Polymer solid powder denitration agent for flue gas denitration and preparation method thereof

A solid powder and polymer technology, applied in the field of flue gas denitrification, can solve the problems of corrosion of incinerators, secondary pollution, easy moisture absorption of denitrification agents, etc., and achieve the effects of improving utilization rate, improving contact and reducing secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

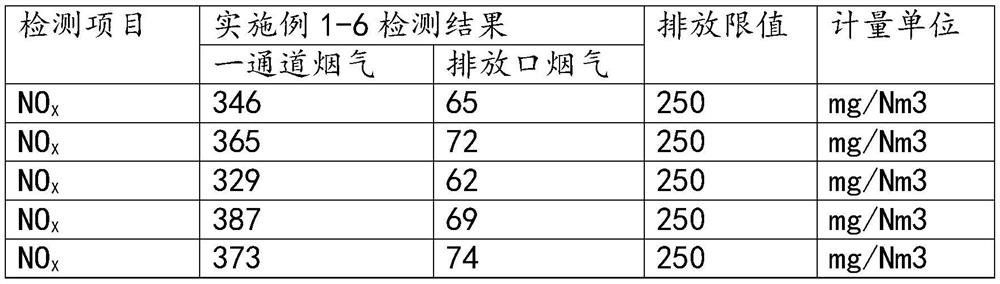

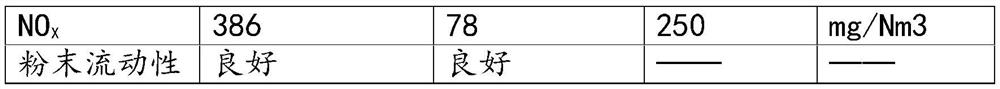

Examples

Embodiment 1

[0027] A preparation method for a polymer solid powder denitration agent for flue gas denitration, comprising the following steps:

[0028] S1. Weigh raw materials, weigh 10g sulfonamide, 34g cyanuric acid, 12g ammonium bicarbonate and 25g calcium carbonate powder, mix them through a sieve with 50-60 meshes, and reach the specified size powder;

[0029] S2. For the powder of specified size obtained in S1, add 6g of additives under stirring conditions to obtain a homogeneous powder that is uniformly mixed;

[0030] S3. Add 12 g of rare earth ore powder to the homogeneous powder obtained in S2 under stirring conditions, and stir evenly to obtain a polymer solid powder denitrification agent.

Embodiment 2

[0032] A preparation method for a polymer solid powder denitration agent for flue gas denitration, comprising the following steps:

[0033] S1. Weigh raw materials, weigh 12g thiourea, 25g melamine, 10g ammonium bicarbonate and 25.5g calcite, mix them through a sieve with 50-60 meshes, and reach the specified size powder;

[0034] S2. Add 3.7 g of additives to the powder of specified size obtained in S1 under stirring conditions to obtain a homogeneous powder mixed uniformly;

[0035] S3. Add 11.3 g of rare earth ore powder to the homogeneous powder obtained in S2 under stirring conditions, and stir evenly to obtain a polymer solid powder denitrification agent.

Embodiment 3

[0037] A preparation method for a polymer solid powder denitration agent for flue gas denitration, comprising the following steps:

[0038] S1, take raw materials, take by weighing 15g ammonium sulfonate, 28g cyanuric acid, 12g urea and 24.3g dolomite, after mixing it through a 50-60 mesh screen, reach the powder of specified size;

[0039] S2. Add 7.4 g of additives to the powder of specified size obtained in S1 under stirring conditions to obtain a homogeneous powder that is uniformly mixed;

[0040]S3. Add 13.9 g of rare earth ore powder to the homogeneous powder obtained in S2 under the condition of stirring, and after stirring evenly, a polymer solid powder denitrification agent can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com