Multi-stage aerobic-anaerobic compound biological filter bed

A biological filter bed and oxygen composite technology, applied in the field of biological filter bed, can solve the problems of nitrogen accumulation and other problems, achieve good filtering effect, bed depth, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

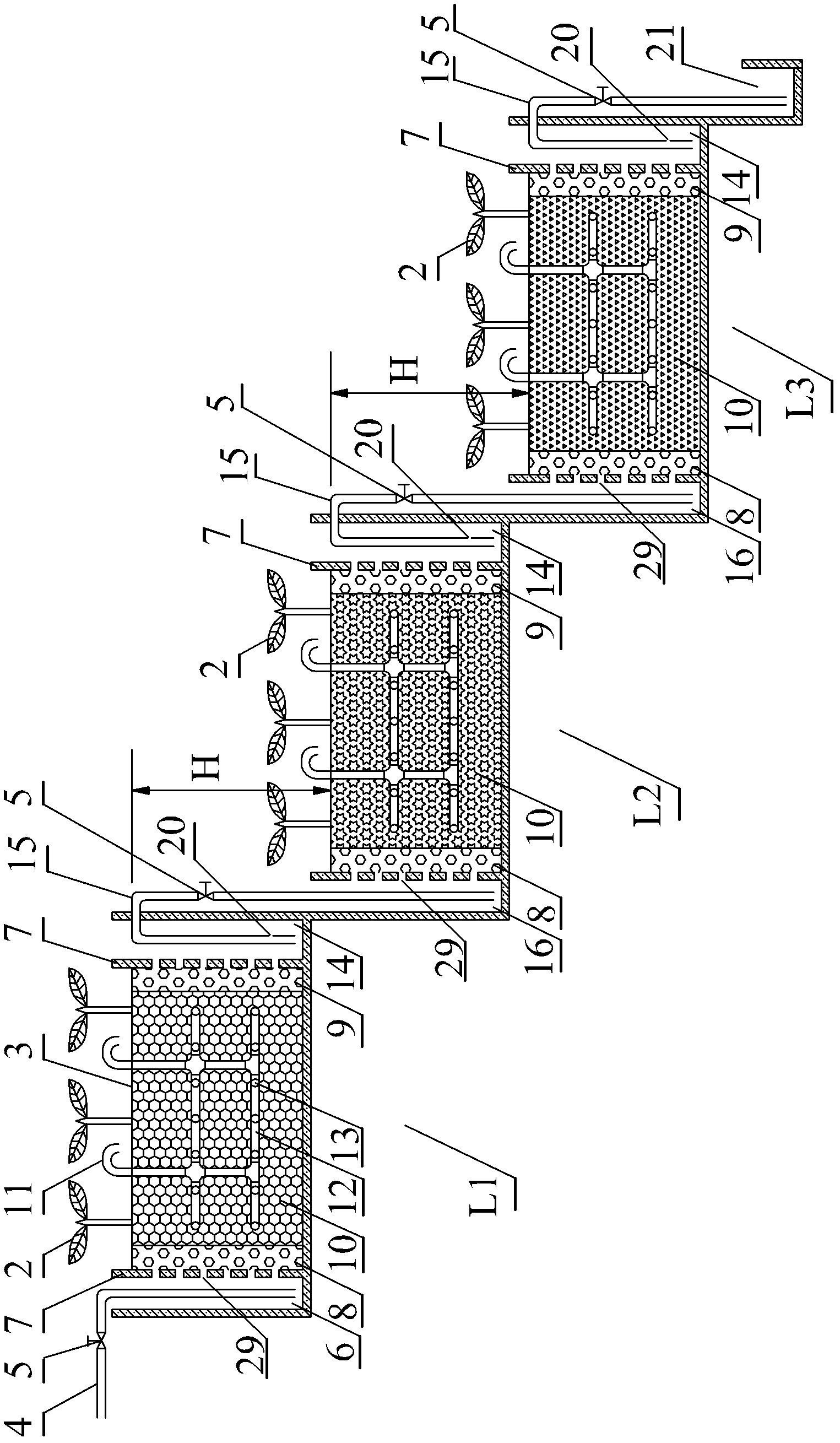

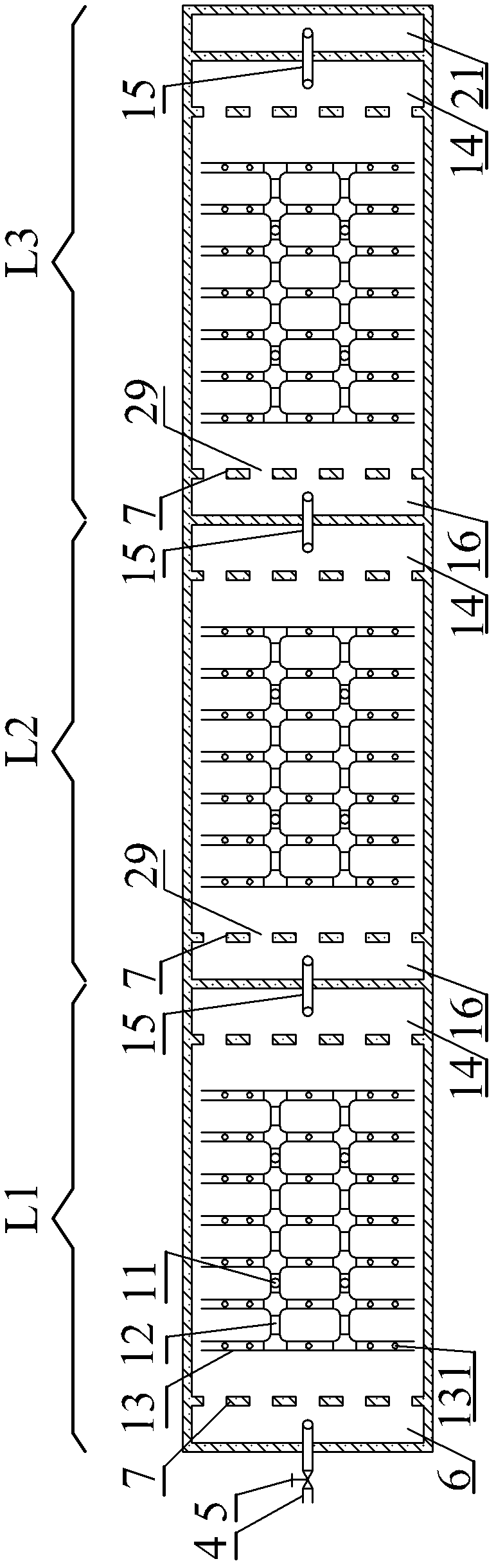

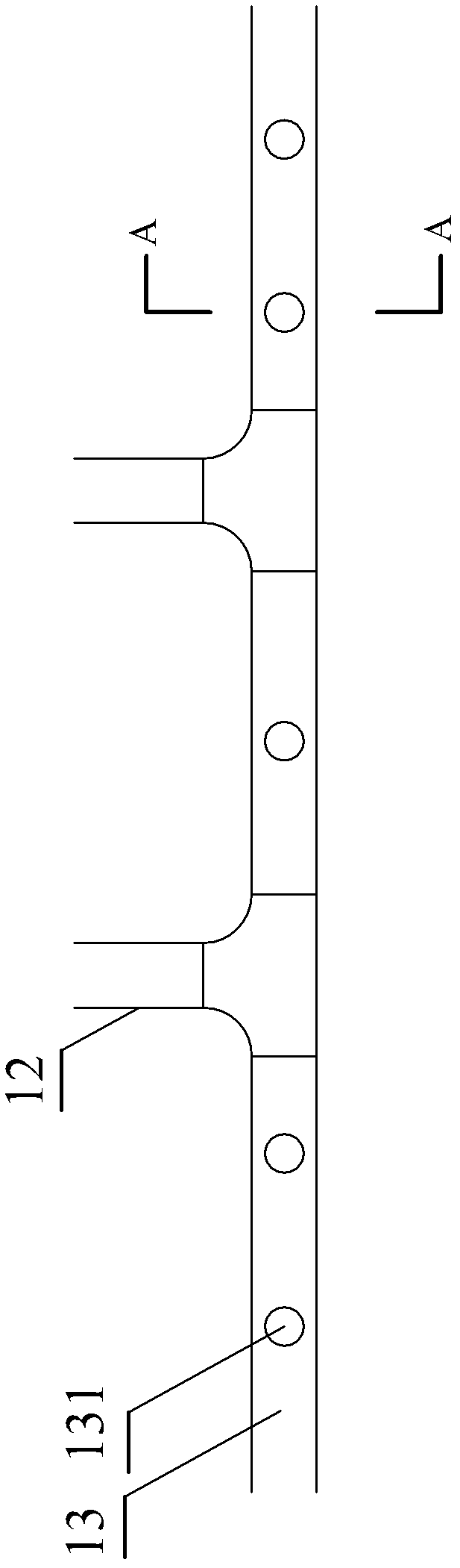

[0026] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-6 :

[0027] A multi-stage aerobic-anaerobic composite biological filter bed, comprising water inlet pipe 4 and filter bed (L1, L2, L3), described filter bed (L1, L2, L3) has more than two stages (the present invention is 3 level), the liquid level of each level of filter bed decreases step by step, and each level of filter bed is divided into water inlet tanks (6, 16), filter chambers 3 and water outlet tanks 14 by rectifying walls 7 uniformly distributed on both sides with perforations 29, The packing layer (8,9,10) that filler is formed in the filter chamber 3 is packed, and described packing layer (8,9,10) is horizontal stratification, and the filler particle size of packing layer (8,9,10) is : the filler particle size of the packing layers (8, 9) on both sides is large, the filler particle size of the middle packing layer 10 is sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com