Feed turning device

A technology of turning device and turning mechanism, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of unstable force, high labor intensity, and low production efficiency, so as to improve production efficiency, reduce labor intensity of workers, and reduce materials. The effect of the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

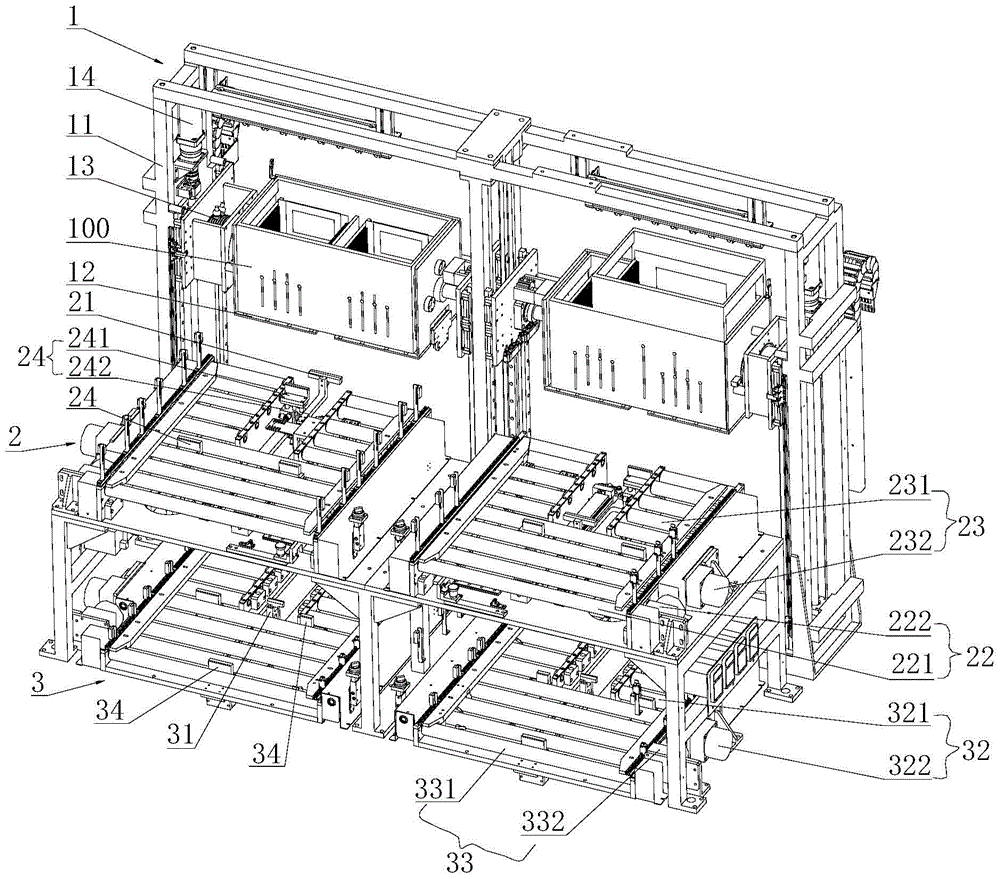

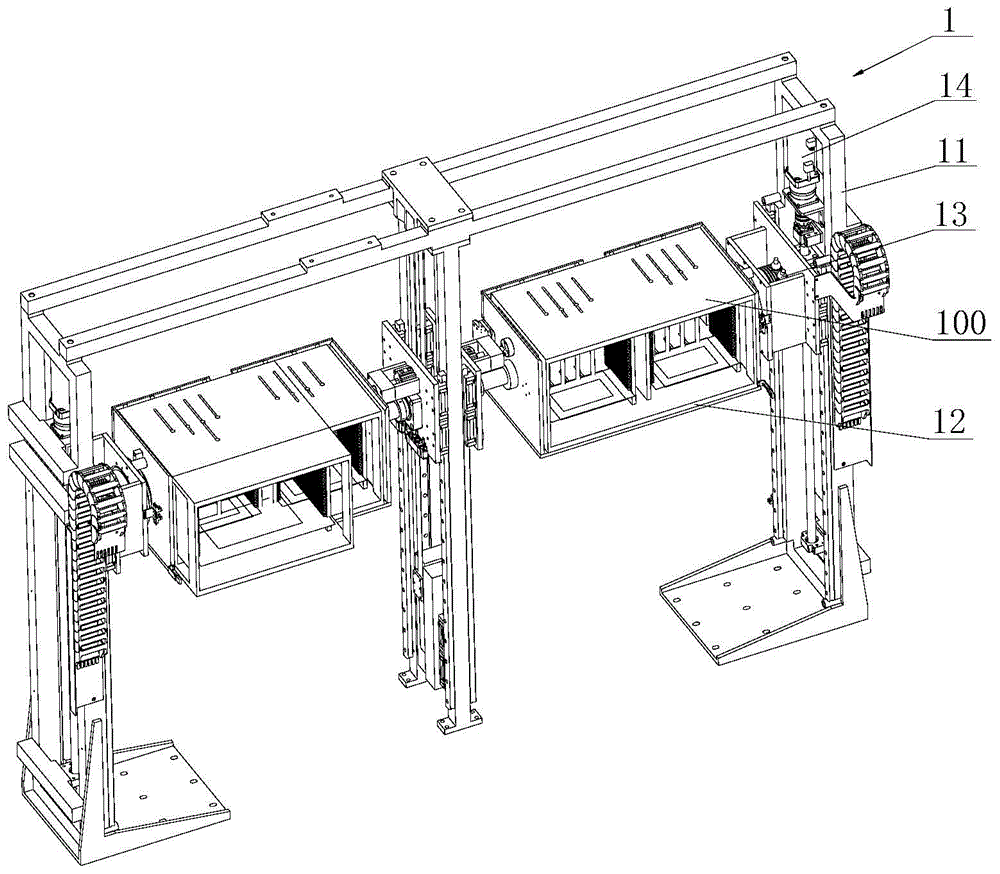

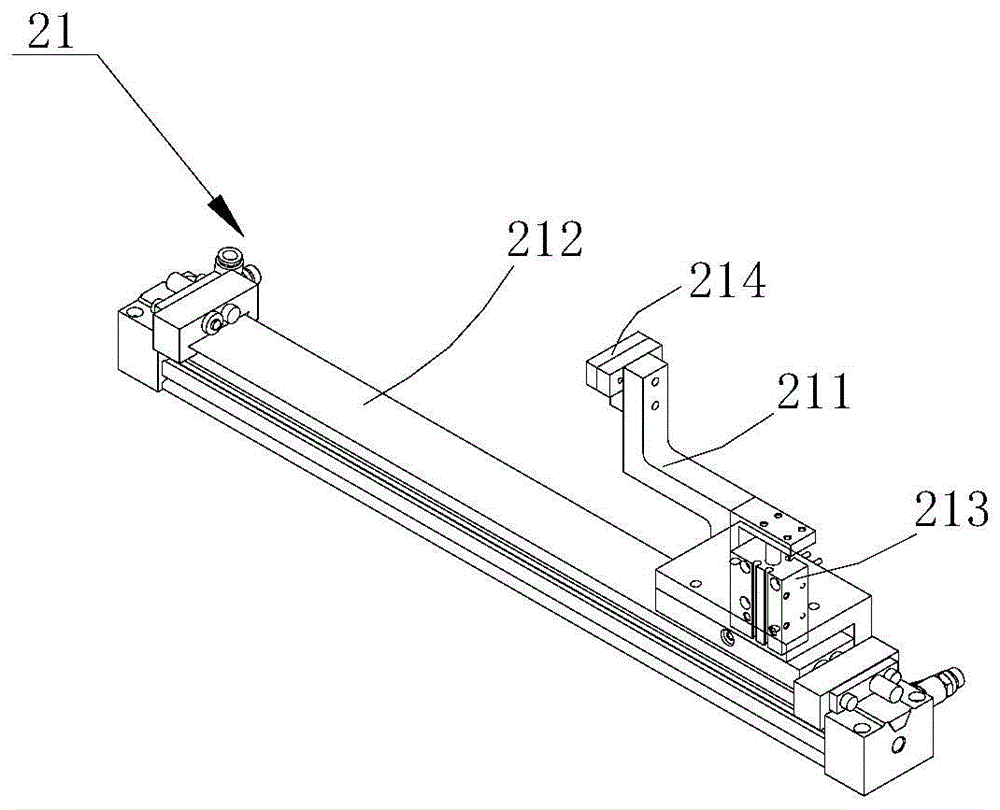

[0032] see figure 1 and figure 2 The feeding and turning device shown includes a turning mechanism 1, a feeding mechanism 2 and a feeding mechanism 3, and the feeding mechanism 2 and the returning mechanism 3 are layered and arranged in front of the turning mechanism 1 along the vertical direction.

[0033] Turning mechanism 1 comprises fixed frame 11, can place material box 100 correspondingly and drives material box 100 to turn over the flipping box 12 that turns over synchronously thereupon when turning over, and turning box 12 can lift up and down and can be arranged on the fixed frame 11 that can turn back and forth. The box 100 has an upward opening, and the upper end and the front of the flip box 12 have openings respectively, and the specification of the flip box 12 can be set according to the size of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com