Method for treating leachate in domestic refuses landfill site by tower type aged-refuse bioreactor

A technology of mineralized garbage and biological reaction, applied in biological water/sewage treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve environmental sanitation and safety problems in operation, lack of process design and operation experience, and accelerate landfill Field stabilization process and other issues, to achieve the effect of strong impact resistance, easy to realize, and little influence of external conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

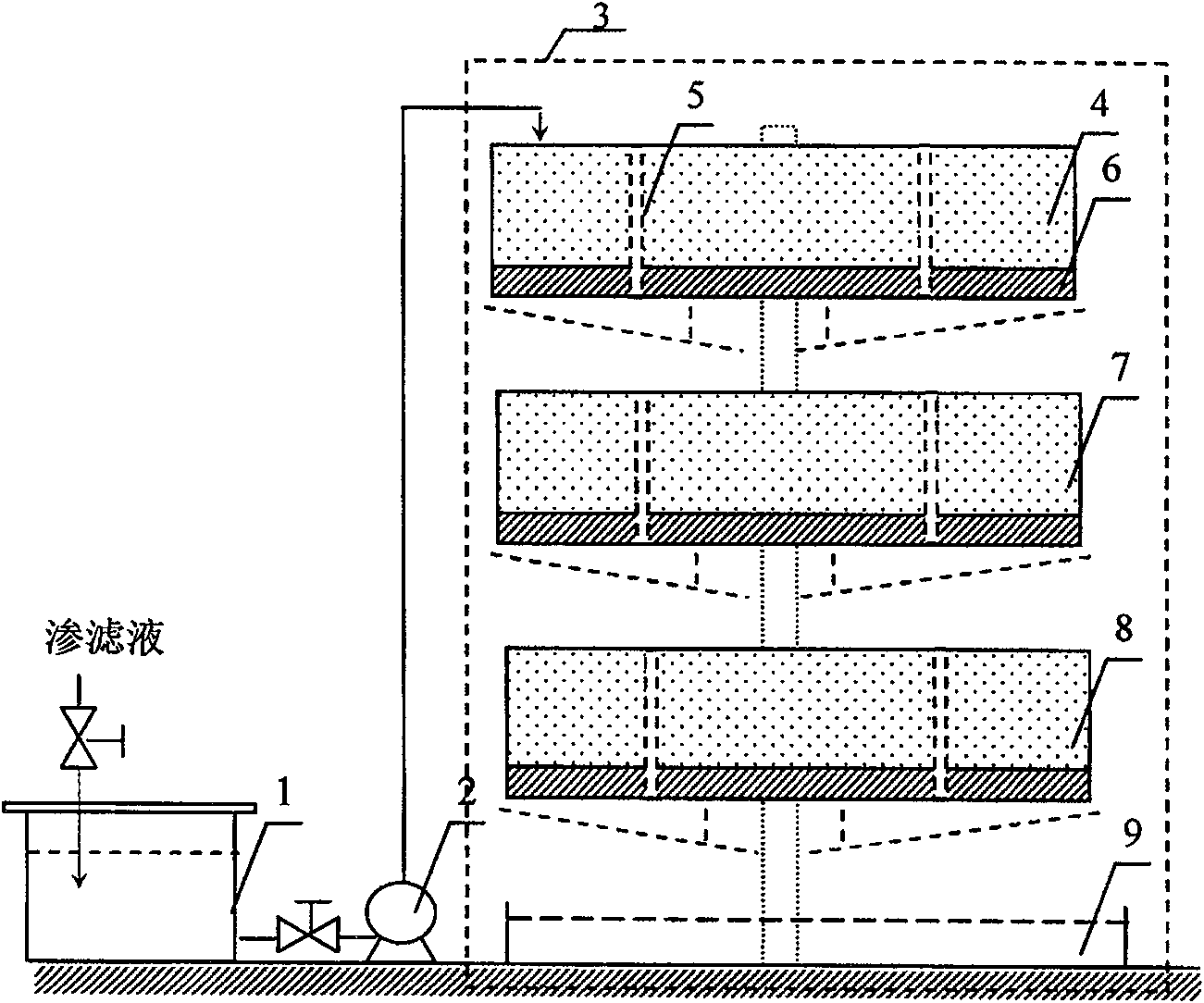

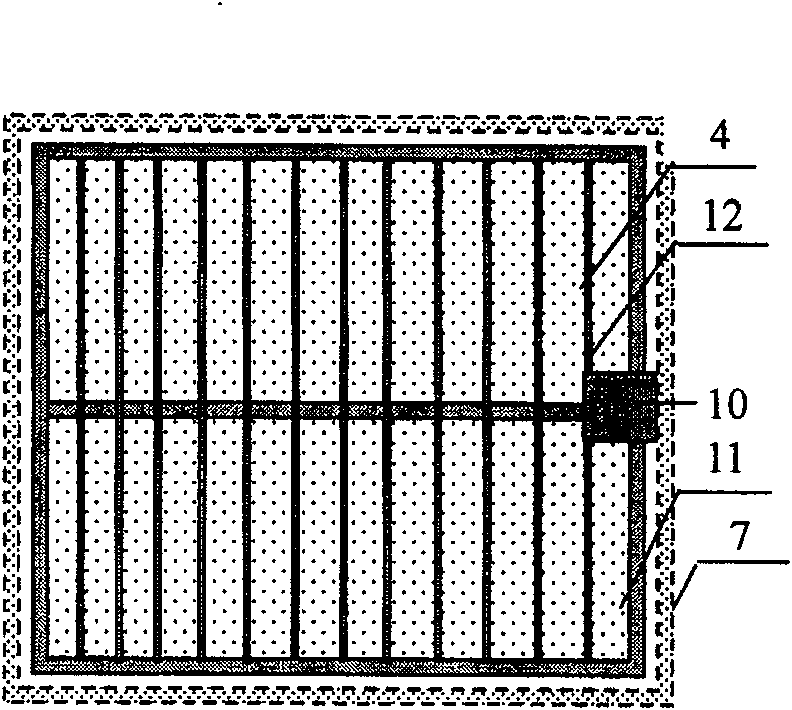

[0031] A tidal flat landfill in Shanghai adopts the attached figure 1 The process flow of the three-stage vertical series mineralized garbage bioreactor bed is shown, and the pilot experiment of leachate treatment of 1-5t / d is carried out. The basic properties of the mineralized garbage fines are shown in Table 1. The leachate to be treated (COD: 8200-12000 mg / L) is taken from the adjustment tank and treated in the anaerobic tank 1 for 30 days (COD is reduced to 4200-6000 mg / L). , using high-pressure pump 2 to extract water to the surface of the first-stage reaction bed, and the design parameters of the water distribution system are shown in Table 2. The cross-section of the three-stage reaction