Patents

Literature

81results about "Water circulation promotion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

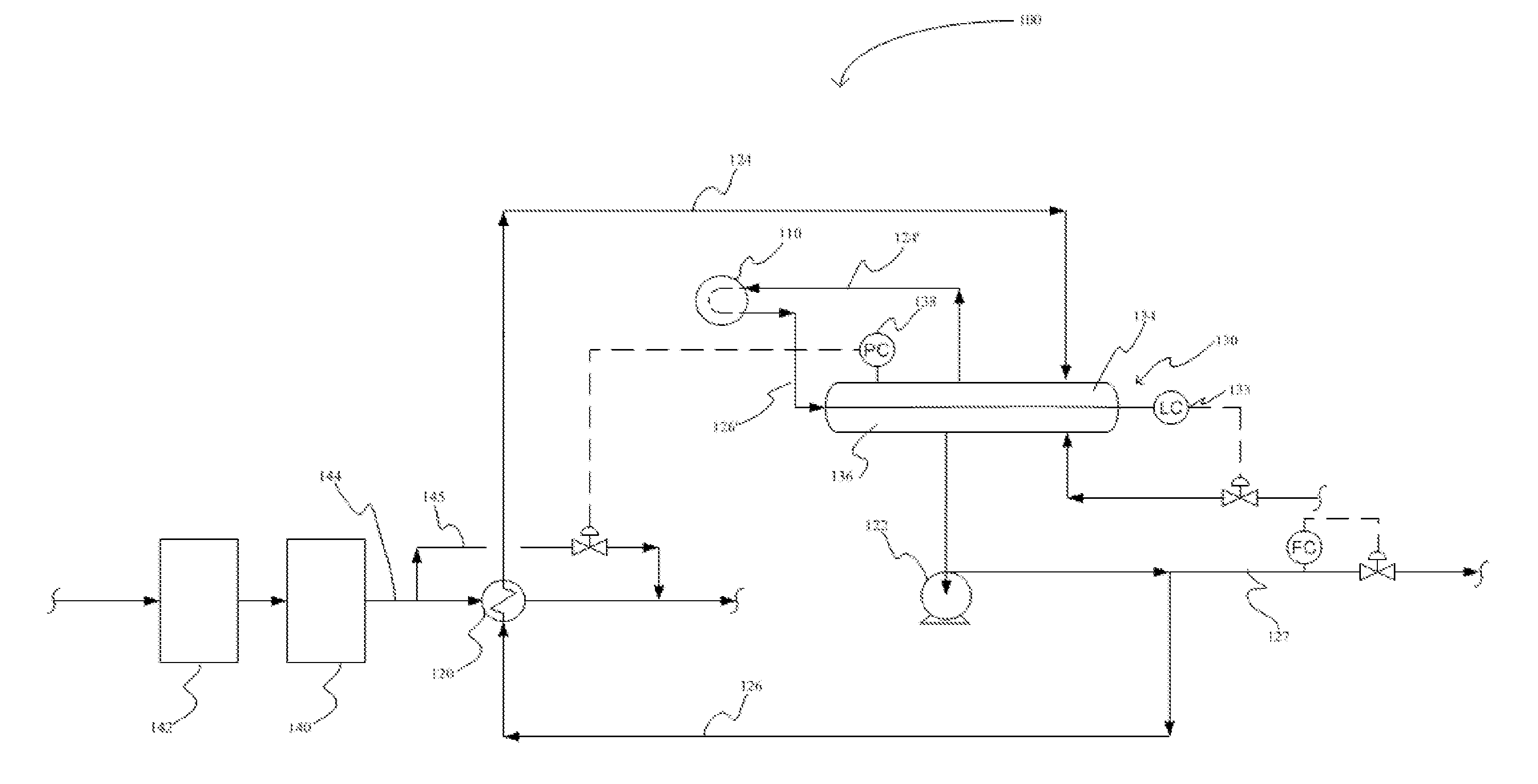

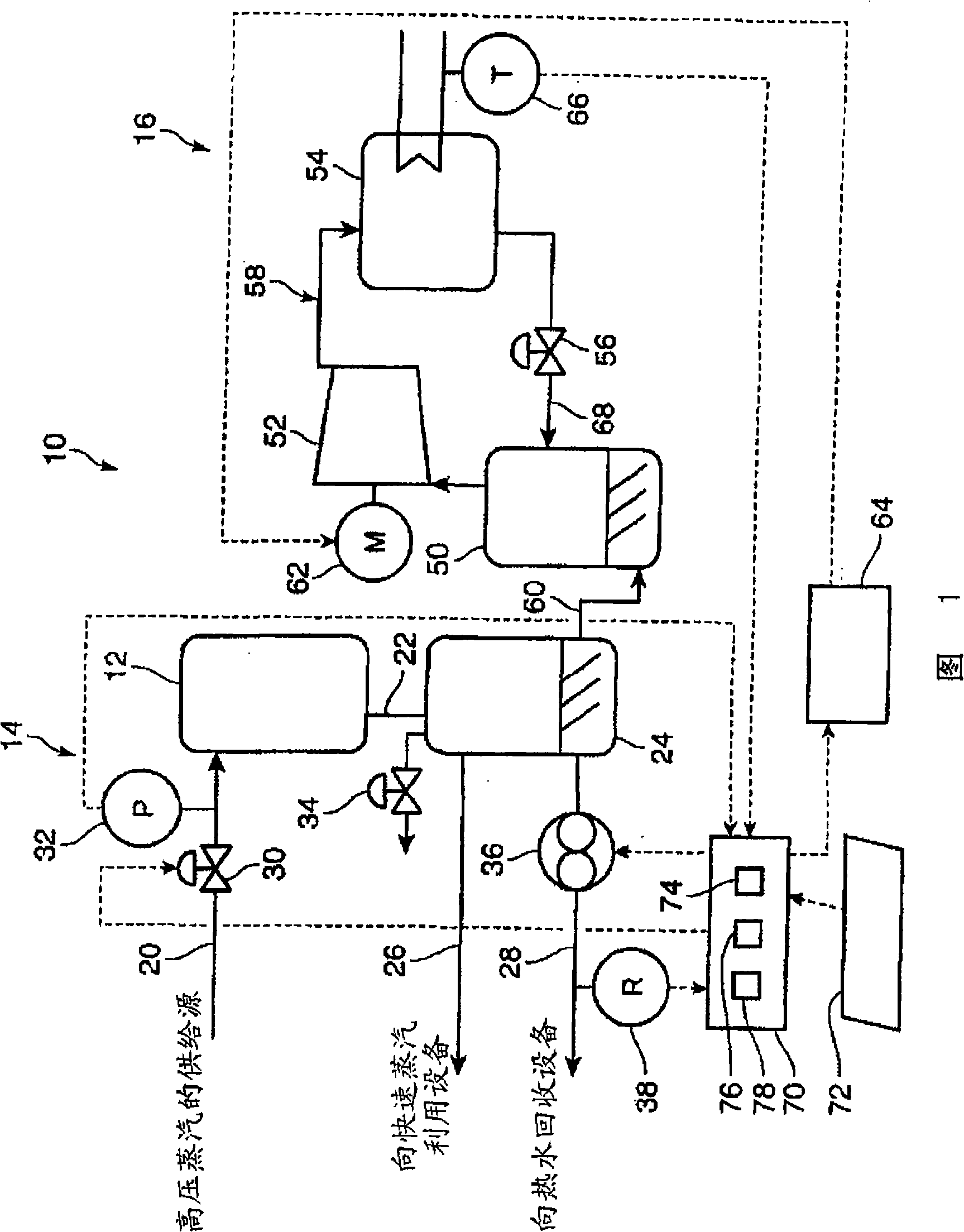

Configurations and methods of generating low-pressure steam

ActiveUS20120204817A1Heat recoverySteam generation heating methodsEnergy industryReboilerEngineering

Low-pressure steam for a steam consuming device, and particularly a steam reboiler, is generated at the steam consumption pressure to maximize the heat recovery from a utility fuel and / or waste heat source. Most preferably, steam is generated at the lowest possible pressure by fluidly coupling the steam generator to the steam consuming device (e.g., by integrating the condensate drum with the steam drum). Therefore, it should be appreciated that the steam generator pressure in such configurations and methods will ride on the reboiler pressure.

Owner:FLUOR TECH CORP

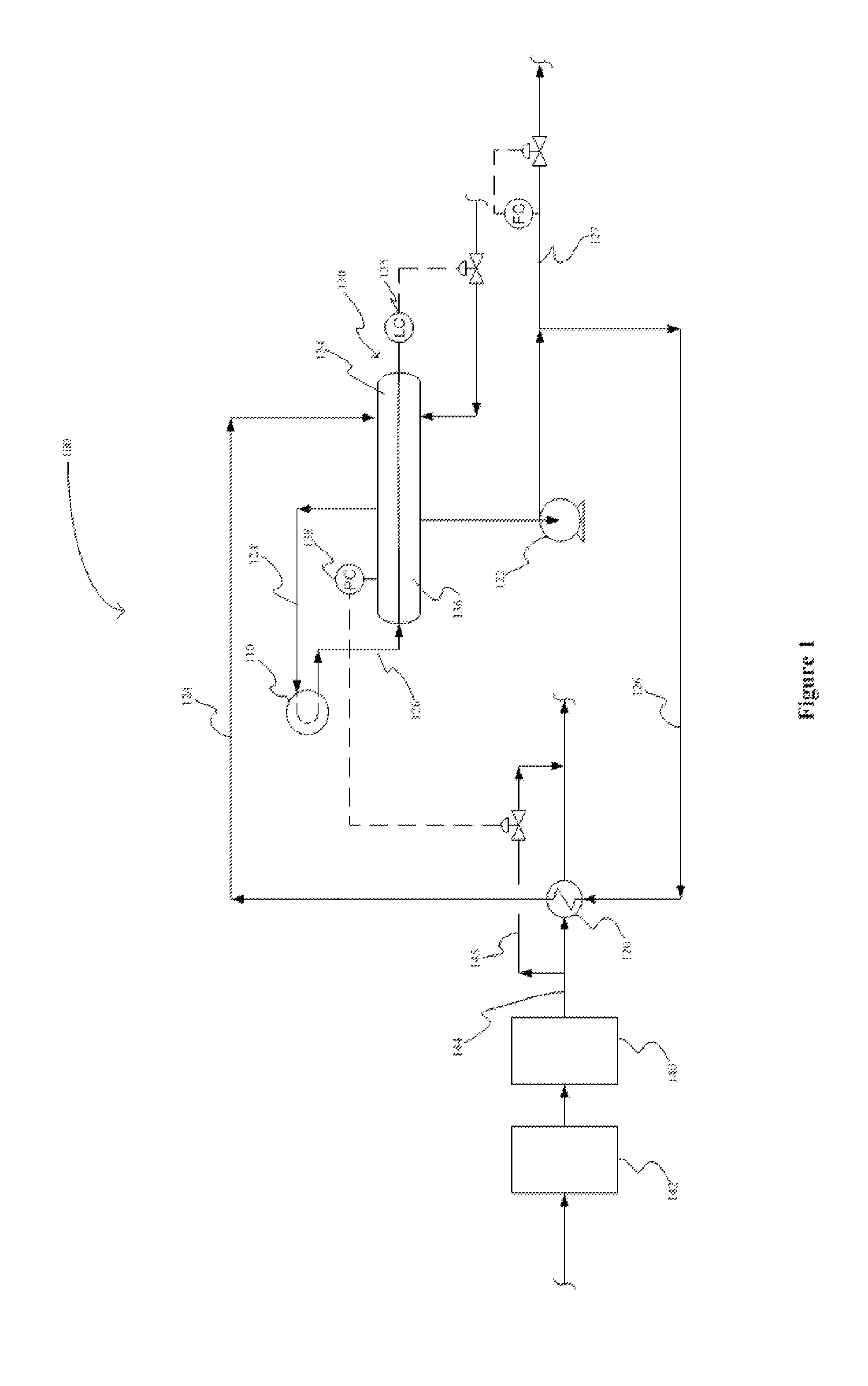

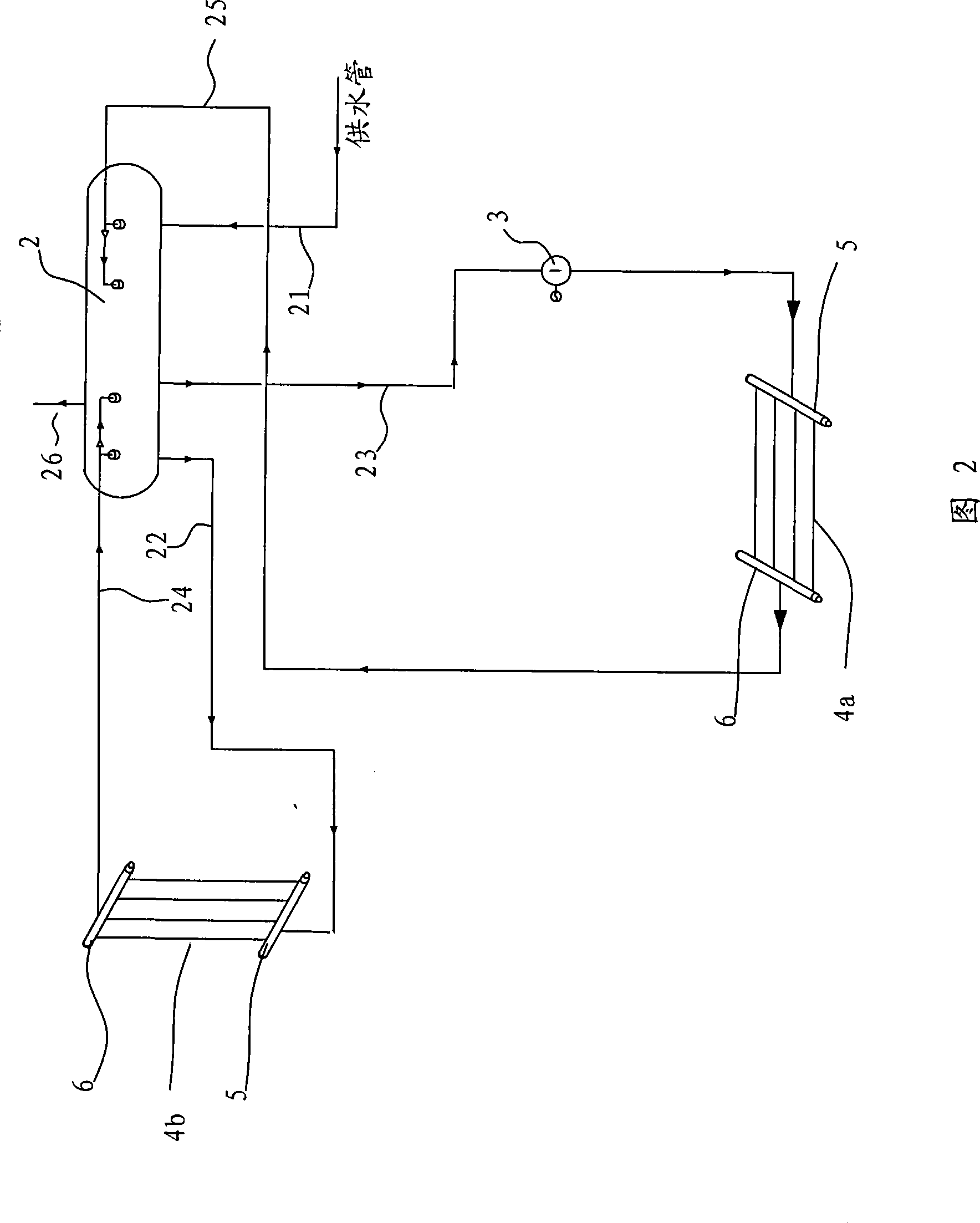

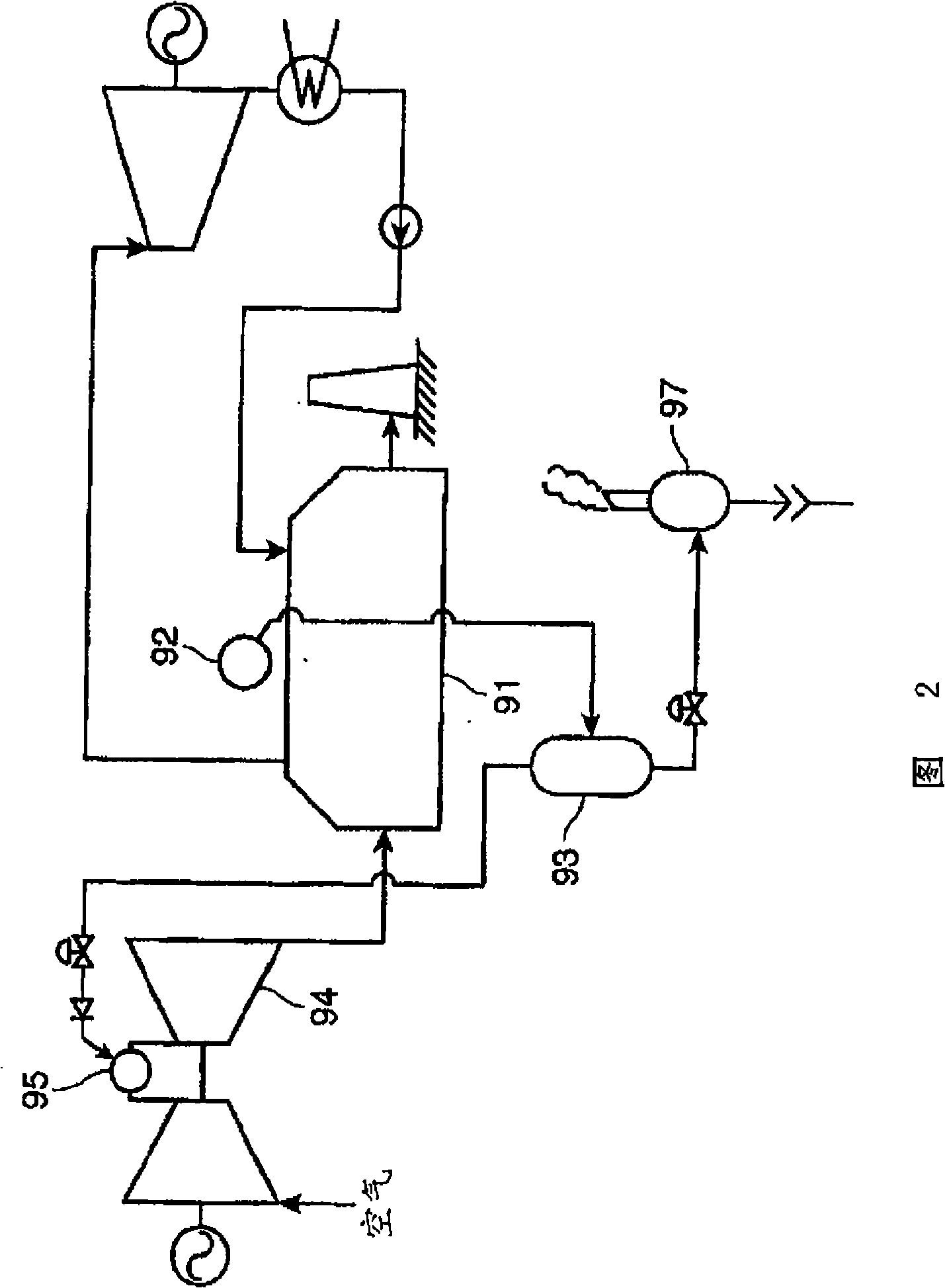

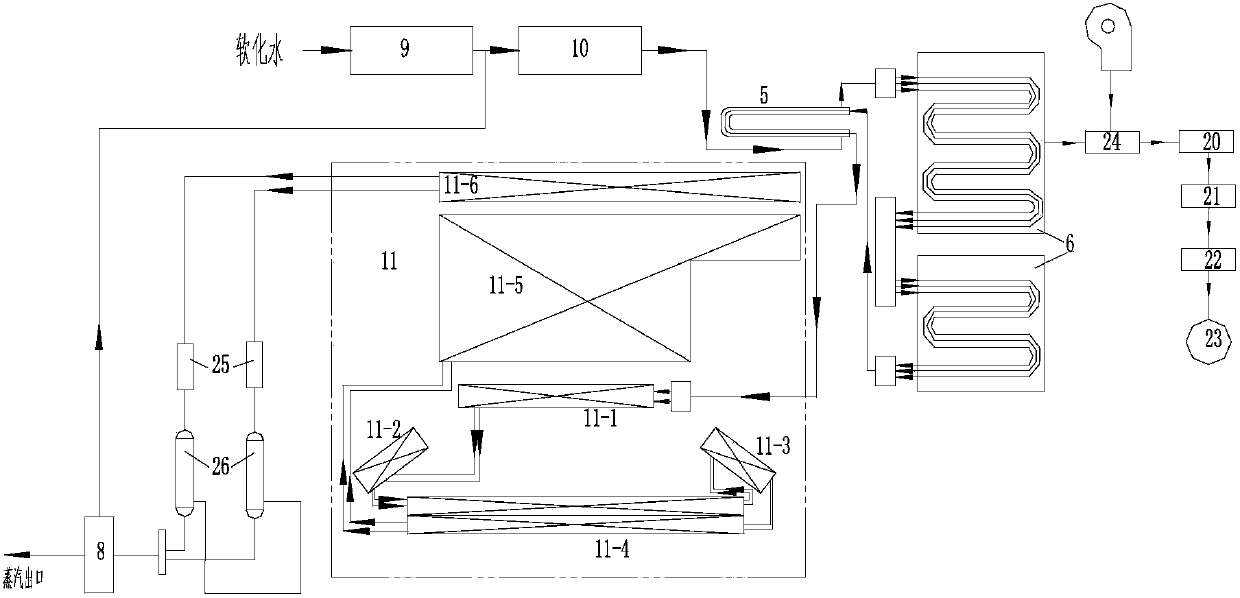

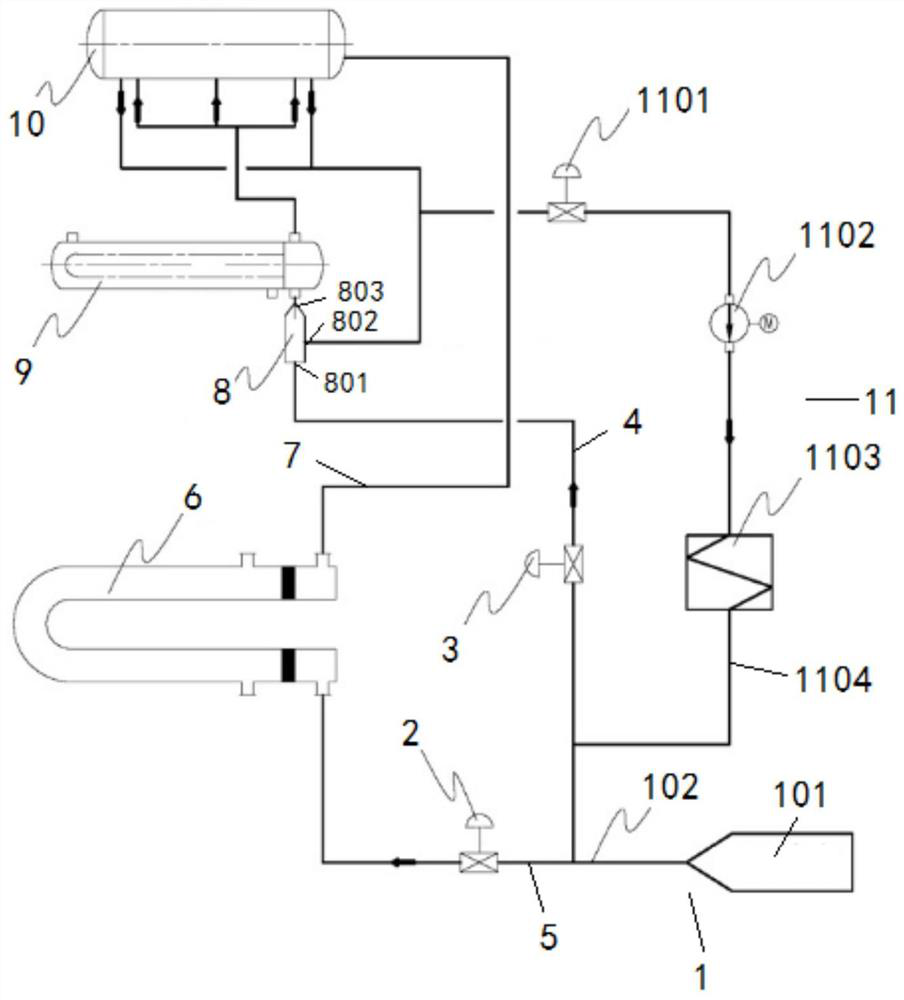

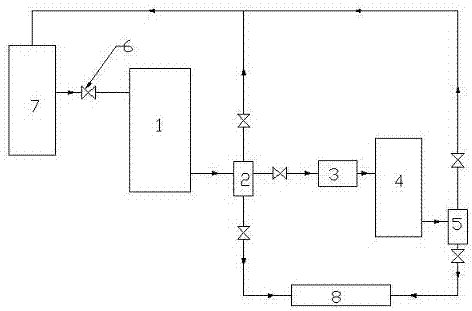

Circulating system of exhaust-heating boiler

ActiveCN101451706ASo as not to damageLow costWater circulationWater circulation promotionRefluxCirculator pump

The invention discloses a cycling system of a waste heat boiler, comprising a steam bag which is provided respectively with a natural cycling water outlet pipe, a forced cycling water outlet pipe, a natural cycling reflux pipe, a forced cycling reflux pipe and a steam outlet pipe, a natural cycling heat exchanger arranged at the natural cycling heating surface of the waste heat boiler the entrance and the exit of which are respectively connected with the steam bag through the natural cycling water outlet pipe and the natural cycling reflux pipe, a forced cycling heat exchanger arranged at the forced cycling heating surface of the waste heat boiler the entrance and the exit of which are respectively connected with the steam bag through the forced cycling water outlet pipe and the forced cycling reflux pipe and a cycling pump arranged at the forced cycling water outlet pipe. The cycling system of the waste heat boiler overcomes the defect existing in a single cycling system and combines the advantages of two cycling systems, overcomes limitations on the arrangement of the natural cycling heating surface and poor effects of dust removal, reduces flux and load of the recycling pump, improves reliability, and is provided with the advantages of light accumulated dust, small volume, energy saving, etc.

