A Flow Distribution Method for Enhanced Nitrogen Removal by Staged Inlet A/O Biofilm Process

A segmented water intake and flow distribution technology, applied in flow control, aerobic and anaerobic process treatment, non-electric variable control, etc., can solve problems such as incomplete application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

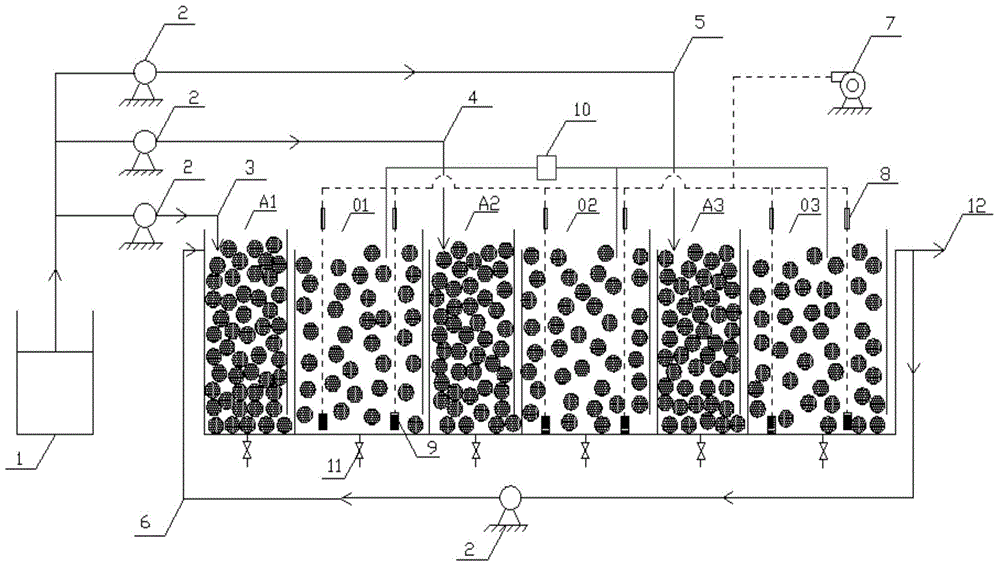

[0026] Implementation case: Taking the three-stage A / O process of segmental inflow as the research object to carry out flow distribution, and investigate its treatment effect on domestic sewage in a family area of a university. Experimental results show that the present invention has strong practicability, is easy to popularize, and can realize high-efficiency and low-consumption treatment of municipal sewage.

[0027] The three-stage A / O process of segmented water inflow is anoxic zone A1, aerobic zone O1, anoxic zone A2, aerobic zone O2, anoxic zone A3, and aerobic zone O3, which are 30L, 60L, 30L, 60L, 40L, 50L. All anoxic and aerobic areas are filled with suspended floating ball fillers, and the interior of the suspended floating balls is filled with three-dimensional sponges and Pall rings. The ratio of the two is 2:1, and the filling ratio is controlled between 70% and 80%. The filling rate of drift balls in the anoxic zone A1, A2 and A3 is controlled between 80% and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com