Method for recycling aluminum hydroxide powder by using titanium dioxide waste acid and secondary aluminum ash

A technology of aluminum hydroxide and titanium dioxide waste acid, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of low utilization rate of valuable resources, difficult disposal of waste residue, high process cost, and increase disposal costs. The effect of income, less impurity content and high denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

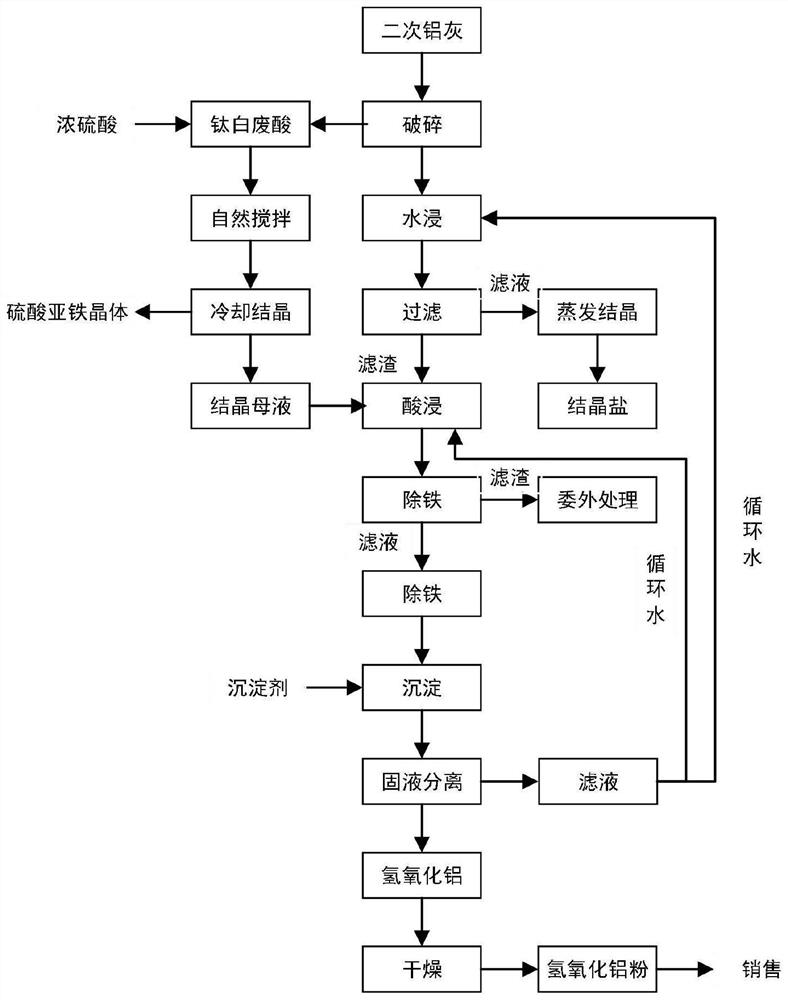

[0046] Such as figure 1 Shown, a kind of method of utilizing titanium white waste acid and secondary aluminum ash to reclaim aluminum hydroxide powder of the present invention may further comprise the steps:

[0047] Step 1: Add concentrated sulfuric acid with a concentration of 98% to titanium white waste acid with a sulfuric acid mass concentration of 20% and a ferrous sulfate mass concentration of 5%. The final concentration of the titanium white waste acid is 45%, and the stirring reaction time is 0.5 h, cooling temperature 35 ℃, after crystallization, solid-liquid separation, obtain ferrous sulfate concentration and be 0.32% titanium white waste acid after pretreatment, ferrous sulfate removal rate is 93.6%;

[0048] Step 2: Use crushing equipment to crush and screen the secondary aluminum ash to obtain 80 meshes of crushed aluminum ash for later use;

[0049] Step 3: Add water to the reaction tank, then add the 80-mesh broken aluminum ash obtained in step 2 into the re...

Embodiment 2

[0055] Such as figure 1 Shown, a kind of method of utilizing titanium white waste acid and secondary aluminum ash to reclaim aluminum hydroxide powder of the present invention may further comprise the steps:

[0056] Step 1: Add concentrated sulfuric acid with a concentration of 80% to titanium white waste acid with a sulfuric acid mass concentration of 65% and a ferrous sulfate mass concentration of 10%. The final concentration of the titanium white waste acid is 65%, and the stirring reaction time is 3h , Cooling temperature 65 ℃, after crystallization, solid-liquid separation, obtain ferrous sulfate concentration and be 0.12% titanium white waste acid after pretreatment, the removal rate of ferrous sulfate is 98.8%;

[0057] Step 2: Use crushing equipment to crush and screen the secondary aluminum ash to obtain 200 meshes of crushed aluminum ash for later use;

[0058] Step 3: Add circulating water into the reaction tank, and then add the 200-mesh broken aluminum ash obta...

Embodiment 3

[0064] Such as figure 1 Shown, a kind of method of utilizing titanium white waste acid and secondary aluminum ash to reclaim aluminum hydroxide powder of the present invention may further comprise the steps:

[0065] Step 1: Add concentrated sulfuric acid with a concentration of 90% to titanium white waste acid with a sulfuric acid mass concentration of 55% and a ferrous sulfate mass concentration of 8%. The final concentration of the titanium white waste acid is 55%, and the stirring reaction time is 2h , Cooling temperature 45 ℃, after crystallization, solid-liquid separation, obtain ferrous sulfate concentration and be 0.2% titanium white waste acid after pretreatment, the removal rate of ferrous sulfate is 97.5%;

[0066] Step 2: Use crushing equipment to crush and screen the secondary aluminum ash to obtain 18 meshes of crushed aluminum ash for later use;

[0067] Step 3: Add tap water to the reaction tank, and then add the 18 mesh broken aluminum ash obtained in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com