Owner:CHINA ENFI ENGINEERING CORPORATION

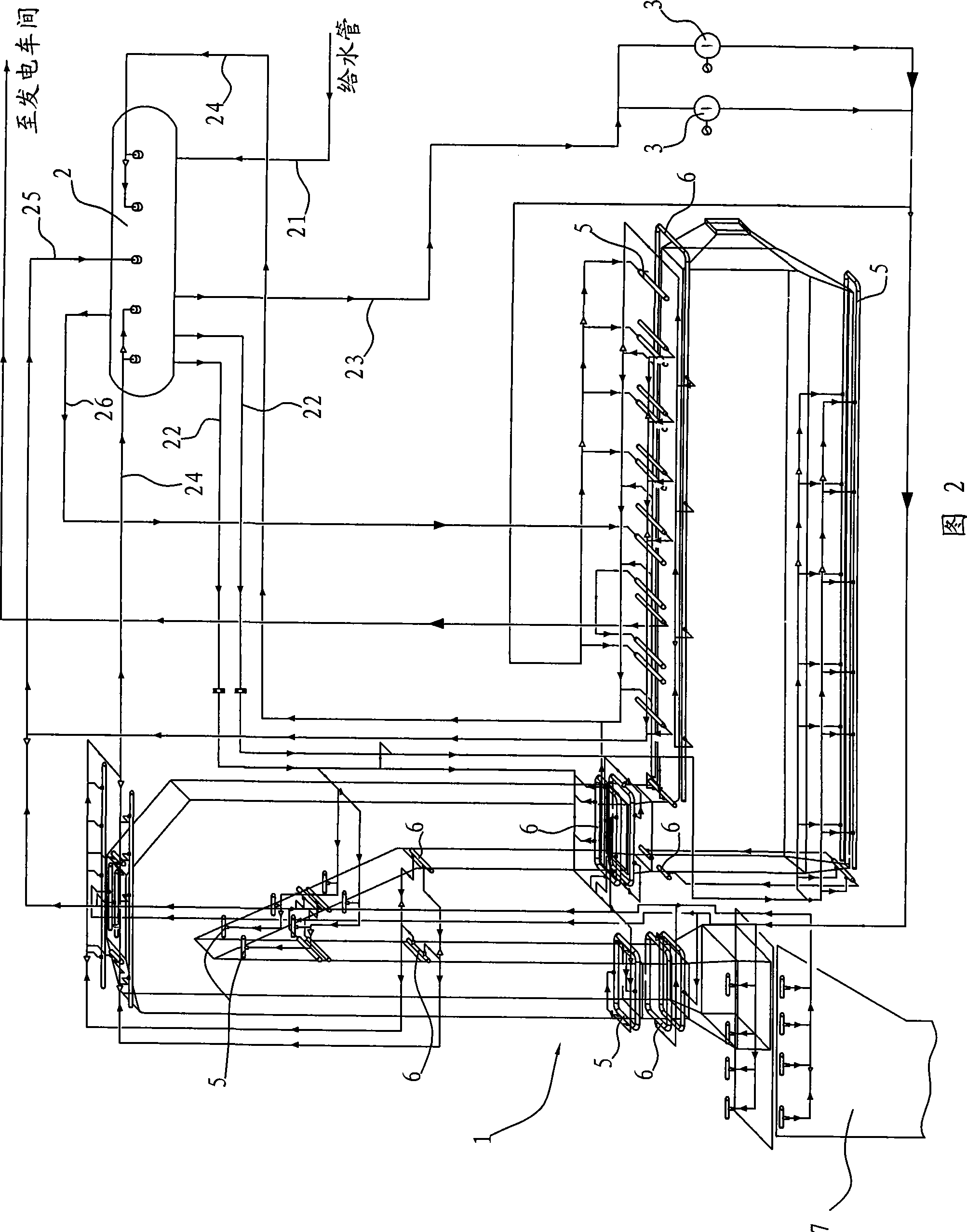

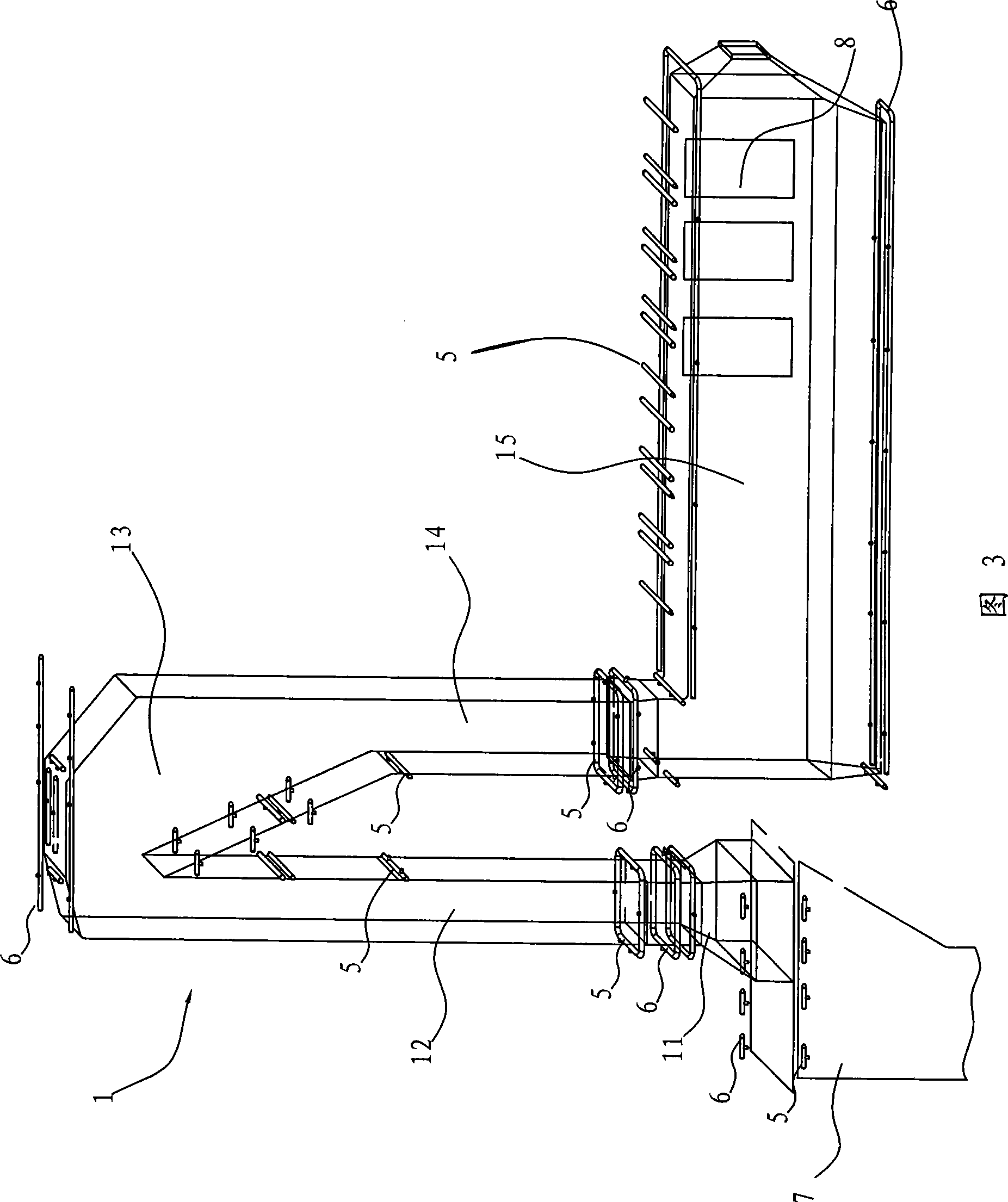

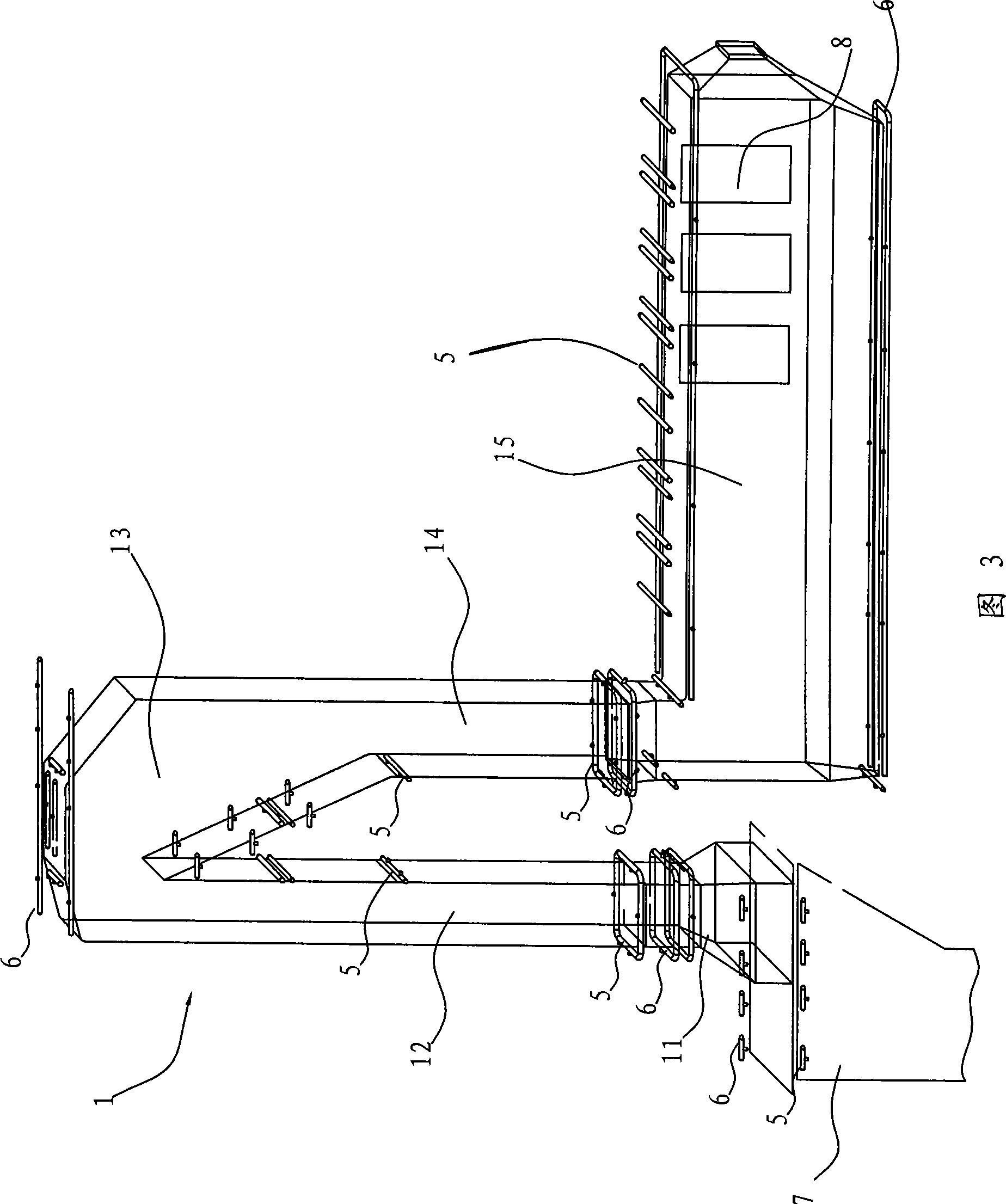

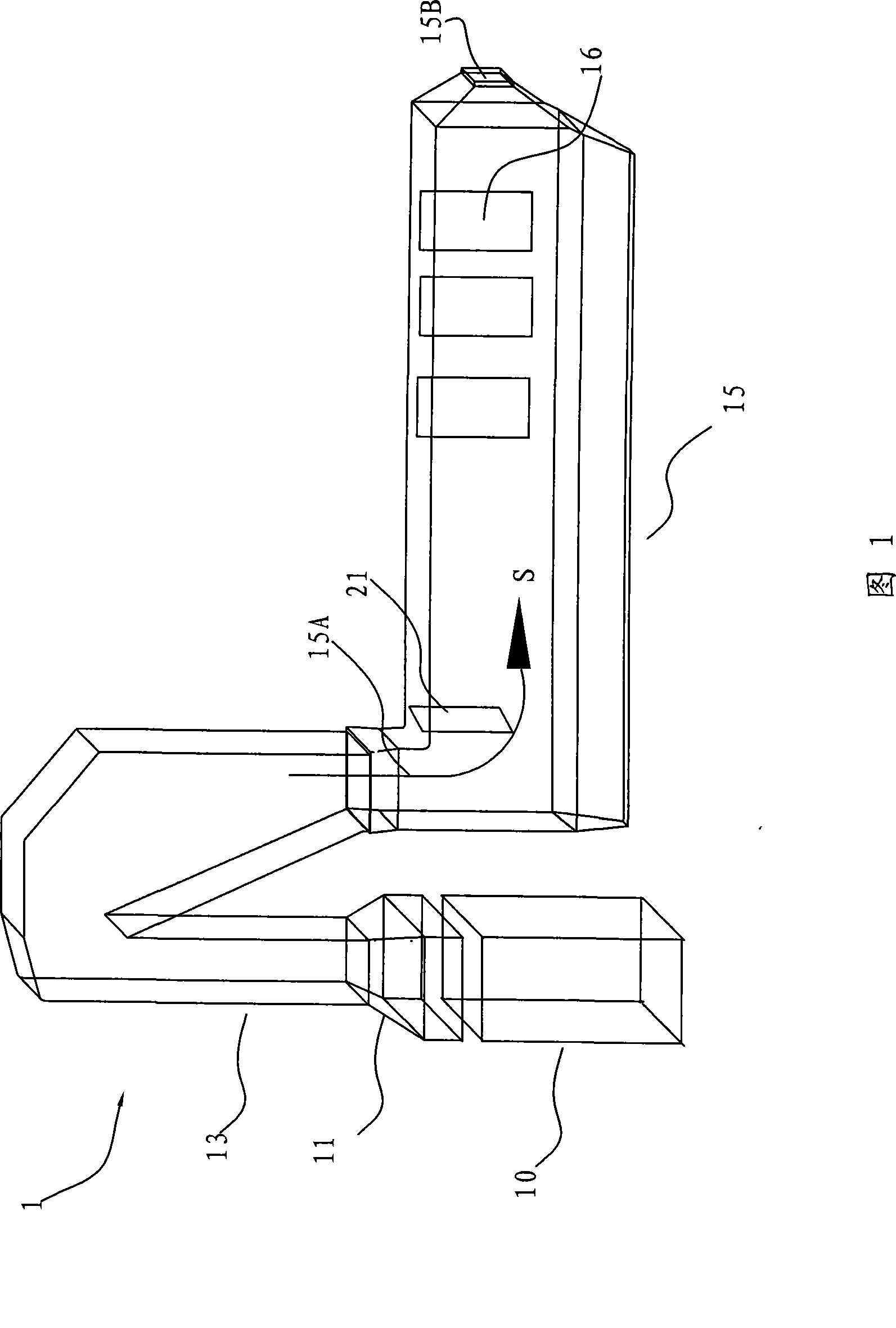

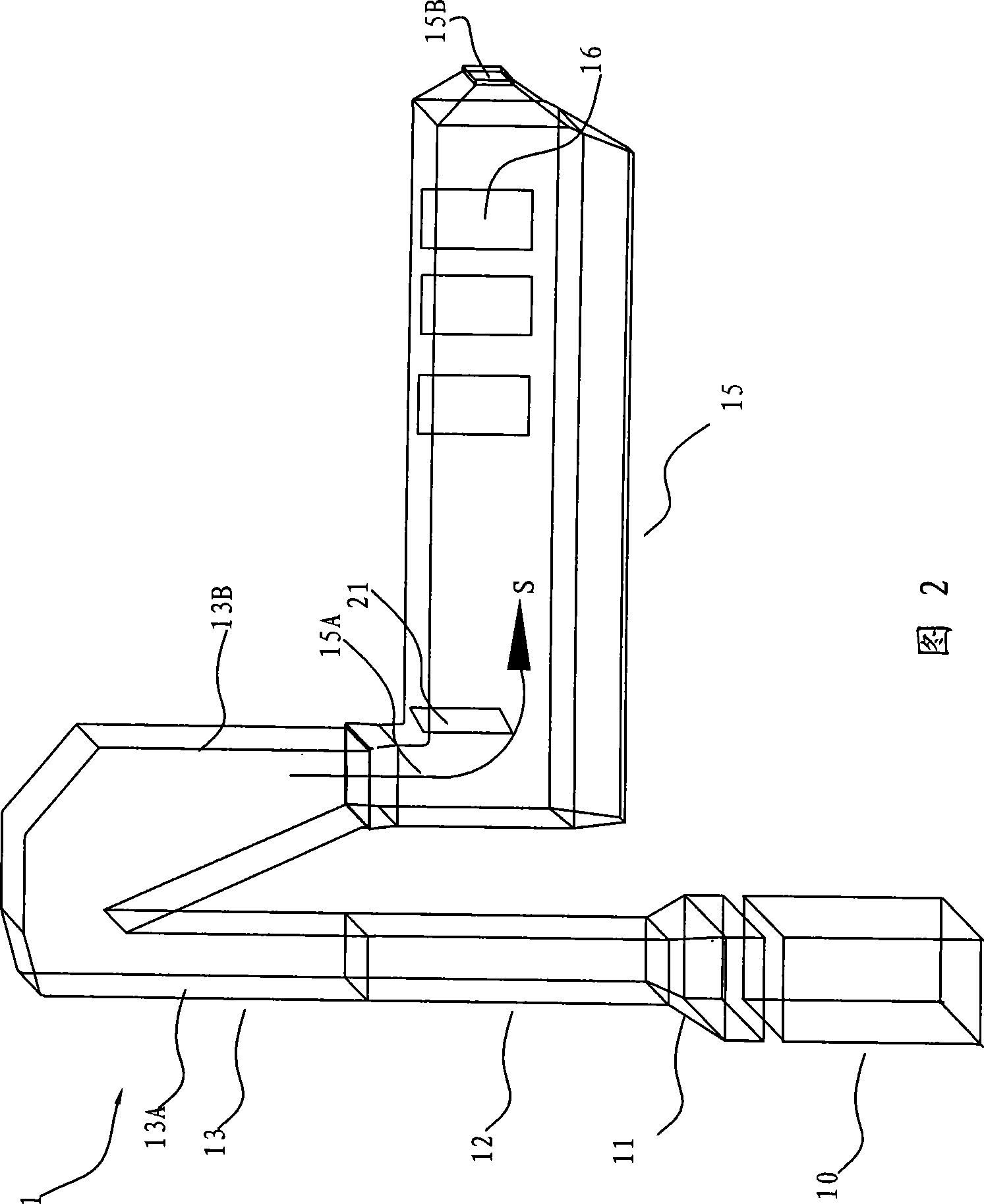

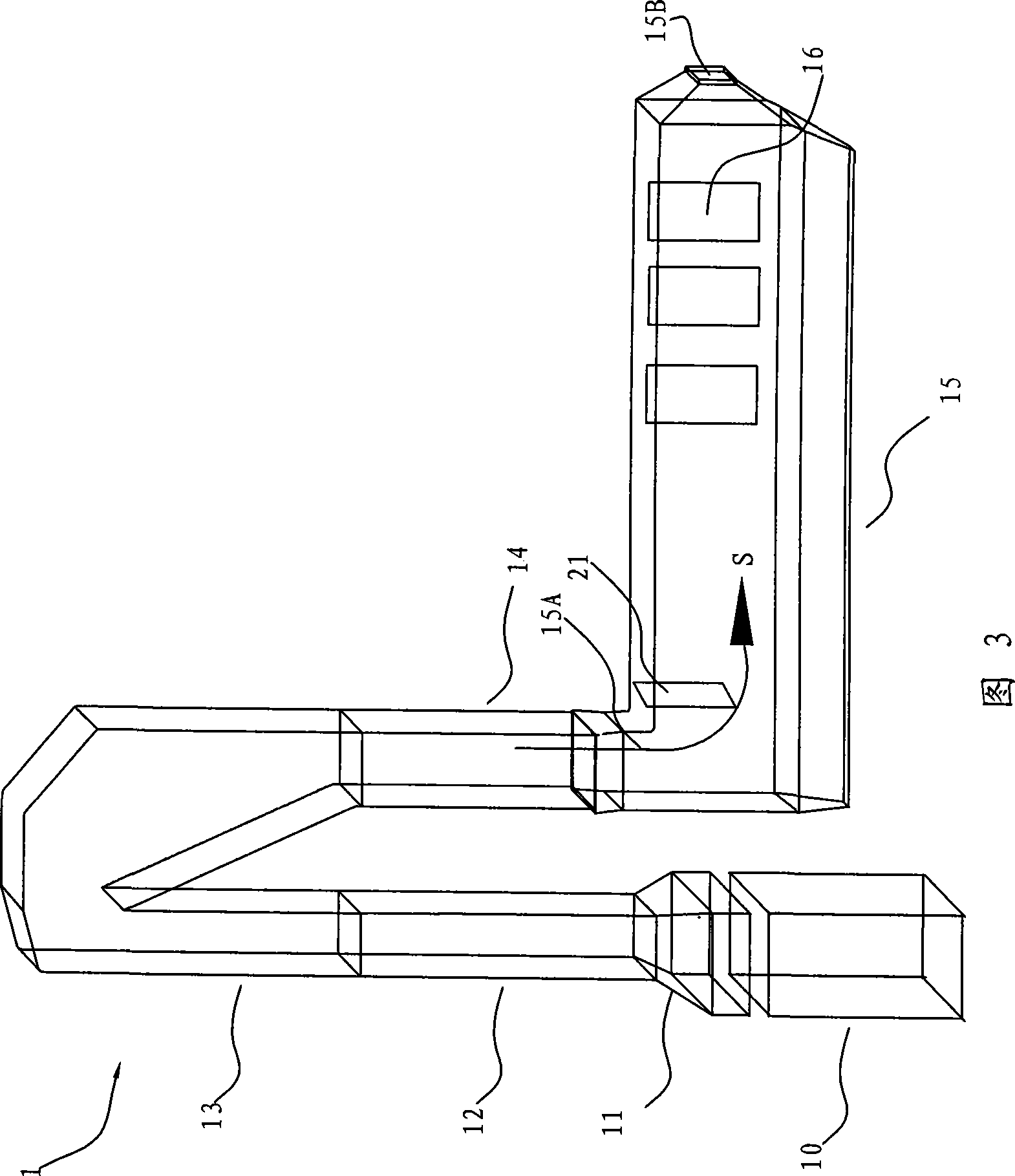

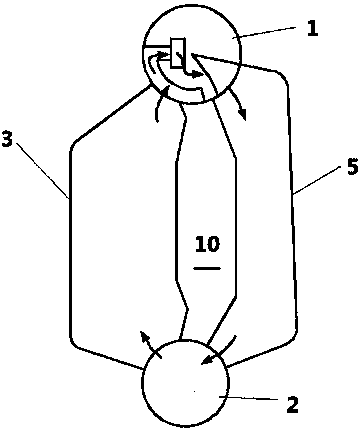

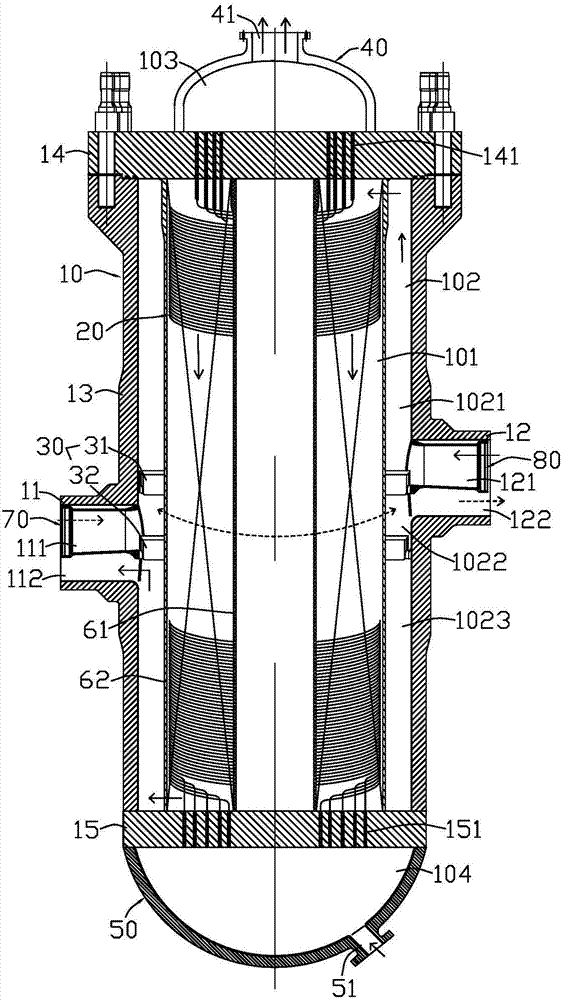

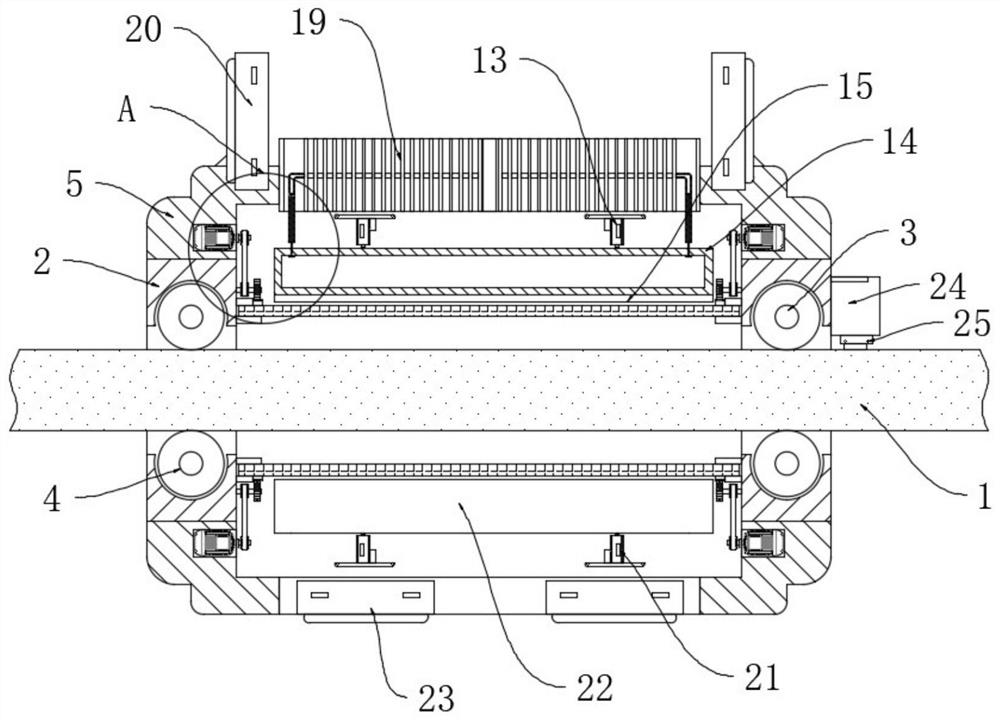

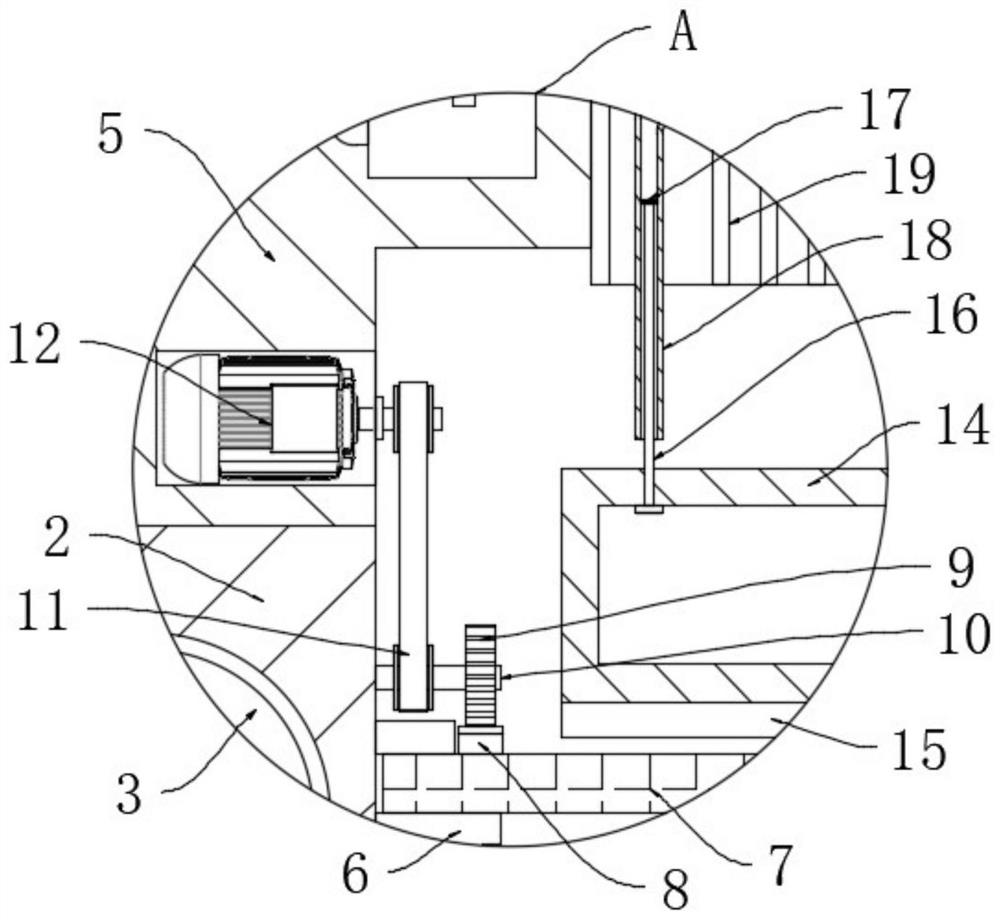

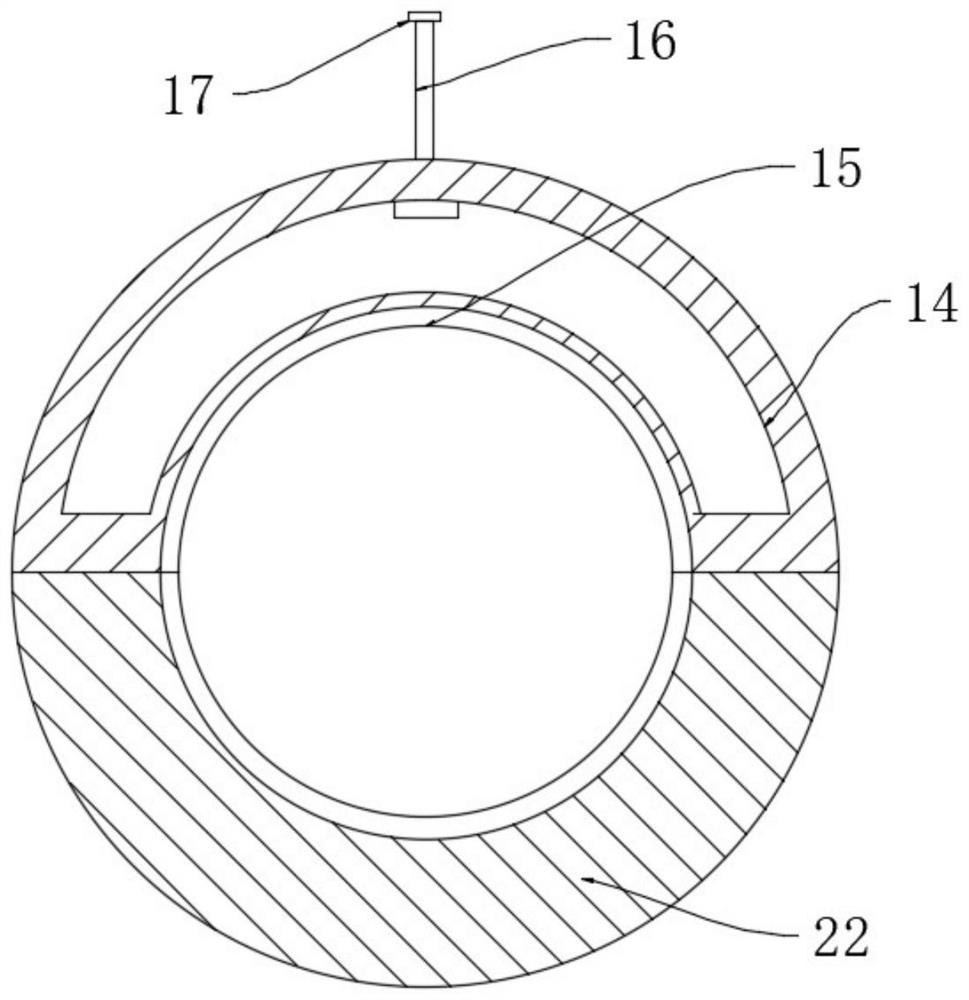

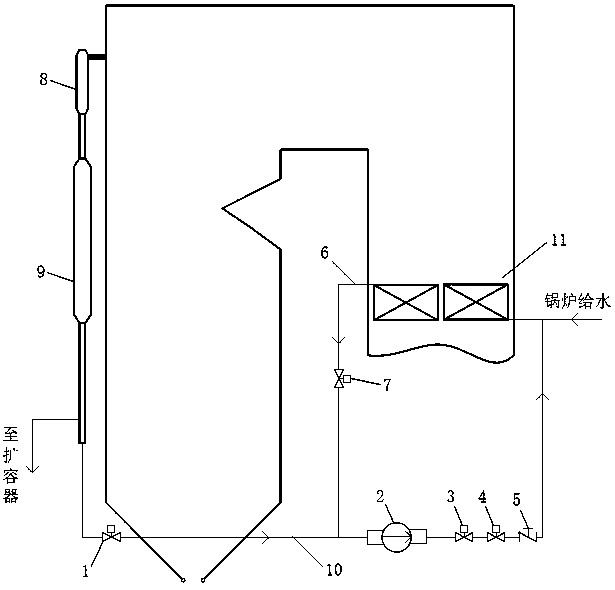

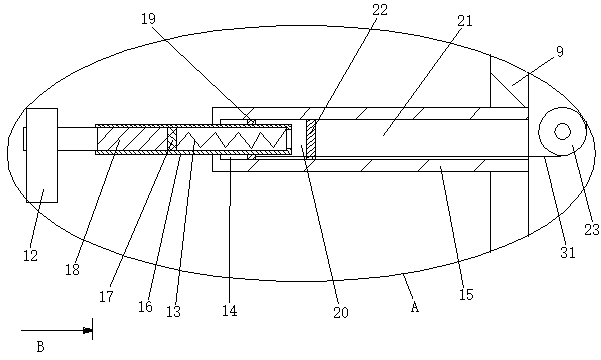

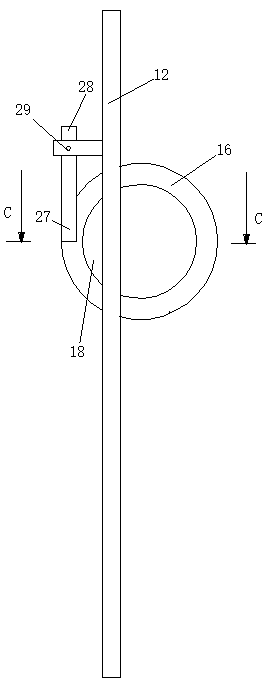

Exhaust-heating boiler

ActiveCN101451705ASo as not to damageLow costWater circulationWater circulation promotionRefluxEngineering

The invention discloses a waste heat boiler, comprising a boiler body provided with a natural cycling heating surface and a forced cycling heating surface, a cycling system which comprises a water inlet pipe respectively arranged and used for supplying water to steam bag, a natural cycling water outlet pipe, a forced cycling water outlet pipe, a natural cycling reflux pipe, a forced cycling reflux pipe and the steam bags of a steam outlet pipe, a natural cycling heat exchanger arranged at the natural cycling heating surface the entrance and the exit of which are respectively connected with the steam bag through the natural cycling water outlet pipe and the natural cycling reflux pipe, a forced cycling heat exchanger arranged at the forced cycling heating surface the entrance and the exit of which are respectively connected with the steam bag through the forced cycling water outlet pipe and the forced cycling reflux pipe and a cycling pump arranged at the forced cycling water outlet pipe. By combining advantages of two cycling systems, the waste heat boiler overcomes limitations on the arrangement of the natural cycling heating surface and poor effects of dust removal, reduces flux and load of the recycling pump, improves reliability, and is provided with the advantages of light accumulated dust, small volume, energy saving, etc.

Owner:CHINA ENFI ENGINEERING CORPORATION

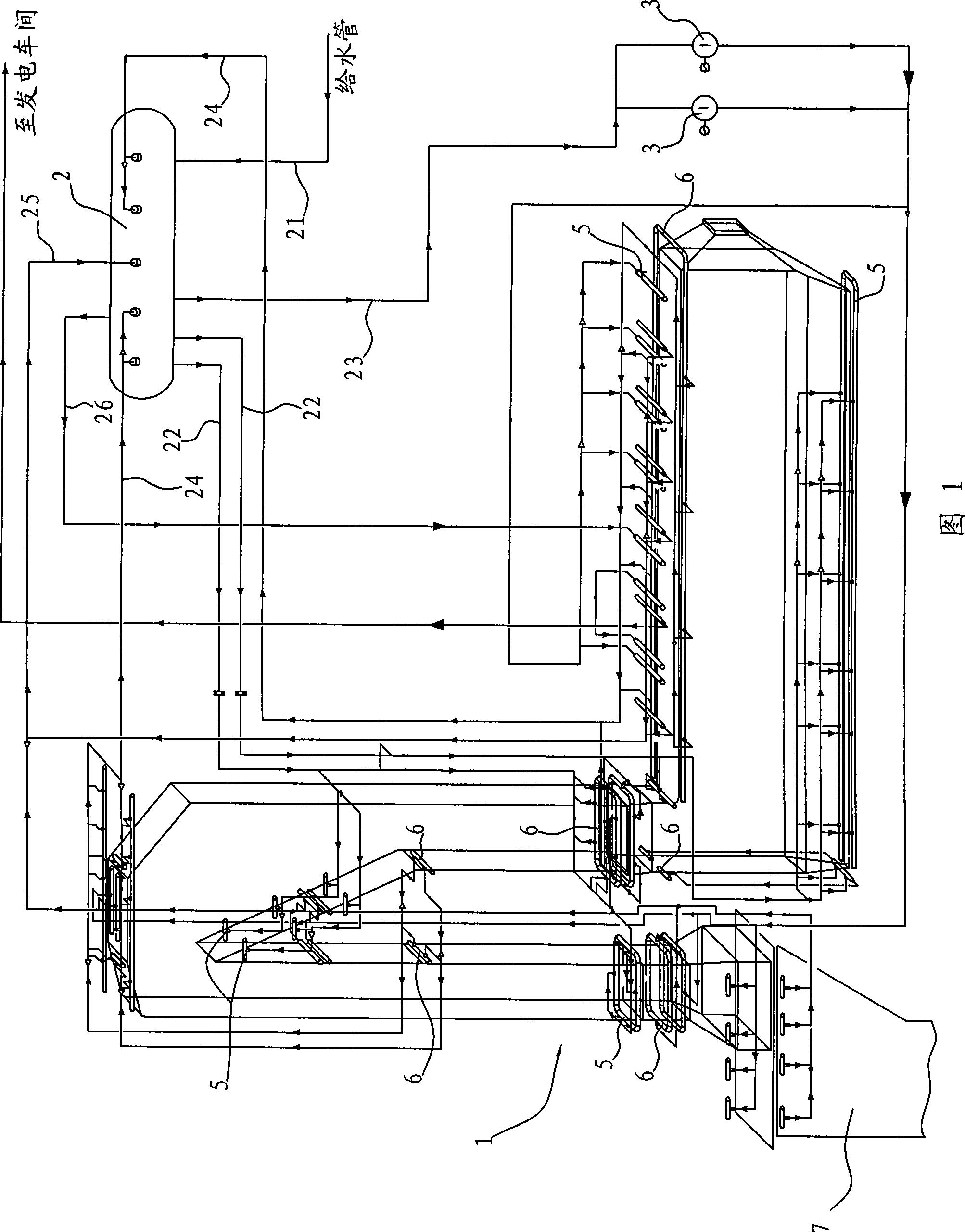

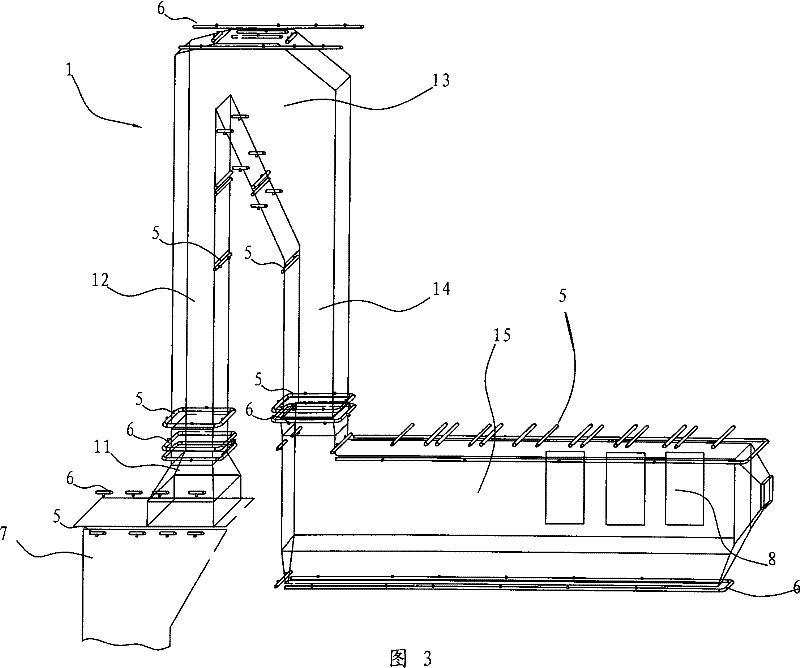

Exhaust-heating boiler and furnace body thereof

InactiveCN101451703AExtend your lifeImprove waste heat recovery efficiencyWater circulation promotionWater-tube boilersFlue gasEngineering

The invention discloses a body of waste heat boiler, comprising a transition section flue which comprises an ascending part and a descending part, wherein, the top end of the ascending part is connected with the top end of the descending part, and a convection section flue, wherein, a smoke inlet of the convection flue is connected with the lower end of the descending part of the transition section flue and a smoke outlet forms at the smoke discharging end of the convection section flue. According to the boiler body of the invention, since the transition