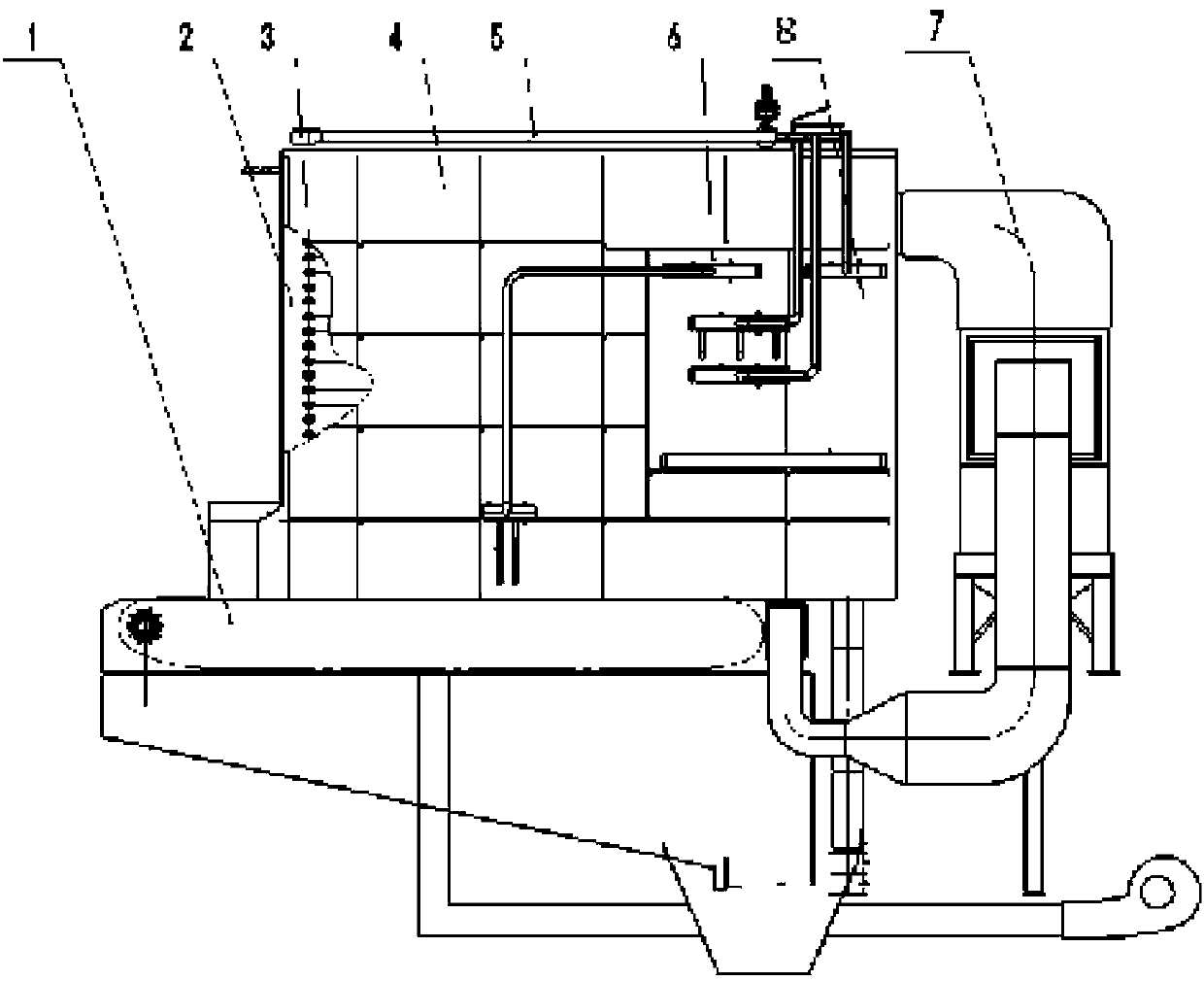

Oil field fuel coal steam-injection boiler

A steam injection boiler and coal-fired technology, which is applied to steam boilers, steam generation, mining fluids, etc., can solve the problems of high cost and poor economy, and achieve the effects of reducing mining costs, reducing steam humidity, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

