Patents

Literature

196results about How to "Reduce the cost of denitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

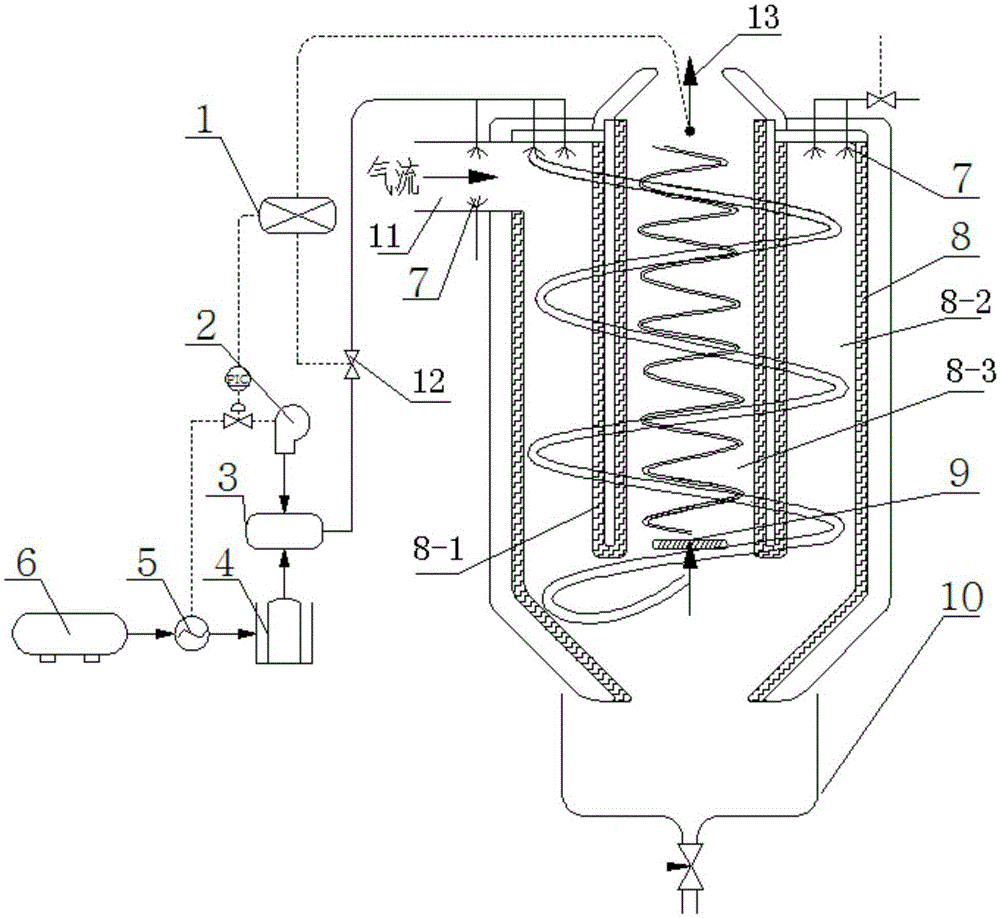

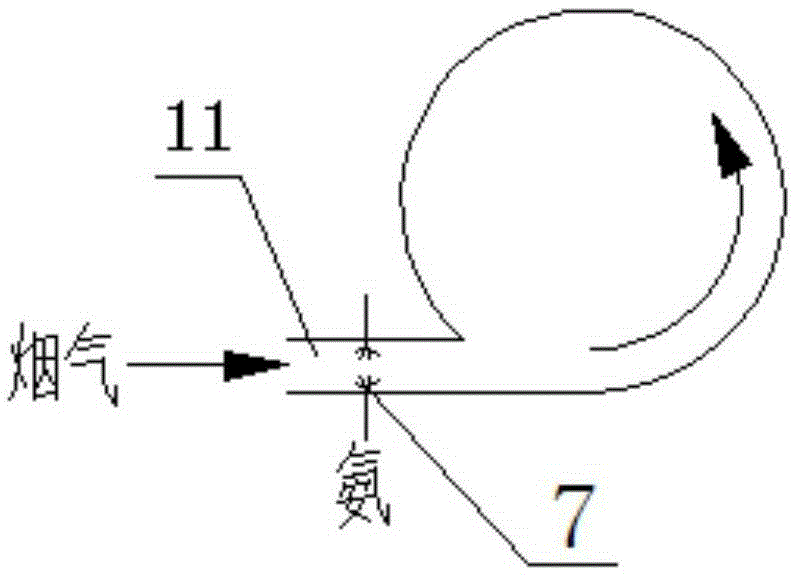

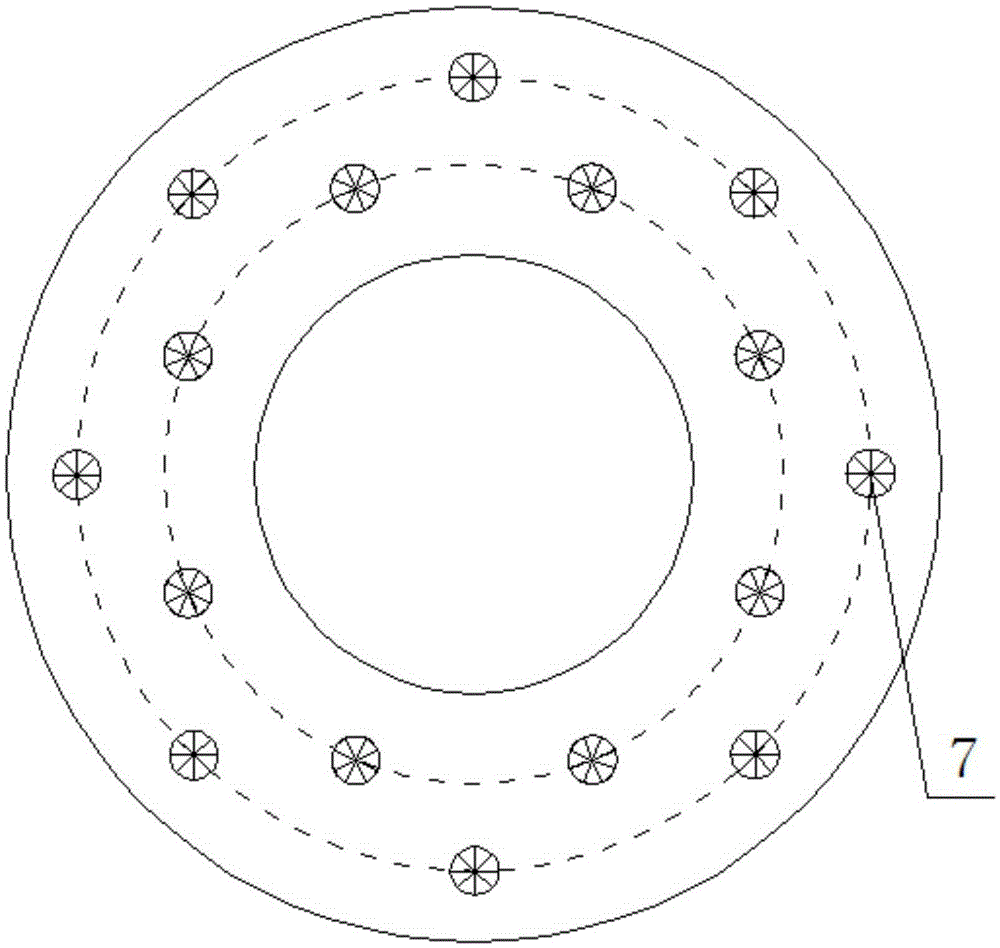

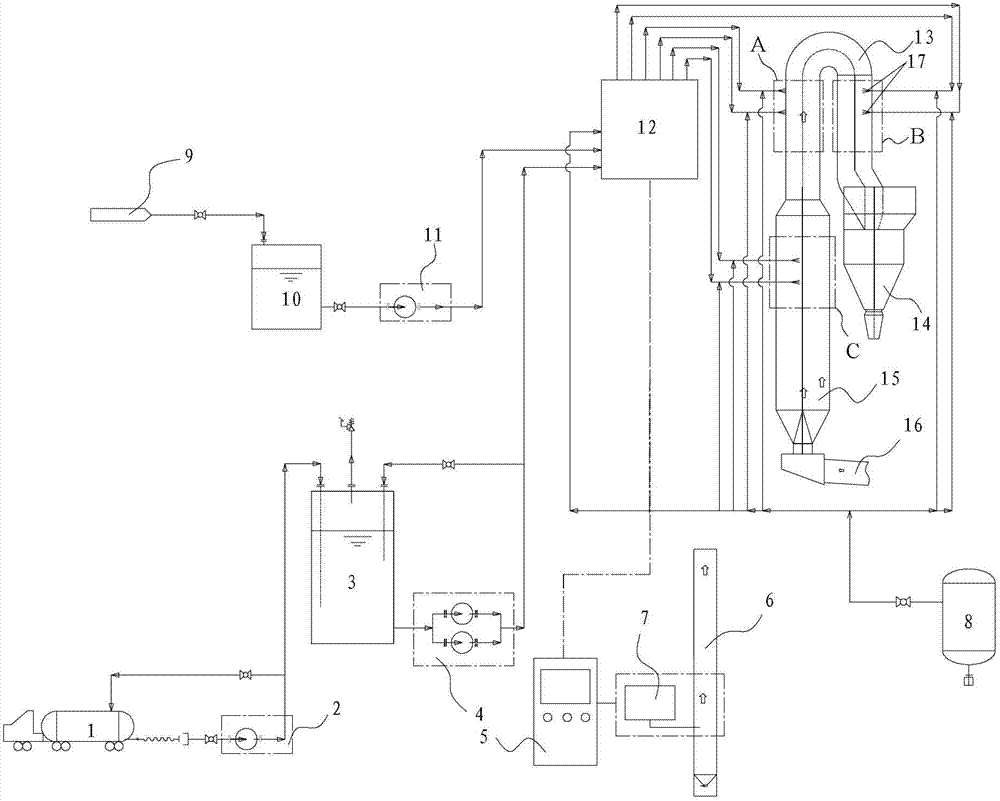

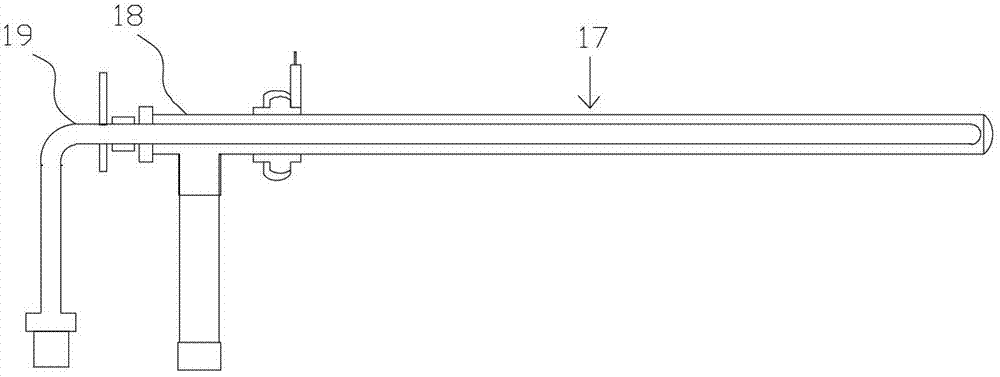

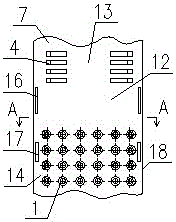

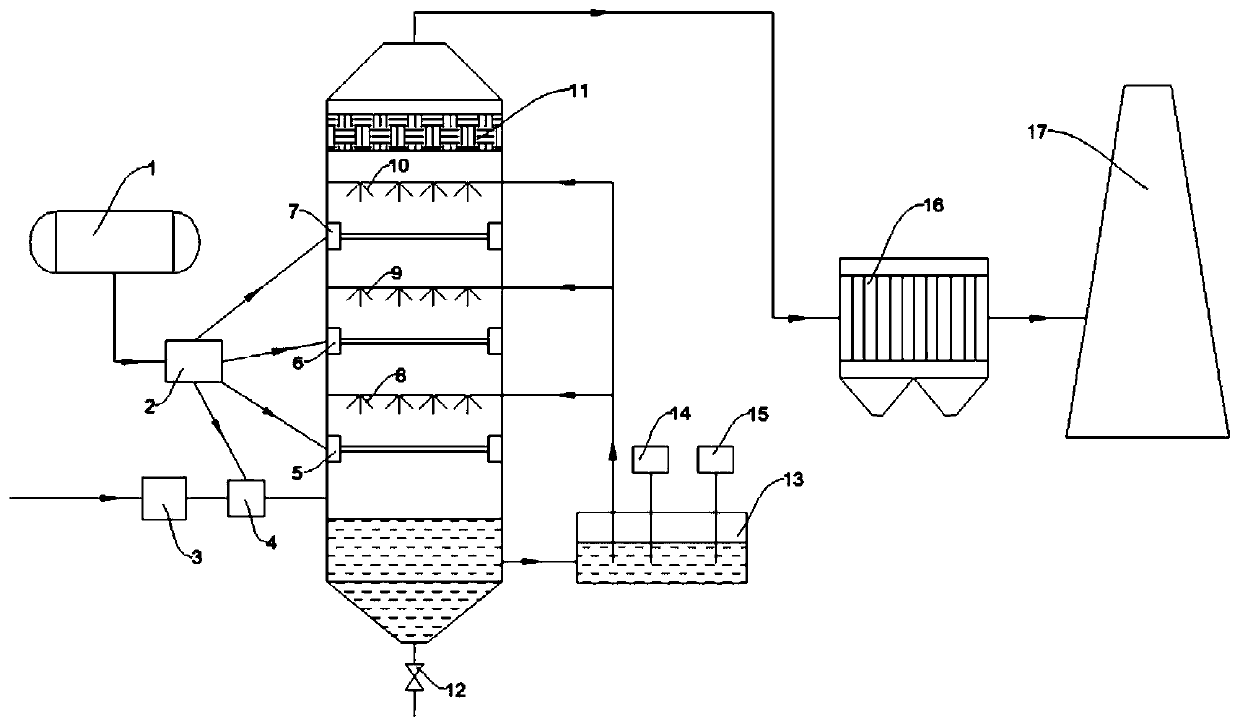

Double-rotation SCR denitration method and apparatus thereof

ActiveCN105289301AImprove denitrification efficiencyIncrease contact timeDispersed particle separationCycloneFlue gas

The invention discloses a double-rotation SCR denitration method and an apparatus thereof. According to the invention, a first eddy flow catalytic reaction chamber and a second eddy flow catalytic reaction chamber are arranged along a denitrating tower body; a flue gas introduction pipeline is arranged on a sidewall of the denitrating tower body; several eddy flow atomizing nozzles are respectively arranged on inner periphery of the flue gas introduction pipeline and the inner periphery at top of the first eddy flow catalytic reaction chamber; when flue gas is introduced into the flue gas introduction pipeline, the flue gas and ammonia gas injected by the eddy flow atomizing nozzle are mixed, and a mixture enables spiral sinking along circumference of the first eddy flow catalytic reaction chamber from up to down in a tangent circle mode, under effect of a cyclone, and then the mixture enable spiral rise along circumference of the second eddy flow catalytic reaction chamber from down to up in the tangent circle mode. Under prerequisite that high efficiency denitration is ensured, catalyst amount is less, operation of technical means is simple and easy, compared with the prior art, a denitrating tower structure is simple, cost of the apparatus is low, denitration efficiency is high, energy consumption is low, escapement ratio of ammonia is reduced, denitration cost is greatly reduced, and economic benefit is obviously increased.

