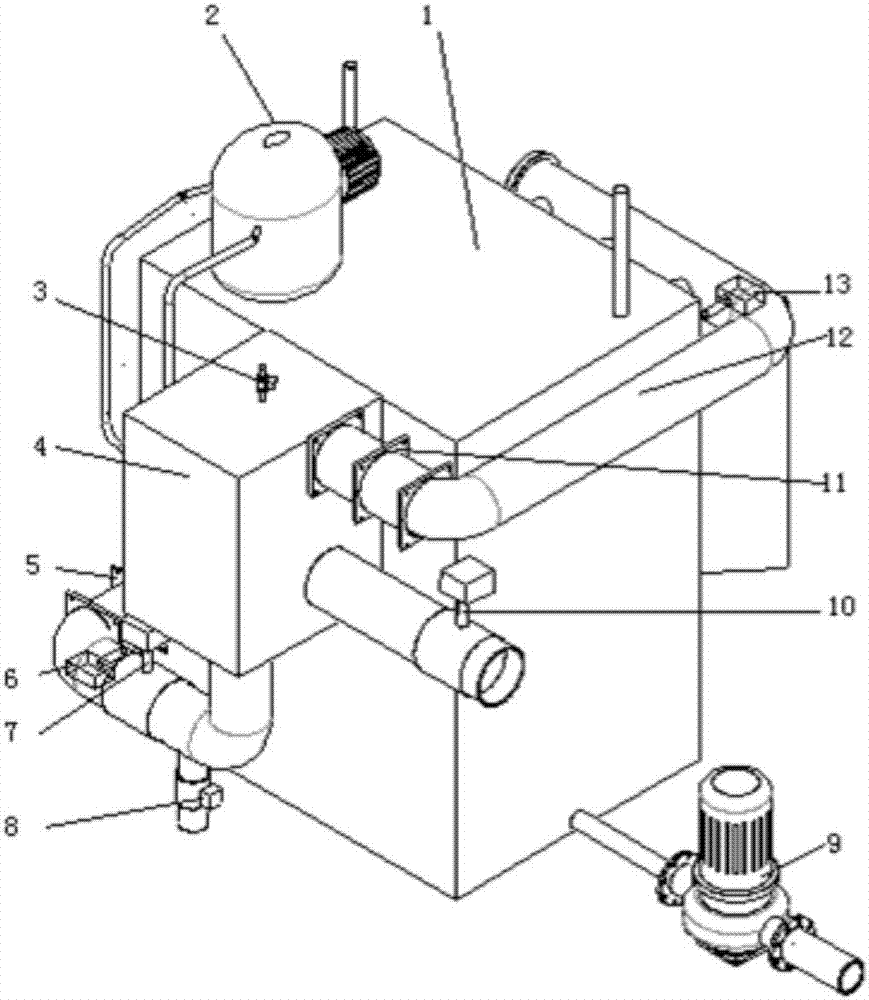

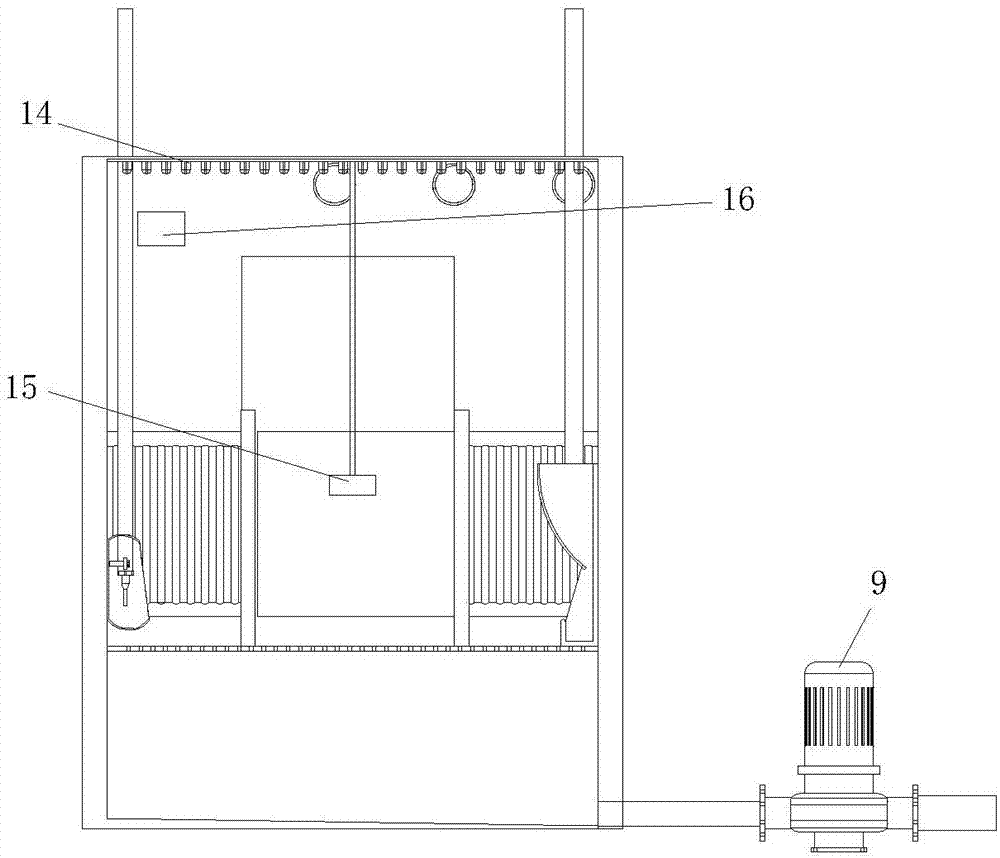

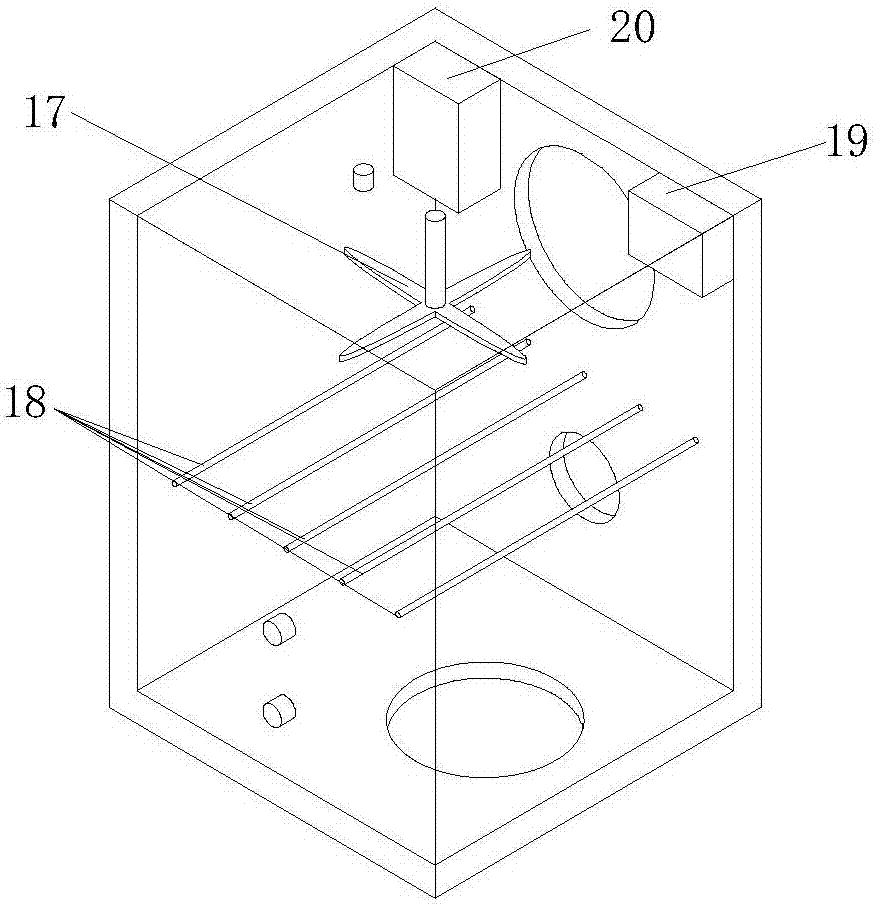

PendingCN107514623AEasy to useSimple structureWeather/light/corrosion resistanceWater circulation promotionWater storage tankTest chamber

The invention discloses an automatic waterway circulation device for a thermal-humidity test chamber waterway system. The automatic waterway circulation device comprises a water pump (2) connected with a water storage tank (1). A one-way valve (3), a pressure controller (4), a hand valve (5), a water pressure gauge (6) and an electromagnetic valve (7) are sequentially arranged on a pipeline between the water storage tank (1) and a humidifying boiler (11), a mechanical