Patents

Literature

139results about How to "Increase the heating surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-ejection grading combustion method and W flame boiler device for realizing same

ActiveCN101832549ALower the feverImprove flame stabilityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir velocityCombustion

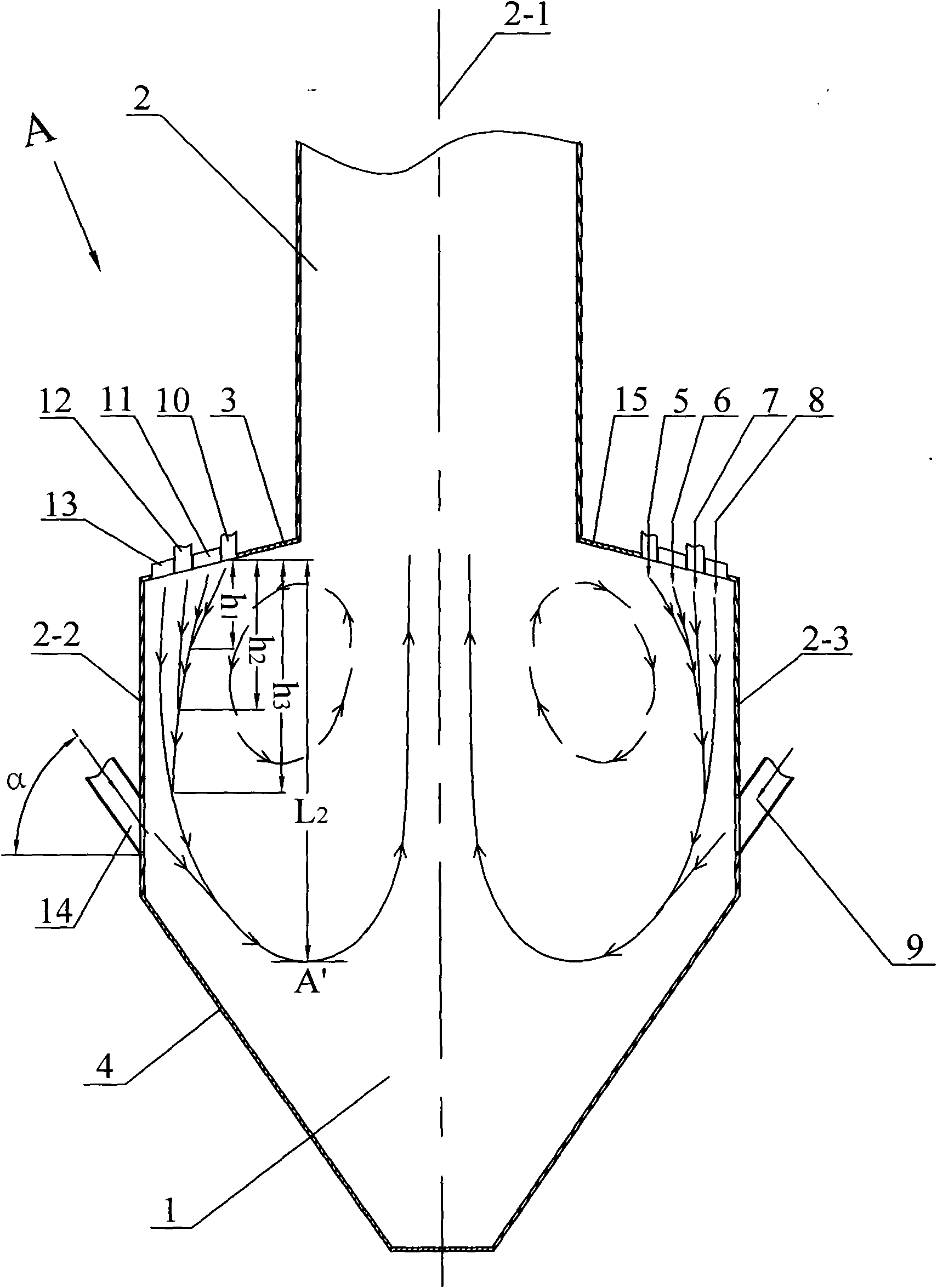

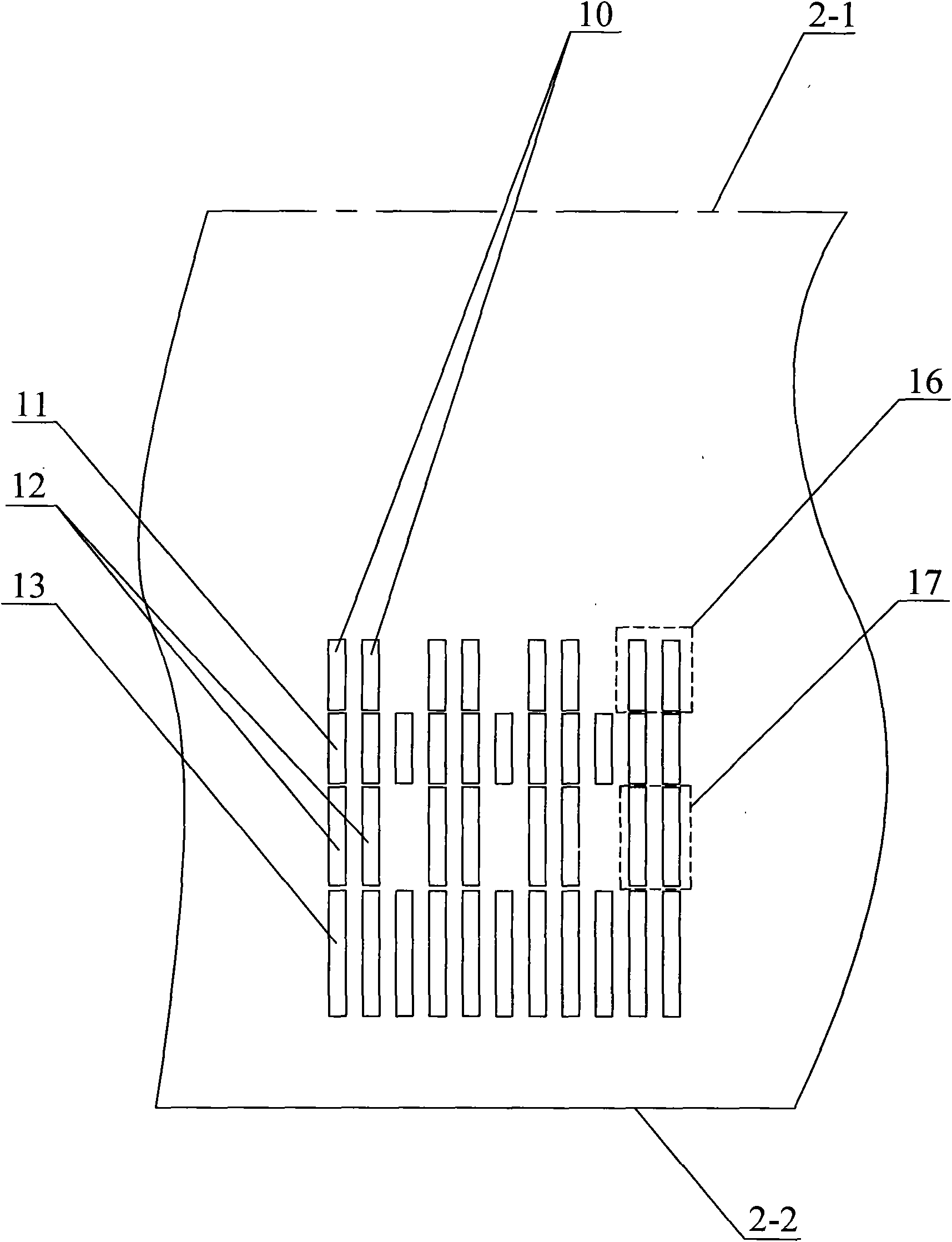

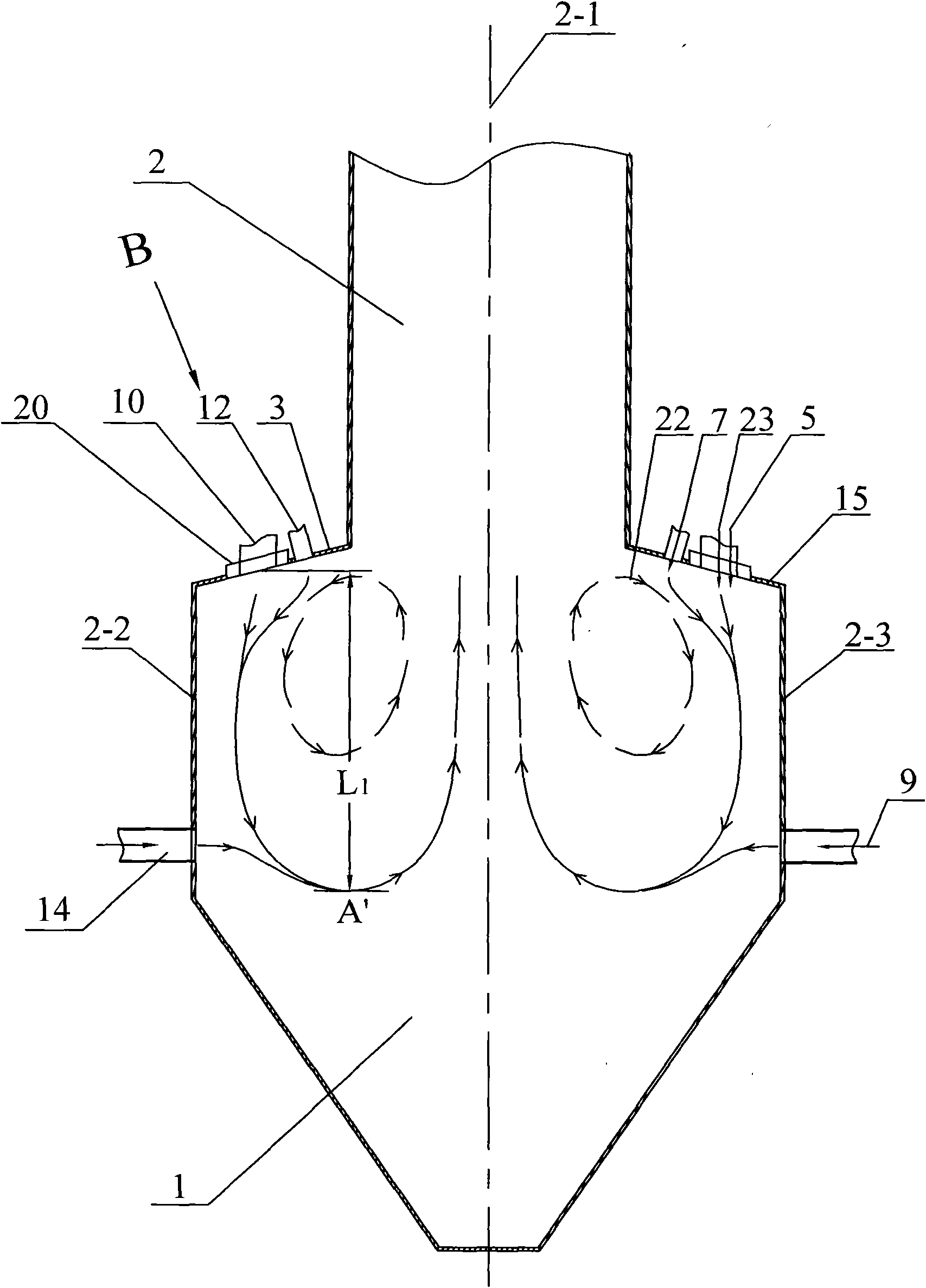

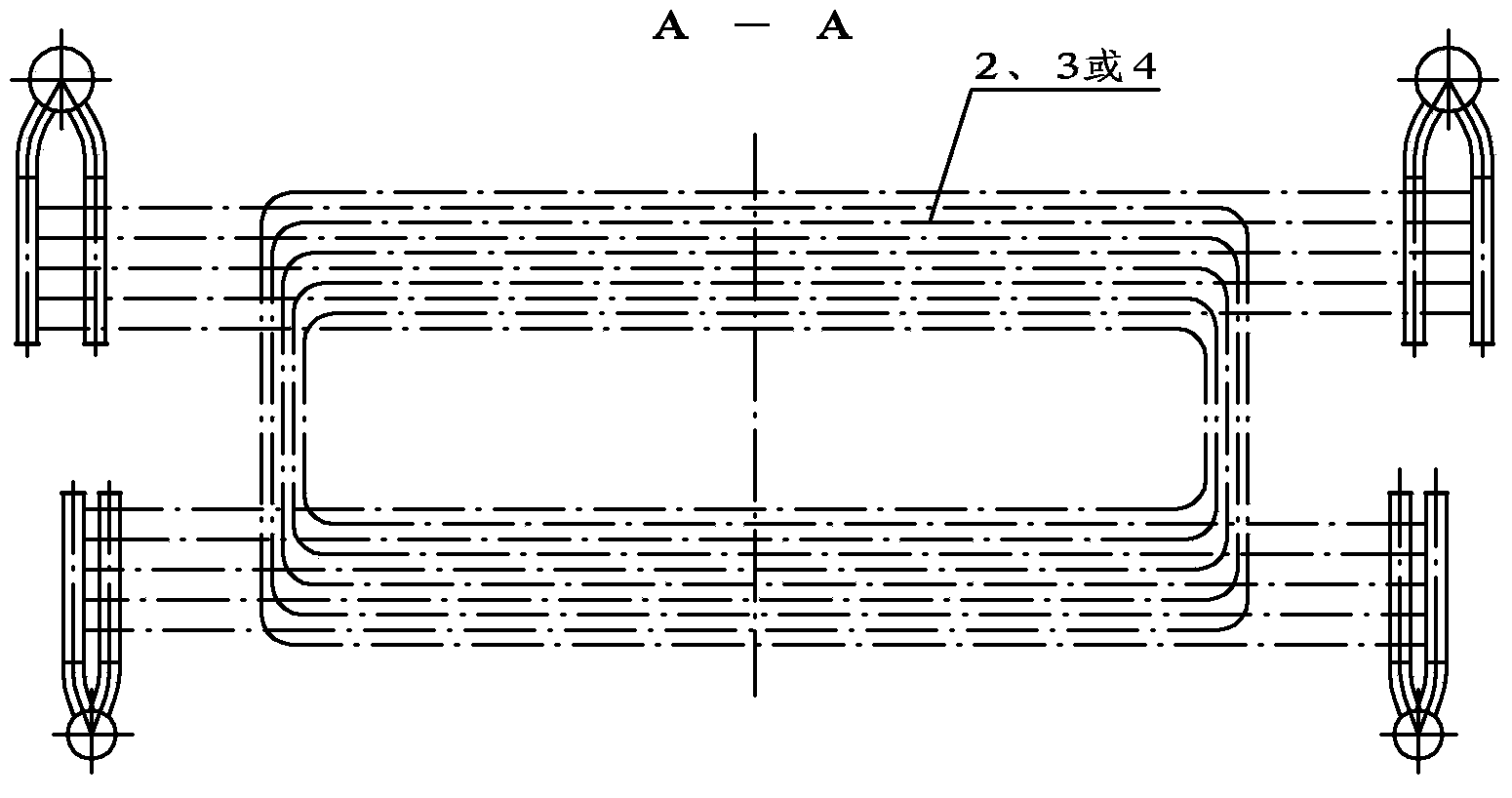

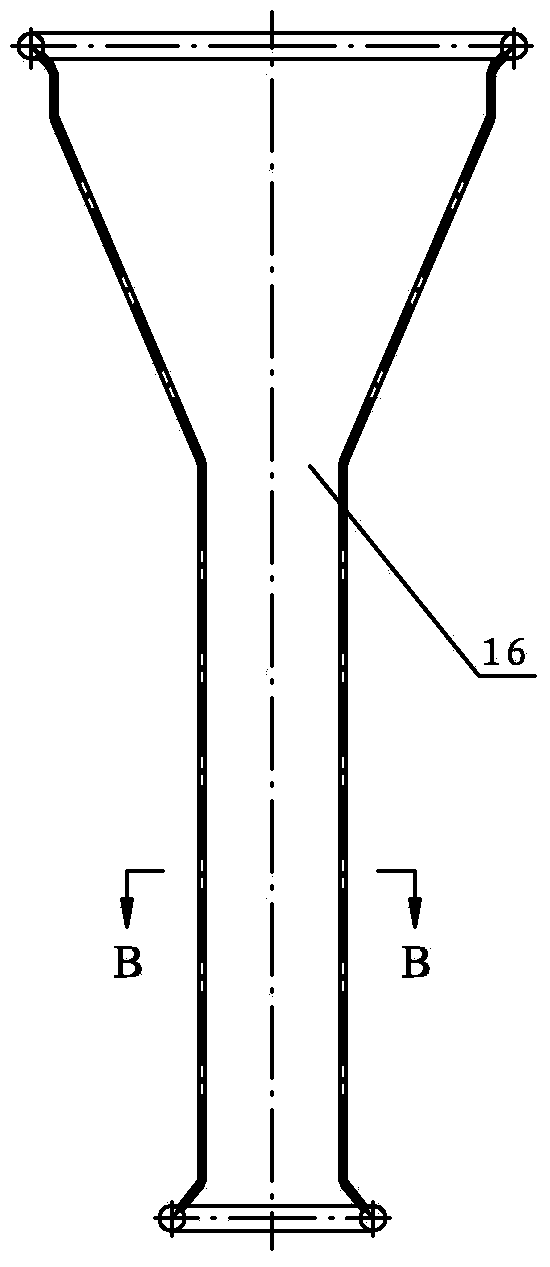

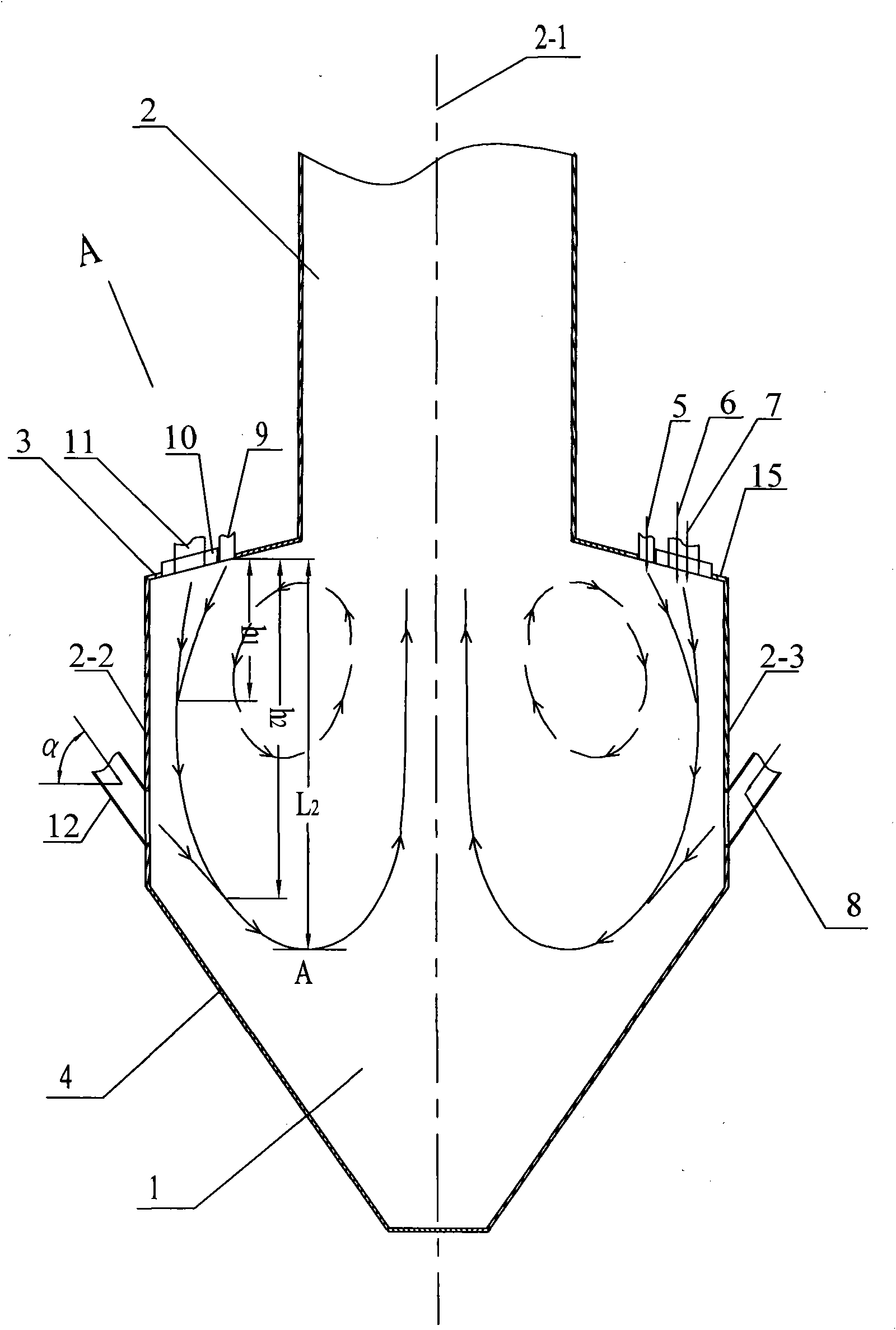

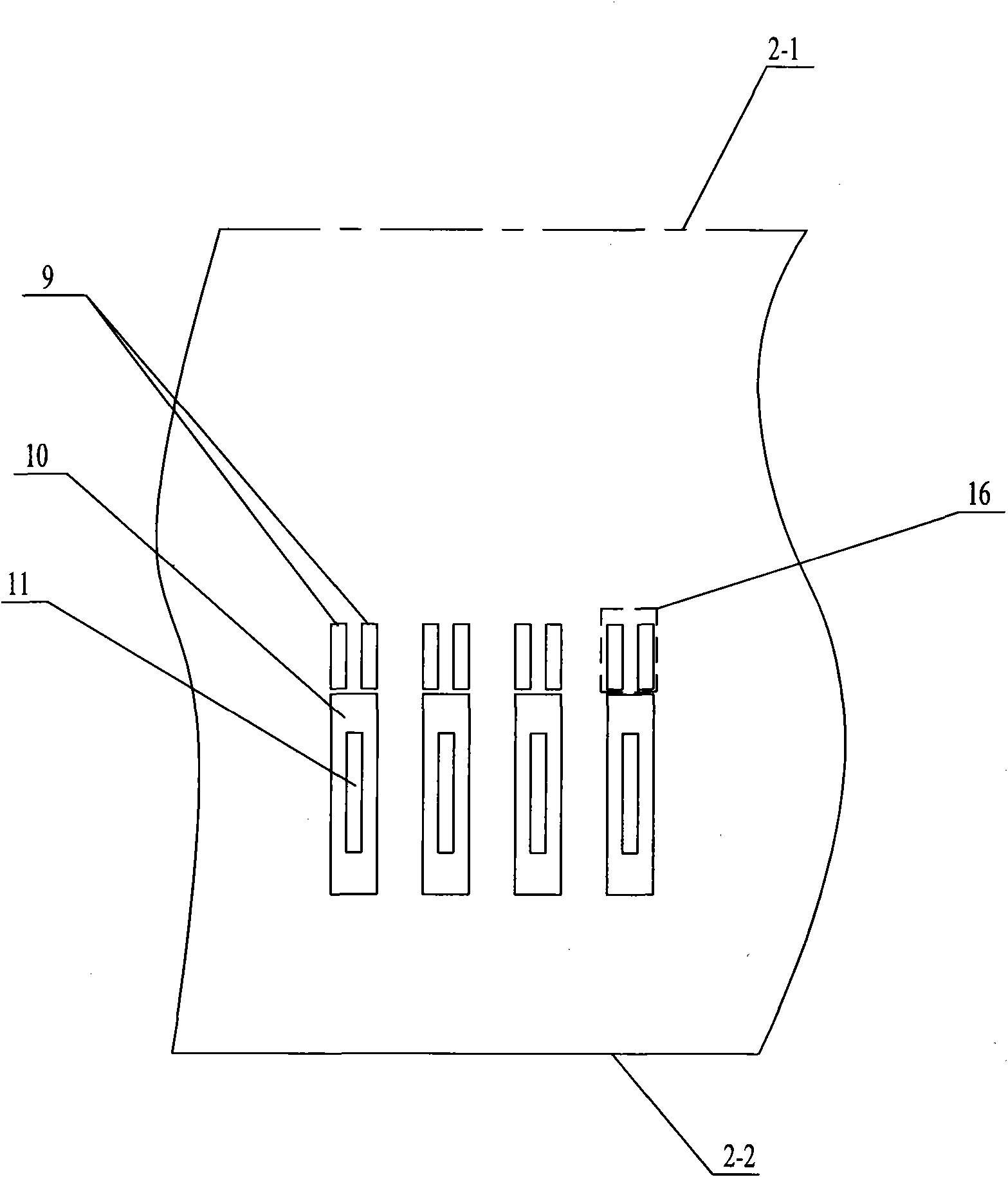

The invention discloses a W flame boiler device for realizing a multi-ejection grading combustion and a method thereof, and relates to a W flame boiler device of a grading combustion and a method, which aims at the problems of high NOx exhaust, high fly ash combustible material content, late fire of the pulverized coal airflow and bad flame stability in the W type flame boiler referred in the background technology.The method comprises the following steps of: ejecting internal and external secondary air at the air speed of 35-65m / s step by step and downwards ejecting by carrying a concentrated coal dust airflow at the air speed of 10-20m / s to realize first and second stage grading combustion; and injecting arch lower secondary air at the air speed of 35-65m / s into the lower heath by an arch lower secondary air nozzle to realize third stage grading combustion. A concentrated coal dust airflow nozzle, an internal secondary air nozzle, a light coal dust airflow nozzle and an external secondary air nozzle are sequentially distributed from the center side of the hearth to the water-cooling wall of the front and rear wall of the lower hearth on a boiler arch; and the front and rear wall of the lower hearth is provided with the arch lower secondary air nozzle along the width direction of the hearth. The invention can greatly reduce NOx exhaust and fly ash combustible material content when used for the W flame boiler.