Owner:SOUTH CHINA UNIV OF TECH

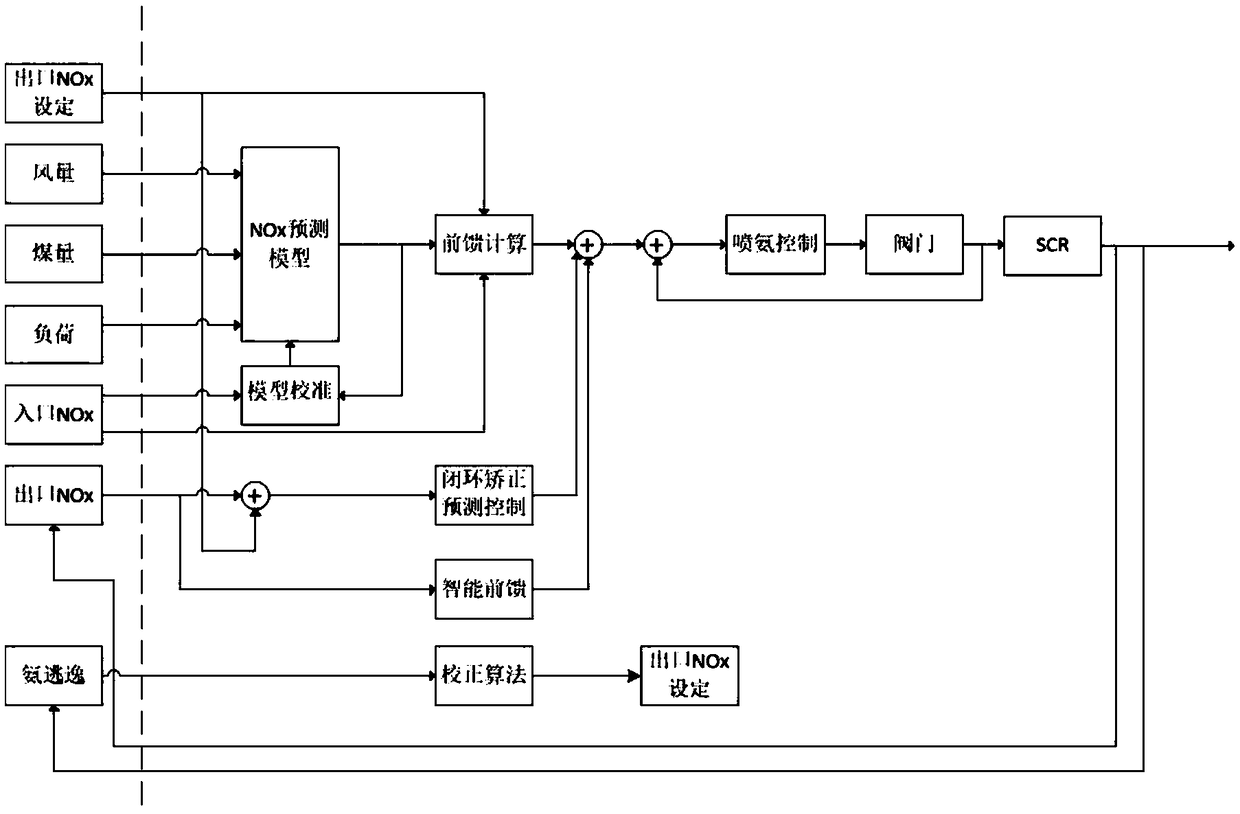

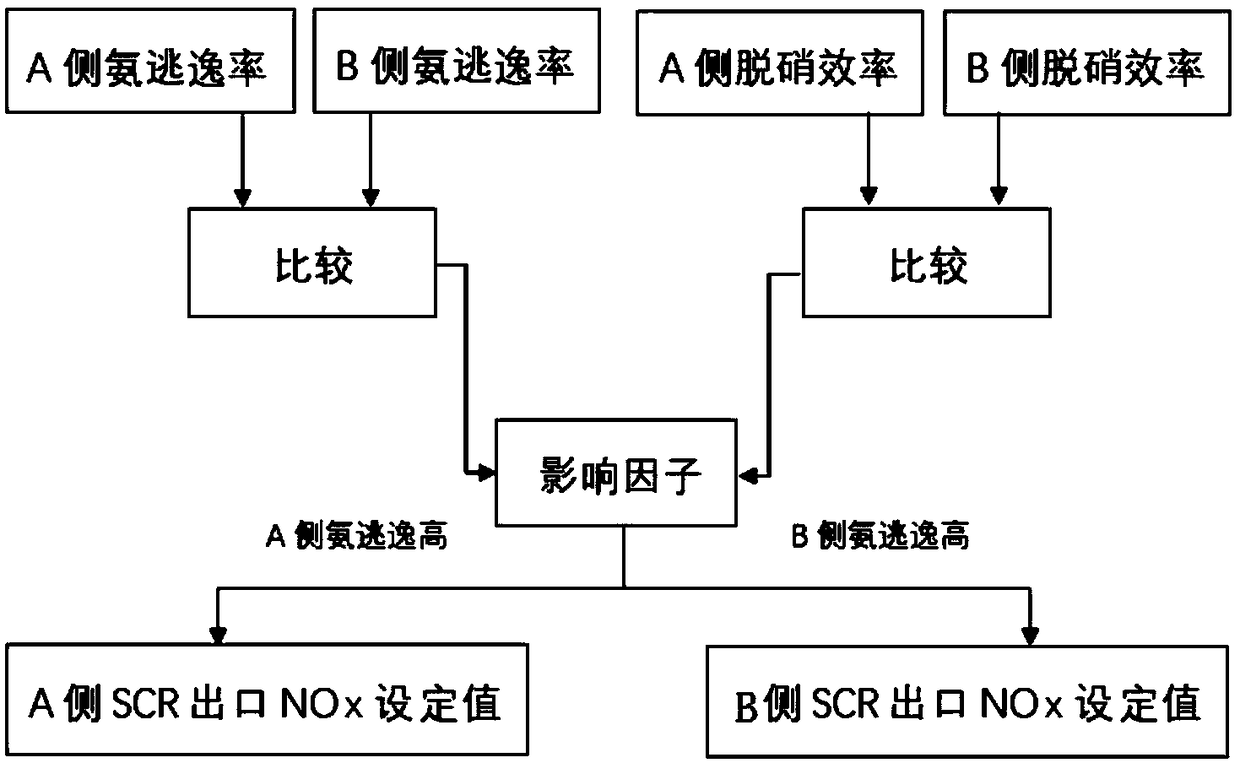

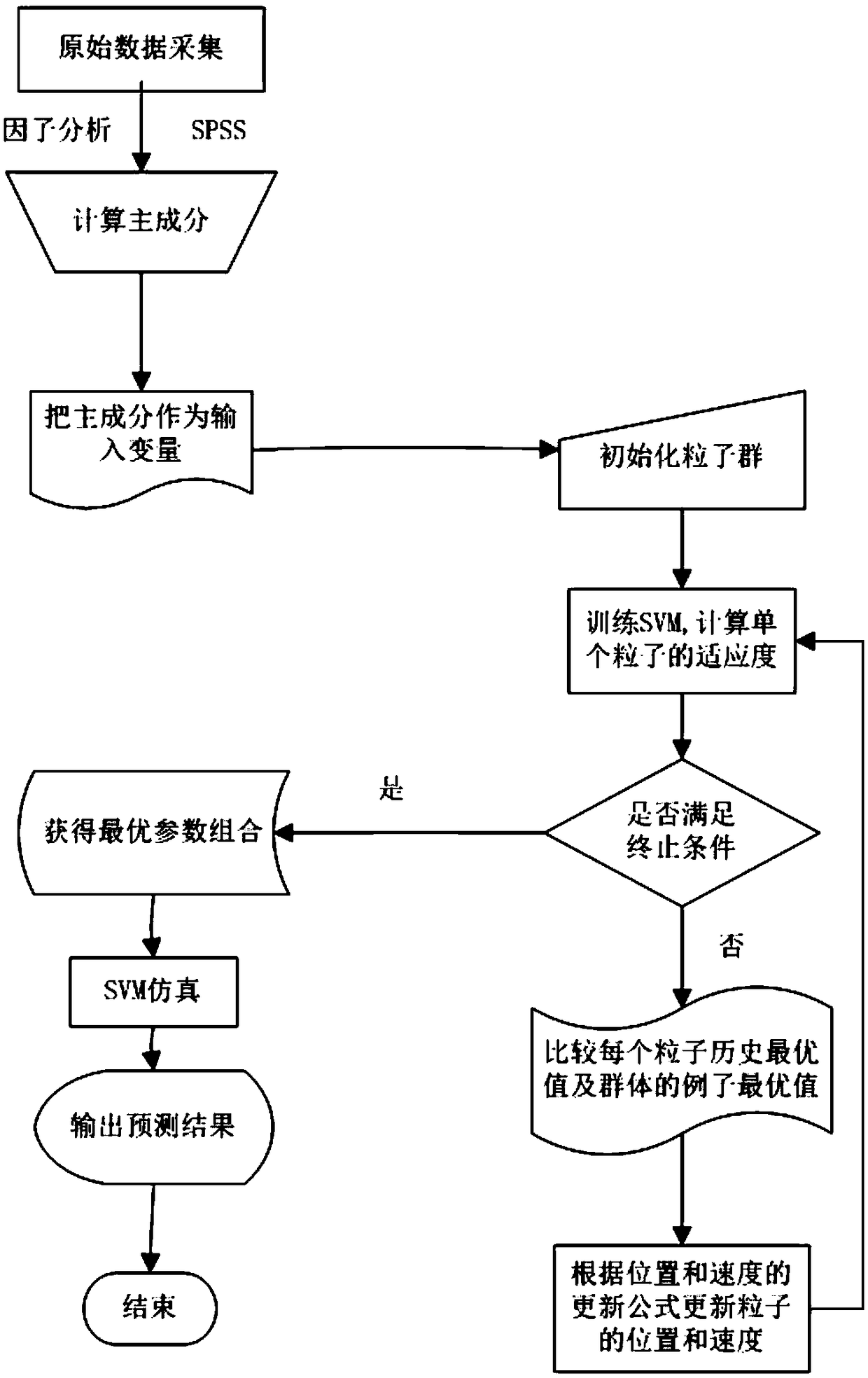

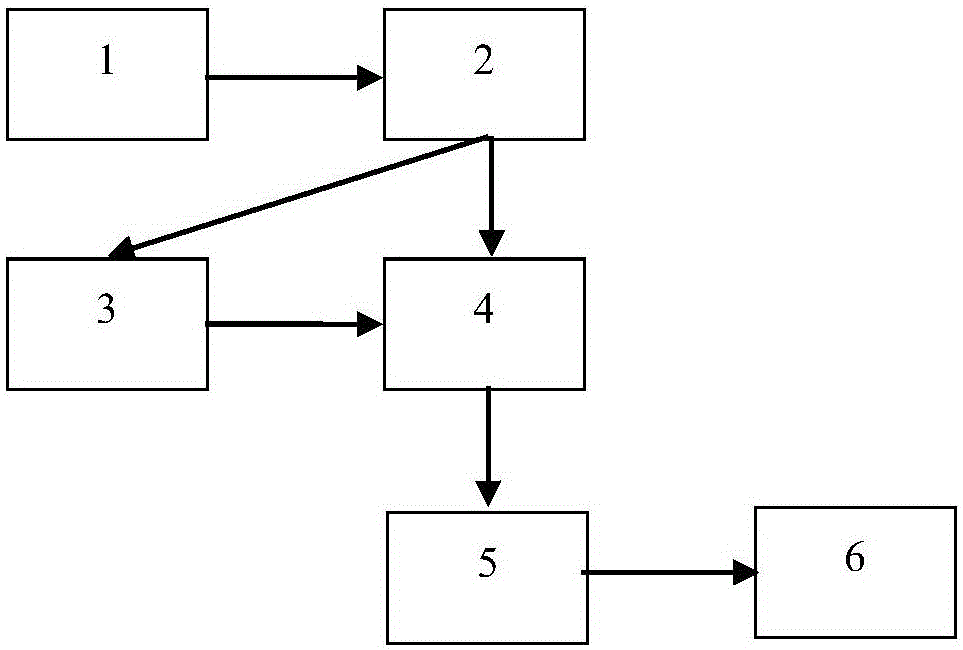

Denitration ammonia spraying control method based on multi-variable correction

ActiveCN109062053AReduce volatilityReduce excess spaceDispersed particle separationAdaptive controlAmmoniaComputer science

The invention relates to a denitration ammonia spraying control method based on multi-variable correction, belongs to the technical field of ammonia spraying control of a denitration system of a thermal power generating set, and solves the problem that NOx fluctuation in an outlet of an SCR system in the prior art is severe. The method comprises the steps of acquiring measurement data and workingcondition information of a denitration system instrument in real time; constructing a NOx content prediction model at the inlet of the SCR denitration system, and predicting the NOx content at the inlet of the SCR system at the current moment; and carrying out ammonia spraying amount feedforward control and prediction correction on the basis of the predicted NOx content at the inlet of the SCR system and the measured data, generating an ammonia spraying amount control instruction at the current moment, controlling an ammonia spraying adjusting valve and adjusting the ammonia spraying amount. According to the method, the NOx content precision prediction model of the SCR inlet denitration system and the intelligent feedforward control method are adopted, so that NOx fluctuation at the outletof the SCR denitration system and space deviation are greatly reduced under the premise that smoke NOx emission satisfies the environmental protection index, the average value of the outlet NOx is increased, the ammonia spraying amount is reduced, the ammonia escape level is reduced, and the denitration cost is lowered.

Owner:JIANGSU GUOXIN JINGJIANG POWER GENERATION CO LTD +1

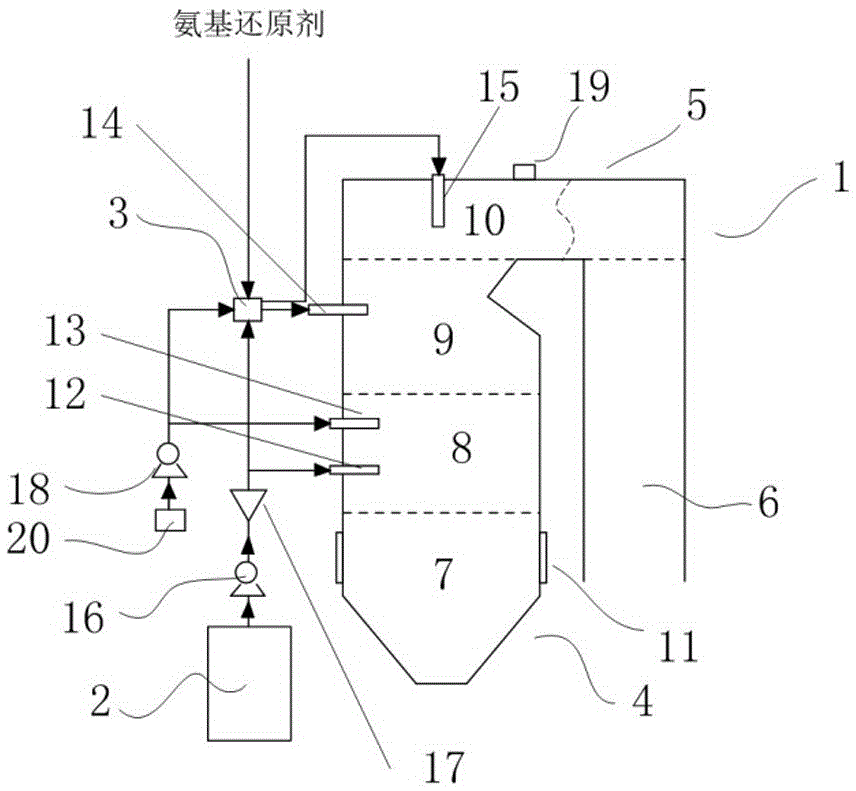

Method and device for controlling NOx concentration in smoke gas of cement kiln

ActiveCN102921284AIncrease profitReduce consumptionDispersed particle separationMulti siteMonitoring system

The invention discloses a method and device for controlling NOx concentration in smoke gas of a cement kiln; the device comprises a decomposing kiln, a preheater and a reducing agent supply device, wherein the bottom of the decomposing kiln is communicated with a kiln tail chimney of the cement kiln by an inlet smoke flue; the top of the decomposing kiln is communicated with the preheater by an outlet smoke flue; a plurality of spray guns communicated with the reducing agent supply devices are arranged at or / or in the middle upper part of the decomposing kiln or / and the outlet smoke flue in a layered way; and the device further comprises a central controller and a smoke gas automatic monitoring system, wherein the central controller is connected to the reducing agent supply devices; and the smoke gas automatic monitoring system is used for monitoring NOx concentration and smoke gas flow information in the kiln tail chimney and transmitting the NOx concentration and smoke gas flow information to the central controller. According to the invention, as a reducing agent is sprayed into the decomposing kiln through multi-site combined control, high removal rate of the NOx can be achieved without an SNCR (Selective Non Catalytic Reduction) and SCR (Selective Catalytic Reduction) combined technology.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

