Double-treatment cleaning and regenerating method for vanadium-titanium based denitration catalyst

A denitration catalyst and a vanadium-titanium-based technology, applied in the field of denitration catalysts, can solve the problem that the regeneration effect of the vanadium-titanium-based denitration catalyst is not very good, and achieve the effects of improving redox capacity, reducing poisoning substances, and increasing active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

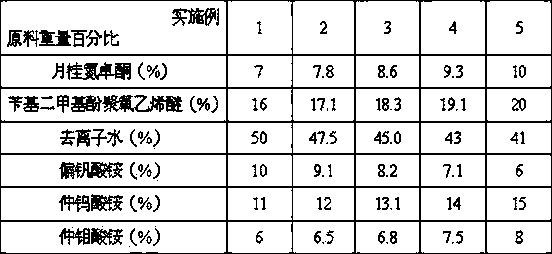

Examples

Embodiment Construction

[0013] A dual-treatment, cleaning and regeneration method for a vanadium-titanium-based denitrification catalyst, wherein the deactivated honeycomb vanadium-titanium-based denitration catalyst is treated to restore its activity, comprising the following steps:

[0014] a, prepare air-ozone mixed gas, standby;

[0015] b. placing the deactivated honeycomb-shaped vanadium-titanium-based denitration catalyst in a catalyst regeneration reactor;

[0016] c. Filling the air-ozone mixed gas into the catalyst regeneration reactor and performing oxidation treatment to obtain a regenerated vanadium-titanium-based denitration catalyst;

[0017] The point is: the described method also includes the following steps:

[0018] d, prepare catalyst active liquid, standby;

[0019] e. Put the regenerated vanadium-titanium-based denitration catalyst obtained in step c into the catalyst active liquid obtained in step d, take it out after soaking for 4 to 6 hours, dry it in dry air at 50 to 60°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com