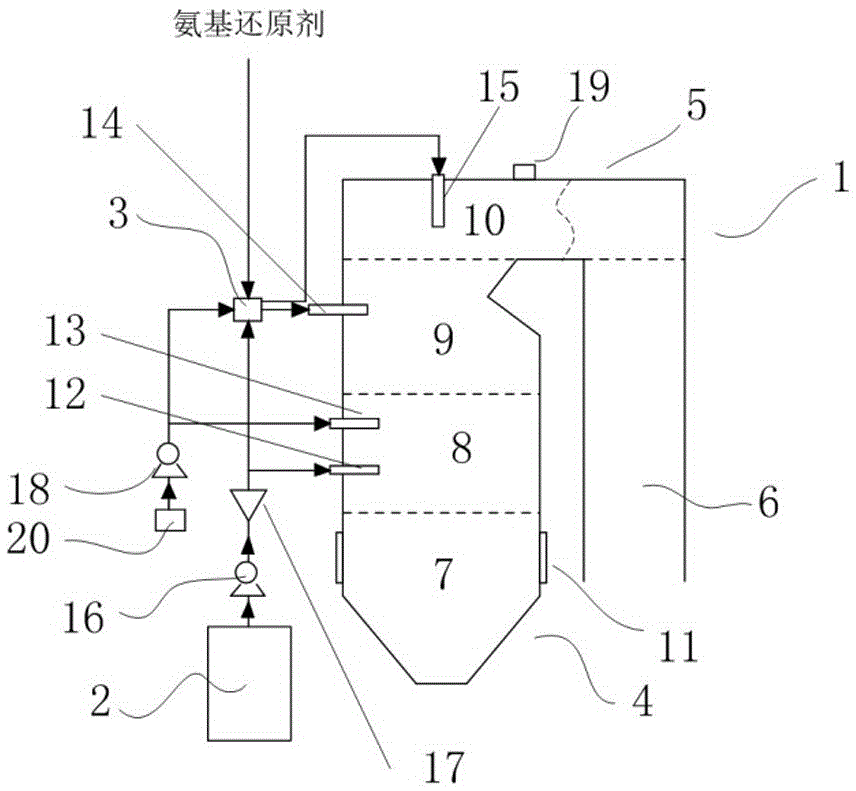

Composite denitration method and device

A mixing device and denitrification technology, which is applied in the field of compound denitrification, can solve the problems of increasing denitrification costs, and achieve the effects of avoiding incomplete combustion of fuel, improving denitrification efficiency, and reducing denitrification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] The implementation method is as follows: the analytical gas produced by the analytical gas source in the ammonia synthesis process is pressurized by the first pressurizing device 16, flows through the reducing waste gas delivery pipe and the reducing waste gas separation valve 17, and is separated through the separation valve 17, according to 4: The ratio of 1 flows into the reducing exhaust gas pipeline a and the reducing exhaust gas pipeline b; the reducing exhaust gas pipeline a is connected to the first nozzle 12, and this part of the analytical gas is sprayed into the reburning zone 8, and the temperature range of the interval is between 1100 ° C and 1300°C, the amount of desorption gas added is represented by the molar ratio of the amount of effective reducing substances in the desorption gas to the main combustion fuel. The preferred value is 0.2~0.3. The two nozzles 13 communicate, and enter the reburning zone 8 as secondary air; the reducing waste gas pipeline b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com