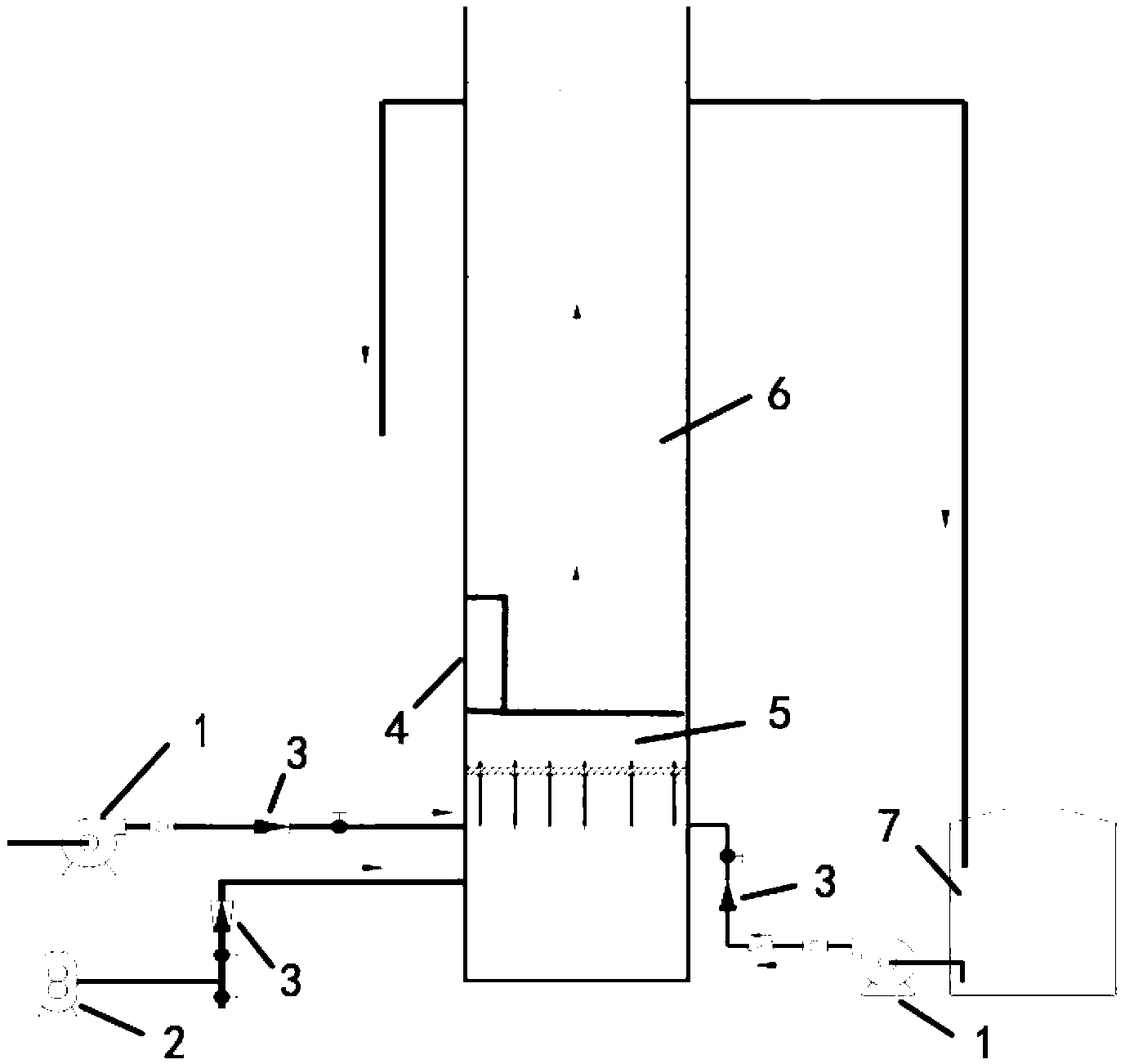

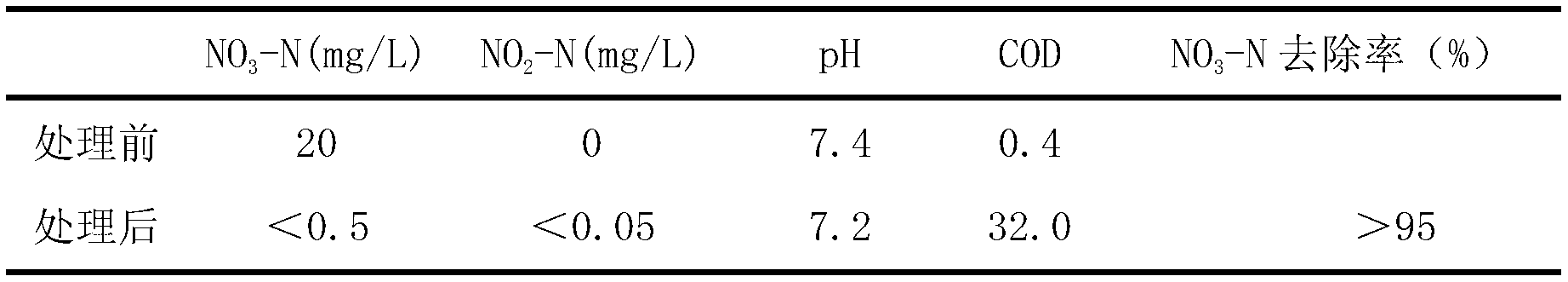

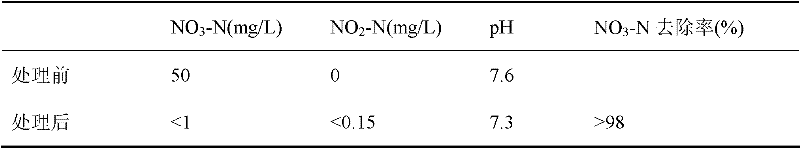

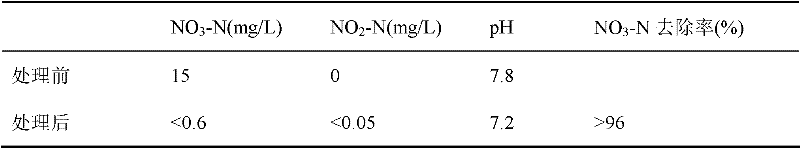

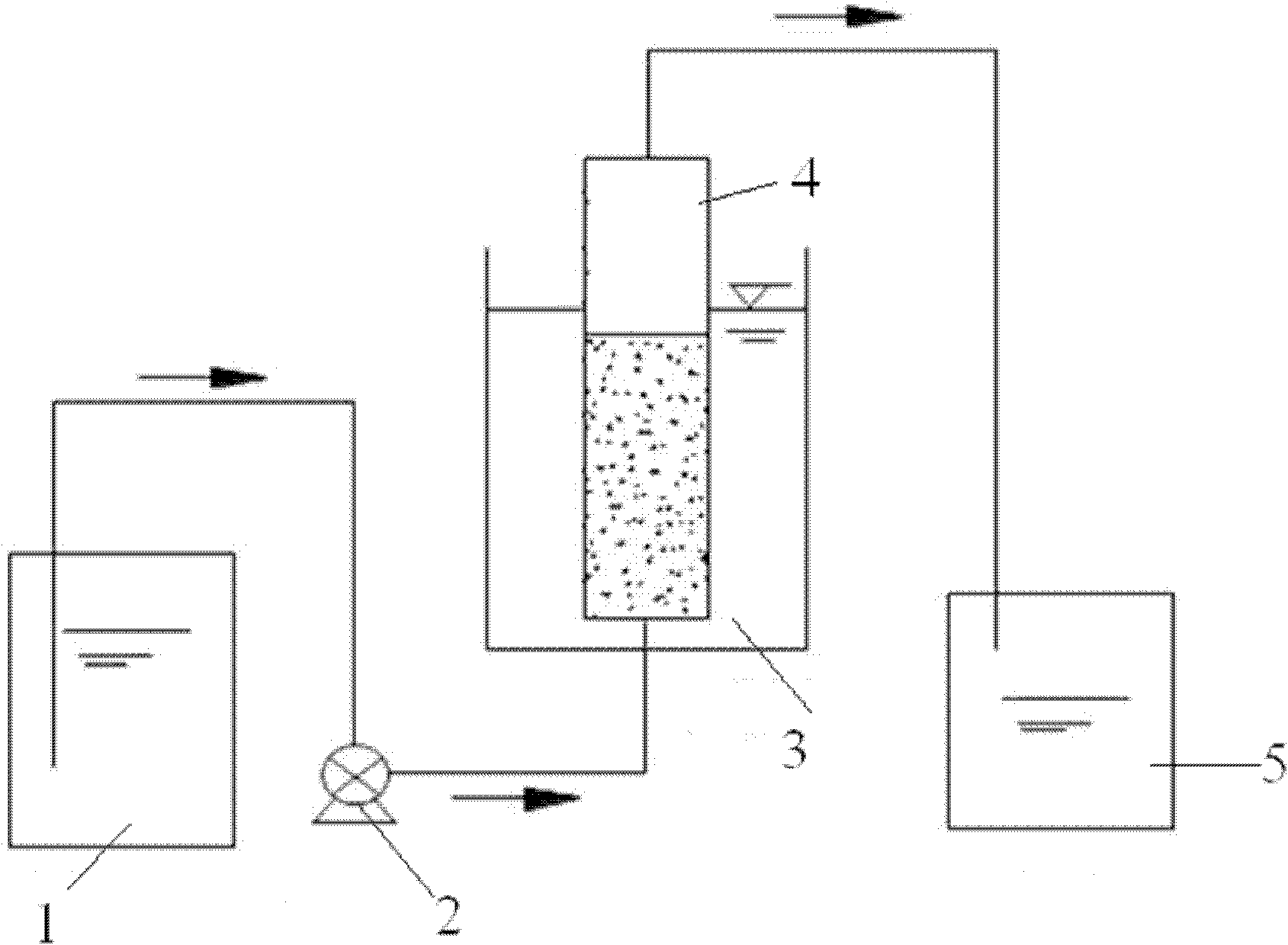

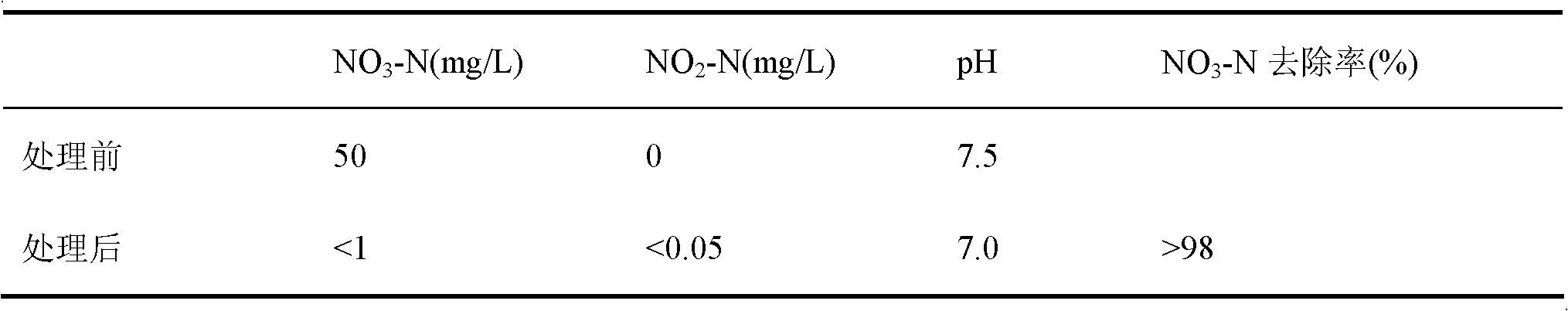

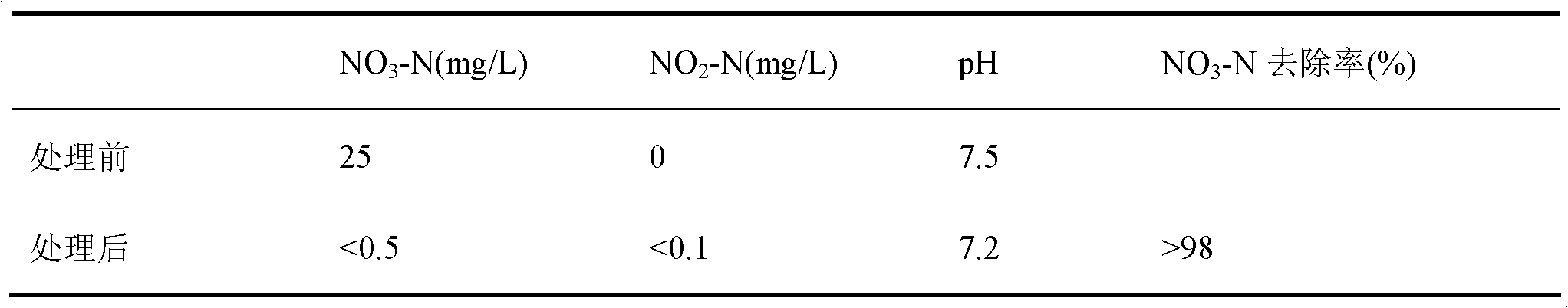

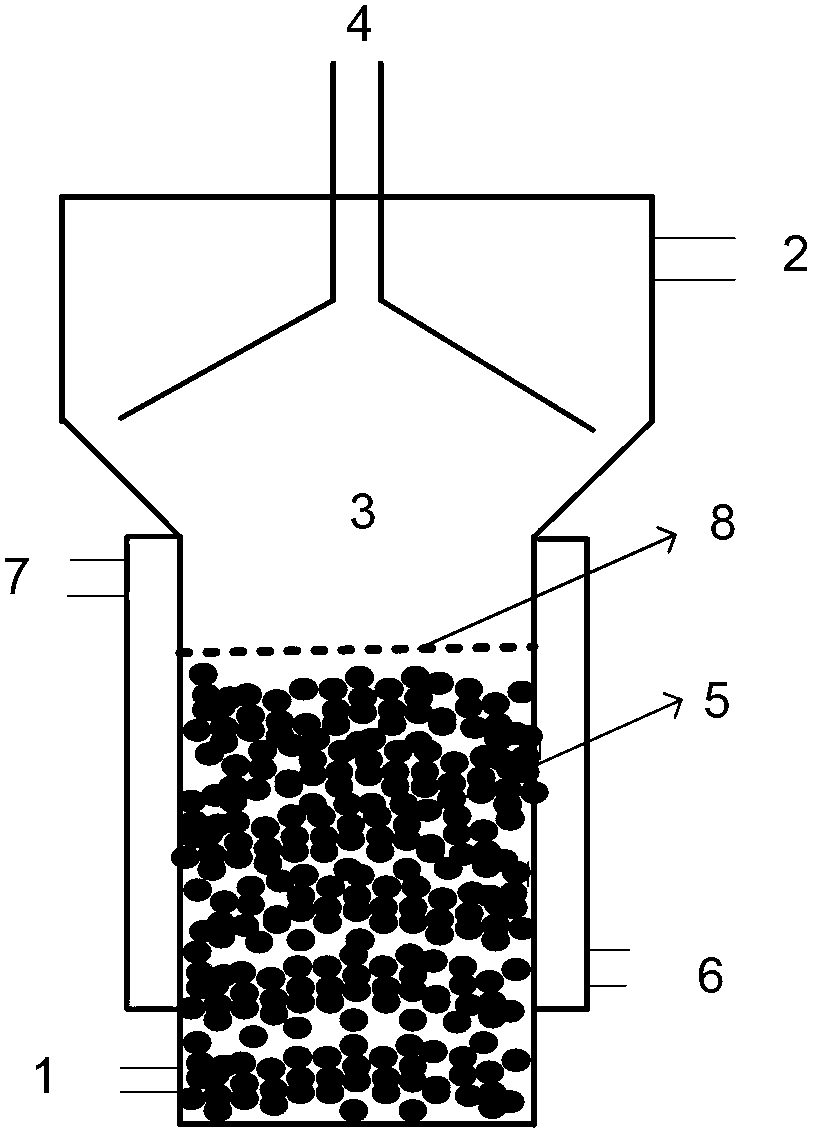

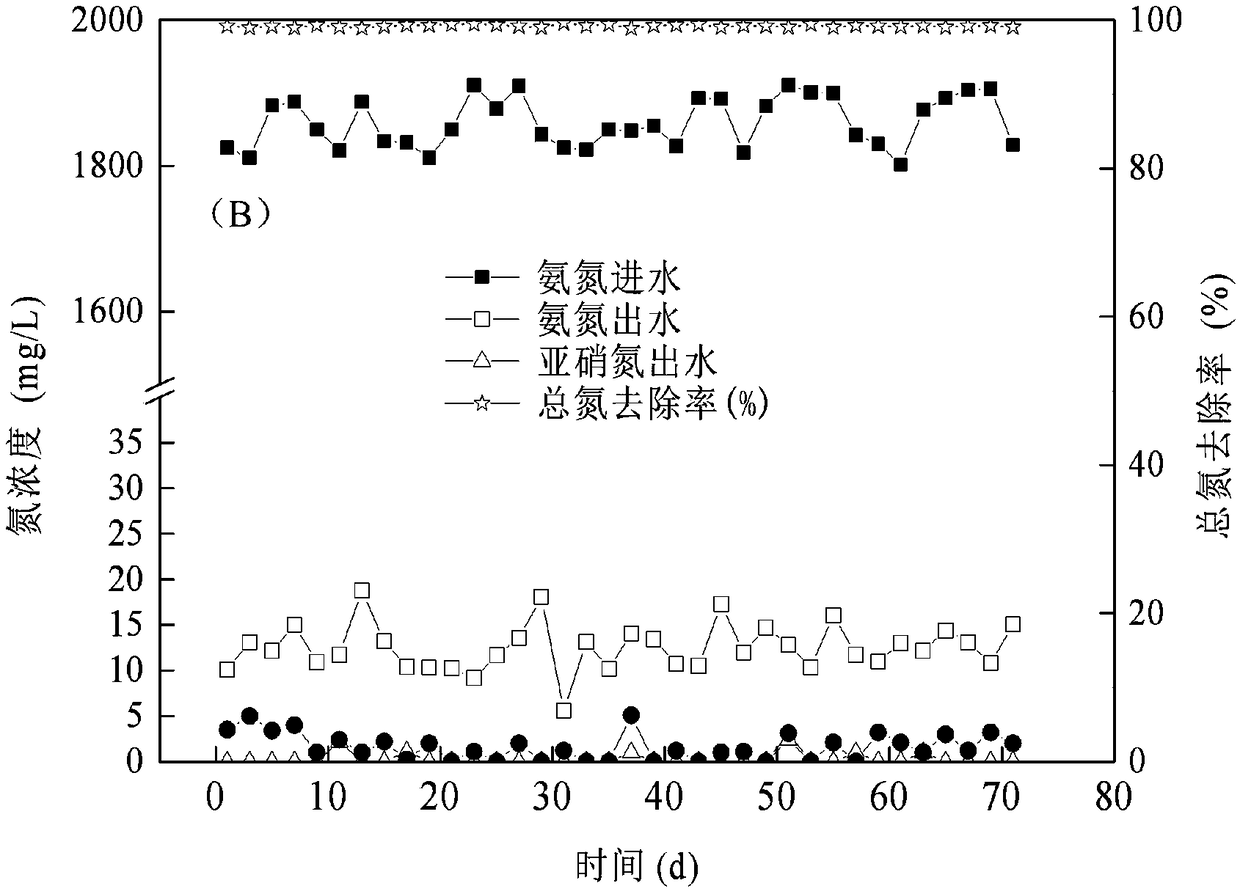

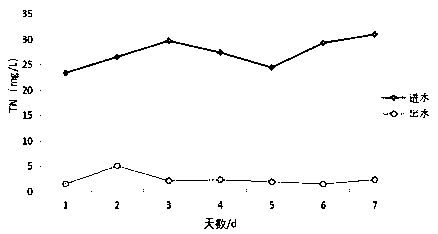

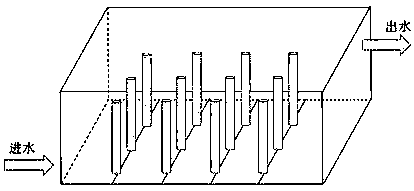

Method for realizing synchronous nitrification and denitrification nitrogen removal by utilizing immobilized microorganism technology

InactiveCN110482715ASolve problemsReduce consumptionWater contaminantsTreatment with aerobic and anaerobic processesNitrogen removalMicroorganism

The invention relates to the technical field of sewage treatment. The invention particularly provides a method for realizing synchronous nitrification and denitrification nitrogen removal by utilizingan immobilized microorganism technology. The adopted immobilized microorganism technology comprises the following steps: mixing a nitrifying bacterium agent and a denitrifying bacterium agent according to a certain ratio and adsorbing the mixture by using an adsorbent; embedding the adsorbed microbial inoculum by adopting an embedding agent; after embedding, adding dropwise a gel solution into across-linking agent to form gel beads with biological activity. The prepared gel beads sequentially form aerobic, anoxic and anaerobic environments from the surface to the inside which perform nitrification reaction, denitrification reaction and hydrolytic acidification respectively, nitrification liquid backflow is not needed, and synchronous nitrification and denitrification nitrogen removal canbe realized. Compared with a traditional biological denitrification process, the method has higher denitrification efficiency, and is simple in operation process, convenient to maintain and manage and easy to popularize.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

All-carbon flue gas denitrification system and method

ActiveCN105107379AAdaptableEfficient denitrificationDispersed particle separationAdditive ingredientNitric oxide

The invention discloses an all-carbon flue gas denitrification system and method. Nitric oxides can be effectively removed with a carbon-based material as a catalyst and carbon monoxide as a reducing agent. The method includes the following steps that a reaction mode is determined according to the content of oxygen in flue gas and is divided into a high-oxygen mode and a low-oxygen mode; according to the high-oxygen mode, the flue gas and the reducing gas enter different reaction regions respectively to react for set time, then the flue gas enters the reaction region of the reducing gas for reacting, and the reducing gas enters the reaction region of the flue gas for reacting; according to the low-oxygen mode, the flue gas and the reducing gas enter the same reaction region to react; each reaction region contains the carbon support catalyst. By the adoption of the all-carbon denitrification system, efficient denitrification with the carbon-based material as the catalyst and the carbon monoxide as the reducing agent can be achieved, the denitrification cost is low, no other harmful ingredients are generated, and the all-carbon flue gas denitrification system is high in adaptability to temperature and components of the flue gas and particularly suitable for a power plant, a steel metallurgical industry and other industries with carbon materials as fuel.

