Patents

Literature

92results about How to "Lower emission value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

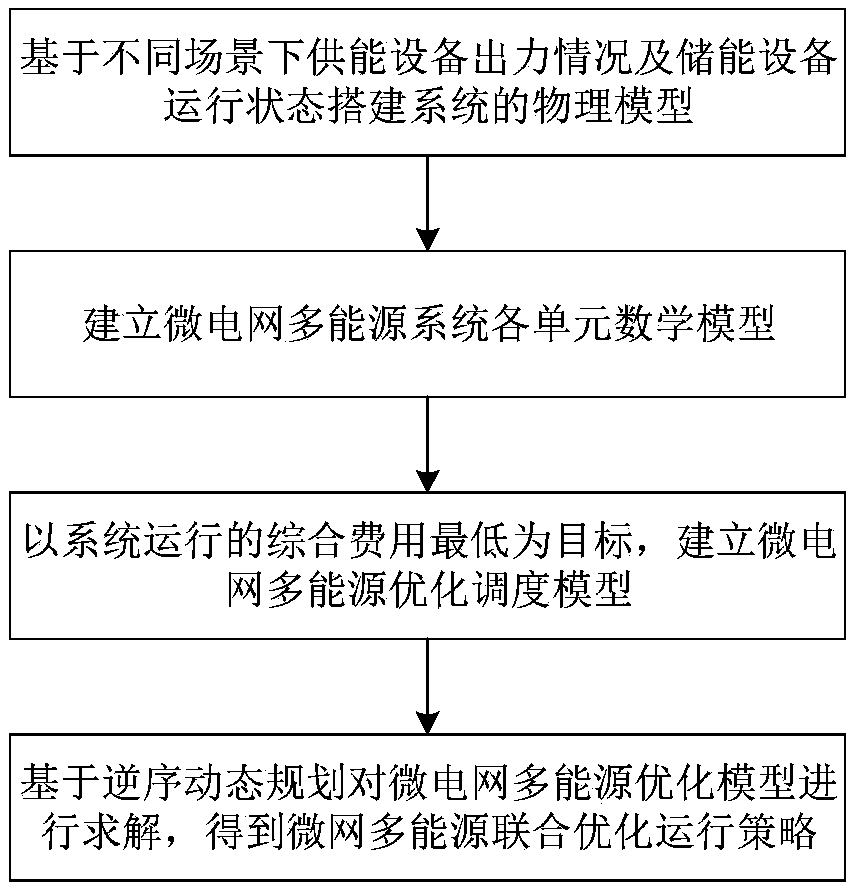

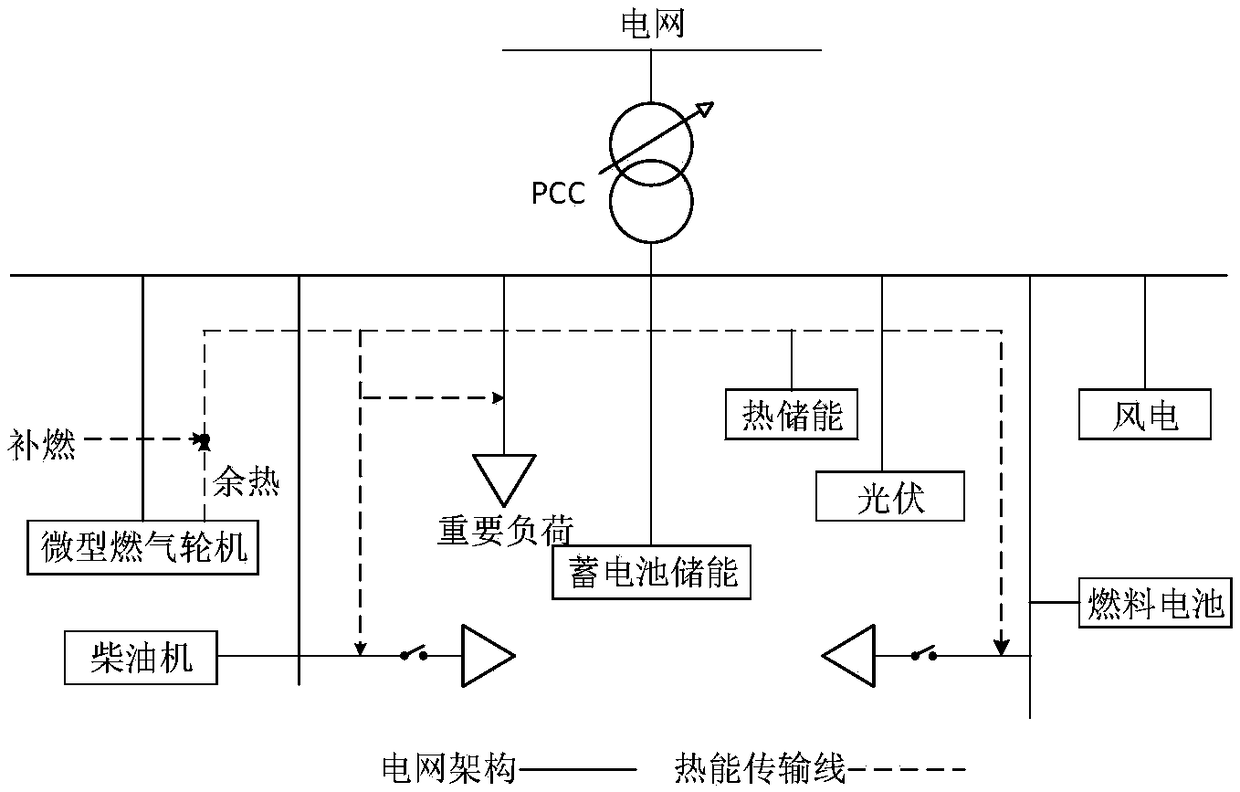

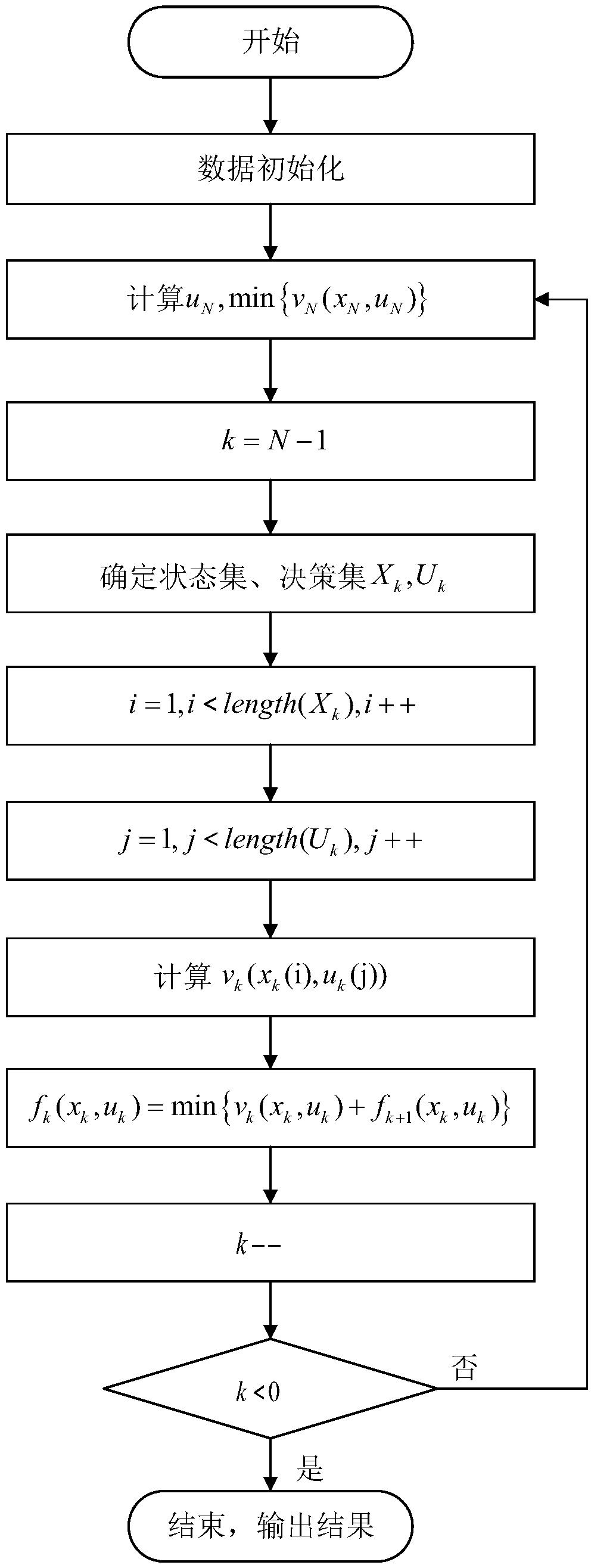

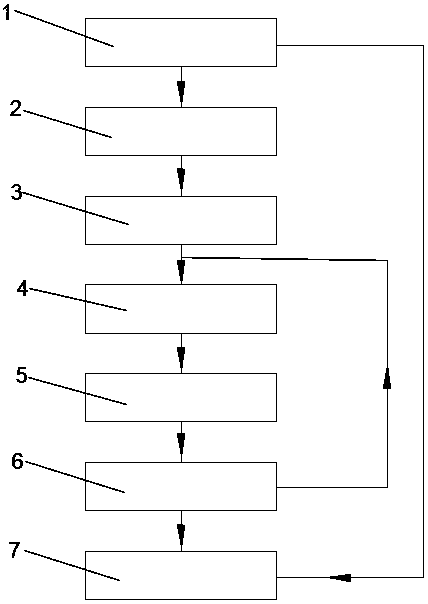

Microgrid multi-energy joint optimal scheduling method

ActiveCN109327042AEasy to guideGood motivationSingle network parallel feeding arrangementsWind energy generationMicrogridDynamic planning

The invention relates to a microgrid multi-energy joint optimal scheduling method. The method includes: step 1, on the basis of force application conditions of energy supply equipment and operating states of energy storage equipment in different scenes, constructing a physical model of a multi-energy system; step 2, establishing unit mathematical models, including a wind power generator model, a photovoltaic power generation model, a micro-gas turbine model, a fuel cell model and an energy storage model, of the microgrid multi-energy system; step 3, in order to realize lowest comprehensive cost in system operation, constructing a microgrid multi-energy optimal scheduling model by taking DG operation constraints, system safety constraints and multi-energy coupling characteristics into comprehensive consideration; step 4, on the basis of reversed order dynamic planning, solving the microgrid multi-energy optimal scheduling model to obtain a microgrid multi-energy joint optimal operatingstrategy. By the microgrid multi-energy joint optimal scheduling method, operating demands in different scenes can be met, electricity-thermal coordinated optimal scheduling schemes are provided for operating of a comprehensive energy microgrid in different scenes, and high integral operating efficiency and high economic benefits are realized.

