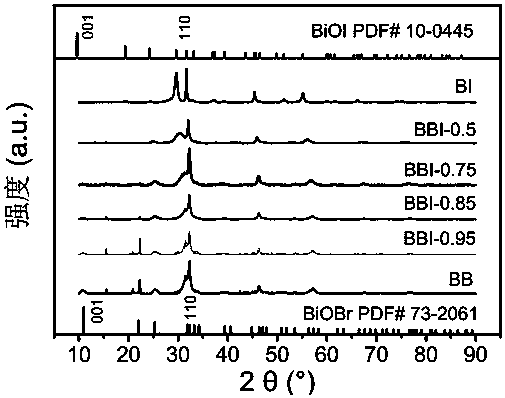

Preparation method of two-dimensional ultrathin bismuth oxyhalide solid solution nanosheet photocatalyst

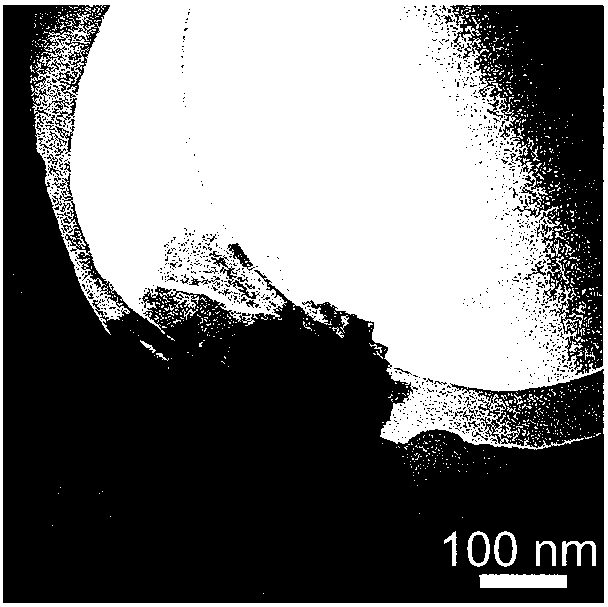

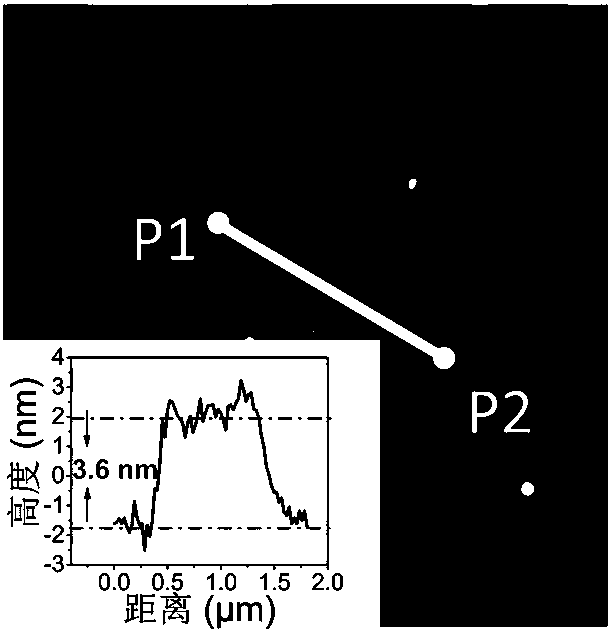

A technology of bismuth oxyhalide and photocatalyst, which is applied in the field of photocatalysis, can solve the problems of low photocatalytic efficiency, achieve good activity, simple equipment, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: what this embodiment records is a kind of preparation method of two-dimensional ultra-thin bismuth oxyhalide solid solution nanosheet photocatalyst, and the specific steps of the method are as follows:

[0023] Step 1: Add inorganic bismuth salt and 0.1 g~0.6 g dispersant in 5~30 mL deionized water, do not stir during the addition process to avoid hydrolysis of bismuth salt, then add 5~30 mL structure directing agent, stir for 30~60 min to form Uniform and transparent A solution;

[0024] Step 2: Dissolve the halide in 5mL deionized water to obtain a halide solution, then add all the obtained halide solution dropwise into solution A, continue stirring for 10~30min, and then pour into 100mL polytetrafluoroethylene In a lined stainless steel hydrothermal synthesis reactor, react at 100-200°C for 3-24 hours, and cool naturally to room temperature;

[0025] Step 3: Centrifuge the product obtained in Step 2 at 10,000r / min for 3 minutes, then wash th...

specific Embodiment approach 2

[0026] Embodiment 2: In the preparation method of a two-dimensional ultrathin bismuth oxyhalide solid solution nanosheet photocatalyst described in Embodiment 1, in step 1, the inorganic bismuth salt is bismuth nitrate or bismuth chloride.

specific Embodiment approach 3

[0027] Specific embodiment three: the preparation method of a kind of two-dimensional ultrathin bismuth oxyhalide solid solution nanosheet photocatalyst described in specific embodiment one or two, in step two, described halide is chloride, bromide or iodide One or more of them, wherein the chloride is sodium chloride or potassium chloride, the bromide is sodium bromide or potassium bromide, and the iodide is sodium iodide or potassium iodide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com