water floating ball (8) and an electronic water floating ball (12) are installed on the upper portion inside the humidifying boiler (11), the electronic water floating ball (12) is connected with a relay of the water pump (2), a heating bar (9) is installed on the lower portion inside the humidifying boiler (11), and a steam outlet (10) is arranged on the top of the humidifying boiler (11). The reliability of the thermal-humidity test equipment waterway circulation system is improved, and defects in the prior art are overcome.

Owner:CHINA AERO POLYTECH ESTAB

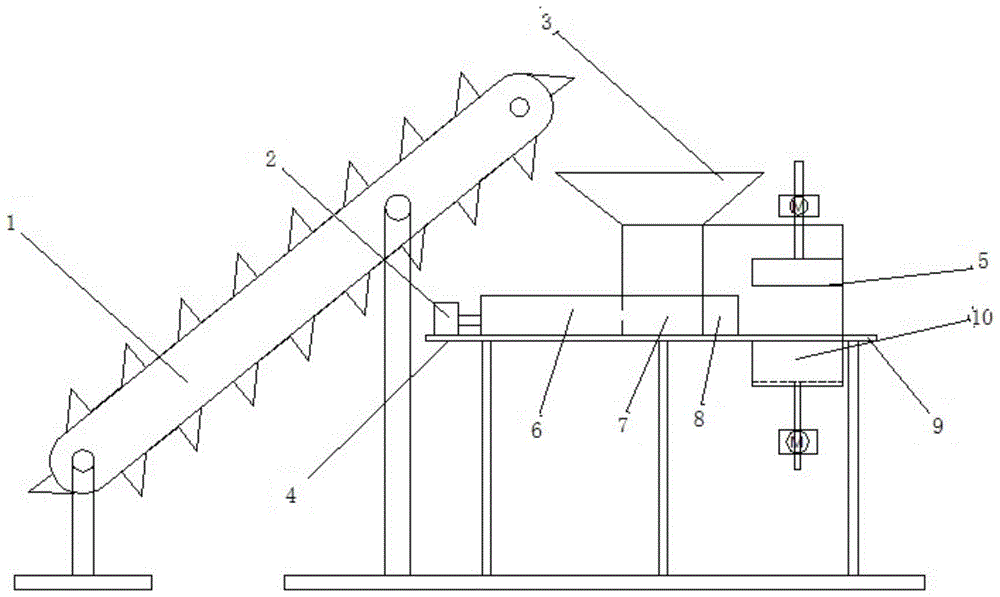

An automatic press molding system for the production of water glass expansion vitrified microbead lightweight insulation board