bed is rectangular (10m×3m). The effective heights of mineralized garbage fillers in the first, second, and third-stage beds are 0.4m, 0.6m, and 1m respectively, and the vertical distance between adjacent beds is 0.3m.

[0032] After a 30d acclimation period, the system will be dosed ...

Embodiment 2

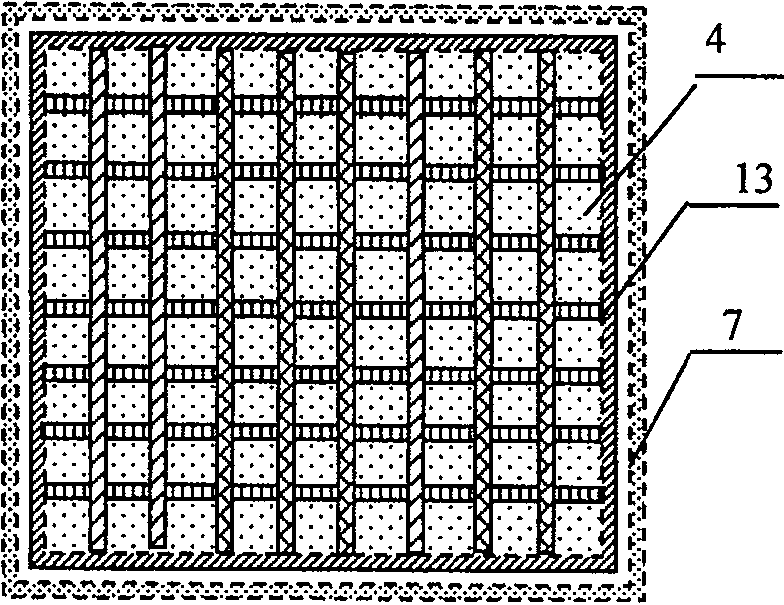

[0042] A valley-type landfill in Qingdao City, Shandong Province adopts the attached Figure 4 The three-stage horizontal series mineralized garbage bioreactor bed process shown is for the engineering application of 70t / d leachate treatment. The landfill age of mineralized waste is 9 years, and the sieving particle size is less than 60mm. Only inert materials such as stones, plastics, glass, and wooden sticks with large particles are sorted out. The leachate to be treated (COD: 6500-9000mg / L) is taken from the adjustment pond. The anaerobic pond is transformed from a facultative pond with HDPE membrane cover. After the leachate stays in it for about 60 days (COD drops to 3000-4500mg / L L), three high-pressure pumps and three sets of large-resistance pipeline distribution systems are used to extract and distribute water to the surface of the three-stage reaction bed, and the design parameters of the water distribution system are similar to those in Table 2. The tertiary reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com