Application method of sulfur autotrophic denitrification biological carrier in anoxic tank

A biological carrier and application method technology, which is applied in chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., can solve problems such as difficulty in the application of autotrophic denitrification, low mass transfer effect, and excessive total nitrogen, and achieve Increase the utilization rate of sulfur sources, reduce the amount of materials used, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0033] Preparation example 1 Preparation of sulfur autotrophic denitrification biological carrier

[0034] Mix the sulfur source and the common carrier according to the required ratio, ball mill, heat treatment under the protection of argon, and mix with the inert carrier evenly after cooling. The ball milling time is 2h; the heating rate of heat treatment is 15°C / min, the heat treatment temperature is 150°C, and the heat treatment time is 20min.

[0035]The above-mentioned sulfur source is pyrite, the common carrier is limestone, and the inert carrier is silicon dioxide. The particle size of ordinary carrier and inert carrier is 5-10mm, both of ordinary carrier and inert carrier are porous structure, with large pores > 10um, pore volume distribution > 70%; 2 ~ 50nm mesopores, pore volume distribution > 10%; 600 BET 2 / g. The mass ratio of the common carrier to the inert carrier is 2:1, and the mass ratio of the sulfur element in the sulfur source to the mass of the common c...

preparation example 2

[0036] Preparation example 2 Preparation of sulfur autotrophic denitrification biological carrier

[0037] Mix the sulfur source and the common carrier according to the required ratio, ball mill, heat treatment under the protection of argon, and mix with the inert carrier evenly after cooling. The ball milling time is 3h; the heating rate of heat treatment is 10°C / min, the heat treatment temperature is 200°C, and the heat treatment time is 30min.

[0038] The above-mentioned sulfur source is pyrite, the common carrier is limestone, and the inert carrier is silicon dioxide. The particle size of ordinary carrier and inert carrier is 10-30mm, both of ordinary carrier and inert carrier are porous structure, with large pores > 10um, pore volume distribution > 70%; 2 ~ 50nm mesopores, pore volume distribution > 10%; 600 BET 2 / g. The mass ratio of the common carrier to the inert carrier is 3.5:1, and the mass ratio of the sulfur element in the sulfur source to the mass of the comm...

Embodiment 1

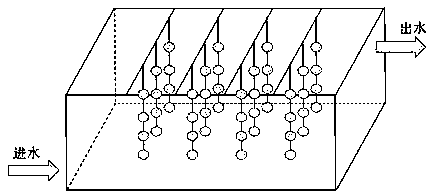

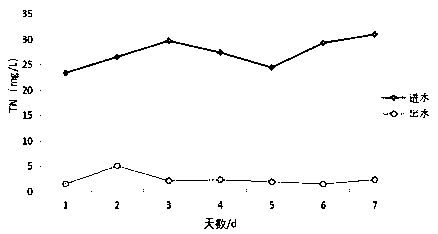

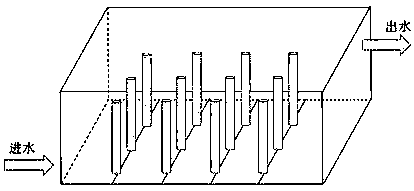

[0039] Example 1 Application of a sulfur autotrophic denitrification biological carrier in anoxic ponds

[0040] This example is applied to the treatment of domestic sewage in a community in Beijing. The sulfur autotrophic denitrification biological carrier prepared in Preparation Example 1 is added to the spherical reticulated shell. The amount of biological carrier added is calculated according to the following method. The filling of a single spherical reticulated shell The volume percentage is 50%.

[0041] The usage calculation method is as follows:

[0042]

[0043] in, is the safety factor of the amount of biological carrier, which is a constant, Choose 1.3; As the benchmark dosage, it is a constant, 80 kg / m 3 ; is the influent total nitrogen concentration; is the concentration of organic matter in water; is the hydraulic retention time of the anoxic pond; to consume time; is the sludge concentration in the anoxic pond; for unit concentration. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com