InactiveCN103878866BControllable weightCompaction density controllableFeeding arrangmentsVolumetric Mass DensityEngineering

The invention discloses an automatic compression forming system used for production of lightweight heat-insulating plates made of water glass expanded glass beads. The system comprises a conveying belt, a collection device, a transmission platform, a mould and a pressurizing device. The conveying device is used for conveying water glass expanded glass bead materials to the collection device; the collection device comprises a collection hopper and a storage bin; the collection hopper is funnel shaped and used for collecting the materials conveyed by the conveying belt and conveying the materials to the storage bin; the storage bin with the top and bottom open is provided with side walls all around; a force application device is arranged at one end of the transmission platform and connected with the storage bin to push the storage bin to move leftwards and rightwards; the other end of the transmission platform is provided with an opening, and the mould is positioned below the opening; the pressurizing device is used for pressurizing the materials in the mould to form the heat-insulating plates. The automatic compression forming system has the advantages of high production efficiency, light weight of the heat-insulating plates, controllability in compression density, uniformity in force applied to each portion of the heat-insulating plates and the like.

Owner:谭学俊

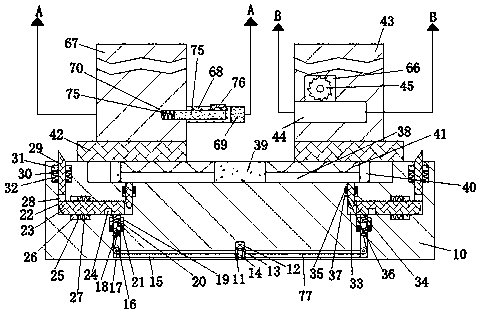

A kind of automatic packing equipment for ointment base

InactiveCN105366085BAvoid uneven thicknessImprove work efficiencyLiquid materialControl valvesAutomation

The invention relates to the field of automatic unguent tray-loading equipment, in particular to automatic unguent base tray-loading equipment. The automatic unguent base tray-loading equipment comprises a base, a pneumatic feeding device and a pneumatic discharging device, wherein the pneumatic feeding device is fixed to the base through a support and provided with a hopper and a pushing pipe; a discharging pipe communicated with the pushing pipe is arranged at the bottom of the hopper; a control valve is mounted in the connecting position of the pushing pipe and the discharging pipe. A pushing rod is driven by a feeding air cylinder in the pneumatic feeding device to move in the pushing pipe, materials are sucked into the pushing pipe from the hopper and are conveyed into the pneumatic discharging device by the pushing pipe via a feeding hose, the pneumatic discharging device is used for feeding the materials onto a tray quantitatively, the situation that the thickness of bases is not even due to manual filling is avoided, the traditional manual filling work is replaced, the degree of automation is high, and the filling work efficiency is improved.