Owner:HARBIN INST OF TECH

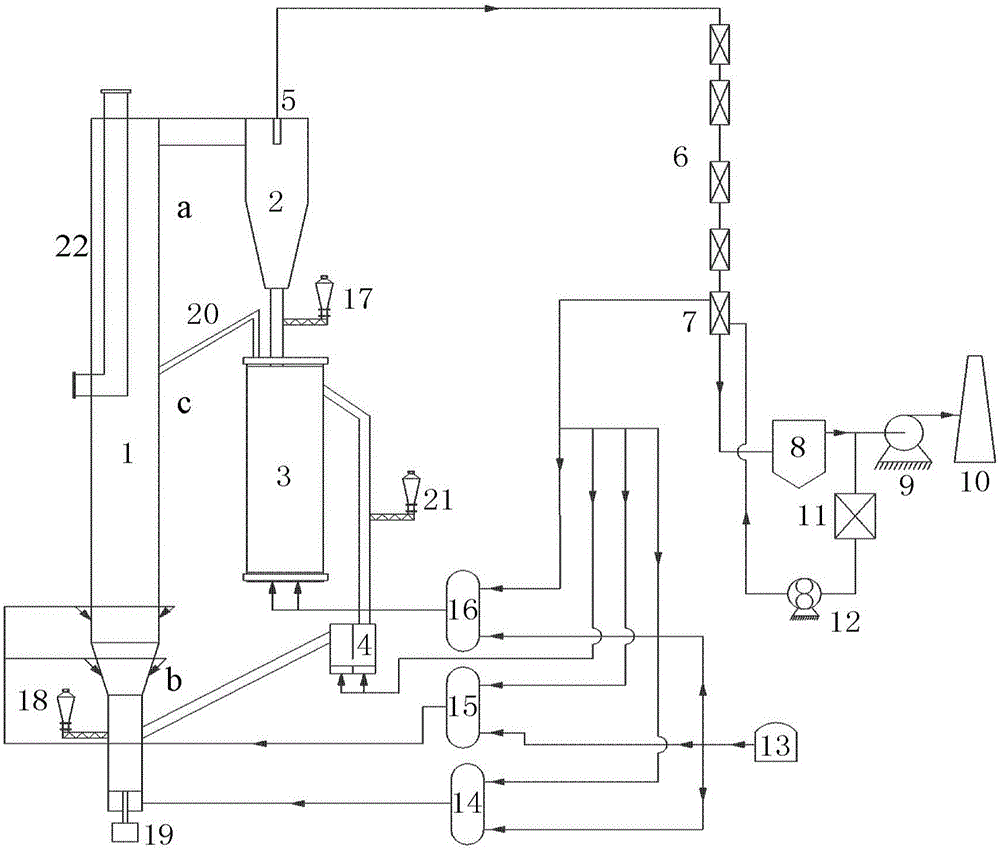

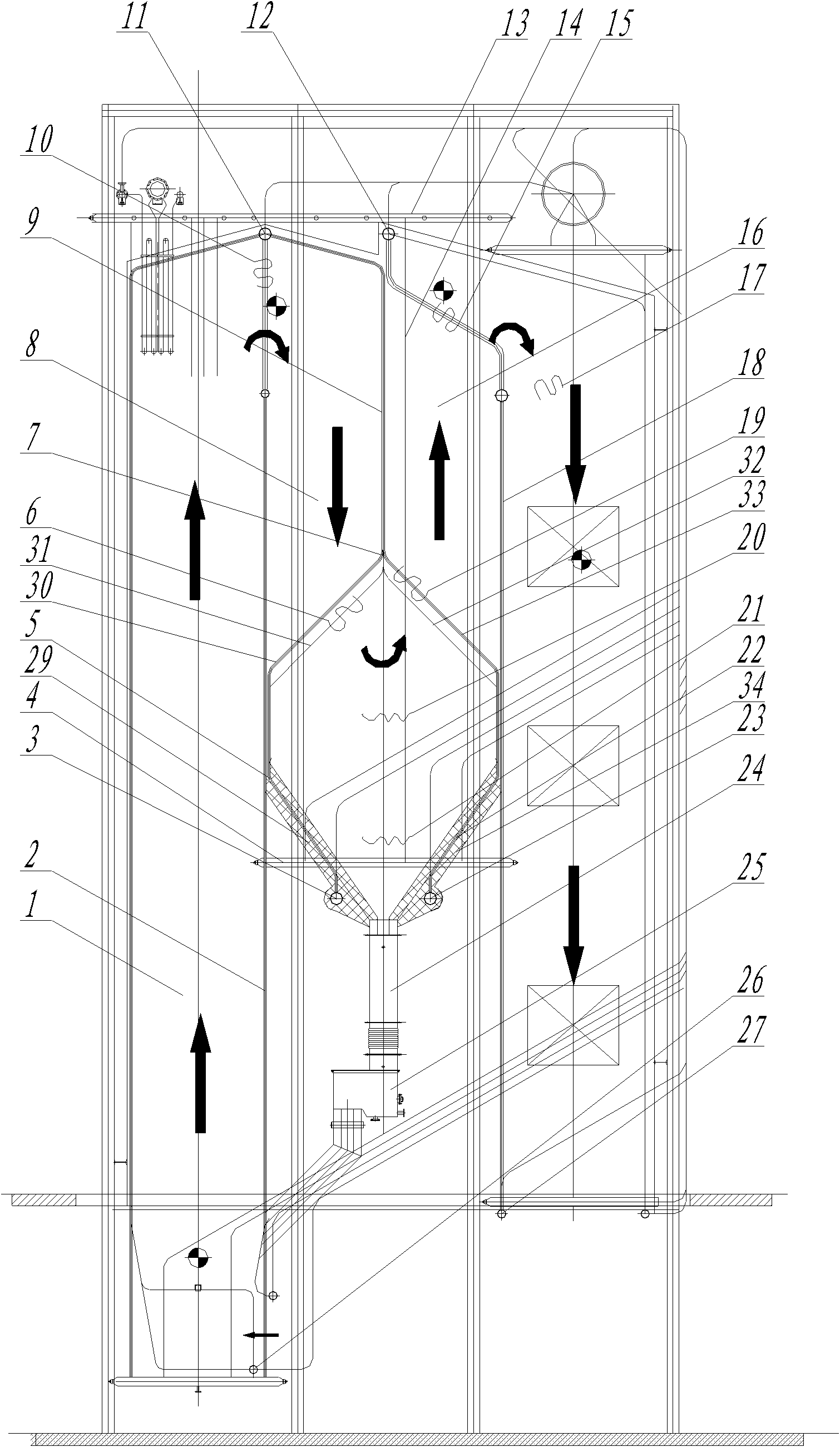

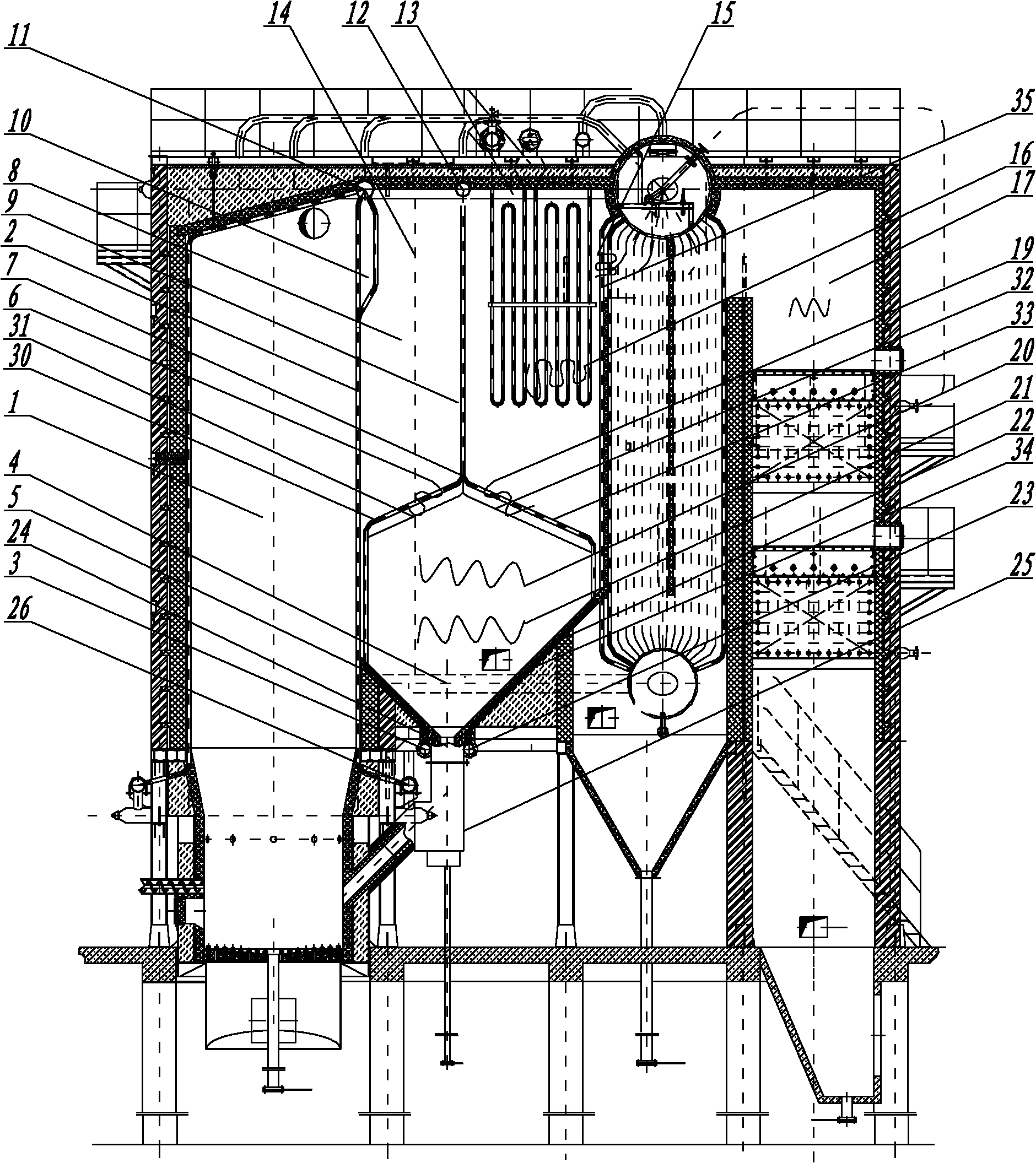

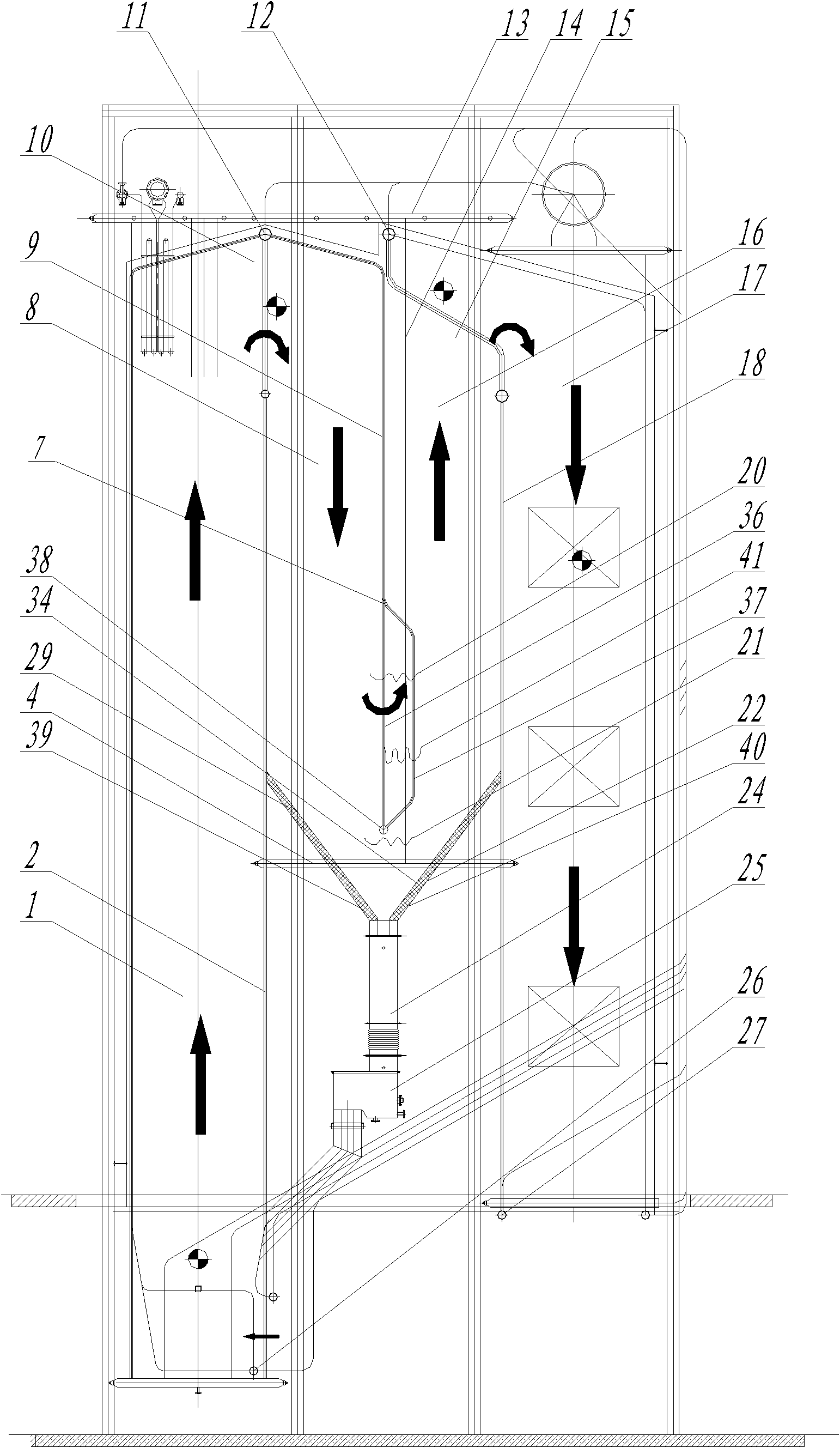

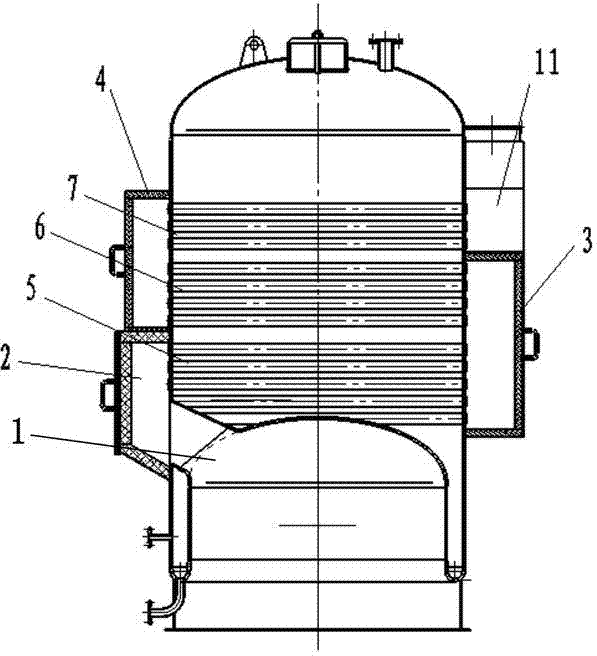

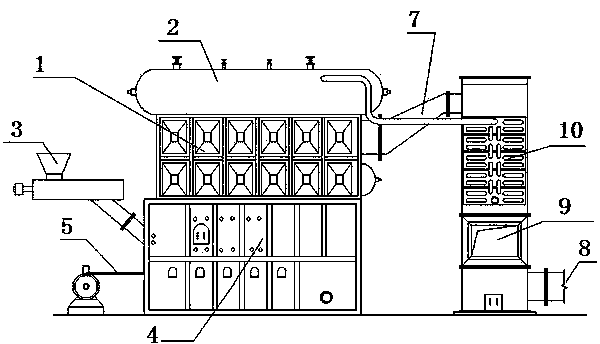

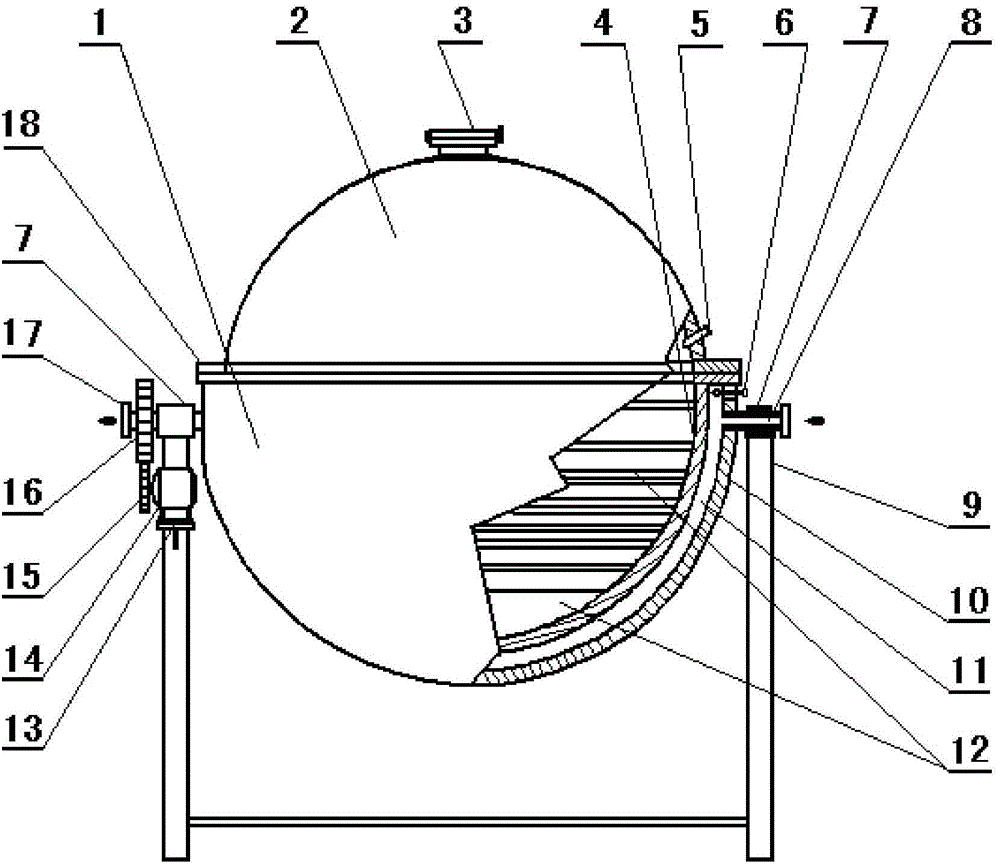

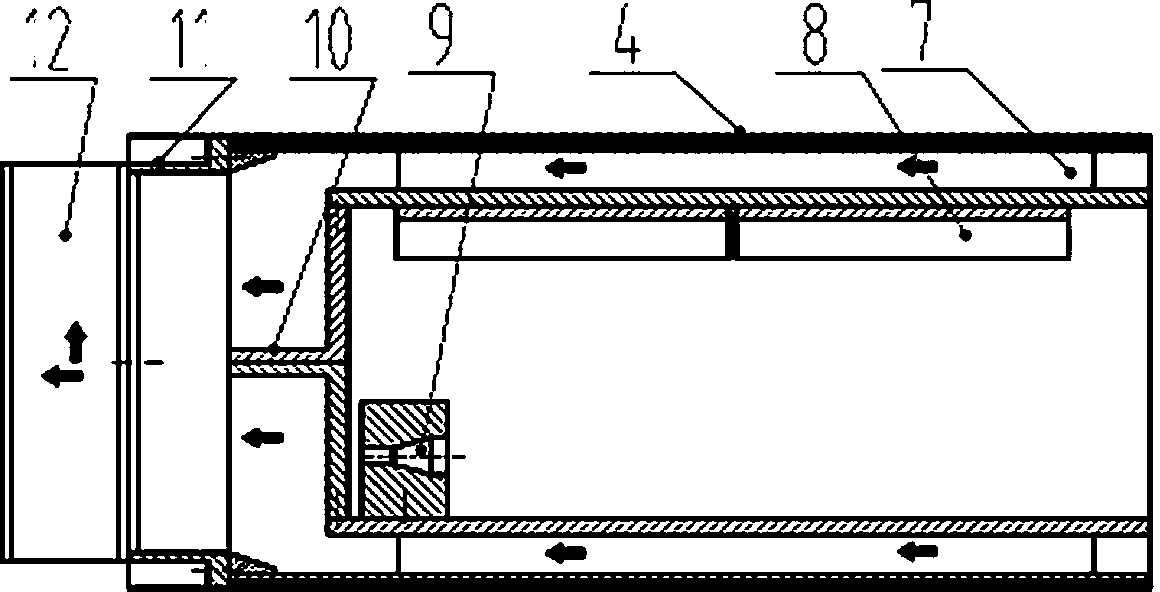

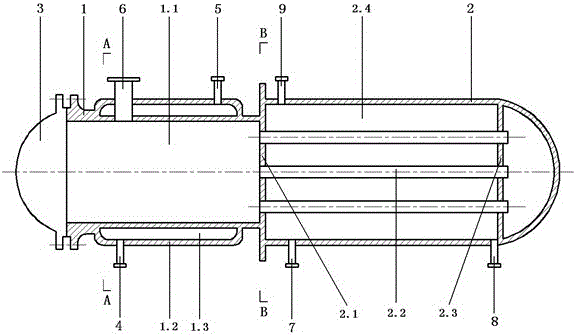

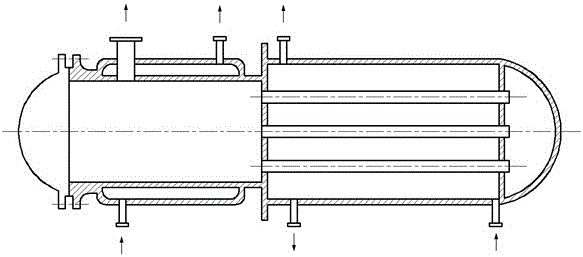

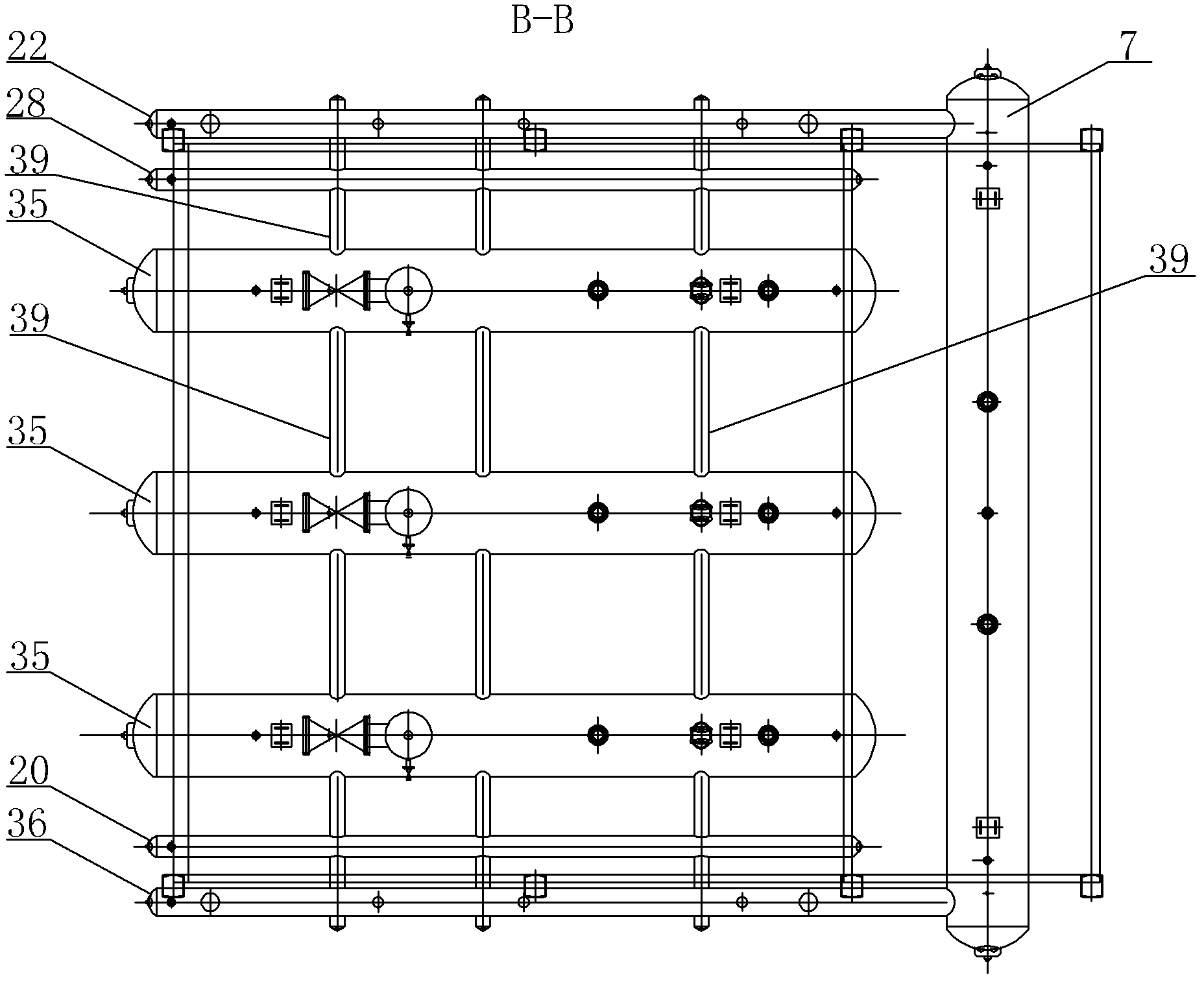

Forced water circulation high-capacity hot water boiler of circulating fluidized bed

ActiveCN103644648AImplement security requirementsAvoid damageFluidized bed combustionWater heatersWater circulationHearth

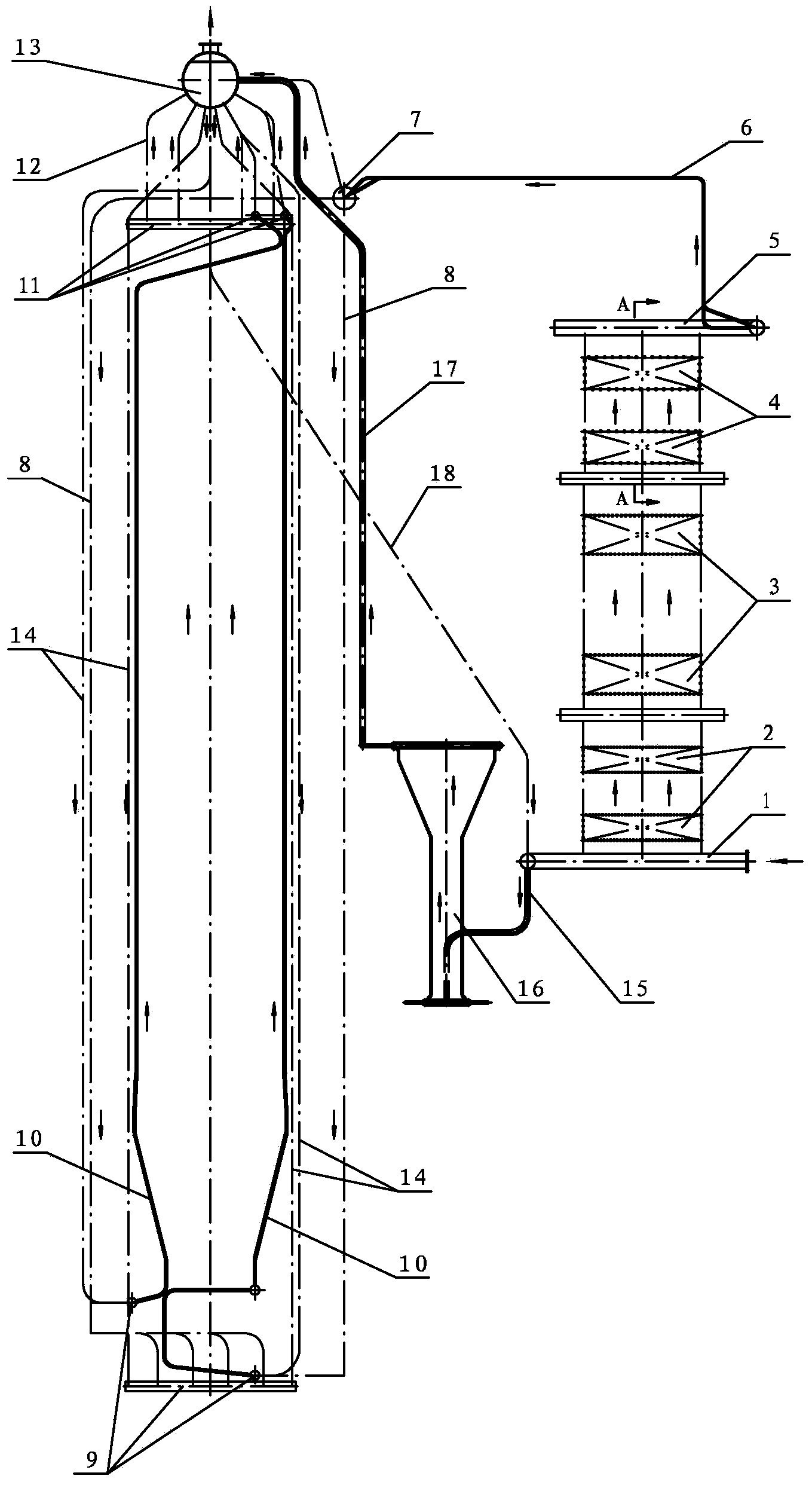

The invention discloses a forced water circulation high-capacity hot water boiler of a circulating fluidized bed, which relates to a hot water boiler of a fluidized bed, and aims to ensure water circulation safety and power failure protection of a high-capacity hot water boiler of a circulating fluidized bed. A water supply distribution header is connected with lower coal economizers; the lower coal economizers, middle coal economizers and upper coal economizers are sequentially connected with one another; the upper coal economizers are connected with a coal economizer upper header; the coal economizer upper header is connected with a collection water bag by a coal economizer coating pipe; the collection water bag is connected with water cooling wall lower headers by a descending pipe; the water cooling wall lower headers are connected with a hearth water cooling wall; the hearth water cooling wall is connected with water cooling wall upper headers; the water cooling wall upper headers are connected with a boiler cylinder by extraction pipes; the water supply distribution header is connected with a separator water cooling sleeve by a water cooling sleeve water intake pipe; the separator water cooling sleeve is connected with the boiler cylinder by a water cooling sleeve water outlet pipe; the boiler cylinder is connected with the water cooling wall lower headers by communicating pipes, and is connected with the water supply distribution header by a power failure water supply pipe. The forced water circulation high-capacity hot water boiler provided by the invention is applied to large concentrated heat supply and warming.

Owner:哈尔滨红光锅炉总厂有限责任公司

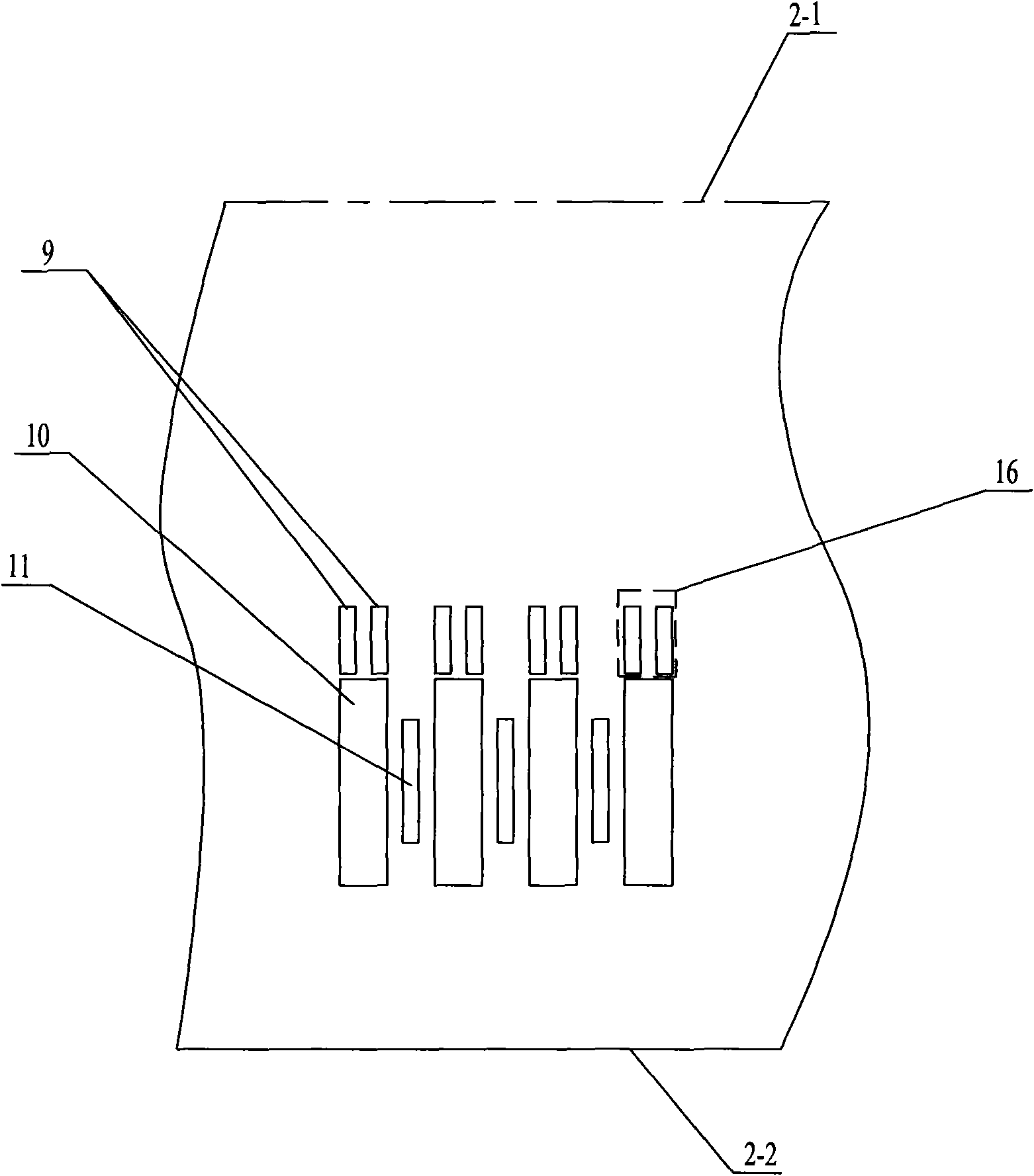

Method for arch single-stage injection fractional combustion and W flame boiler for realizing method

ActiveCN101832548AReduce combustible contentReduce slaggingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionSingle stage

A method for arch single-stage injection fractional combustion and a W flame boiler for realizing the method relate to a fractional combustion method and a W flame boiler. The invention aims at the problems that the W flame boiler has high NOx discharge, high flying ash combustible content, serious lagging on water cool wall front and behind a lower hearth and inferior flame stability. The method of the invention comprises the steps of gradually injecting through arch secondary air with an air speed of 35 to 65 m / s, taking thick coal powder airflow with the air speed of 10 to 20 m / s to inject downwards, and injecting the arch secondary air with the air speed of 35 to 65 m / s into the furnace through an arch secondary air nozzle. The boiler of the invention comprises a thick coal powder airflow nozzle, an arch secondary air nozzle and a thin coal powder airflow nozzle which are arranged on the furnace arch from the center of the furnace to the front and back water cool walls, wherein the thick coal powder airflow nozzle is abutted to the arch secondary air nozzle and an arch lower secondary air nozzle is arranged on the front and back water cool walls on the lower furnace along the width direction of the furnace. The W flame boiler for realizing the method of the invention can decrease the W flame boiler and the flying ash combustible content.

