Denitrification and decarbonizing treatment system and method of landfill leachate in late period

A landfill leachate and carbon treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high cost and difficulty in reaching the standard of effluent total nitrogen, and prevent churn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

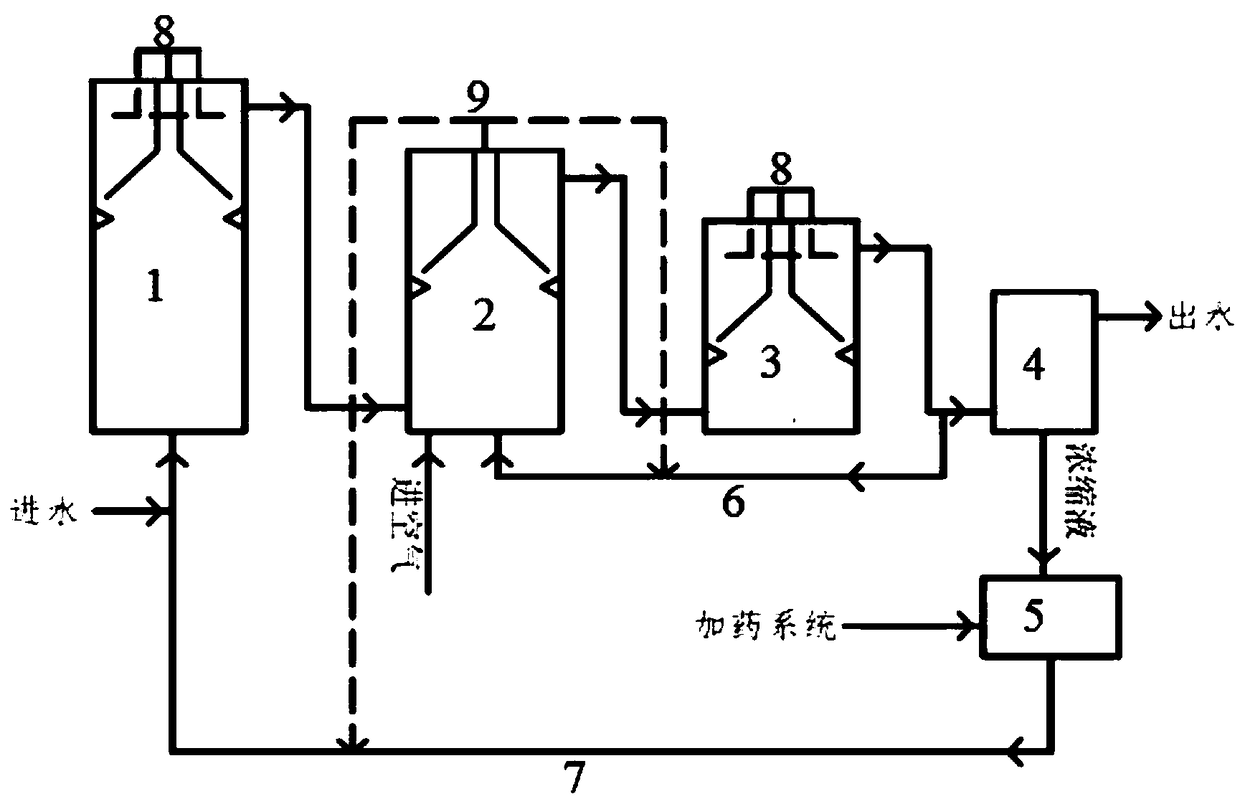

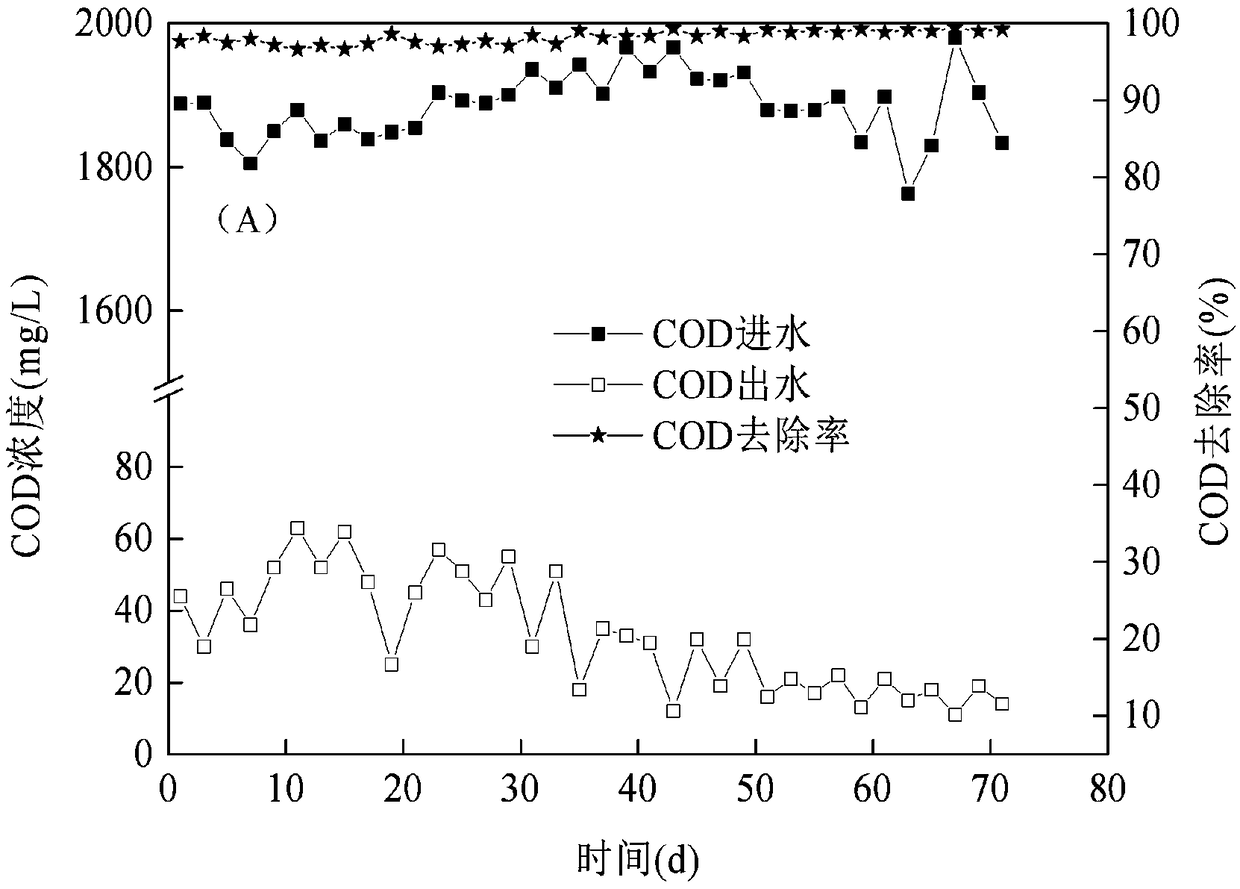

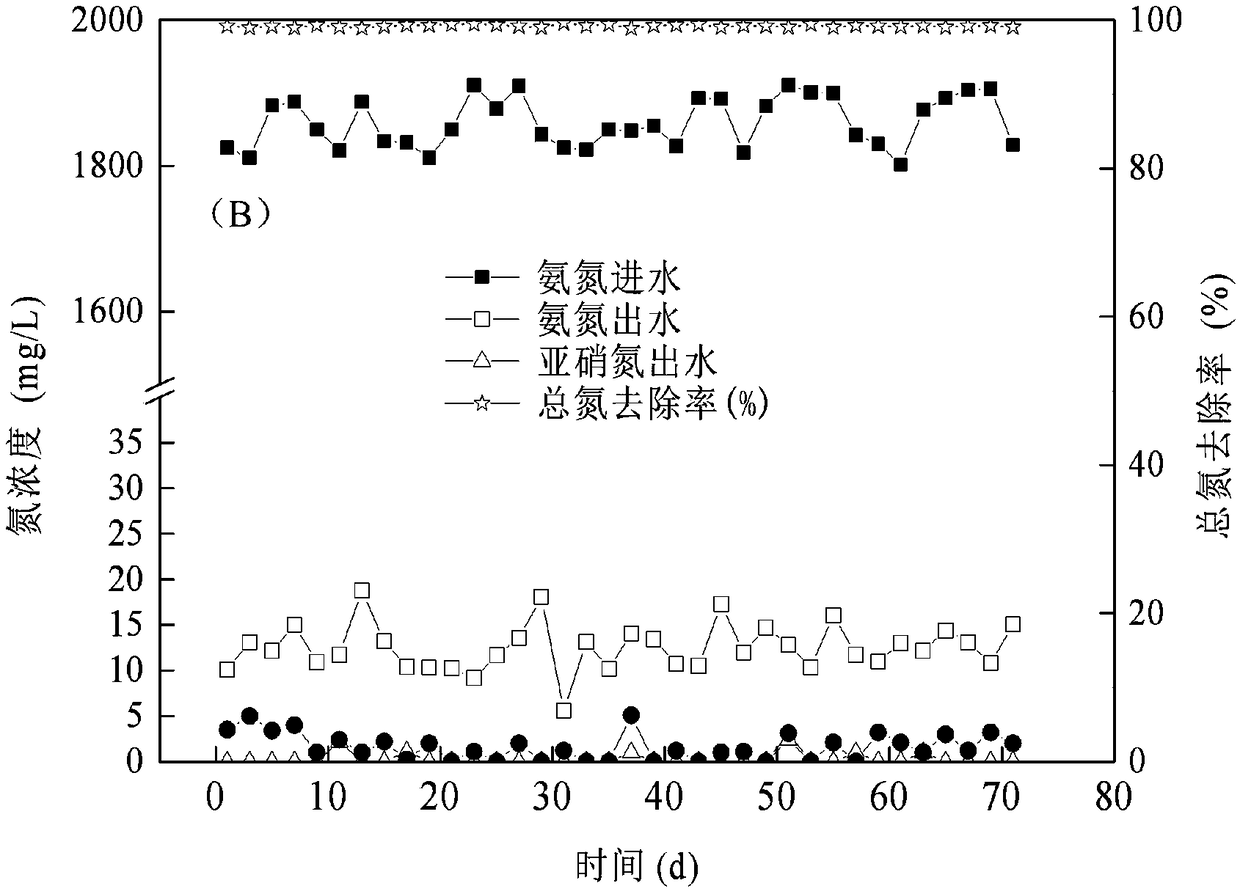

[0067] The system of the present invention is used to treat late-age landfill leachate from a certain landfill in Suzhou. The landfill has been in operation for more than 20 years. Winter is the dry season, and the wastewater quality is characterized by COD 1800-2200mg / L, BOD 400-500mg / L, NH 4 + -N 1700~1900mg / L, pH 7.7~8.1.

