Automatic unguent base tray-loading equipment

A base and automatic technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve problems such as uneven base thickness, achieve automation, improve work efficiency, and avoid uneven base thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

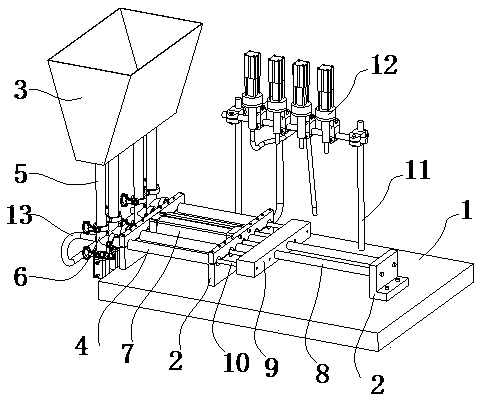

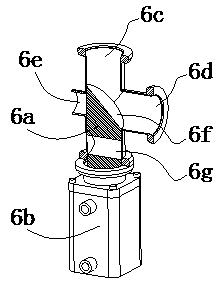

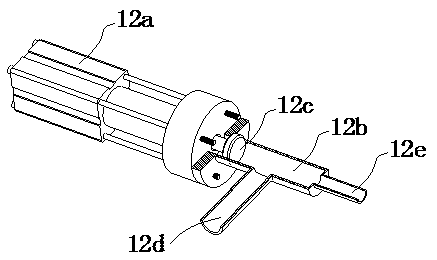

[0016] refer to Figure 1 to Figure 3 A kind of ointment base automatic packing equipment shown, comprises base 1, pneumatic feeding device and pneumatic discharging device; Said pneumatic feeding device is fixed on the base 1 by bracket 2; Said pneumatic feeding device is provided with hopper 3 and pusher Feeding pipe 4; the bottom of the hopper 3 is provided with a feeding pipe 5 communicating with the feeding pipe 4; a control valve 6 is installed at the connection between the feeding pipe 4 and the feeding pipe 5; the control valve 6 is provided with The first valve port 6c communicated with the drop pipe 5, the second valve port 6d communicated with the push pipe 4, and the third valve port 6e; the third valve port 6e is connected to the pneumatic discharge device through the feeding hose 13 .

[0017] The pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com