Owner:NANJING UNIV OF POSTS & TELECOMM

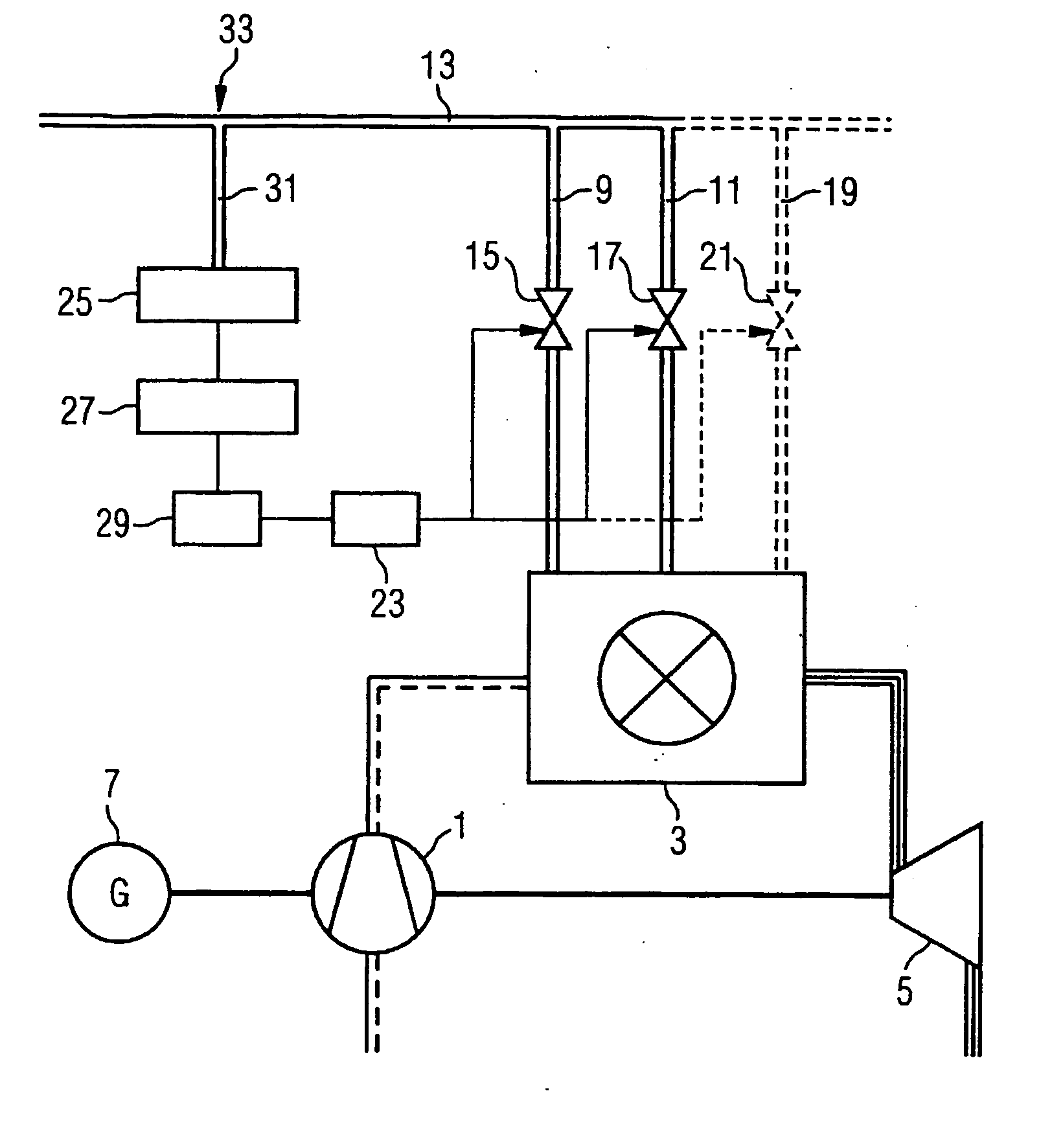

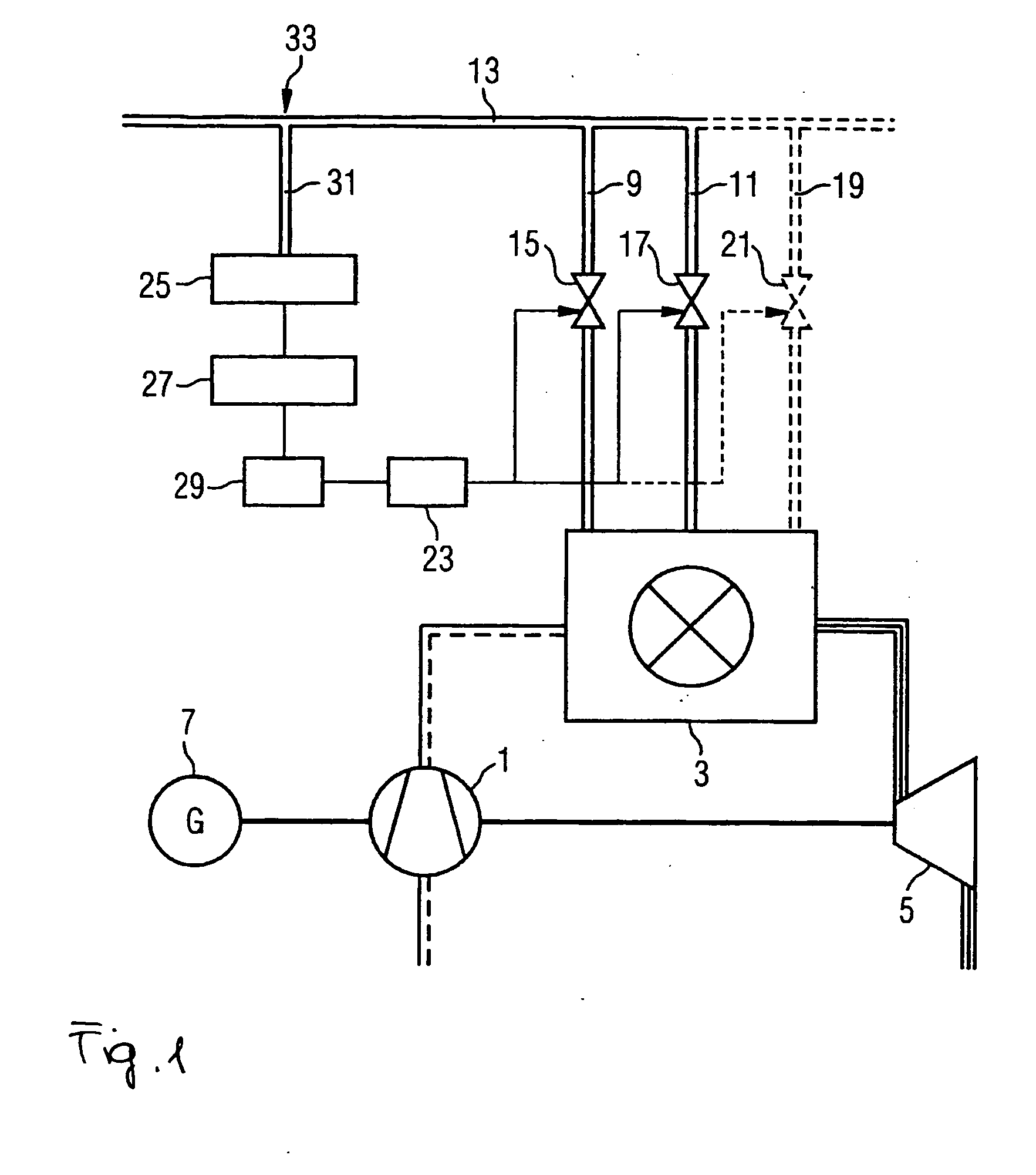