Owner:嘉兴实新企业服务有限公司

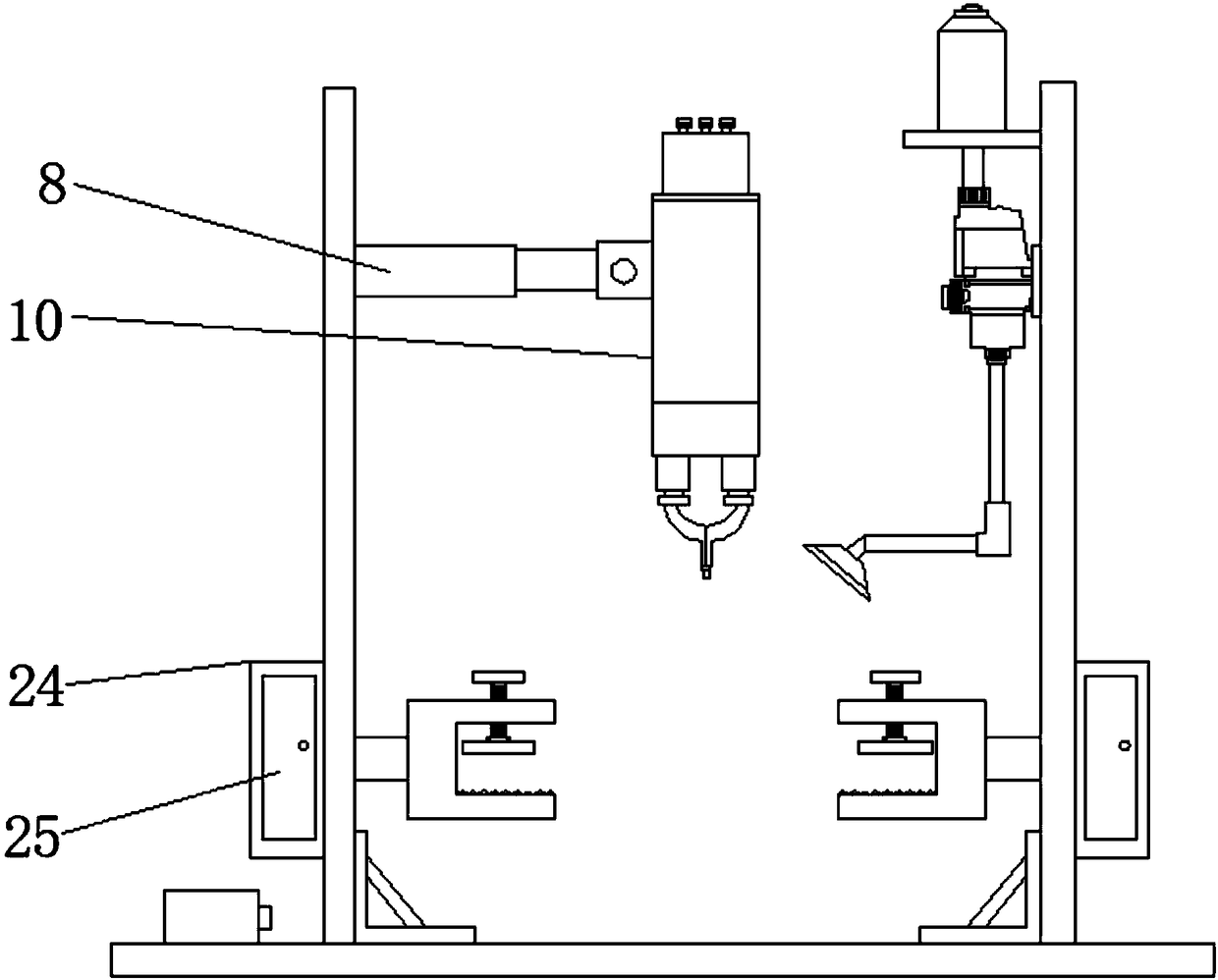

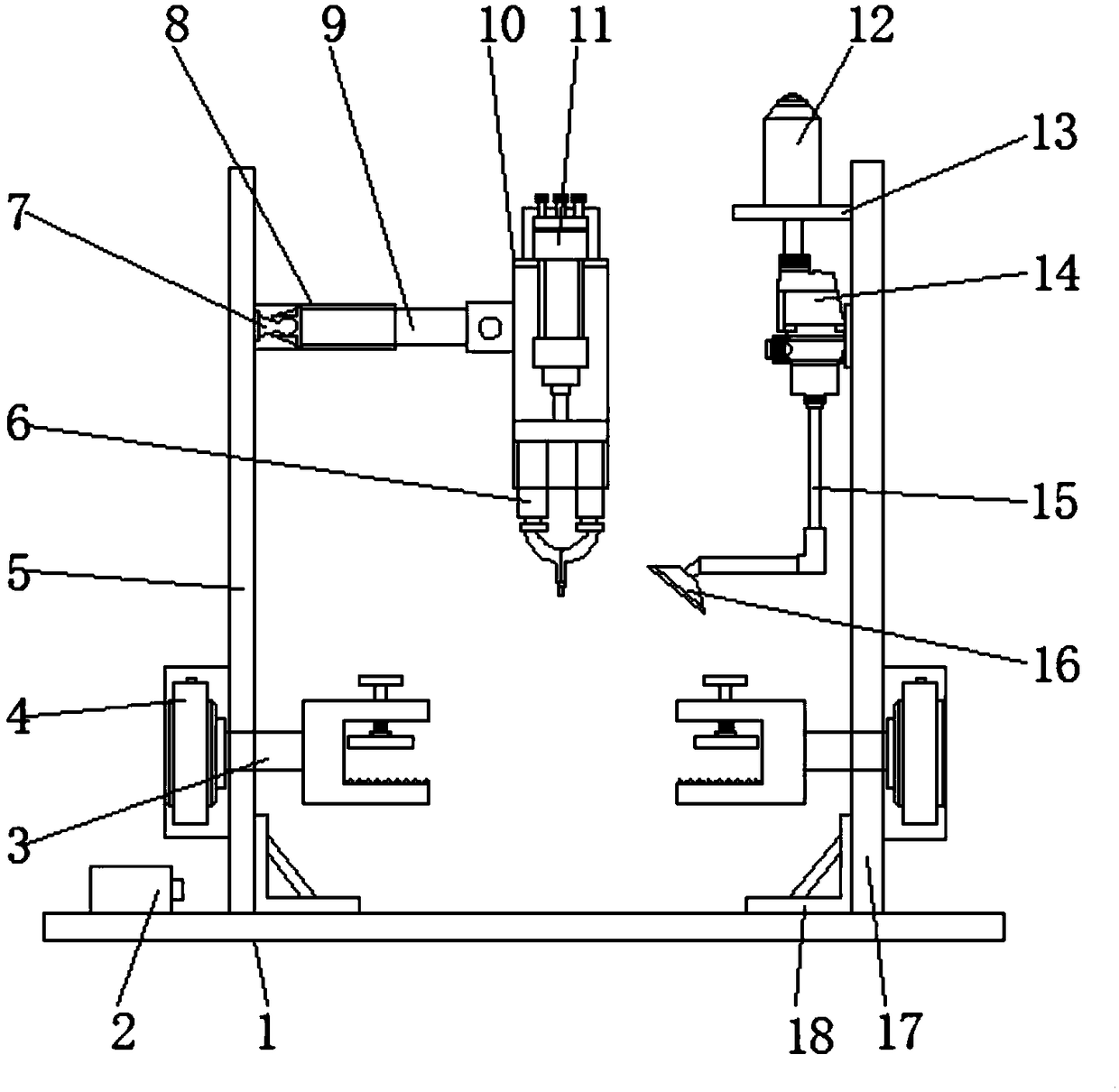

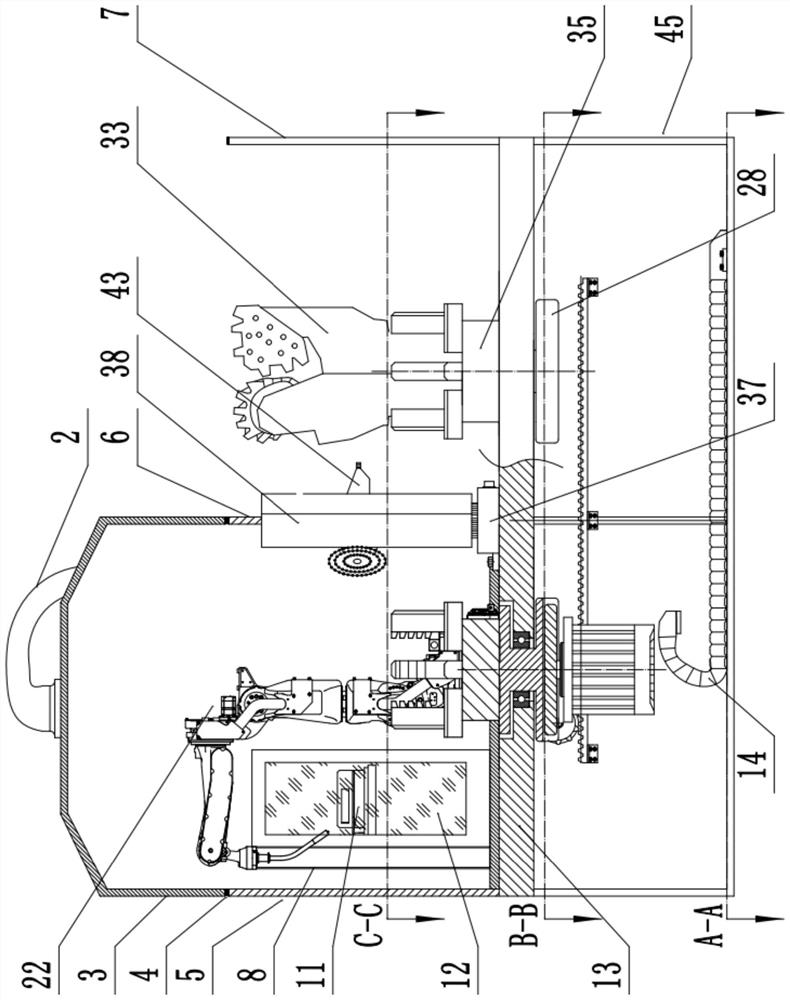