Owner:SHANDONG UNIV

Composite denitration method and device

ActiveCN105485664ALess quantityImprove denitrification efficiencyGas treatmentDispersed particle separationReaction temperatureEngineering

The invention relates to the technical field of boiler improvement, in particular to a composite denitration method and device suitable for power station boilers, industrial boilers and other burning devices. A method is provided, reducibility industrial waste gas serves as a composite additive, on one hand, the reducibility industrial waste gas serves as reburning gas to reduce nitric oxide in the reducing atmosphere, the amount of nitric oxide generated through burning is reduced; and on the other hand, the SNCR reaction temperature is reduced, the SNCR proper temperature area is widened, the reduction of nitric oxide through SNCR is promoted, accordingly, the denitration rate is increased, and ammonia leakage is reduced. The industrially-common reducibility waste gas is effectively and resourcefully utilized, meanwhile, the burning denitration efficiency of a boiler is improved from two aspects, and the emission load of nitric oxide is reduced by more than 80%. The boiler equipment is simple, implementation is easy, the adopted additive is low in price and easy to obtain, the burning process in the boiler is not affected, obvious secondary pollution cannot be generated, and reliability is high. The method is mainly applied to the industrial waste gas reutilization and nitric oxide control aspects.

Owner:SHANXI UNIV +1

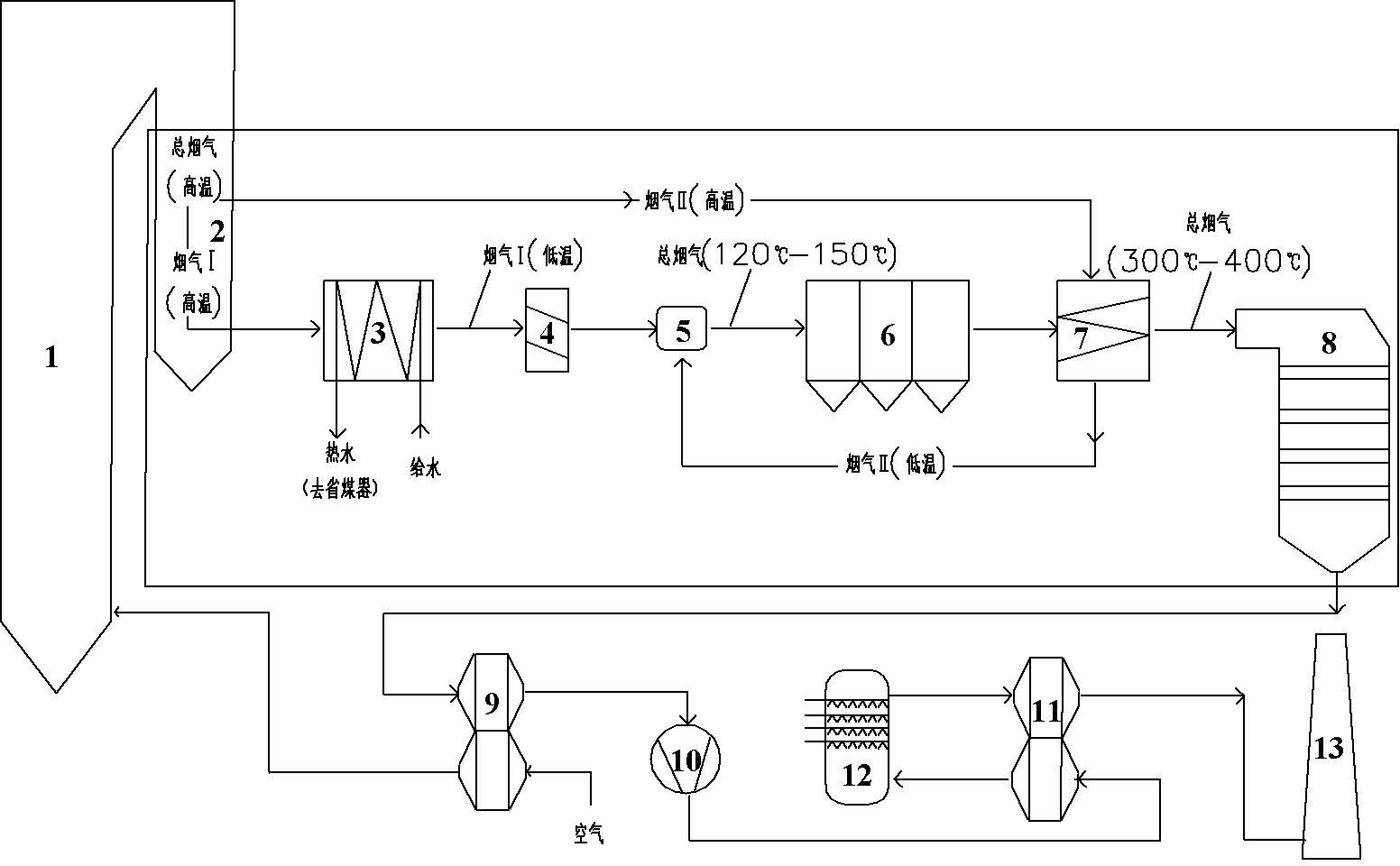

Dedusting and denitration system for thermal power plant fire coal smoke

ActiveCN102309918AImprove catalytic performanceExtend your lifeDispersed particle separationAir preheaterSilicon-controlled rectifier

The invention provides a dedusting and denitration system for thermal power plant fire coal smoke, which lowers denitration cost while ensuring that the system efficiently denitrate. The dedusting and denitration system is characterized in that heat exchangers comprise a heat exchanger I and a heat exchanger II; a coal economizer is provided with two smoke outlets, wherein one smoke outlet is ledto the high-temperature inlet of the heat exchanger I, and the other smoke outlet is led to the high-temperature inlet of the heat exchanger II; the high-temperature outlet of the heat exchanger I isconnected with the inlet of a smoke flow regulation valve; the outlet of the smoke flow regulation valve is connected with one inlet of a smoke mixer; the high-temperature outlet of the heat exchanger II is connected with the other inlet of the smoke mixer; the outlet of the smoke mixer is connected with the inlet of an efficient dust remover; the outlet of the efficient dust remover is connectedwith the low-temperature inlet of the heat exchanger II; the low-temperature outlet of the heat exchanger II is connected with the inlet of an SCR (Silicon Controlled Rectifier) reactor; the outlet of the SCR reactor is connected with an air preheater; and the low-temperature inlet to the low-temperature outlet of the heat exchanger I is low-temperature liquid.

Owner:WUXI HUAGUANG BOILER

Double-treatment cleaning and regenerating method for vanadium-titanium based denitration catalyst

InactiveCN103386313AImprove redox abilityToxic substance reductionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsTitaniumMixed gas

The invention discloses a double-treatment cleaning and regenerating method for a vanadium-titanium based denitration catalyst and aims to solve the technical problem that the regenerating effect of the traditional vanadium-titanium based denitration catalyst is not so good. According to the technical scheme, the double-treatment cleaning and regenerating method comprises the following steps of: introducing air-ozone mixed gas into a catalyst regenerating reactor, and carrying out oxidation treatment to obtain a regenerated vanadium-titanium based denitration catalyst; then, placing the regenerated vanadium-titanium based denitration catalyst into a catalyst activity liquid, dipping the regenerated vanadium-titanium based denitration catalyst for 4-6h, then, taking out the regenerated vanadium-titanium based denitration catalyst, drying the regenerated vanadium-titanium based denitration catalyst in dry air at 50-60 DEG C for 1-3h, and then, repeating the operation once; and then, roasting the regenerated vanadium-titanium based denitration catalyst at the temperature of 160-200 DEG C for 1-3h, and then, roasting the regenerated vanadium-titanium based denitration catalyst at the temperature of 300-400 DEG C for 1-3h to obtain the cleaned and regenerated vanadium-titanium based denitration catalyst. The double-treatment cleaning and regenerating method has the beneficial effects that the denitration ratio of the regenerated vanadium-titanium based denitration catalyst can be up to 87%, so that efficient regeneration is realized, meanwhile, the conversion ratio of SO2 / SO3 is effectively reduced, and the denitration cost is greatly reduced.

Owner:HEBEI MILSON TITANIUM DIOXIDE

Face-fired boiler advanced denitration burning method

ActiveCN106247320AReduce concentrationLower emission valueCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasHearth

The invention discloses a face-fired boiler advanced denitration burning method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of turbulent burners in each of layers of turbulent burners arranged on a front wall and a rear wall and is burnt, secondary air is introduced through secondary air nozzles of the turbulent burners, over fire air is introduced through one or more layers of over fire air nozzles on the front wall and the rear wall, the primary air and the secondary air on the front wall and the rear wall are oppositely introduced, the excess air coefficient range of the main burning area of the turbulent burners is 0.5-1.05, and the fire coal undergoes low oxygen burning; the excess air coefficient range of the over fire area of the over fire air nozzles is 1.05-1.3, and oxygen rich burning is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over fire layer to reduce nitrogen oxides in flue gas in high temperature environment in the hearth and inhibit generation of new nitrogen oxides. The face-fired boiler advanced denitration burning method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

W-firing boiler advanced denitration combustion method

ActiveCN106247321AReduce concentrationLower emission valueFluegas recirculationIndirect carbon-dioxide mitigationHearthEngineering

The invention discloses a W-firing boiler advanced denitration combustion method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of main combustors on boiler arches of a front wall and a rear wall and is combusted, secondary air and under-arch secondary air are respectively introduced through secondary air nozzles and under-arch secondary air nozzles, exhaust gas wind is introduced through exhaust gas wind nozzles on the front wall and the rear wall, one or two layers of over-fire air are introduced through over-fire air nozzles, the excess air coefficient range of a main combustion area is 0.7-1.05, and the fire coal undergoes low oxygen combustion; the excess air coefficient range of an over-fire area is 1.05-1.3, and oxygen rich combustion is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over-fire air layer to reduce nitrogen oxides in flue gas and inhibit generation of new nitrogen oxides. The W-firing boiler advanced denitration combustion method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

Preparation method of mixture of polyester and thermoplastic starch rich in starch and application thereof

ActiveCN103194050AImprove the mixing effectStrong mechanical propertiesWater contaminantsBiological water/sewage treatmentSolid carbonThermoplastic

The invention discloses a preparation method of a mixture of polyester and thermoplastic starch rich in starch and an application thereof, belonging to the technical field of environment protection. According to the method, the polyester and the thermoplastic starch rich in starch are taken as the raw materials, and addition agents such as aluminic acid ester coupling reagent and the like are added, thermoplastic starch / polyester blending material is prepared through banburying by a torque rheometer, and then a product is prepared through smashing, extrusion and pelleting. The thermoplastic starch base mixture rich in starch can be used as both a carbon source and a biofilm carrier for denitrification in the water treatment deep denitrification technology, so that the defect that the carbon source dosage is not easy to control in a conventional denitrification technology is overcome, the defects that the microorganism is difficult to form a membrane, the cost is high and the staring time is long when only biodegradable polymer is taken as a solid carbon source are overcome, and the thermoplastic starch base mixture rich in starch has strong adaptability to both water dissolved oxygen concentration and pH.