Owner:HARBIN INST OF TECH

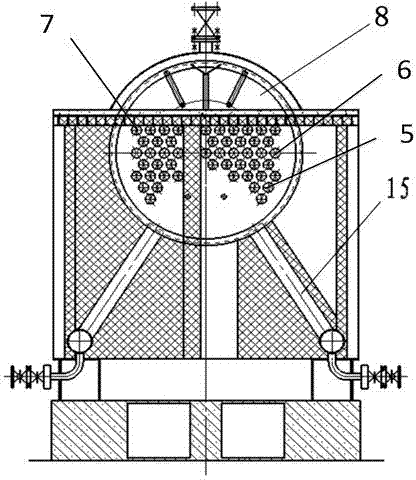

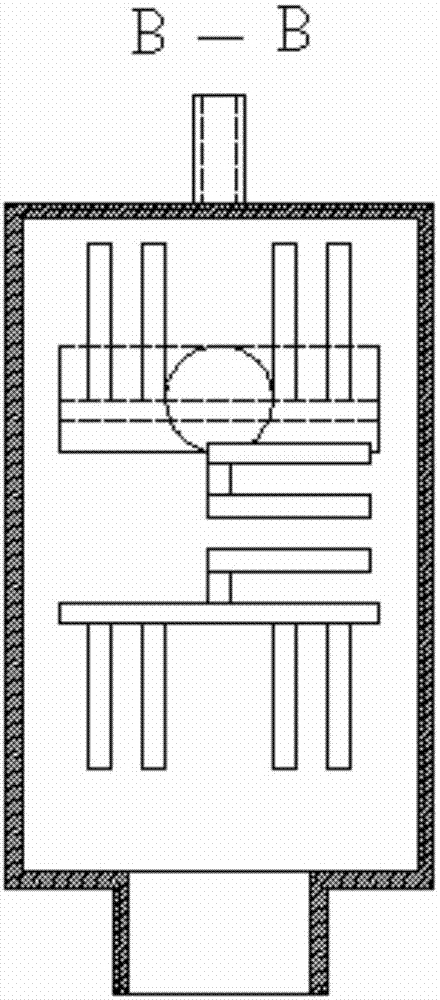

Oxygen-enriched combustion boiler system for circulating fluidized bed

ActiveCN106838891AReduce initial investment costReduce operating costsFluidized bed combustionIndirect carbon-dioxide mitigationCycloneCombustion chamber

An oxygen-enriched combustion boiler system for a circulating fluidized bed comprises a hearth, a cyclone separator, an externally-arranged combustion chamber, a tail smoke flue and an air supply unit. An outlet of the hearth is connected to the cyclone separator and used for outputting smoke gas containing circulating materials from the hearth; after the smoke gas containing the circulating materials is separated by the cyclone separator, the circulating materials enter the externally-arranged combustion chamber from an outlet of the lower portion of the cyclone separator, and the smoke gas portion enters the tail smoke flue from an outlet of the upper portion of the cyclone separator; and the circulating materials are input into the externally-arranged combustion chamber by the cyclone separator, fluidizing air is input into the externally-arranged combustion chamber by the air supply unit, and an outlet of the externally-arranged combustion chamber is connected to the inlet end of the hearth. According to the oxygen-enriched combustion boiler system for the circulating fluidized bed, the mode that burning is conducted on the inlet under the high oxygen concentration is adopted, the sizes of a boiler body and an auxiliary machine are greatly reduced, initial investment and operating cost of a boiler can be reduced, and the occupied area of a boiler island is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

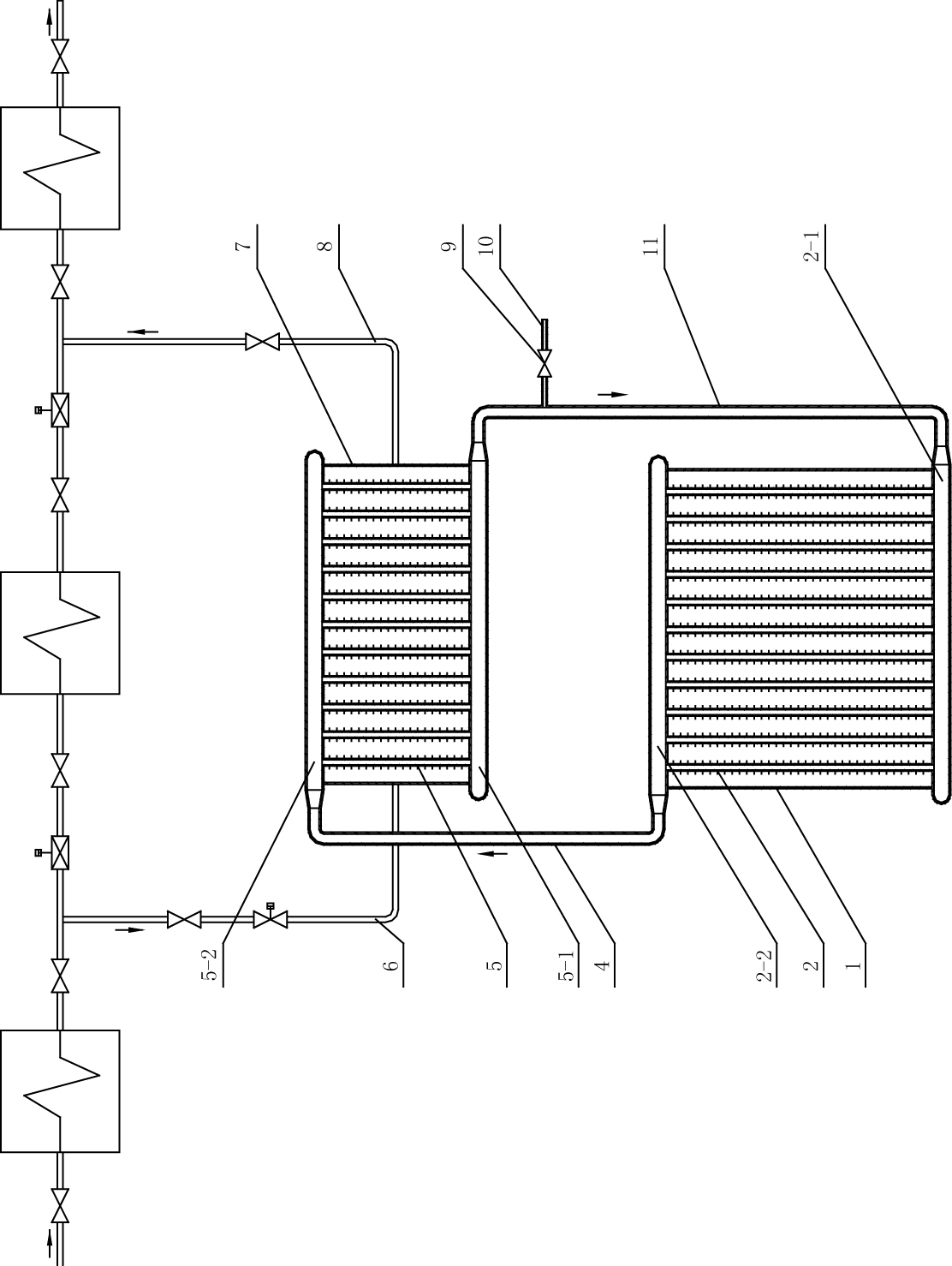

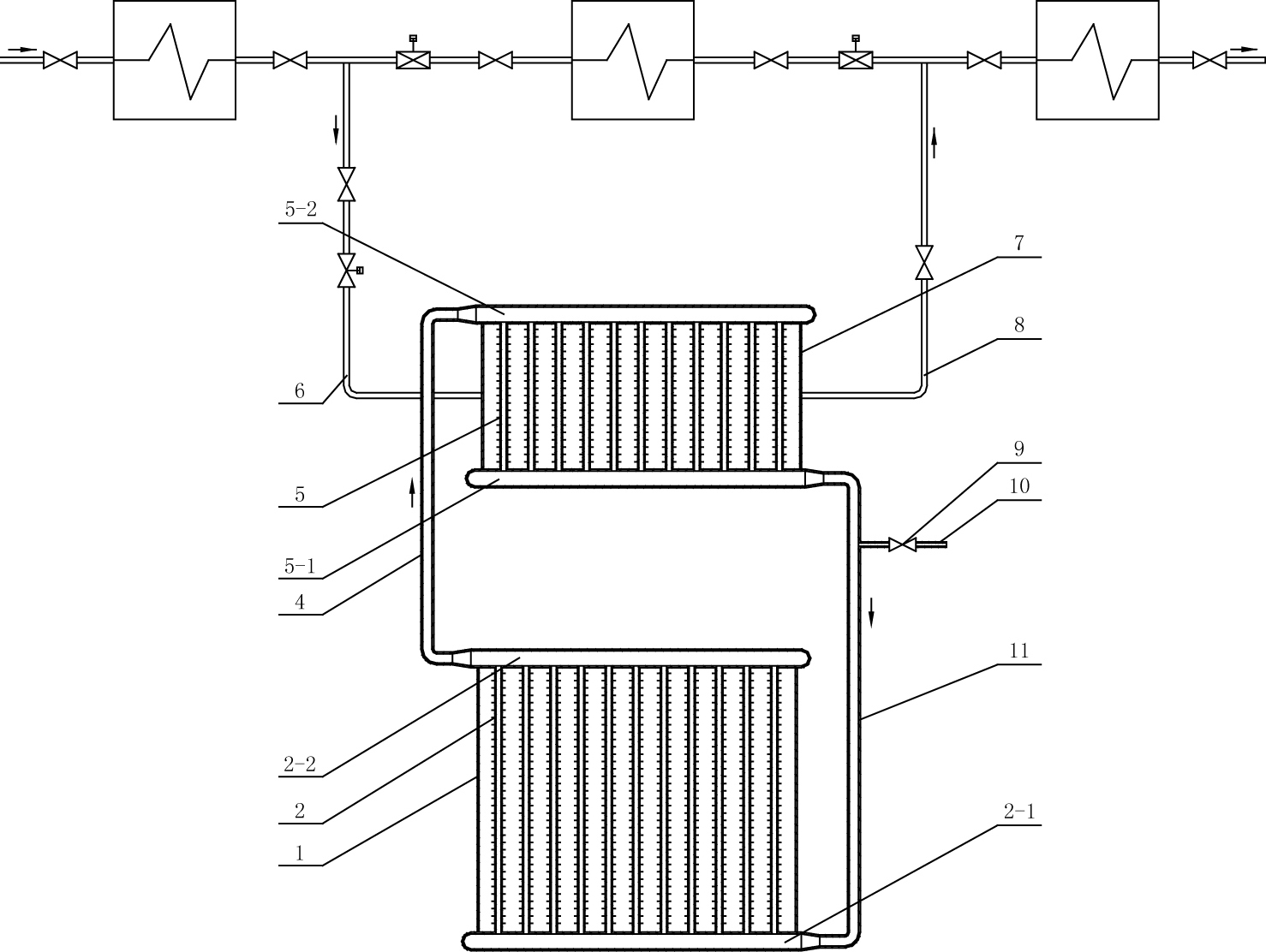

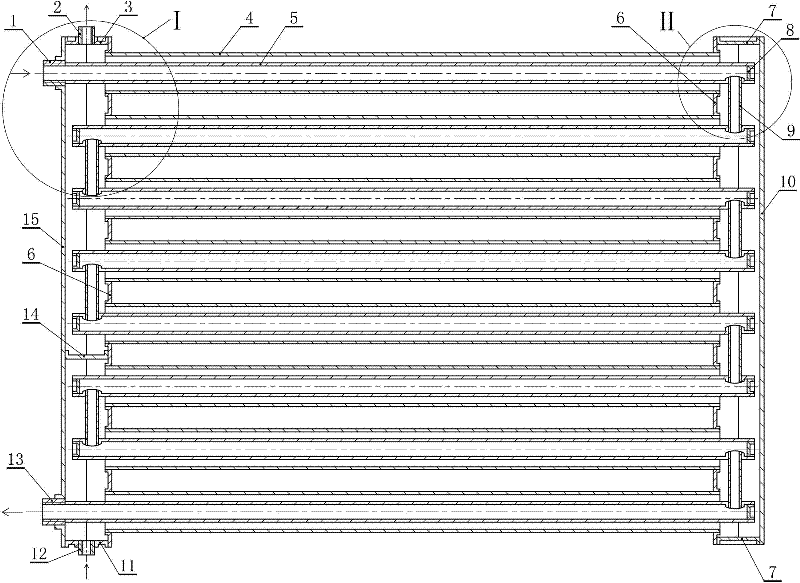

Separate low pressure coal economizer of elliptical fin heat pipe

InactiveCN101881436AReduce volumeReduce power consumptionIndirect heat exchangersTubular elementsPipingCoal

The invention relates to a separate low pressure coal economizer of an elliptical fin heat pipe, relating to boiler waste heat recovery energy-saving equipment, in particular to a separate low pressure coal economizer of an elliptical fin heat pipe. The invention solves the problems of high investment and severe abrasion of banks of pipes caused by large volume and high resistance of a heat exchanger of the traditional boiler low pressure coal economizer. In the invention, both ends of a plurality of elliptical fin heat pipes arranged in parallel in a pipe panel of an evaporation section of the elliptical fin heat pipes are respectively communicated with a corresponding condensation water inlet header and a steam outlet header; both ends of a plurality of elliptical fin heat pipes arranged in parallel in a pipe panel of a condensation section of the elliptical fin heat pipes are respectively communicated with a corresponding condensation water outlet header and a corresponding steam inlet header; the steam outlet header of the pipe panel of the evaporation section is communicated with the steam inlet header of the pipe panel of the condensation section through a steam gas guide tube; and the condensation water outlet header of the pipe panel of the condensation section is communicated with the condensation water inlet header of the pipe panel of the evaporation section through a water return pipe. The invention is particularly suitable for the utilization of the waste heat of the discharge smoke of an electric plant boiler.

Owner:HEILONGJIANG ELECTRIC POWER RES INST

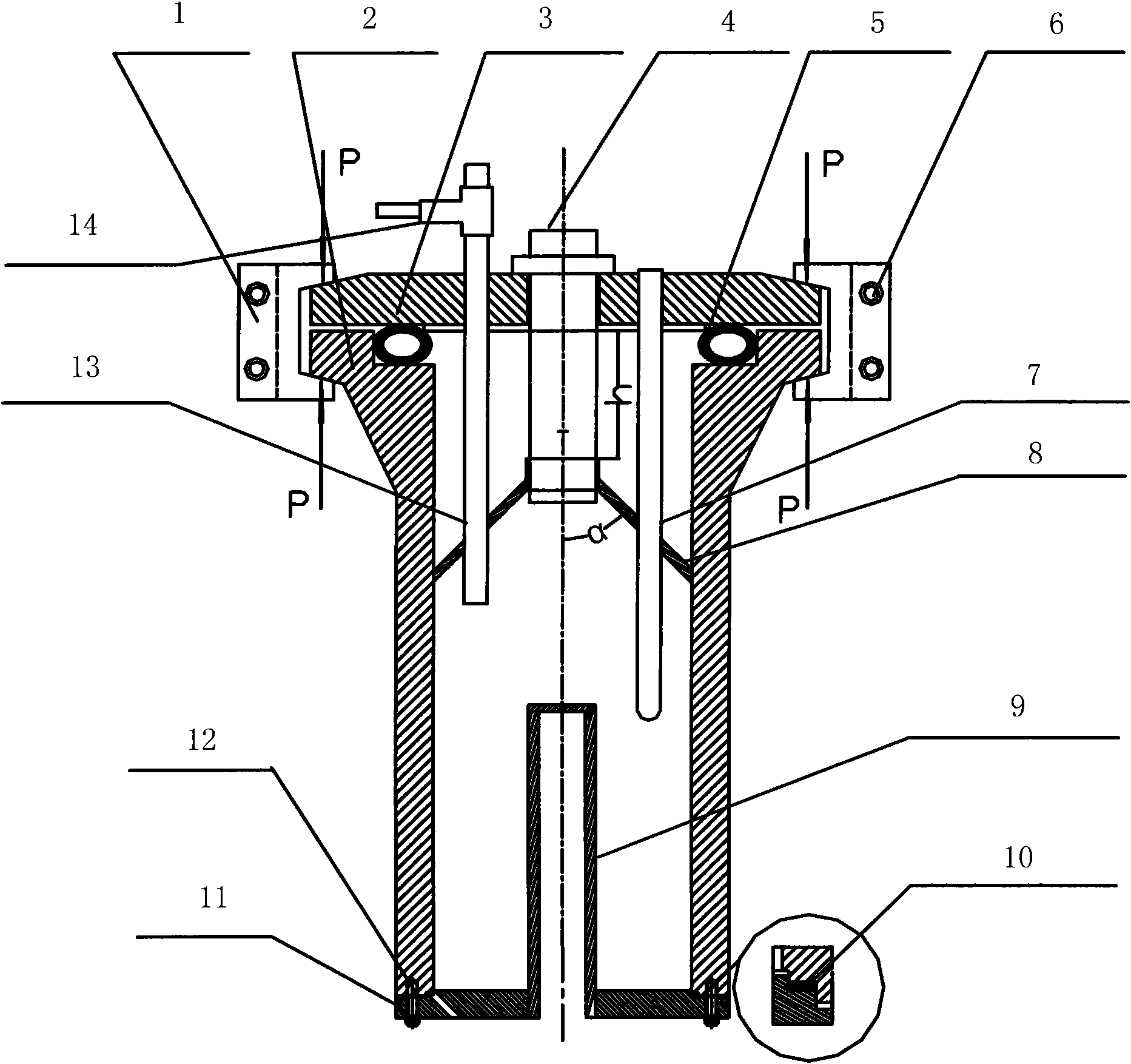

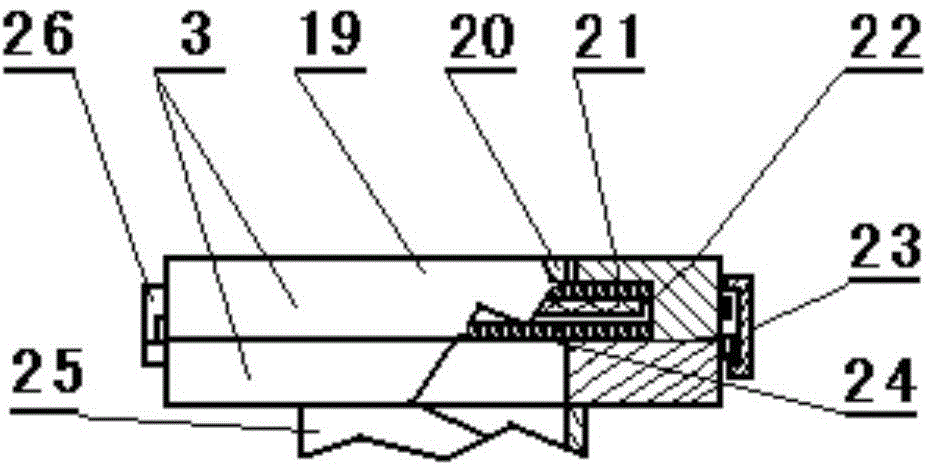

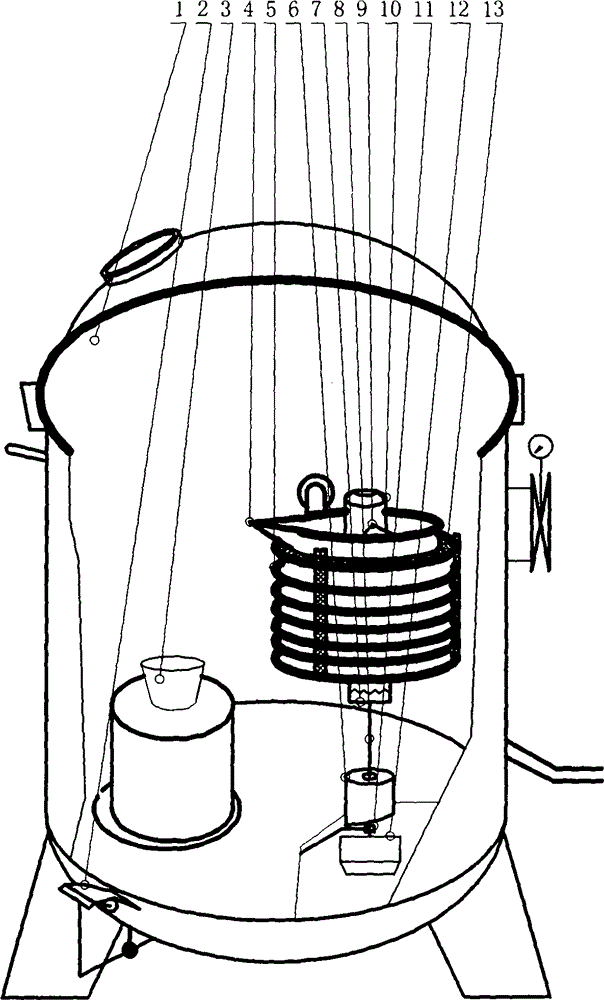

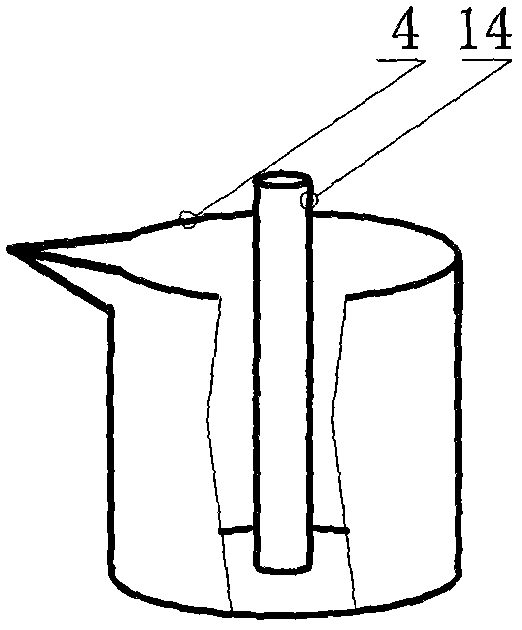

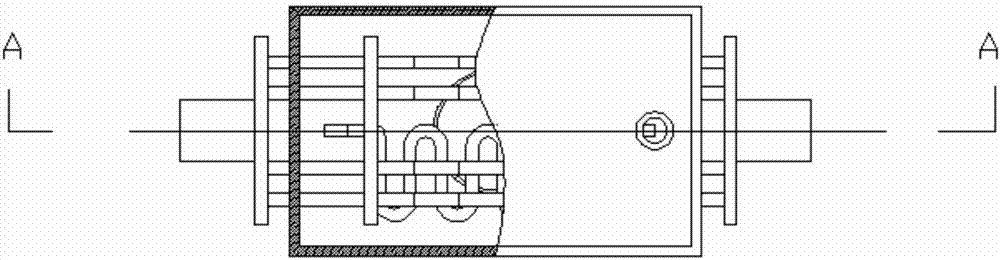

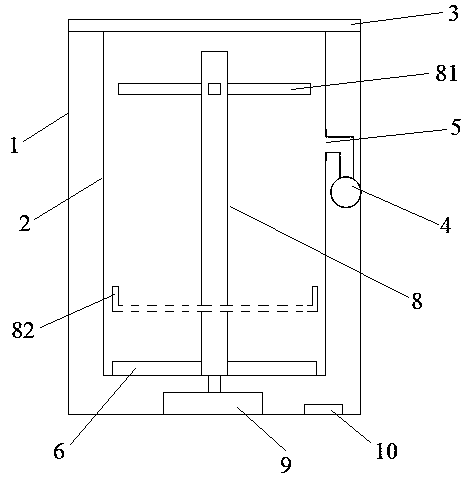

Intermittent vacuum pyrolysis reactor with built-in heat conducting pipe

InactiveCN101812316AIncrease the heating surfaceImprove heat transfer performanceProductsReagentsBiochemical engineeringHeat conducting

The invention relates to an intermittent vacuum pyrolysis reactor with a built-in heat conducting pipe, which comprises an upper end cover, a barrel, a pyrolysis product discharging pipe, a thermocouple sheath, an air inlet pipe, a lower end cover, an O-shaped sealing ring, a baffle and the built-in heat conducting pipe. The upper end cover and the lower end cover are respectively arranged on the upper and lower ends of the barrel; the thermocouple sheath, the air inlet pipe and the pyrolysis product discharging pipe are arranged on the upper end cover; the lower end of the pyrolysis product discharging pipe is connected with the baffle; the thermocouple sheath and the air inlet pipe are respectively positioned on two sides of the pyrolysis product discharging pipe and pass through the flared baffle; the upper end cover and the barrel are sealed by the O-shaped sealing ring; and the built-in heat conducting pipe is welded in the center of the lower end cover. Through the structure, the reactor of the invention not only strengthens the heat conducting effect of the device, effectively solves the problem of the incomplete pyrolysis reaction and much more by-products caused by uneven heating and has excellent sealing property, but also can effectively solve the problems that the end cover is difficult to open because the pyrolysis product solidifies and deposits at the joint between the end cover and the barrel and the like. The device is convenient to disassemble and operate.

Owner:TONGJI UNIV

Gas and solid separator of recirculating fluidized bed boiler and boiler containing same

InactiveCN102062395AExtended service lifeSave wear-resistant and high-temperature resistant materialsFluidized bed combustionDispersed particle separationFlue gasFluidized bed

The invention discloses a gas and solid separator of a recirculating fluidized bed boiler, which comprises a downstream flue and an upstream flue which are partitioned by a guiding flue gas up-down replicating film type screen, wherein the downstream flue and the upstream flue are communicated with storage bins hermetically installed below the downstream flue and the upstream flue through a turning channel, the front upper part of the gas and solid separator is provided with a flue gas inlet, the back upper part of the gas and solid separator is provided with a flue gas outlet, and four walls of the gas and solid separator are all heated water-cooling walls integrated with the boiler; and the gas and solid separator also comprises a uniform flow separating pipe bundle positioned on the turning channel, the upper end of the uniform flow separating pipe bundle on the turning channel is communicated with the guiding flue gas up-down replicating film type screen, and the lower end of the uniform flow separating pipe bundle on the turning channel is communicated with a lower transverse container. The invention also discloses a recirculating fluidized bed boiler containing two sets of gas and solid separators. The recirculating fluidized bed boiler has the advantages of wide application range, advanced process, simple manufacturing and installation, energy saving, consumption reduction and obvious emission reduction.

Owner:王森

Circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and manufacturing process thereof

ActiveCN102418956ASolve the problem of water leakage under pressureReduce difficultySpace heating and ventilation detailsHeat exchanger casingsPlate heat exchangerWater leakage

The invention discloses a circular pipe communicated, spliced, edge-pinched, and welded pressure-bearing heat exchanger, and a manufacturing process thereof. The heat exchanger comprises two headers, wherein a tap water communication pipe is fixedly connected between the two headers; a hot air heat supply pipe passes through the tap water communication pipe; each header is formed by welding two arc plates; the plate edges of the arc plates are flanged outwards; the plate edges of the two arc plates are aligned with each other and are subjected to edge-pinching and self-fluxing welding to form a circular tubular header cylinder body; head blocking plates of the headers are flanged outwards and are embedded at two ports of the circular tubular headers; and the two edges are aligned with a pipe wall surface, are spliced and are subjected to the edge-pinching and the self-fluxing welding to form the headers. An installation hole is punched on each arc plate; the installation hole is stretched inward an arc to form an edge; the aperture and the height of are stretched according to the arc plates; and the end surfaces of the two ends of the tap water communication pipe are subjected to R-angle cutting according to the stretching hole diameter and the stretching height of the arc plates, and then the tap water communication pipe is inserted into the installation holes stretched from the arc plates, are matched with each other, are spliced and are subjected to edge-pinching and self-fluxing welding connection. In the heat exchanger, welding seams are spliced, the edge-pinching welding is easy to realize, and water leakage is avoided; and the heat exchanger is good in pressure-bearing performance, and low in maintenance cost.

