Wide-load denitration and stable combustion system and method for assisting coal-fired unit

A technology for coal-fired units and loads, applied in separation methods, chemical instruments and methods, and indication of boiler working conditions, etc., can solve problems such as excessive nitrogen oxide emissions, damaged catalyst life, and increased ammonia consumption. Improve the outlet smoke temperature, ensure normal operation, and ensure the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

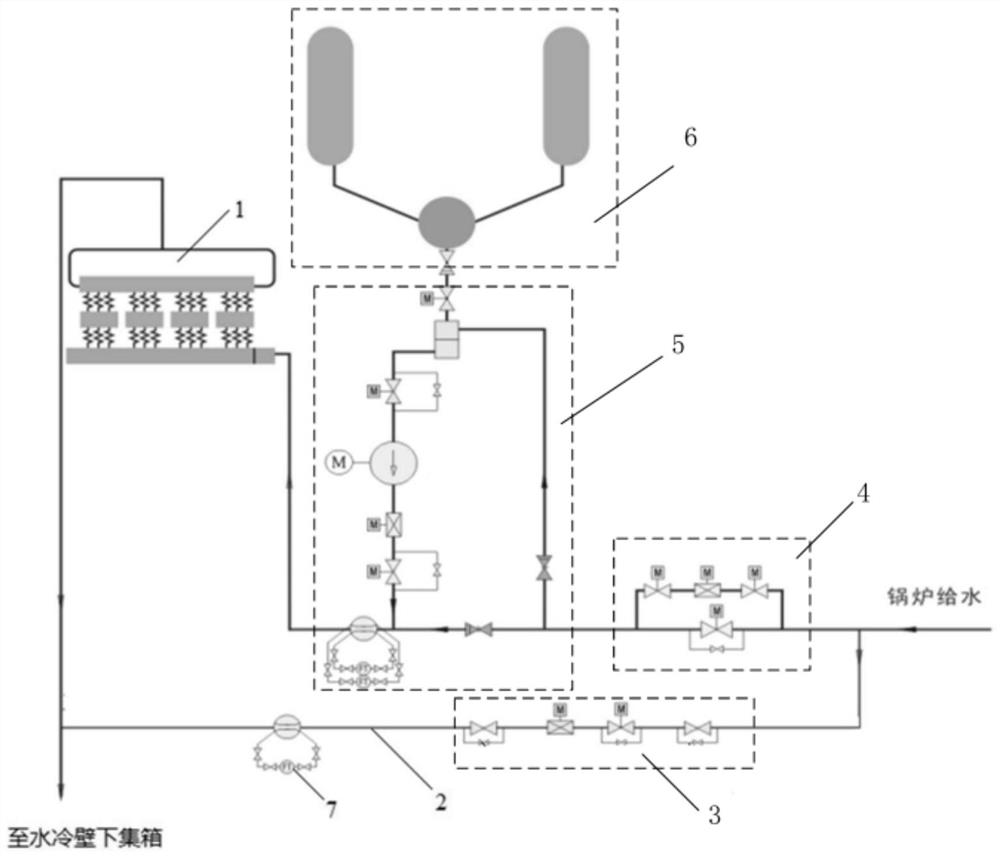

[0025] refer to figure 1 , a wide-load denitrification and stable combustion system for auxiliary coal-fired units, including hot water recirculation pipeline 5, boiler water supply valve 4, economizer water bypass pipeline 2, and the inlet of economizer water bypass pipeline 2 Set on the water supply pipe in front of the boiler water valve, the outlet of the economizer water bypass pipe 2 is set on the economizer water outlet pipe; the economizer water bypass pipe 2 is equipped with a valve 3

[0026] Such as figure 1 As shown, after the hot water flows out from the steam-water separator 6, the hot water recirculation is realized by using the existing boiler water circulation pump and the hot water recirculation pipeline 5, and the existing boiler water valve 4 is used to throttle and increase the pressure. increase the economizer water bypass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com