Device and process for biochemically denitrifying high-ammonia nitrogen tanning wastewater

A technology of tanning wastewater and treatment device, which is applied in the field of industrial wastewater treatment to achieve the effects of reducing energy consumption, low treatment and operation costs, and saving carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

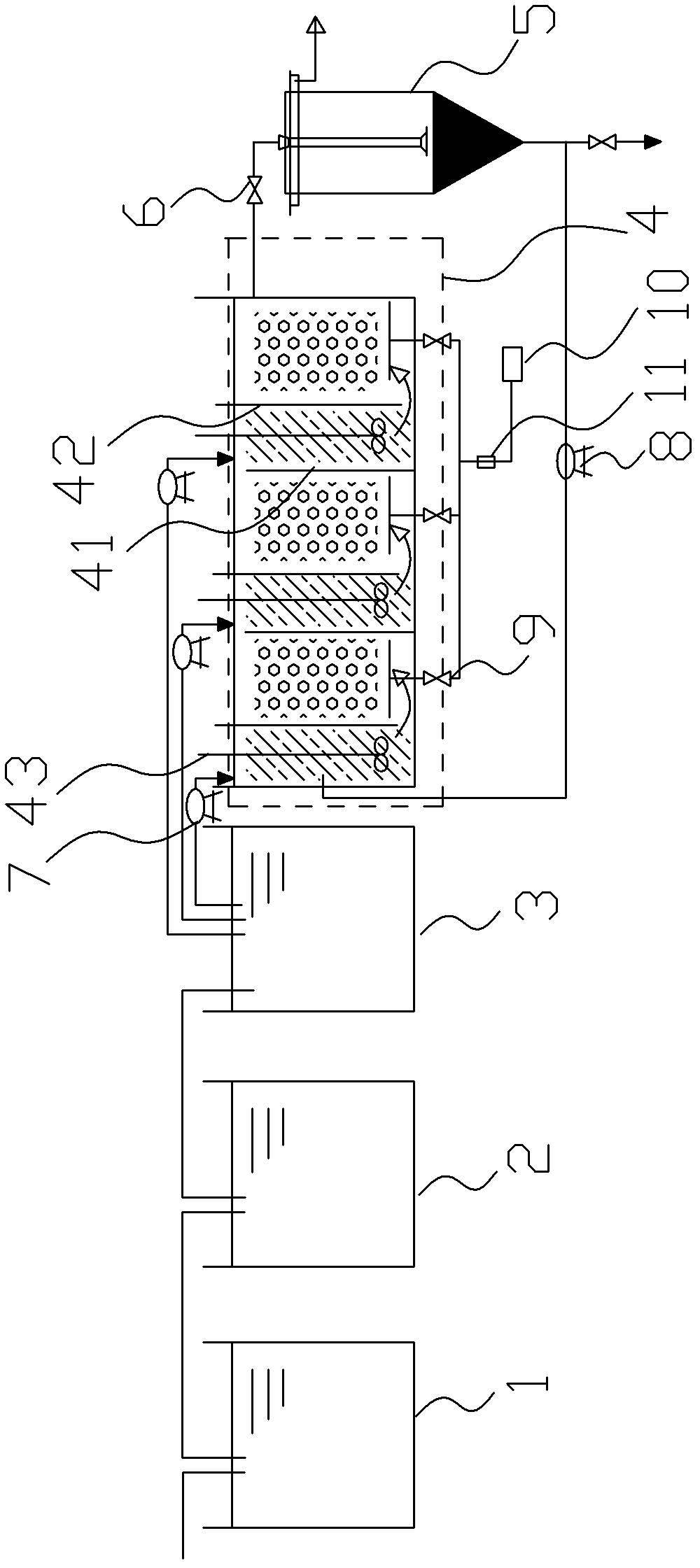

[0027] refer to figure 1 , a biochemical denitrification treatment device for high ammonia nitrogen tannery wastewater of the present invention, comprising a physical and chemical pretreatment unit 1, a biochemical pretreatment unit 2, a regulating pool 3, a three-stage anoxic / aerobic treatment unit 4 and a mud-water separation unit 5, The three-level anoxic / aerobic treatment unit 4 is formed by connecting three groups of anoxic and aerobic reaction units in series, and the reaction unit is composed of an anoxic reaction zone and an aerobic reaction zone in series, and the anoxic reaction zone at each level is A partition 41 is provided in the reaction zone and the aerobic reaction zone, and the partition separates the anoxic reaction zone from the upper part of the aerobic reaction zone and communicates with the lower part, and a partition 42 is arranged in the aerobic reaction zone and the anoxic reaction zone , the clapboard makes the upper part of the aerobic reaction zone...

