Shale gas thermal recovery method and system by using deep geothermal resources

A technology of geothermal resources and shale gas, which is applied to collectors using underground pools to accumulate working fluids, geothermal energy power generation, and mining fluids, etc., can solve the problems of inability to desorb adsorbed gas, low recovery degree, and high mining costs. Achieve the effects of reducing mining costs, promoting desorption of adsorbed gas, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0026] A method for thermally recovering shale gas by using deep geothermal resources, comprising the following steps:

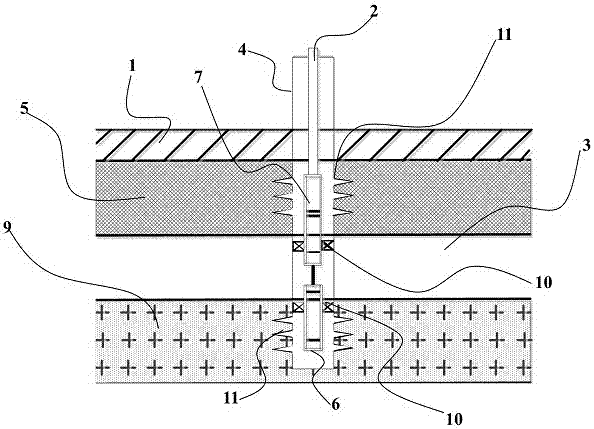

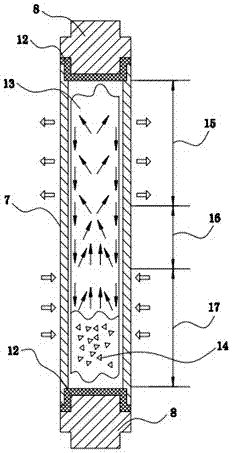

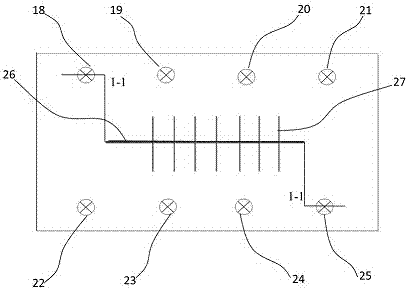

[0027] The first step is the layout of the well pattern. Drilling equipment is used in the production area. According to the trajectory of the production design wellbore and the trajectory parameters of the production design wellbore, the geosteering drilling technology is used to drill to form a horizontal well, and the casing is run in the horizontal well and injected. cementing, followed by perforation and completion in the horizontal well section, and finally multi-stage fracturing in the horizontal well section of the horizontal well; a row-shaped well pattern is used, and the row-shaped well pattern is divided into two rows, and the two-row well pattern Located on both sides of the horizontal wells, four buried wells are arranged in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com