An electroslag feeding method for improving the crystallization quality of large steel ingots

A feeding and crystallization technology, applied in the field of electroslag metallurgy, can solve the problems of poor solidification quality of large steel ingots, and achieve the effects of improving purity, improving purification effect, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

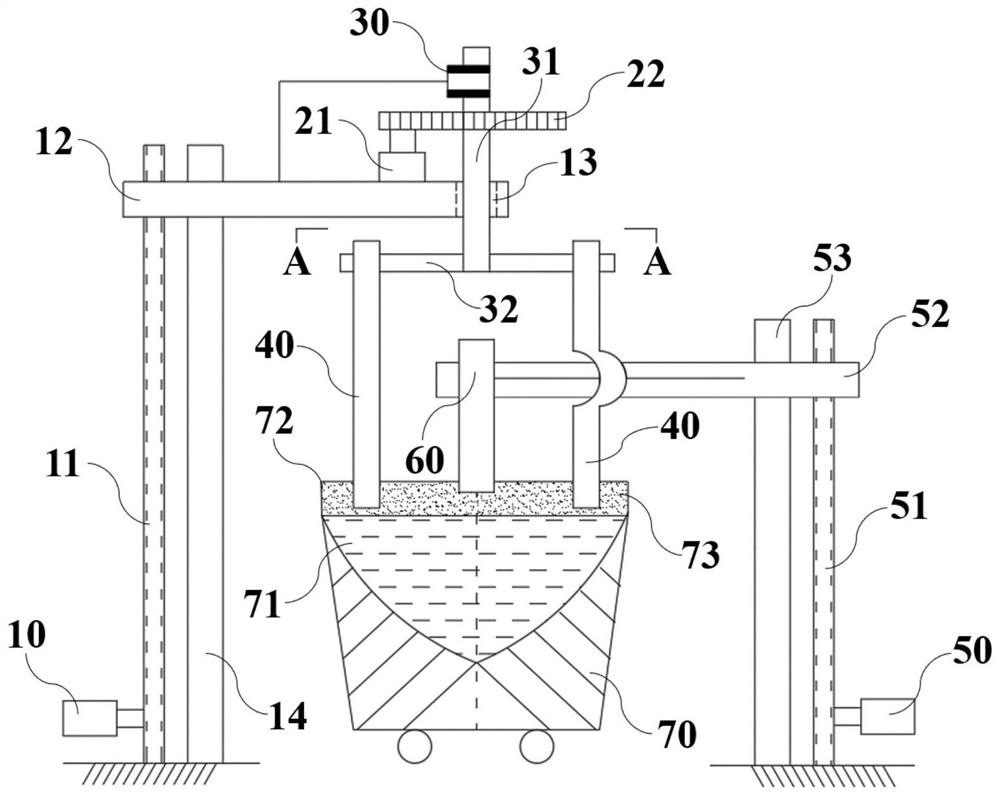

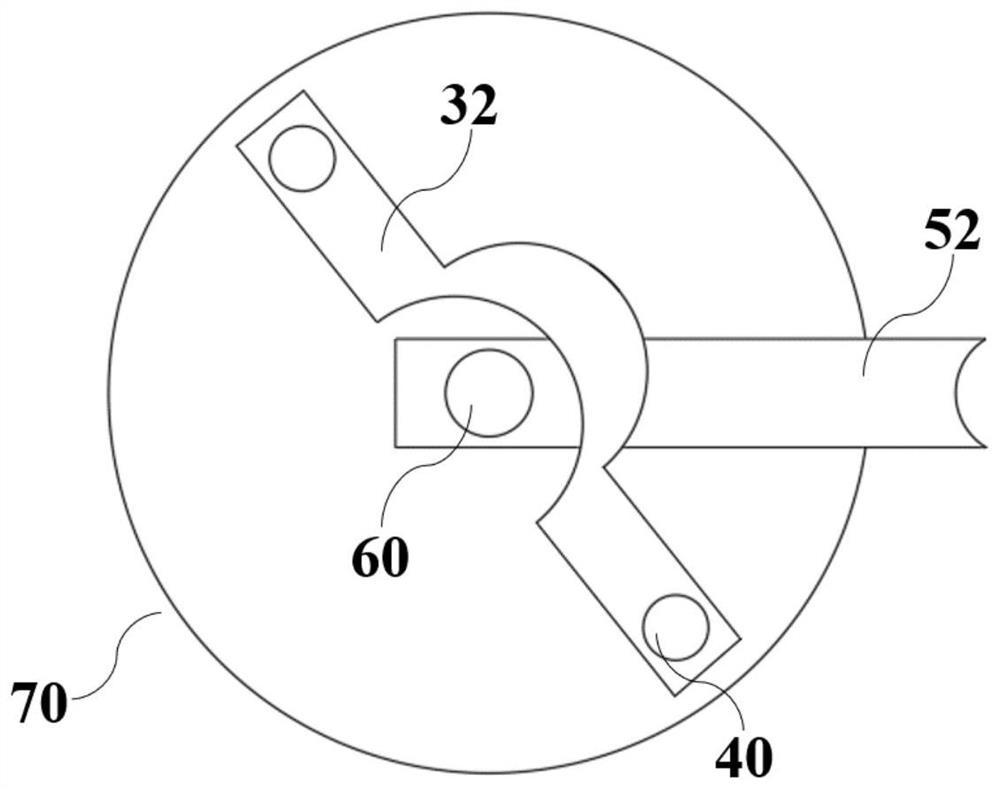

[0041] An electroslag feeding method for improving the crystallization quality of a large steel ingot in this embodiment adopts an electroslag feeding device for improving the crystallization quality of a large steel ingot, combined with figure 1 and figure 2 , the feeding device includes a steel ingot mold 70, a metal consumable electrode 40 and a graphite electrode 60, wherein the graphite electrode 60 is arranged at the center of the steel ingot mold 70; two metal consumable electrodes 40 are provided, and 2 The metal self-consumable electrodes 40 are symmetrically arranged on both sides of the graphite electrode 60. It is worth noting that the metal consumable electrodes 40 in this embodiment are made of the same material as the large steel ingot. The metal consumable electrode 40 rotates, and the rotation center of the metal consumable electrode 40 is the graphite electrode 60 .

[0042] Furthermore, the metal consumable electrode 40 in this embodiment is controlled to ...

Embodiment 2

[0053] A kind of electroslag feeding method for improving the crystallization quality of large steel ingots in this embodiment is basically the same as in Embodiment 1, further: as figure 1 As shown, in this embodiment, the metal consumable electrode 40 is inserted into the slag pool 73 at a depth greater than the graphite electrode 60 inserted into the slag pool 73 .