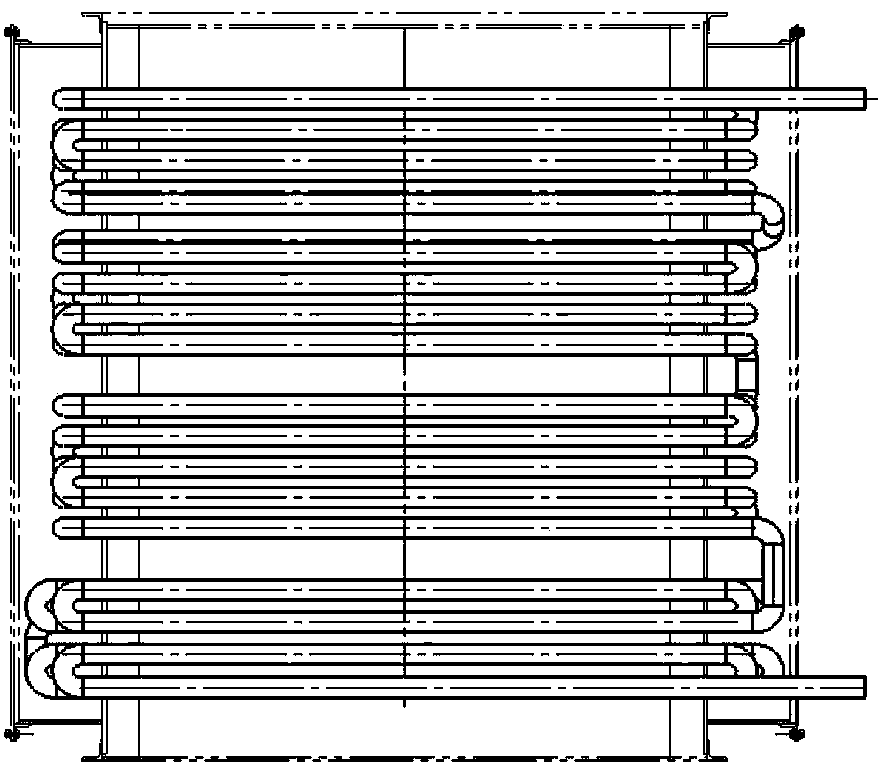

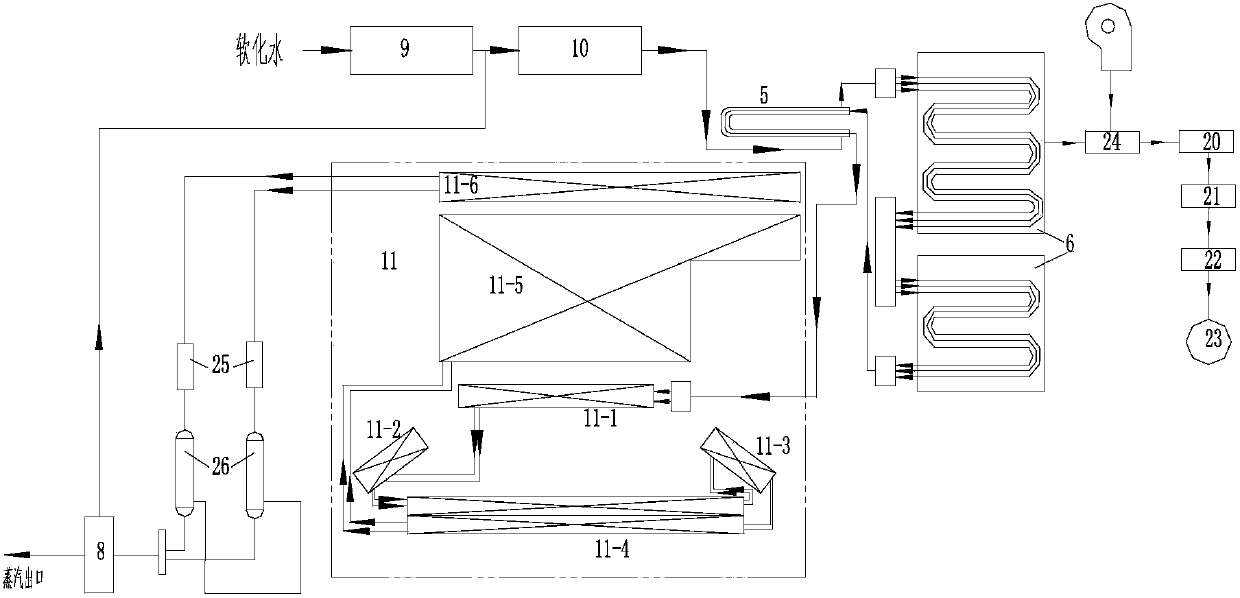

[0024] Embodiment 1: The water treated by the water treatment tank 9 does not contain Ca and Mg ions (that is, contains Na, K, Cl and other ions). The inlet end of the plunger pump 10 is connected to a water treatment tank 9, and the water treated by the water treatment tank 9 is boosted by the plunger pump 10 and injected into the outer pipe of the water heat exchanger 5, and the water in the outer pipe of the water heat exchanger 5 flows through the convection section 6. The water heated by the convection section 6 enters the inner tube of the water heat exchanger 5, and the water in the inner tube of the water heat exchanger 5 can heat the water in the outer tube at the same time, and the water in the inner tube enters the furnace body 11 after heat exchange, followed by After the middle arch pipe 11-1 and the front arch pipe 11-2 enter the anti-scorch pipe 11-4, the water flowing out from the anti-scorch pipe 11-4 flows back to the anti-scorch pipe 11-4 after passing throug...

Embodiment 2

[0027]Embodiment two: the water treated by the water treatment tank 9 does not contain Ca, Mg, Na, K, Cl plasma, and the water is injected into the outer pipe of the water heat exchanger 5 after the plunger pump 10 boosts the pressure, and the water heat exchanger 5 The water in the outer pipe flows through the convection section 6, and the water heated by the convection section 6 enters the inner pipe of the water heat exchanger 5, and the water in the inner pipe of the water heat exchanger 5 enters the furnace body 11 after exchanging heat with the water of the outer pipe, and is heated by the furnace. The water flowing out of the body 11 directly enters the superheater 8 to form steam to be discharged, and the separated water is injected back into the plunger pump 10 . Since the water in the whole process does not contain Na, K, Cl plasma, the high-efficiency steam-water separator 26 is omitted in this process, and the water flowing out from the furnace body 11 can directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com