Owner:张伟

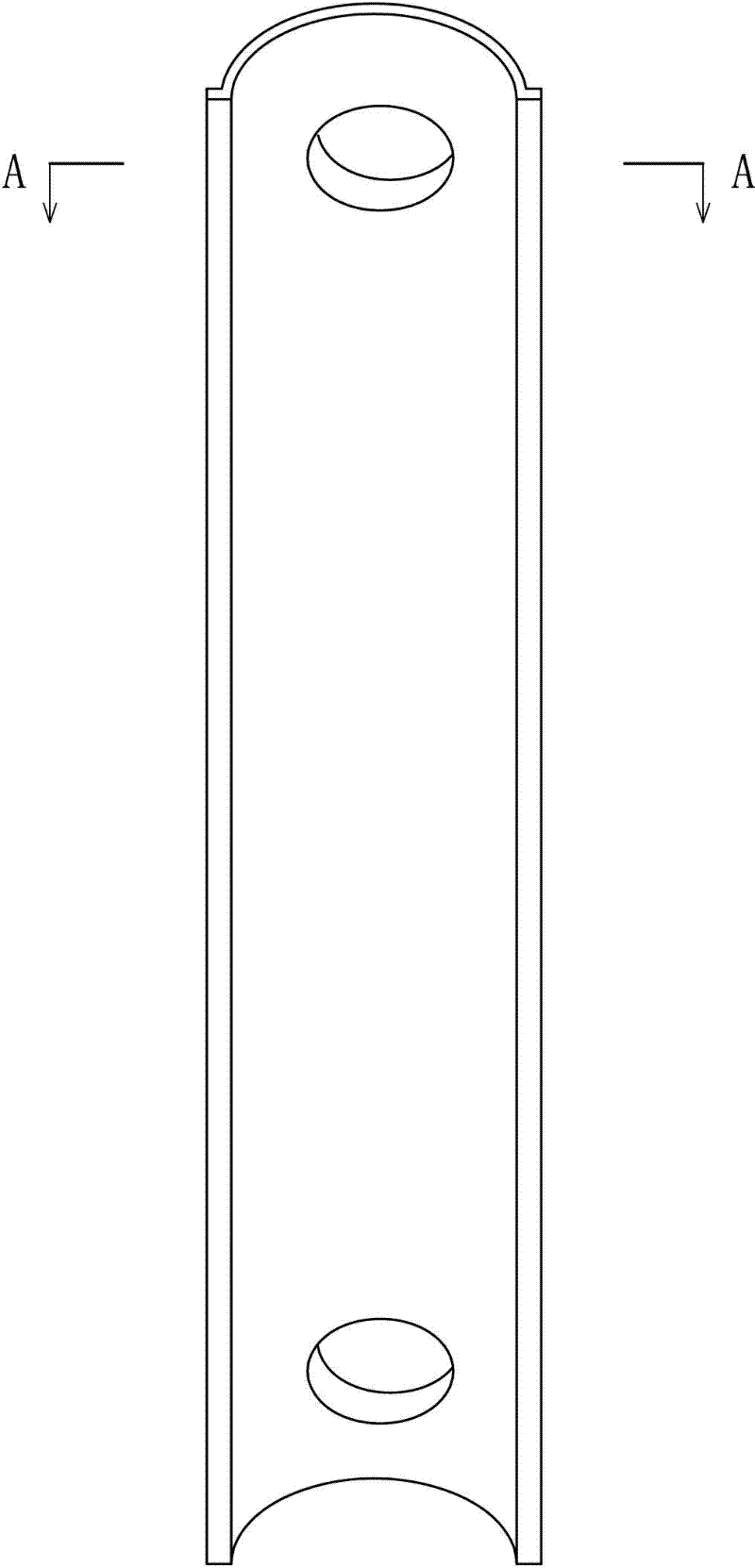

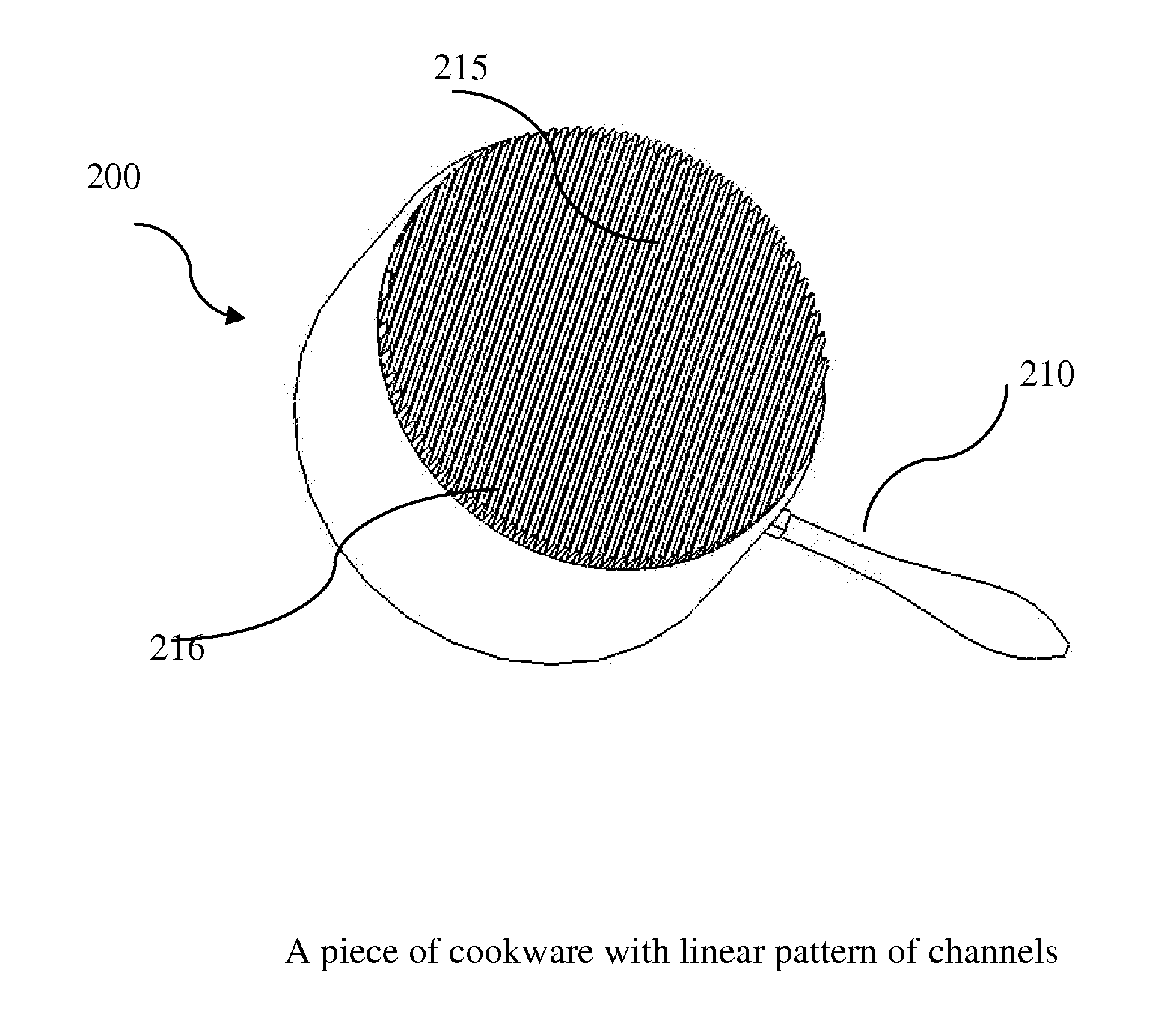

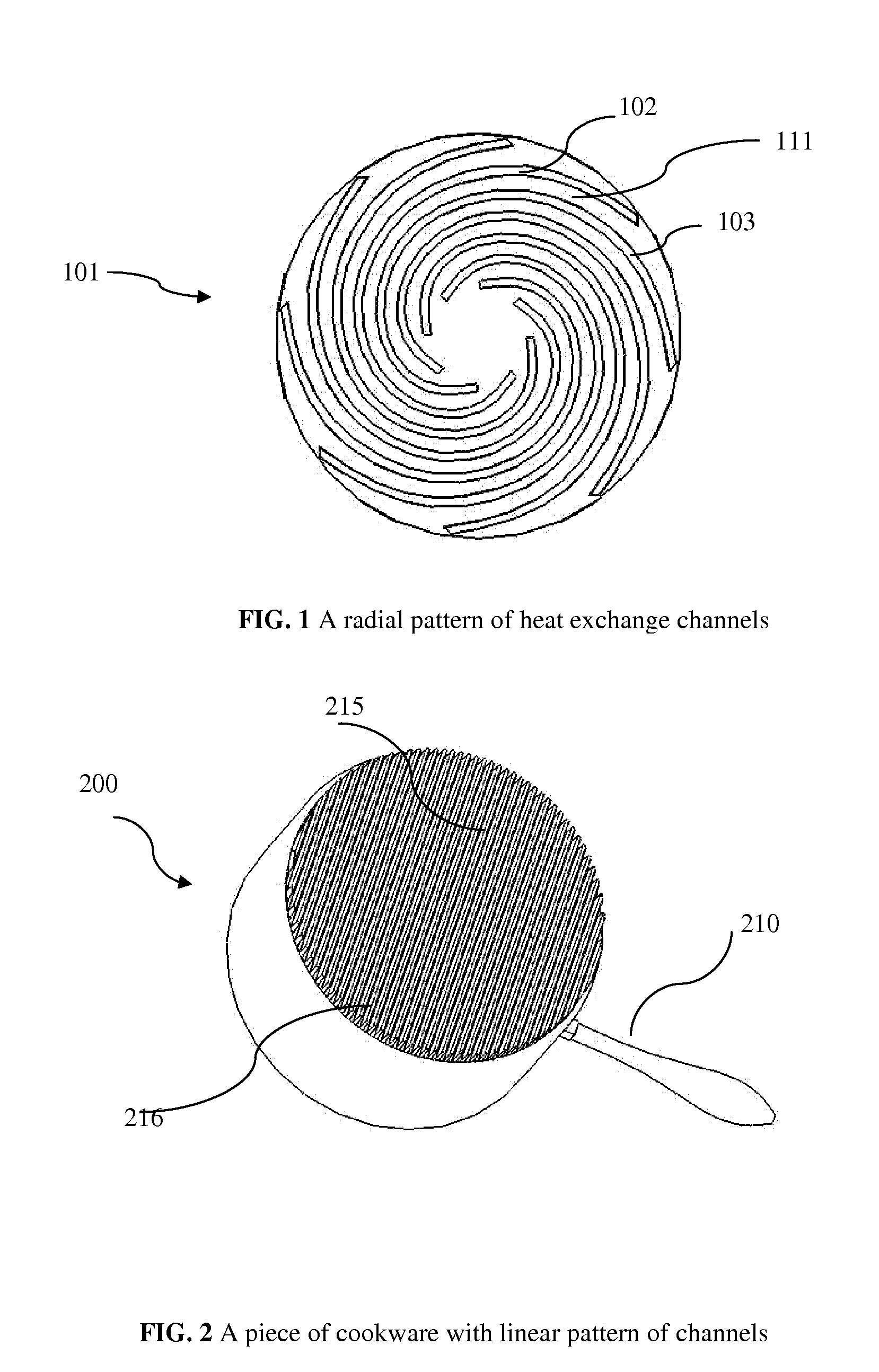

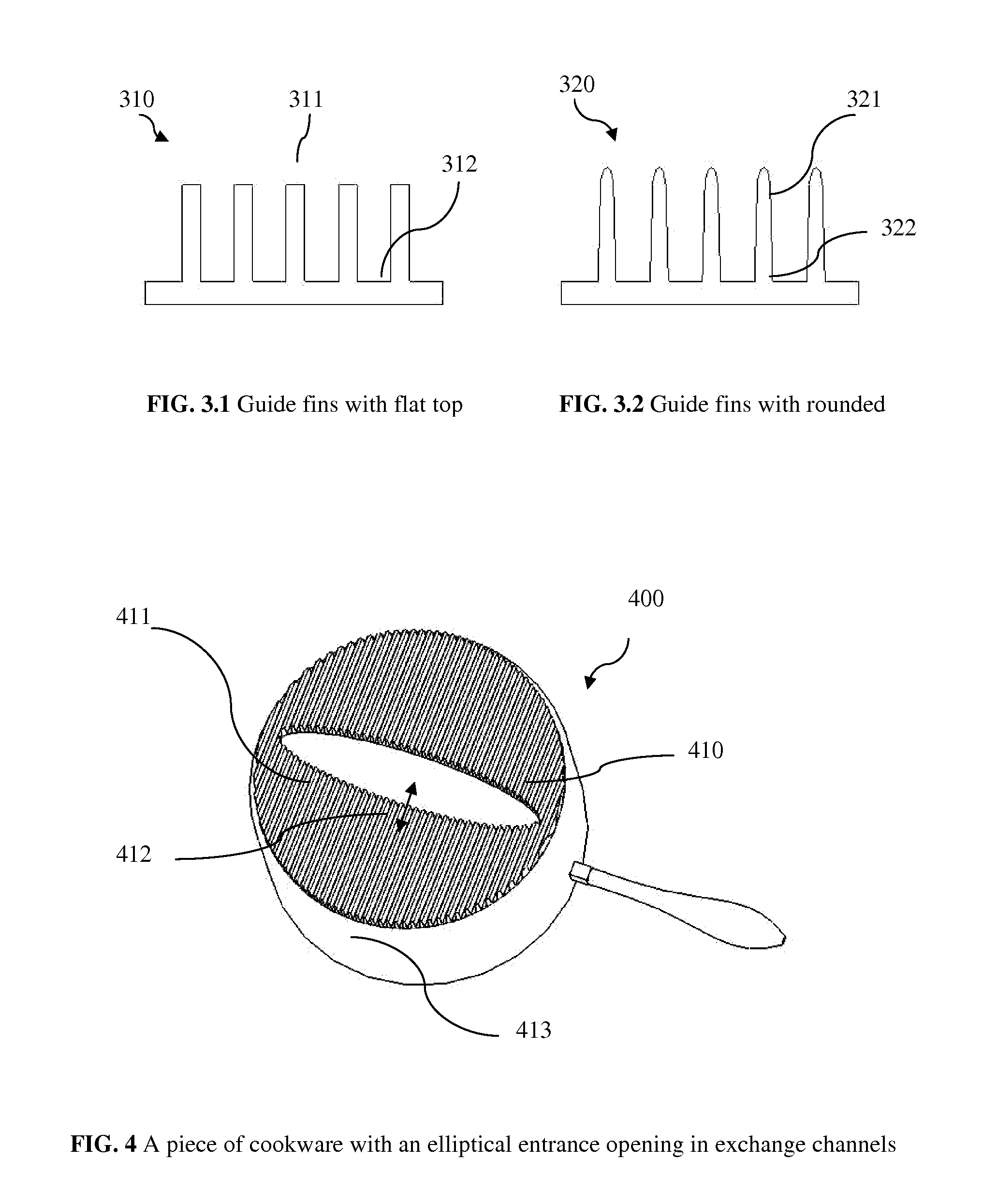

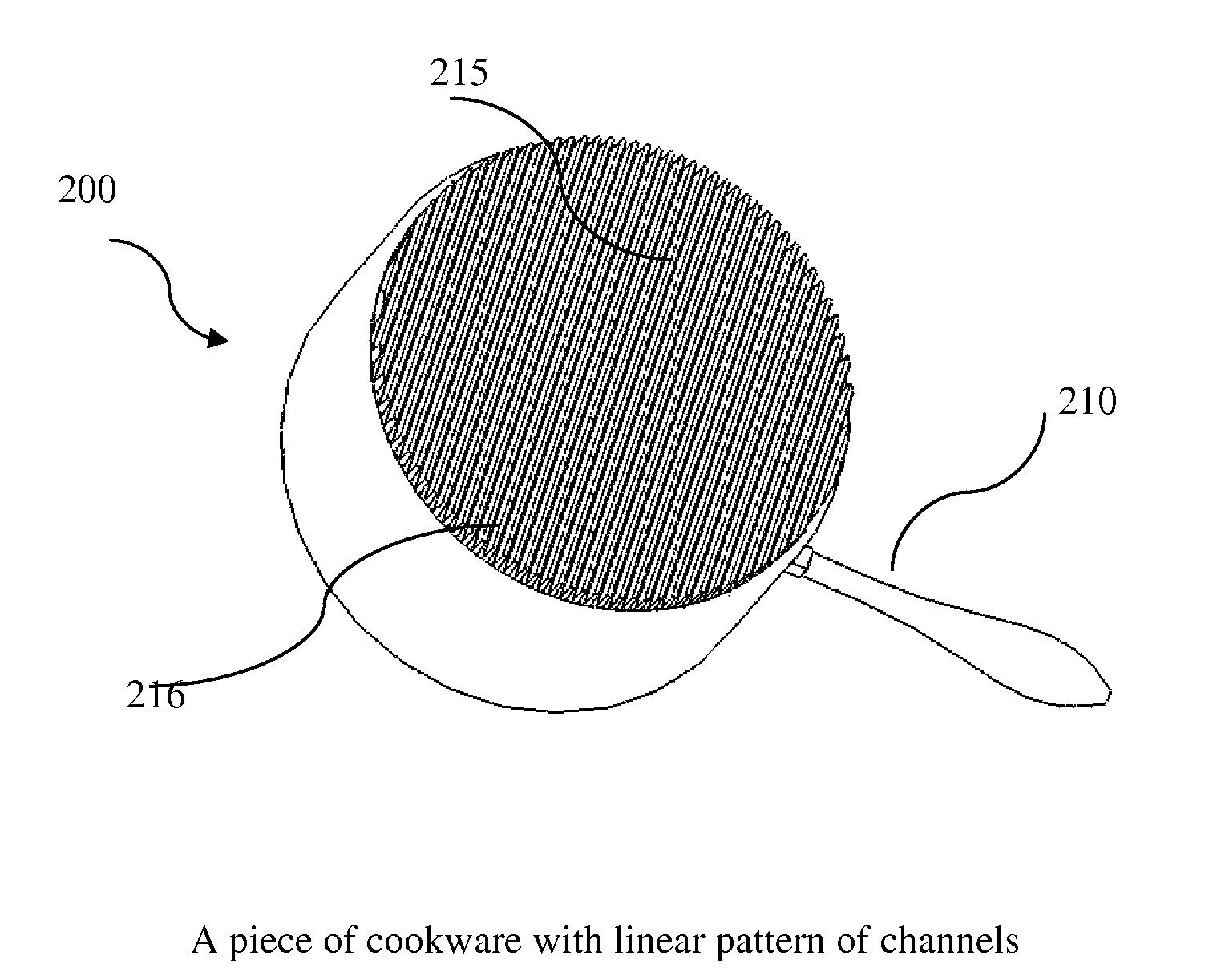

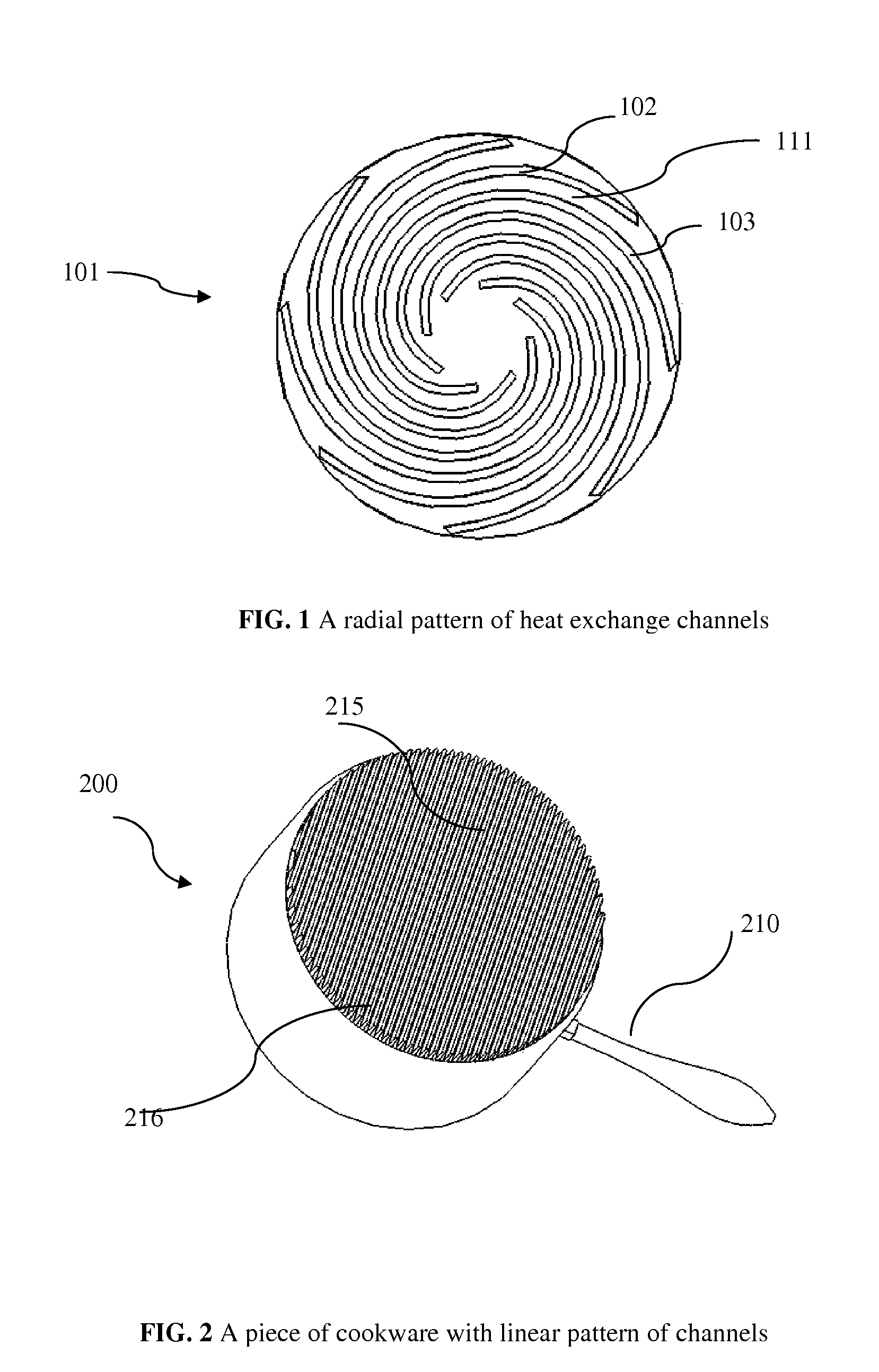

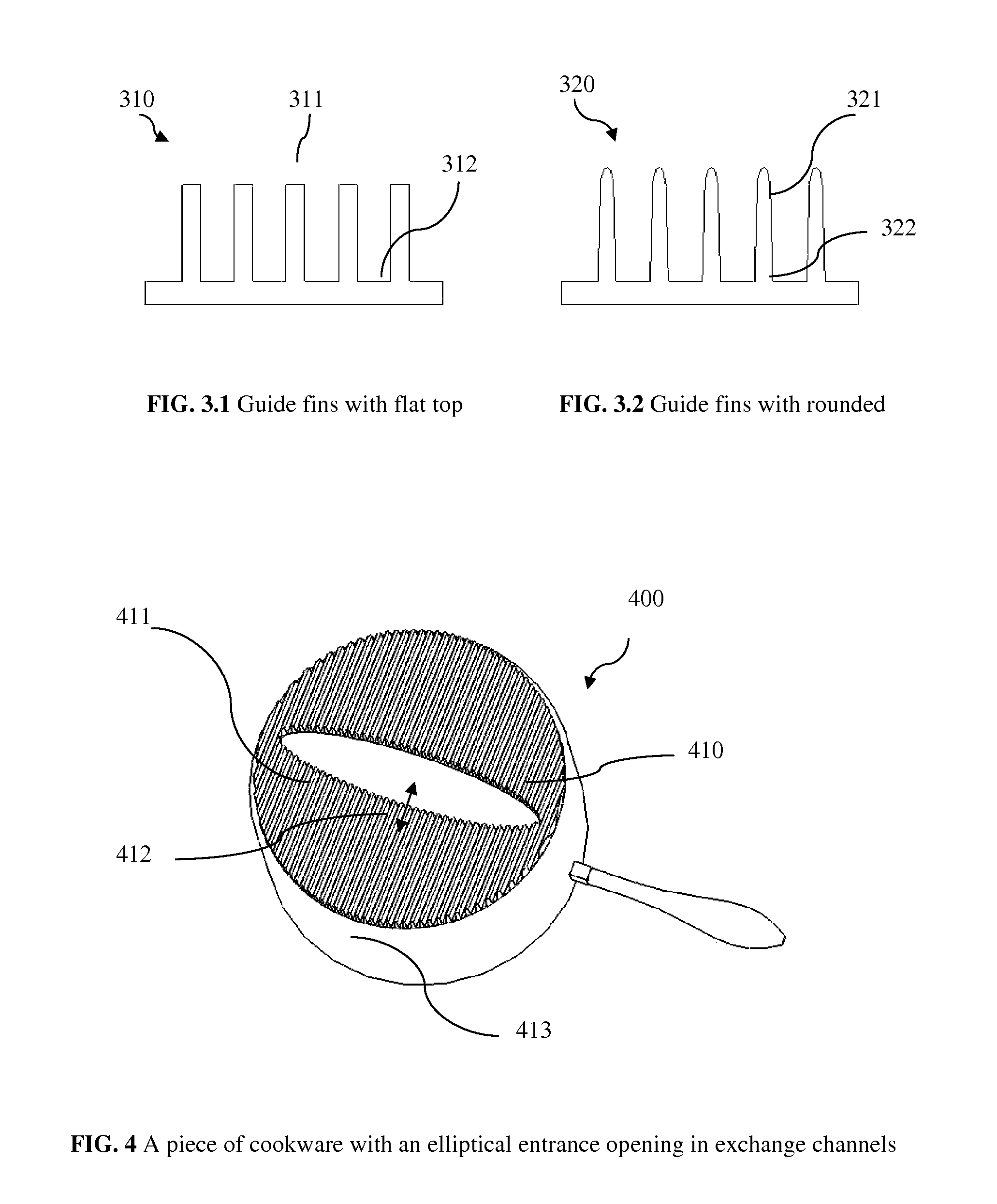

Methods of Making Energy Efficient Cookware

InactiveUS20100242257A1Reduce time and material scrapLower costDomestic vesselsCooking vessel constructionsProcess engineeringCooker

Techniques for designing and creating energy efficient cookware are provided. In accordance with the techniques cookware can include a cookware base having a cooking surface and heating surface. The heating surface can have a pattern of fins forming heat exchange channels. The channel fins can improve energy transfer while providing even distribution throughout the cooking surface. Methods of making the energy efficient cookware are provided. Methods of direct forming channel fins by impact bonding and forging are disclosed.

Owner:ENERON

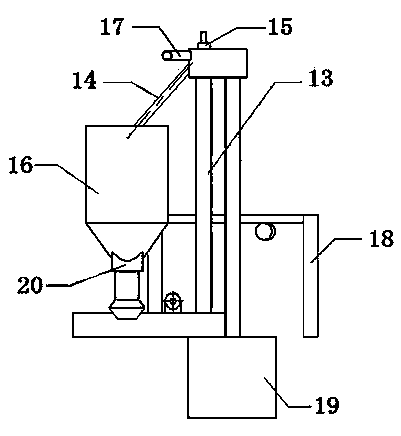

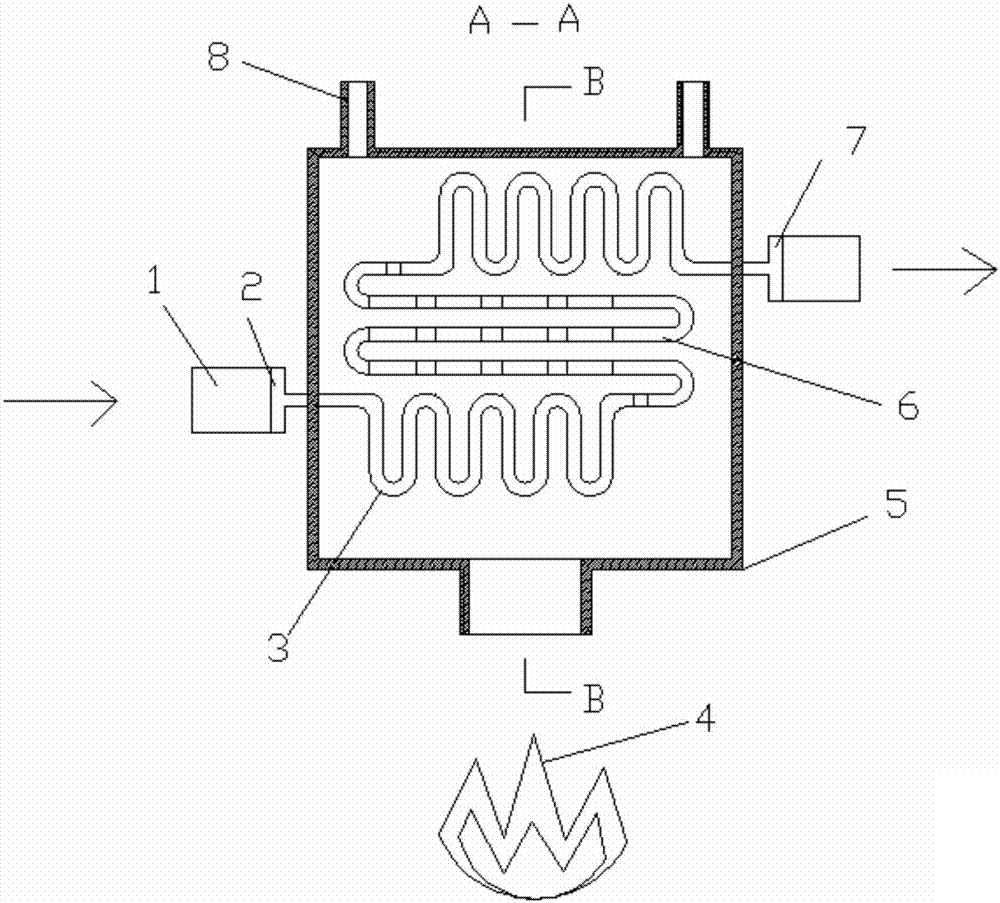

Energy-efficient steam boiler

InactiveCN103486564AHigh heat conversion efficiencyIncrease the heating areaSteam boilersCombustion chamberEngineering

The invention discloses an energy-efficient steam boiler, which belongs to boiler technical field. The energy-efficient steam boiler comprises a boiler body, a furnace body and a chimney. A multi-flue return folded structure is arranged in the boiler body, down pipe is arranged on the lower part of the drum, which is connected with the drum; the cross section of the firebox is oval, which is provided with injected screw feeder whose discharge port inclines upwardly to connect with inlet of firebox. The energy-efficient steam boiler has advantages of high combustion efficiency and heat utilization efficiency, good heat transition effects, easy operation and maintenance.