section flue is arranged, high temperature flue gas containing dust enters into the ascending part of the transition section flue from a melting furnace and the dust contained in the high temperature flue gas can fall by depending on gravity during ascending process, thus the dust is not easy to stick on inner wall of the boiler body and accumulated dust is light in the boiler body, thus reducing dust removal operation, improving service life of the boiler body, prolonging operation time of the high temperature flue gas in the boiler body and improving recycling efficiency of the waste heat.

Owner:CHINA ENFI ENGINEERING CORPORATION

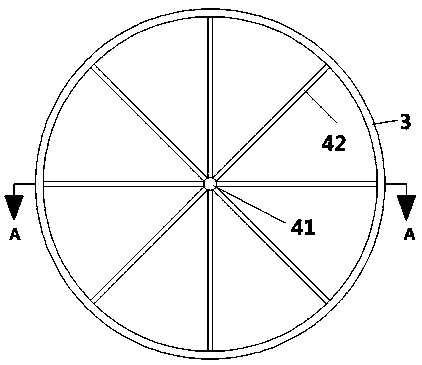

Steam boiler

ActiveCN108332181ASpeed up the flowHas the effect of reducing vibration and noiseBoiler water tubesWater circulation promotionEngineeringHeat transfer

The invention provides a steam boiler which comprises an upper boiler barrel, a lower boiler barrel, ascending pipes and descending pipes; the ascending pipes and the descending pipes are connected between the upper boiler barrel and the lower boiler barrel; flow stabilization devices are arranged in the ascending pipes; each flow stabilization device comprises a core body axially arranged the center of the corresponding ascending pipe and a plurality of radial rods extending along the center rod to the radial directions; a plurality of fins extending from the radial rod downwards are arrangedon each radial rod; the fins are provided with sharp parts; and the sharp parts face downwards. With the adoption of the novel structure steam boiler with the flow stabilization devices, when gas-liquid two-phase flowing exists in the ascending pipes, heat transfer is improved, vibration of the ascending pipes is weakened, and the level of noise is lowered.

Owner:青岛吉云德和商贸有限公司

Thermal water utilization device and steam treatment device

InactiveCN101285572ALess quantityEfficient use ofWater circulationClimate change adaptationEngineeringThermal water

The invention relates to a hot water utilizing device and a steam processing equipment; the hot water utilizing device has a hot water container connected with a flash tank and leading in the hot water from the flash tank, a compressing mechanism for absorbing the steal in the hot water container and compressing the same, a heat exchanger for providing the heat of the steam compressed by the compressing mechanism to the exterior utilized heat medium, an expansion valve for expanding the hot water through the heat exchanger and a capacity control mechanism for controlling the capacity of the compressing mechanism according to the test value of the temperature sensor. The rest hot water not utilized by the hot water recovering equipment is led in the hot water container. Through the structure, the amount of the condensed water discharged from the flash tank is reduced as possible; and the invention is bale to realize the effect utilization of the steam and condensed water.