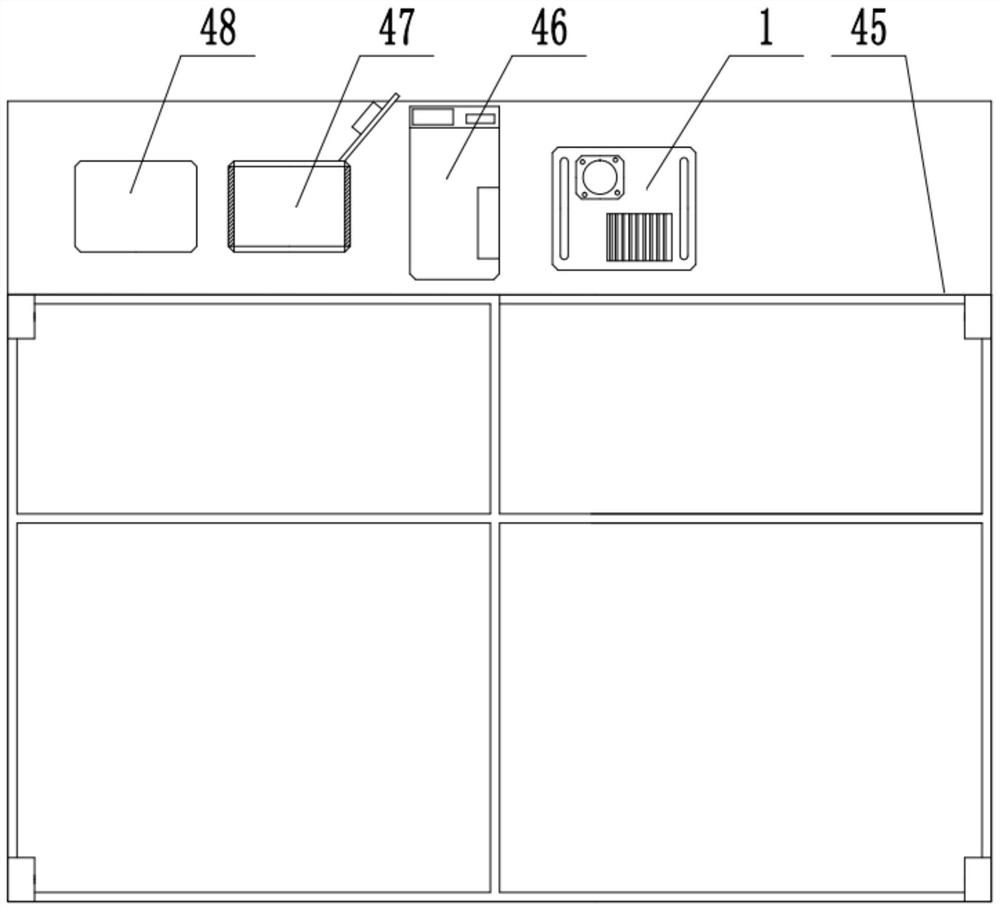

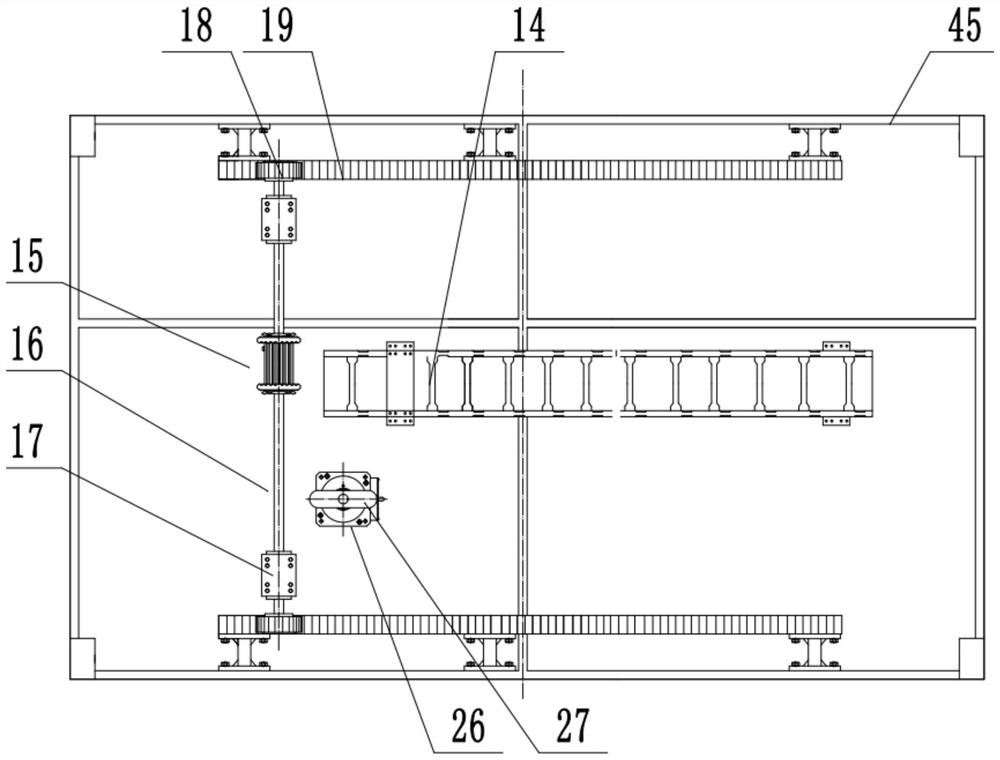

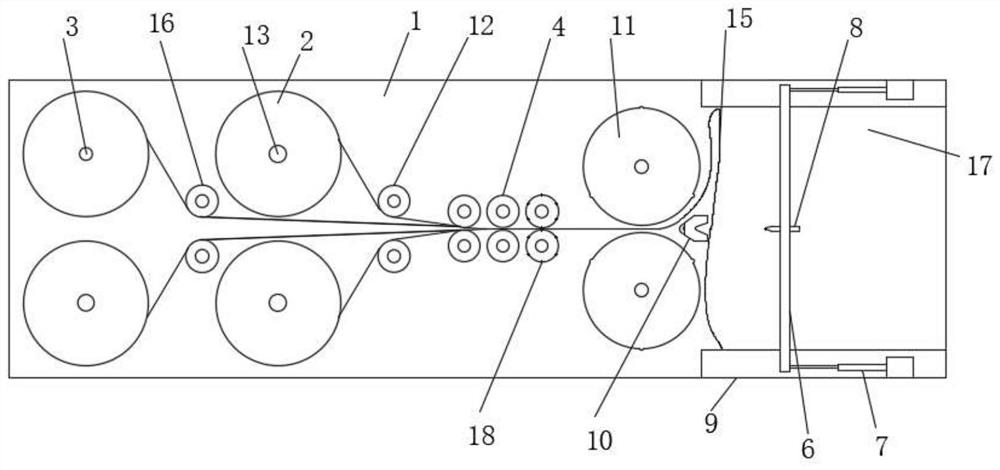

A double-station automatic tooth palm welding and process grinding equipment and welding method

ActiveCN110549050BImprove protectionDegree of automationEdge grinding machinesGrinding carriagesButt weldingIndustrial engineering

