Brine treatment method

A brine and treatment device technology, which is applied in the field of brine treatment, can solve the problems of increased concentration of divalent ions, unstable operation of equipment, etc., and achieve the effect of reducing the cost of raw materials and reducing the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

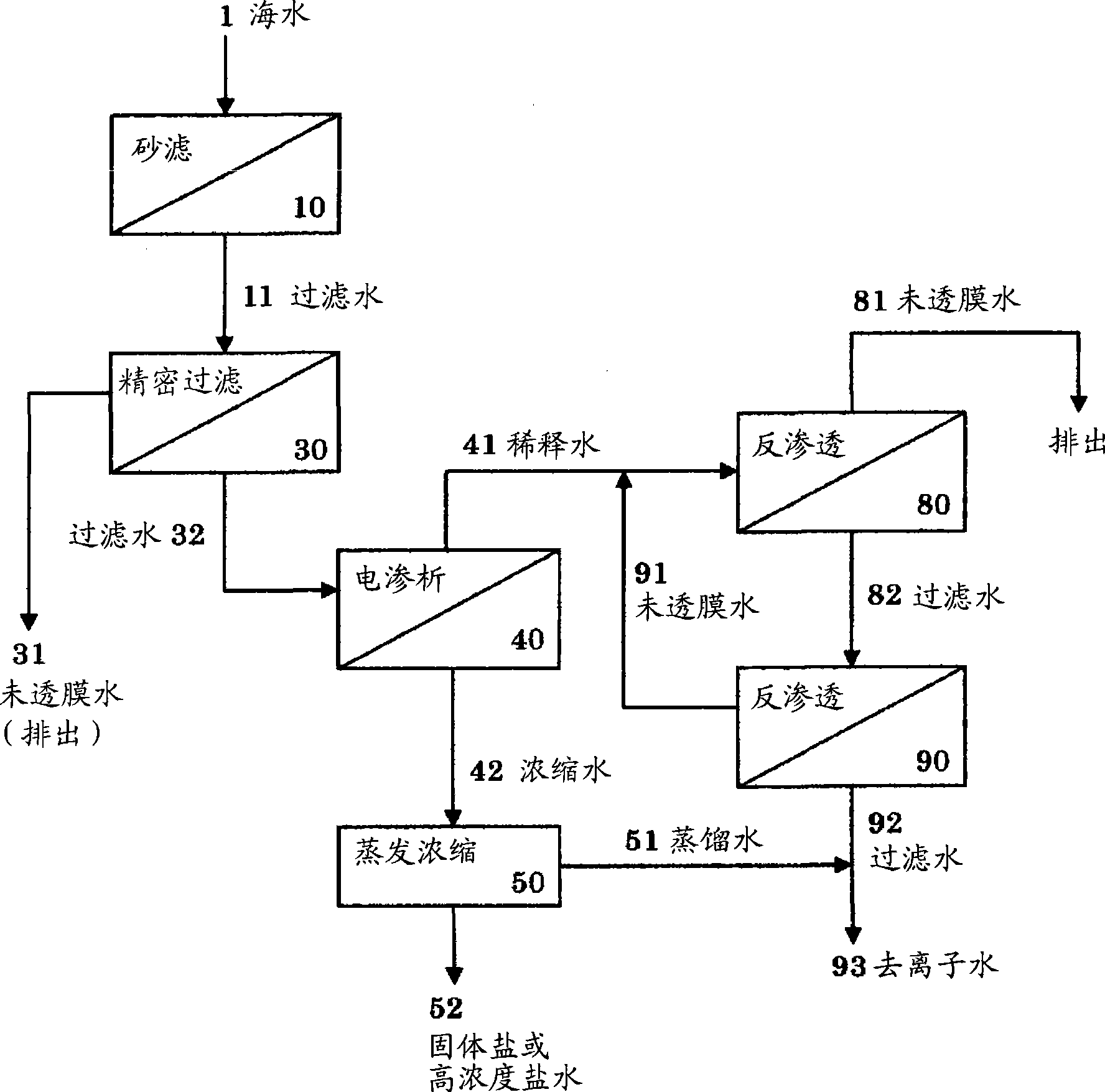

Embodiment 1

[0043] A sand filter (trade name DynaSand Filter) manufactured by Sanki Industry Co., Ltd. was used for the sand filter, and a porous filter membrane (MF) manufactured by Asahi Kasei Chemical Co., Ltd. (trade name MicrozaUNA-620A) was used for the porous filter membrane (MF). The total membrane area was 100 m 2 , The monovalent ion selective permeation ion exchange membrane used for electrodialysis uses cation exchange membrane (trade name Neosepta, CIMS) and anion exchange membrane (trade name Neosepta, ACS) manufactured by ASTOM Co., Ltd., and the total membrane area of the exchange membrane is 220m 2 , the reverse osmosis membrane (RO) of the first stage uses a reverse osmosis membrane (trade name HU10155EI) manufactured by Toyobo Co., Ltd., and the reverse osmosis membrane (RO) of the second stage uses two reverse osmosis membranes manufactured by FILMTEC (trade name BW30-400). And prepare the membrane processing equipment suitable for each separation membrane separatel...