Owner:KOBE STEEL LTD

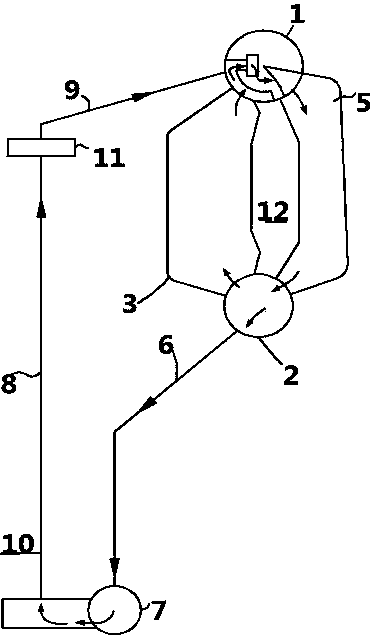

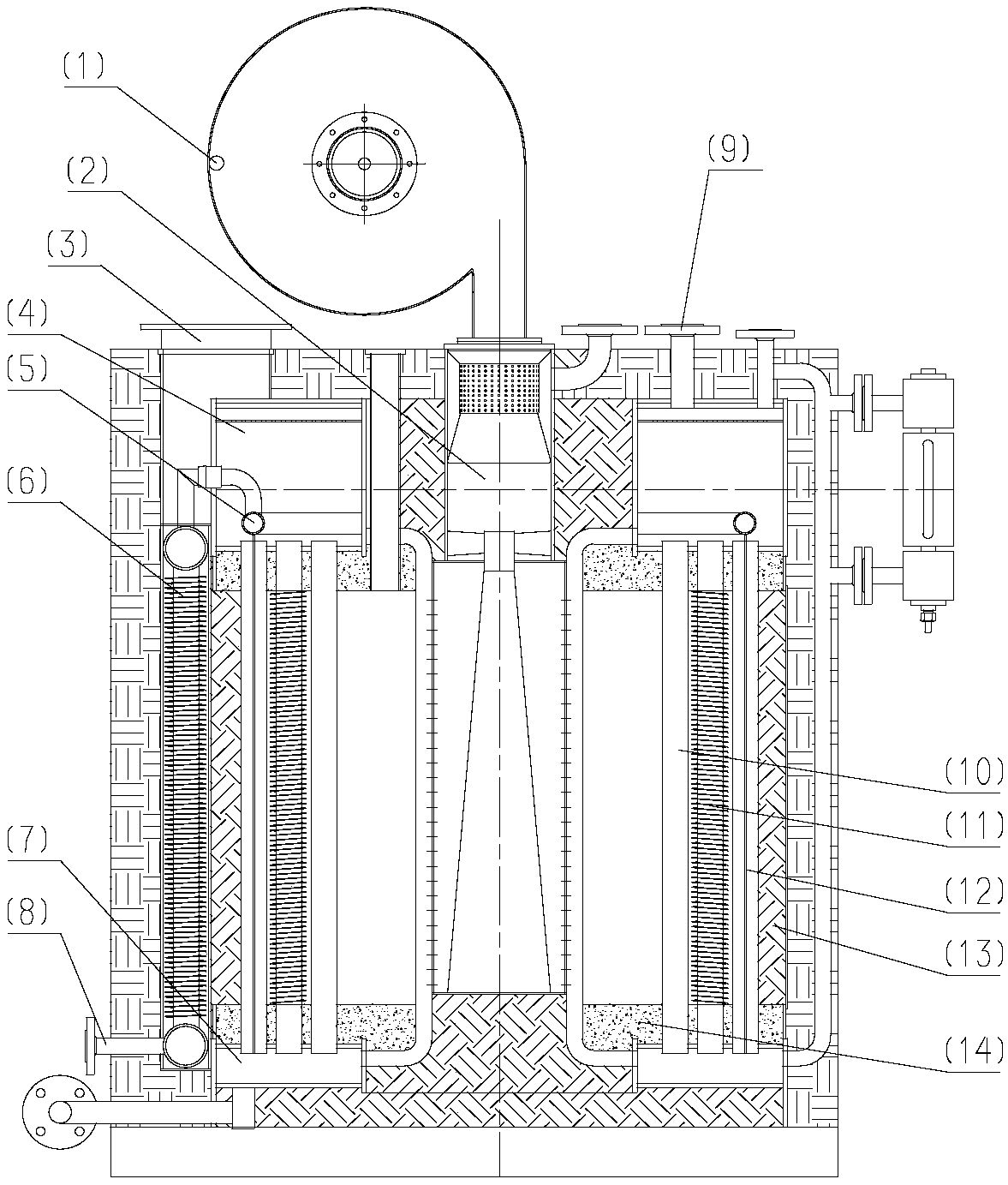

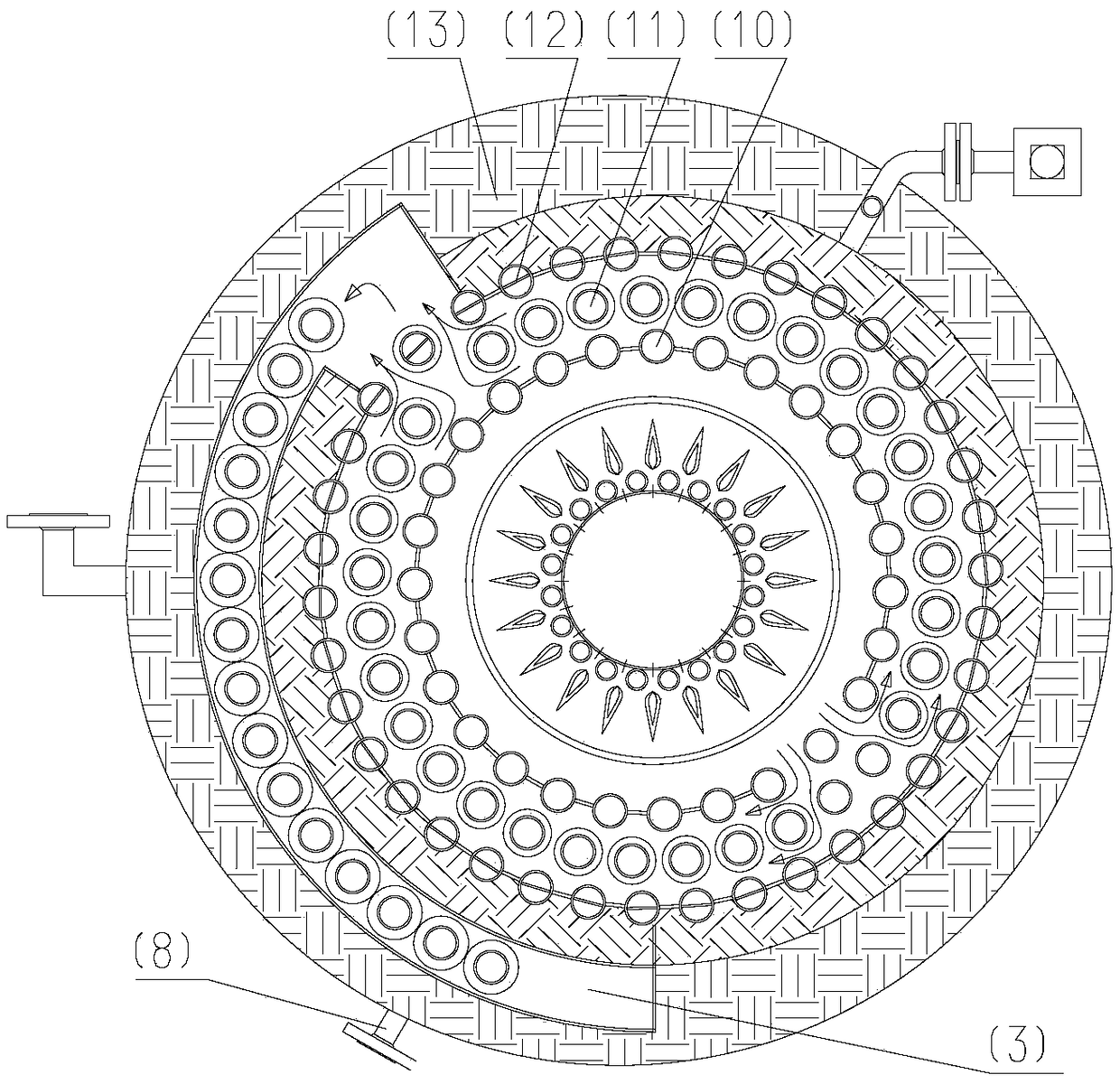

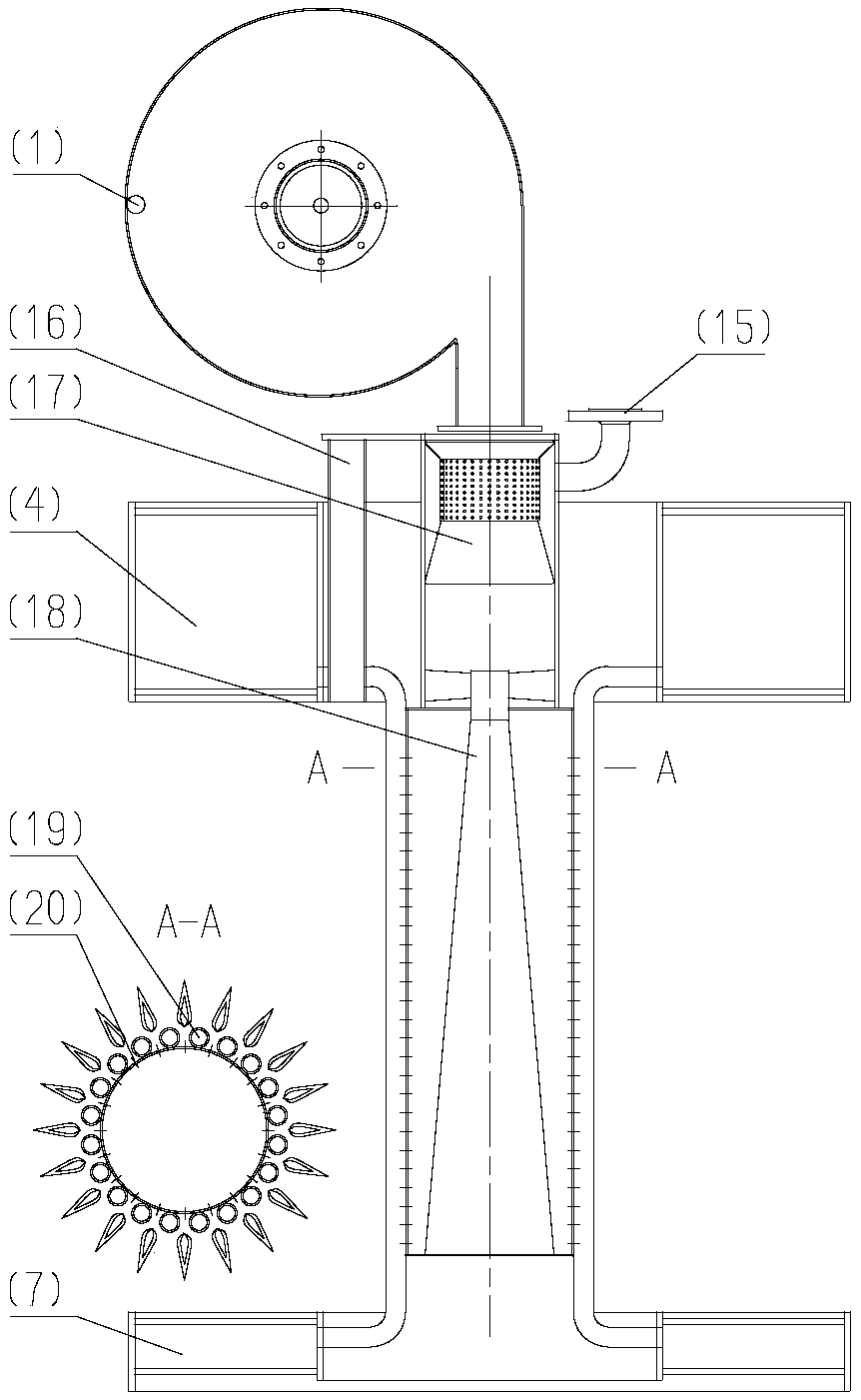

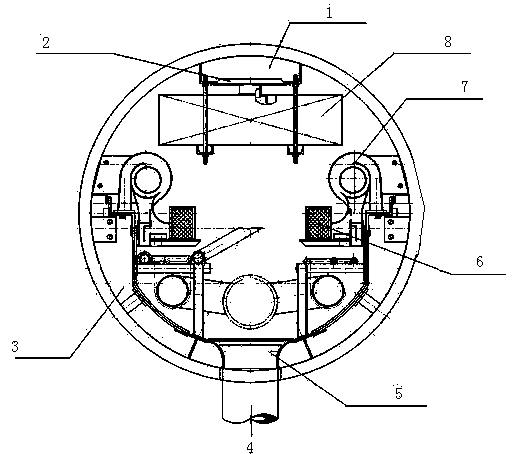

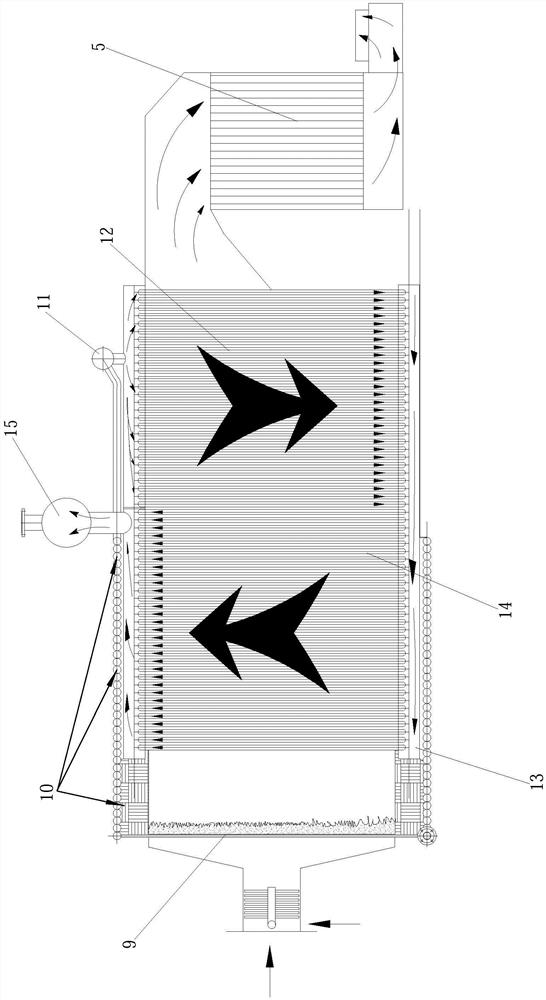

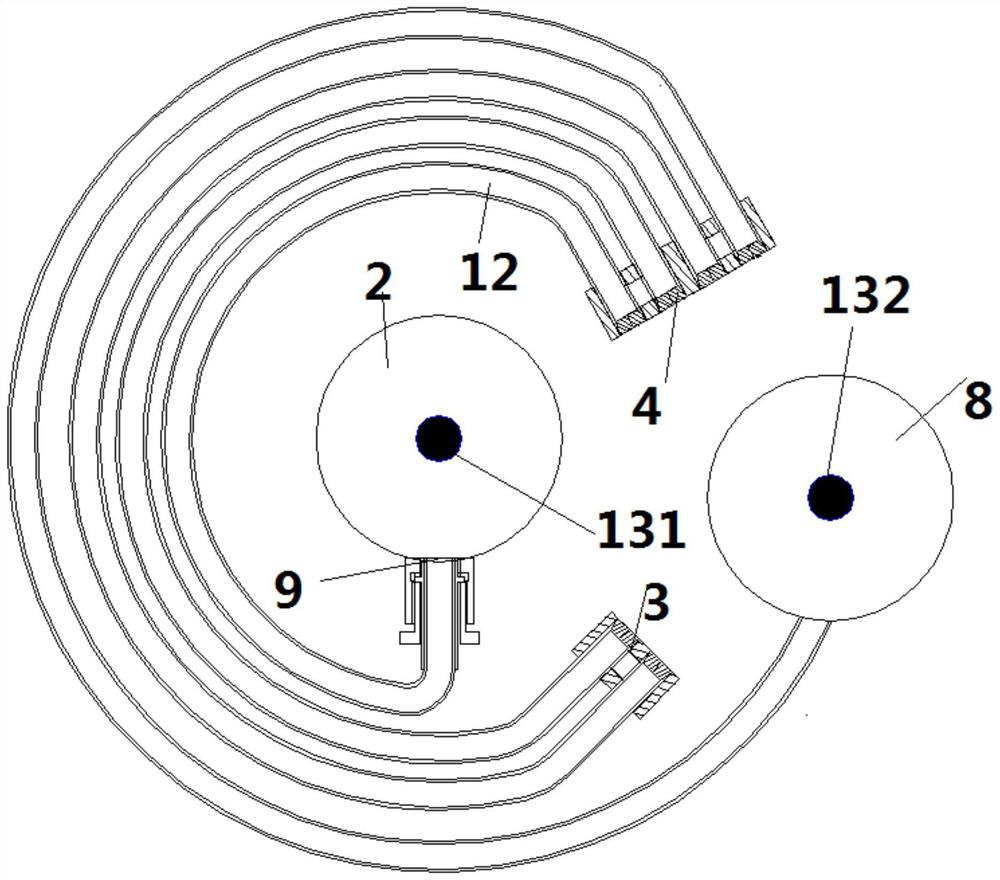

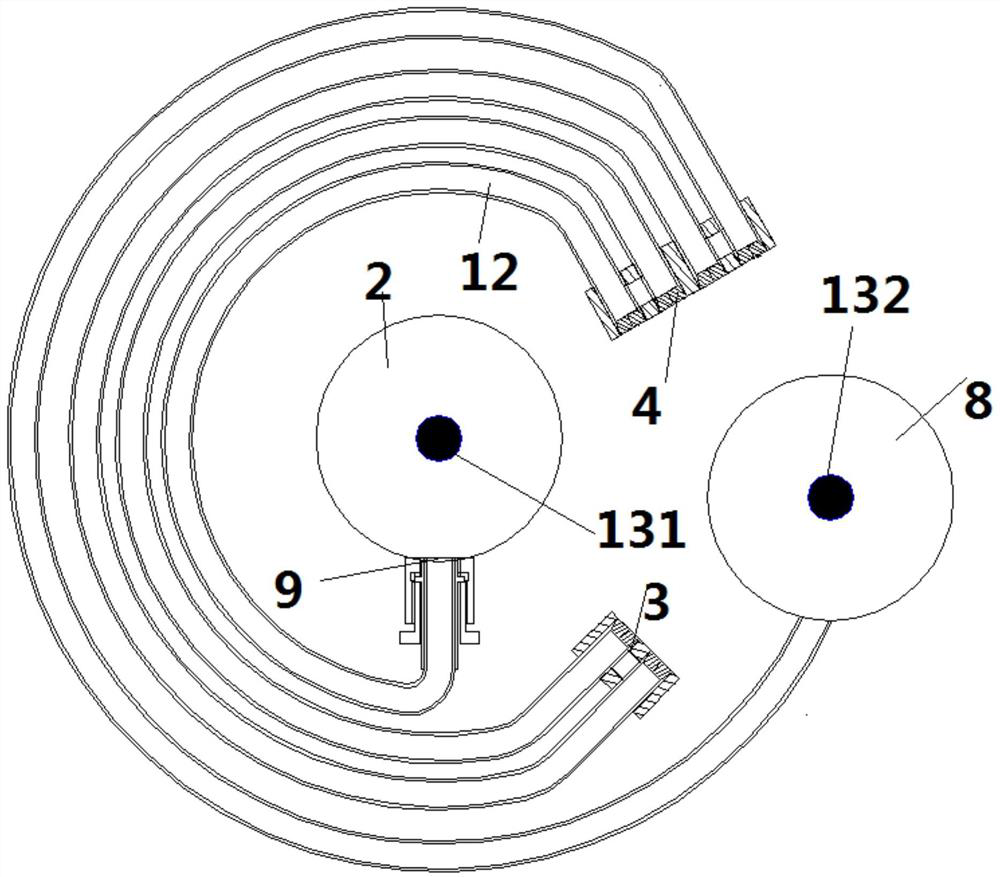

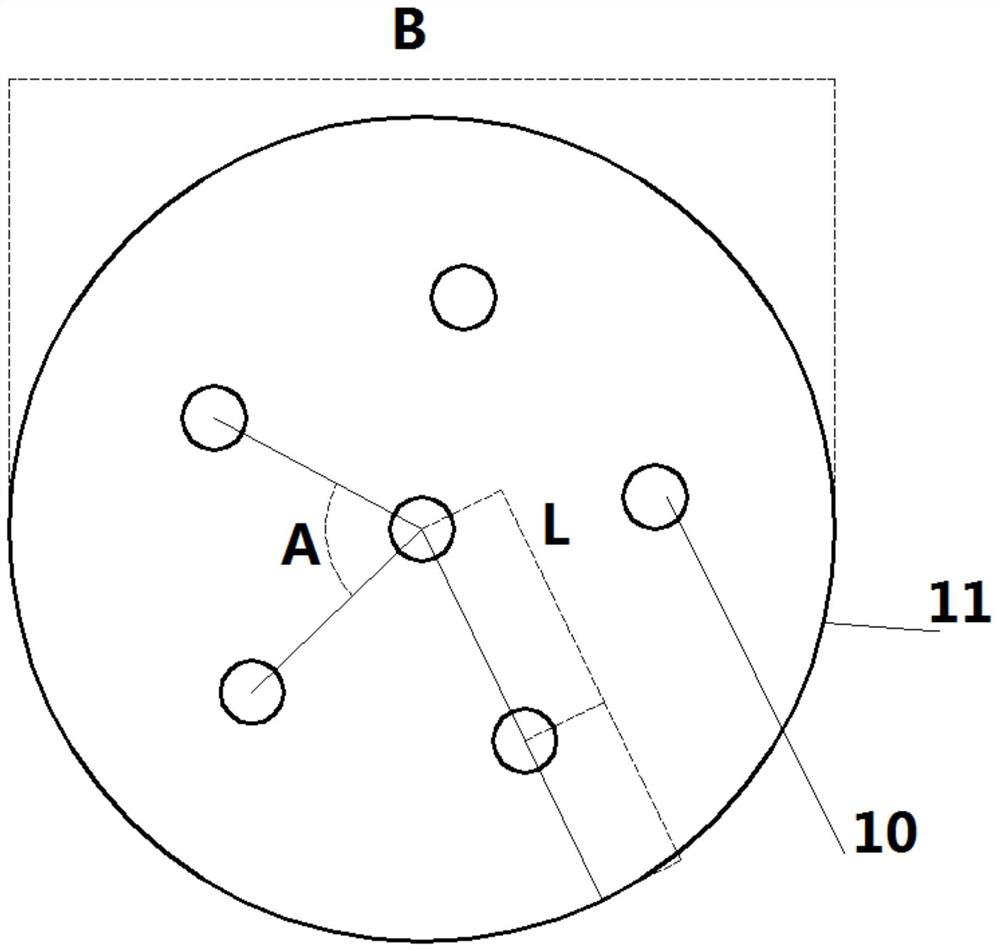

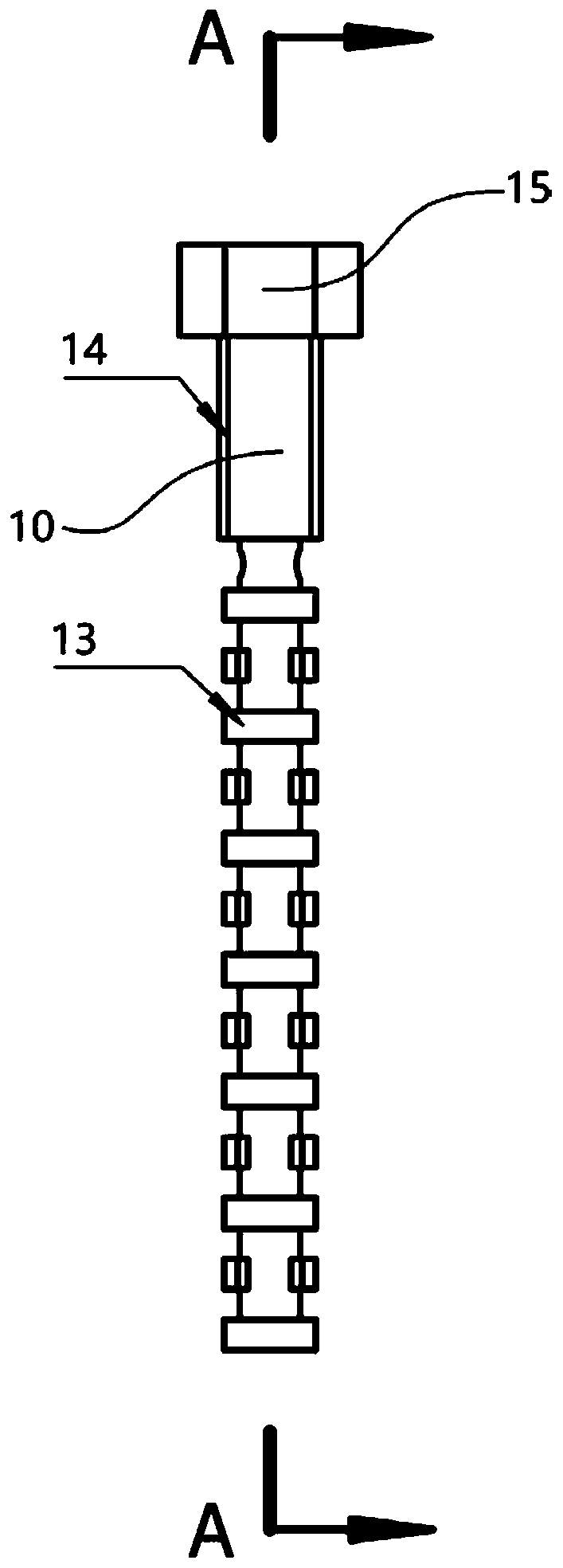

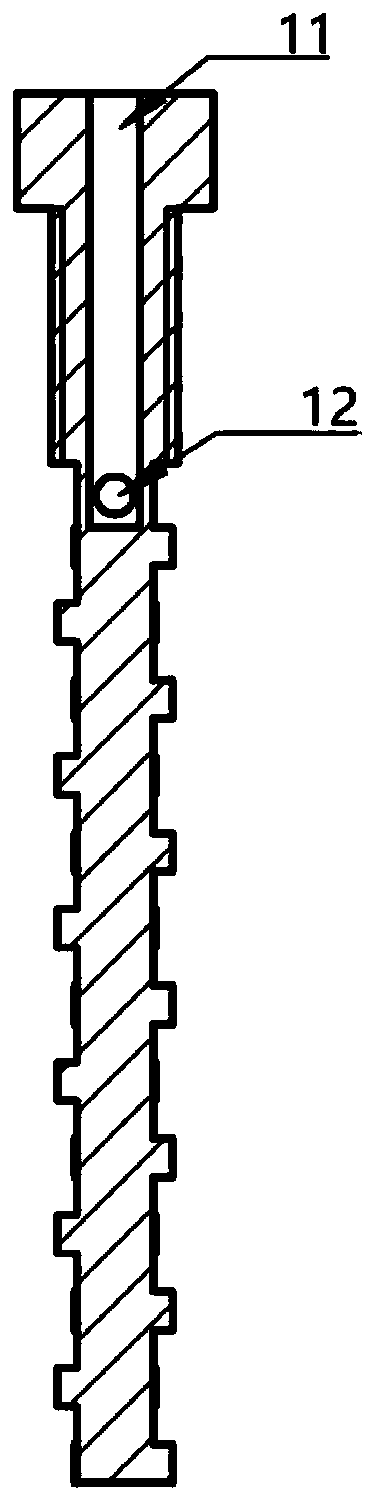

Cross flow type fully-premixed low-NOx boiler

PendingCN109442366ASimple structureCompact structureWater circulation promotionSteam boilersCoalCorrosion

The invention provides a cross flow type fully-premixed low-NOx boiler. The cross flow type fully-premixed low-NOx boiler comprises a draught fan (1), a burner (2), a smoke outlet (3), an upper annular collecting box (4), a feed water circulating device (5), a coal economizer (6), a lower annular collecting box (7), a water feed port (8), a steam outlet (9), inner ring membrane type wall pipes (10), middle ring finned pipes (11), outer ring membrane type wall pipes (12), a heat insulating layer (13) and a fireproof layer (14). Through the structural optimization and integrated design of a body, the burner and the coal economizer, the heating surface is enlarged, the overall structure is more compact, the occupied land is small, the standarization degree is high, and the efficiency is high.The structure of the coal economizer is optimized, and the occupied space of the coal economizer is greatly reduced. Meanwhile, a smoke channel structure of the coal economizer is optimized, and theheat transfer utilization rate of the body and the coal economizer is greatly increased. In addition, the steam-water connection of the coal economizer is optimized, dead zones and connectors are reduced, the possibility of oxygen corrosion is reduced, and the service life of the coal economizer is prolonged.

Owner:JIANGSU SHUANGLIANG BOILER

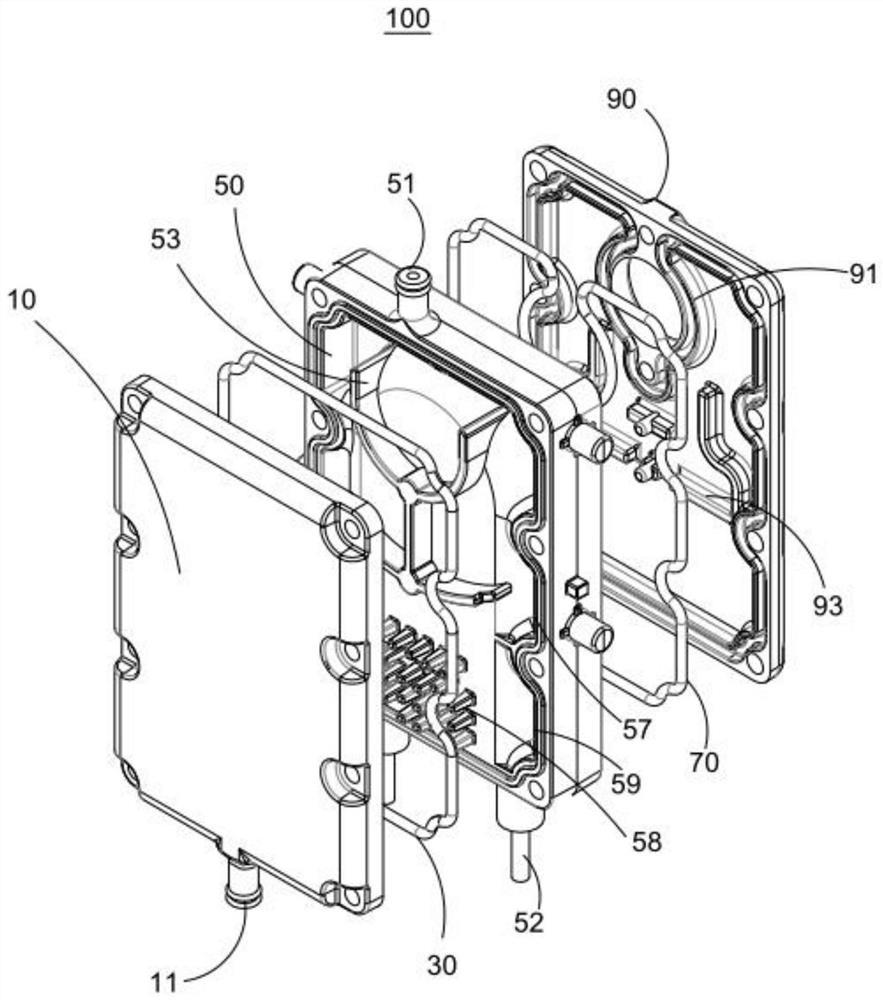

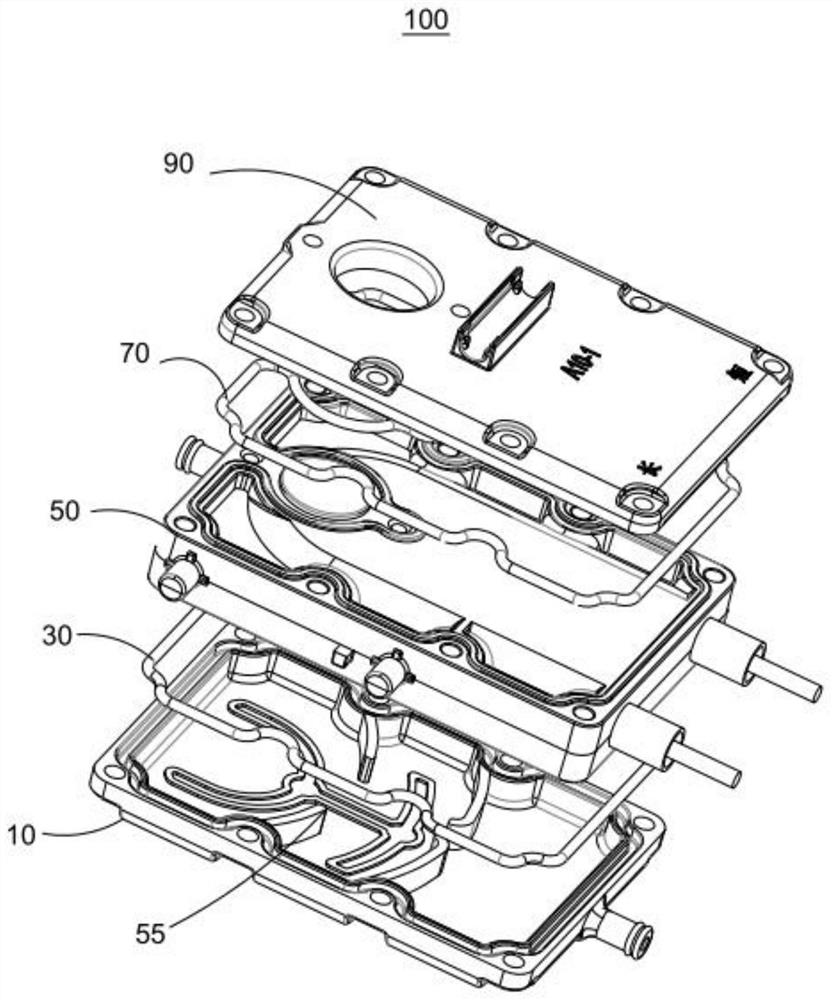

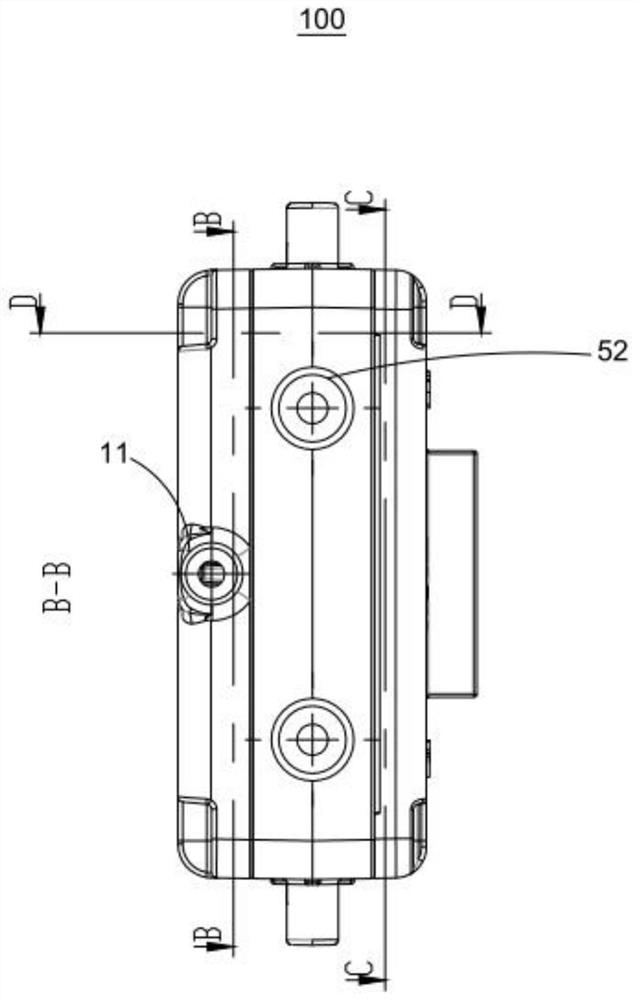

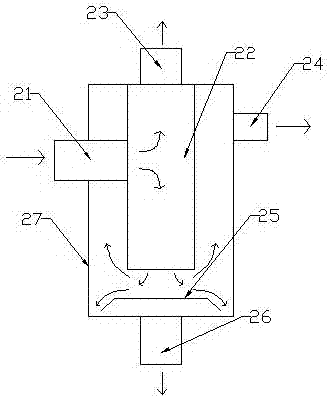

Steam heating device

InactiveCN111964027AAvoid the phenomenon of no heatingComplete vaporizationBoiler drums/headersSteam generation heating methodsThermodynamicsWater vapor

The invention provides a steam heating device. The steam heating device comprises an upper cover, a lower cover and a heater body, wherein the heater body, the upper cover and the lower cover are buckled and packaged to form an upper layer channel and a lower layer channel; the upper layer channel communicates with the outside through a water inlet and a steam outlet; the heater body is provided with a baffle plate, a water vapor inlet, a steam channel port and a built-in U-shaped heating pipe; the baffle plate directly faces the water inlet to enable water flow to be dispersed, and the waterflow flows from the water vapor inlet to the lower layer channel to be fully vaporized and flows from the steam channel port to the steam outlet to be sprayed out; a water-proof heating platform witha matching temperature is arranged on one side toward the lower cover of the heater body. According to the steam heating device., the water-proof heating platform with the matching temperature is designed through improvement, and the phenomenon that the water flow is not heated due to the fact that the water flow encounters the cold area is avoided; and the steam heating area is divided into two blocks, the steam outlet channel is longer, the vaporization is more complete, the heating loss is reduced, and the steam outlet rate is improved at the same power.

