Fast molten salt furnace

A molten salt furnace and fast technology, applied in the field of aluminum alloy casting, can solve the problems of labor consumption, power consumption and high cost, and achieve the effects of increasing the heating surface, saving costs, and facilitating reversal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

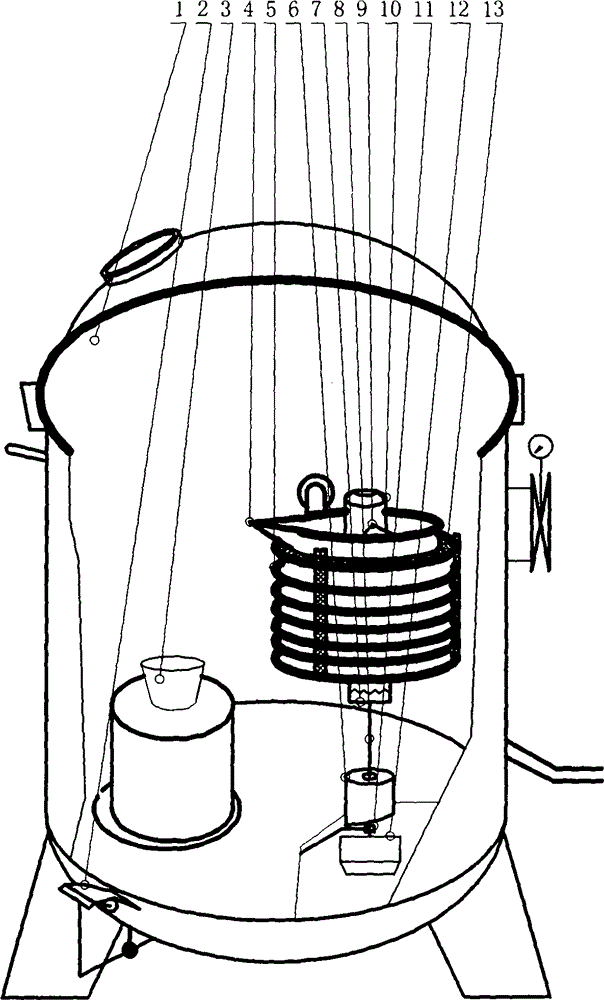

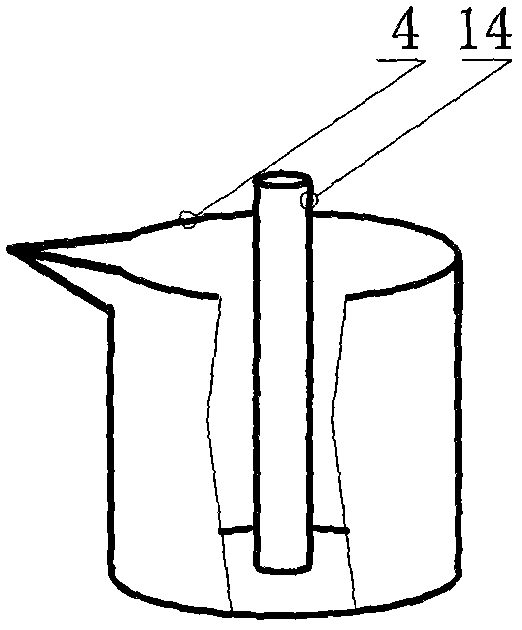

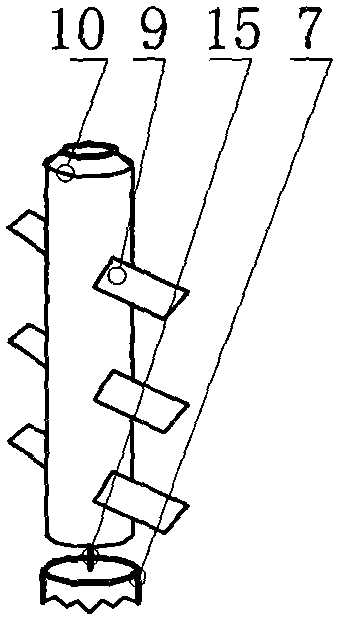

[0016] figure 1 , figure 2 , image 3 Including vacuum furnace shell 1, pedal 2, salt core mold 3, alloy crucible 4, induction heating ring 5, sealing sleeve 6, clutch 7, joint shaft 8, stirring blade 9, stirring sleeve 10, telescopic sleeve 11, Stirring motor 12, heat insulation cover 13, crucible core 14, etc.

[0017] figure 1 As shown, a fast molten salt furnace of the present invention is characterized in that it includes a vacuum mechanism, a melting mechanism, a stirring mechanism, and a control mechanism.

[0018] The vacuum mechanism includes a vacuum furnace shell 1, a salt core mold 3, and a sealing sleeve 6; the melting mechanism and the salt core mold 3 are arranged in the vacuum furnace shell 1; There is a stirring mechanism, and a control mechanism is arranged under the vacuum furnace shell 1 .

[0019] The melting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com