[0068]Two sets of UASB were used as the denitrification reactor and the anammox reactor respectively, with an effective volume of 1.8L. An upflow membrane bioreactor is used as a partial nitrosation reactor with an effective volume of 9L. Denitrification reactors are inoculated with denitrification granular sludge; some nitrification reactors use mature nitrosation biofilms, and the pH value is controlled at 8. The anammox reactor was inoculated with domesticated anammox granular sludge, and the pH value was controlled at 8. The concentration tank adopts cellulose acetate membrane and RO membrane with a pore size of 0.45 μm, and the effective volume...

Embodiment 2

[0072] In summer, due to excessive rain, the concentration of late-age landfill leachate is at the lowest value in a year, and the system of the present invention is used to treat the landfill leachate in this period. The water quality of landfill leachate in the flood season is COD 1100~1300mg / L, BOD200~350mg / L, NH 4 + -N 1000~1250mg / L, pH 7.8~8.1.

[0073] Two sets of UASB were used as the denitrification reactor and the anammox reactor respectively, with an effective volume of 1.8L. An upflow reactor is used as a partial nitrosation reactor with an effective volume of 9L. The denitrification tank is inoculated with mature denitrification biofilm. Some nitrosation reactors use mature nitrosation biofilms. The anammox reactor is inoculated with the anammox granular sludge that has been domesticated. The concentration tank adopts cellulose acetate membrane and RO membrane with a pore size of 0.45 μm, and the effective volume is 5L. The effective volume of the oxidation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com