Owner:GUANGXI SKYRANINBOW BOILER

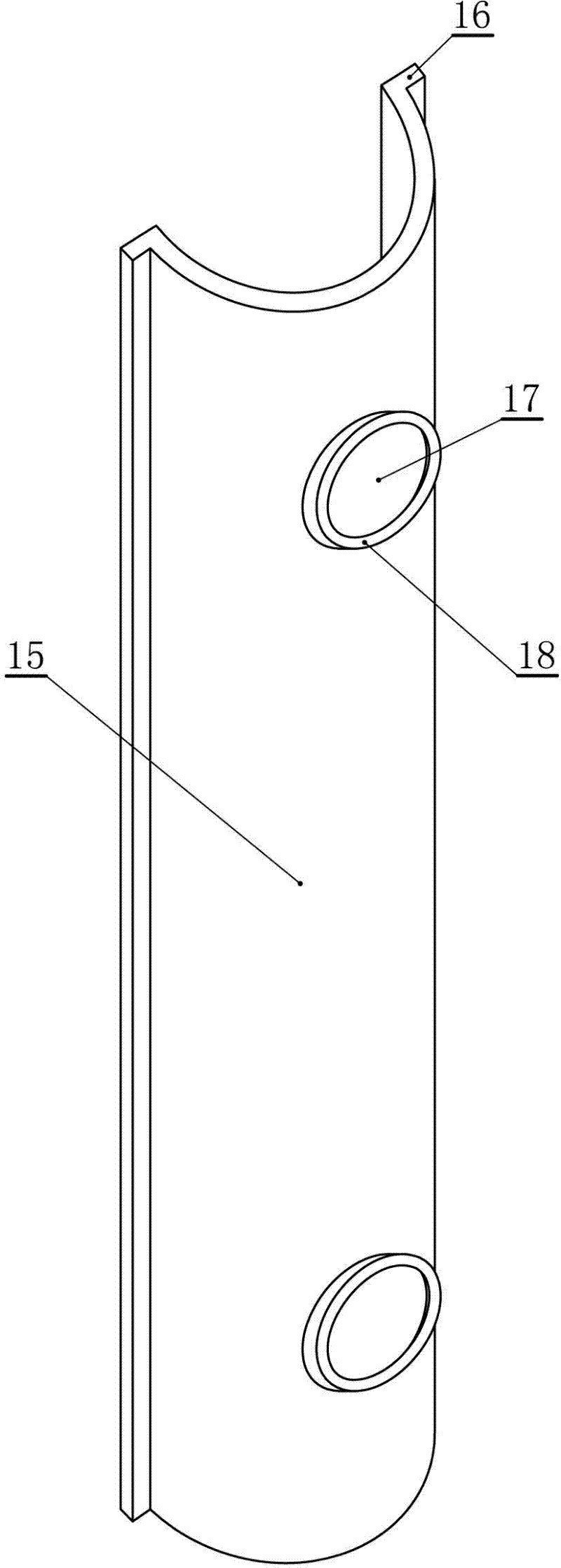

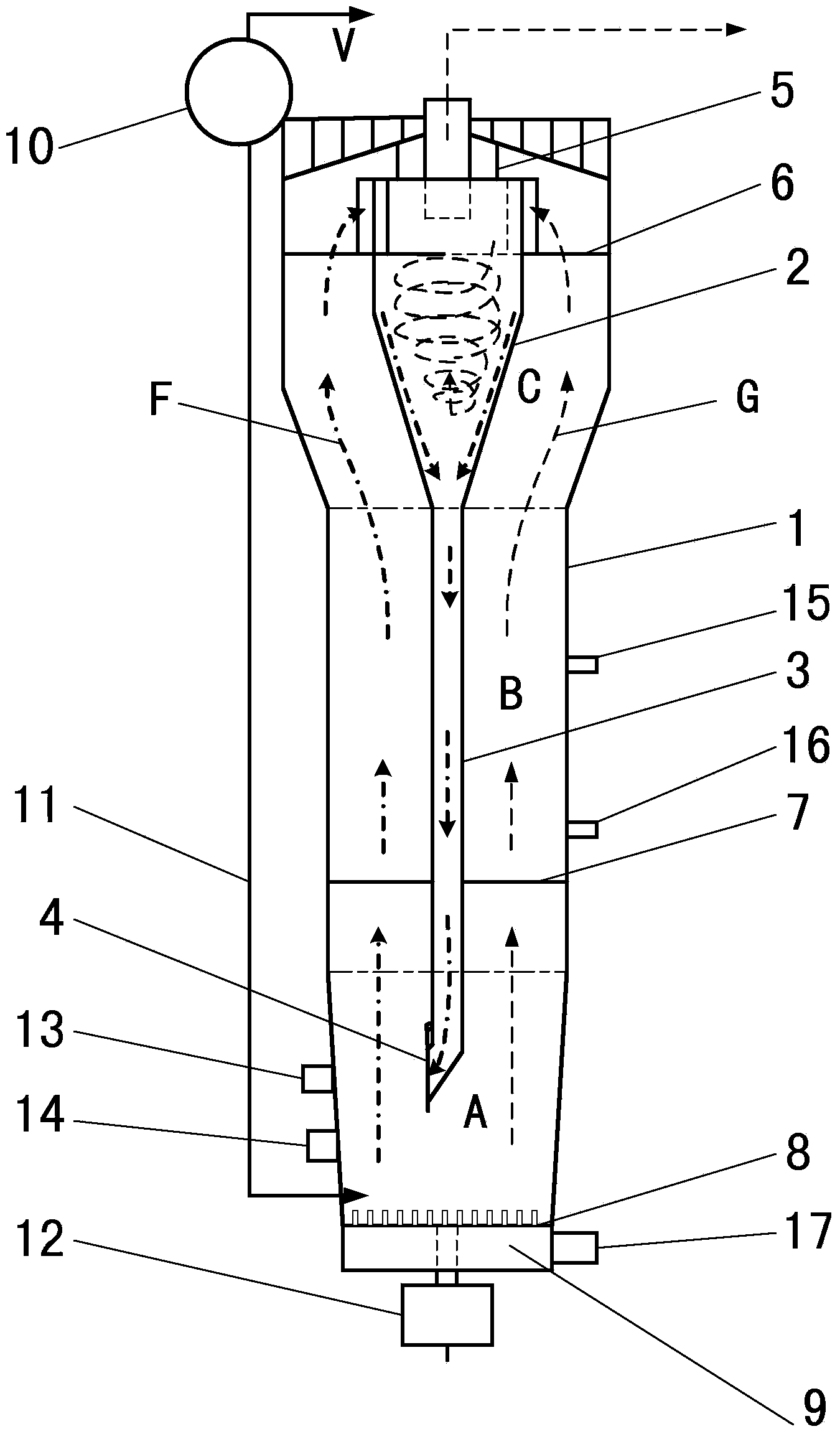

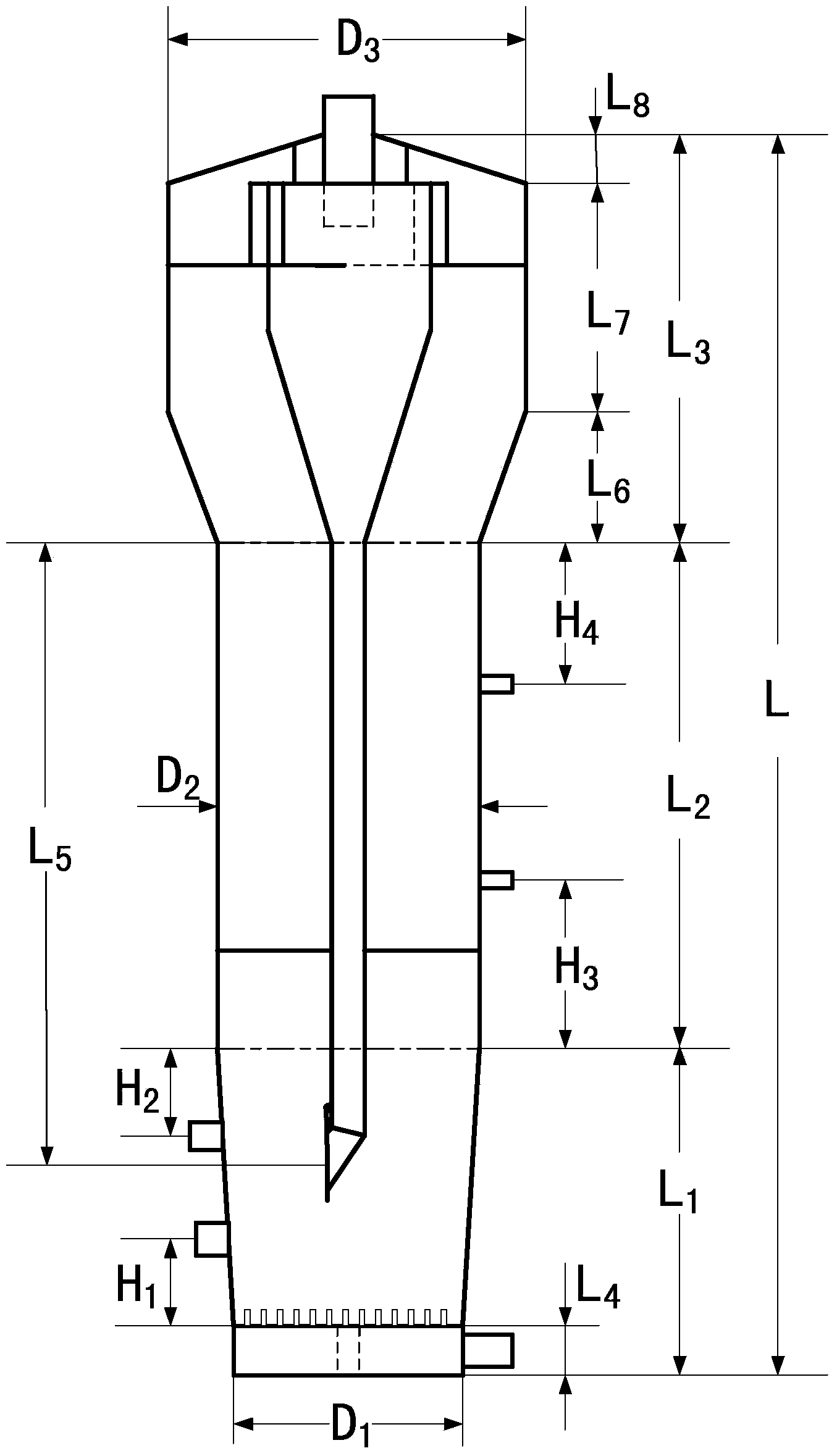

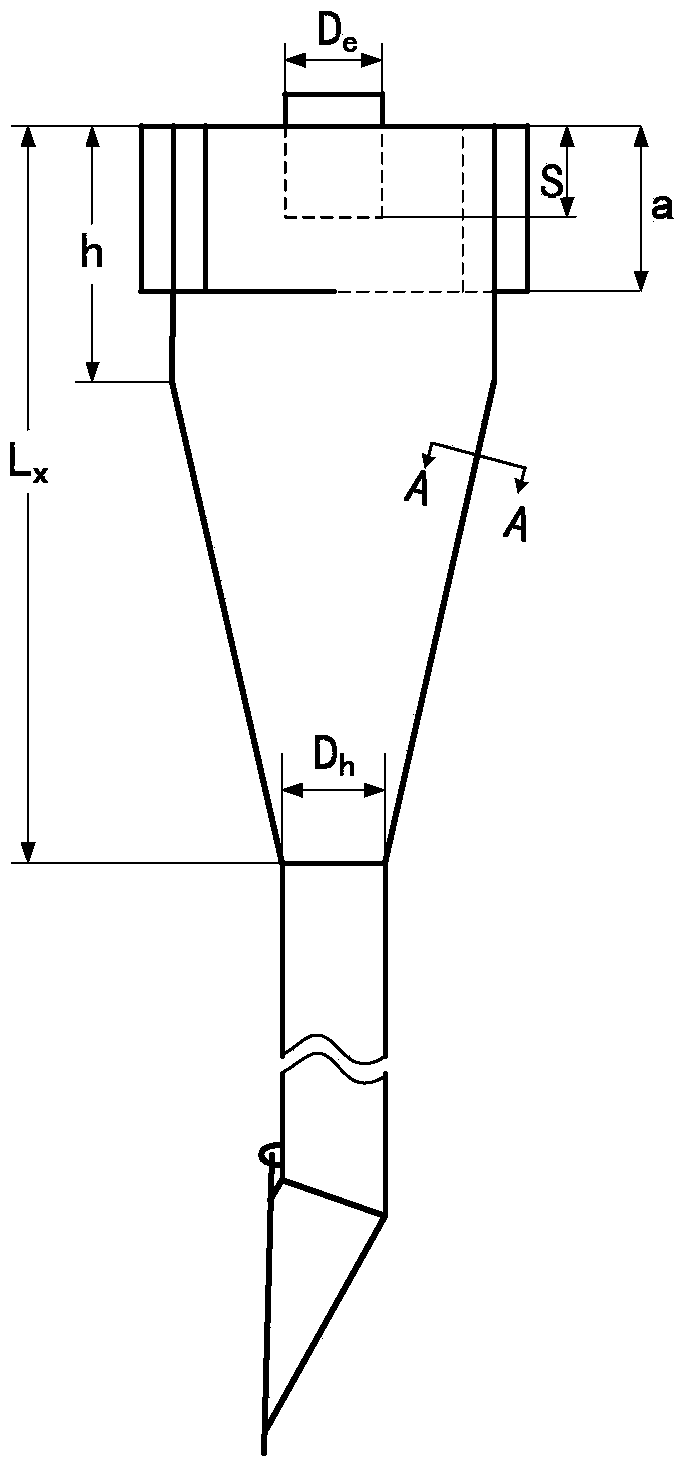

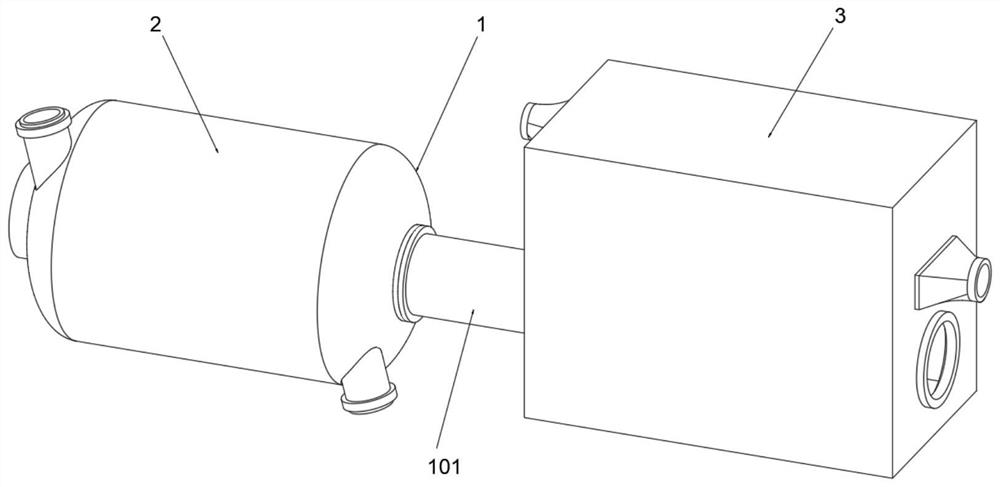

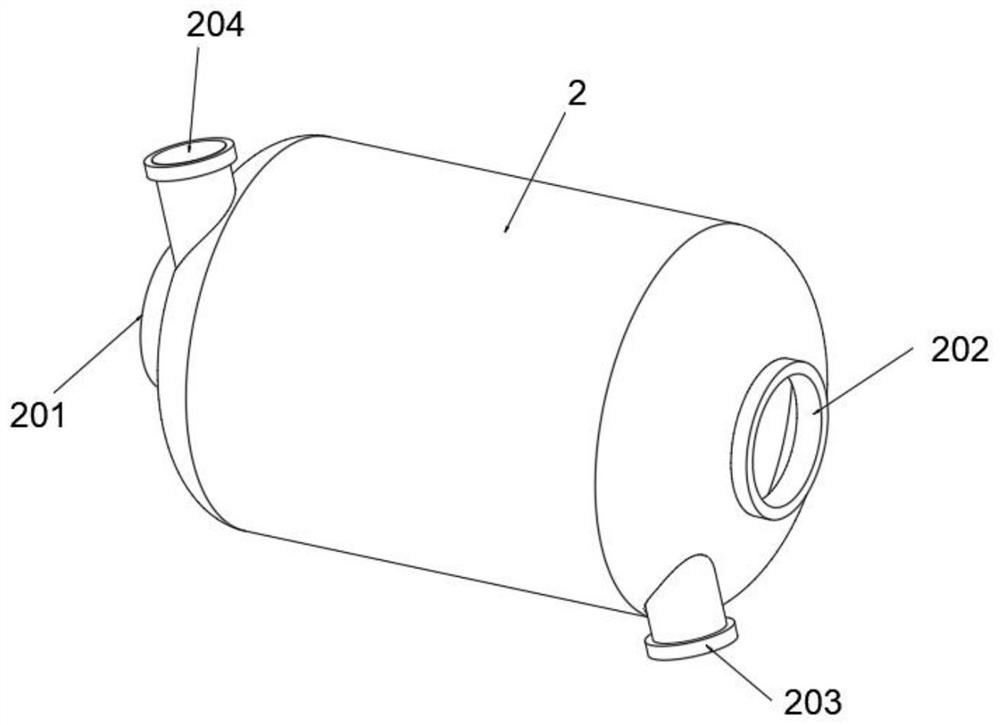

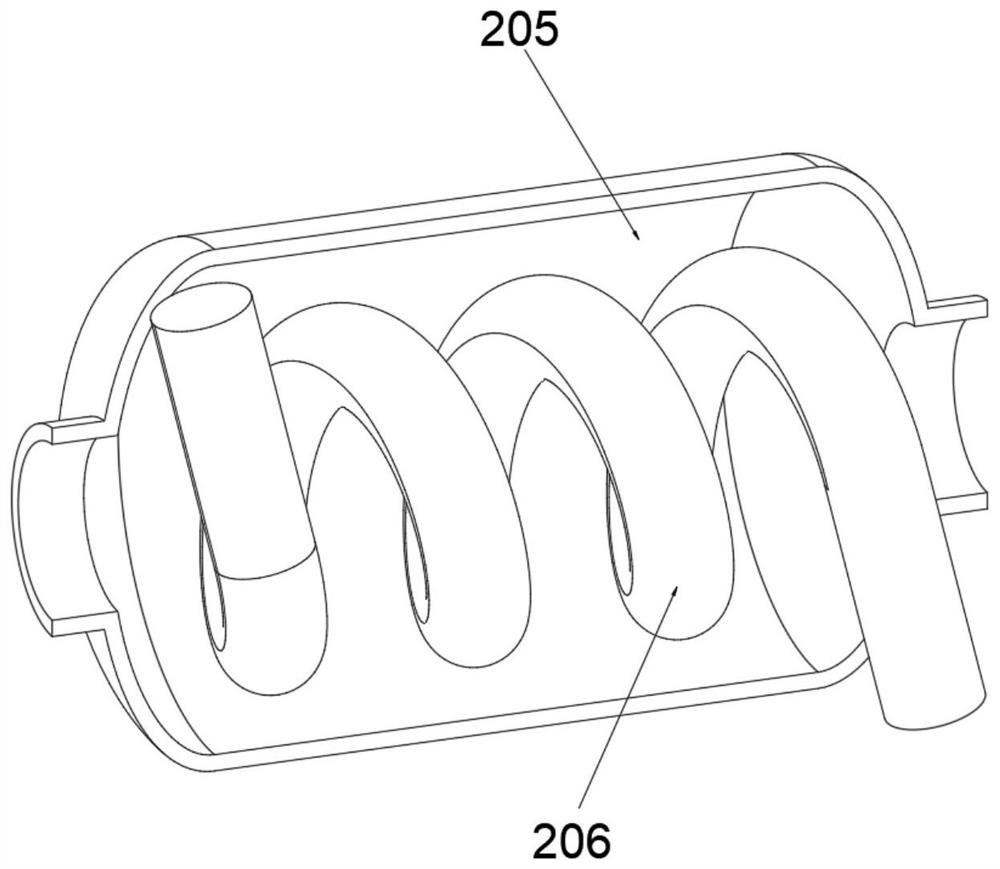

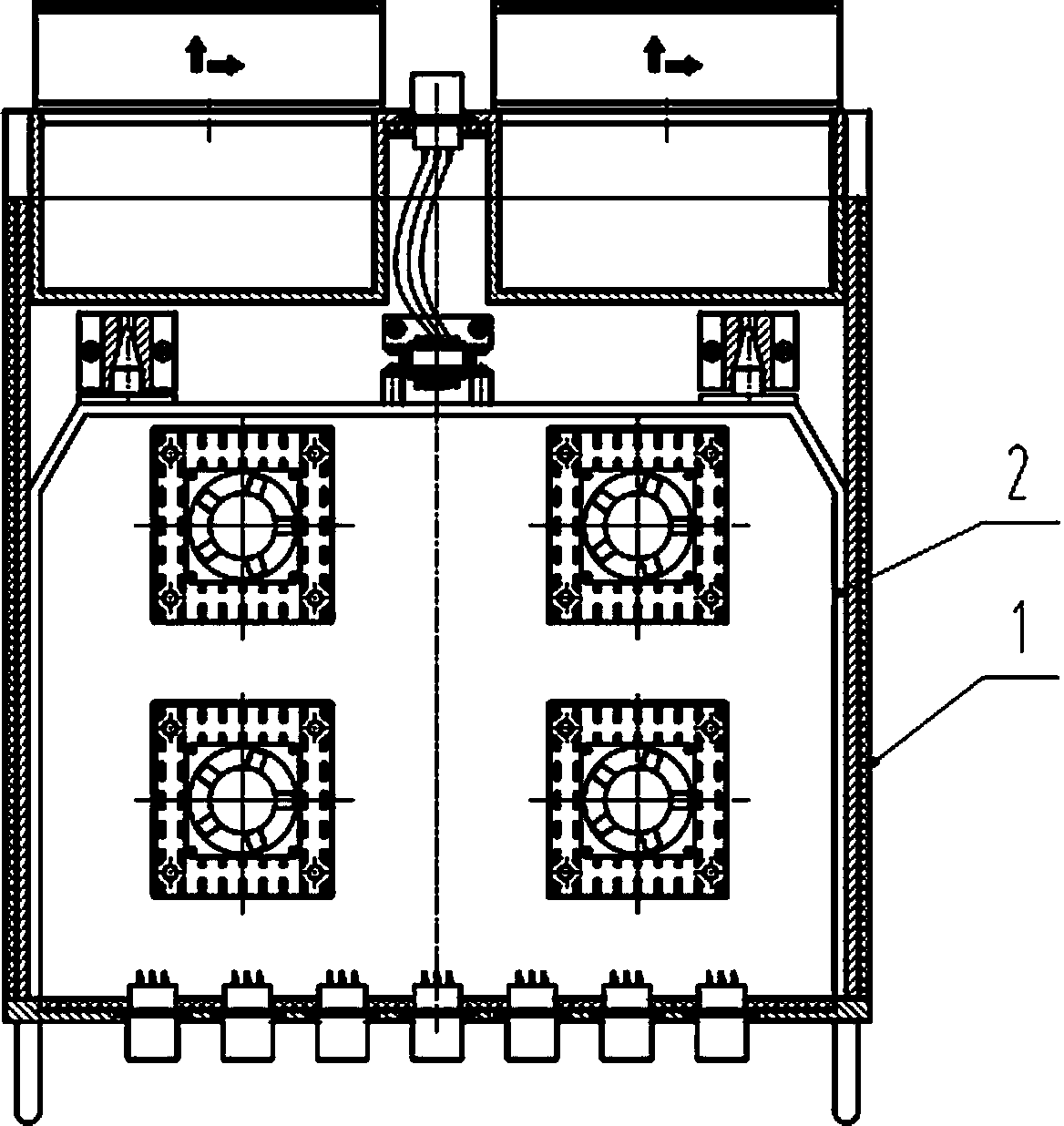

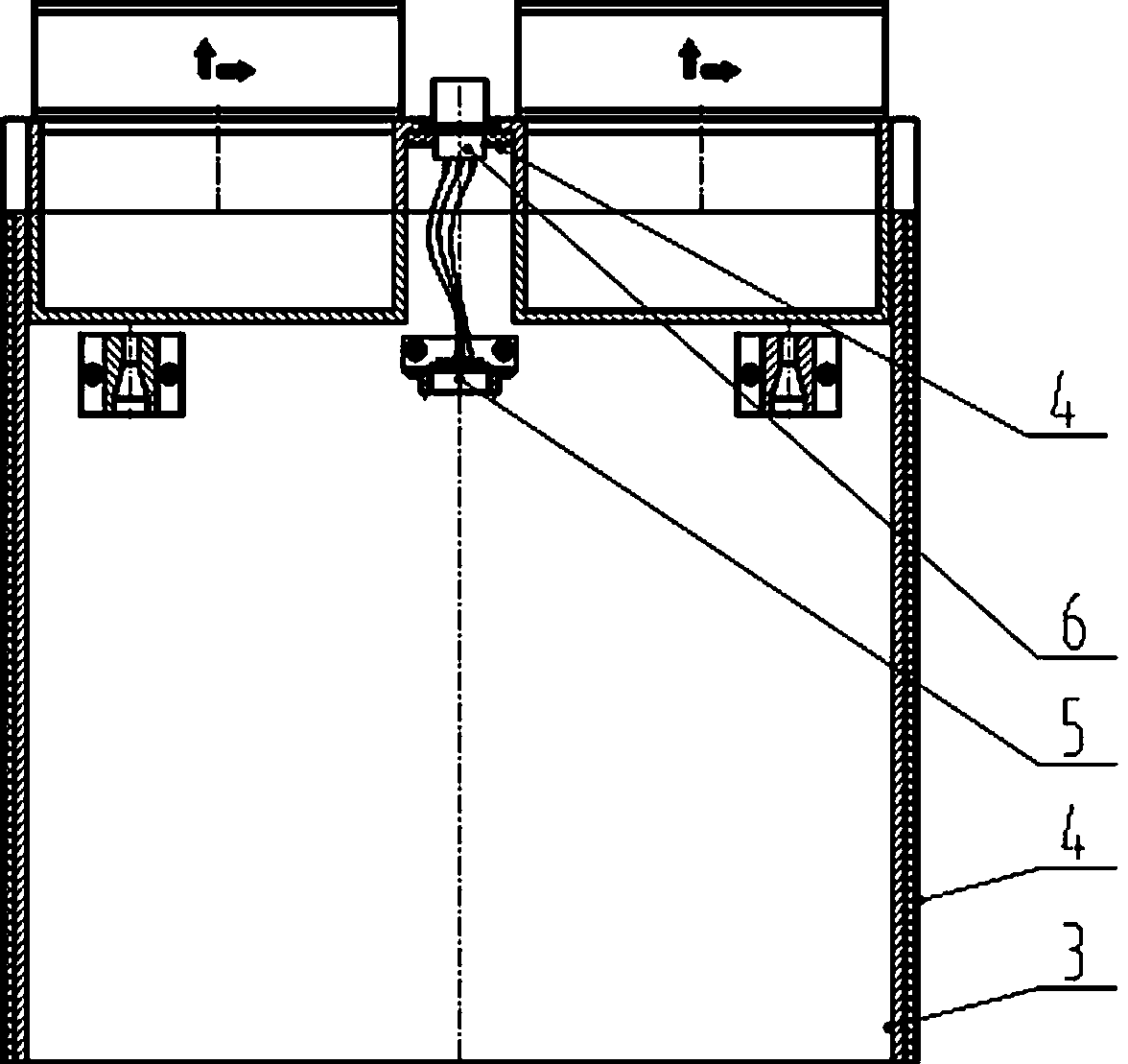

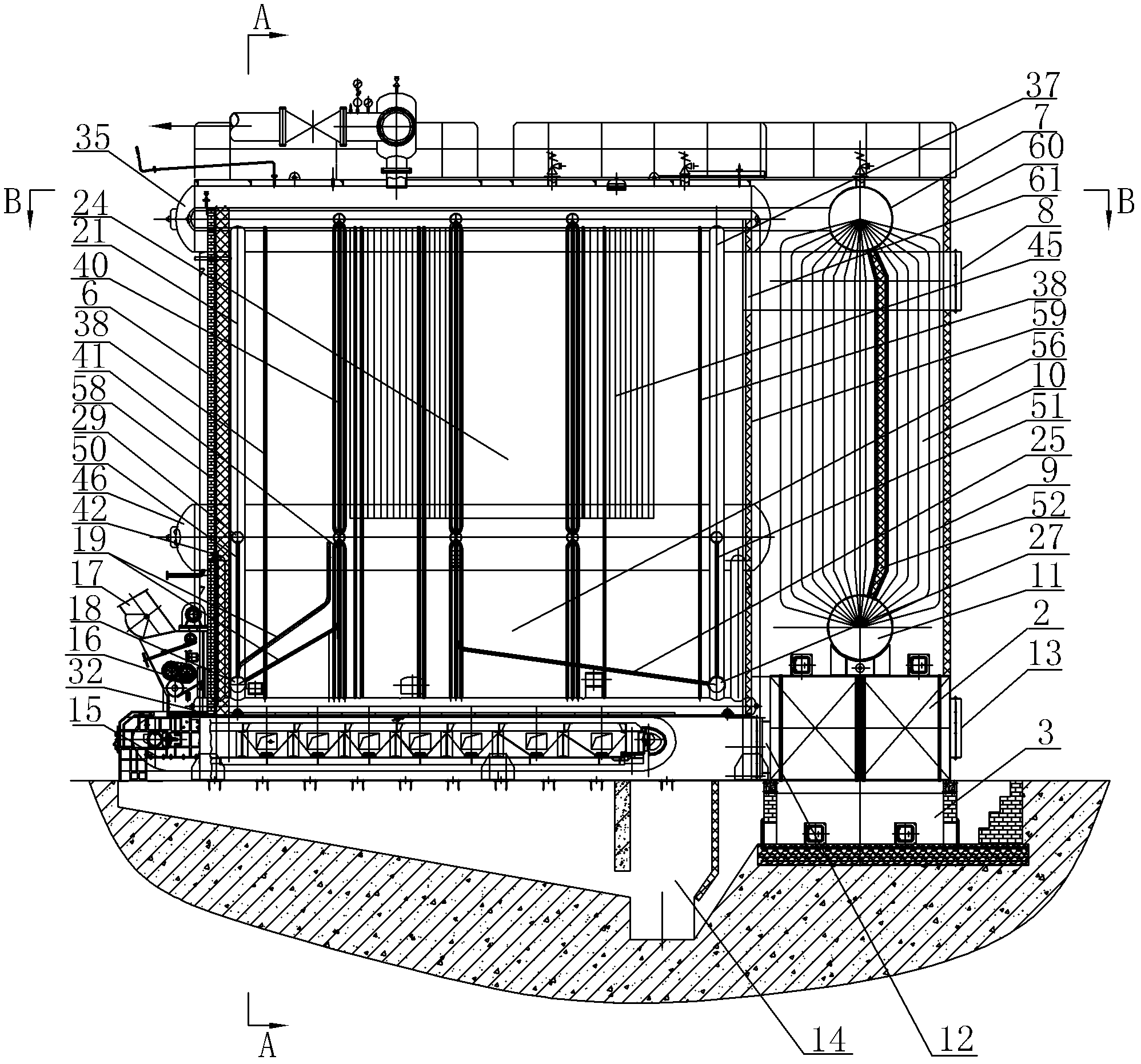

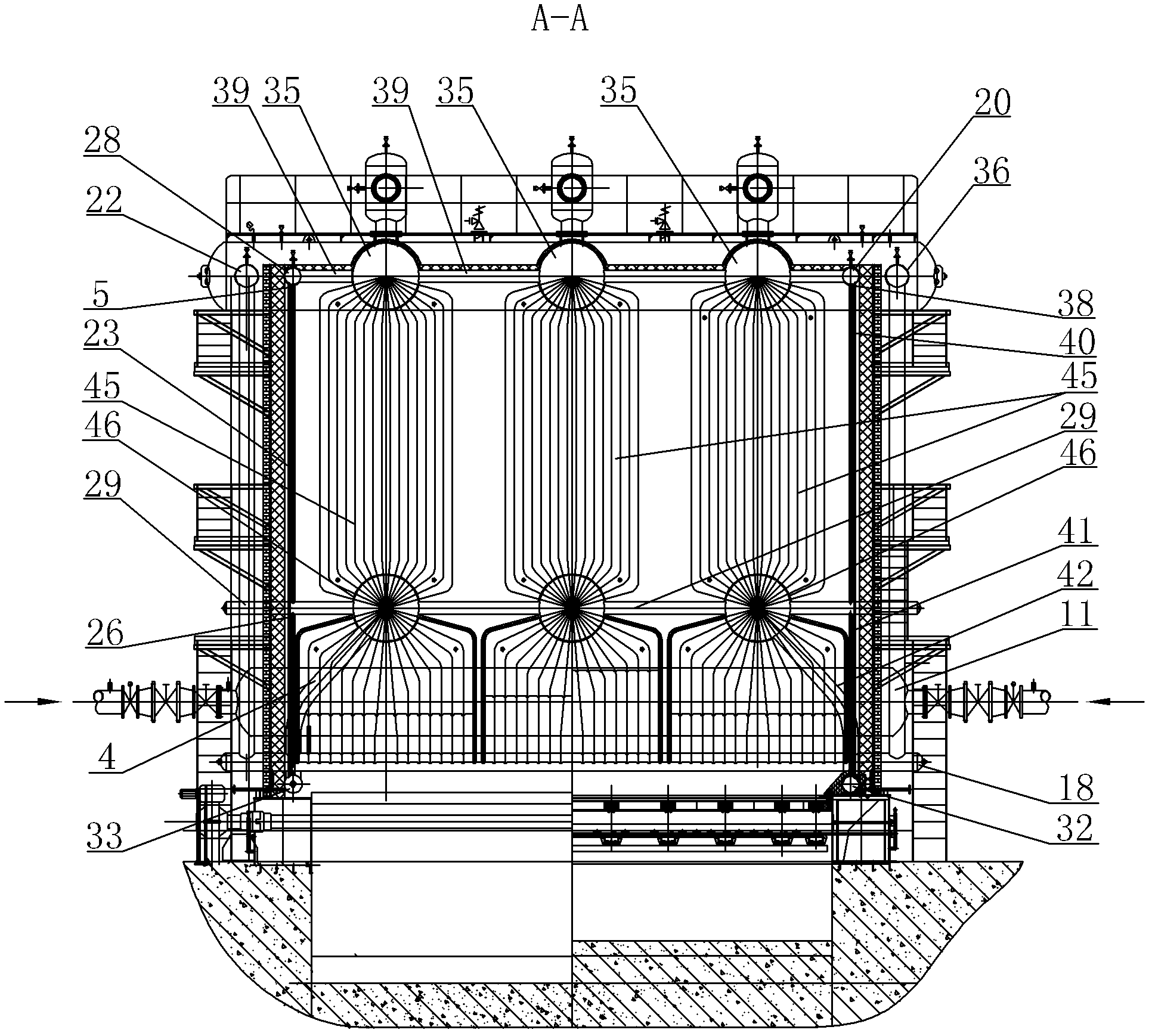

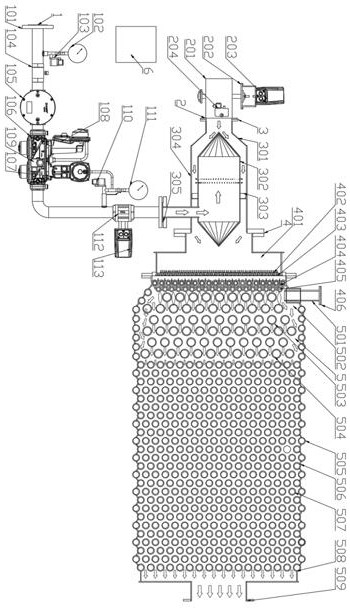

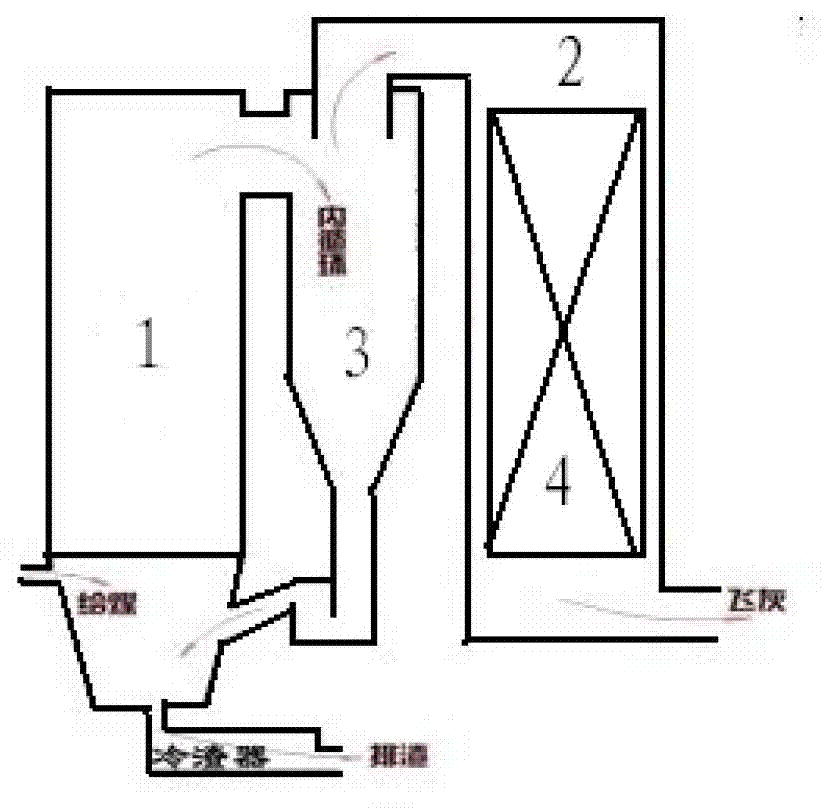

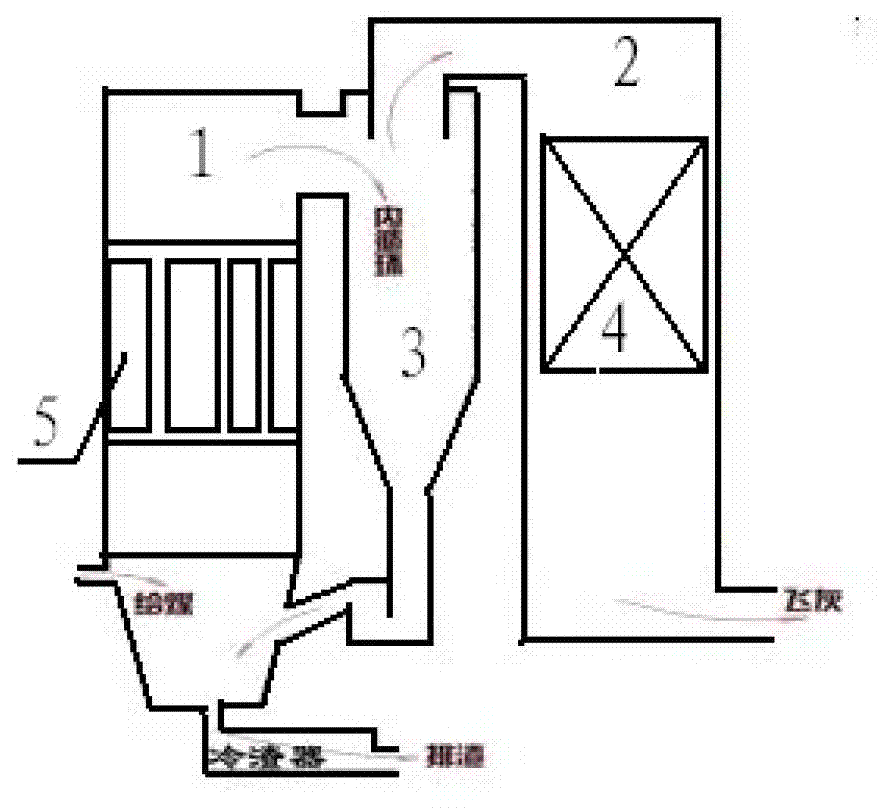

Circulating fluidized bed combustion device with internal double-inlet cyclone separator

ActiveCN103822205ACompact structureSmall footprintFluidized bed combustionApparatus for fluidised bed combustionCycloneFlue gas

The invention discloses a circulating fluidized bed combustion device with an internal double-inlet cyclone separator. The combustion device comprises a furnace chamber body (1), the double-inlet cyclone separator (2), a refeed downcomer (3) and a gas-water separator (10), wherein the inner wall of the vertically arranged furnace chamber body (1) is provided with a water wall; the furnace chamber body (1) comprises a furnace chamber dense-phase area (A), a furnace chamber lifting area (B) and a furnace chamber separating area (C) that are sequentially arranged from the bottom to up; the double-inlet cyclone separator (2) is coaxially arranged with a bed body in the furnace chamber separating area (C); the upper part of the flue gas inlet of the double-inlet cyclone separator (2) is arranged at the upper part of the furnace chamber separating area (C). According to the invention, gas-solid separating efficiency is improved, heat loss is reduced and boiler heat efficiency is improved.

Owner:SOUTHEAST UNIV

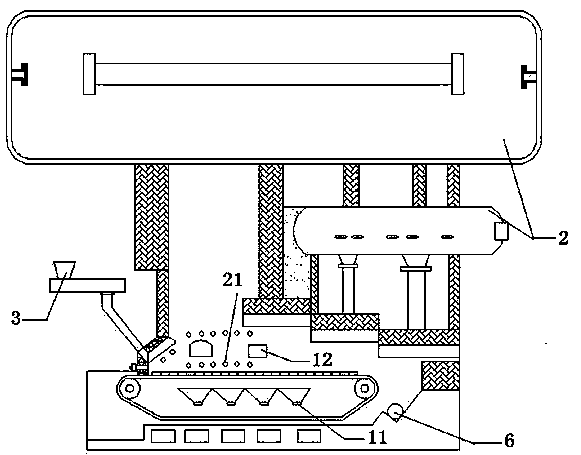

High-efficiency energy-saving biomass boiler system

ActiveCN103644561AIncrease profitDoes not affect temperatureBoiler controlSolid fuel combustionAir preheaterAutomatic control

The invention provides a high-efficiency energy-saving biomass boiler system which comprises a boiler body, a feeding system, a fire grate, a discharging device, a smoke discharging opening, a primary air inlet chamber, a secondary air inlet pipe and an air inlet chamber. A combustion chamber and a water vapor system placed above the combustion chamber are arranged in the boiler body. The feeding system is connected with the boiler body, so that biomass forming fuel is sent into the combustion chamber. The fire grate and the discharging device are placed at the bottom of the combustion chamber. The smoke discharging opening is communicated with the combustion chamber and penetrates through the water vapor system. The primary air inlet chamber is arranged below the fire grate. The secondary air inlet pipe and the air inlet chamber are arranged above the fire grate. Hot smoke discharged from the smoke discharging opening is recycled through a smoke discharging pipe and then passes through a water preheater and a secondary air preheater, wherein an outlet of the secondary air preheater is connected with a secondary air inlet chamber of the combustion chamber, inlet air is heated, and the water preheater is connected with a water inlet of a boiler, so that inlet water has certain temperature. According to the high-efficiency energy-saving biomass boiler system, burning is complete, boiler operation cost is low, feeding is convenient, heat using rate after biomass forming material burning releasing is improved, and steam production amount can be guaranteed by achieving automatic control over parameters.

Owner:浙江中吉新能源有限公司

Methods of making energy efficient cookware

InactiveUS8806737B2Improve cookwareIncrease surface areaDomestic vesselsMetal working apparatusEnergy transferProcess engineering

Techniques for designing and creating energy efficient cookware are provided. In accordance with the techniques cookware can include a cookware base having a cooking surface and heating surface. The heating surface can have a pattern of fins forming heat exchange channels. The channel fins can improve energy transfer while providing even distribution throughout the cooking surface. Methods of making the energy efficient cookware are provided. Methods of direct forming channel fins by impact bonding and forging are disclosed.

Owner:ENERON

Environment-friendly and energy-saving recovery device for boiler combustion boiler smoke gas

InactiveCN112344365ALower exhaust gas temperatureFast heatingCombustion processIndirect carbon-dioxide mitigationCold airCombustion

The invention relates to the technical field of boiler combustion boiler smoke gas recovery, in particular to an environment-friendly and energy-saving recovery device for boiler combustion boiler smoke gas. The environment-friendly and energy-saving recovery device comprises a hot air circulation device, the hot air circulation device is internally provided with a first shell, an air inlet is formed in the left side of the first shell, a cold air inlet is formed in the position, close to the top of the air inlet, of the side wall of the first shell, a hot air outlet is formed in the position,close to the bottom of an air outlet, of the side wall of the first shell, a heat exchange cavity is formed in the first shell, the top of the inner wall of the heat exchange cavity is fixedly connected with an upper baffle plate, the bottom of the inner wall of the heat exchange cavity is fixedly connected with a lower baffle plate, an inner cavity of the heat exchange cavity is fixedly connected with a first heat pipe, and heat conduction fins are arranged. According to the environment-friendly and energy-saving recovery device, the arrangement of the heat conduction fins is conductive to increasing the heating surface and improving the heat transfer efficiency; and the heat conduction fins are provided with upper fin bodies and lower fin bodies, and air ducts formed by the upper fin bodies and the lower fin bodies, so that the effective contact areas between the high-temperature smoke gas and second heat pipes are further increased while an effect on guiding the smoke gas is achieved, and then the heat transfer efficiency is improved.