[0054] Specifically, the insertion depth of the graphite electrode 60 in the slag pool 73 in this embodiment is 20mm-30mm, which can be 20mm, 22mm, 23mm, 25mm...28mm or 30mm;

[0055] The insertion depth of the metal consumable electrode 40 in the slag pool 73 is 30-60 mm, which can be 30 mm, 36 mm, 40 mm, ... 50 mm ... or 60 mm.

[0056] Since in the actual production process, cooling water is sprayed on the outside of the heat preservation cap 72, the surrounding temperature must be lower than the temperature of the core. For this reason, controlling the difference in the insertion depth of the graphite elect...

Embodiment 3

[0062] An electroslag feeding method for improving the crystallization quality of large steel ingots in this embodiment is basically the same as in Embodiment 2, further: the heavy slag component located in the slag pool 73 is 80% CaF by mass percentage 2 , 15% CaO and 5% Al 2 o 3 , and the thickness of the slag layer is 250mm-300mm, which can be 250mm, 260mm, 280mm...295mm or 300mm. The metal droplets are desulfurized, dephosphorized and non-metallic inclusions are removed by heavy slag to purify the metal droplets.

[0063] It is worth noting that in this example, by controlling the Al in the heavy slag group 2 o 3 content, so that the content of T.O in the molten steel 71 reaches 15ppm-20ppm, which can effectively improve the quality of the steel ingot. In the prior art, due to Al 2 o 3 Can significantly reduce the conductivity of slag, reduce power consumption, therefore, the Al in the prior art 2 o 3 The content is relatively high, and generally its content is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com