Owner:CHONGQING UNIV

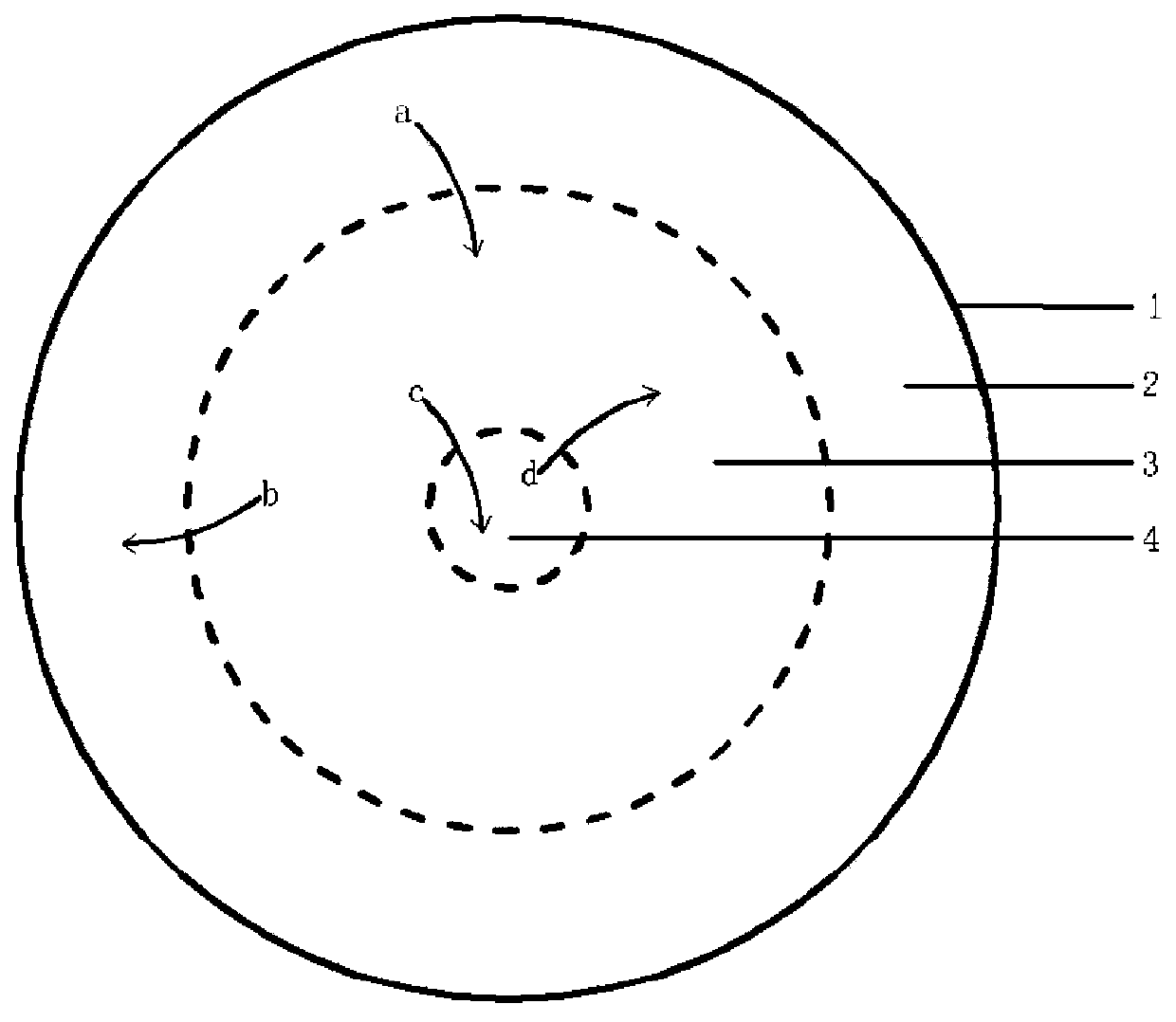

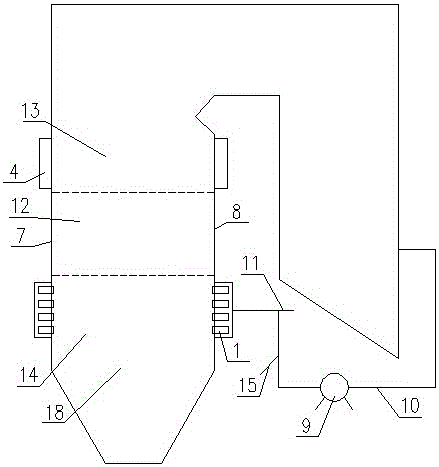

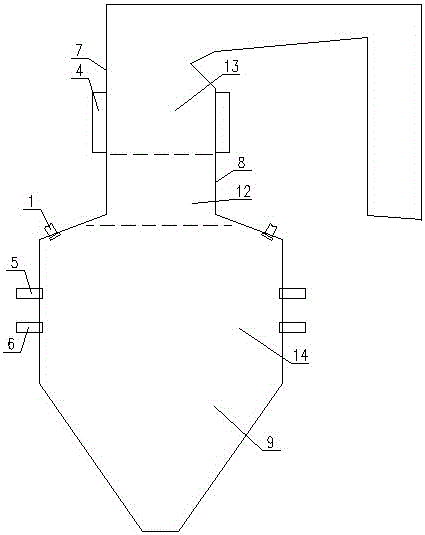

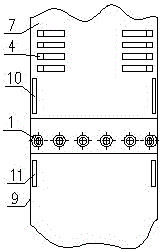

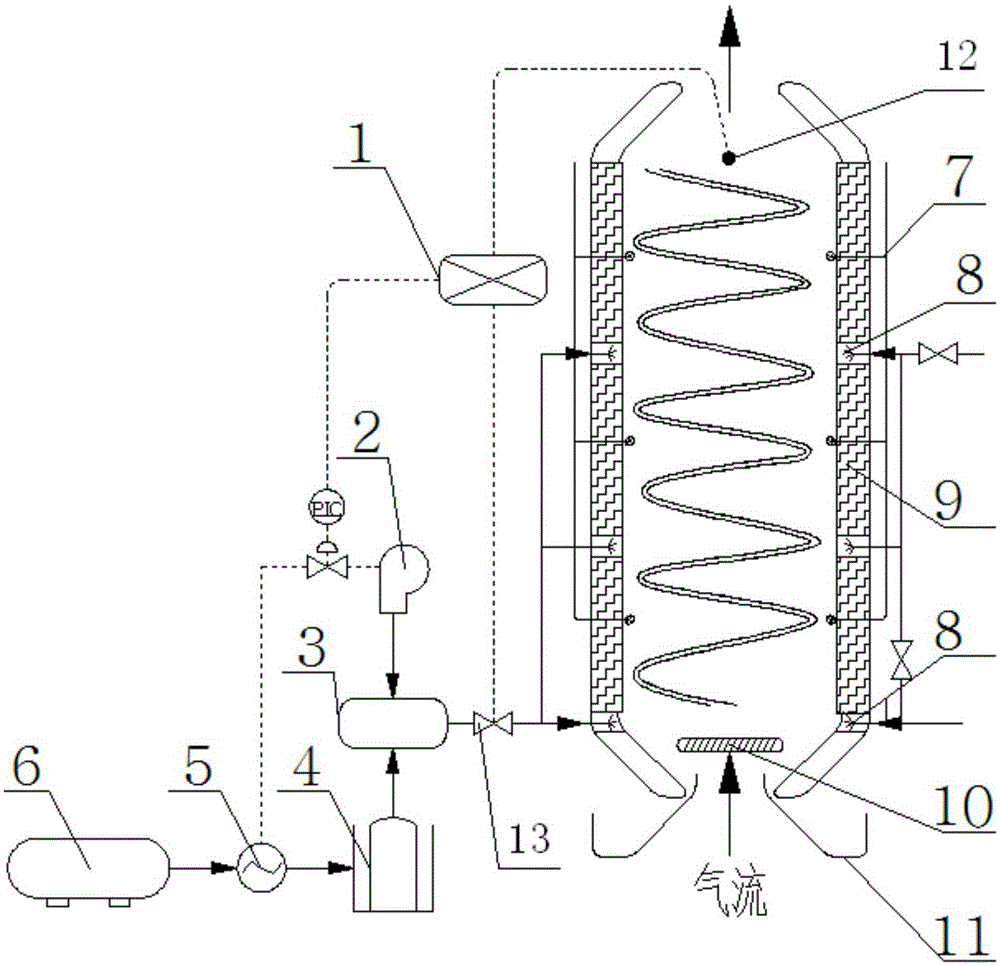

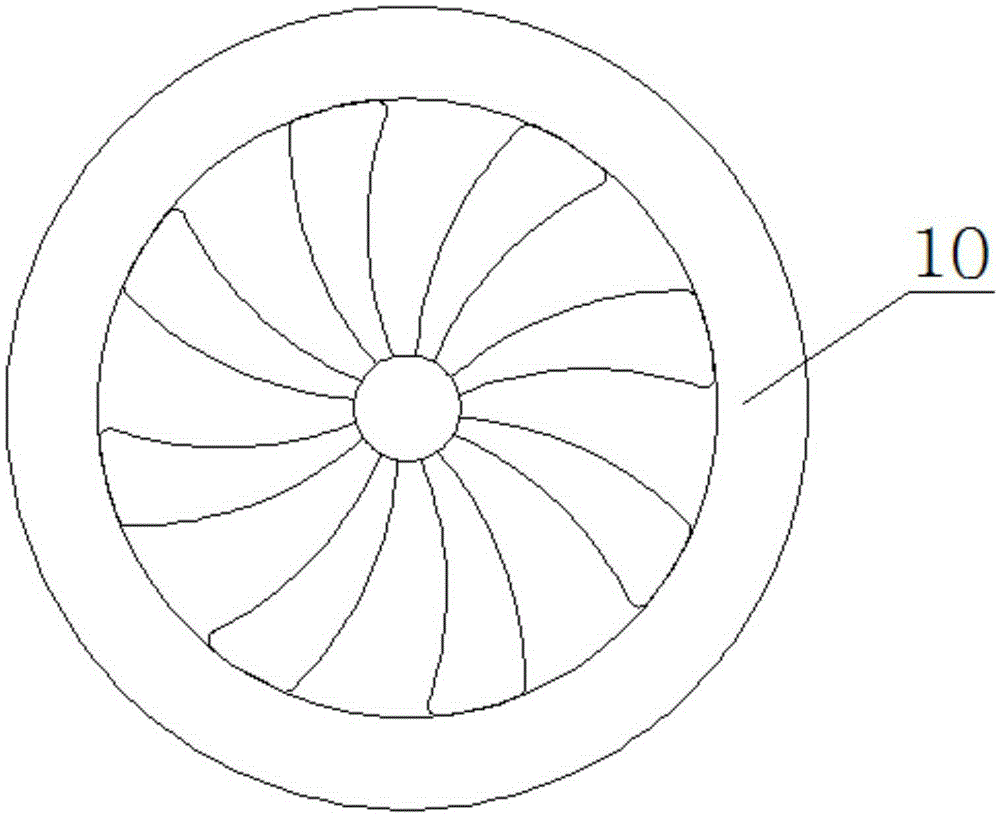

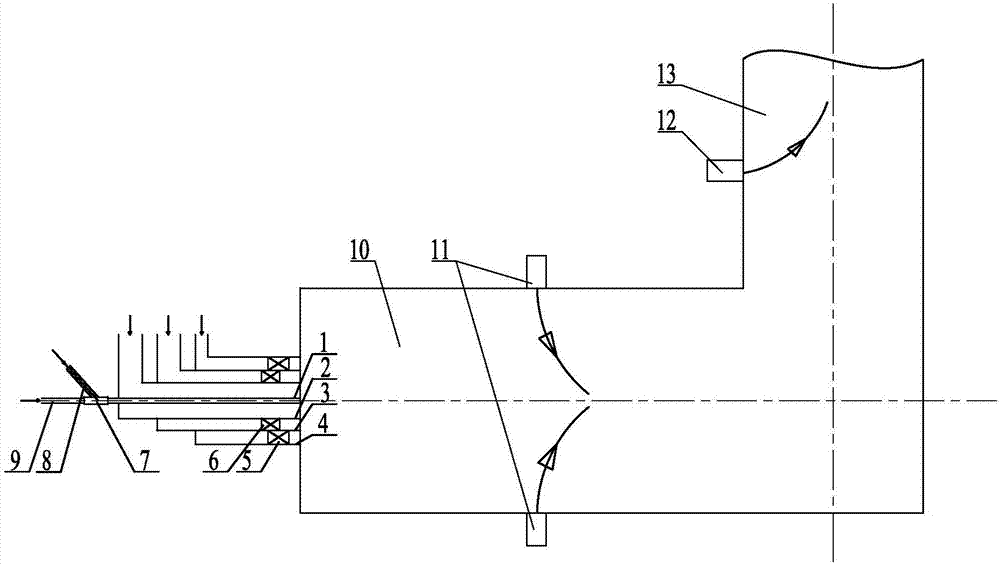

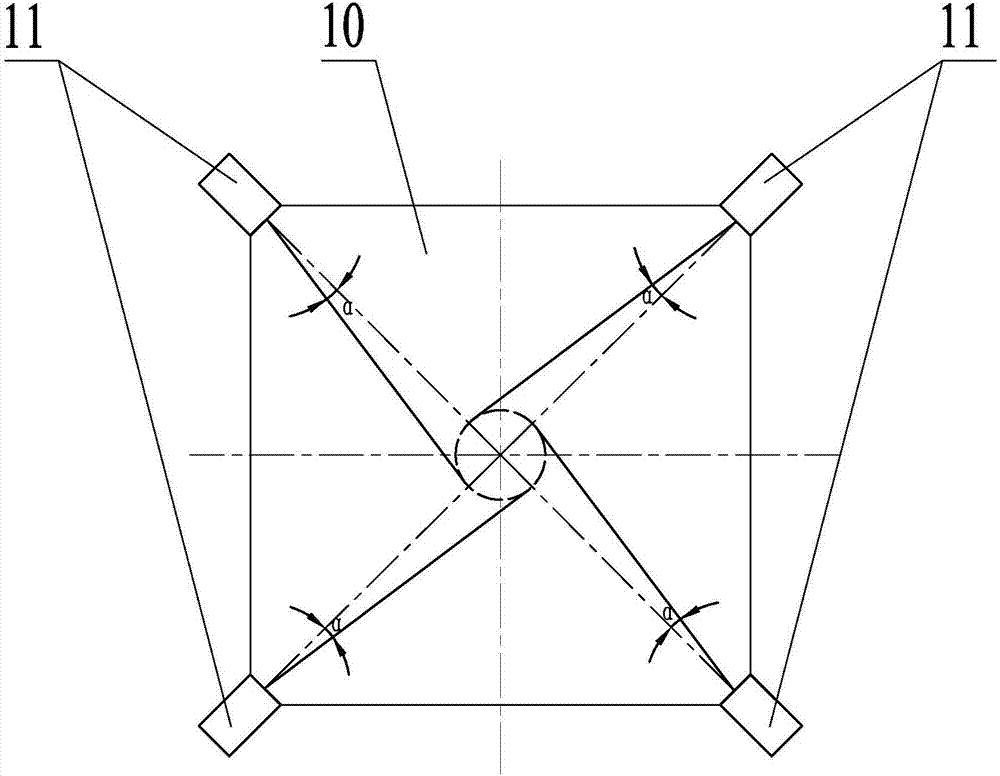

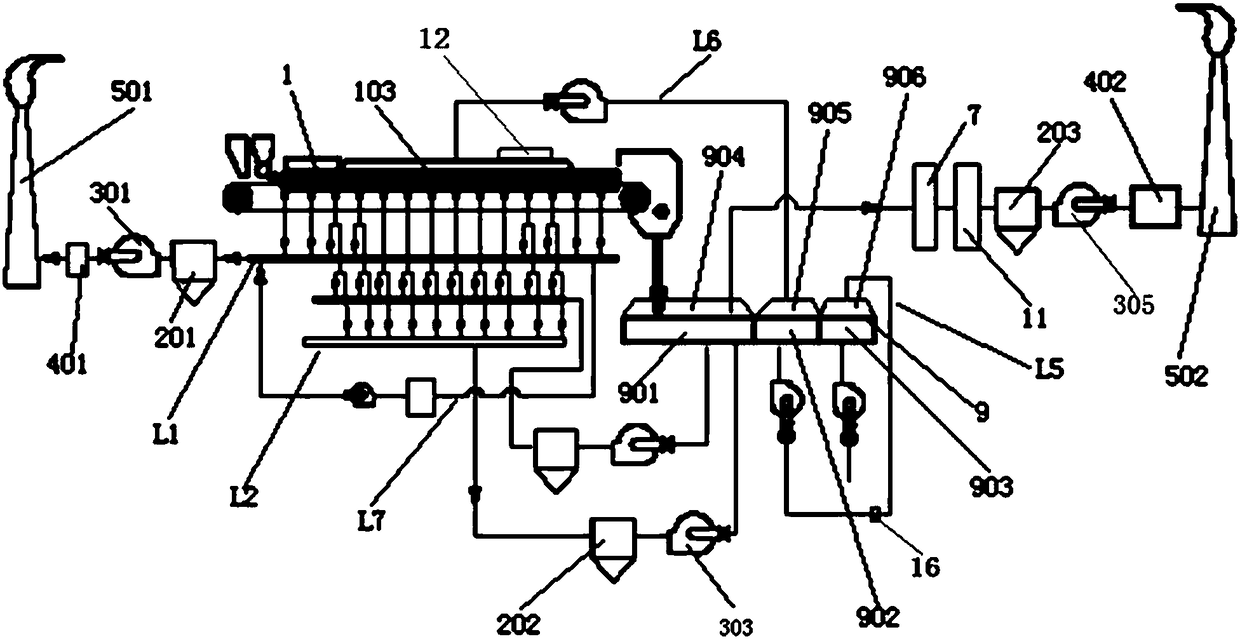

Rotational flow plate type SCR denitration tower and denitration method thereof

ActiveCN105289300AExtended stayThe catalytic reduction reaction is fullyDispersed particle separationFlue gasEscape rate

The invention discloses a rotational flow plate type SCR denitration tower and a denitration method thereof. The denitration tower comprises a denitration tower body and a corrugated plate type catalyst layer arranged along the inner circumference face of the denitration tower body, and the corrugated plate type catalyst layer forms a flue gas channel. A plurality of layers of rotational flow atomizing nozzles performing jetting in the contact circle direction are distributed on the circumference face of the corrugated plate type catalyst layer from bottom to top. When flue gas enters the flue gas channel from the bottom of the denitration tower body, and the flue gas encounters ammonia gas jetted by the whirlwind atomizing nozzles, the flue gas and the ammonia gas are mixed in an entrainment mode and spirally raises in the inner circumference direction of the flue gas channel in a contact circle mode because the ammonia gas is jetted in a rotational flow mode in the contact circle direction. On the premise that efficient denitration is guaranteed, the catalyst use amount of the denitration tower is small, the technical means is easy and convenient to use. Compared with the prior art, the denitration tower is simple in structure, low in manufacturing cost, high in denitration efficiency and low in energy consumption, reduces the ammonia escape rate, makes denitration cost greatly reduced, and remarkably improves economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application of starch and poly(butylene succinate) thermoplastic blend

InactiveCN102226014AReduce the cost of denitrificationReduce startup timeWater contaminantsTreatment with anaerobic digestion processesChemistryCarbon source

The present invention discloses a preparation method and an application of a starch and poly(butylene succinate) thermoplastic blend, belonging to the technical field of environmental protection. The preparation method comprises the following steps of: adding a plasticizer and other additives to starch and poly(butylene succinate) serving as the raw materials, uniformly mixing under stirring, completely extruding with a twin-screw extruder and granulating to obtain a product. The obtained starch and poly(butylene succinate) thermoplastic blend is simultaneously used as a denitrification microbial carbon source and a biofilm carrier for water treatment, thus avoiding the defects that the carbon source adding amount is difficult to control in the conventional denitrification processes usingthe liquid carbon sources, and has strong adaptability to the DO (dissolved oxygen) content and pH value of inflow water.

Owner:TSINGHUA UNIV

Preparation method and application of crosslinked starch, polycaprolactone and polylactic acid mixture

InactiveCN102206363AReduce the cost of denitrificationShort startup timeTreatment with anaerobic digestion processesOxygenBiological membrane

The invention discloses a preparation method and application of a crosslinked starch, polycaprolactone and polylactic acid mixture, which belongs to the technical field of environment protection. The preparation method comprises the following steps of: adding auxiliary agents such as a plasticizing agent and the like into crosslinked starch, polycaprolactone and polylactic acid which serve as rawmaterials; stirring and mixing uniformly; extruding by using a double-screw extruder at a time; and pelleting to obtain a product. The crosslinked starch, polycaprolactone and polylactic acid mixturecan be simultaneously used as a denitrification carbon source and a biomembrane carrier during water treatment, overcomes the defect that the adding amount of the carbon source is difficult to regulate and control in the conventional denitrification process, and has higher adaptability to inflow water dissolved oxygen concentration and pH; simultaneously, low-cost starch is added into the mixed carbon source, so that denitrification cost is reduced.