Owner:周福明

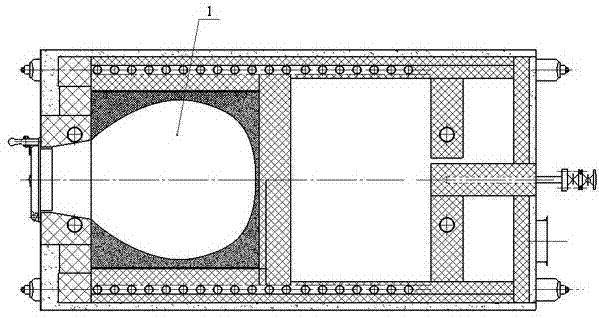

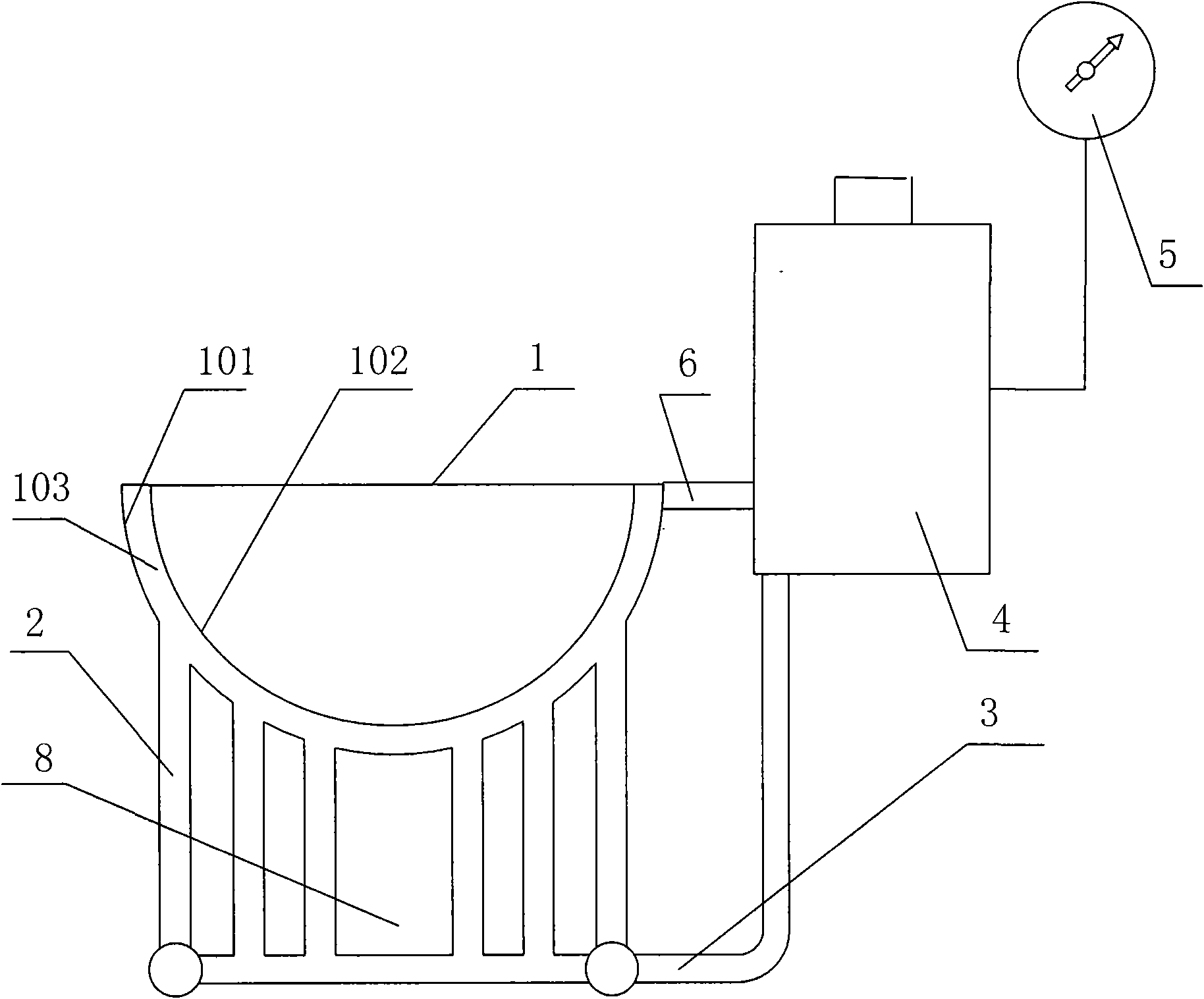

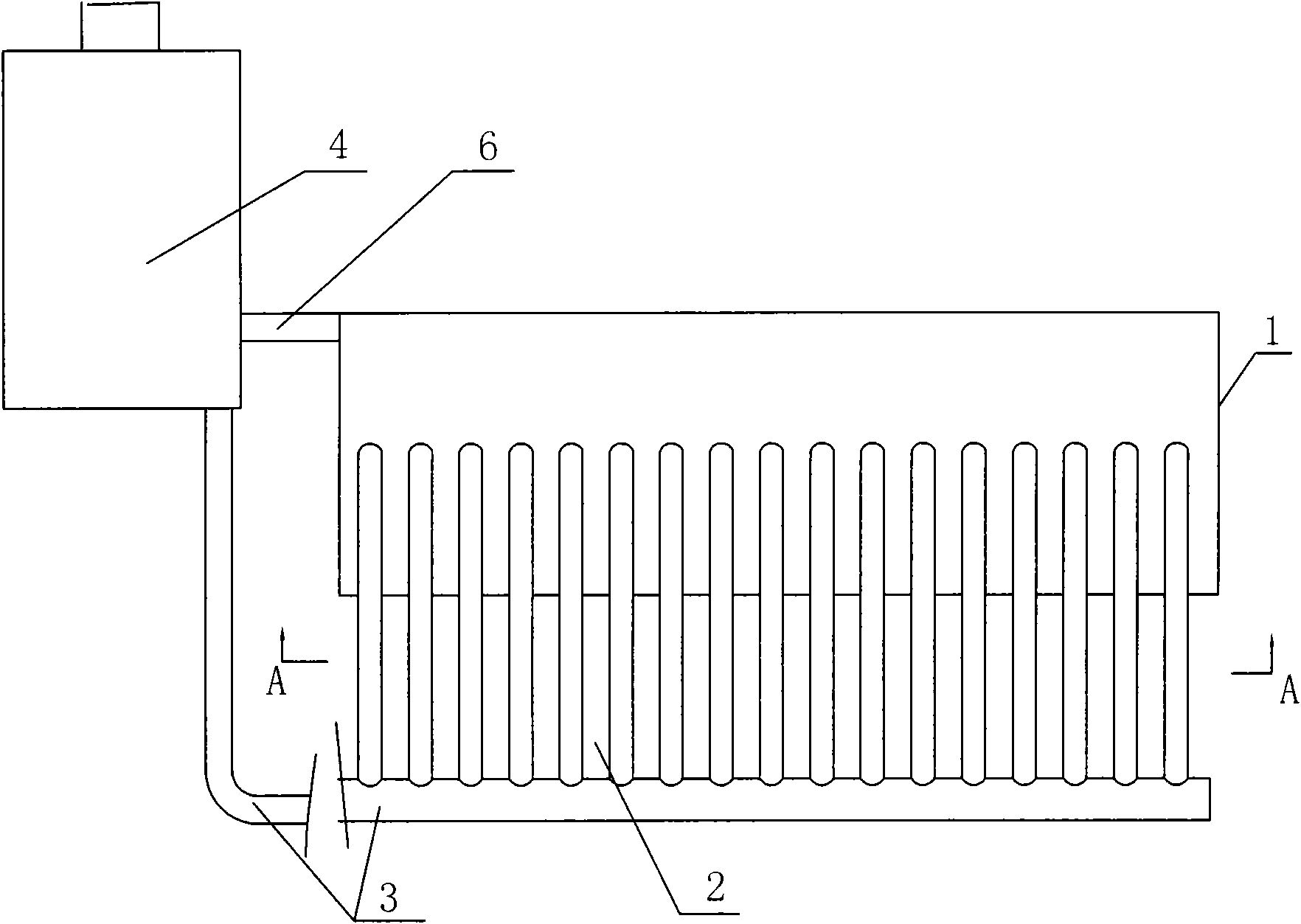

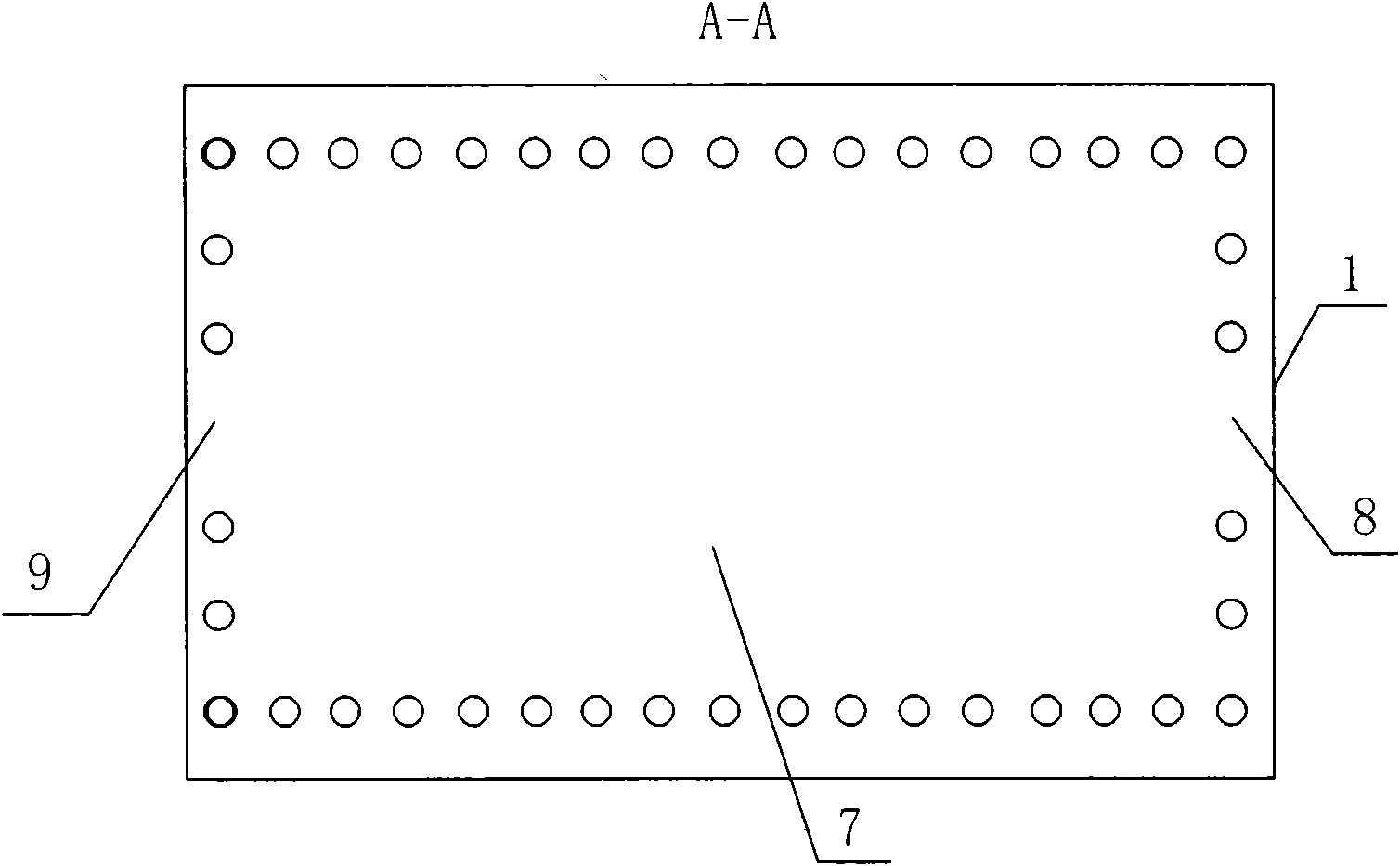

Spherical jacketed kettle for drying or mixing powdery materials

InactiveCN104983568AIncrease the heating surfaceImprove heat transfer efficiencyFood processingFood preservationSocial benefitsPolymer science

The invention discloses a spherical jacketed kettle for drying or mixing powdery materials. The jacketed kettle comprises a lower kettle body, an upper kettle body, a feeding port cover, a heat transmission layer, a medium pipe or / and a support pipe, a bearing frame, lower kettle body material stir-fry plates, a motor, a driven wheel, a driving wheel and a coupler. The spherical jacketed kettle for drying or mixing powdery materials can heat, dry or mix materials by means of circulated liquid or steam, and can dry materials without heating and mixing the materials, the material drying / mixing time is short, the spherical jacketed kettle has a good effect and has substantial economic benefit and social benefit, energy is saved, and the spherical jacketed kettle is suitable for drying or mixing powdery materials in the pharmacy industry and the foodstuff industry.

Owner:唐婧婵

Blade server oriented box-sleeving type heat preservation/heat dissipation device

ActiveCN103699196AIncrease floor areaReduce thicknessDigital data processing detailsEnergy efficient computingHeat fluxSurface mounting

Disclosed is a blade server oriented box-sleeving type heat preservation / heat dissipation device. An inner-outer box sleeving structure is adopted, an inner box is an electrical appliance bearing box body, and an outer box is a heat preservation / heat dissipation box body. An upper and a lower flat surface of the outer box of the device are air duct heat preservation / heat transfer surfaces, the rest surfaces are heat insulation surfaces, heat dissipation and heat preservation of a case are controlled by controlling on and off of air flow in upper and lower heat transfer air ducts, and finished product heat dissipators are arranged on an upper air duct plate by surface mounting to enlarge a heating surface of the outer box so as to improve heat dissipation efficiency. Heating chips in the inner box adopt an upward convection and downward conduction dual-path heat transfer mode to lower heat flux and improve heat transfer efficiency. The inner box and the outer box are separated and fastened by means of separation and reunion of taper pin holes. The device takes economical and safe natural air as a heat transfer medium, and has a safe, energy-saving and compact heat preservation / heat dissipation function without depending on cooling facilities but by structural design.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

Heating kettle

InactiveCN101991344AReasonable structureIncrease the heating surfaceWarming devicesCombustion chamberHeat conducting

The invention relates to a heating kettle which comprises a kettle body and is characterized in that the kettle body comprises an outer-layer kettle body and an inner-layer kettle body; a sealed interlayer cavity is formed between the outer-layer kettle body and the inner-layer kettle body; a plurality of heat conducting pipes which are arranged in a frame shape and are communicated with the interlayer cavity are arranged at the periphery of the bottom of the outer-layer kettle body; the inside space of the heat conducting pipes which are arranged in the frame shape forms a combustion chamber; a charging opening is arranged at the initial end of the combustion chamber, and a smoke discharging outlet is arranged corresponding to the tail end of the combustion chamber; each heat conducting pipe is communicated with the bottom of an expansion oil tank through an oil inlet pipe; and an oil outlet pipe is arranged at the upper end of the outer-layer kettle body and is used for communicating the interlayer cavity and the expansion oil tank. The kettle body of the invention has large heating area, uniform heating and high temperature-rising speed, thereby preventing materials in the kettle body from being brown partially and sticking on the kettle to prolong the service life of the kettle body. The invention has the advantages of high heat utilization ratio, high material cooking speed and fuel saving and is especially suitable for processing and cooking aquatic products such as fishes, shrimps and the like.

Owner:刘增军

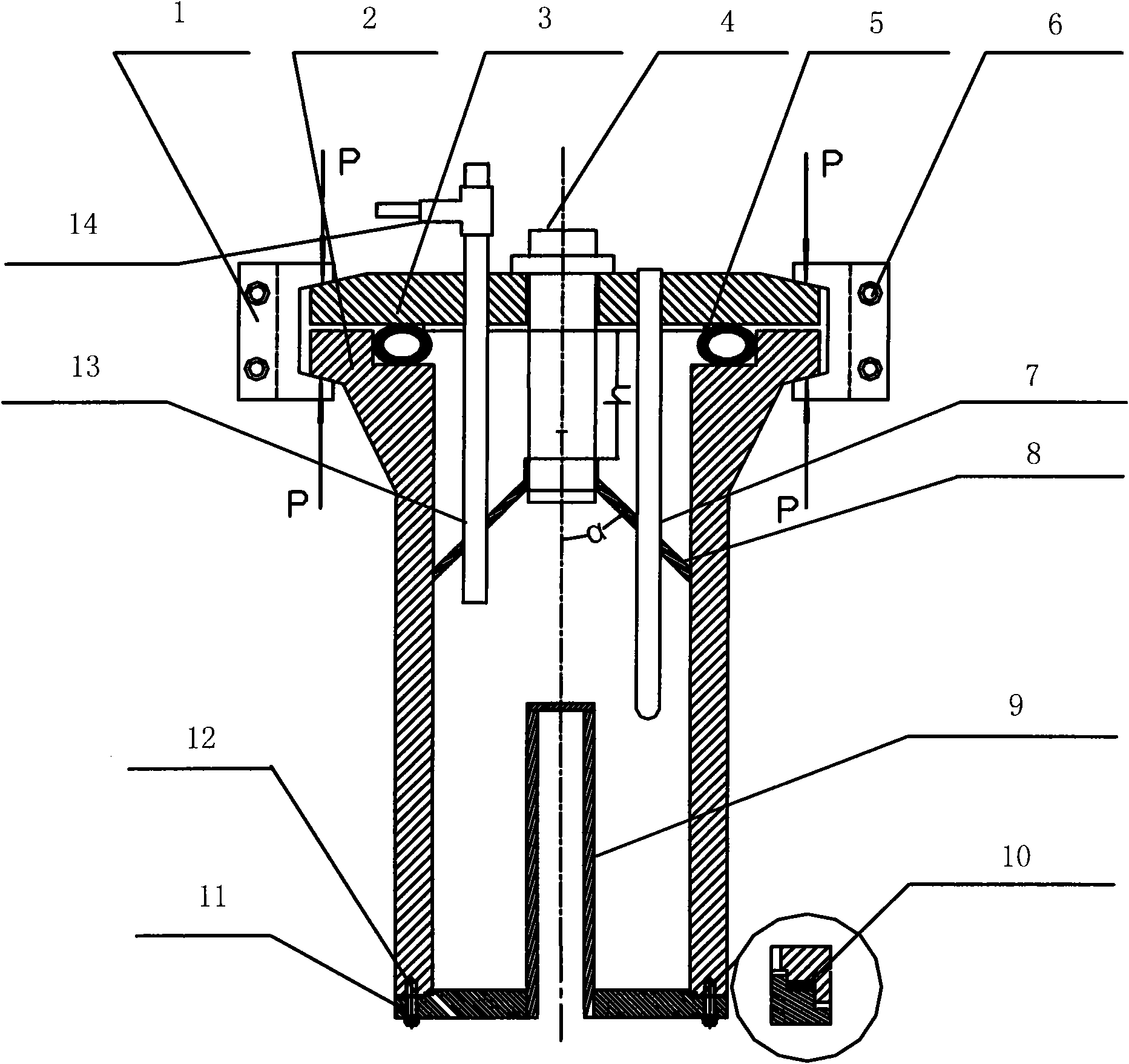

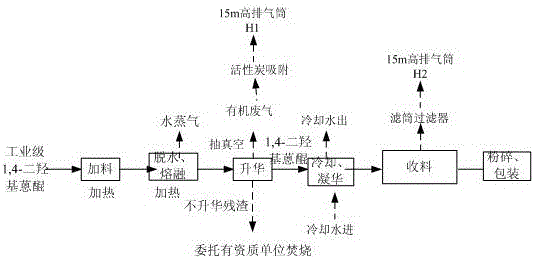

Method for purifying 1, 4-dihydroxy anthraquinone by sublimation under high vacuum

InactiveCN105884592ANo chemical reactionNo secondary pollutionQuinone separation/purificationSublimationActivated carbonChemical reaction

The invention discloses a method for purifying 1, 4-dihydroxy anthraquinone by sublimation under high vacuum. The method comprises the following preparation steps: feeding; dehydrating and fusing; purifying by sublimation; cooling and condensing; opening a tank, collecting and weighing after cooling is finished; and producing a next batch of 1, 4-dihydroxy anthraquinone. By the method provided by the invention, other chemical raw materials are not added, chemical reaction does not exist, waste water does not exist either, a small amount of waste gas can be adsorbed and removed by activated carbon, waste residues are incinerated by qualified units, and therefore, emission of the waste gas, the waste water and the waste residues is avoided basically. Compared with purification by a chemical method and a solvent method, the method has the advantages that the purity of the product is high (greater than or equal to 99%, the yield is high (greater than or equal to 97%), and is environmentally friendly; and secondary pollution is avoided. In addition, the invention further discloses a honeycomb sublimator which is designed according to the principle of infinitesimal. Compared with a reaction kettle type sublimator, the honeycomb sublimator has the features that sublimation time is shortened by more than 5 times, and energy is saved by 70%.

