Fluorine removal agent prepared from fly ash, fluorine removal method and application of fluorine removal agent

A technology of defluoridation agent and fly ash, which is applied in the field of environmental restoration, can solve the problems of rapid adsorption performance attenuation, high cost, and fast filtration speed, and achieve excellent adsorption and defluorination performance, less investment in production equipment, and large exchange capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

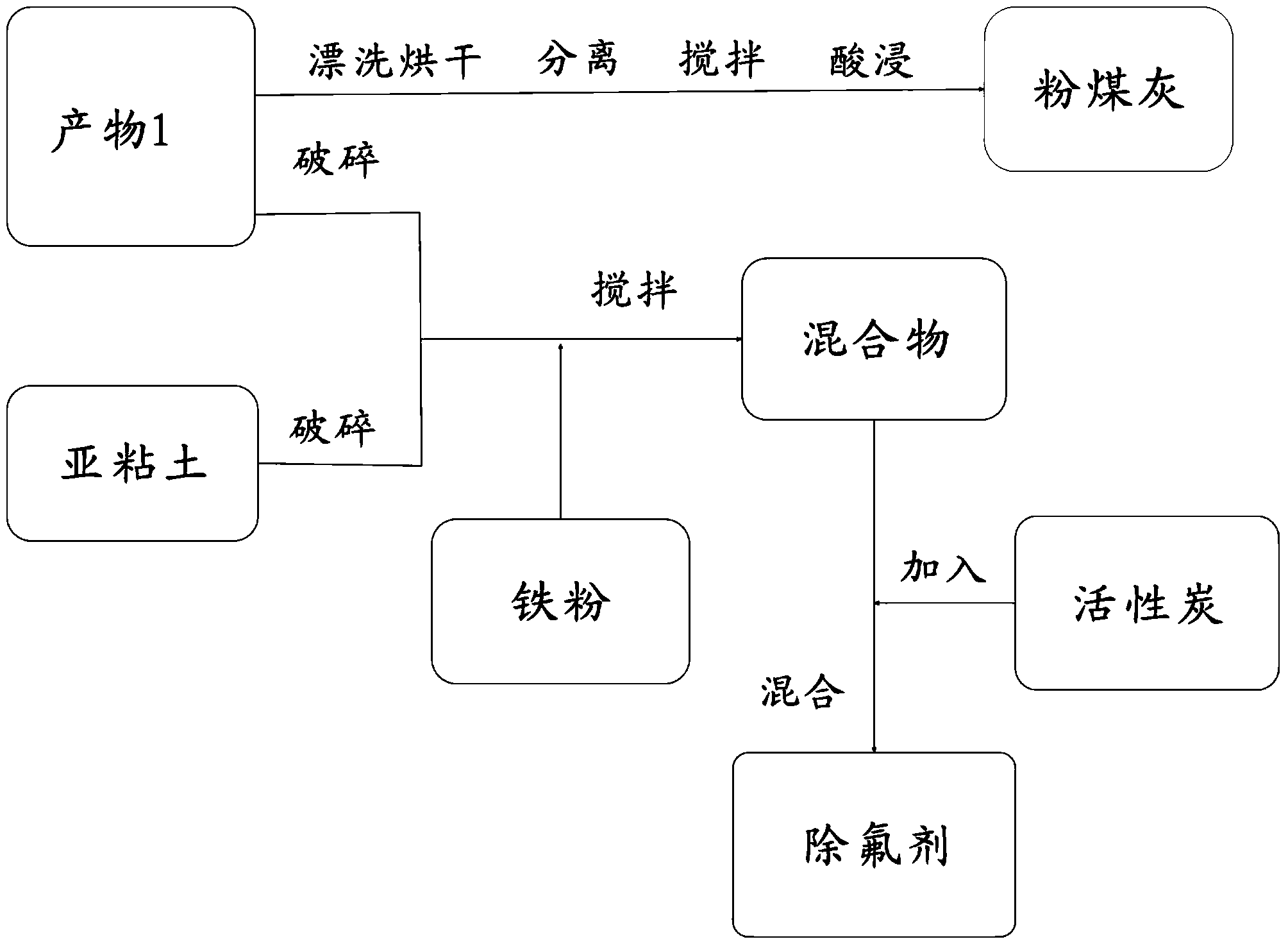

[0027] Preparation of product 1:

[0028] Remove the harmful substances contained in the fly ash by acid leaching, leaching at a stirring rate of 85-120r / min under the condition of hydrochloric acid concentration of 18%-25%, slurry ratio of 1:4-1:5, 70°C-80°C 2h~4h, after stopping stirring, stand and age at 15°C~25°C for 2~6h, use filtration method for solid-liquid separation, rinse and dry at 60°C~80°C.

