A treatment method for tungsten smelting phosphorus removal slag

A treatment method and technology for phosphorus slag, applied in the direction of improving process efficiency, can solve the problems of waste of tungsten resources, high tungsten content in phosphorus removal slag, affecting plant production, and recovery rate indicators, etc., to achieve cost savings and good process connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

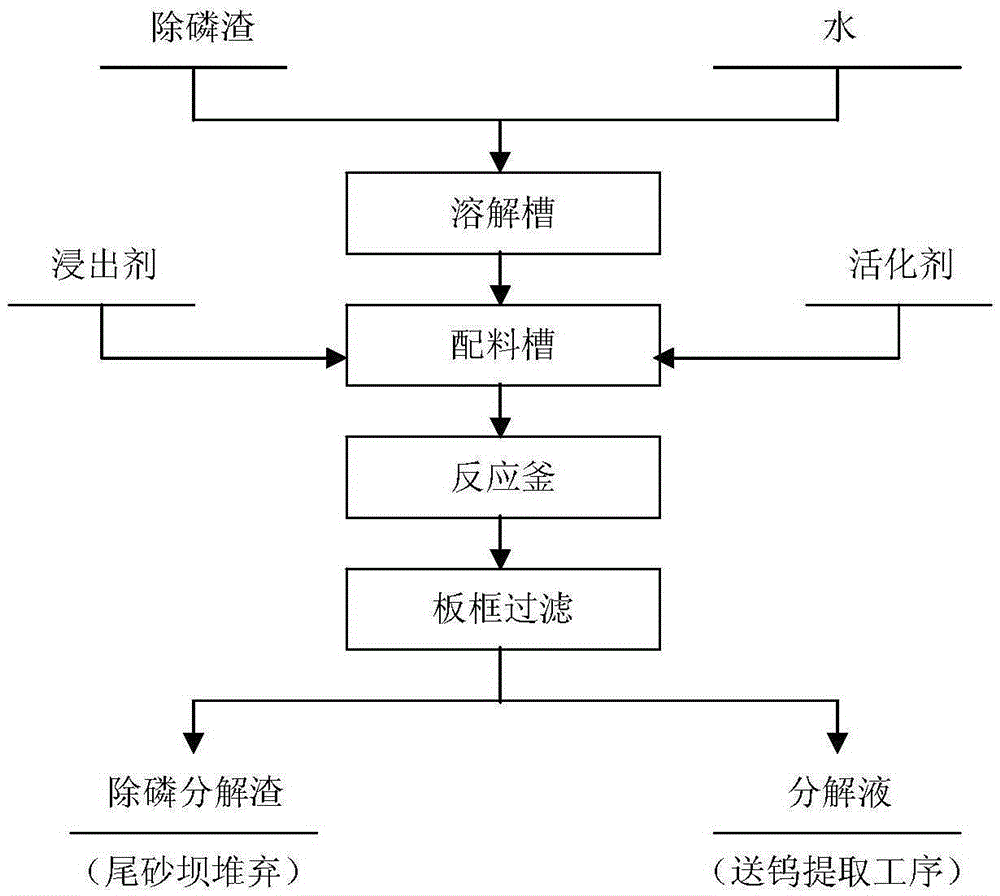

Image

Examples

Embodiment 1

[0013] The phosphorus removal slag described in the present invention is the phosphorus removal slag produced in the process of the process of patent application number 201110032596.x: a method of deep purification and phosphorus removal of crude sodium tungstate solution-crystallization mother liquor.

[0014] 01 batches of phosphorus removal slag containing WO 3 20.67%, the wet weight of phosphorus removal slag is 1035Kg, the water content is 50%, and the dry weight is 517.5Kg. 3 The amount of metal is 106.97Kg. First pour the phosphorus removal slag into the slag returning tank and add water to stir. The liquid-solid ratio of water and slag is controlled at 4:1. After mixing evenly, put the material liquid into the middle tank, turn on the middle tank to stir, and add Add 79Kg of caustic soda to 100cm of water, stir evenly, put it into the middle tank and stir thoroughly, clean the residual alkali in the alkali-dissolving tank with clean water, add 66Kg85% industrial phosp...

Embodiment 2

[0016] 02 batches of phosphorus removal slag containing WO 3 31.74%, the wet weight of phosphorus removal slag is 1134Kg, the moisture content is 53%, and the dry weight is 533Kg. 3 The amount of metal is 169.17Kg. First pour the phosphorus removal slag into the slag returning tank and add water to stir. The liquid-solid ratio of water and slag is controlled at 4:1. After mixing evenly, put the material liquid into the middle tank, turn on the middle tank to stir, and add Add 118Kg caustic soda to 100cm of water, stir evenly, put it into the middle tank and stir fully, clean the residual alkali in the alkali-dissolving tank with clean water, add 100Kg phosphoric acid to the middle tank, and clean the residual acid in the alkali-dissolving tank with clean water after adding; After the completion, the material is fed into the reactor for full reaction. The temperature of the reactor is raised to 185°C, and the temperature is kept for 0.5 hours. After that, the exhaust is discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com