Owner:马骋

Drum vertical chain grate hot water boiler

ActiveCN102297509AImprove thermal efficiencyHigh thermal efficiencyWater heatersEngineeringEconomizer

The invention discloses a boiler drum longitudinally arranged chain grate hot water boiler, and relates to a hot water boiler to solve the problems that the conventional boiler has low thermal efficiency and high coal consumption, pipes are easy to block, and smoke discharging temperature is high. The boiler drum longitudinally arranged chain grate hot water boiler comprises a left longitudinal upper header, a right longitudinal upper header, a left longitudinal water tank, two first vertical water distributing pipes, two second vertical water distributing pipes, a plurality of upper transverse headers, a plurality of lower transverse headers, a front transverse header, a rear transverse header, a plurality of first water cooling wall pipes, a plurality of second water cooling wall pipes,a plurality of groups of third water cooling wall pipes, a plurality of groups of fourth water cooling wall pipes, a plurality of groups of fifth water cooling wall pipes, a plurality of groups of sixth water cooling wall pipes, a plurality of groups of upper convection banks, a plurality of groups of front convection banks, a plurality of groups of rear convection banks, and at least one convection economizer, wherein the front transverse header and the rear transverse header are communicated with a left coking prevention ark and a right coking prevention ark; adjacent upper boiler drums in a plurality of upper boiler drums, and the left longitudinal upper header and the right longitudinal upper header and the respectively adjacent upper boiler drums are communicated thorough the plurality of upper transverse headers. The boiler drum longitudinally arranged chain grate hot water boiler is used for central heating.

Owner:HARBIN TIANDIKUAN ENERGY SAVING TECH

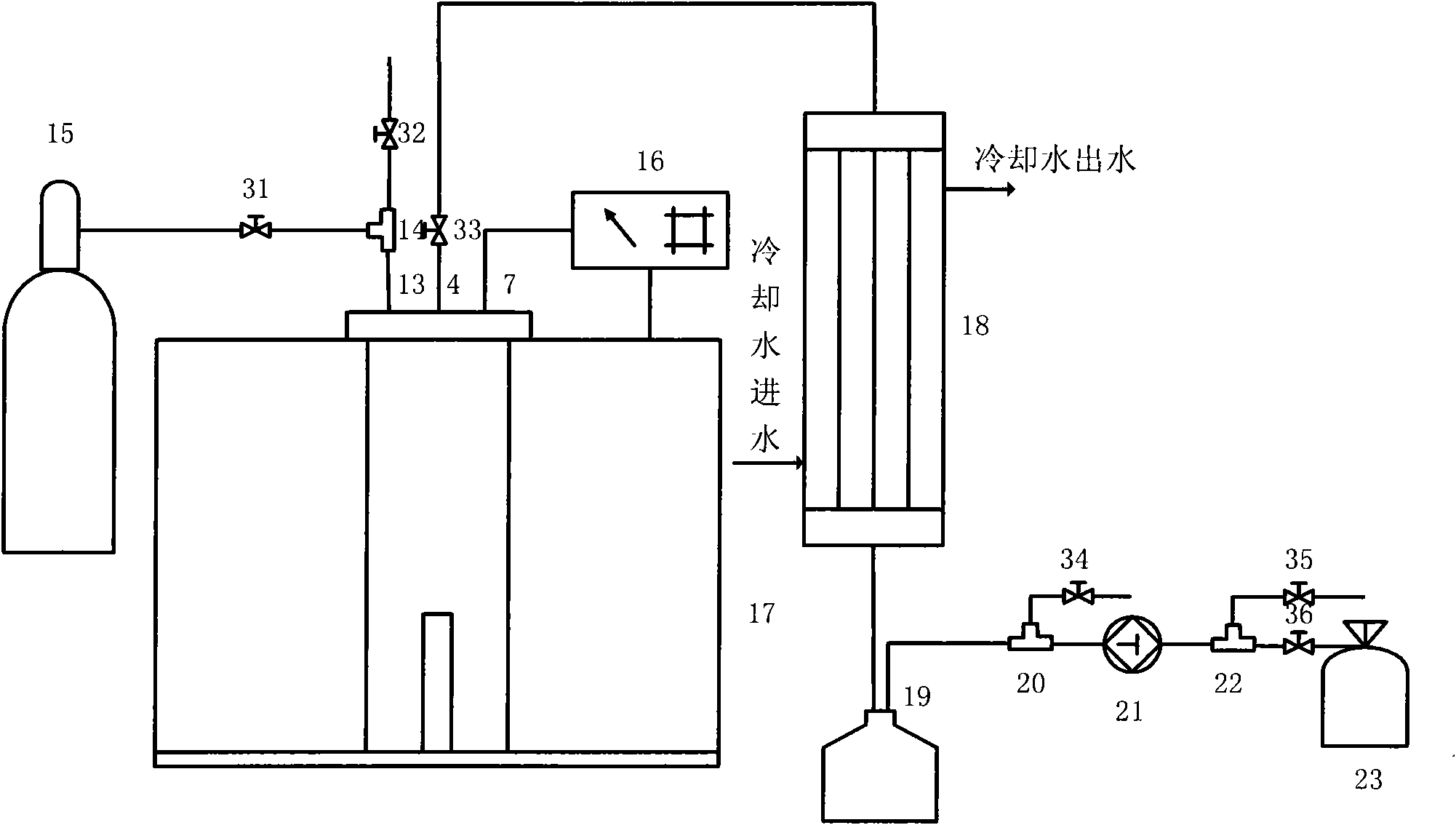

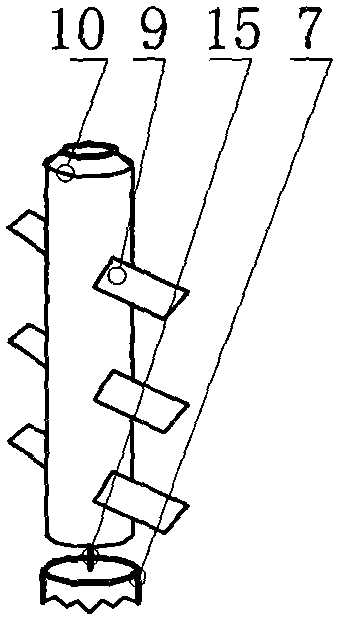

Fast molten salt furnace

InactiveCN104801675AIncrease the areaIncrease the heating surfaceFoundry mouldsFoundry coresCrucibleMolten salt

The invention relates to a fast molten salt furnace, which is characterized by comprising a vacuum mechanism, a melting mechanism, a stirring mechanism and a control mechanism, wherein the melting mechanism, a salt core mold 3 and a sealing sleeve 6 are arranged in a vacuum furnace casing 1, the stirring mechanism is arranged in the melting mechanism, the control mechanism is arranged under the vacuum furnace casing 1, the melting mechanism is provided with a sensing heating coil 5, a heat insulation sleeve 13 is arranged in the sensing heating ring 5, and a crucible core 14 is arranged in an alloy crucible 4; a stirring blade 9 is arranged on a stirring sleeve 10, and a stirring shaft 15 is arranged in the stirring sleeve 10, a core connecting shaft 8 is arranged under a clutch 7, and a stirring motor 12 is arranged under a telescopic sleeve 11. The crucible core arranged in the alloy crucible, the stirring sleeve and the stirring blade are adopted, the area of a sensing heating body is effectively increased, and the salt melting speed is accelerated; the telescopic sleeve clutch arranged under the core connecting shaft is adopted, the distance between clutch contact blocks is increased, the reverse turning of induction furnace can be conveniently realized, and the productivity of the molten vacuum salt furnace is improved.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

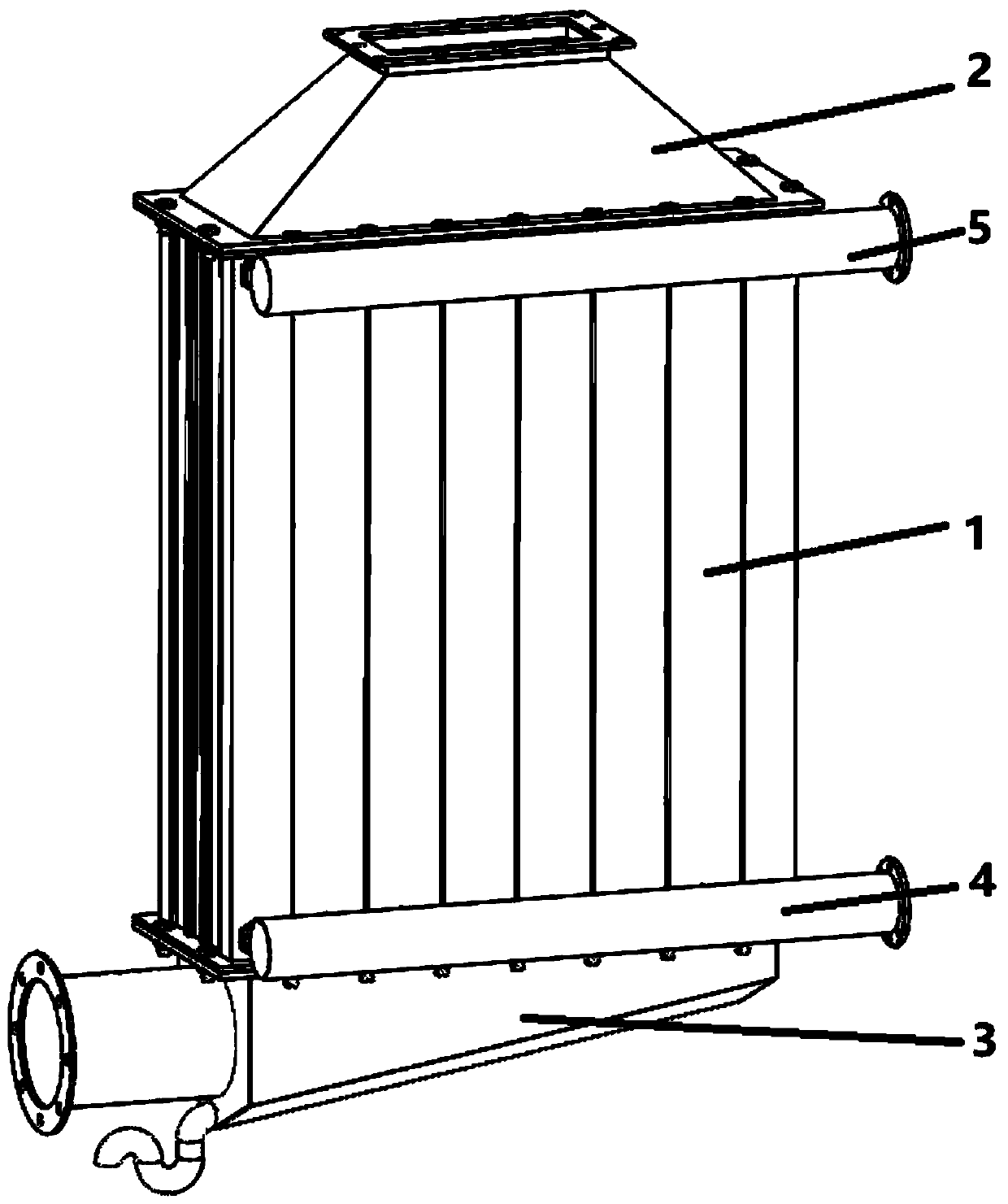

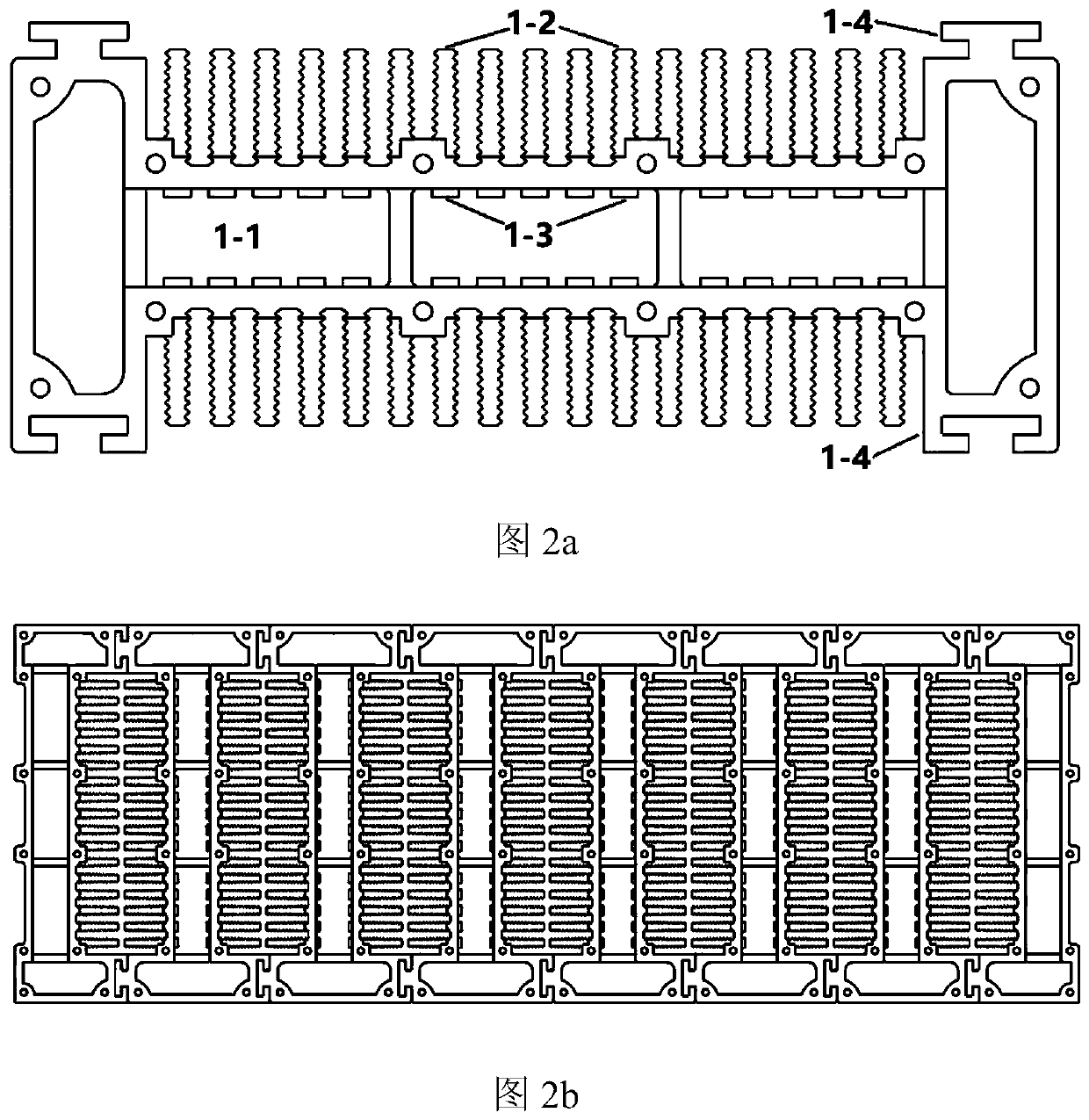

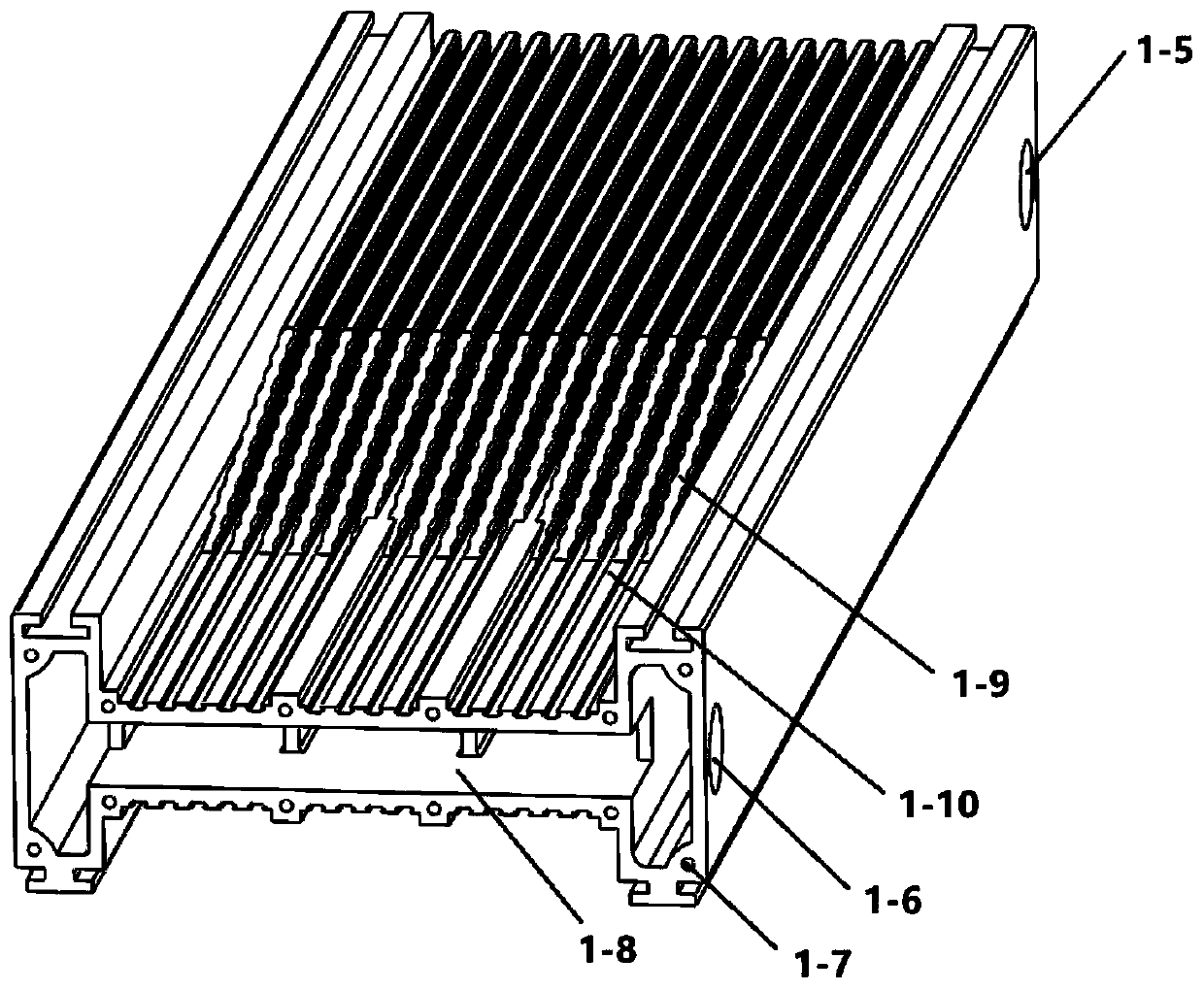

Modular extrusion aluminum condensation heat exchanger and condensation boiler

PendingCN110006174AReduce design costReduce manufacturing costAir heatersIndirect heat exchangersEngineeringErosion

The invention discloses a modular extrusion aluminum condensation heat exchanger and condensation boiler. According to the opposite arrangement of a burner and the extrusion aluminium condensation heat exchanger, the single, left-right or upper-lower split condensation boiler is formed, and the condensation boiler is composed of extrusion aluminium heat transfer units, an inlet gradually expandingflue, a dew tray, an inlet header, an outlet header and the fully premixed fire exhaust burner; after extrusion forming, an aluminium rod becomes the extrusion aluminium heat transfer unit with complete waterways by the secondary machining and assembly, and the extrusion aluminium heat transfer units are combined into the condensation heat exchanger or a main part of the condensation boiler; a combustion head of the fully premixed fire exhaust burner extends between the extrusion aluminum heat transfer units to avoid the deformation and leakage of a sealing cover plate caused by flame erosion; extrusion aluminium has the advantages of high tensile strength, low density and corrosion resistance, and the cost of the extrusion aluminium is only 30% that of cast aluminium-silicon and 60% thatof stainless steel; and according to the surplus design of the extrusion aluminium heat transfer units, the efficiency of the boiler is improved by more than 6%, energy and gas are saved, and the shortage of natural gas is alleviated.

Owner:XI AN JIAOTONG UNIV

Ultra-low-nitrogen combustion equipment with post-premixing cold flame combustion coupling matrix tube mode wall structure

ActiveCN112815312AGuaranteed stabilityReduce the temperatureGaseous fuel burnerCombustion chamberAir volume

The invention relates to ultra-low-nitrogen combustion equipment with a post-premixing cold flame combustion coupling matrix tube mode wall structure. The ultra-low-nitrogen combustion equipment comprises a fuel gas regulation and control device, an air volume regulation and control device, an air-gas mixing device, a cold flame combustion device, a matrix tube and mode wall device and a comprehensive controller. The fuel gas regulation and control device provides fuel gas for the air-gas mixing device; the air volume regulation and control device provides combustion-supporting air for the air-gas mixing device; the air-gas mixing device conducts jet flow mixing on combustible gas provided by the fuel gas regulation and control device and the combustion-supporting air provided by the air volume regulation and control device, and the combustible gas and the combustion-supporting air are evenly mixed through the air-gas mixing device and then injected into the cold flame combustion device; the mixed gas sequentially passes through a double-layer rectifying plate, a hexagonal heat pipe type cooling fire-retardant tube nest and a flame cooling tube nest in the cold flame combustion device and then enters a combustion chamber for combustion; and after combustion, high-temperature flue gas is subjected to radiation and convective heat exchange in the combustion chamber, then exchanges heat with a medium in the matrix tube and mode wall device and then is discharged into a flue.

Owner:BEIJING BOOSTER BOILER

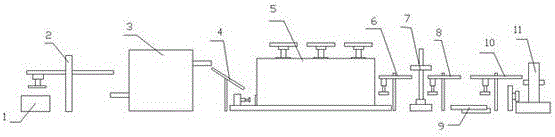

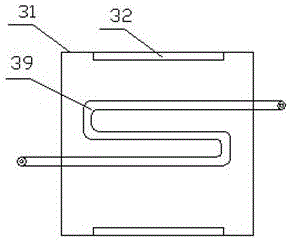

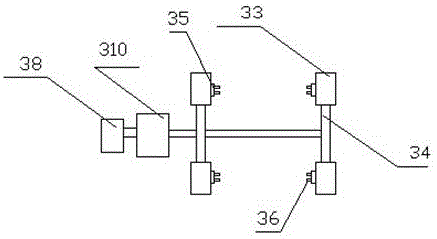

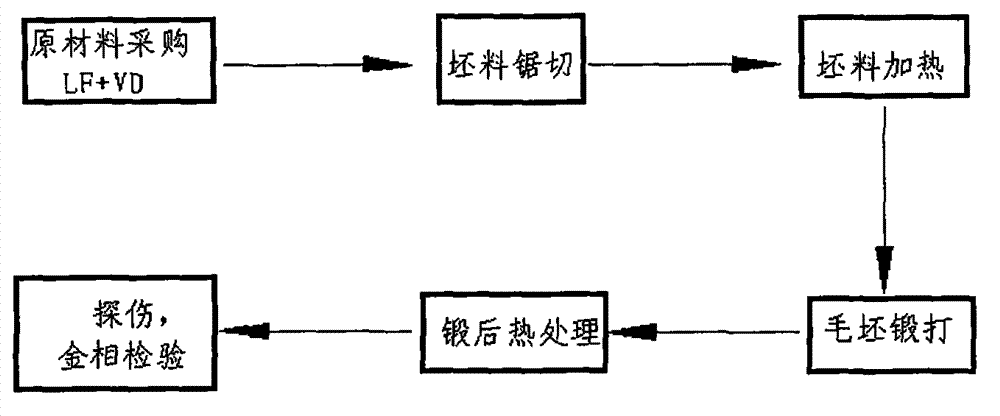

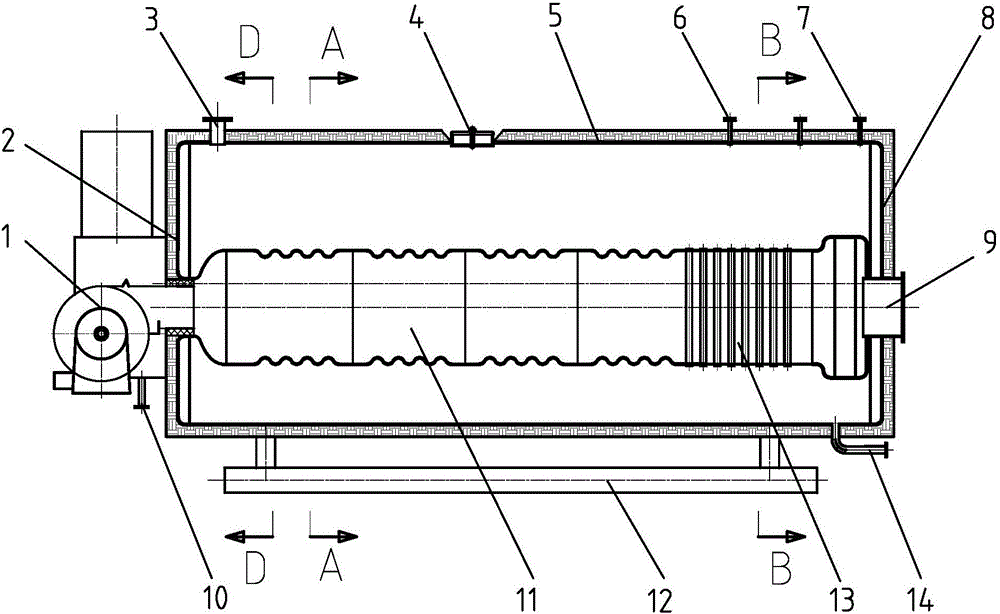

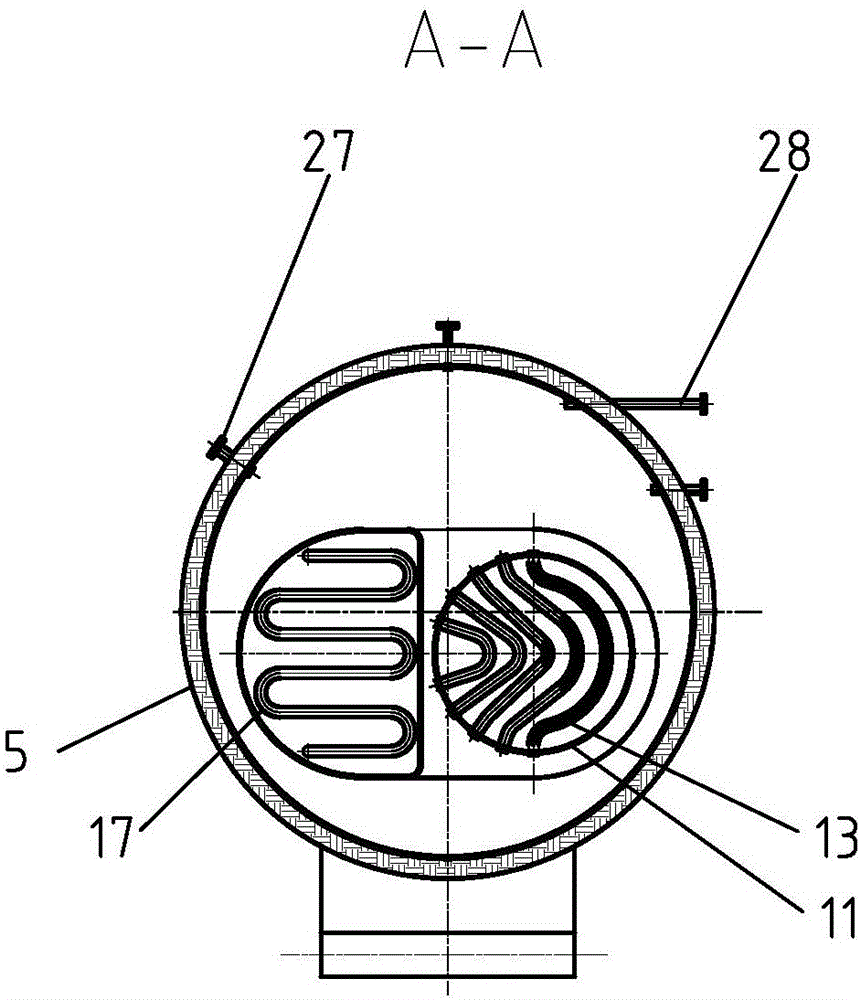

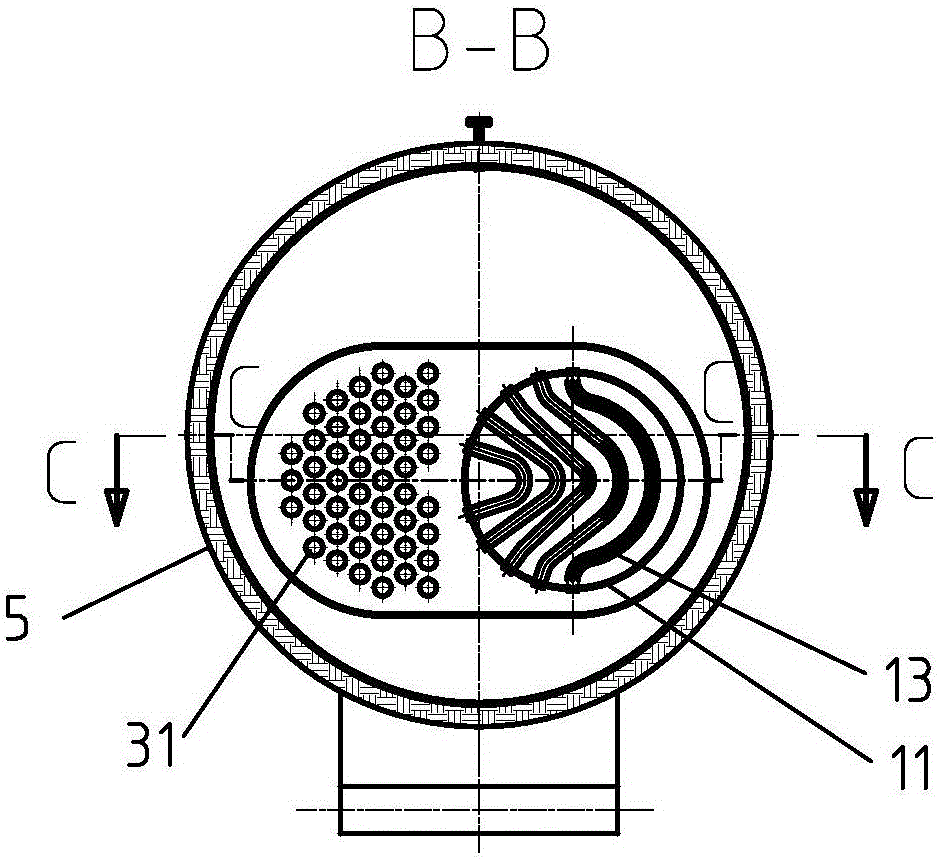

Turbine blade molding line

ActiveCN106334778ARealize continuous moldingPhysical health effectsPower hammersHammer drivesComing outSteam turbine blade

The invention discloses a turbine blade molding line which includes a roughcast warehouse, a conveyer, a heating furnace, a blank forging machine, a blade forming machine, ingot stripper and edge-trimming machine; a conveying swash plate is installed between the said heating furnace and blank forging machine to convey by conveyor; the ingot stripper stripes the mould; blade after the de-molding is transported to edge-trimming machine for end trimming; the said heating furnace includes shell, heater element and sigmoid curve conveying mechanism; and both ends of the sigmoid curve conveying mechanism come out from the shell, and heater element is arranged inside of the shell, and sigmoid curve conveying mechanism is located between heater elements. The invention can realize a continuous molding of turbine blades, which improves molding efficiency, and the blank is heated evenly.