Owner:TSINGHUA UNIV

Industrial pulverized coal boiler burning device used for spraying ammonia in center of burner

ActiveCN107477573AEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorEngineering

The invention provides an industrial pulverized coal boiler burning device used for spraying ammonia in the center of a burner, and relates to the technical field of industrial pulverized coal boilers. The problems that according to an existing horizontal industrial pulverized coal boiler, the NOx emission amount is high, the NOx emission reduction cost is high, the burnout condition of pulverized coal is poor, the adjusting capacity for load change is poor, the boiler thermal efficiency is low, and slagging is severe are solved. The burning device comprises a primary air pipe, a direct flow secondary air pipe, a rotational flow inner secondary air pipe, a rotational flow outer secondary air pipe, a mixer, an amino reducing agent conveying pipe, a concentrated pulverized coal conveying pipe, a hearth and a two-stage over-fire air system. The primary air pipe, the direct flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are sequentially arranged from inside to outside. The amino reducing agent conveying pipe and the concentrated pulverized coal conveying pipe are connected with the inlet end of the mixer. The outlet end of the mixer is connected with the inlet end of the primary air pipe. The two-stage over-fire air system is arranged on the wall of the hearth. The burning device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

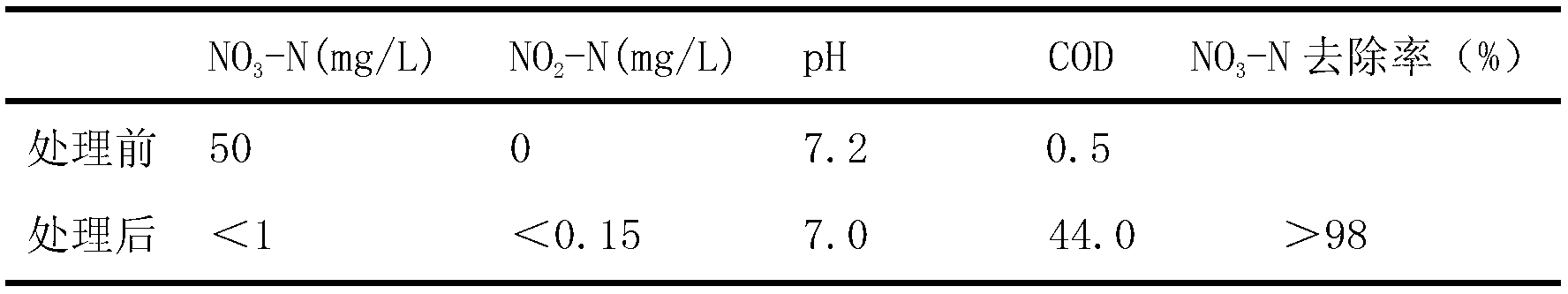

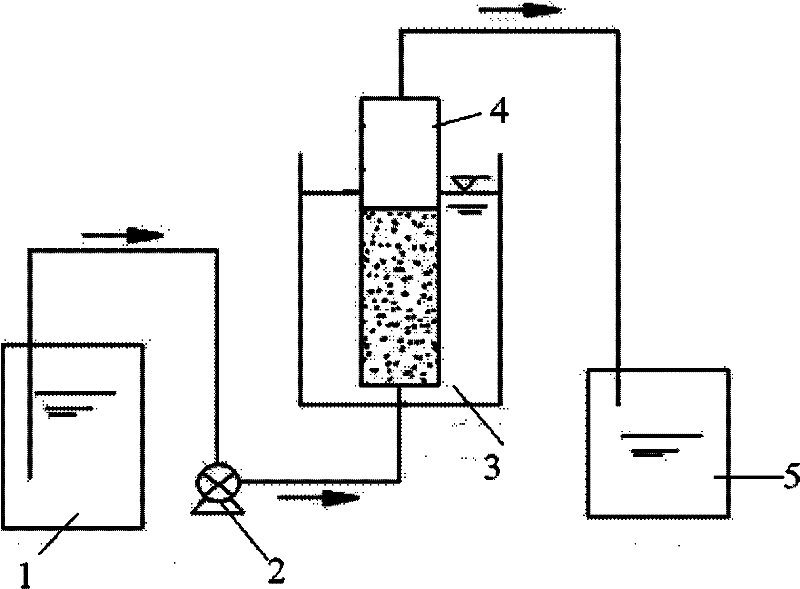

Method for removing nitrate nitrogen in water by using blended material including PHBV (Polyhydroxylbutyrate Valerate) and bamboo powder

ActiveCN103011398APromote degradationReduce startup timeWater contaminantsTreatment with anaerobic digestion processesSolid carbonStart time

The invention belongs to the technical field of water treatment methods and particularly relates to a method for removing nitrate nitrogen in water by using a blended material including PHBV (Polyhydroxylbutyrate Valerate) and bamboo powder. The method comprises the following steps of: adding blended particles, including the PHBV and the bamboo powder, with the particle size being 0.3-0.5cm into a fixed-bed reactor, wherein the filling rate is 30-60%; and adding underground water into the reactor directly without adding any seed sludge, and starting the reactor, wherein the initial hydraulic retention time (HRT) is 17h, and HRT is gradually reduced after the nitrate nitrogen concentration of effluent reaches 2-5mg / L. According to the invention, the blended material including the PHBV and the bamboo powder is taken as both a carrier of a biological membrane and a carbon source for denitrification, and has the advantages of obviously improving the biodegradability of materials, shortening the starting time of the reactor and reducing the denitrification cost; the underground water instead of sludge of a sewage treatment plant is added into the solid carbon-source reactor directly for acclimation starting, so that pathogenic bacteria in the sludge of the sewage treatment plant can be prevented from being introduced, thus the method is particularly suitable for the denitrification treatment of underground water and drinking water; and the reactor is simple in operation and running, easy to control and good in effluent quality.

Owner:TSINGHUA UNIV

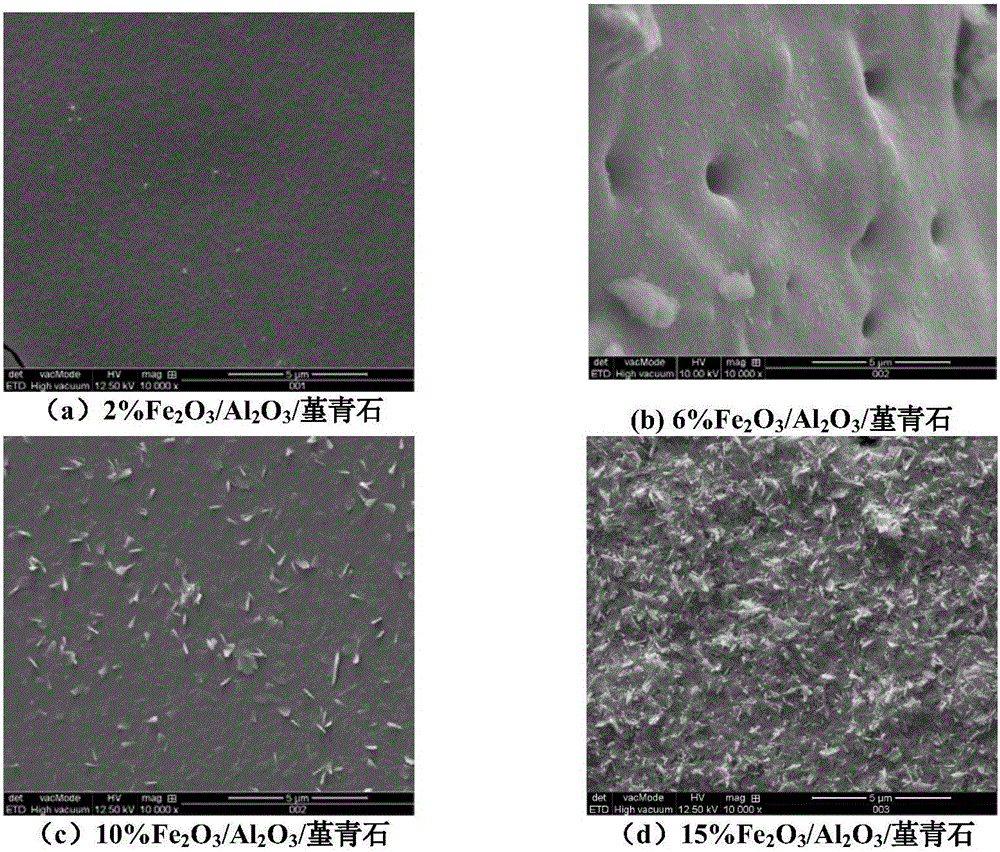

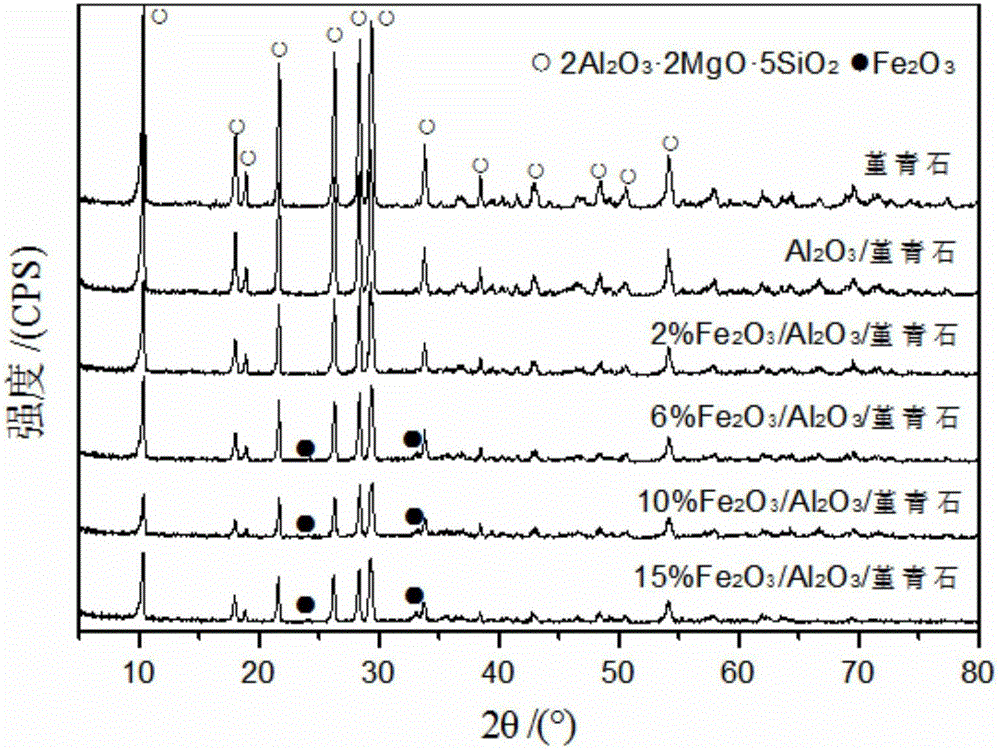

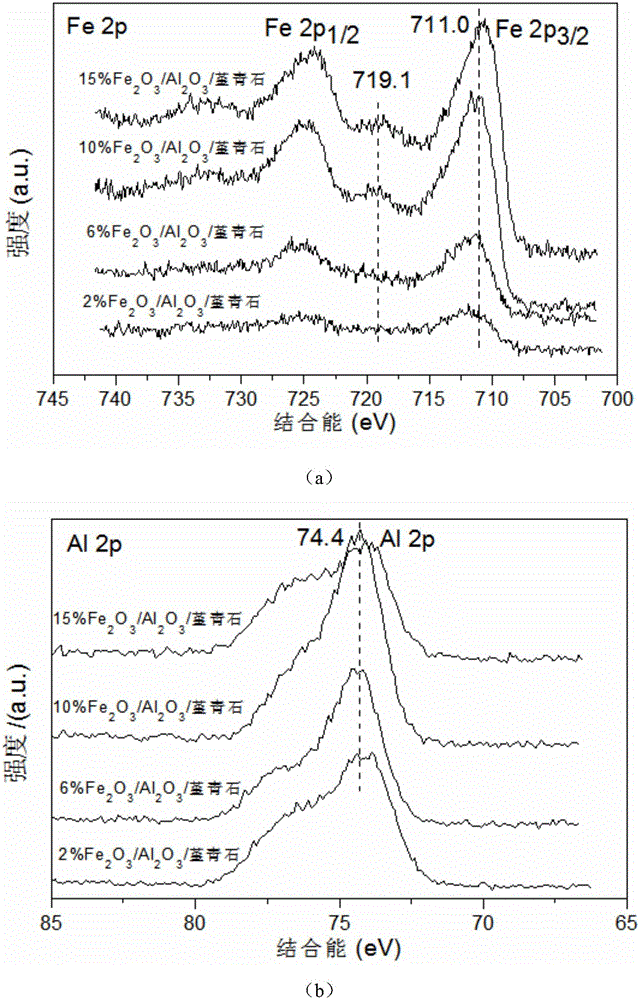

Fe2O3/Al2O3/cordierite catalyst and preparation method thereof

InactiveCN105148914AEfficient denitrification efficiencyChemically activeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasThin layer

The invention relates to a Fe2O3 / Al2O3 / cordierite catalyst and a preparation method thereof. According to the invention, the catalyst comprises cordierite used as a carrier, an Al2O3 sol layer coated on the surface of the cordierite, and an iron oxide layer dispersed on the surface of the Al2O3 sol layer; the preparation method comprises the following steps: pretreatment of the carrier, preparation of aluminum sol, coating of the aluminum sol and impregnation of Fe(NO3)3; and NOX in industrial flue gas is removed with the Fe2O3 / Al2O3 / cordierite monolithic catalyst as the catalyst and with hydrocarbon as a reducing agent. The invention has the following beneficial effects: the aluminum sol is well coated on the surface of the cordierite, so a thin layer of amorphous aluminium oxide is formed; nanometer-grade iron oxide is uniformly dispersed on the aluminium oxide coating, so an SCR active center is formed; and the hydrocarbon is used as the reducing agent, so highly-efficient denitration efficiency is obtained.

Owner:DONGHUA UNIV

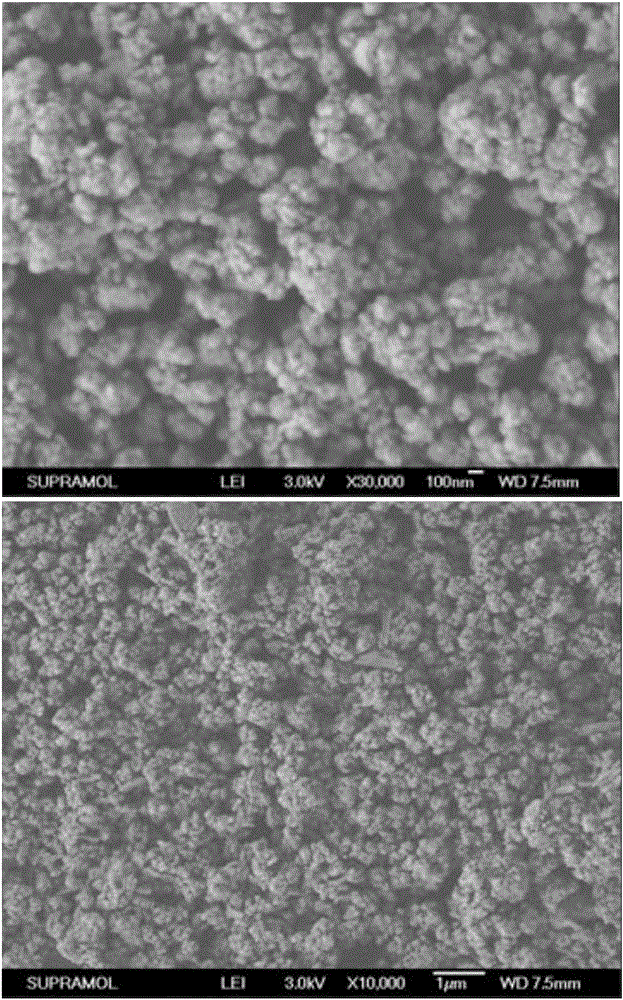

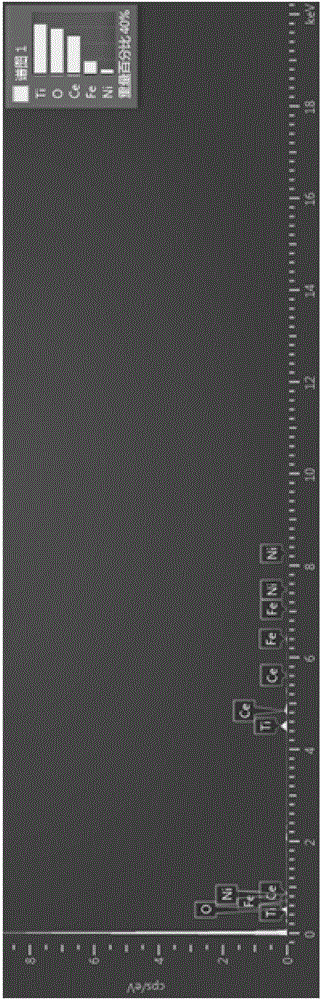

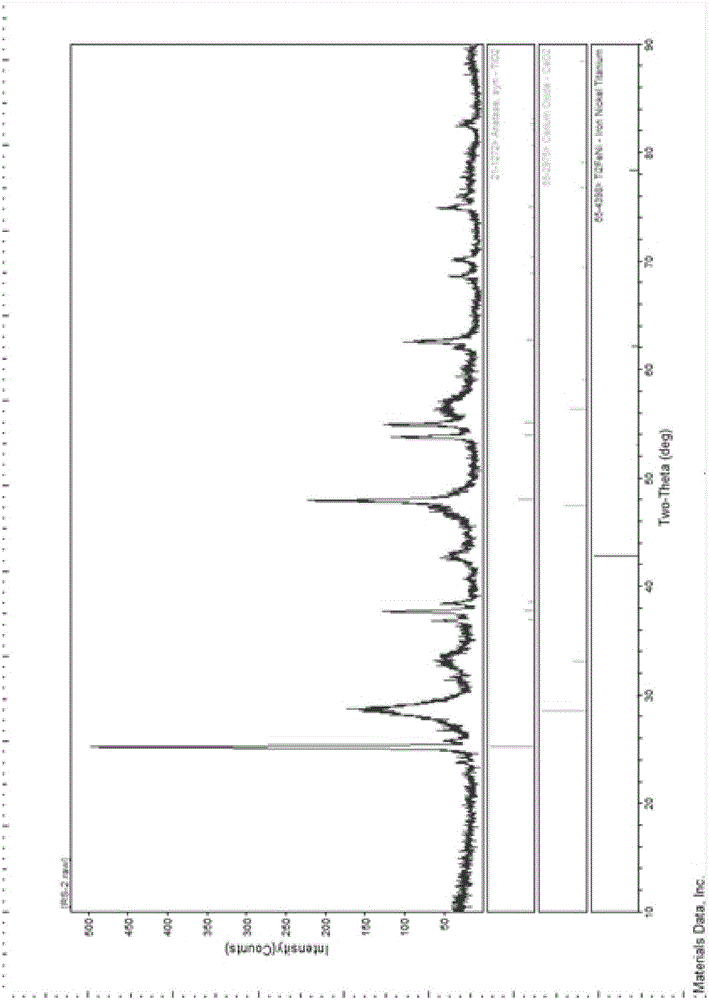

Catalyst for flue gas denitrification and preparation method of catalyst

InactiveCN106732624AReduce the cost of denitrificationImprove catalytic performanceGas treatmentHeterogenous catalyst chemical elementsHigh resistanceFlue gas

The invention provides a catalyst for flue gas denitrification. The catalyst is multi-component metal oxide comprising Fe2O3, CeO2, NiO and TiO2. The Fe2O3-CeO2-NiO / TiO2 multi-component metal oxide serving as an SCR (selective catalytic reduction) flue gas denitrification catalyst has the advantages of high resistance to H2O and SO2 poisoning, low denitrification cost and the like and also has higher thermal stability, wider temperature window and better low-temperature denitrification activity.

