Rod end bearing extreme temperature test fixture and its test method

A technology of extreme temperature and test fixture, applied in the direction of mechanical bearing testing, etc., can solve the problems of difficult to ensure the center of the fixture, prone to eccentricity, waste of money, time and resources, etc., to improve the efficiency of equipment use, ensure accuracy and accuracy, reduce The effect of the frequency of the tour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

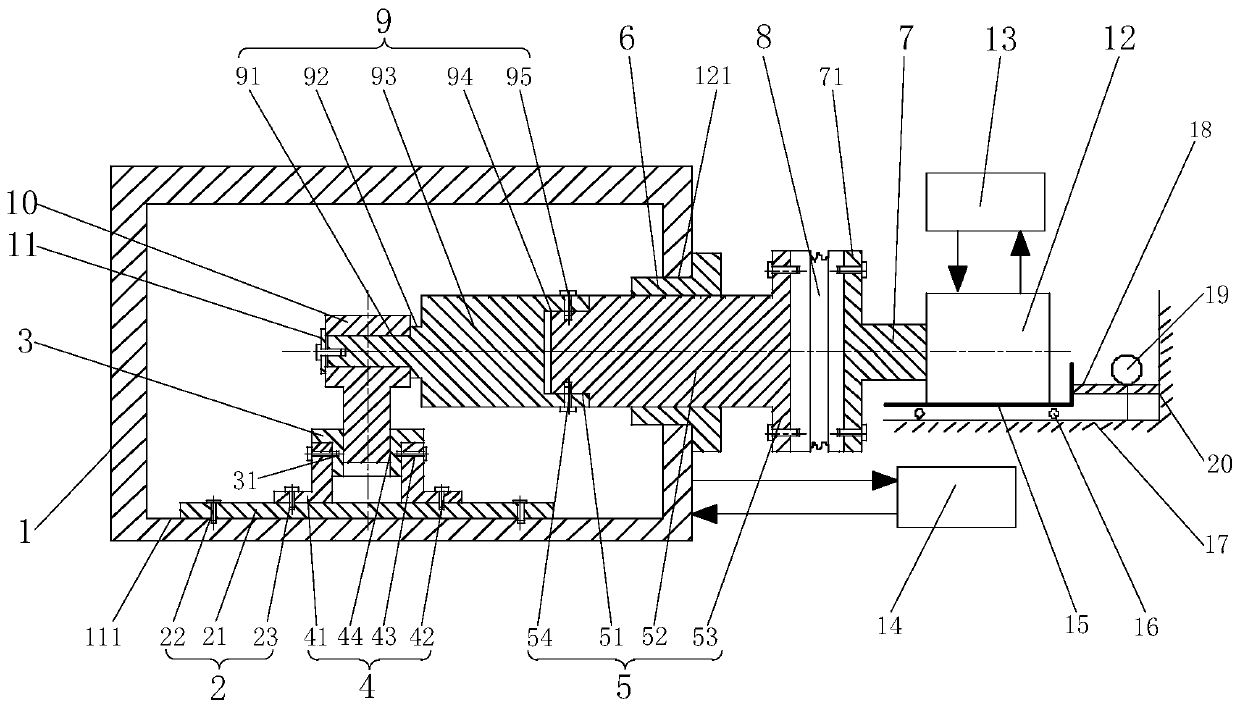

[0030] The invention provides a rod end bearing extreme temperature test fixture, such as figure 1 As shown, it includes a fixed table 2, an adapter seat 3, a base 4, a box-through connecting shaft 5, a plastic sleeve 6, a motor shaft 7, a coupling 8, a fixture connecting shaft 9 and a retaining ring 11. The fixed table 2 is provided with Two sets of threaded holes, and each set of threaded holes are evenly distributed on two concentric circles, the plate body 21 of the fixing table 2 is fixedly connected to the bottom plate 111 of the temperature test chamber 1 through the first set of threaded holes 22 with screws, The base 4 is provided with a third threaded hole group 42, a fourth threaded hole group 43 and an adapter mounting hole 44, and screws pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com