Owner:WUXI YOSHIOKA PRECISION TECH CORP LTD

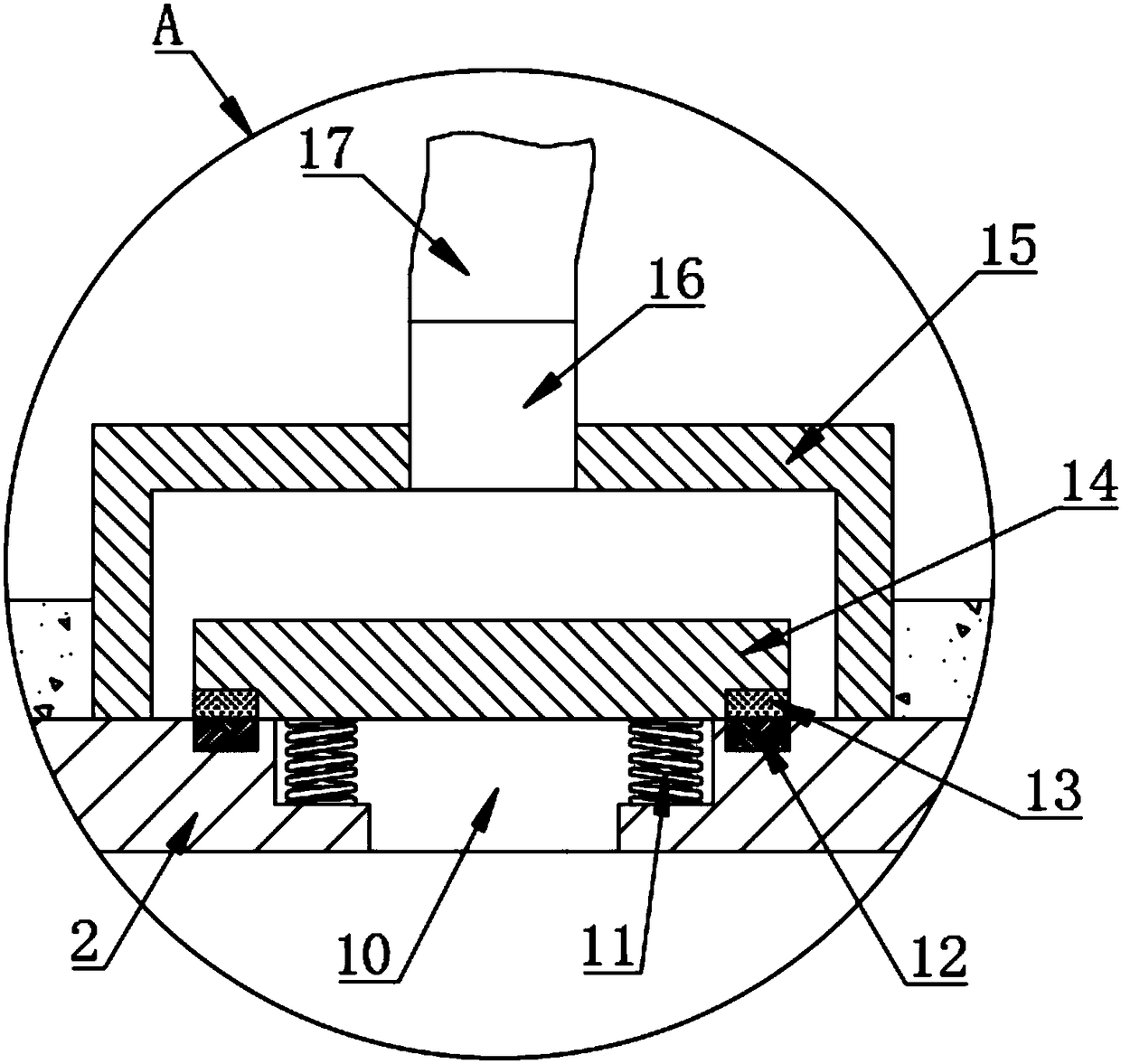

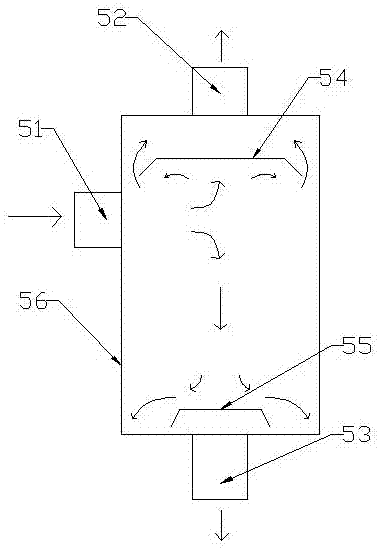

Supercharged steam-water dual-purpose energy-saving boiler

InactiveCN108180457AHigh boiling pointEasy to useSteam generation heating methodsWater circulation promotionBoiling pointEngineering

The invention discloses a supercharged steam-water dual-purpose energy-saving boiler. The boiler comprises a base, wherein a boiler is fixedly arranged on the top of the base through a support; a water inlet is formed in the left side of the top of the boiler; an electric heating disc is fixedly arranged at the bottom in the boiler through a support; a steam outlet which is a stepped hole is formed in the right side of the top of the boiler; a plurality of springs are uniformly connected at the step of the steam outlet; a baffle plate which is matched with the steam outlet is connected at thetop ends of the springs; the baffle plate is propped against the top of the boiler; a sealing cover which is matched with the steam outlet is fixedly connected on the top of the boiler; the baffle plate is arranged in the sealing cover; a steam outlet pipe is connected on the top of the sealing cover; and a steam outlet hose is connected at the steam outlet end of the steam outlet pipe. The boilerdisclosed by the invention has the beneficial effects that the steam outlet is sealed by the baffle plate through the inter-attraction of an annular iron piece and a ring magnet and the pressure in the boiler is increased, so that the boiling point of water is increased, the water temperature and the steam temperature are higher and the using effect of the boiler is better.

Owner:丁文海

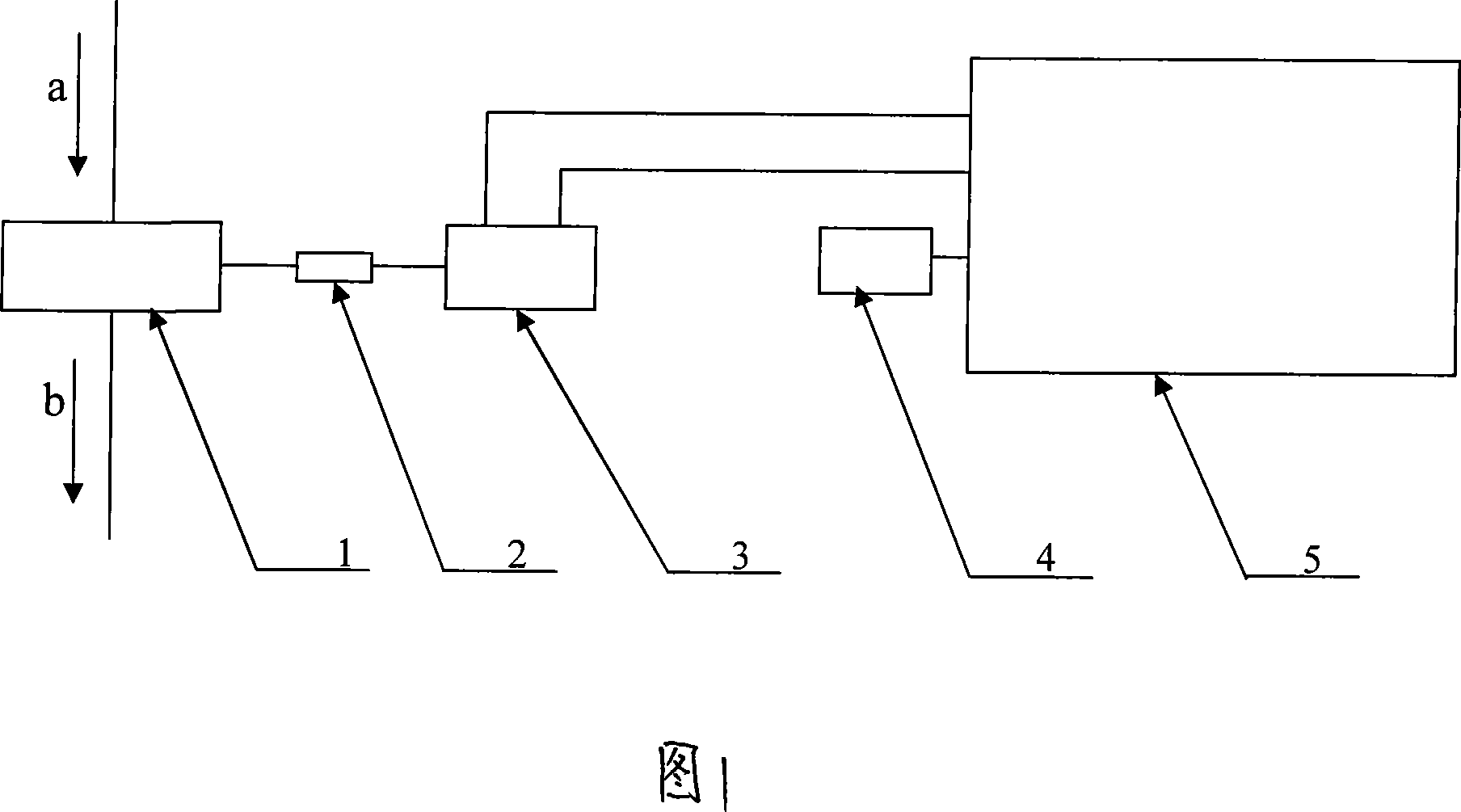

Hydraulic pressure type vapor recovery device

InactiveCN101201160AImprove qualityLow oxygenWater circulationFeed water supplyHydraulic cylinderCoupling

The invention discloses a hydraulic steam recycling device which is characterized in that the invention comprises a pressurizer (1) and the pressurizer (1) is connected with a hydraulic cylinder (3) through a heat insulated shaft joint (2). The hydraulic cylinder (3) is connected with a hydraulic station (5). The hydraulic station (5) is provided with an electrical control gear (4). The invention has the advantages of small size, beauty, simple and flexible mounting as well as stable and reliable operation. Simultaneously the invention is simple, convenient and east to control the devices. The reciprocating speed of the hydraulic cylinder can be adjusted at any time according to the size of a boiler output and the amount of the steam with water in a closed loop to lead the devices to be in a reasonable operation state at any time; thereby greatly improving the stability and reliability of the whole set of the devices.

Owner:刘德胜

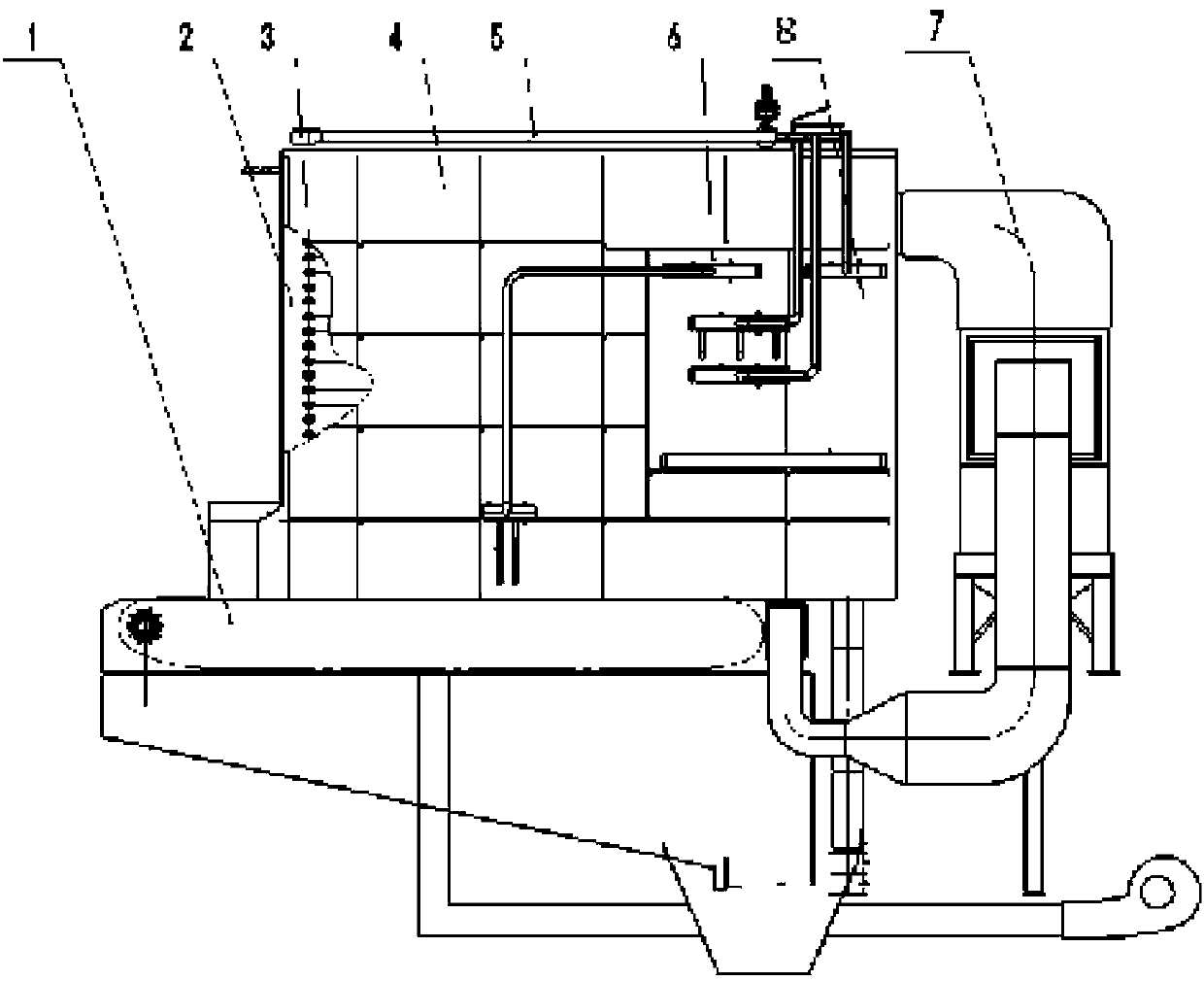

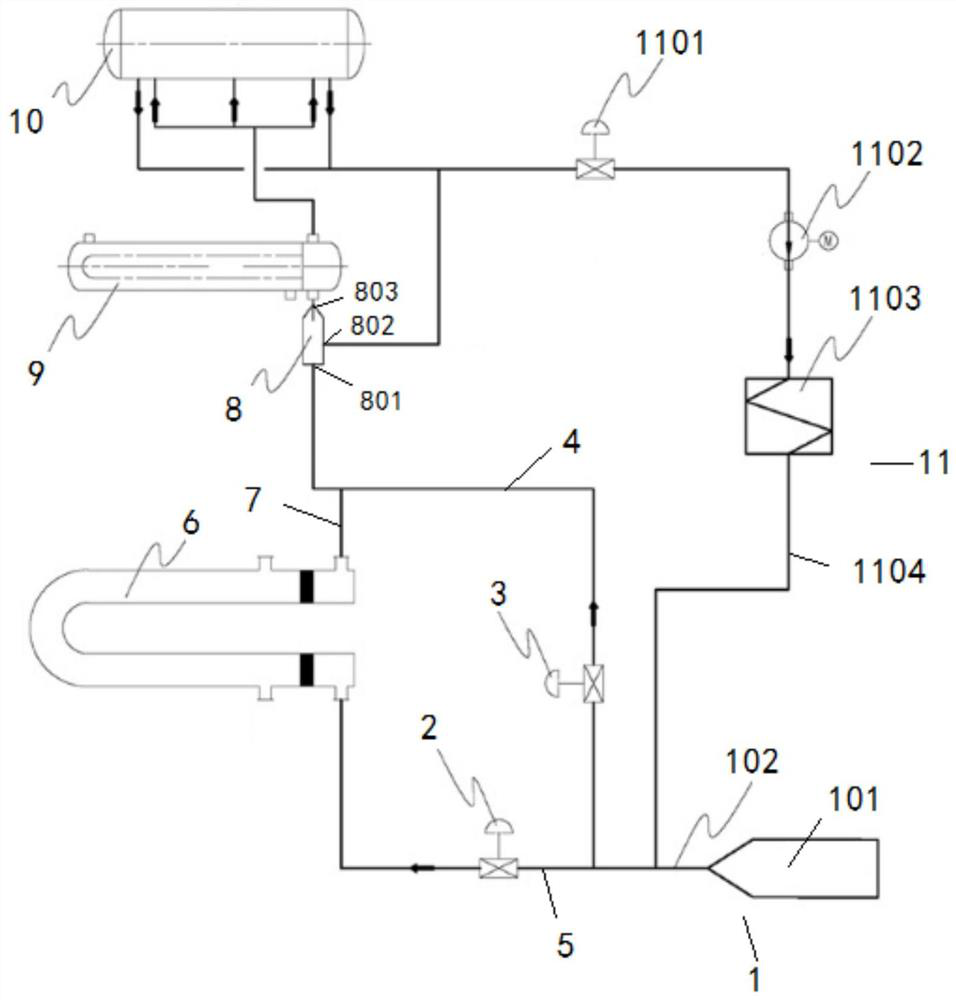

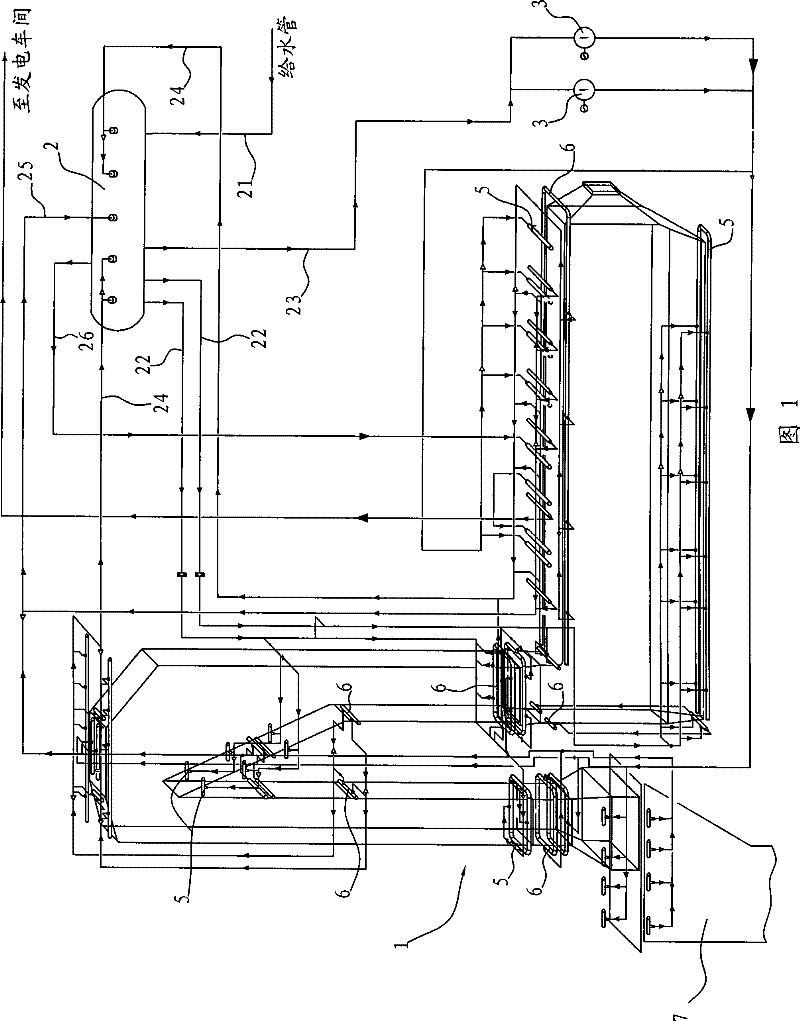

Oil field fuel coal steam-injection boiler

ActiveCN103423727AReduce mining costsReduce humidityFluid removalWater circulation promotionSuperheaterFuel oil

Provided is an oil field fuel coal steam-injection boiler. The problem that an existing fuel oil and fuel gas steam-injection boiler is high in cost and bad in economy is mainly solved. The oil field fuel coal steam-injection boiler is characterized in that an inlet end of a plunger pump (10) is connected with a water processing tank (9), water processed by the water processing tank (9) is subjected to pressure rising thought the plunger pump (10) and then is injected to an outer pipe of a water heat exchanger (5), water of the outer pipe of the water heat exchanger (5) flows through a convection section (6), is heated by the convection section (6) and then enters an inner pipe of the water heat exchanger (5), then the water enters a boiler body (11), water which flows out of the boiler body (11) enters a high-efficiency steam-water separator (26), separated steam enters a superheater (8), generated steam is exhausted, and water separated by the high-efficiency steam-water separator (26) is injected back to the plunger pump (10). The oil field fuel coal steam-injection boiler can provide superheated steam with low moisture and high temperature, so that requirements for thickened oil extraction are better met, heat efficiency is high, operation is easy, operation is stable, and fault rate is low.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

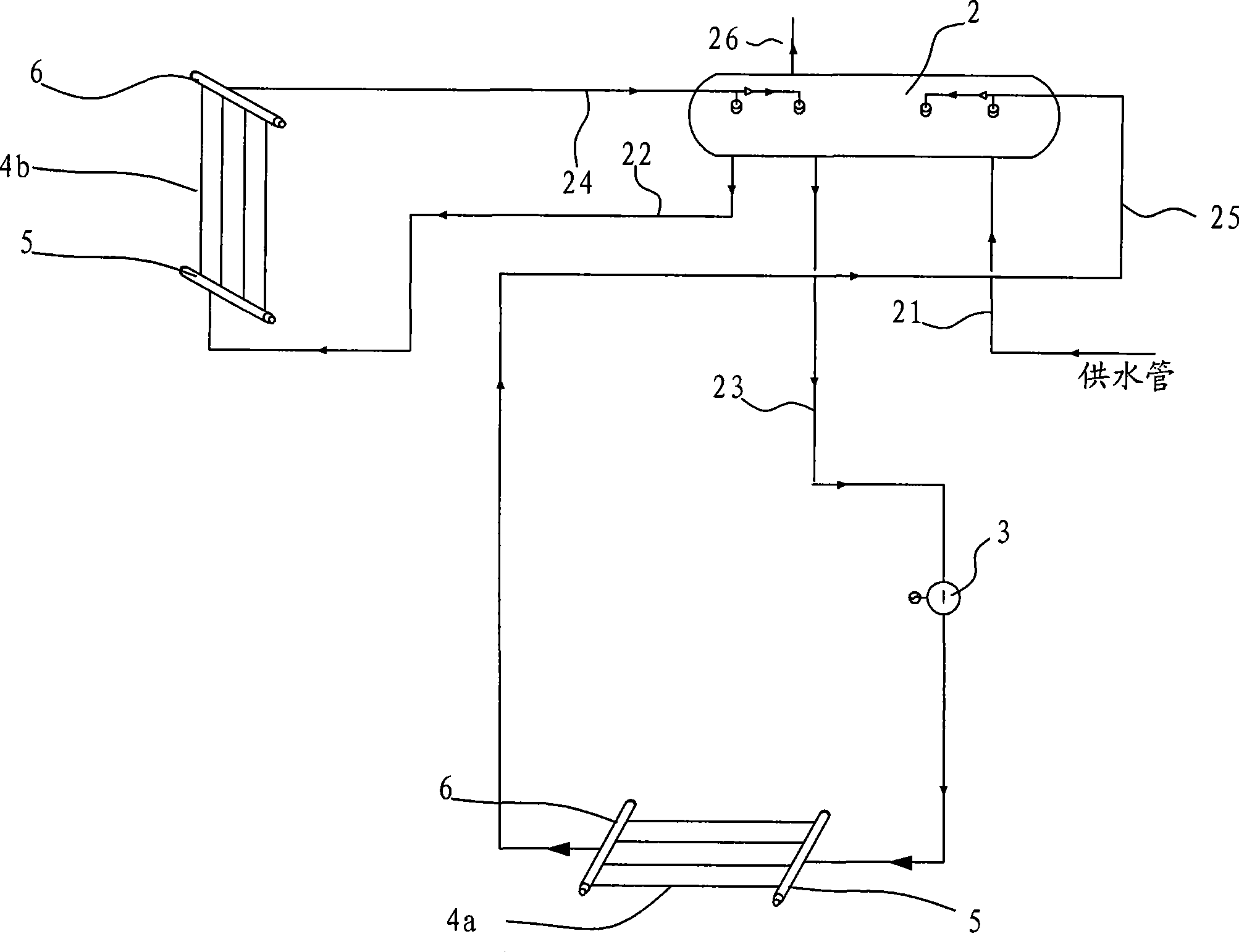

Domestic water heating system

ActiveUS20190203952A1Steam generation heating methodsSpecific water treatment objectivesThermal waterWater heating

The invention relates to a domestic water heating system, which comprises: (A) a main water tank; and (B) an accelerator having a sleeve, which in turn comprises a mechanism for flushing lime scale accumulated at the bottom of the internal hollow of the sleeve, said mechanism causes a flow of cold-water from a cold-water inlet, to said bottom of the internal hollow of the sleeve, and from there to the main tank via hollows in the sleeve.

Owner:AVIVI NETANEL

Natural circulation boiler

A natural circulation boiler comprises a steam collecting chamber, a steam evening pore plate, a jacket space, a down pipe, a rotation preventing device, a screen separator, a horizontal separator and a louver separator. After being guided out of a boiler barrel, saturated steam is guided into an upper header at an inlet pass position of a steam-cooled cyclone separator by a saturated steam connection pipe, is guided into a lower header of the steam-cooled cyclone separator by a connection pipe after downing to a cooling pass, is guided into a front wall-enclosure lower header and a rear wall-enclosure lower header by wall-enclosure connection pipes, goes upwards to enter a middle wall-enclosure lower header, namely a low-temperature superheater inlet header, cools a rear-pass low-temperature superheater pipe nest after flowing reversely upwards and returns to a high-temperature superheater in a tail shaft rear pass from the boiler, and finally, qualified superheated steam is guided out of two sides of a high-temperature superheater outlet header.

