Process for realizing low-cost denitration by utilizing waste heat of sintered ores to heat sintering waste gas

A low-cost technology for sintering ore, which is applied in the field of waste heat utilization and sintering sintering, and can solve the problem of high operation cost of sintering and denitration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

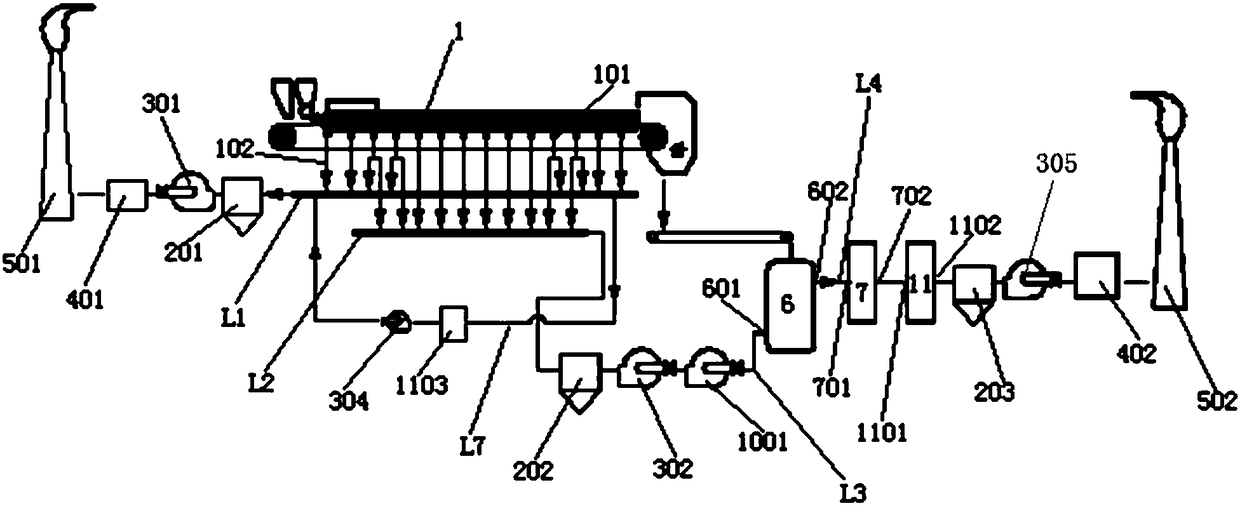

Embodiment 1

[0143] A system that uses sinter waste heat to heat sinter waste gas to achieve low-cost denitrification, the system includes:

[0144] A sintering machine 1, 28 bellows 101 are arranged under the trolley of the sintering machine 1;

[0145] The non-denitration flue gas pipeline L1 and the denitrification flue gas pipeline L2 provided under the sintering machine 1,

[0146] cooling system 6, and

[0147] Denitrification system 7;

[0148] Among them, according to the running direction of the mineral material on the sintering machine 1, the bellows of the sintering machine 1 are divided into 5 sections, the first section includes 3 bellows, the second section includes 2 bellows, and the third section The first section includes 16 bellows, the fourth section includes 2 bellows, and the fifth section includes 5 bellows;

[0149] Each wind box 101 belonging to the first section is connected to the non-denitration flue gas pipeline L1 through its respective wind box branch pipe ...