Embodiment 2

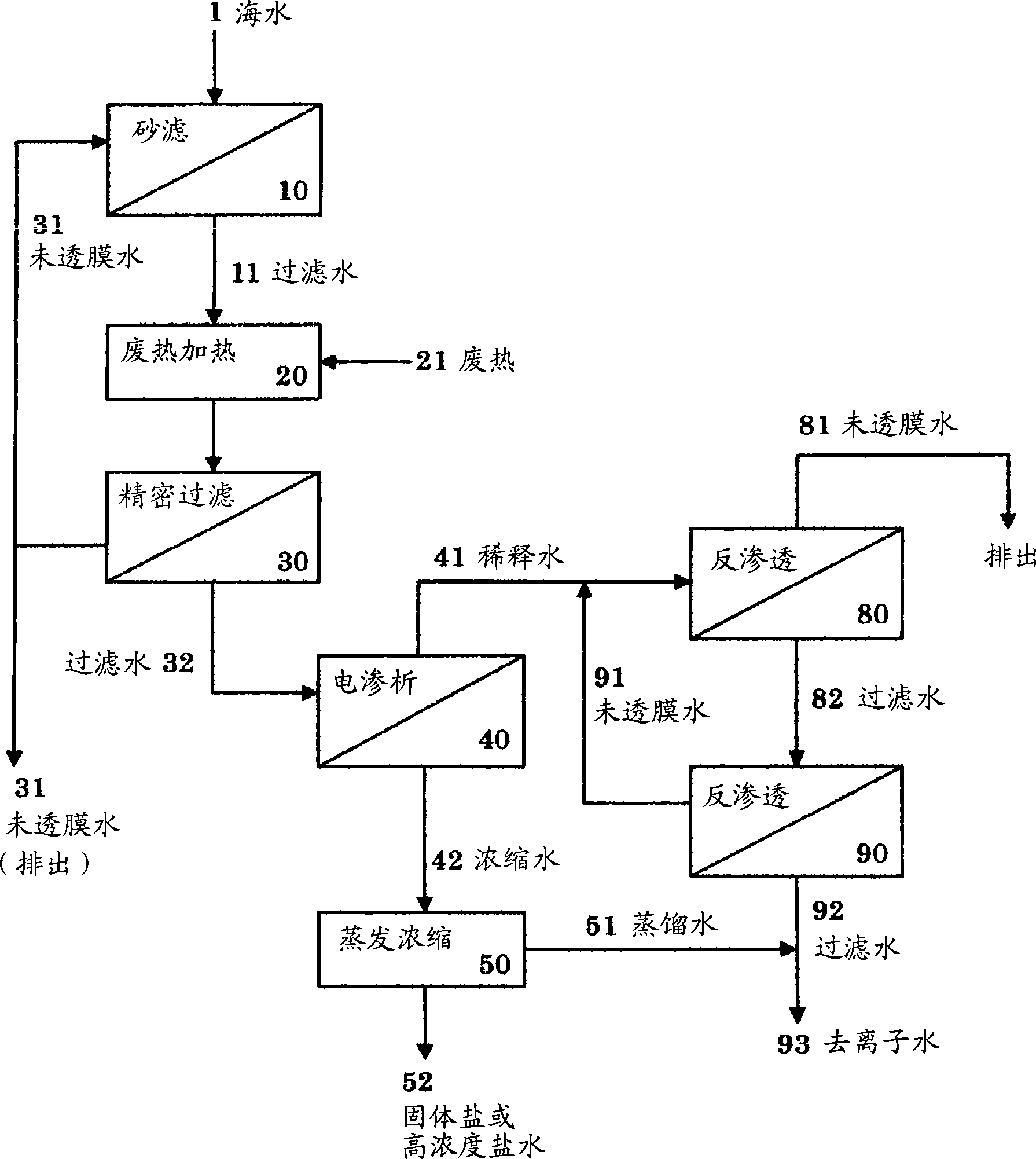

[0048] In the brine treatment equipment of Embodiment 1, a waste heat heating device 20 is further provided between the sand filter device 10 and the porous filter device 30, and the filtered water 11 is heated by using the waste heat 21 generated by a power station that supplies power to the equipment; A part of the non-membrane water 31 of the filter device 30 is returned to the inlet of the sand filter device 10 to effectively utilize heat and seawater; the seawater treatment capacity is 480000kg / day, and the membrane area increases proportionally to the seawater treatment capacity; The recovery rate in the osmosis device is such that the first stage and the second stage add up to 28%, except for the above-mentioned differences, are all the same as the specifications in Example 1, and constitute image 3 The membrane processing equipment shown. The average seawater temperature at the inlet of the porous filtering device 30 is 22° C. by using the waste heat heating device 20...