Owner:CANGZHOU GREAT DRILL

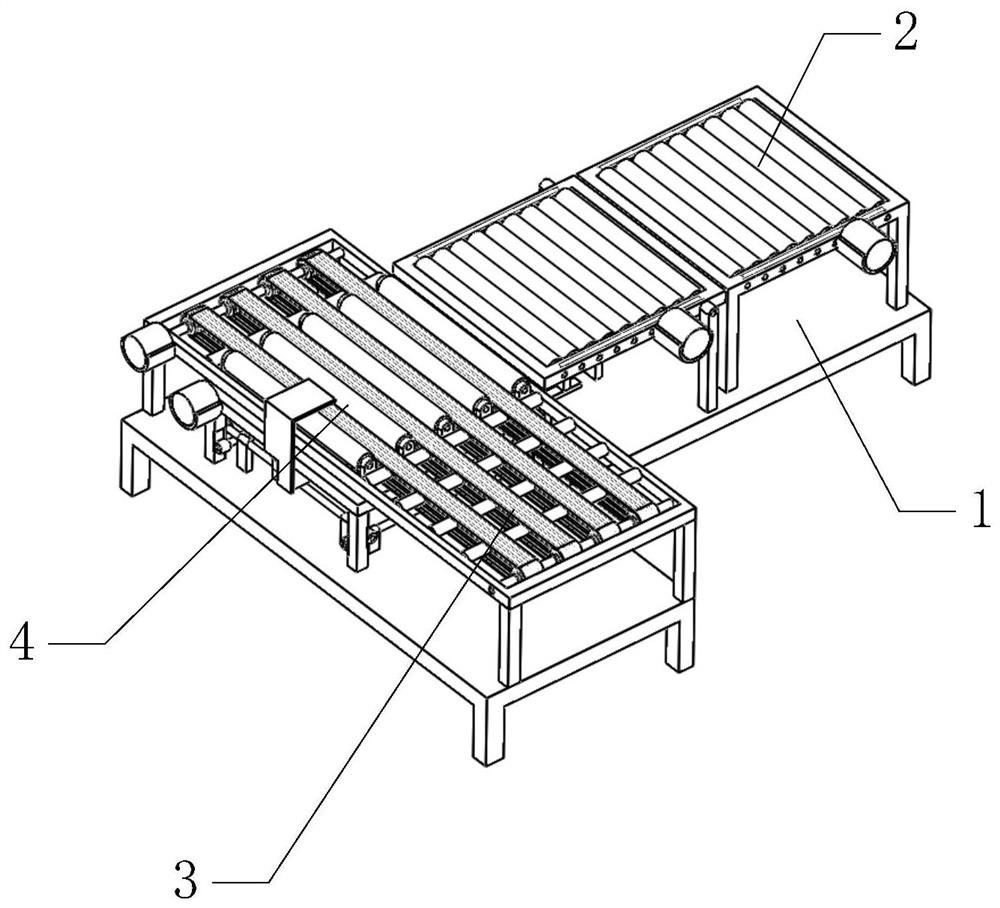

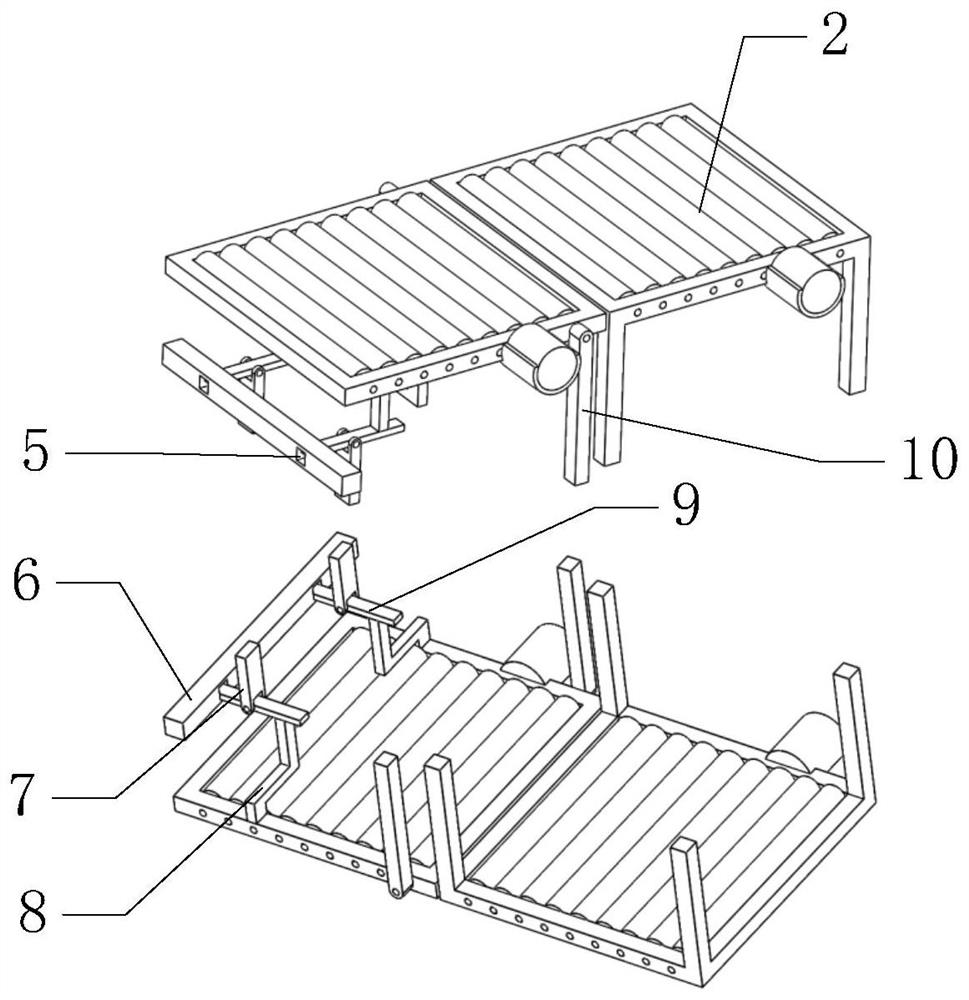

Corner conveying equipment for tile processing

ActiveCN113666067ALow costEasy to operateConveyor partsMechanical conveyorsStructural engineeringMechanical engineering

The invention belongs to the technical field of tile conveying, and particularly relates to corner conveying equipment for tile processing. The corner conveying equipment comprises a base, first conveying mechanisms, a second conveying mechanism and a third conveying mechanism, wherein the second conveying mechanism is fixedly mounted on the upper side of the base, the third conveying mechanism is mounted on the upper side of the base in an up-down sliding manner, the third conveying mechanism and the second conveying mechanism are distributed in a staggered mode, and the conveying direction of the third conveying mechanism is perpendicular to that of the second conveying mechanism; the two first conveying mechanisms are installed on the upper side of the base side by side and are next to the third conveying mechanism; and the first conveying mechanism, close to the third conveying mechanism, in the two first conveying mechanisms is installed on the upper side of the base in a swinging mode. Through the design of the first conveying mechanisms, the second conveying mechanism and the third conveying mechanism, corner conveying of tiles is achieved by means of the gravity of the tiles under the condition that no lifting mechanism is designed; and compared with traditional equipment with a specially designed lifting mechanism, the corner conveying equipment reduces the cost, is easy to operate and has a certain degree of automation.

Owner:江西格仕祺陶瓷有限公司

Rapid unfolding and folding device for medical gauze swab

InactiveCN112811253ANo human intervention requiredDegree of automationFolding thin materialsGauze swabMedicine

The invention relates to the technical field of medical instruments, in particular to a rapid unfolding and folding device for a medical gauze swab. The device comprises a workbench, supporting legs are evenly arranged at the bottom of the workbench, a tray is installed on one side of the workbench, and a first gauze roller is vertically arranged in the middle of the upper end face of the tray. A first gauze bundle is wound on the first gauze roller, a plurality of pairs of conveying rollers and a first traction roller are rotationally installed in the middle of the workbench and connected with an external driving mechanism through transmission chains, and a pair of baffles is installed on the other side of the workbench. A placing groove used for placing the gauge is formed between the pair of the baffles and the upper end face of the workbench. A telescopic rod is installed on the upper end face of the baffles. According to the rapid unfolding and folding device for the medical gauze swab, the work of multi-layer unfolding and folding of the gauze is achieved, manual intervention is not needed in the whole process, and the rapid unfolding and folding device has the advantages of being high in automation degree and high in machining efficiency.