Owner:HEILONGJIANG DAMING DAIRY MACHINERY

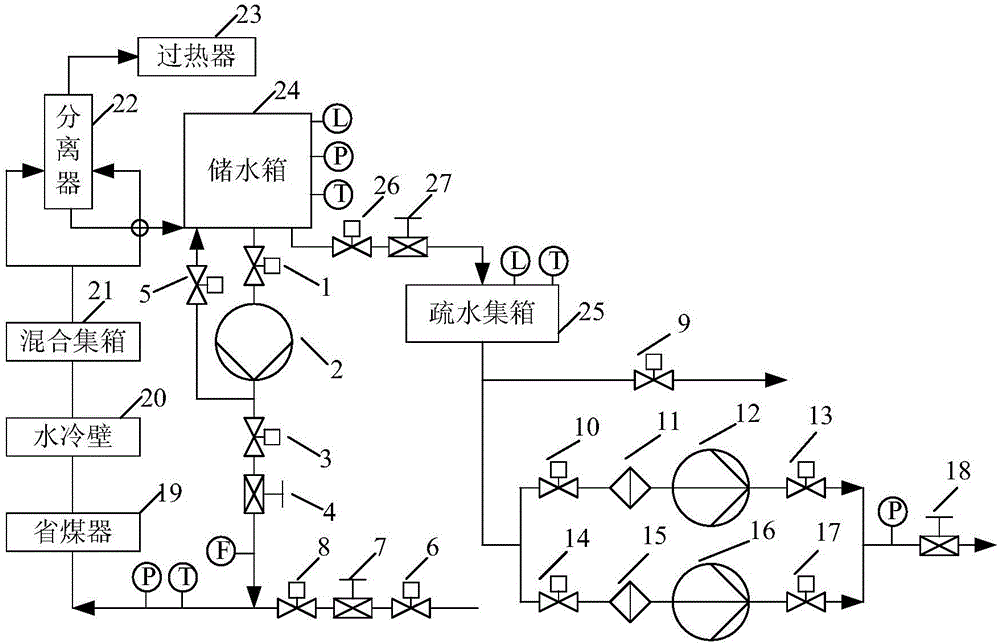

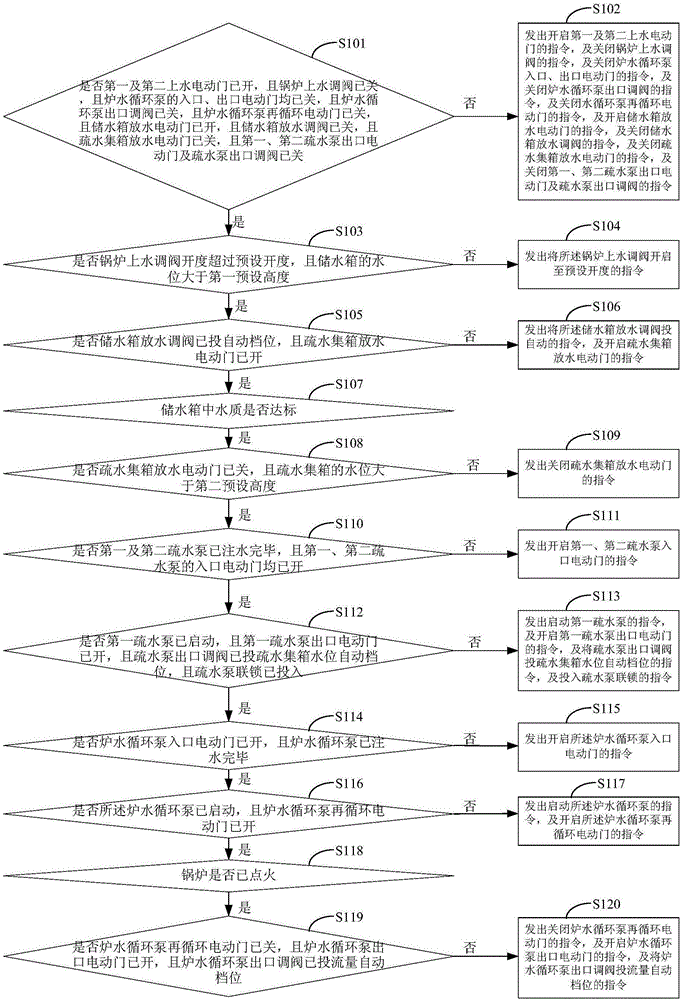

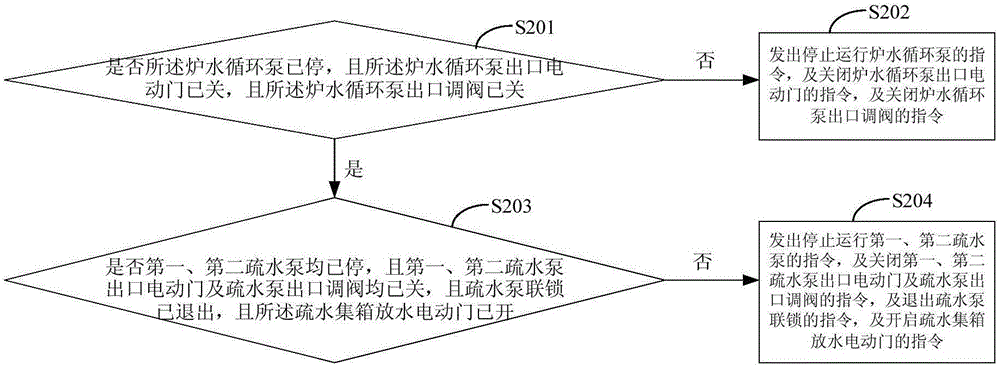

Heat-engine plant boiler start steam water system and start-stop control method thereof

PendingCN106765028AImplement autostartRealize automatic stopBoiler controlWater circulation promotionWater dischargeBoiler feedwater pump

The invention provides a heat-engine plant boiler start steam water system and a start-stop control method thereof. The system comprises a water feeding adjustment valve, a coal economizer, a water-cooling wall, a mixed collection box, a steam water separator, an overheater, a water storage tank, a boiler water circulating pump, a boiler water circulating pump outlet adjustment valve, a drainage collection box, two drainage pumps and a plurality of pipes. The coal economizer is connected with the water-cooling wall, and the water-cooling wall penetrates through the mixed collection box to be connected with the steam water separator; and the water feeding adjustment valve is arranged between a boiler water feeding pump and the coal economizer. The overheater is connected with a steam outlet in the upper portion of the separator; and the water storage tank is connected with a water outlet in the lower portion of the separator. The two ends of the boiler water circulating pump are provided with an inlet electric door and an outlet electric door correspondingly, and a recycling electric door is arranged between a water outlet of the boiler water circulating pump and the water storage tank. The boiler water circulating pump outlet adjustment valve is arranged between the outlet electric door and the coal economizer. A water discharging electric door and a water discharging adjustment valve are arranged between the water storage tank and the drainage collection box. The two drainage pumps are connected in parallel and are arranged at a drainage opening of the drainage collection box, inlets are all provided with filter screens, and outlets are provided with the outlet adjustment valve.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

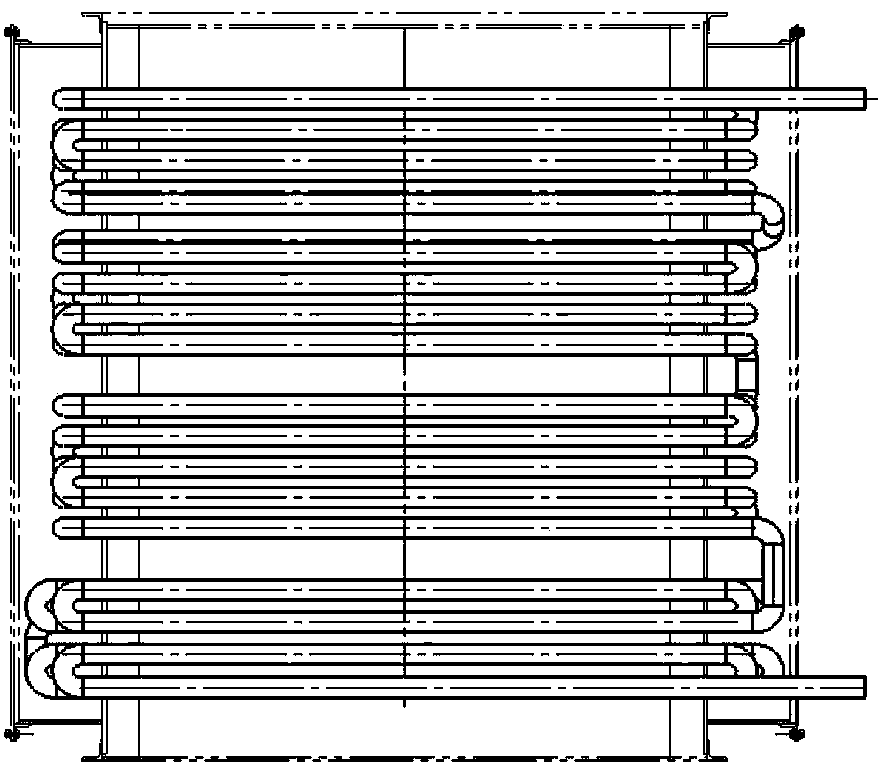

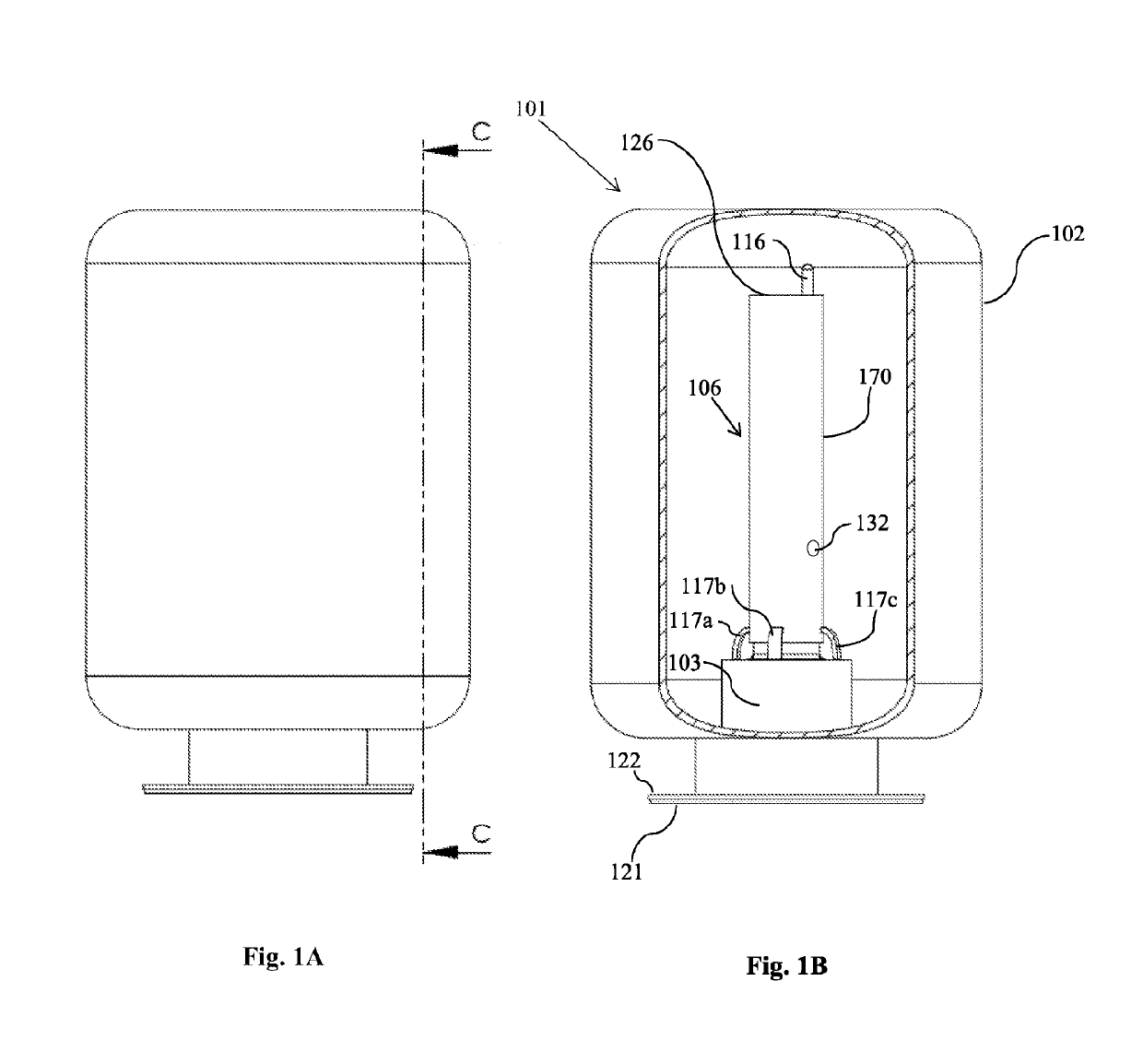

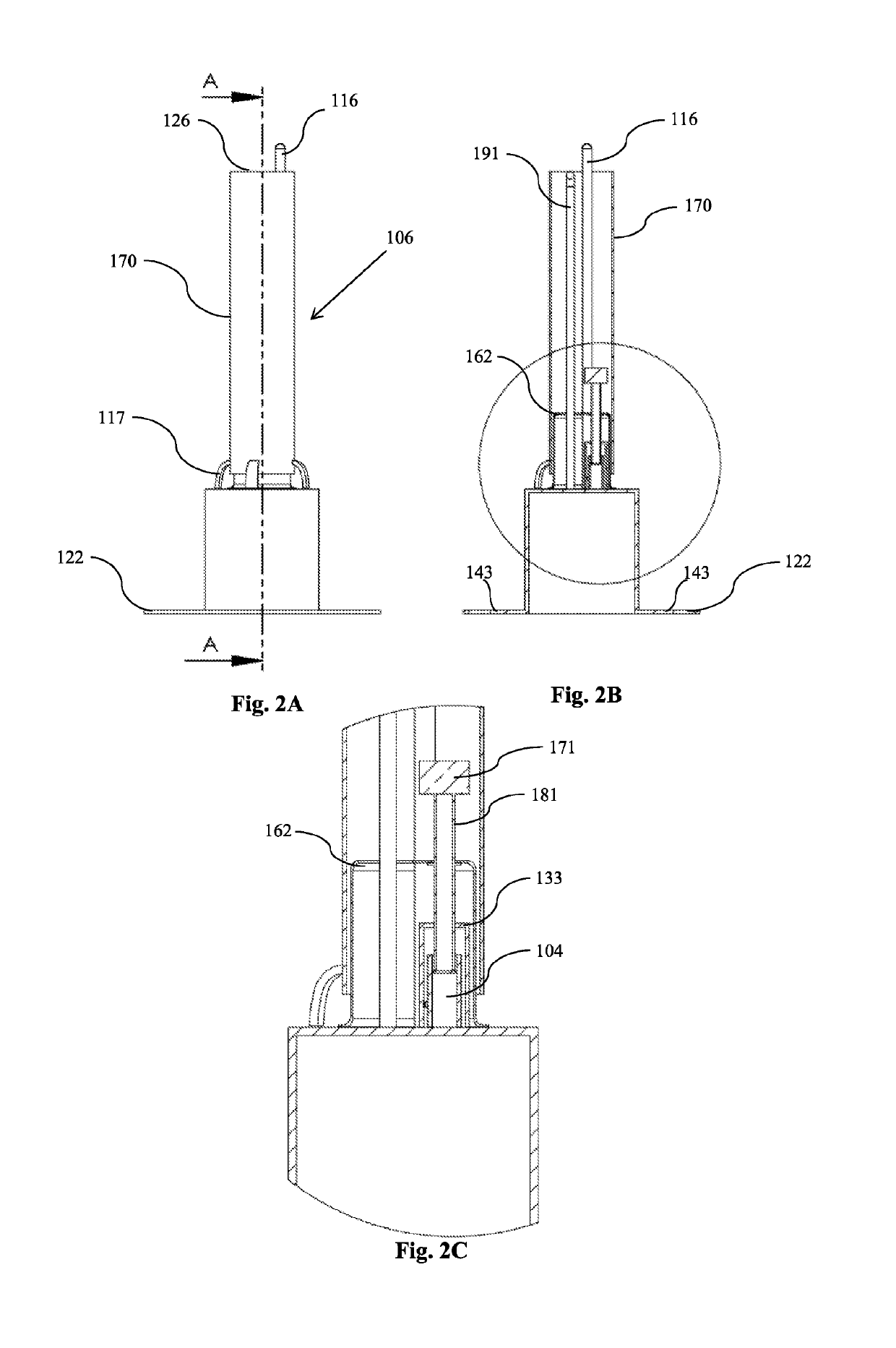

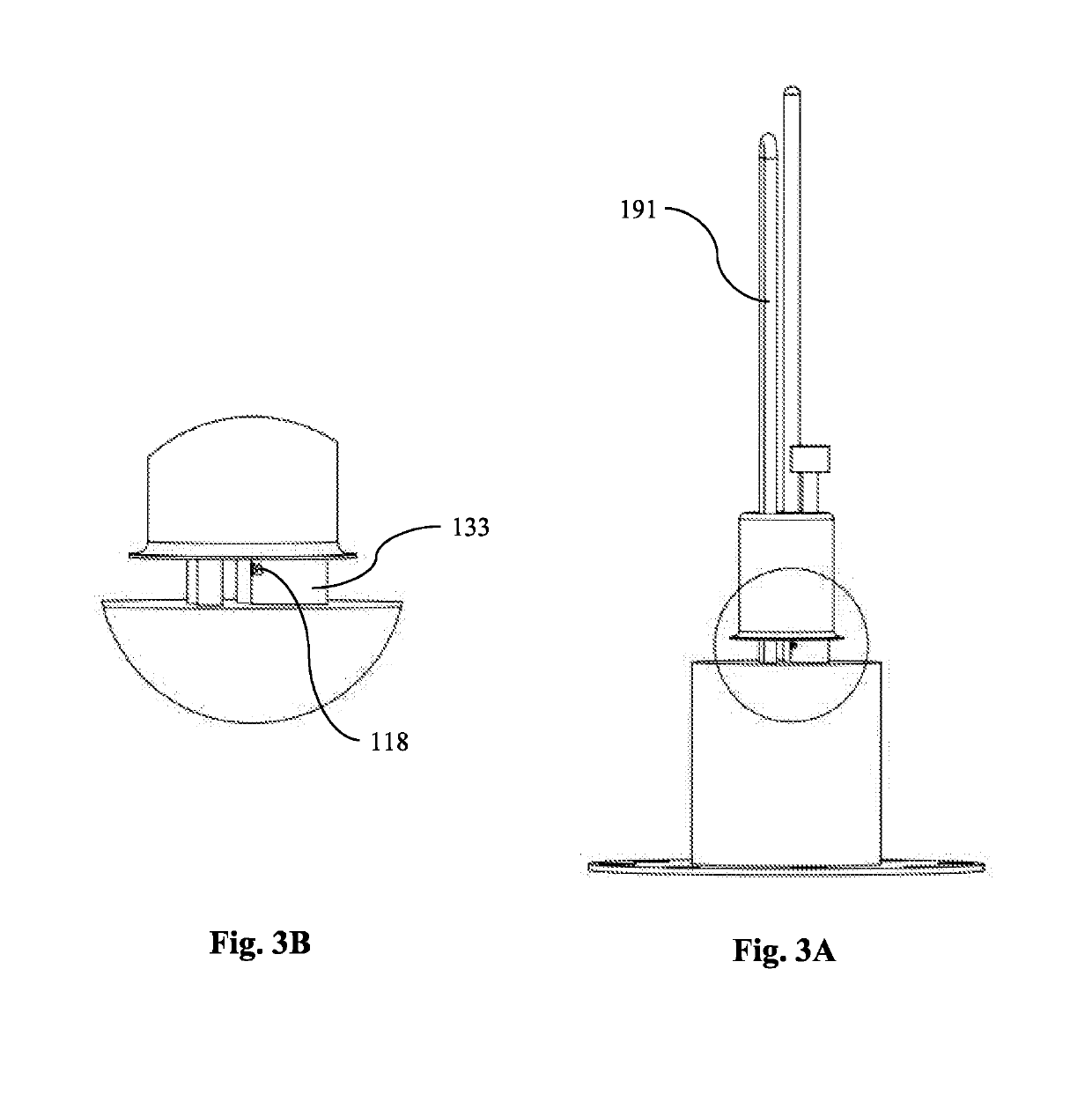

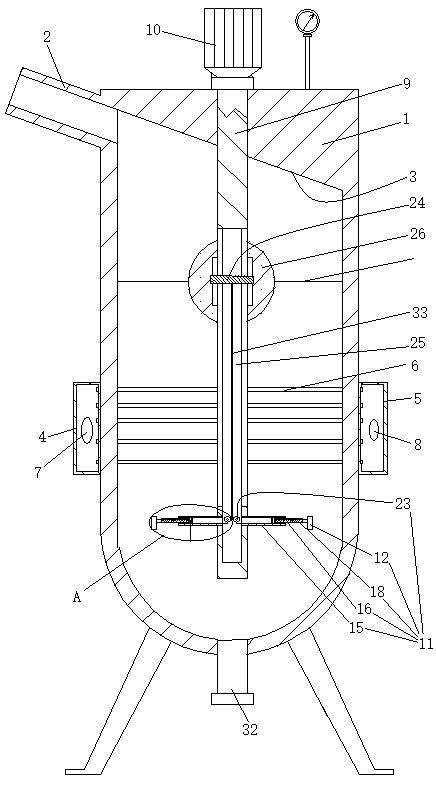

Tubular steam generator

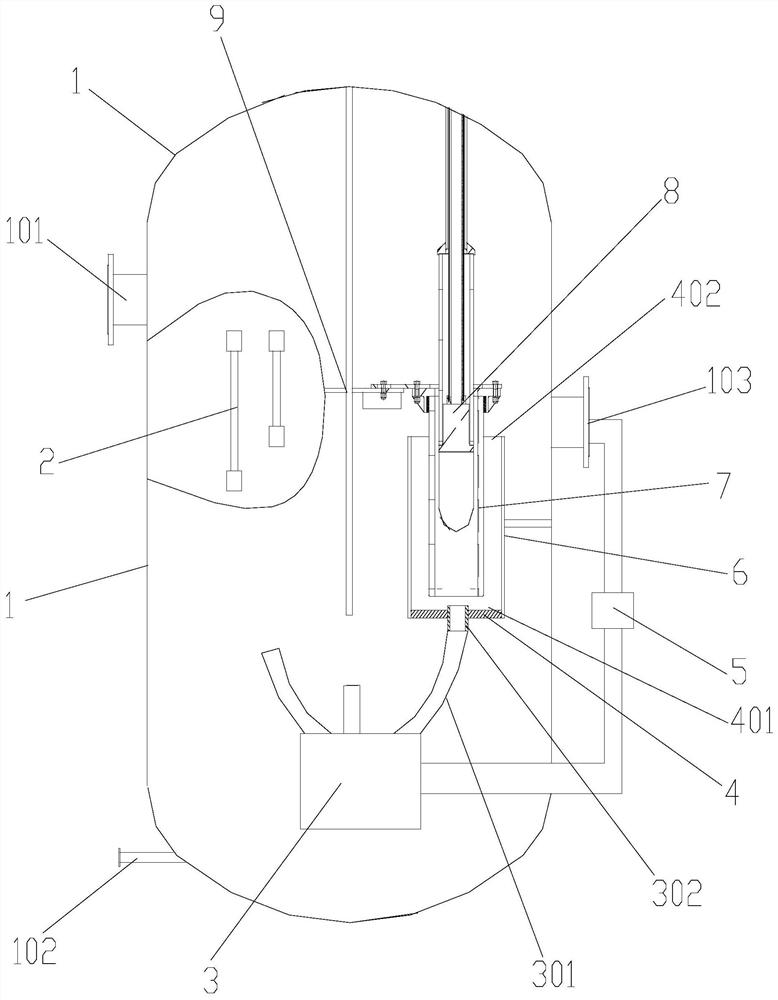

ActiveCN107101185ACompact layoutImprove applicabilityWater circulation promotionSteam boilersStress ProblemEngineering

The invention discloses a tubular steam generator which comprises a closed container body, a heat exchanging pipe and a partition board assembly, wherein a first chamber and a second chamber isolated from each other are radially distributed in the closed container body from inside to outside; the heat exchanging pipe is arranged in the first chamber and extends from top to bottom along the first chamber; and the partition board assembly is arranged in the second chamber and divides the second chamber into an upper cavity, a middle cavity and a lower cavity isolated from each other. According to the tubular steam generator, through unique passage design, compact arrangement among the steam generator, a pressure container and a main pump is realized, and the arrangement has obvious advantages under the condition that the space is limited. A spiral pipe is adopted as the heat exchanging pipe, so that on one hand, heat transferring is enhanced, the required heat transferring area is reduced, and the heat exchanging efficiency is improved, and on the other hand, the problem about thermal expansion difference between a heat transferring pipe and a tube plate is solved, and the thermal stress problem can be solved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

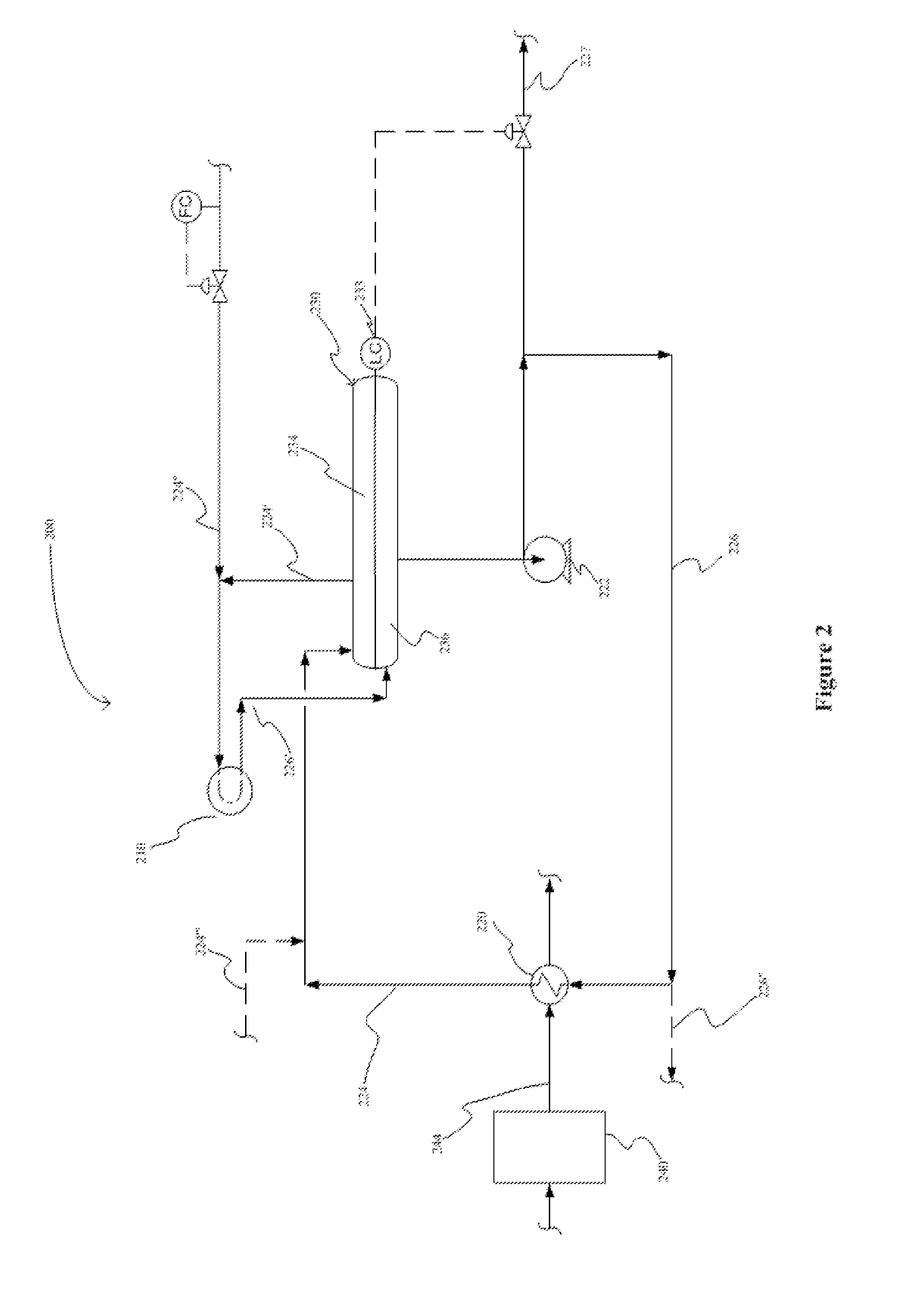

Evaporative cooling system with function of controlling high-loop enhanced steam-water separation and method thereof

PendingCN114034029AEasy to separateImprove work efficiencyFeed water supplySteam separation arrangementsWater dischargeCirculator pump

The invention relates to the technical field of ferrous metallurgy, in particular to an evaporative cooling system with a function of controlling high-loop enhanced steam-water separation and a method therfeof. The system comprises a steam pocket body, and a water replenishing system and a steam outlet pipeline which are connected with the steam pocket body, and further comprises a forced circulation system and a natural circulation system; the forced circulation system comprises a forced circulation pump and a first heat exchanger which are sequentially connected through a pipeline, wherein the input end and the output end of the forced circulation system are connected with the steam pocket body to form a forced circulation loop, and water in the steam pocket body enters the steam pocket body from a high position after passing through the forced circulation system; the natural circulation system comprises a second heat exchanger, and the second heat exchanger and the steam pocket body are connected through a pipeline to form a loop. Convenience is provided for earlier-stage testing and later-stage user maintenance, the water discharge amount is reduced, meanwhile, the steam-water separation effect of return water in the evaporative cooling system is enhanced, the overall steam-water separation effect is improved, flow dynamic adjustment is achieved through control, and the overall performance is improved.