Owner:JILIN ELECTRIC POWER RES INST LTD

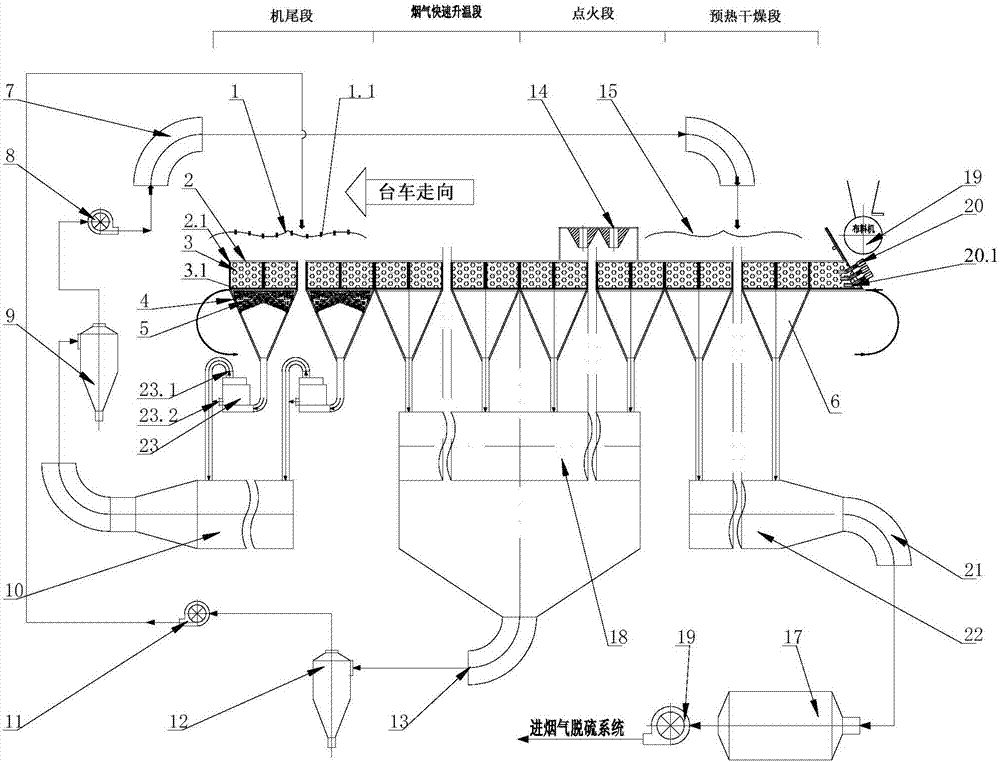

NOx emission reduction system based on ignition and sintering of dry mixture

ActiveCN107314677AFully warm upFull drying effectFurnace typesWaste heat treatmentFluidized bedFlue gas

The invention discloses a NOx emission reduction system based on ignition and sintering of a dry mixture. According to the technical scheme, the system comprises a sintering machine; bellows are arranged below trolleys of the sintering machine; the sintering is sequentially divided into four areas including a preheating and drying section, an ignition section, a flue gas quick-heating section and a tail section in the advancing direction of the trolleys; the bellows below the tail section are connected through fluidized bed reactors, a high-temperature flue gas main flue, a high-temperature flue gas dust remover, a high-temperature flue gas circulating fan and a high-temperature flue gas circulating pipe sequentially with a high-temperature circulating flue gas cover located above the preheating and drying section. With the system, the pollution emission amount is small, the recovery rate of waste heat of sintering flue gas is high, no outsourced denitration catalyst is used, and generation of NOx in the flue gas is effectively reduced.

Owner:武汉钢铁有限公司 +2

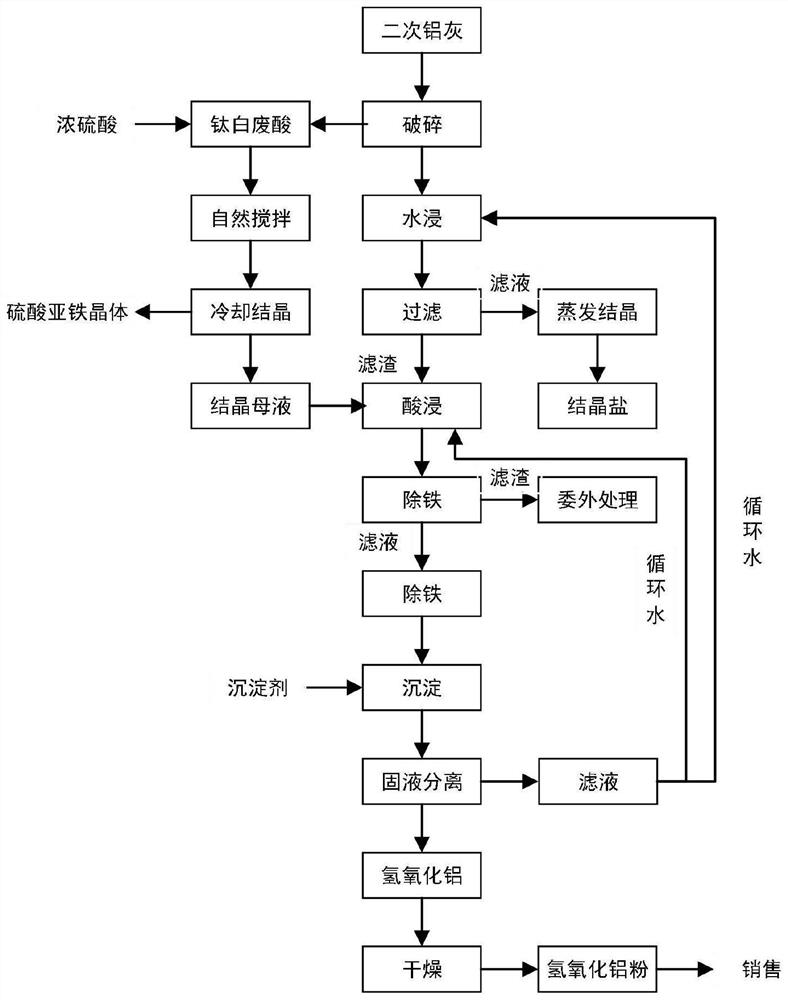

Method for recycling aluminum hydroxide powder by using titanium dioxide waste acid and secondary aluminum ash

ActiveCN112553470ALow utilization of valuable resourcesLow costAluminium compoundsProcess efficiency improvementAluminium industryAluminium hydroxide

The invention discloses a method for recycling aluminum hydroxide powder by using titanium dioxide waste acid and secondary aluminum ash, and belongs to the field of aluminum industrial waste treatment. The method comprises the steps of crushing, water leaching denitrification and desalination, waste acid pretreatment, acid leaching, impurity removal, precipitation and drying. The method for recycling the aluminum hydroxide powder by using the titanium dioxide waste acid and the secondary aluminum ash has the beneficial effects that the secondary aluminum ash is subjected to acid leaching after the titanium dioxide waste acid is pretreated, and the aluminum hydroxide powder is recycled; compared with a traditional process, the method has the advantages of being low in material consumption,low in treatment cost, good in economic benefit and the like; and valuable resources are recycled through a method of using waste to treat waste, the concept of circular economy, energy conservationand emission reduction is met, and the method can be widely applied to treatment of aluminum industrial waste.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

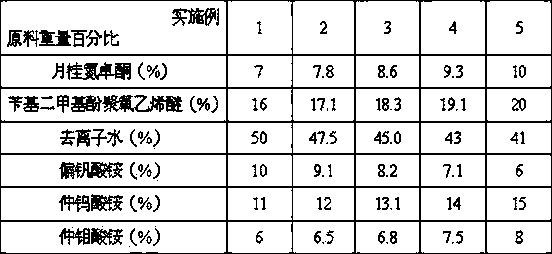

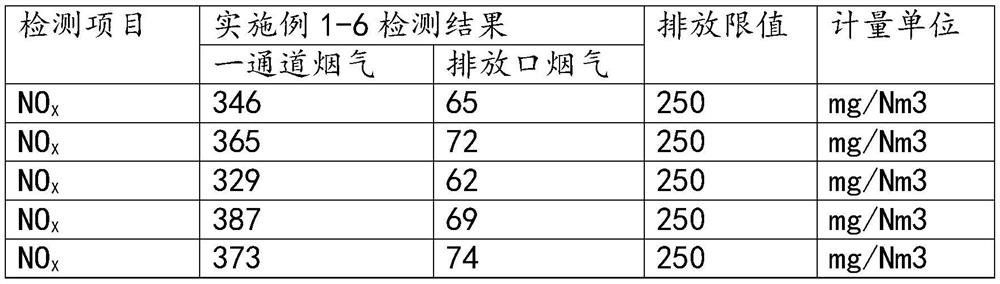

Polymer solid powder denitration agent for flue gas denitration and preparation method thereof

InactiveCN111686564AImprove liquidityLiquidityGas treatmentDispersed particle separationFlue gasPolymer

The invention discloses a polymer solid powder denitration agent for flue gas denitration and a preparation method thereof. The polymer solid powder denitration agent comprises the following raw materials in percentage by weight: 10-70% of an organic amino active compound, 10-40% of an inorganic active amino compound, 5-40% of inorganic mineral substance powder, 5-30% of active mineral substance powder and 1-10% of an additive. The polymer solid powder denitration agent has the advantages of simple components, easily available raw materials, simple preparation method, high denitration efficiency, high cost performance and good fluidity, is convenient for conveying the denitration agent in a denitration process, can improve the denitration efficiency of the denitration agent and reduce secondary pollution, and overcomes the defects in the prior art.

Owner:SICHUAN JIUDINGZHIYUAN INTPROP OPERATIONS CO LTD

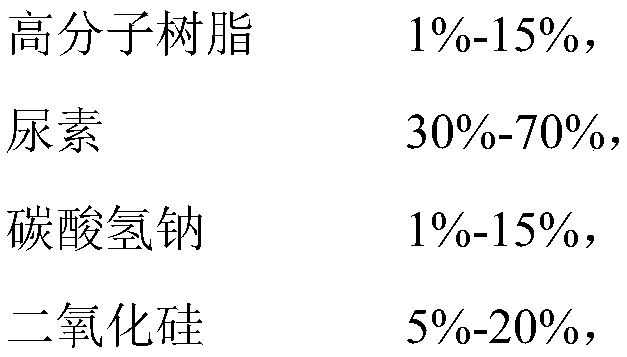

Denitrification agent, preparation method and dry-method denitrification method

InactiveCN109316892AReduce the cost of denitrificationReduce the difficulty of operationGas treatmentDispersed particle separationChemistryUrea

The invention discloses a denitrification agent, a preparation method and a dry-method denitrification method, and relates to the technical field of smoke treatment. The denitrification agent is prepared from: 1 to 15 percent of macromolecular resin, 30 to 70 percent of urea, 1 to 15 percent of sodium hydrogen carbonate, 5 to 20 percent of silicon dioxide, 10 to 20 percent of kaolin, 5 to 10 percent of talcum powder, 5 to 20 percent of diacetonitrile, and 1 to 30 percent of bentonite. The method comprises the following steps: mixing all the raw materials to obtain the denitrification agent. The denitrification method comprises the following steps: spraying the denitrification agent into a temperature area of 750 to 1000 DEG C in a hearth, reacting, and removing the nitrogen oxide in the smoke. The denitrification efficiency of the denitrification agent for the smoke is at least 80 percent or above; the SCR process can be completely substituted; the denitrification cost can be reduced;the operation difficulty can be reduced; the denitrification efficiency can be improved, and the emission standard of the nitrogen oxide can be reached.