Owner:孙娟

Garbage recycling device capable of recycling urban garbage

InactiveCN109896210AReduce labor intensitySolve the trouble of difficult transportationRefuse vehiclesManual handlingUrban waste

The invention discloses a garbage recycling device capable of recycling urban garbage. A garbage storage cavity with an upward opening is arranged in a device main body, a filter plate assembly are arranged in the garbage storage cavity, and the filter plate assembly can carry out solid-liquid separation on the garbage thrown into the garbage storage cavity; and an opening cavity with a forward opening is formed in the inner wall at the front side of the garbage storage cavity, wherein the upper end of the inner wall at the rear side of the opening cavity and the upper end of the inner wall atthe front side of the garbage storage cavity are connected and are provided with an opening groove with an upward opening, and a garbage can clamping block is slidably arranged in the opening cavity.The garbage recycling device aims to replace manual handling of the garbage can and pour the garbage in the garbage can into a collecting cavity.

Owner:广州轻舟科技有限公司

A false corbel wire cutting device

ActiveCN105459274BAchieve reductionImprove cutting efficiencyStone-like material working toolsHydraulic cylinderArchitectural engineering

The invention discloses a linear cutting device for false brackets. The linear cutting device comprises a locating plate, a first connecting rod is fixed to the front end of the locating plate, a second connecting rod is fixed to the middle of the first connecting rod, a sliding block is installed on the right of the locating plate, a connecting plate is arranged in front of the locating plate, a hydraulic cylinder is fixed to the second connecting rod, an air cylinder is fixed to the front end of the connecting plate, and a cutting device is fixed to the right end of the air cylinder. The linear cutting device has the advantages that the structural design is simple, use is convenient, the cutting device and the connecting plate are matched for cutting the false brackets, manual cutting is replaced, the automation degree is high, the cutting efficiency of the false brackets is improved, the cutting quality of the false brackets is guaranteed, and the manpower and material resources are saved.

Owner:江苏旭志光学眼镜有限公司

Functional textile fabric and manufacturing method thereof

The invention discloses functional textile fabric and a manufacturing method thereof. A device included in the method comprises a device body, a moving device arranged in the device body and a wax coating device arranged in the device body. The moving device comprises a first rotating cavity arranged in the device body, and a power wheel is rotationally arranged in the first rotating cavity. At present, with flourishing of the clothing industry, more and more novel clothing materials appear on the market, waterproof clothes are more and more popular in the trend that functions matter, most ofwaterproof materials on the current market need manual waterproof medium coating on material surfaces, coating uniformity is unlikely to achieve, labor and time are consumed, and the production efficiency is low. By means of the functional textile fabric and the manufacturing method thereof, the materials can be automatically coated with waterproof media, and meanwhile coating uniformity can be ensured.

Owner:何纪全

Rod end bearing extreme temperature test fixture and its test method

ActiveCN109839273BSave storage spaceImprove general performanceMachine bearings testingCouplingElectric machinery

The invention relates to a rod end bearing limit temperature test fixture and a test method thereof. The rod end bearing limit temperature test fixture comprises a fixing table, an adapter seat, a base, a box passing connection shaft, a plastic sleeve, a motor shaft, a coupling, a fixture connection shaft and a retaining ring, wherein the adapter seat is mounted on the base; the base is mounted onthe fixing table; during the test, a tested bearing is connected to the inner threaded hole of the adapter seat through the outer thread of the rod end, and the outer diameter of the adapter seat ismatched with the inner hole of the base, a screw passing through the retaining ring is clamped to the fixture connection shaft, and the shaft is driven by the motor to realize the radial rotation of the inner ring of the tested bearing; and the fixture connection shaft is provided with a groove, the box passing connection shaft is provided with a connection shoulder, the box passing connection shaft passes through the temperature test box to be connected with the motor through the coupling, and the box passing connection shaft passes through the temperature test box through the plastic sleeve.The fixture has a simple structure, disassembly is facilitated, the mounting preparation time is shortened, and the device use efficiency is improved.

Owner:CHINA AERO POLYTECH ESTAB

A device for finishing and cutting brush bristles

The invention provides a brush hair sorting, cutting and manufacturing device. The device comprises a workbench, the upper end of the workbench is provided with support legs for supporting on the ground, the upper end face of the workbench is provided with a push cylinder, the front end of a push cylinder piston rod is connected with a baffle, the side face of the workbench at the front end of the baffle is provided with a conveyor belt device, a brush material is conveyed to the workbench through a conveyor belt, the workbench at the front end of the baffle is provided with a support frame, the upper end and the lower end of the support frame are both provided with clamping cylinders, the front end of the piston rod of each clamping cylinder is provided with a baffle, the back end of the support frame is provided with a cutter, the cutter is connected with a cylinder, and a groove is formed in the lower end of the cutter relative to the workbench. According to the brush hair sorting, cutting and manufacturing device, the brush material is conveyed to the workbench through the conveyor belt device, then the cylinder and the baffle are pushed to put the brush material into a leveling device composed of a cylinder at the upper end and two cylinders at the lower end, the leveling is carried out, the brush material is compressed at the same time, then, the brush material is cut through the cutter, the automation level is high, and the device is convenient and reliable.

Owner:安徽三和刷业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com