Cross flow type fully-premixed low-NOx boiler

A fully premixed, cross-flow technology, applied to steam boilers, preheating, feed water heaters, etc., can solve problems such as the inability to effectively reduce NOx generation, poor definition of the minimum safe water level, and non-continuous and stable operation of boilers, etc., to achieve Effect of increasing effective heating area, reducing dead zone and interface, and optimizing economizer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

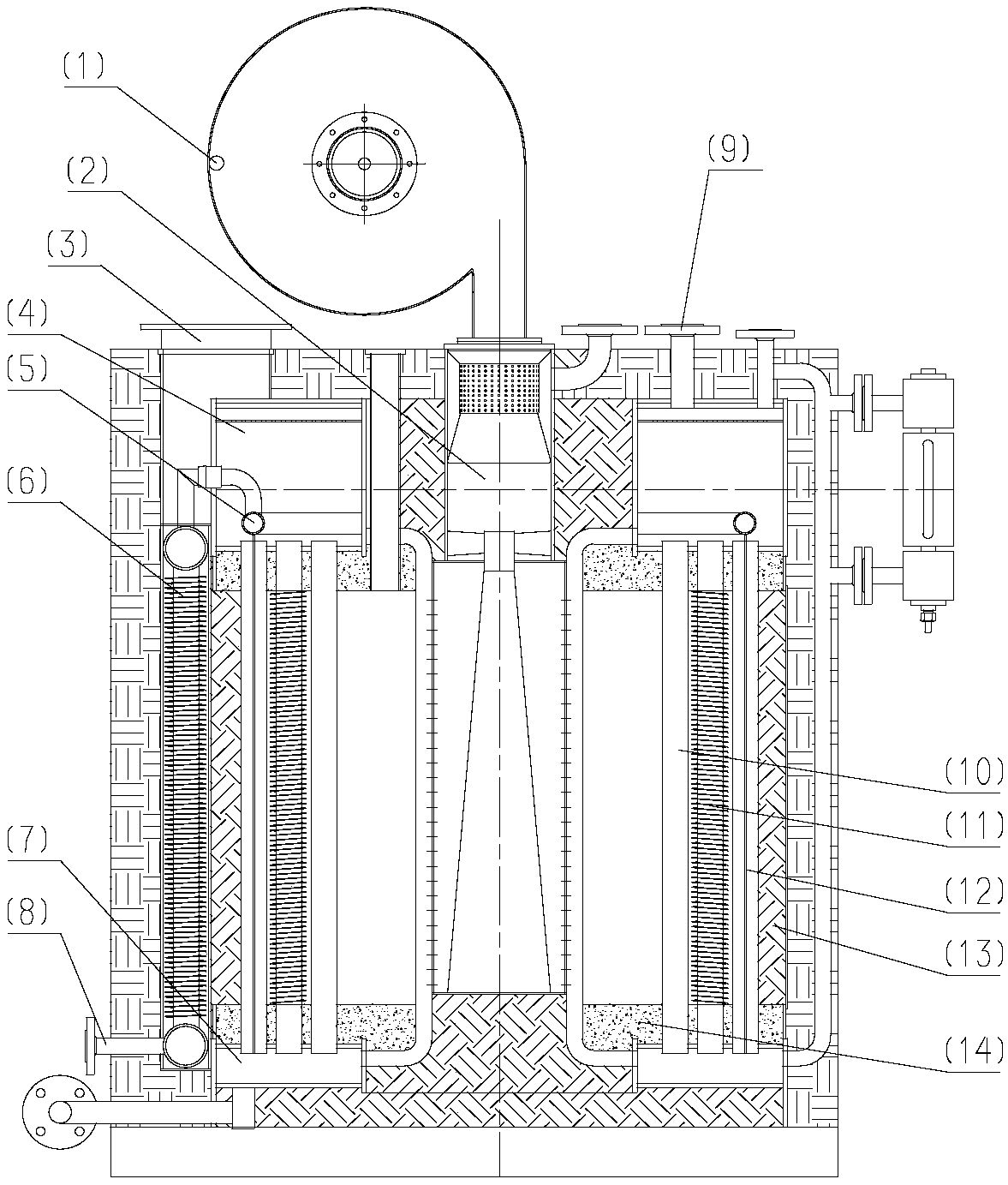

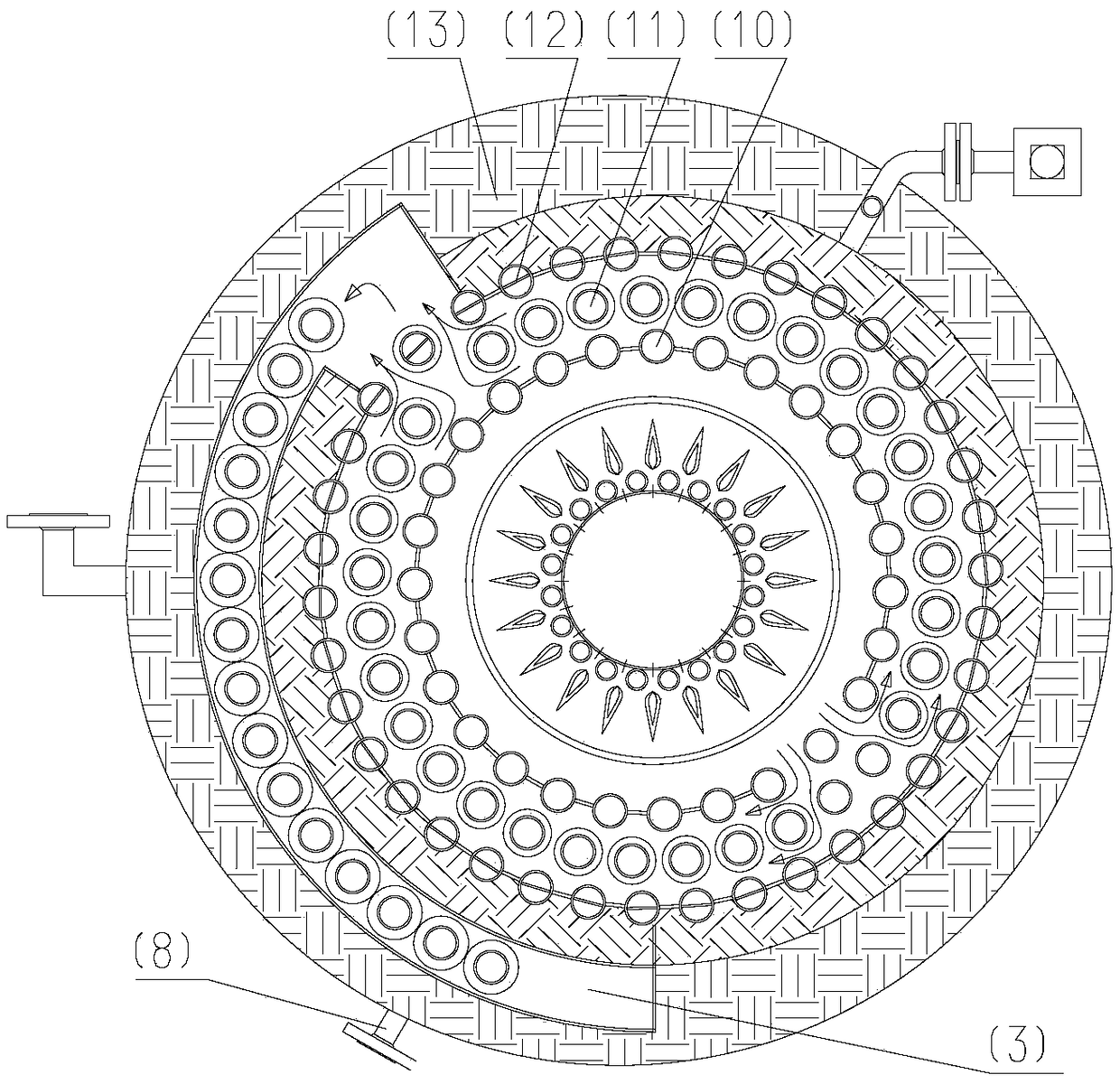

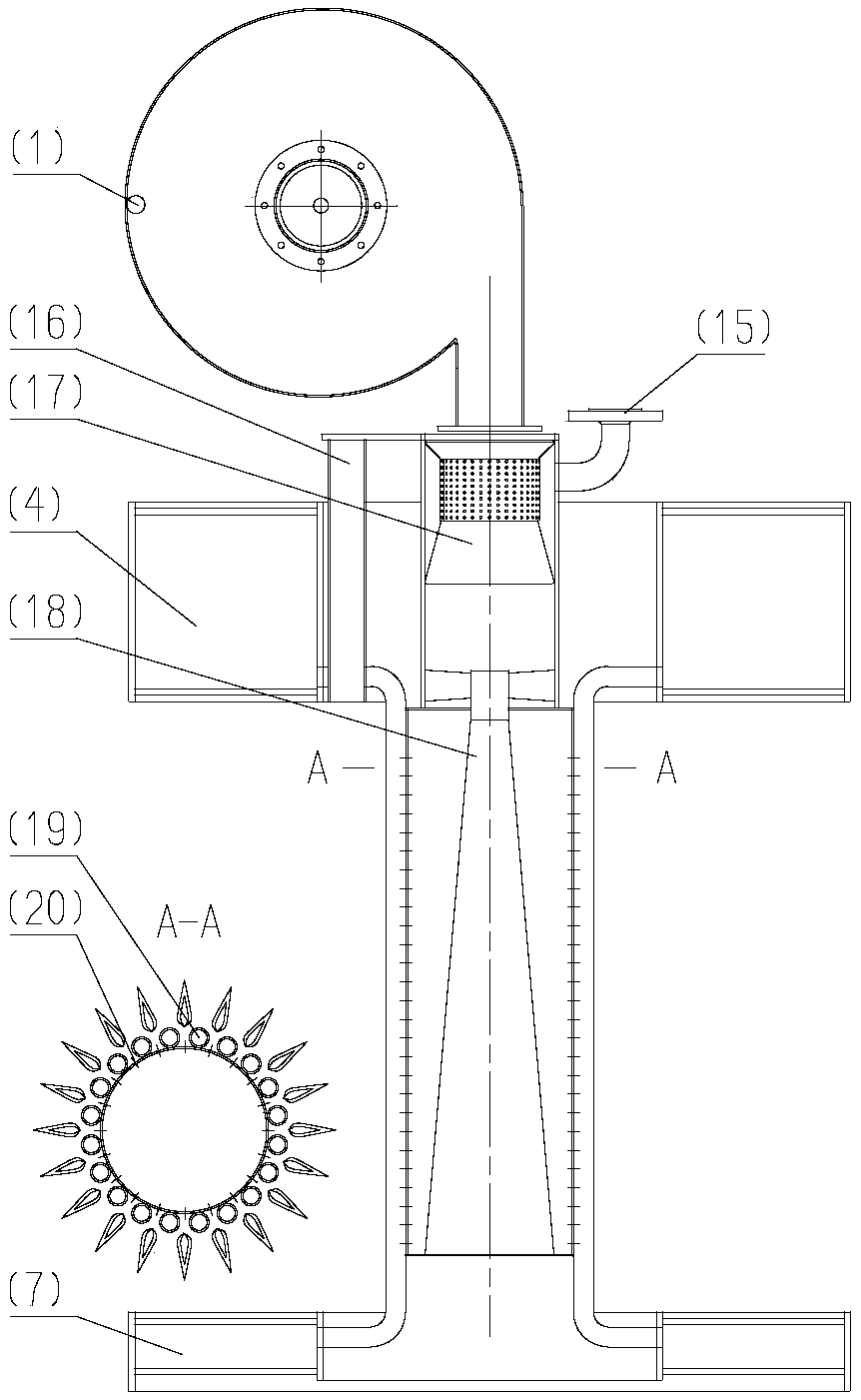

[0026] as attached figure 1 , 2 As shown, a through-flow fully premixed low NO of the present invention x The steam boiler includes fan 1, burner 2, smoke outlet 3, upper annular header 4, water supply circulation device 5, economizer 6, lower annular header 7, water supply port 8, steam outlet 9, inner membrane type Wall pipe 10 , finned pipe 11 in the middle circle, membrane wall pipe 12 in the outer circle, insulation layer 13 and refractory layer 14 . The burner 2 is installed at the inner center of the boiler body, the fan 1 is installed above the burner 2, an upper annular header 4 is arranged at the inner upper part of the boiler body, and an upper annular header 4 is arranged at the inner lower part of the boiler body. A lower annular header 7 is provided, and an inner ring membrane wall tube 10, a middle ring finned tube 11, an outer ring membrane wall tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com