Silk-derived nitrogen-doped graphene fibers

A graphene fiber and silk fiber technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems affecting the oxygen reduction electrocatalytic activity of materials, performance discounts, and biomass carbon-nitrogen materials stability and followability. , to achieve the effect of favorable diffusion and gas desorption, high specific surface area, high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

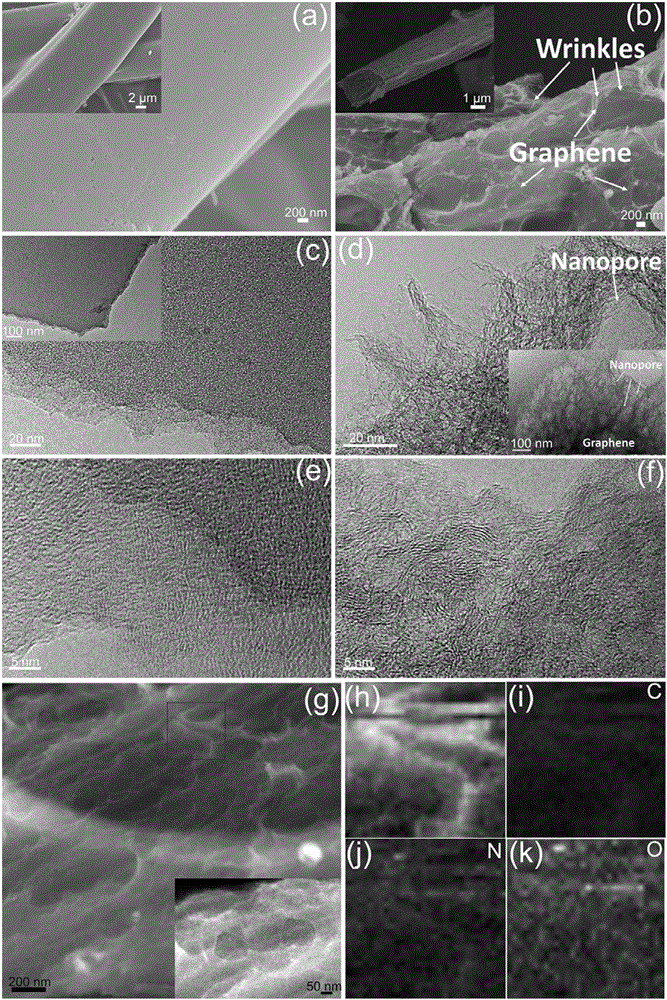

[0029] Its preparation method of nitrogen-doped graphene-like fiber derived from silk comprises the steps:

[0030] (1) Pretreatment: Put the silk fiber (mulberry silkworm) in deionized water, soak it for 3 hours and rinse it repeatedly for 3 times, then put it into a vacuum oven for drying, and set the temperature of the oven at 60°C for 6 hours.

[0031] (2) Activation: Soak the dried silk fibers of step (1) in saturated potassium chloride solution for 3 hours, rinse with deionized water 3 times after the end and put them into a vacuum oven for drying. The oven temperature is set at Dry at 60°C for 6 hours.

[0032] (3) Carbonization: put the dried silk fiber in step (2) into a corundum boat, and then place the corundum boat in the middle of the tube furnace. Turn on the protective gas for the silk fibers to make the tube furnace reach a vacuum state and start to heat up; the protective gas is formed by mixing 90% of inert gas (argon) and 10% of reducing gas (ammonia). Rai...

Embodiment 2

[0034] Its preparation method of nitrogen-doped graphene-like fiber derived from silk comprises the steps:

[0035] (1) Pretreatment: Put the silk fiber (tussah) in deionized water, soak it for 6 hours and rinse it repeatedly for 3 times, then put it into a vacuum oven for drying, and set the temperature of the oven at 60°C for 6 hours.

[0036] (2) Activation: Soak the dried silk fibers of step (1) in a saturated zinc chloride solution for 24 hours, rinse with deionized water for 3 times and dry in a vacuum oven after the end, and the oven temperature is set at Dry at 60°C for 6 hours.

[0037](3) Carbonization: put the dried silk fiber in step (2) into a corundum boat, and then place the corundum boat in the middle of the tube furnace. The silk fiber is opened with protective gas to make the tube furnace reach a vacuum state and then start to heat up; the protective gas is formed by mixing 99% of inert gas (nitrogen) and 1% of reducing gas (hydrogen). Raise the temperature...

Embodiment 3

[0039] Its preparation method of nitrogen-doped graphene-like fiber derived from silk comprises the steps:

[0040] (1) Pretreatment: Put the silk fiber (cassava silkworm) in deionized water, soak it for 5 hours and rinse it repeatedly for 3 times, then put it into a vacuum oven for drying, and set the temperature of the oven at 60°C for 6 hours.

[0041] (2) Activation: Soak the dried silk fiber in step (1) in a saturated cobalt nitrate solution for 10 hours, rinse it with deionized water for 3 times and dry it in a vacuum oven. The oven temperature is set at 60 °C for 6 hours.

[0042] (3) Carbonization: put the dried silk fiber in step (2) into a corundum boat, and then place the corundum boat in the middle of the tube furnace. The silk fiber is turned on with a protective gas to make the tube furnace reach a vacuum state and then start to heat up; the protective gas is formed by mixing 95% of an inert gas (argon) and 5% of a reducing gas (ammonia). Raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com