Embodiment 2

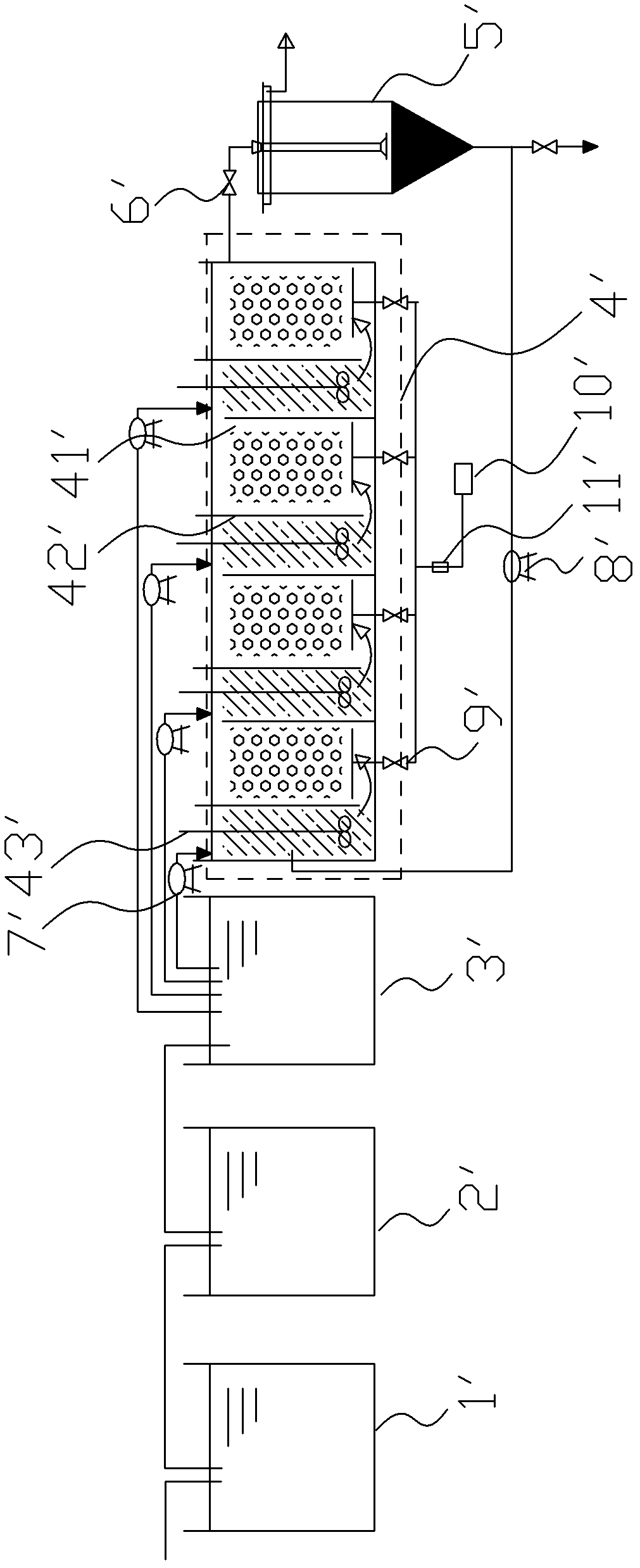

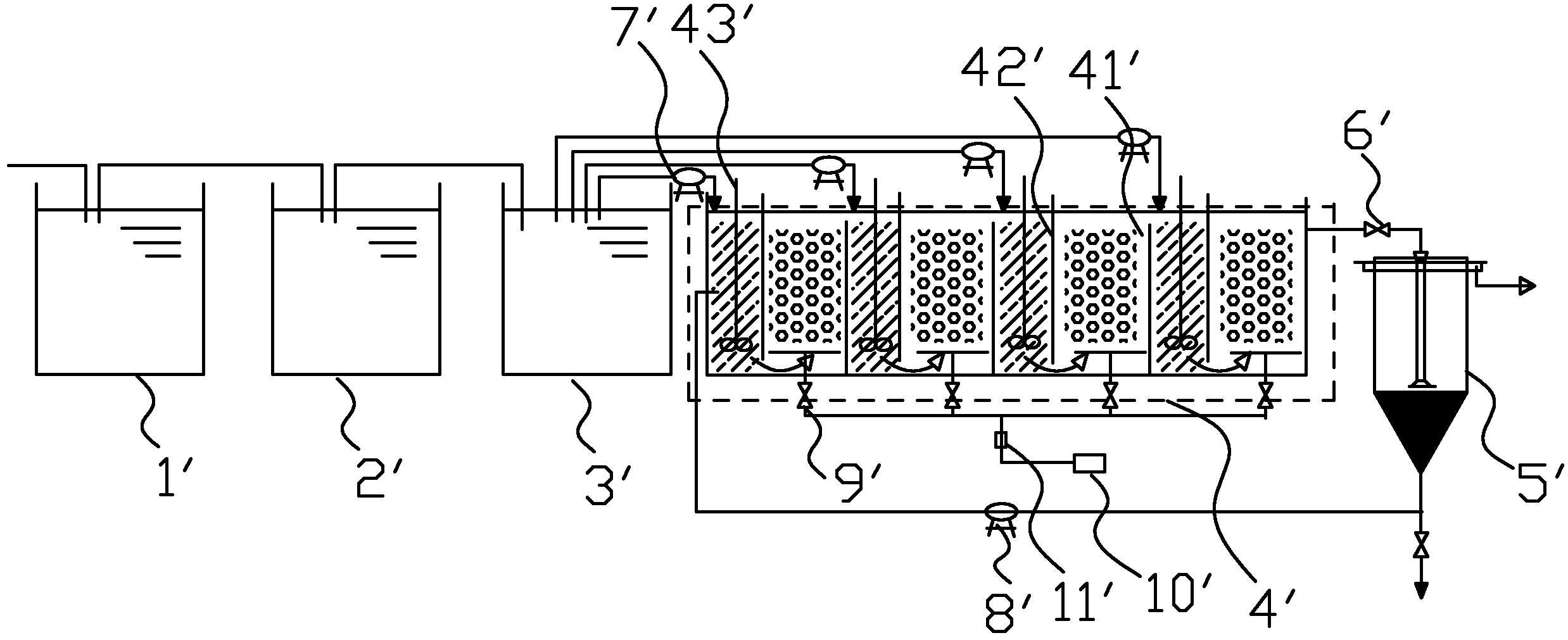

[0037] refer to figure 2 , a biochemical denitrification treatment device for high ammonia nitrogen tannery wastewater of the present invention, comprising a physical and chemical pretreatment unit 1', a biochemical pretreatment unit 2', a regulating pool 3', a four-stage anoxic / aerobic treatment unit 4' and muddy water The separation unit 5', the four-stage anoxic / aerobic treatment unit 4' is composed of four sets of anoxic and aerobic reaction units in series, and the reaction unit is composed of an anoxic reaction zone and an aerobic reaction zone in series, The anoxic reaction zone and the aerobic reaction zone at all levels are provided with a partition 41', the partition separates the anoxic reaction zone from the aerobic reaction zone, and communicates with the lower part, and the aerobic reaction zone and the anoxic reaction zone at all levels are connected to each other. A partition 42' is arranged in the zone, and the partition connects the upper part of the aerobic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com