Face-fired boiler advanced denitration burning method

A combustion method and boiler technology, applied in the direction of combustion method, use of multiple fuels, combustion types, etc., can solve problems such as limited scope of application, ammonia escape, high requirements for boiler working conditions, etc., to achieve wide applicability and reduce emissions Value, the effect of reducing the cost of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

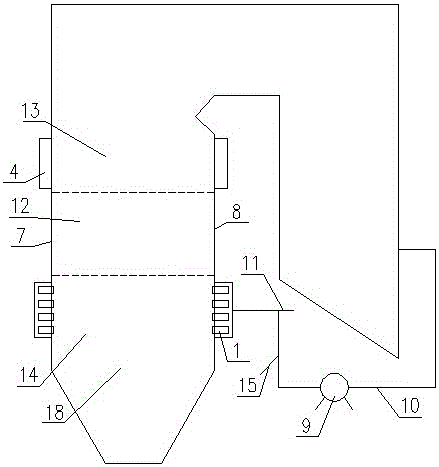

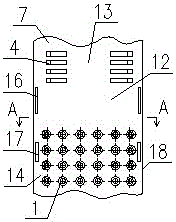

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the hedging boiler has several layers of burn-off air nozzles 4 on the upper part of the front wall 7 and rear wall 8 of the furnace, and several layers of swirl burners on each layer of the lower part of the front wall 7 and rear wall 8 of the furnace. 1. The swirl burner 1 is provided with a primary air nozzle 2 and a secondary air nozzle 3, and the center line of the swirl burner 1 close to the two side walls 18 of each layer is offset from the center of the furnace by 5° to 45°; the furnace is from From bottom to top, it is divided into the main combustion zone 14 corresponding to the swirl burner 1, the reduction zone 12 between the overburning air nozzle 4 and the swirl burner 1, and the burnout zone 13 corresponding to the overburning air nozzle 4. The front and rear walls of the reduction zone 12 and the main combustion zone 14 are provided with purge air nozzles 16 and 17 on both sides of the fron...

Embodiment 2

[0047] Such as Figure 5 , Figure 6 As shown, the difference between the present embodiment and the first embodiment is that an independent reduction inhibitor nozzle 19 is set in the primary air nozzle 2 of several swirl burners 1, and the end of the reduction inhibitor nozzle 19 is located at the primary air nozzle 2 Outside the end of the exhaust, the reduction inhibitor nozzle 19 is connected to the tail flue before the air preheater through the pipeline 10 and the fan 9, and the mixing pipe 15 is connected to the pipeline 10; during combustion, the tail smoke from the boiler air preheater The channel extracts part of the flue gas through the blower 9 as the transport medium of the amino reduction inhibitor, mixes it with the amino reduction inhibitor mixed through the dosing pipe 15, and sprays it into the furnace from the reduction inhibitor nozzle 19; this embodiment is more conducive to the realization of the furnace The reducing atmosphere and the temperature of the...

Embodiment 3

[0049] Such as Figure 7 , Figure 8 As shown, the difference between the present embodiment and the second embodiment is only that several reduction inhibitor spouts 20 are relocated to the four corners of the hearth between the two-layer swirl burners 1 and on the front wall 7 and the rear wall 8; , the amino reduction inhibitor is injected into the amino reduction inhibitor through several reduction inhibitor spouts 20, and the amino reduction inhibitor of the same layer is sprayed in the manner of forming two imaginary tangential circles in the furnace; wherein the reduction inhibitor spout 20 aperture is 1~ 10mm, the opening is fan-shaped, the opening angle is between 10° and 150°, the injection speed of the amino reduction inhibitor is between 10m / s and 400m / s, and the diameter of the tangential circle can be adjusted by adjusting the deflection angle of the reduction inhibitor nozzle 20 The size and direction of rotation meet the needs of different working conditions; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com