Method for removing nitrate nitrogen in water by using blended material including PHBV (Polyhydroxylbutyrate Valerate) and bamboo powder

A technology for nitrogen nitrate and water removal, applied in the field of water treatment, can solve the problems of difficult carbon source dosage, difficult control of carbon-nitrogen ratio, inconvenient transportation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The mass ratio of PHBV to bamboo powder in the blend material is 1:1, and the filling rate of the carrier is 35%;

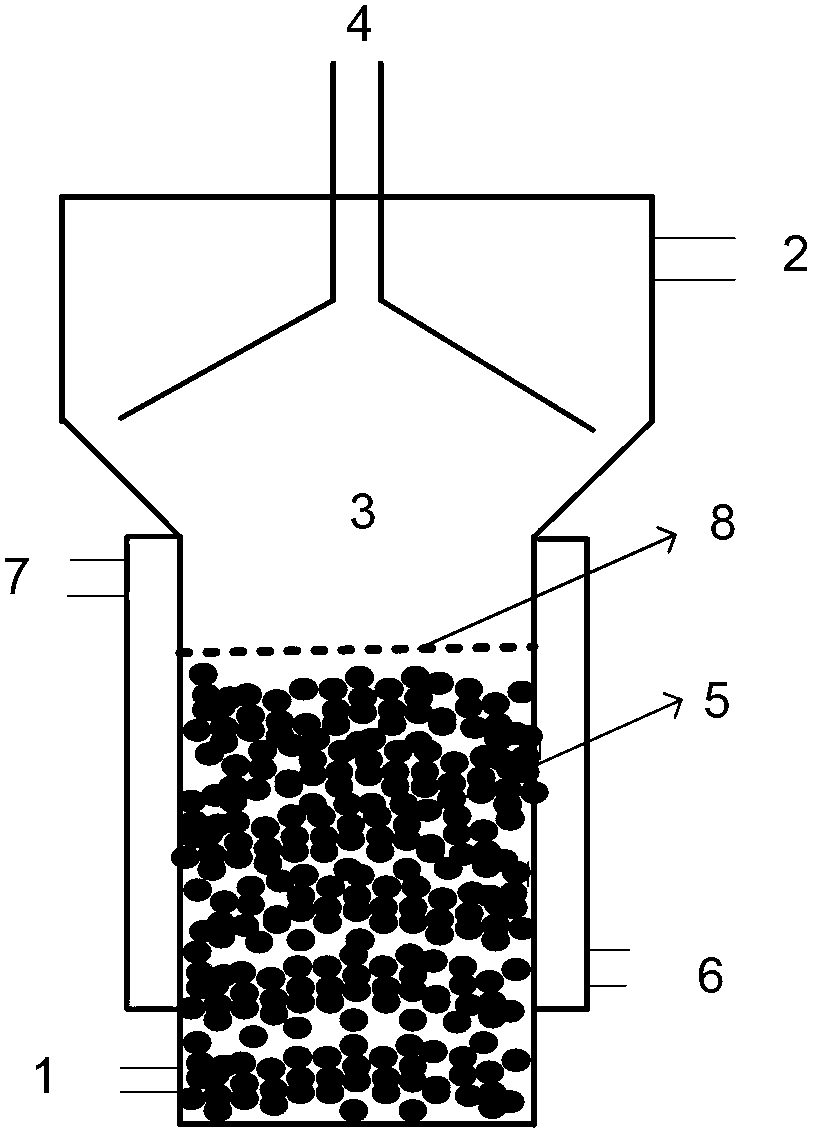

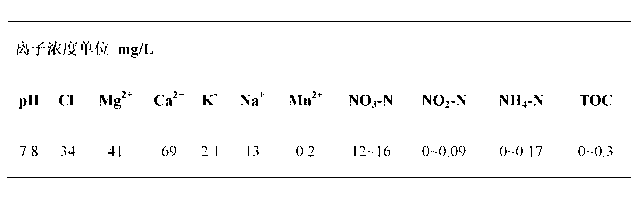

[0023] (1) The material of the fixed bed reactor is plexiglass, cylindrical, with an effective volume of 0.55 L, and an external water bath jacket is used to maintain the temperature of the reactor at 22 o C ~24 o C; as attached figure 1 As shown, the water enters the bottom and the water exits the upper part; the groundwater is taken from the Changping Campus of Tsinghua University in Beijing; the property indicators of the groundwater are shown in Table 1;

[0024] (3) The reactor was inoculated without adding any sludge, and was started directly by adding groundwater, and the initial hydraulic retention time was set to 17 h; although the microorganisms in the groundwater were relatively poor, due to the good biodegradability of PHBV and bamboo powder, the reactor was started After 5 days, the concentration of nitrate nitrogen in the effluent can b...

Embodiment 2

[0027] (1) The mass of PHBV and bamboo powder in the blend material is 1:1, and the filling rate of the carrier is 45%;

[0028] (2) The material of the fixed bed reactor is plexiglass, cylindrical, with an effective volume of 0.55 L, and an external water bath jacket is used to maintain the temperature of the reactor at 22 o C ~24 o C; as attached figure 1 As shown, the water enters the bottom and the water exits the upper part; the groundwater is taken from the Changping Campus of Tsinghua University in Beijing; the property indicators of the groundwater are shown in Table 1;

[0029] (3) The reactor does not add seed mud, but directly adds groundwater to start, and the initial residence time is set to 17 h; after 5 days after the reactor is started, the concentration of nitrate nitrogen in the effluent can be reduced to below 2.0 mg / L, and the nitrogen removal rate can be reach more than 85%;

[0030] (4) Gradually reduce the HRT. The specific plan is: maintain 2 days at...

Embodiment 3

[0032] (1) The mass ratio of PHBV to bamboo powder in the blend material is 3:1, and the filling rate of the carrier is 35%;

[0033] (2) The material of the fixed bed reactor is plexiglass, cylindrical, with an effective volume of 0.55 L, and an external water bath jacket is used to maintain the temperature of the reactor at 22 o C ~24 o C; as attached figure 1 As shown, the water enters the bottom and the water exits the upper part; the groundwater is taken from the Changping Campus of Tsinghua University in Beijing; the property indicators of the groundwater are shown in Table 1;

[0034] (3) The reactor does not add any sludge to inoculate, and directly adds groundwater to start, and the initial residence time is set to 17 h; after 8 days after the reactor is started, the concentration of nitrate nitrogen in the effluent can be reduced to below 2.0 mg / L, and the removal rate of nitrogen Above 85%.

[0035](3) Gradually reduce the HRT. The specific plan is: maintain 3 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com