Owner:WISDRI ENG & RES INC LTD

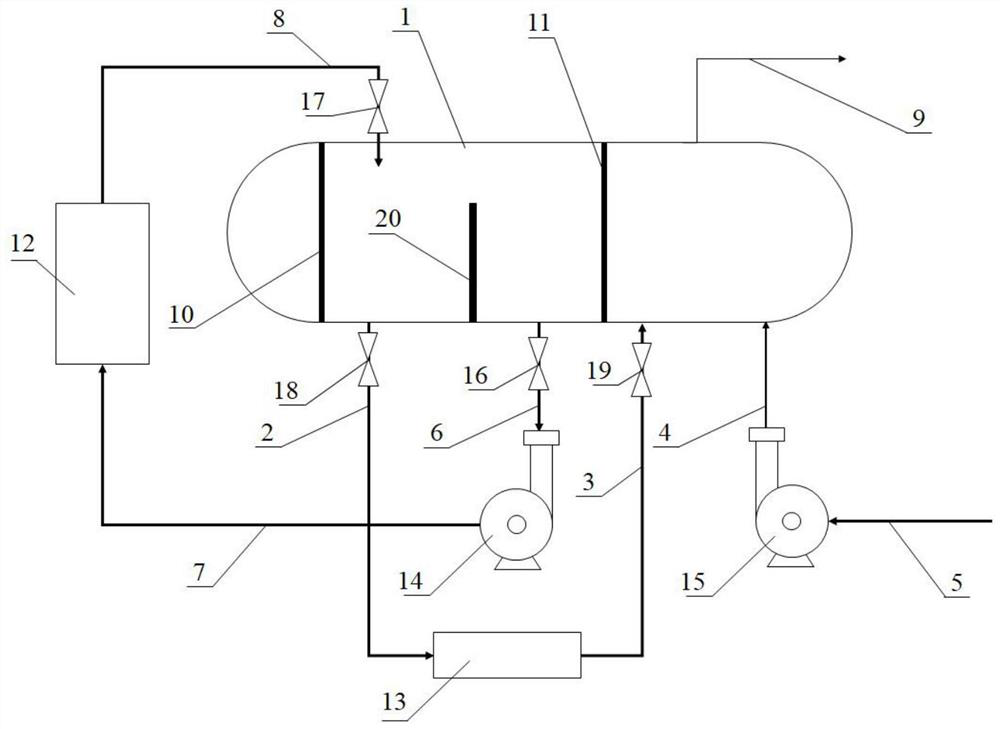

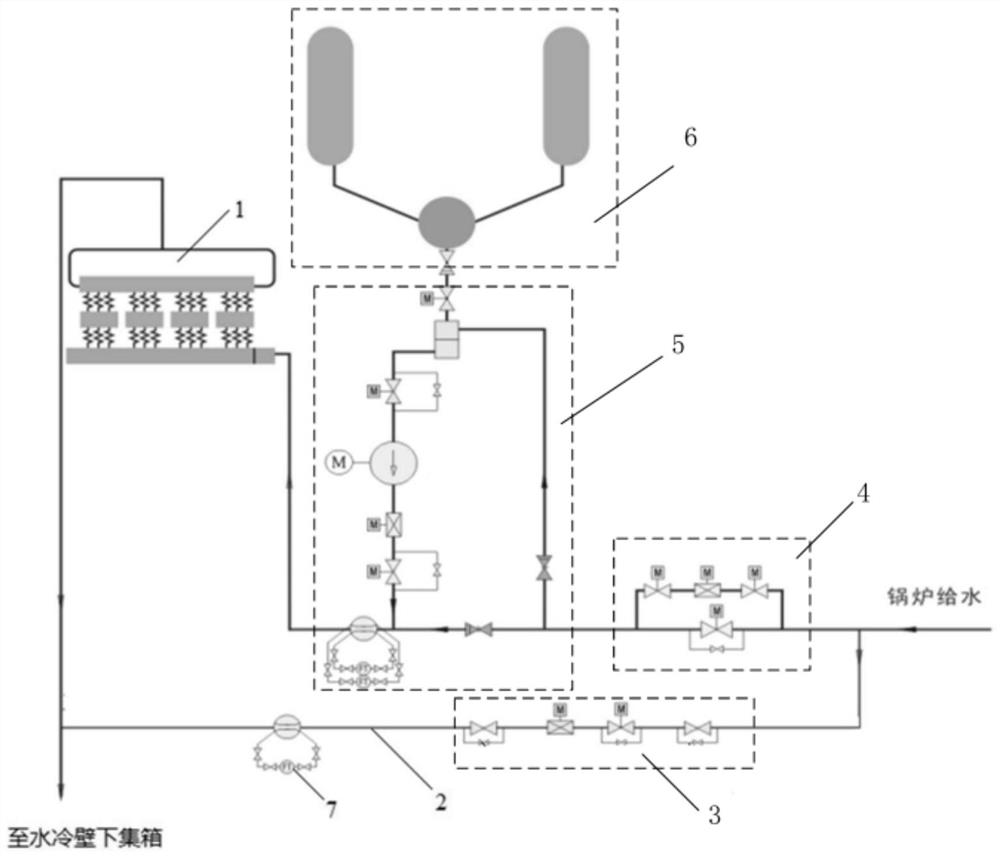

Forced recirculation water pipe steam boiler system and operating method thereof

ActiveCN111981455ASave on energy costsLarge adjustment ratioBoiler cleaning apparatusSteam separation arrangementsBoiler feedwater pumpCombustor

The invention provides a forced recirculation water pipe steam boiler system and an operating method thereof. A floater water carrier is arranged in a water tank, the floater water carrier is connected to a condenser through a boiler water supply pipeline, a boiler feed pump is connected in series to the boiler water supply pipeline, the condenser is connected to a buffer liquid control tank through a water feeding pipeline, the buffer liquid control tank is connected to a water inlet of a boiler body through a high-temperature water supply pipeline, a high-temperature circulation pump is connected in series on the high-temperature water supply pipeline, the water inlet of the boiler body communicates to a burner plate and a square coil pipe of a hearth, the square coil pipe of the hearthis connected to a tail gathering header, the tail gathering header is connected to a fin type downcomer economizer, the fin type downcomer economizer is connected to a bottom converging header, the bottom converging header is connected to a boiling ascension pipe of the hearth, the boiling ascension pipe of the hearth is connected to a top gathering header, a steam-water mixing outlet of the top gathering header is connected to a steam-water separator through a steam-water mixing pipeline, and a liquid outlet of the steam-water separator is connected to the buffer liquid control tank through areflow pipeline.

Owner:ZHEJIANG TUFF BOILER

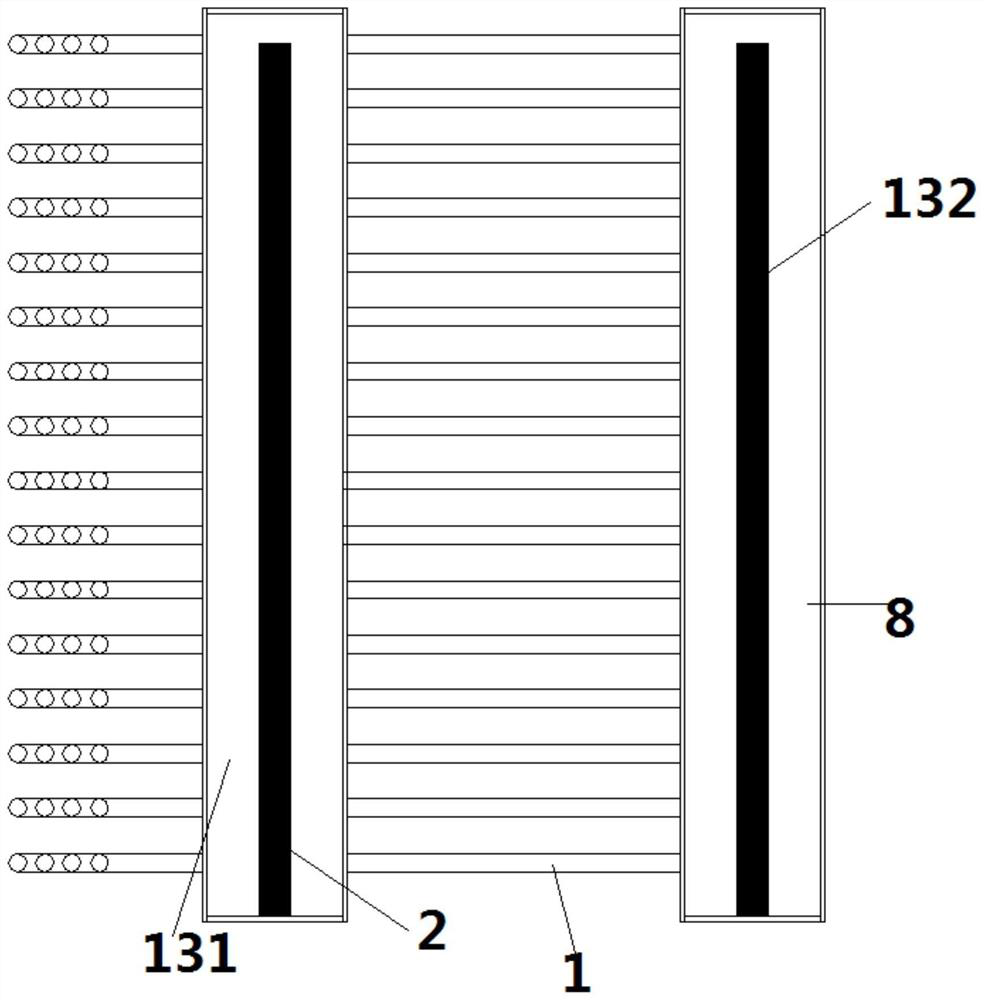

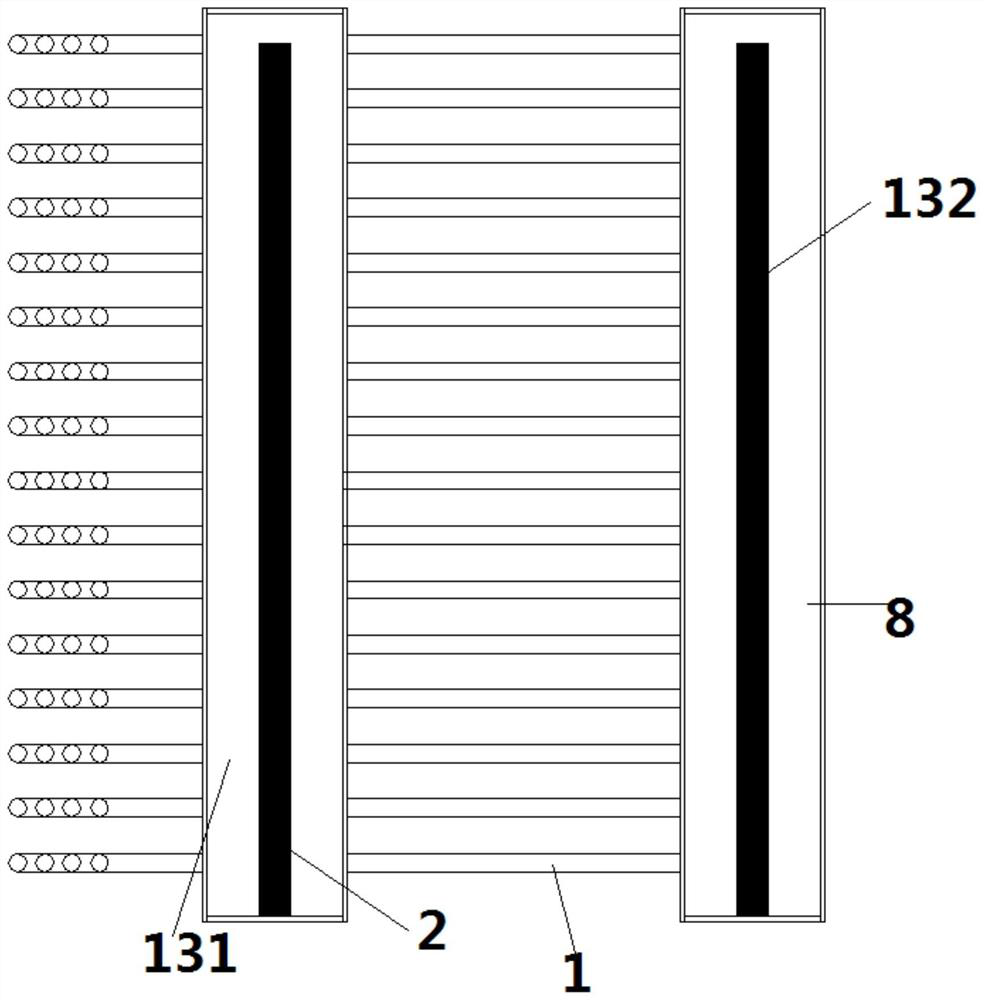

Fully submerged electrode boiler with internal water distributor structure

ActiveCN112503501BAvoid turbulenceThere will be no tripping phenomenonSteam generation heating methodsWater circulation promotionThermodynamicsMechanical engineering

This application discloses a fully submerged electrode boiler with an internal water distributor structure, including a pot shell, a phase electrode, a zero electrode and an isolation shield. The phase electrode and the zero electrode are fixed in the pot shell, and the phase electrode is located In the zero electrode, the isolation shield is movably arranged in the pot shell, and the isolation shield is located between the phase electrode and the zero electrode, the number of the phase electrode and the zero electrode is equal, and the number of the phase electrode It is an integer multiple of 3. Optionally, it also includes a water distributor, a connecting pipe and a flexible sealing sheet. The water port is sealed with the flexible sealing sheet, the water outlet port of the zero electrode is open, the water inlet of the water distributor communicates with the circulation outlet, and the water outlet of the water distributor communicates with the circulation outlet through the connecting pipe. The spaces in the zero electrode are connected, and the tube lengths of each connecting tube are equal.

Owner:ZHEJIANG SHANGNENG BOILER

Wide-load denitration and stable combustion system and method for assisting coal-fired unit

InactiveCN111706848AMeet the needs of smoke temperatureIncrease smoke temperatureGas treatmentWater circulationCombustion systemThermodynamics

The invention discloses a wide-load denitration and stable combustion system and method for assisting a coal-fired unit. The system involves a hot water recirculation pipeline, a boiler water feedingvalve and an economizer water bypass pipeline, wherein the economizer water bypass pipeline is arranged in front of the boiler water feeding valve and on an economizer water outlet pipeline; the economizer water bypass pipeline is provided with a valve, and the economizer water bypass pipeline is additionally arranged on the position, in front of the boiler water feeding valve, of a water feedingpipeline. Hot water recirculation is achieved through a boiler water circulating pump, and the boiler water feeding valve is used for adjusting the boiler water feeding flow to increase the pressure difference, so that flow of the economizer water bypass is increased; the water inlet amount of an economizer is reduced through the economizer water bypass pipeline, and meanwhile, high-temperature boiler water is injected into the water feeding pipeline through the boiler water circulating pump, so that the inlet water temperature of the economizer is increased, the heat exchange amount of the economizer is reduced, and the SCR inlet flue gas temperature is increased; and the water amount of an economizer water feeding bypass is reasonably adjusted, so that it is guaranteed that economizer water feeding is achieved, boiling is avoided, and normal operation of denitration under the low load is guaranteed while safe operation is achieved.

Owner:HUANENG POWER INT CO LTD RIZHAO POWER PLANT

Low-load water supply circulating system for power station boiler

InactiveCN112097237AEffective coolingPrevent decarbonizationWater circulation promotionSteam boilersSynchronous motorDrive wheel

The invention relates to the technical field of thermoelectric equipment, in particular to a low-load water supply circulating system for a power station boiler. The low-load water supply circulatingsystem comprises a circulating pipe, and an inner sleeve frame is connected to the circulating pipe in a sleeving mode. A driving wheel and a limiting wheel are arranged on the inner sleeve frame, andan outer sleeve is fixedly arranged on the inner sleeve frame. A sliding rail is fixedly arranged on the inner sleeve frame, and a heat insulation plate is arranged in the sliding rail in a sliding mode. A rack is fixedly arranged on the heat insulation plate, a gear is engaged on the rack and fixedly arranged on a driving shaft, and the driving shaft is connected to a synchronous motor through abelt wheel pair. The whole system can be driven to move on the circulating pipe through the arranged driving wheel, and the system is stopped at the high-temperature local part of the circulating pipe in cooperation with detection of a temperature sensor. Effective heat dissipation of the circulating pipe is conducted, so that the situations that due to low-load operation of the boiler, a pipeline is locally overheated, the overheated part is decarburized, and the heated surface is thinned are prevented, and pipe explosion is avoided.

Owner:江苏中润能源装备有限公司

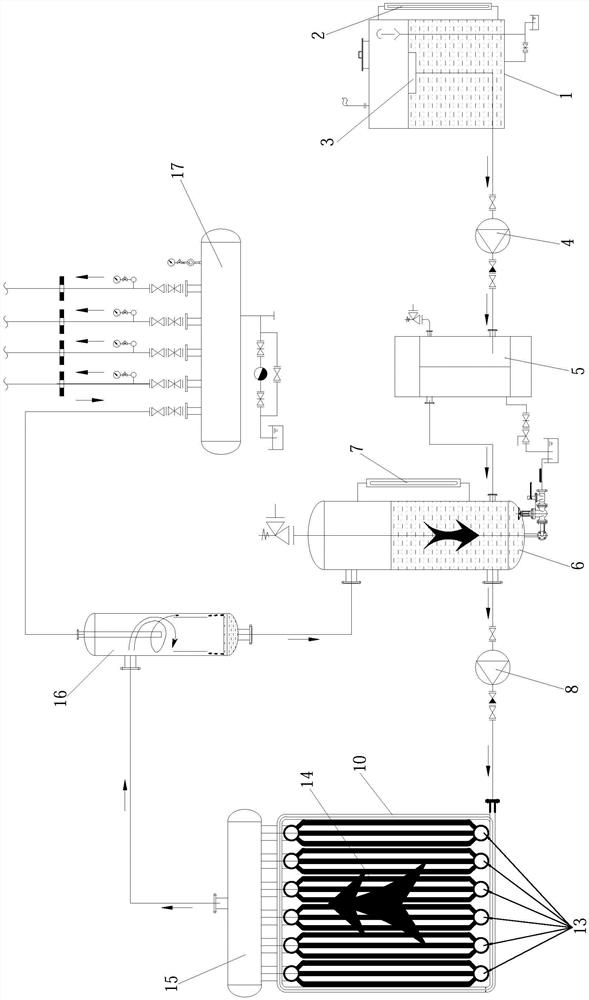

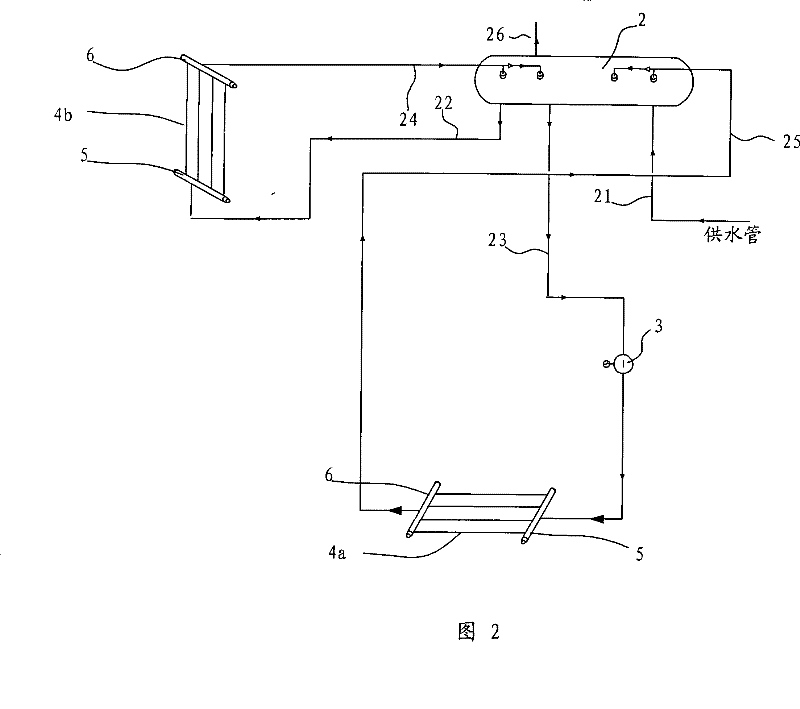

Steam generation system for solar photo-thermal power station and operation method of steam generation system

PendingCN112097228ALess investmentSave electricityFrom solar energyWater circulation promotionCirculator pumpMolten salt

The invention relates to a steam generation system for a solar photo-thermal power station and an operation method of the steam generation system. The steam generation system provides a water workingmedium through a water supply unit, and the steam generation system comprises a preheater, a venturi nozzle, an evaporator, a steam pocket and a starting unit. According to the steam generation systemand the operation method of the steam generation system, the feed water kinetic energy is utilized, meanwhile, the venturi nozzle principle is utilized, on one hand, the circulation volume of the steam-water medium between the evaporator and the steam pocket is promoted through the accelerated mixing function of the venturi nozzle, and the structure is between natural circulation and forced circulation; and on the other hand, when the feed water temperature is lower than the molten salt freezing point, the feed water can be mixed with steam water in a steam pocket downcomer through the venturi nozzle, and finally the temperature of the feed water entering the evaporator is increased. According to the steam generation system and the operation method of the steam generation system, the investment of a forced circulation pump is saved, the reliability of system operation is improved, and meanwhile the auxiliary power is saved.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

System for achieving economizer hot water recycling by adopting start circulation pump and working method

PendingCN109695867AEasy to operateLow costWater circulation promotionWater storage tankThermal water

The invention relates to a system for achieving economizer hot water recycling by adopting a start circulation pump and a working method, and belongs to the field of coal-fired power station boilers.The system comprises the start circulation pump, an economizer recycling pipeline, a start separator, a water storage tank, an economizer inlet pipeline and an economizer. The function of economizer hot water recycling is achieved by the start circulation pump matched with the boiler. A circulation pump is not additionally required, and only a simple pipeline and a valve are needed. The system issimple in structure, is easy to improve, and is low in cost. Cost required for the circulation pump is greatly reduced, and the cost is saved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Exhaust-heating boiler

The invention discloses a waste heat boiler, comprising a boiler body provided with a natural cycling heating surface and a forced cycling heating surface, a cycling system which comprises a water inlet pipe respectively arranged and used for supplying water to steam bag, a natural cycling water outlet pipe, a forced cycling water outlet pipe, a natural cycling reflux pipe, a forced cycling reflux pipe and the steam bags of a steam outlet pipe, a natural cycling heat exchanger arranged at the natural cycling heating surface the entrance and the exit of which are respectively connected with the steam bag through the natural cycling water outlet pipe and the natural cycling reflux pipe, a forced cycling heat exchanger arranged at the forced cycling heating surface the entrance and the exit of which are respectively connected with the steam bag through the forced cycling water outlet pipe and the forced cycling reflux pipe and a cycling pump arranged at the forced cycling water outlet pipe. By combining advantages of two cycling systems, the waste heat boiler overcomes limitations on the arrangement of the natural cycling heating surface and poor effects of dust removal, reduces fluxand load of the recycling pump, improves reliability, and is provided with the advantages of light accumulated dust, small volume, energy saving, etc.