[0029] Preparation of high-efficiency fluoride removal agent:

[0030] The defluorinating agent of the present invention is raw material with product 1, loam, activated carbon, iron powder, and its preparation method is as follows: product 1, loam, activated carbon (the composition of above-mentioned 3 kinds of raw materials see Table 2-4), iron powder with A certain percentage by weight (Table 1) is mixed homogeneously, placed in image 3 The fluorine removal device shown removes fluorine in water, in which the particle size of product 1 is 0.45mm-0.9mm, the particle size...

Embodiment 2

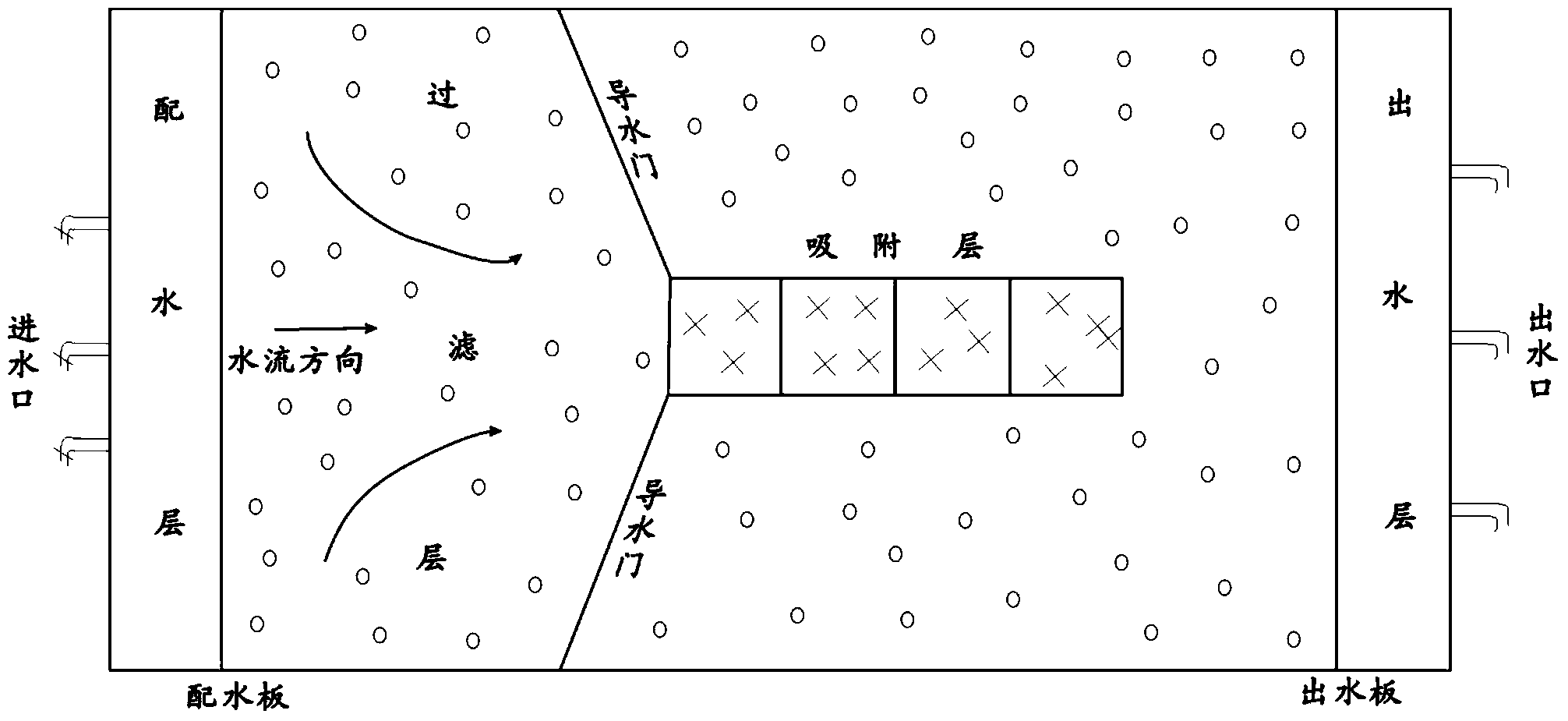

[0044] Determination of operating parameters:

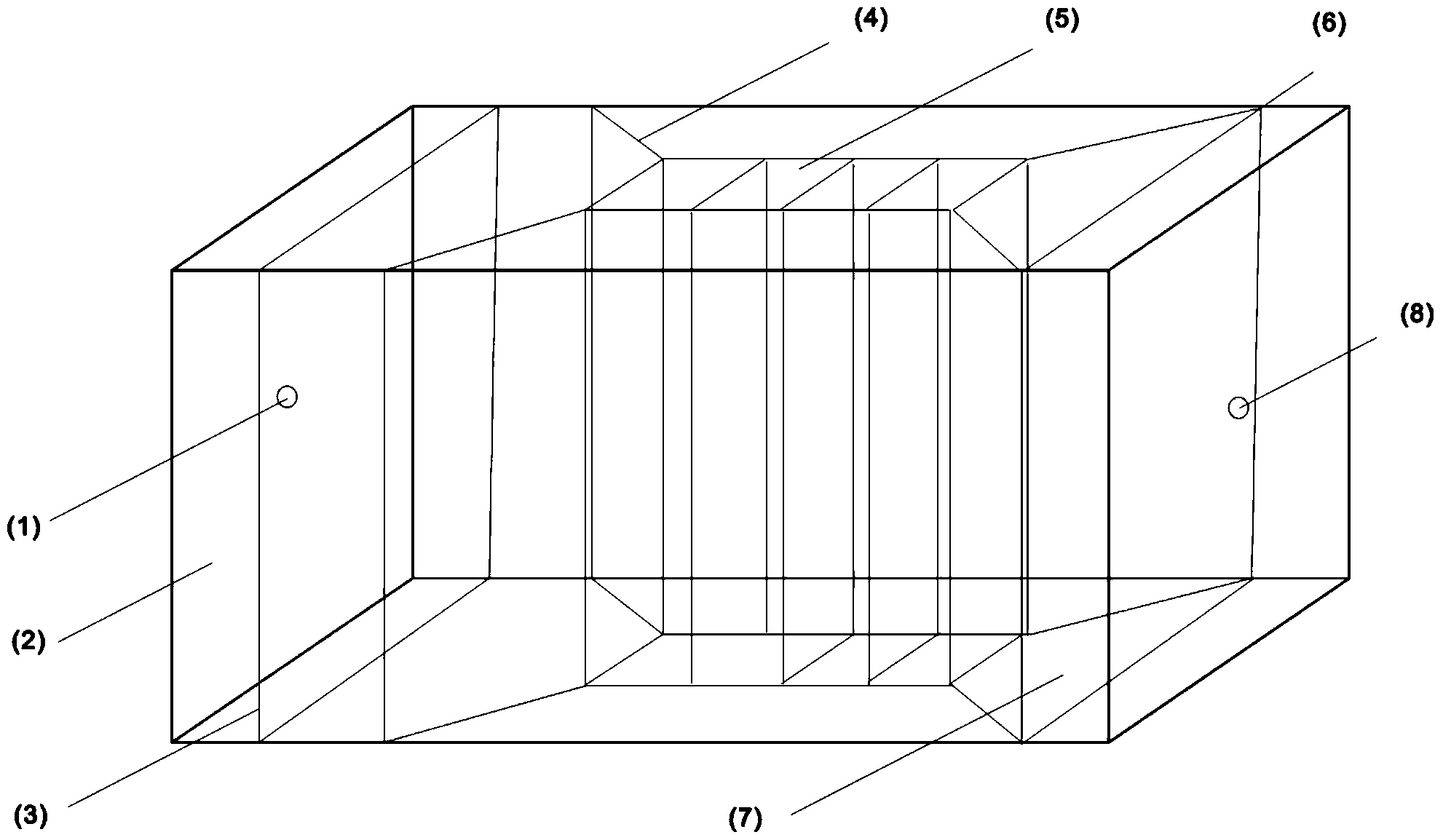

[0045] Adopt the best high-efficiency defluoridation agent formula with the best removal effect obtained in Example 1, with a certain weight percentage of product 131%, activated carbon 31%, loam clay 23%, zero-valent iron powder 15%, and the particle size of product 1 is 0.45. mm ~ 0.9mm, the particle size of activated carbon is 0.15mm ~ 0.45mm, the particle size of sub-clay powder is less than 0.15mm, and the particle size of zero-valent iron powder is greater than 5mm. placed in image 3 The high fluoride water is repaired in the defluoridation device shown. The special fluorine pollution defluorination device of the present invention is a complete set of plexiglass device made of glass glue. From left to right, upside down after inversion, it includes water inlet, water distribution layer, water distribution plate, filter layer, adsorption layer, and water outlet. Layer, water outlet plate, water outlet, water inlet is loca...

Embodiment 3

[0052] Determination of the application method of high-efficiency fluoride removal agent:

[0053] Adopt the best high-efficiency defluoridation agent formula with the best removal effect obtained in Example 1, with a certain weight percentage of product 131%, activated carbon 31%, loam clay 23%, zero-valent iron powder 15%, and the particle size of product 1 is 0.45. mm ~ 0.9mm, the particle size of activated carbon is 0.15mm ~ 0.45mm, the particle size of sub-clay powder is less than 0.15mm, and the particle size of zero-valent iron powder is greater than 5mm. One way of application is: extruding the new mixed adsorbent to a density of 2.4-2.8g / cm 3 Stacking and filling in the first layer of grille to remove fluorine in fluorine-containing water, the filling volume is 10×10×45cm 3 (The thickness of the reaction medium is 10 cm). Another application of the high-efficiency defluoridation agent prepared by using the new type of fly ash is as follows: the product 1, loam, acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com