Owner:德阳瑞能电力科技有限公司

Combustion heat recovery device for combustible exhaust gas of carbonized oven

InactiveCN107270308AAvoid pollutionSave heating energyWater heatersIncinerator apparatusWaste heat recovery unitHeat conducting

The invention discloses a combustion heat recovery device for combustible exhaust gas of a carbonized oven. The device comprises a waste heat recovery cavity and a waste heat recovery pipe which passes through the waste heat recovery cavity. A combustion port and a combustion product exhaust port are formed in the waste heat recovery cavity. A heat-conducting medium flows in the waste heat recovery pipe. The combustion heat recovery device for combustible exhaust gas of the carbonized oven of the structure has the advantages of being simple to operate, convenient to use and good in heat recovery effect, and the comprehensive energy consumption in a production process is greatly reduced.

Owner:CENT SOUTH UNIV

Novel circulating fluidized bed boiler

InactiveCN102818261AMeet heat load requirementsReduce heating surfaceFluidized bed combustionApparatus for fluidised bed combustionCombustionFlue gas

The invention relates to a novel circulating fluidized bed boiler. The novel circulating fluidized bed boiler comprises a hearth, a cyclone separator, a steaming heating surface, a tail shaft well, a flue gas outlet, an air distributor and a deslagging pipe. The steaming heating surface is mainly installed on an outer part of the hearth. A water cooling wall is not used in the hearth. The novel circulating fluidized bed boiler reduces a heating area in a fluidized bed zone, forms a high-temperature zone needed by combustion, increases a heating area in other zones, realizes full combustion of coal gangue or high-quality coal having a calorific value above 850 kilocalories per kilogram, and produces enough heat.

Owner:湖南乾能新能源科技开发有限公司

Forging process for improving metallographic tissue of gear piece billet

The invention discloses a forging process for improving the metallographic tissue of a gear piece billet; the process comprises the following steps that the billet is selected and a riser which is 30 percent of a total raw material is cut off; the billet is heated; then the billet is put into a forge press to be forged; during a whole forging process, according to the crystal segregation characteristics of each billet, force is applied in a direction vertical to the crystallization direction of the billet when the billet is hammered; limit broadening forging is carried out during the forging process, deformation is carried out within a limited extent in a direction during the forging, and the ratio of the residual thickness after pressing to the width after pressing of the limit broadening forging is 0.4; in the last time of heating during the forging, the final finish forging temperature is controlled on the premise of ensuring enough rest forging ratio; diffusion treatment for hydrogen and annealing are carried out on a forged and formed work piece; preparing heat treatment high-temperature positive tempering is carried out no the work piece which is subjected to diffusion treatment for hydrogen and annealing treatment after cooling; and the tempered work piece is detected. The metallographic tissue of the gear billet which is prepared through the forging process is more ideal.

Owner:JIANGYIN NANGONG FORGING

Water-fire tube gas-steam boiler with built-in condenser

InactiveCN106500318ASmall diameterCompact structureAir heatersSustainable buildingsBoiler furnaceCombustor

The invention provides a water-fire tube gas-steam boiler with a built-in condenser, and relates to a gas-steam boiler. An existing smoke-fire tube steam boiler has the problems that the structure occupies large floor area, potential safety hazards exist in the operation process, and steel consumption is high in the using process. The water-fire tube gas-steam boiler comprises a combustor, a steam tube base, a shell, a boiler furnace, a smoke tube assembly, a backdraft chamber, a condensation chamber and a smoke box; the boiler furnace, the smoke tube assembly, the backdraft chamber and the condensation chamber are all arranged in the shell, the combustor is arranged outside the shell and communicates with an inlet of the boiler furnace, an outlet of the boiler furnace communicates with an inlet of the backdraft chamber, an outlet of the backdraft chamber communicates with an inlet of the smoke tube assembly, an outlet of the smoke tube assembly communicates with an inlet of the condensation chamber, the smoke box is arranged outside the shell and communicates with an outlet of the condensation chamber, a smoke outlet is formed in the smoke box, multiple convection banks are arranged in the boiler furnace, condensation tube bundles are arranged in the condensation chamber, and the shell communicates with the steam pipe tube base. The water-fire tube gas-steam boiler is used for generating steam.

Owner:HARBIN INST OF TECH

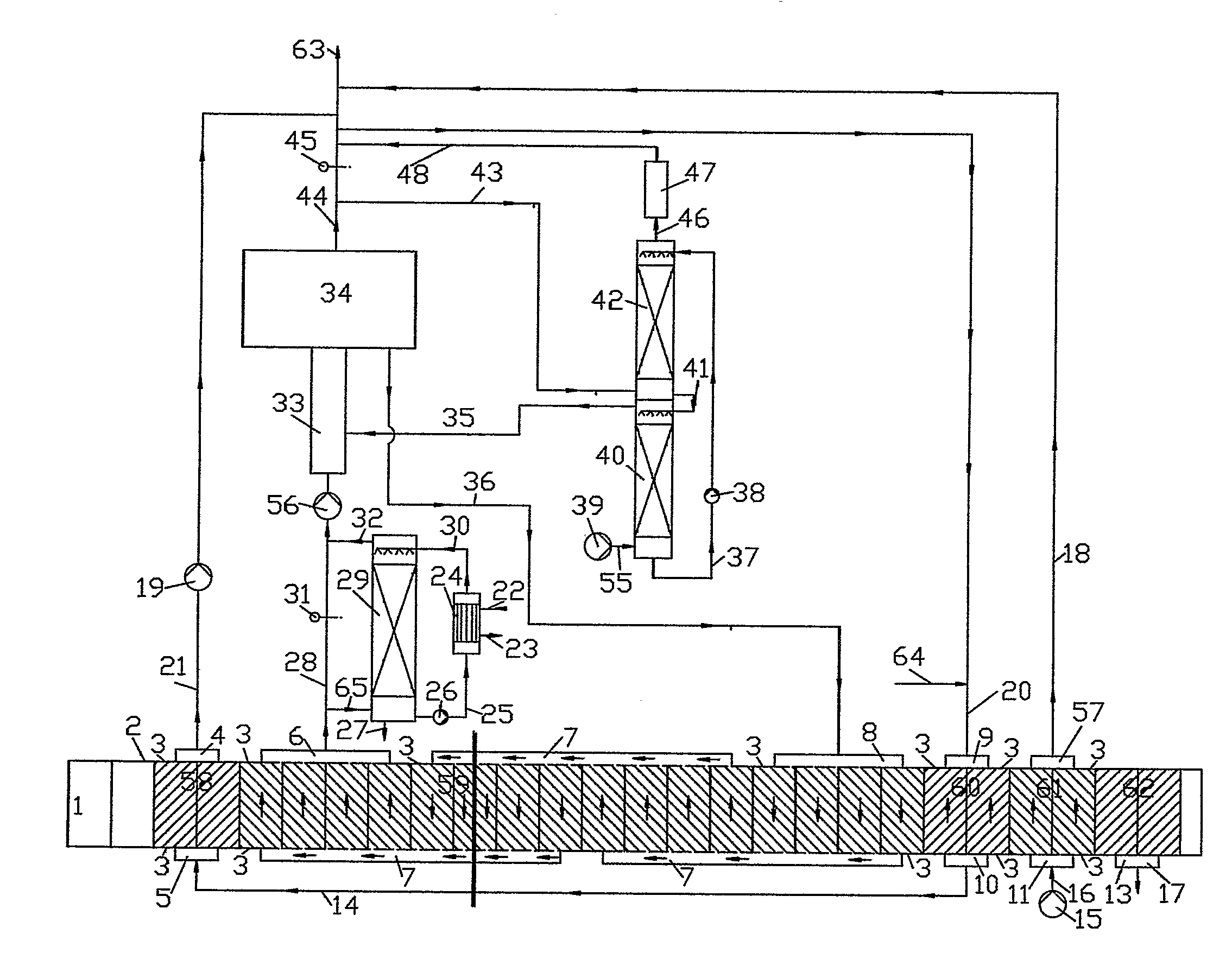

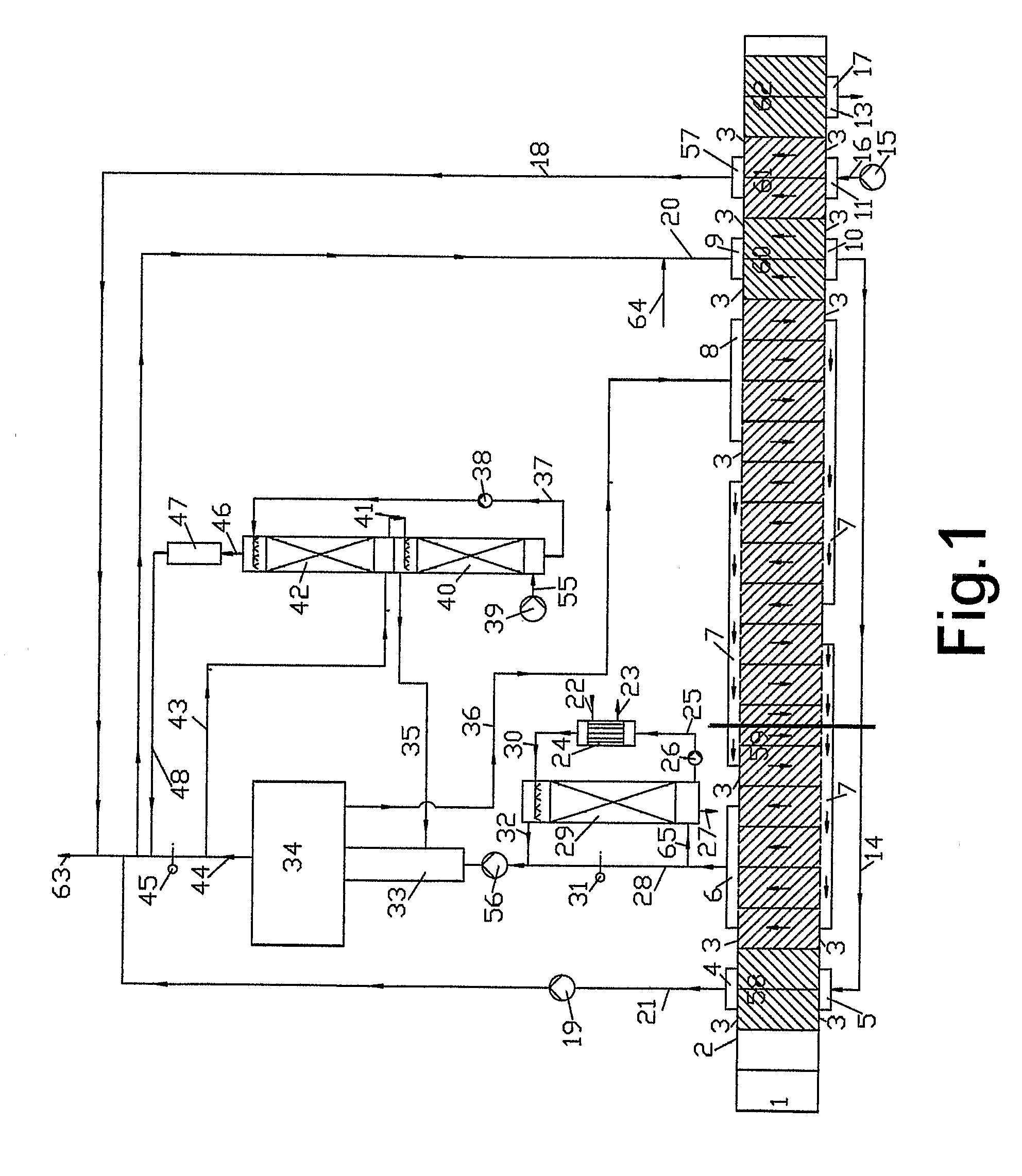

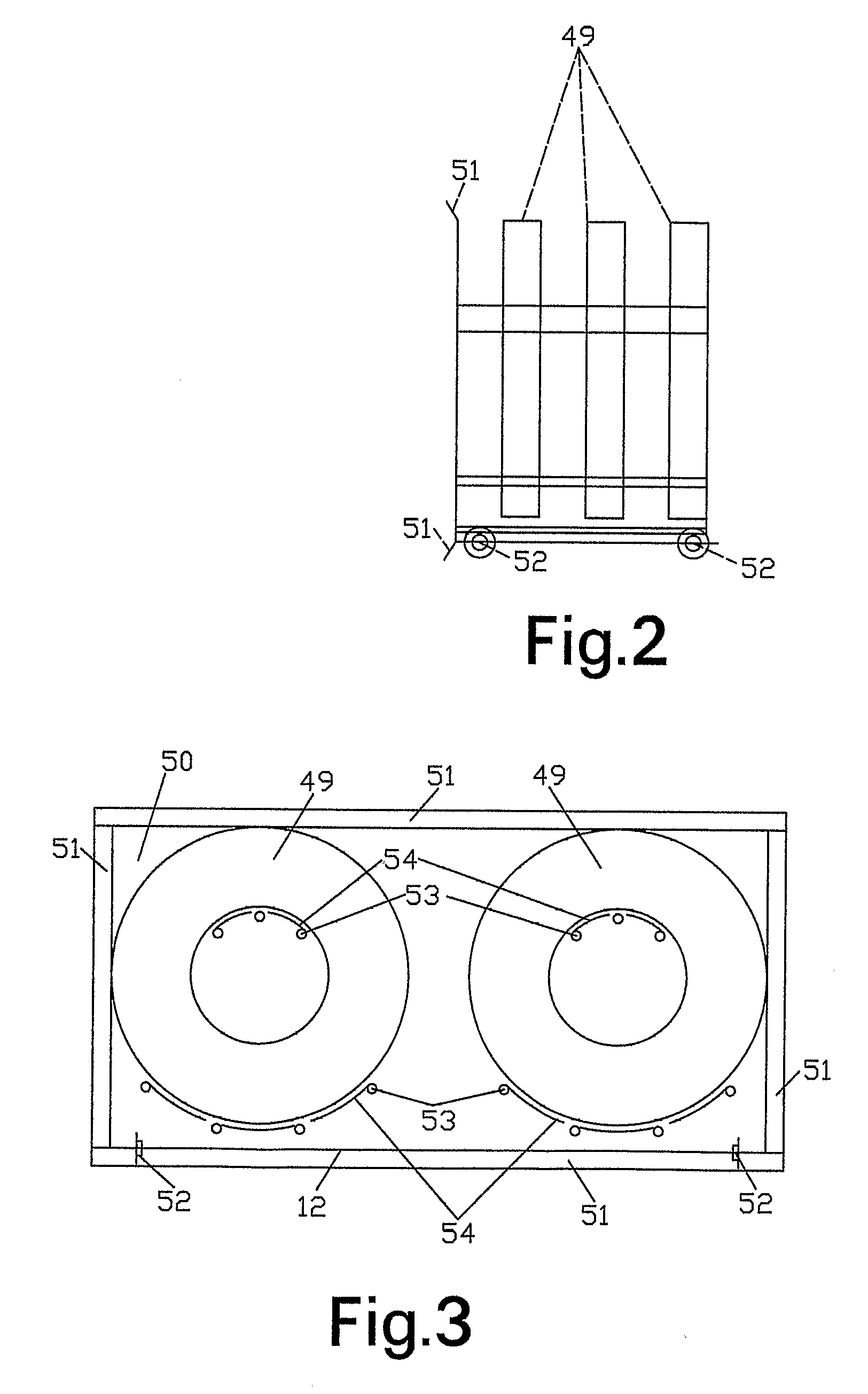

Method and Installation for Pyrolisis of Tires

InactiveUS20080202913A1Reduce energy expenseReduce harmful effectsPigmenting treatmentDirect heating destructive distillationThermal energyAtmospheric air

The present invention relates to a method and apparatus for waste tyres pyrolysis wherein whole tyres are directly heated with flue gases from the combustion of pyrolysis gases, in a tunnel type furnace. The process produces thermal energy, carbon black and mineral oil; the cooled flue gases are cleaned from sulfur oxides before released into the atmosphere.

Owner:KOLEV DIMITAR NIKOLAEV +2

Clothes drier

InactiveCN108035130AEvenly heatedIncrease the heating surfaceTextiles and paperLaundry driersInfrared lampProcess engineering

The invention discloses a clothes drier. The drier comprises a drier housing, an inner cavity and a clothes hanging frame, a drier machine cover is arranged on the top of the drier housing, and an operation panel is arranged on the surface of the drier machine cover; an air-heater is arranged between the drier housing and the inner cavity, and an air inlet is formed in the upper portion of the inner cavity; an infrared heating module is arranged at the bottom of the inner cavity; the clothes hanging frame comprises a central rotary shaft, a plurality of clothes hanging rods and a clothes placing round plate, and the central rotary shaft is connected with a rotating driving motor; a single-chip computer is arranged between the drier housing and the inner cavity, a timer module is arranged in the single-chip computer, and power switches of the air-heater and the infrared heating module are connected with the single-chip computer. According to the clothes drier, hot wind and infrared lamps are used for heating from different angles, so that clothes are uniformly heated to improve the drying efficiency; the clothes hanging frame is provided with the clothes hanging rods and the clothesplacing round plate, and the clothes are hung on the clothes hanging rods or placed smoothly on the clothes placing round plate to increase heated surfaces of the clothes and accelerate the drying speed.

Owner:SUZHOU JIANZHEN UNION TECH CO LTD

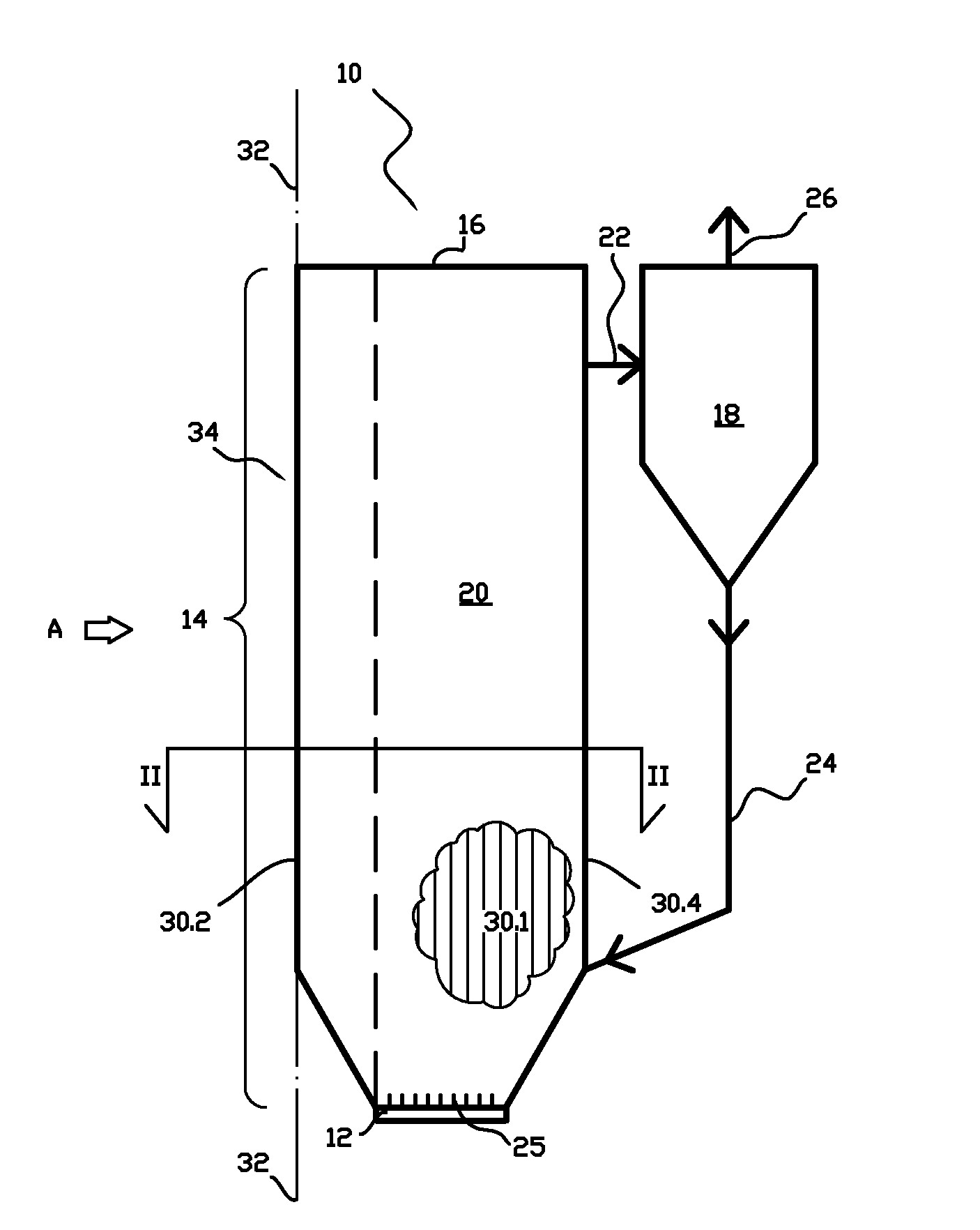

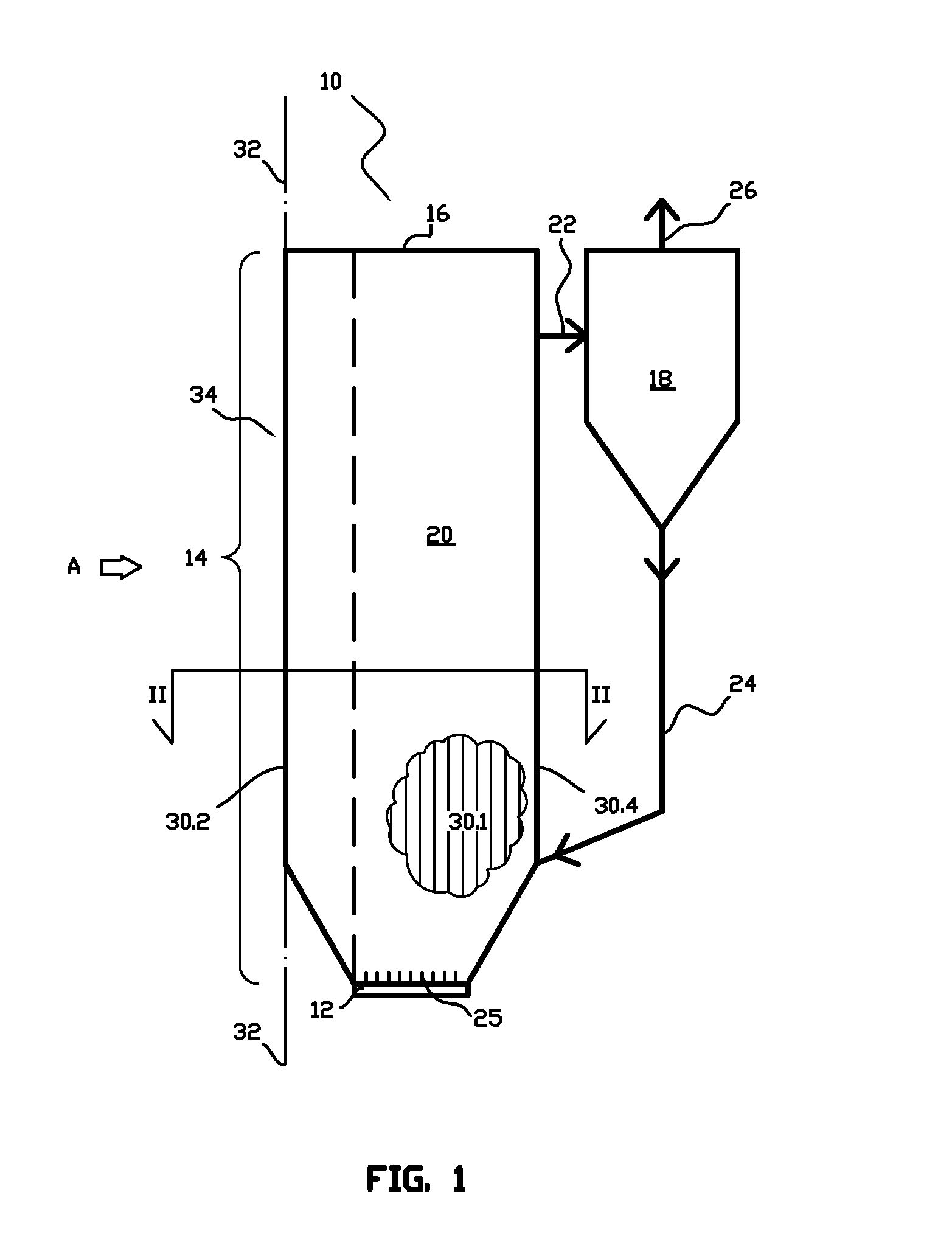

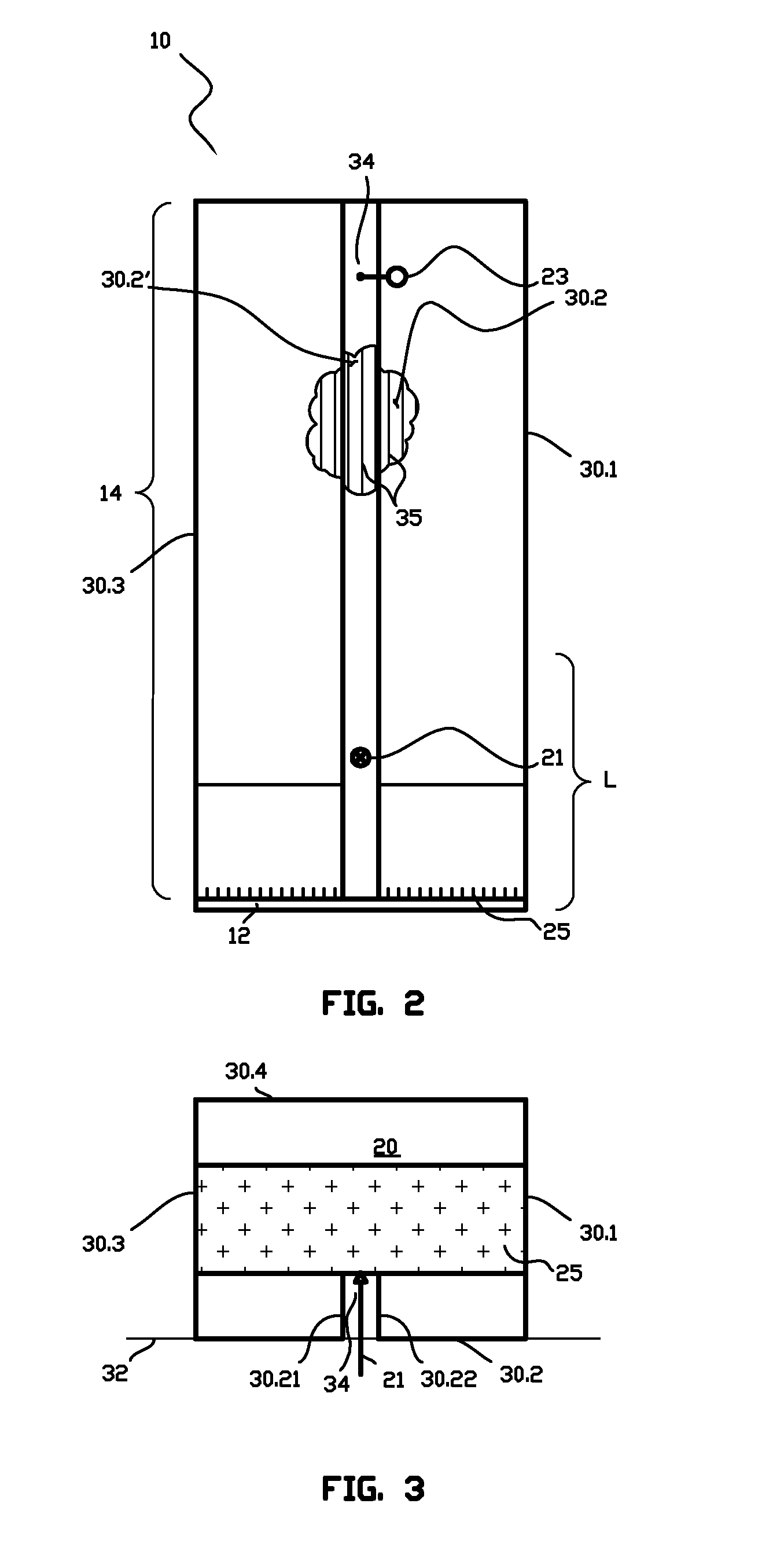

Fluidized Bed Reactor

ActiveUS20120134882A1Large and high-efficiency boilerEasy to manufactureFluidized bed combustionSamplingEngineeringFluidized bed

A fluidized bed reactor includes a bottom portion, a roof portion and side walls vertically extending between the bottom portion and the roof portion, forming a reaction chamber of the fluidized bed reactor. A solids separator is in connection with the reaction chamber. At least one side wall of the reaction chamber forms at least one indentation in the reaction chamber, which indentation is substantially vertical and extends from the plane of the side wall towards the reaction chamber.

Owner:FOSTER WHEELER ENERGIA OY

Popular searches

Brought out in time Safe and stable operation Avoid Burst Accidents Guaranteed uptime Ensure continuous and efficient operation Safe and reliable long-term operation Guaranteed long-term stable operation Emission reduction Achieve energy saving and emission reduction Realize low-carbon environmental protection

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com