Flue gas treatment system and flue gas treatment method for stepped ozone oxidation

A flue gas treatment system, ozone oxidation technology, applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as difficult and increase operating costs, the risk of ozone escape, to avoid secondary pollution and reduce ozone The effect of input amount and complete response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

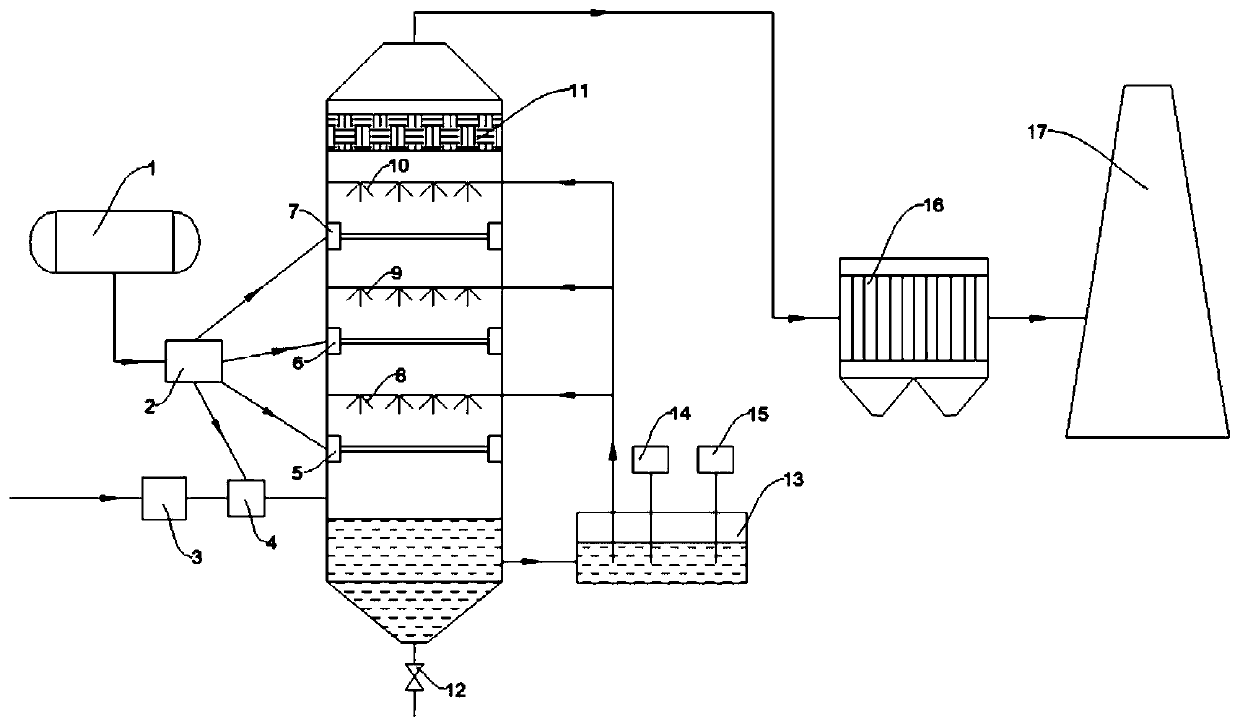

[0077] This embodiment provides a flue gas treatment method of cascade ozonation, using a flue gas treatment system provided by a specific embodiment to perform cascade ozonation on the flue gas. Described flue gas treatment method comprises:

[0078] (I) The ozone generated by the ozone generator 1 is proportionally distributed to different ozone injection devices through the ozone distribution device 2, and the ozone injection amount distributed by the ozone distribution device 2 to each ozone injection device along the sequence of contact between the flue gas and ozone The gradient decreases, specifically, the ozone distributed to the primary ozone injection device 4 by the ozone distribution device 2 and the NO in the flue gas x The molar ratio is 0.8:1, the ozone distributed by the ozone distribution device 2 to the primary ozone injection device 5 and the NO in the flue gas x The molar ratio is 0.6:1, the ozone distributed by the ozone distribution device 2 to the secon...

Embodiment 2

[0083] This embodiment provides a flue gas treatment method of cascade ozonation, using a flue gas treatment system provided by a specific embodiment to perform cascade ozonation on the flue gas. Described flue gas treatment method comprises:

[0084](I) The ozone generated by the ozone generator 1 is proportionally distributed to different ozone injection devices through the ozone distribution device 2, and the ozone injection amount distributed by the ozone distribution device 2 to each ozone injection device along the sequence of contact between the flue gas and ozone The gradient decreases, specifically, the ozone distributed to the primary ozone injection device 4 by the ozone distribution device 2 and the NO in the flue gas x The molar ratio is 1:1, the ozone distributed by the ozone distribution device 2 to the primary ozone injection device 5 and the NO in the flue gas x The molar ratio is 0.8:1, the ozone distributed by the ozone distribution device 2 to the secondar...

Embodiment 3

[0089] This embodiment provides a flue gas treatment method of cascade ozonation, using a flue gas treatment system provided by a specific embodiment to perform cascade ozonation on the flue gas. Described flue gas treatment method comprises:

[0090] (I) The ozone generated by the ozone generator 1 is proportionally distributed to different ozone injection devices through the ozone distribution device 2, and the ozone injection amount distributed by the ozone distribution device 2 to each ozone injection device along the sequence of contact between the flue gas and ozone The gradient decreases, specifically, the ozone distributed to the primary ozone injection device 4 by the ozone distribution device 2 and the NO in the flue gas x The molar ratio is 1.2:1, the ozone distributed by the ozone distribution device 2 to the primary ozone injection device 5 and the NO in the flue gas x The molar ratio is 1:1, the ozone distributed by the ozone distribution device 2 to the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com