Embodiment 3

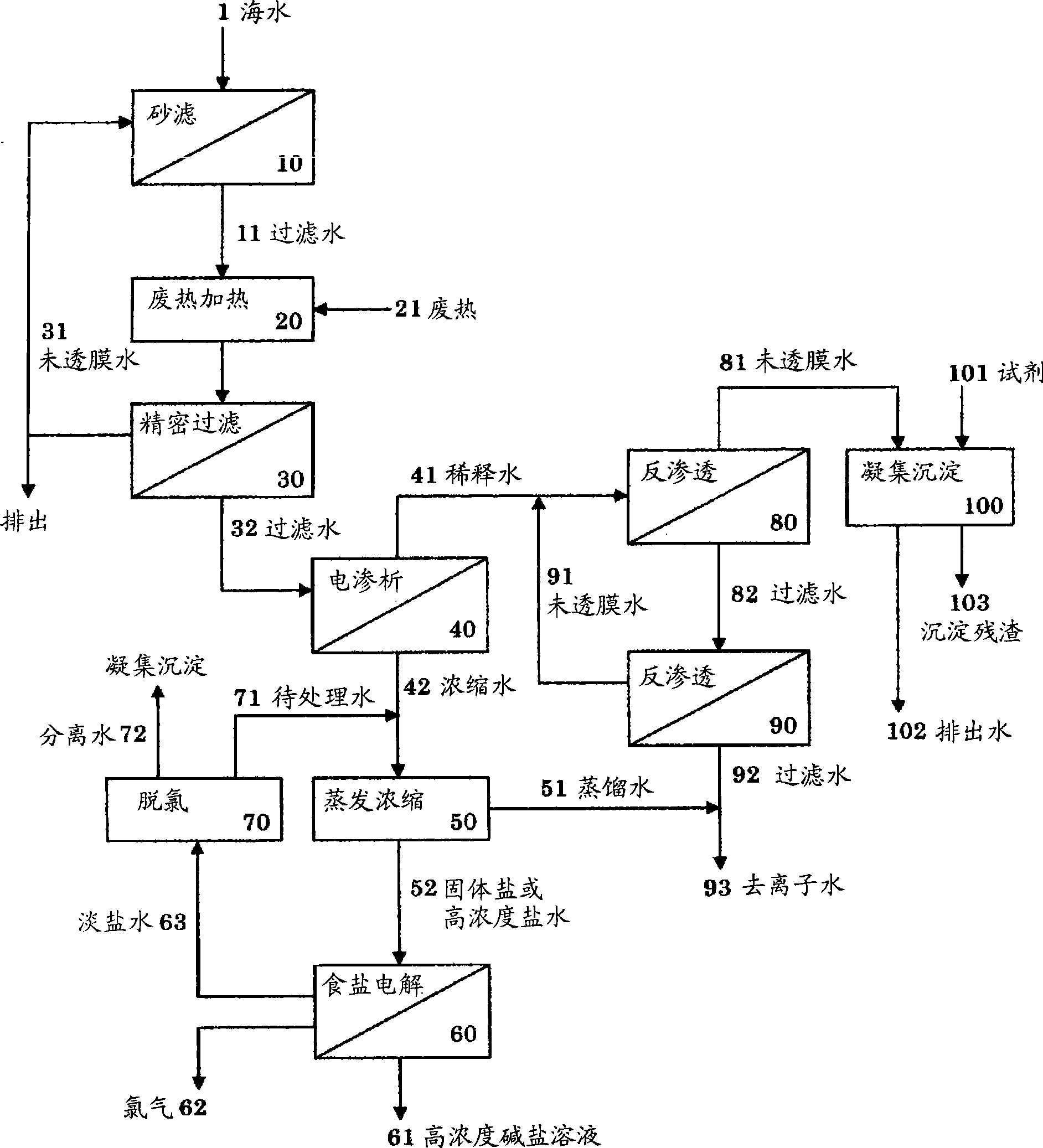

[0050] In the brine treatment equipment of embodiment 2, the coagulation precipitation device 100 that removes divalent ions from the non-permeable membrane water 81 of the reverse osmosis device 80 of the first stage is further provided, and a salt electrolysis device 60 and a dechlorination device 70 are provided, Except for this, the same brine treatment facility as that of Example 2 was configured. The outline of the device consists of figure 1 shown.

[0051] In the coagulation and sedimentation device 100, excessive sodium hydroxide is added to the non-membrane water 81 to precipitate magnesium ions, then sodium carbonate and barium carbonate are added to precipitate calcium ions and sulfate ions, and boron is removed by ion exchange resin, It is then decarbonated and becomes ocean discharge water.

[0052] As the salt electrolysis device 60, a fluorine-based ion exchange membrane (manufactured by Asahi Kasei Chemical Co., Ltd., trade name ACIPLEX-F4401) was used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com