Denitrification agent, preparation method and dry-method denitrification method

A denitrification agent and denitrification technology, applied in the field of denitrification agent, dry denitrification, and preparation, can solve the problems of low efficiency of dry denitrification, achieve the effects of reducing denitrification cost, improving denitrification efficiency, and reducing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

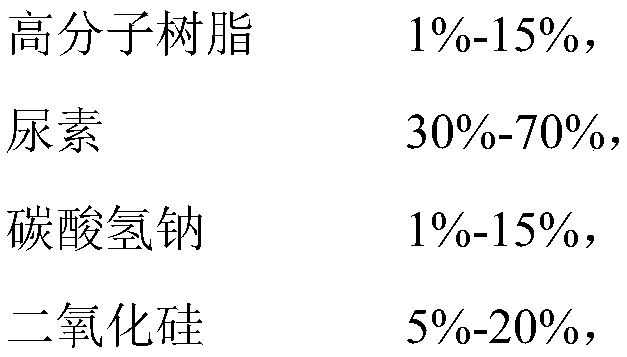

[0027] Embodiment 1 (preparation denitration agent)

[0028] Weigh each raw material according to the following formula, in terms of mass percentage, polyethylene polymer resin 1%, urea 70%, sodium bicarbonate 3%, silicon dioxide 5%, kaolin 10%, talcum powder 5%, bisamide 5% %, 1% bentonite; the denitrification agent is obtained after mixing all raw materials evenly, and the above denitrification agent is a mixture of powder and granules.

Embodiment 2

[0029] Embodiment 2 (preparation denitration agent)

[0030] Weigh each raw material according to the following formula, in terms of mass percent, polyethylene polymer resin 5%, urea 47%, sodium bicarbonate 5%, silicon dioxide 8%, kaolin 13%, talcum powder 7%, bisamide 10% %, 5% bentonite; first grind each raw material powder to a particle size of 100-120 mesh powder, and then mix each raw material evenly to obtain the denitrification agent, and the above denitrification agent is in powder form.

Embodiment 3

[0031] Embodiment 3 (preparation denitration agent)

[0032] Weigh each raw material according to the following formula, in terms of mass percentage, polyethylene polymer resin 8%, urea 30%, sodium bicarbonate 8%, silicon dioxide 10%, kaolin 15%, talcum powder 8%, bisamide 13 %, bentonite 8%; first grind each raw material powder to a particle size of 100-120 mesh powder, then mix polymer resin, urea, sodium bicarbonate, talcum powder, dinitrile amine and bentonite to form the first mixture, and finally to Add silicon dioxide and kaolin to the first mixture, and mix evenly to obtain the denitrification agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com