Owner:南京清青环保科技有限公司

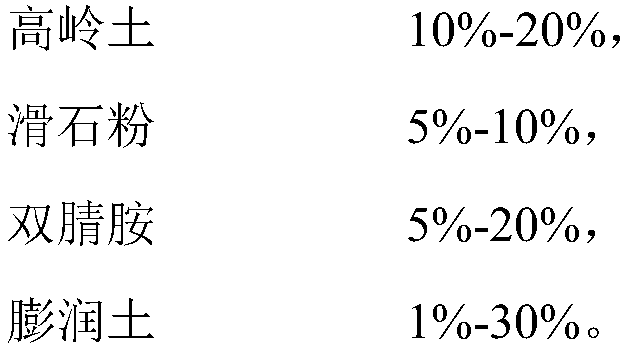

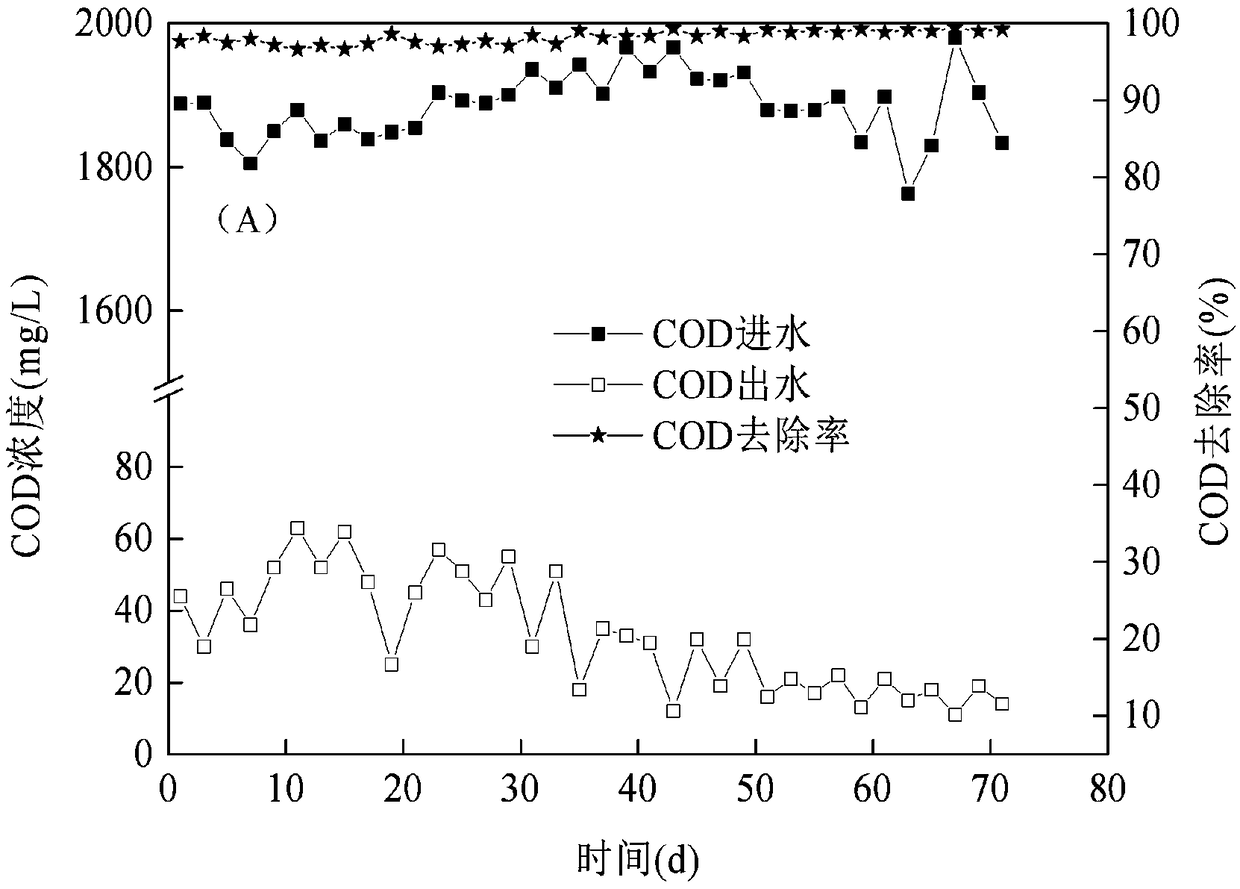

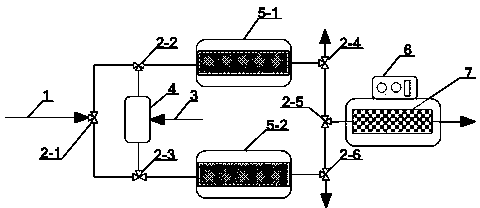

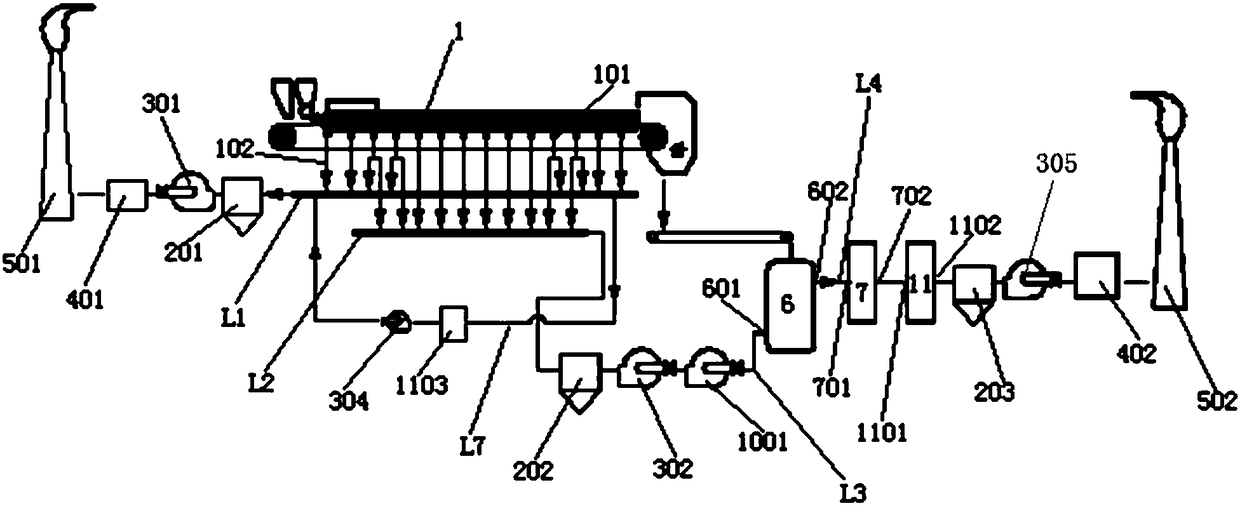

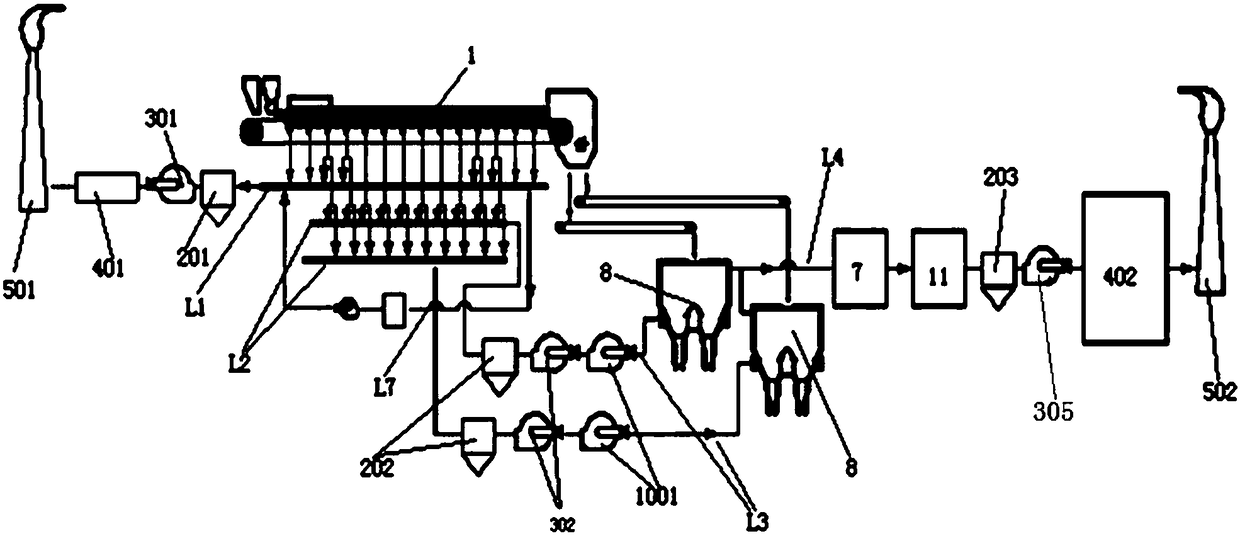

Denitrification and decarbonizing treatment system and method of landfill leachate in late period

ActiveCN109052875AEfficient and low consumption processingEfficient removalWater contaminantsMultistage water/sewage treatmentAmmoniaLeachate

The invention provides a denitrification and decarbonizing treatment system and method of landfill leachate in a late period, and belongs to the field of wastewater treatment. The system comprises a denitrification reactor, a nitrosation reactor, an anaerobic ammonia oxidation reactor, a concentrating pool, an oxidization pool and two return-flow system. According to the system, the concentratingpool is arranged and used for intercepting nondegradable organic substances in water output through the anaerobic ammonia oxidation reactor; the nondegradable organic substances can be oxidized into degradable organic substances through the oxidization pool, so that a carbon source is supplied to the denitrification process; the return-flow system supplies a proper environment to microorganism, and wastewater can be treated with high efficiency and low consumption; with the adoption of the system for treating the landfill leachate in the late period, the high independence of the denitrification process on additional organic substances can be avoided, so that demands on the organic substances can be decreased, and the denitrification cost of the landfill leachate can be decreased.

Owner:SUZHOU UNIV OF SCI & TECH

Method for extracting nitrogen from fuel oil by using polyethylene glycol and its modified compounds

ActiveCN107937013BEfficient removalStable physical propertiesHydrocarbon oils refiningHydrocarbon oils treatmentNitrogen removalPoly(ethylene glycol) dimethyl ether

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Device and process for removing nitrogen oxides under synergistic effect of heteropolyacid and microwave irradiation

InactiveCN103990361AReduce the cost of denitrificationGood removal effectDispersed particle separationActivated carbonNitrogen oxides

The invention relates to a device and a process for removing nitrogen oxides under a synergistic effect of heteropolyacid and microwave irradiation. According to the device, a flue gas conveying pipeline is connected to an inlet of an adsorption bed, an outlet of the adsorption bed passes through a tee valve and then is simultaneously connected to an active carbon bed in a microwave generator and a purified flue gas discharge pipeline, and a desorbing agent generating device is connected to the inlet of the adsorption bed by a tee valve. Flue gas containing NOx is input into the adsorption bed through the tee valve, purified flue gas is discharged through the tee valve, the adsorption bed after adsorption saturation is subjected to the stage of desorbing the NOx with water steam, the NOx which is adsorbed by an adsorbent is desorbed, simultaneously, the adsorbent is regenerated, the desorbed NOx is conveyed to a microwave irradiation type active carbon NOx reducing system through the tee valve, and the NOx is reduced into N2 by the active carbon. By using the device and the process, no oxygen exists in the NOx reducing process, equipment is simple, raw materials are easily obtained, the NOx removing performance is good, and the device and the process are easily operated and conveniently popularized.

Owner:XUZHOU UNIV OF TECH

Flue gas treatment system and flue gas treatment method for stepped ozone oxidation

PendingCN110841450AEfficient denitrificationFully absorbedCombination devicesGas treatmentNitrogen oxidesFlue gas

The invention provides a flue gas treatment system and a flue gas treatment method for stepped ozone oxidation. The flue gas treatment system comprises an ozone supply unit and a desulfurization and denitrification unit which are connected in sequence, wherein the ozone supply unit comprises an ozone generation device, an ozone distribution device and at least three ozone spraying devices, the ozone generation device is connected with the ozone distribution device, and the ozone distribution device is independently connected with the ozone spraying devices respectively; the desulfurization anddenitrification unit comprises a desulfurization and denitrification device, at least two groups of spraying devices are arranged in the desulfurization and denitrification device in the vertical direction, and an ozone spraying device is arranged below each spraying devices; and an ozone spraying device is arranged on a flue gas inlet pipeline of the desulfurization and denitrification unit. According to the invention, a stepped ozone oxidation flue gas treatment process is adopted, and nitrogen oxide is fully absorbed under the condition of low ozone consumption.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

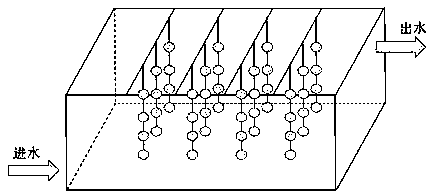

Application method of sulfur autotrophic denitrification biological carrier in anoxic tank

ActiveCN111392859AImprove nitrogen removal efficiencyReduce dosageWater contaminantsBiological treatment apparatusEngineeringBiological organism

The invention discloses an application method of a sulfur autotrophic denitrification biological carrier in an anoxic tank. The invention relates to the technical field of microbiological water treatment. The invention aims to solve a series of problems caused by low mass transfer effect when a sulfur autotrophic denitrification technology is applied. The technical scheme provided by the inventionis as follows: a filler unit assembly is filled with the sulfur autotrophic denitrification biological carrier to form filler units, n groups of the filler units are arranged in each anoxic tank, each group of filler units comprises m filler units, and m and n are positive integers not less than 1; the filler units in the same group are connected in series, and the adjacent filler units are connected with each other through ropes; each group of filler units is fixed at the bottom of the anoxic tank or suspended on a buoy or a truss by connecting the filler units at the head / tail positions inseries, so that the filler units are dispersed in the anoxic tank. By using the method provided by the invention, the denitrification efficiency of the anoxic tank can be greatly improved.

Owner:北京涞澈科技发展有限公司 +1

Method for deep denitriding of waste water in low carbon nitrogen ratio through denitrification

ActiveCN104787882ANo secondary pollutionGood removal effectWater treatment compoundsWater contaminantsFixed bedWater quality

The invention discloses a method for deep denitriding of waste water in a low carbon nitrogen ratio through denitrification. The method comprises the following steps: (1) performing denitriding by utilizing corn cores as an additional carbon source and a biomembrane carrier in a first section reactor A; (2) performing further denitriding by utilizing bamboo charcoal as a fixed bed to load microorganisms in a second section reactor B; (3) setting water inlet points respectively on the two sections of the reactors for raw water, and the water inlet points can be shifted in proportion according to different qualities of the raw water. The method has the following advantages that (1) an organic matter can be slowly released, secondary pollution cannot be generated, and the COD exceeding of effluent cannot be caused; (2) the method has a better removing effect on nitrate nitrogen in the waste water in the low carbon nitrogen ratio and besides can remove ammonia nitrogen in the waste water; (3) secondary pollution cannot be generated, and the standing time of the nitrate nitrogen can be prolonged, so that the quality of the effluent is improved; (4) the denitriding effect of the waste water can be improved, and the removing rate of the nitrate nitrogen is more than 80%, so that the effluent is steady; (5) the technology is simple, easy to operate, low in cost, small in floor space, short in standing time and free from power consumption, and the method has a good application prospect.

Owner:NANJING FORESTRY UNIV

Method for Extracting and Denitrifying Fuel Oil Using Polyethyleneimine

ActiveCN108059972BAppropriate molecular weightStable physical propertiesHydrocarbon oils refiningOrganonitrogen compoundsFuel oil

The invention provides a method for removing organic nitrogen compounds from fuel by using a polyethyleneimine solvent. Extraction operation is performed on high-boiling range diesel oil, coal liquidoil and the like by using polyethyleneimine as an extractant, wherein the mass ratio of the extractant to the fuel is 0.2 to 3, and finally, the denitrification rate can reach 60% to 99%. According tothe invention, selected polyethyleneimine is not insoluble with the fuel, thereby avoiding oil pollution, and alkaline organic nitrogen and non-alkaline organic nitrogen in the fuel can be removed simultaneously.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

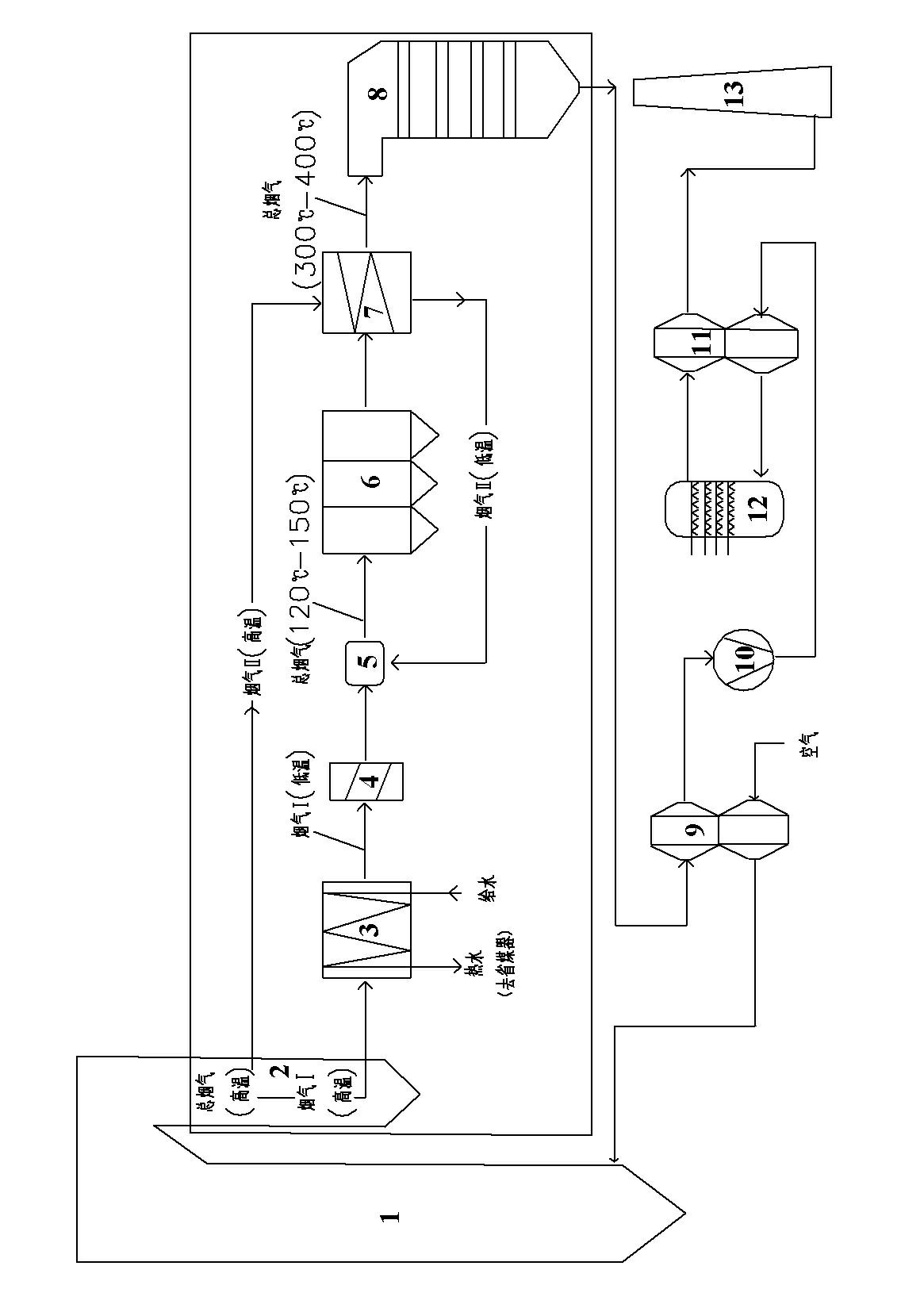

Process for realizing low-cost denitration by utilizing waste heat of sintered ores to heat sintering waste gas

ActiveCN108931141AReduce the cost of denitrificationImprove waste heat utilizationCharge treatment typeHandling discharged materialMetallurgyFlue gas

The invention provides a process for realizing low-cost denitration by utilizing waste heat of sintered ores to heat waste gas. According to the process, flue gas with relatively high NOx concentration in flue gas of a sintering machine is used as a cooling medium to be input into a cooling system for cooling the sintered ores, the part of the flue gas of the sintering machine can be heated to 260-480 DEG C after passing through the cooling system, then the part of the flue gas is input into a denitration system for denitration treatment, then waste heat utilization, dust removal and desulfurization treatment are carried out, and then the emission requirement is met; flue gas with relatively low NOx concentration in the flue gas of the sintering machine undergoes the desulfurization treatment after undergoing the waste heat utilization and the dust removal, and the emission requirement can be met directly, so that the flue gas treatment amount of the denitration system is reduced; andtherefore, the waste heat of the sintered ores in the cooling system is effectively utilized in the process, then the sintering flue gas can reach the required temperature in the denitration system, energy conservation and emission reduction are achieved, and meanwhile, the operation cost of sintering flue gas treatment is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com