Oxygen-enriched combustion boiler system for circulating fluidized bed

A technology of circulating fluidized bed and oxygen-enriched combustion, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc. It can solve the problems of declining economic efficiency, restricting commercial applications, and increasing boiler island investment and operating costs and other issues, to achieve the effect of reducing initial investment and operating costs, saving denitrification costs, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

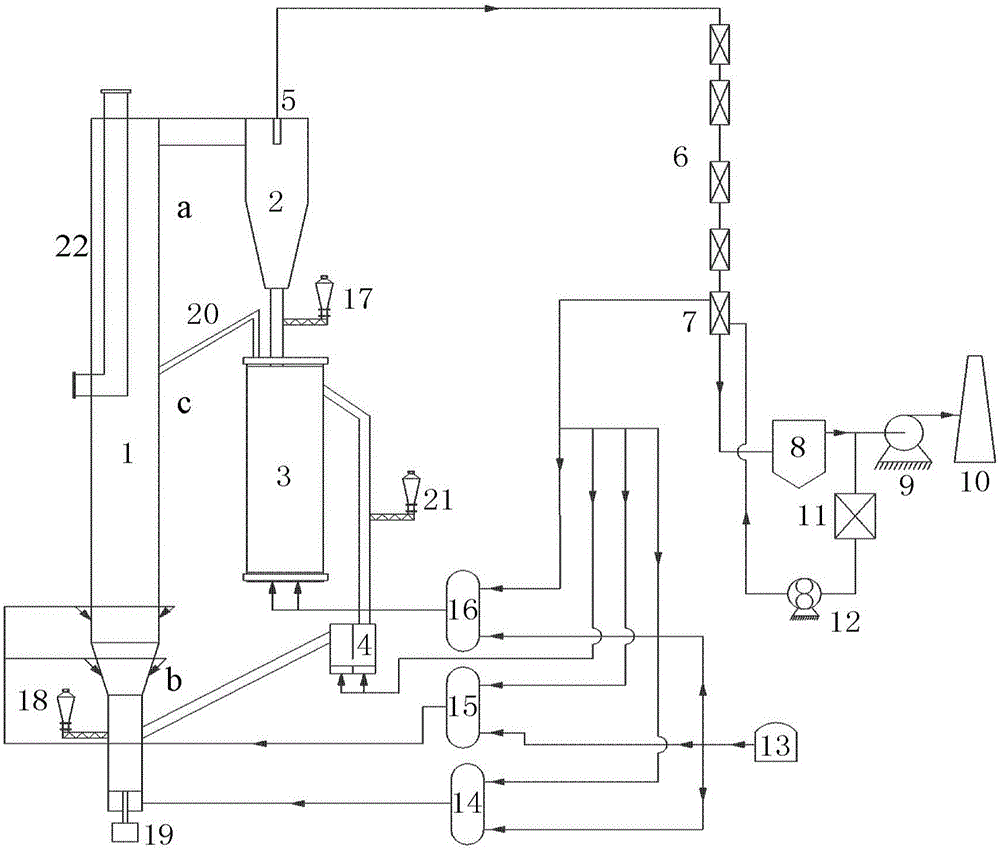

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. The drawings accompanying this description are simplified and used for illustration purposes. The number, shape and size of the components shown in the drawings can be modified according to the actual situation, and the configuration of the components may be more complicated. Other aspects of practice or application can also be carried out in the present invention, and various changes and adjustments can be made without departing from the defined spirit and scope of the present invention.

[0029] According to the basic idea of the present invention, to overcome the disadvantages of poor economic efficiency of the existing oxygen-enriched combustion technology, a circulating fluidized bed oxygen-enriched combustion boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com