Preparation method and application of crosslinked starch, polycaprolactone and polylactic acid mixture

A technology of polycaprolactone and cross-linked starch, applied in anaerobic digestion treatment and other directions, can solve the problems of difficult control of carbon-nitrogen ratio, excessive dosage, etc. The effect of increasing the amount is not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

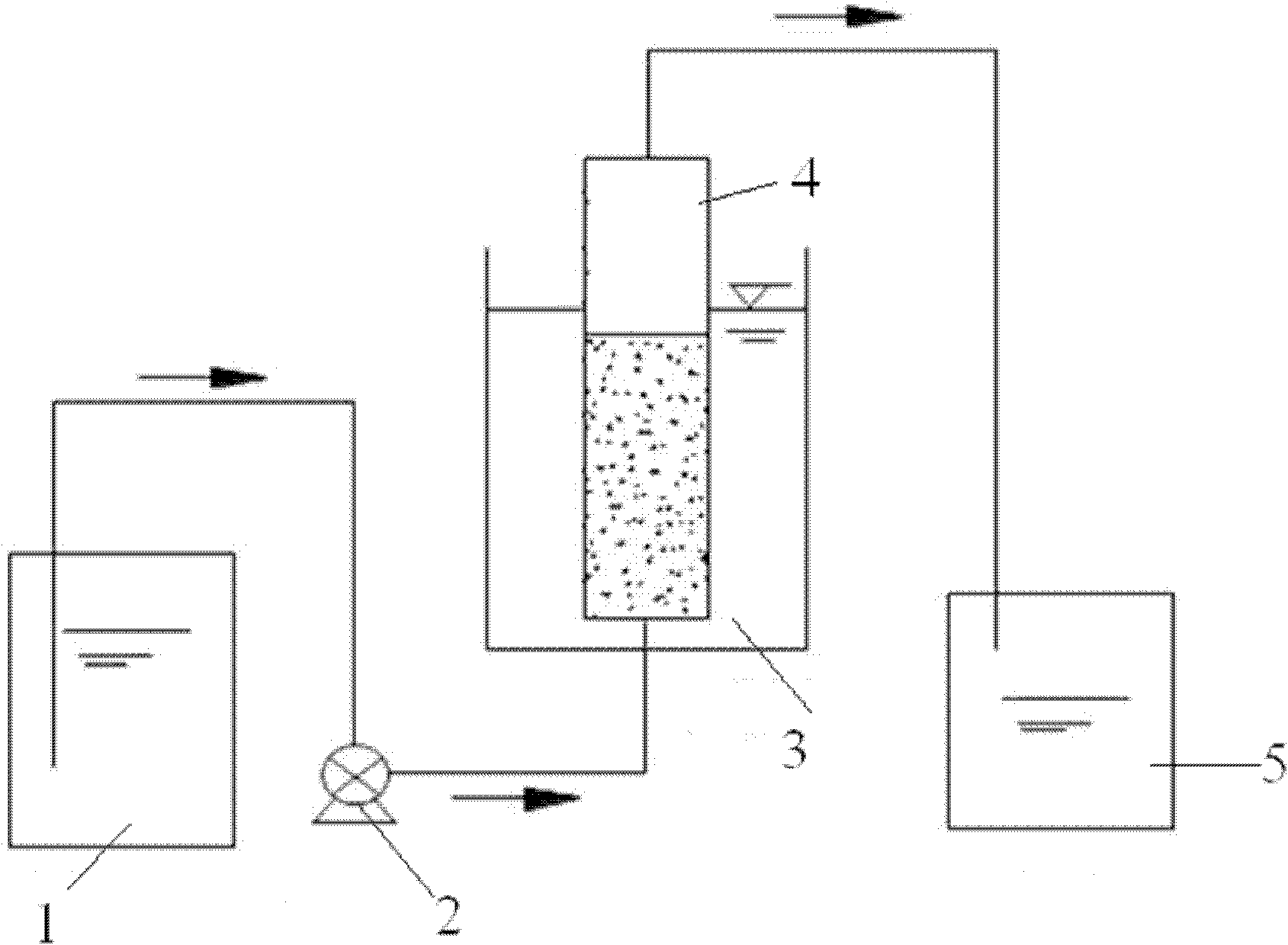

Method used

Image

Examples

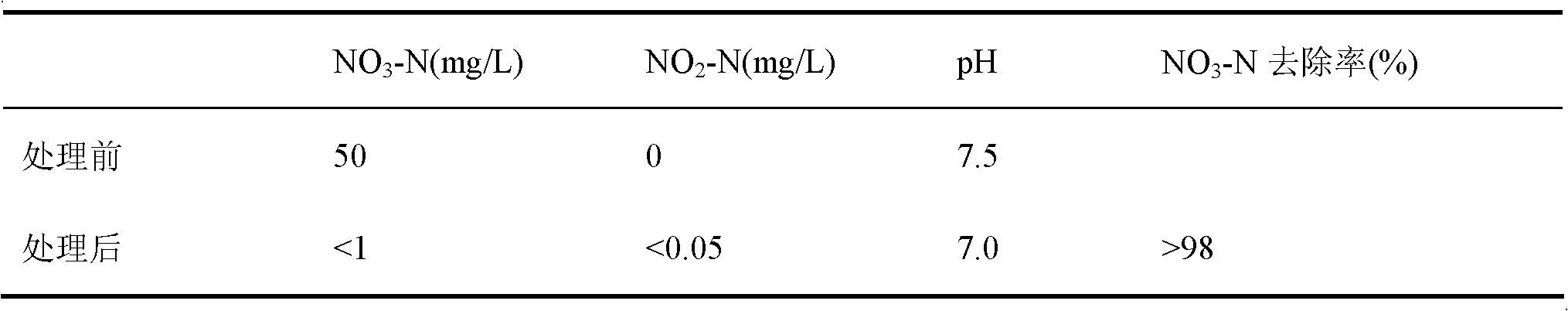

Embodiment 1

[0021] The preparation method of cross-linked starch, polycaprolactone and polylactic acid blend is carried out according to the following steps:

[0022] (1) Starch crosslinking: add 10g starch, 30g water and 0.7g sodium chloride in the reactor, adjust the pH to 9.5 with 0.5mol / L sodium hydroxide solution (adding 0.7g) under mechanical stirring, and heat up to Slowly add 0.8g of epichlorohydrin after 50°C, react at constant temperature for 8 hours, filter, wash, and dry to obtain cross-linked starch;

[0023] (2) Preparation of crosslinked starch, polycaprolactone and polylactic acid blend: 35g crosslinked cornstarch, 25g polycaprolactone (molecular weight 60000), 25g polylactic acid (molecular weight 40000), 11g glycerin, 4g water After stirring evenly, extrude and granulate in a twin-screw extruder at 120-175°C.

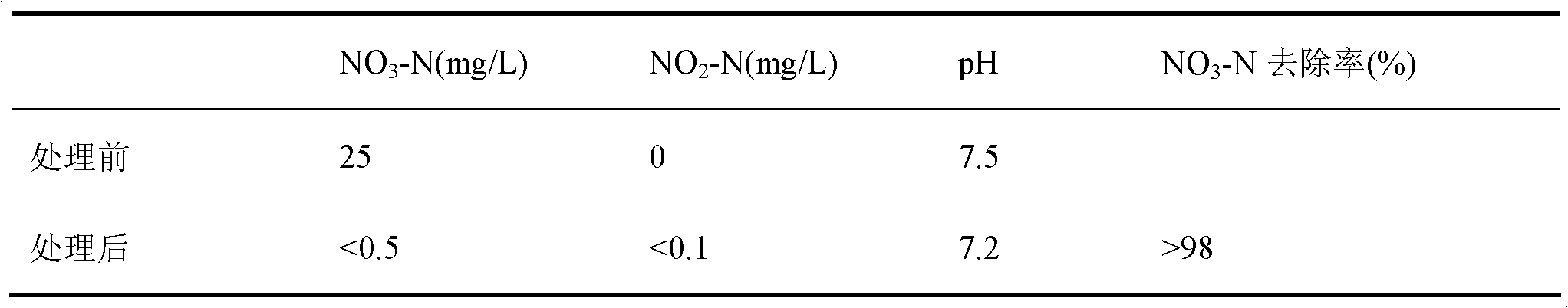

Embodiment 2

[0025] The preparation method of cross-linked starch, polycaprolactone and polylactic acid blend is carried out according to the following steps:

[0026] (1) Starch crosslinking: add 10g starch, 30g water and 0.7g sodium chloride in the reactor, adjust the pH to 9.5 with 0.5mol / L sodium hydroxide solution (adding 0.7g) under mechanical stirring, and heat up to Slowly add 0.8g of epichlorohydrin after 50°C, react at constant temperature for 8 hours, filter, wash, and dry to obtain cross-linked starch;

[0027] (2) Preparation of crosslinked starch, polycaprolactone and polylactic acid blend: 46g crosslinked tapioca starch, 14g polycaprolactone (molecular weight 40000), 14g polylactic acid (molecular weight 80000), 15g glycerin, 5g water After mixing 5g of wood flour and 1g of KH-560 silane coupling agent evenly, extrude and granulate in a twin-screw extruder at 120-175°C.

Embodiment 3

[0029] The preparation method of cross-linked starch, polycaprolactone and polylactic acid blend is carried out according to the following steps:

[0030] (1) Starch crosslinking: add 10g starch, 30g water and 0.7g sodium chloride in the reactor, adjust the pH to 9.5 with 0.5mol / L sodium hydroxide solution (adding 0.7g) under mechanical stirring, and heat up to Slowly add 0.8g of epichlorohydrin after 50°C, react at constant temperature for 8 hours, filter, wash, and dry to obtain cross-linked starch;

[0031] (2) Preparation of crosslinked starch, polycaprolactone and polylactic acid blend: 23.04g crosslinked cornstarch, 23.04g cornstarch, 14.11g polycaprolactone (molecular weight 40000), 14.11g polylactic acid (molecular weight 80000), 14.81g of glycerin, 4.94g of water, 4.95g of wood flour and 1g of KH-560 silane coupling agent were stirred evenly, and extruded and granulated in a twin-screw extruder at 155°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com