Owner:CHINA ENFI ENGINEERING CORPORATION

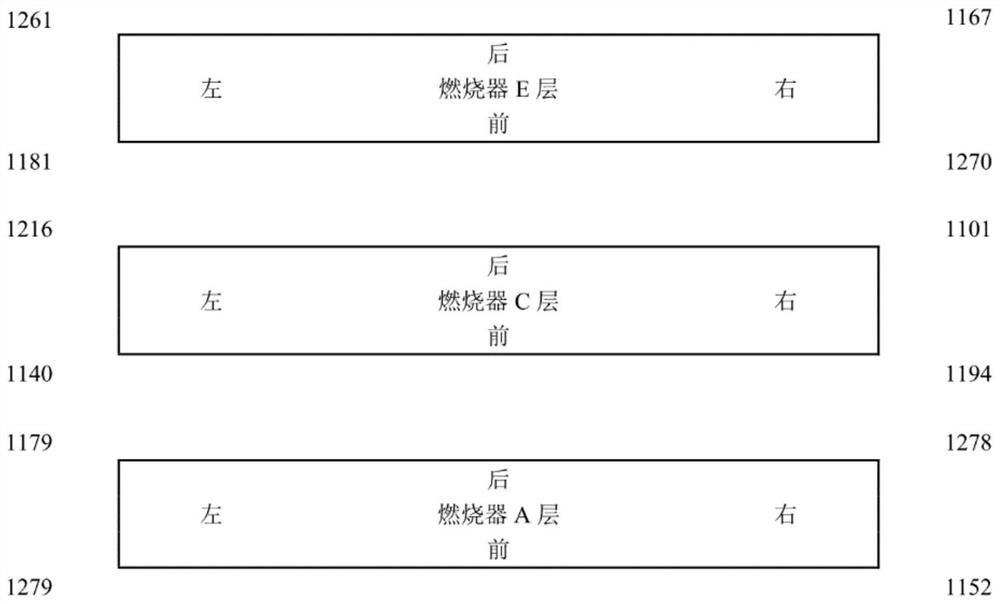

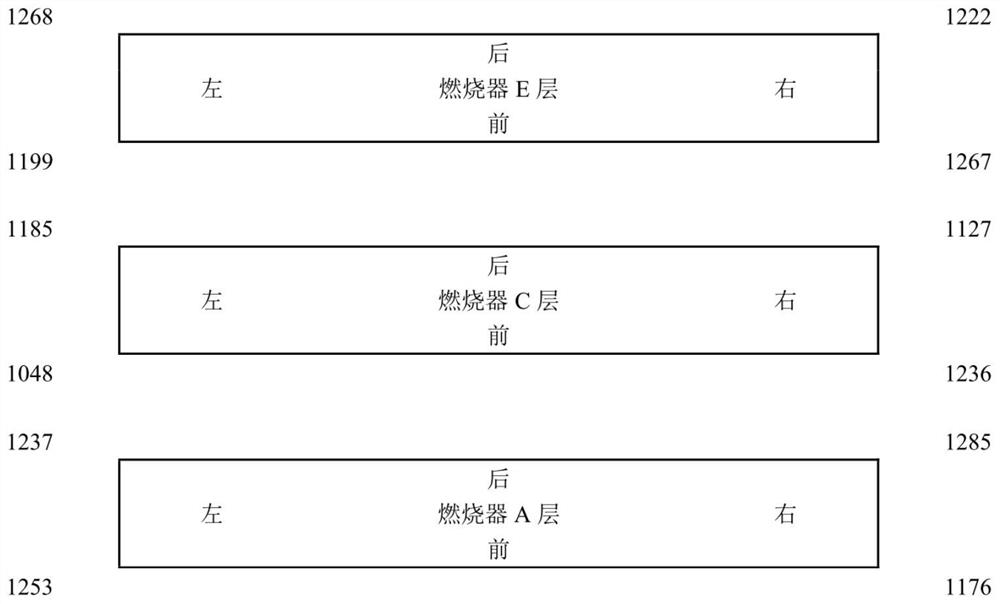

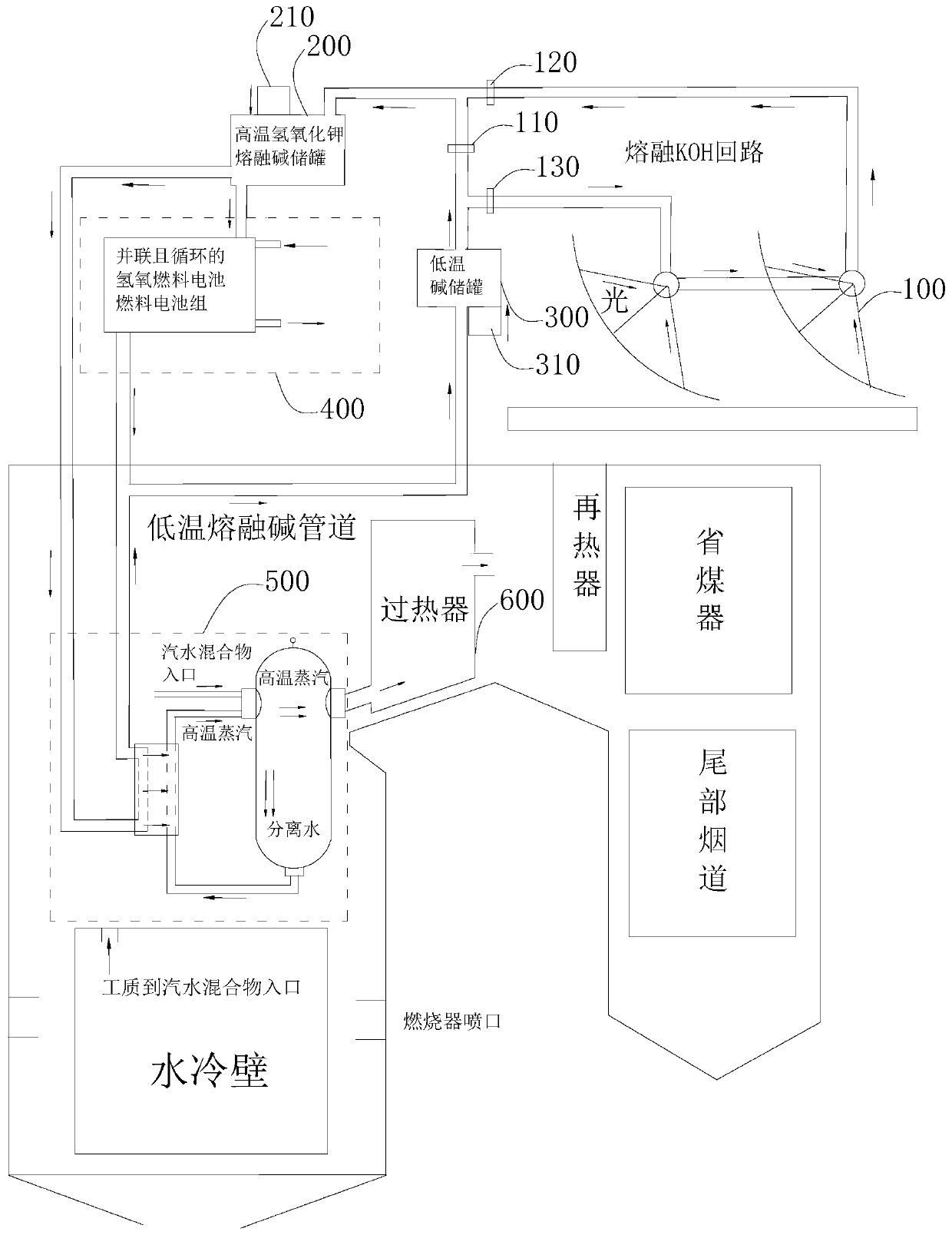

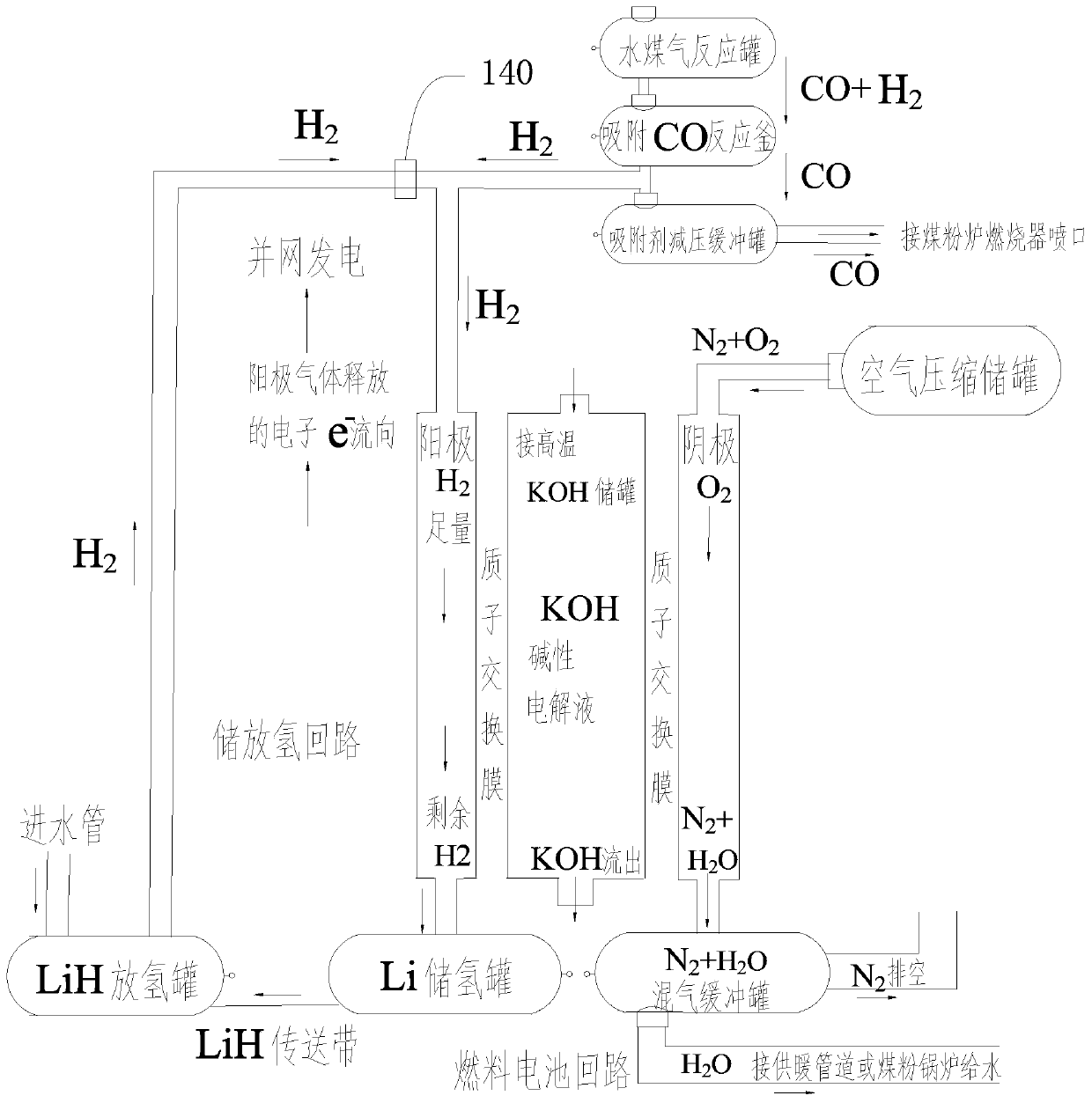

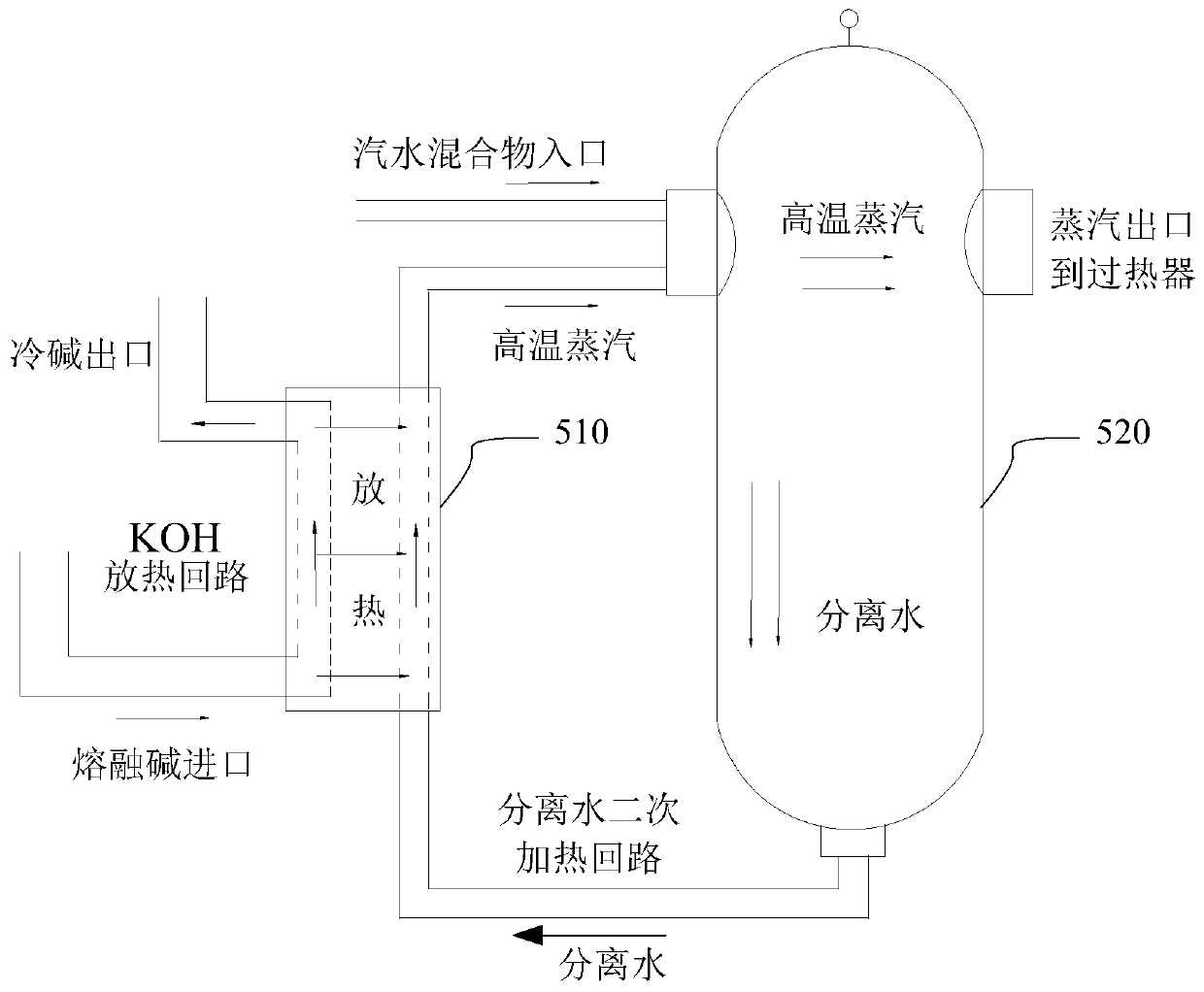

Double-layer clean energy and pulverized coal coupled peak shaving pulverized coal boiler

ActiveCN111425849ARealize comprehensive utilizationFlexible storageCombustion using gaseous and pulverulent fuelSolar heating energyPotassium hydroxideCollector device

The invention discloses a double-layer clean energy and pulverized coal coupled peak shaving pulverized coal boiler, and belongs to the technical field of boiler transformation. The invention aims tosolve the problems that an existing peak shaving boiler adopts a single coupling mode, the fault tolerance is poor, and the structure of the existing peak shaving boiler can cause energy waste. The peak shaving pulverized coal boiler comprises a pulverized coal boiler, a trough type photo-thermal heat collector set, a high-temperature potassium hydroxide molten alkali storage tank, a low-temperature alkali storage tank, a hydrogen energy storage hydrogen-oxygen fuel cell unit, a molten alkali heat energy storage trough type photo-thermal unit and a superheater, and the hydrogen energy storagehydrogen-oxygen fuel cell unit carries out power grid connection coupling peak regulation on the pulverized coal boiler; the molten alkali heat energy storage tank type photo-thermal unit performs high-temperature steam coupling peak regulation on the pulverized coal boiler, and the double-layer coupling structure can perform peak regulation on the pulverized coal boiler at the same time; and evenif one of the two units fails, the other clean energy source can still independently operate to play a role in regulating the peak of the pulverized coal boiler. The peak shaving pulverized coal boiler can be used for peak regulation transformation of the pulverized coal boiler.

Owner:HARBIN BOILER

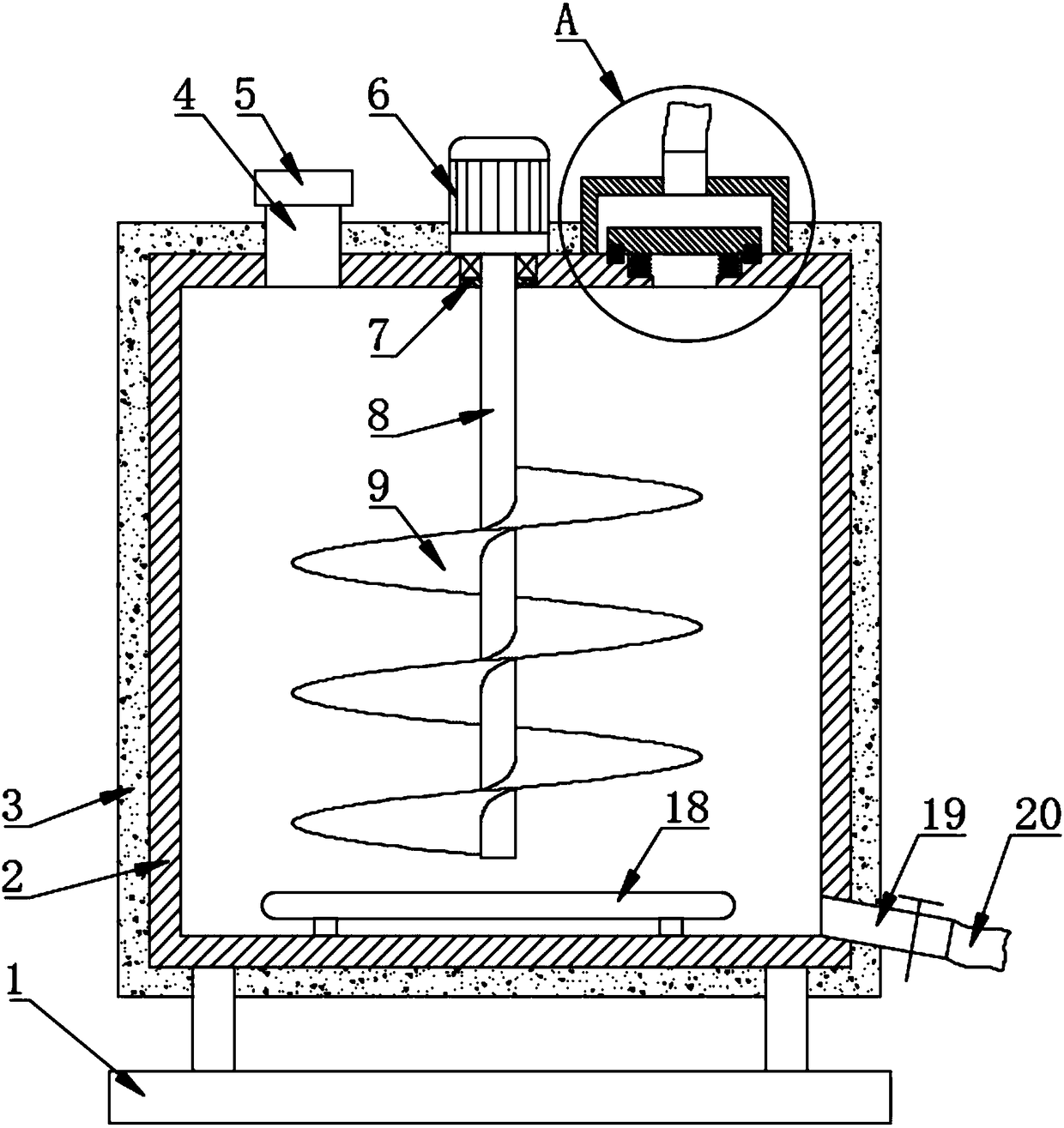

Water circulation system in production of soybean peptide fructose

ActiveCN107013898AImprove separation efficiencySimple structureFeed water supplyDispersed particle separationThermodynamicsProcess engineering

The invention provides a water circulation system in production of soybean peptide fructose. The water circulation system comprises a sugar decocting tank, a first moisture separator, a heater, a sugar melting tank and a second moisture separator; the sugar melting tank and the sugar decocting tank adopt a continuous operation process, and the required temperature for the sugar melting tank is lower than that of the sugar decocting tank; secondary steam after heating of the sugar decocting tank can be directly used for heating the sugar melting tank; for the condition that the requirements of the sugar melting tank cannot be met after temperature loss of the secondary steam, the heater is specially arranged for heat compensation, and the required energy consumption for the heat compensation is much less than the energy consumption caused by primary steam; the moisture separators are arranged at the rear ends of the sugar melting tank and the sugar decocting tank, and the two moisture separators are self-reformed, with simple structures; after mixed steam enters the moisture separators, the steam rises due to specific gravity difference, and condensate water declines; each moisture separator is also internally provided with a flow baffle and a water eliminator; the separation efficiency is improved, and hot steam and the condensate water are recycled fully; and the water circulation system provided by the invention has the advantages of energy saving, emission reduction and energy consumption control.

Owner:荣海生物科技有限公司

Boiler with height alternation starting heating

ActiveCN111780075ASpeed up the flowAdd elastic vibration effectSteam generation heating methodsWater circulation promotionThermodynamicsMechanics

The invention provides a boiler. The boiler comprises an electric heater device and a steam dome. The electric heater device is arranged in the steam dome. The steam dome comprises a water inlet pipeand a steam outlet. The electric heater device comprises a first header, a second header and a coiler. A first electric heater and a second electric heater are arranged in the first header and the second header respectively. The first header and / or the second header are / is filled with phase change fluid. Each electric heater device is arranged in a multi-segment manner in the height direction, each segment is independently controlled, and the multiple segments are started up and shut down periodically along with time. According to the boiler, because the electric heaters are gradually startedup from bottom to top, the fluid on the lower part can be sufficiently heated to form quite good free convection to further promote flow of the fluid, and the elastic vibration effect is improved. According to the boiler, because the electric heaters are arranged in the two headers respectively, and the heating power changes along with time, the fluid can be frequently evaporated to expand and shrunk in elastic tube bundles so as to drive the elastic tube bundles to vibrate unceasingly, the heating efficiency can be further improved, and the descaling operation can be improved further.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

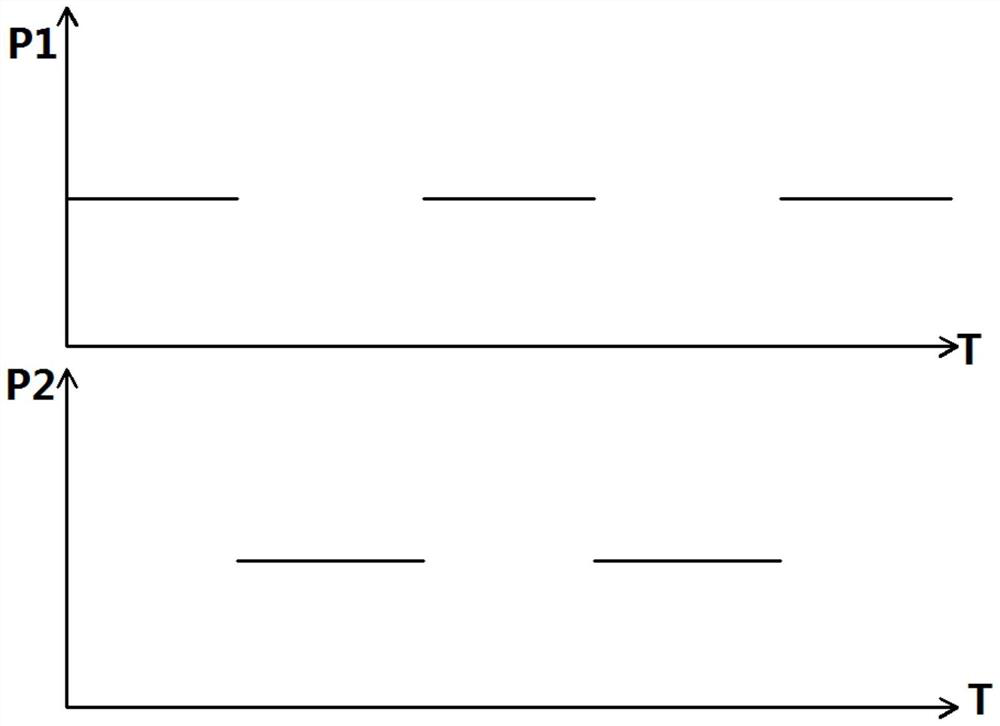

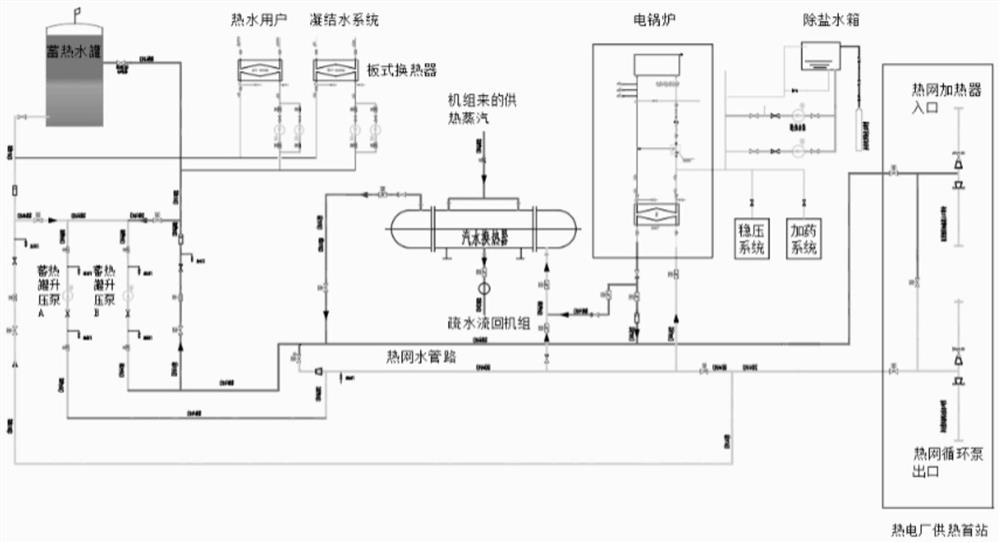

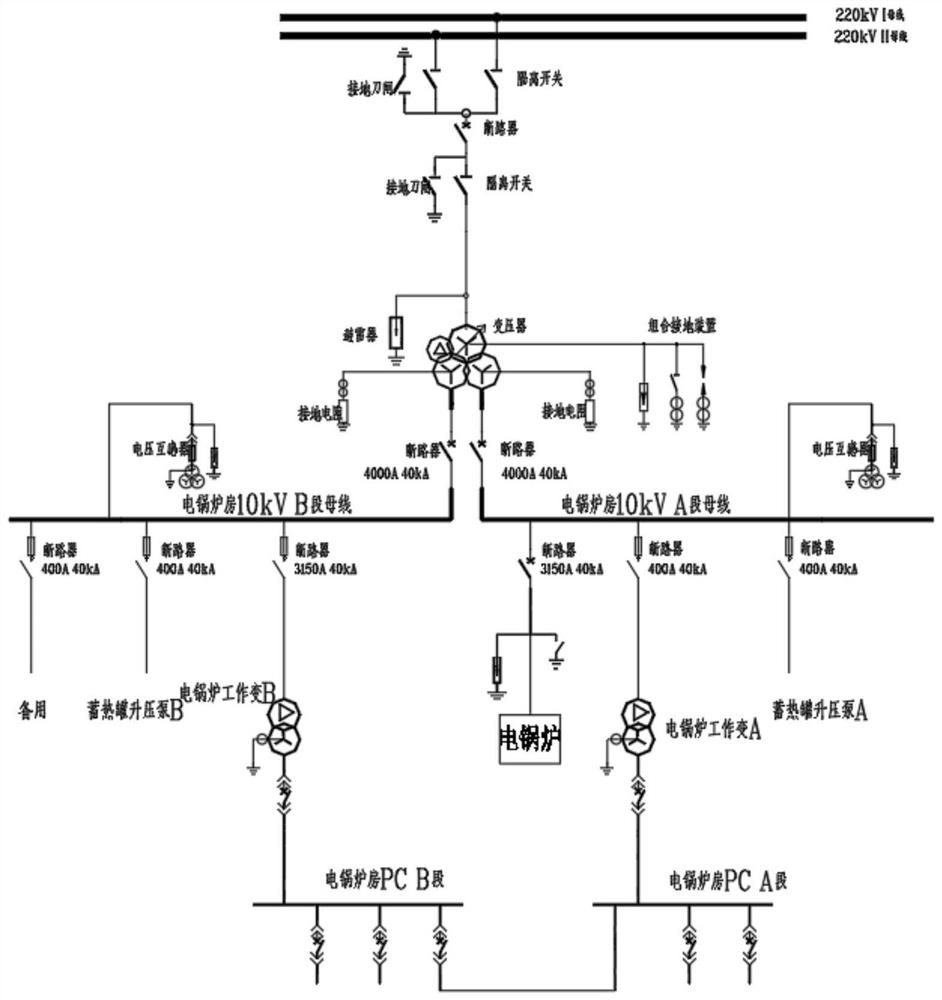

Energy storage peak regulation system based on wind, light and thermal power generation multi-energy complementation

PendingCN114877301AImprove deep peak shaving abilityImprove peak capacityFeed water supplySteam generation using pressureNew energyPower grid

The invention discloses an energy storage peak regulation system based on multi-energy complementation of wind, light and thermal power generation, which comprises a steam-water heat exchanger, and the injection end and the discharge end of the steam-water heat exchanger are connected with a generator set through pipelines. By arranging the proper hot water heat storage tank, under the same peak shaving depth, the electric energy-heat energy conversion amount is reduced, so that the economical efficiency is better, the deep peak shaving capacity of the unit can be improved, the peak capacity of the unit can be improved, the two-way adjusting flexibility of the unit can be enhanced, the operation mode is flexible, and the service life of the unit is prolonged. Compared with the advantages of high fuel adjustment response speed and no adverse effect on boiler operation, the method solves the problems that a power grid in a conventional mode receives new energy electric quantity according to the accommodating capacity, and when the power grid cannot absorb the new energy electric quantity, the new energy generation power is limited to ensure the electric energy quality and safety of the power grid, and all electric energy is converted into heat energy through an electric heat storage peak regulation mode developed in recent years. And the efficiency is relatively low.

Owner:沈阳汇智源电力发展集团有限公司 +1

Remote control temperature difference switching heating steam boiler

ActiveCN112781024BImprove intelligenceEnable Portable MonitoringSteam generation heating methodsBoiler controlAutomatic controlThermodynamics

Owner:SHANDONG JIAOTONG UNIV

Steam forming method achieved through buoyancy adjustment of inclination angle

InactiveCN111207374AImprove heat transfer effectFast heat transferWater circulation promotionSteam generation using hot heat carriersWater storageWater storage tank

The invention discloses a steam forming method through buoyancy adjustment of an inclination angle. The steam forming method is characterized in that air heated by solar energy is used for being inputto a heat exchanger located in a water storage pipe through an air pump to heat water in a water storage tank, the water is heated and then evaporated to form steam to be output from a steam output opening; in the heating process of the heat exchanger, the water in the water storage tank is stirred by a stirrer; in the stirring process, a push plate in the stirrer generates an angle change of theinclination angle under the action that the buoyancy of a floating ball is matched with the tension of a spring so as to change the force of pushing the water up during the rotation of the push plate; and the change process of the inclination angle of the push plate is that the inclination angle of the push plate is increased along with the increase of the liquid level in the water storage tank.The steam forming method has the advantages that the heat exchange speed is fast, and the force of pushing the water up can be increased along with the increase of the water level, and solves the problem that an existing steam generator for hot air heating is slow in heat exchange speed.

Owner:ZHEJIANG BOTHWELL ELECTRIC

Throttle element for direct-current vapor generator

PendingCN110274216AIncrease drag coefficientNo runner gapsBoiler water tubesWater circulation promotionImpellerWater flow

The invention aims at disclosing a throttle element for a direct-current vapor generator. The throttle element comprises a cylindrical body. An inlet runner is arranged in the center of the body. Water flowing holes are symmetrically formed in the two sides of the bottom of the inlet runner. Multiple stages of impellers are arranged on the outer side of the lower portion of the body, and a sealing thread is arranged on the outer side of the upper portion of the body. Compared with the prior art, the throttle element is conveniently mounted at the end of a heat transfer pipe through the sealing thread, the number of the impellers and the size of gaps are selected according to the needed resistance coefficient, the large resistance coefficient can be achieved, no small runner clearance exists, the possibility that blocking happening after long-time operating is reduced, good universality and expansibility are achieved, and the aim of the throttle element is achieved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com