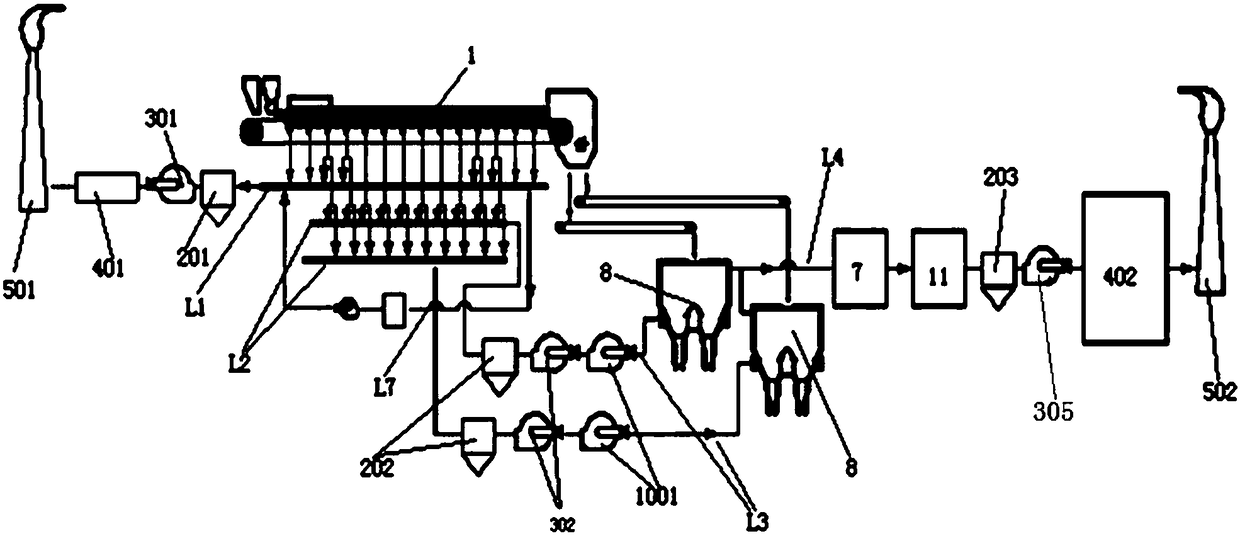

Embodiment 2

[0155] Embodiment 1 is repeated, except that a fourth dust collector 204 is provided on the second flue gas delivery pipeline L4. The second flue gas delivery pipe L4 is connected to the flue gas inlet 701 of the denitrification system 7 after passing through the third waste heat recovery device 1104 . A first temperature detector 1401 and a concentration detector 15 are installed on the non-denitration flue gas pipeline L1. A second temperature detector 1402 is installed on the denitration flue gas pipeline L2. The flue gas outlet 1102 of the first waste heat recovery device 11 is connected to the flue gas inlet of the second desulfurization system 402 through the fifth exhaust fan 305 after passing through the third dust collector 203 . The wind box branch pipes 102 connected to the wind boxes 101 belonging to the fifth section are all directly connected to the third flue gas delivery pipeline L7, and then connected to the non-denitration flue gas pipeline L1 through the fo...

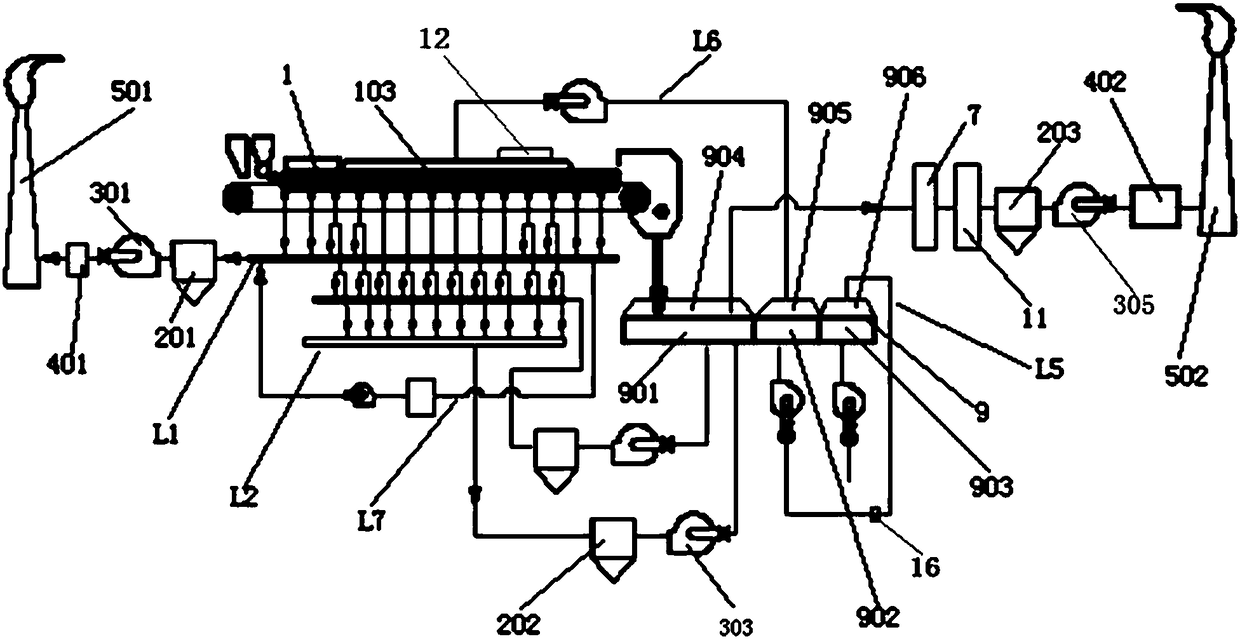

Embodiment 3

[0157] Example 2 was repeated, except that the vertical cooler 8 was replaced by an annular cooler 9 . The annular cooler 9 includes a high temperature section 901 , a medium temperature section 902 and a low temperature section 903 . The denitrification flue gas pipeline L2 passes through the second dust collector 202 and is connected to the air inlet of the high temperature section 901 of the annular cooler 9 . Above the high temperature section 901 is provided a wind cover 904 for the high temperature section of the ring cooler. The air outlet of the wind hood 904 of the high temperature section of the ring cooler is connected to the flue gas inlet 701 of the denitrification system 7 . A third exhaust fan 303 is provided on the first flue gas conveying pipe L3. A sealing cover 103 is provided above the trolley of the sintering machine. The air inlet of the low-temperature section 903 of the annular cooler 9 communicates with the atmosphere. Above the low temperature sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com