Device and process for removing nitrogen oxides under synergistic effect of heteropolyacid and microwave irradiation

A technology of microwave irradiation and nitrogen oxides, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of unsolvable carbon loss, low denitrification rate, carbon loss, etc., and achieve good NOx removal performance , low cost of denitrification, easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

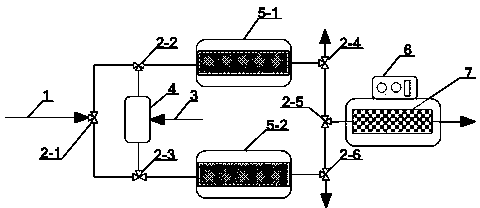

[0028] A method for synergistic removal of nitrogen oxides by heteropoly acid and microwave irradiation, the steps are as follows:

[0029] (1) Heteropolyacid adsorption of NOx in flue gas:

[0030] The flue gas containing NOx after dedusting and desulfurization is input through the flue gas input pipe 1, and enters the No. 1 adsorption bed 5-1 through the three-way valve 2-1, 2-2, and the flue gas after adsorption and purification is discharged through the three-way valve 2-4 . The adsorbent in the adsorption bed is phosphotungstic heteropolyacid H 3 PW 12 o 40 , the adsorption temperature is 150°C, and the flue gas space velocity is 5000h -1 .

[0031] After the adsorption is saturated, switch the three-way valve 2-1 so that the flue gas passes through the three-way valve 2-3 and enters the No. 2 adsorption bed 5-2, and the flue gas after adsorption and purification is discharged through the three-way valve 2-6;

[0032] The No. 1 adsorption bed after adsorption sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com