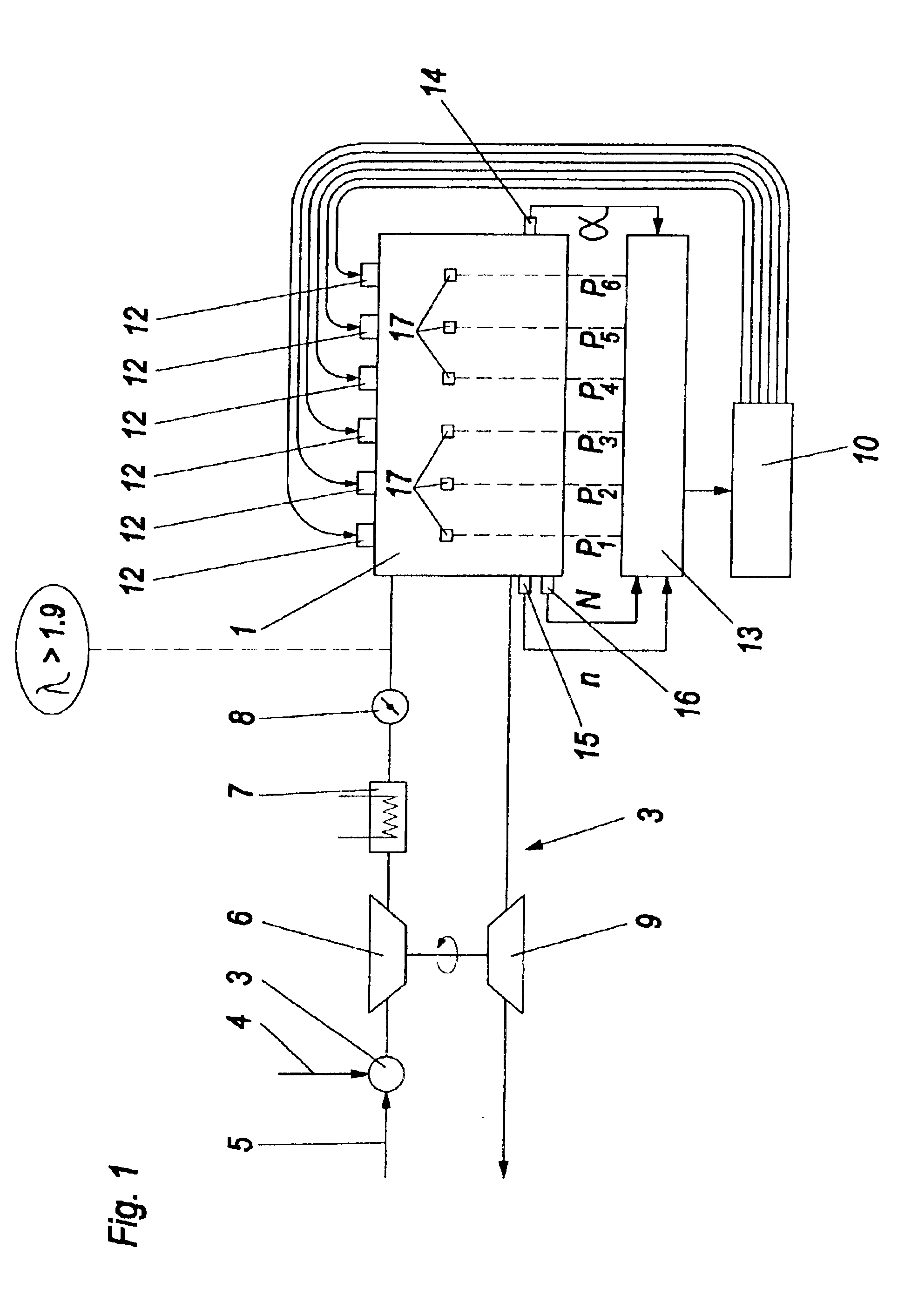

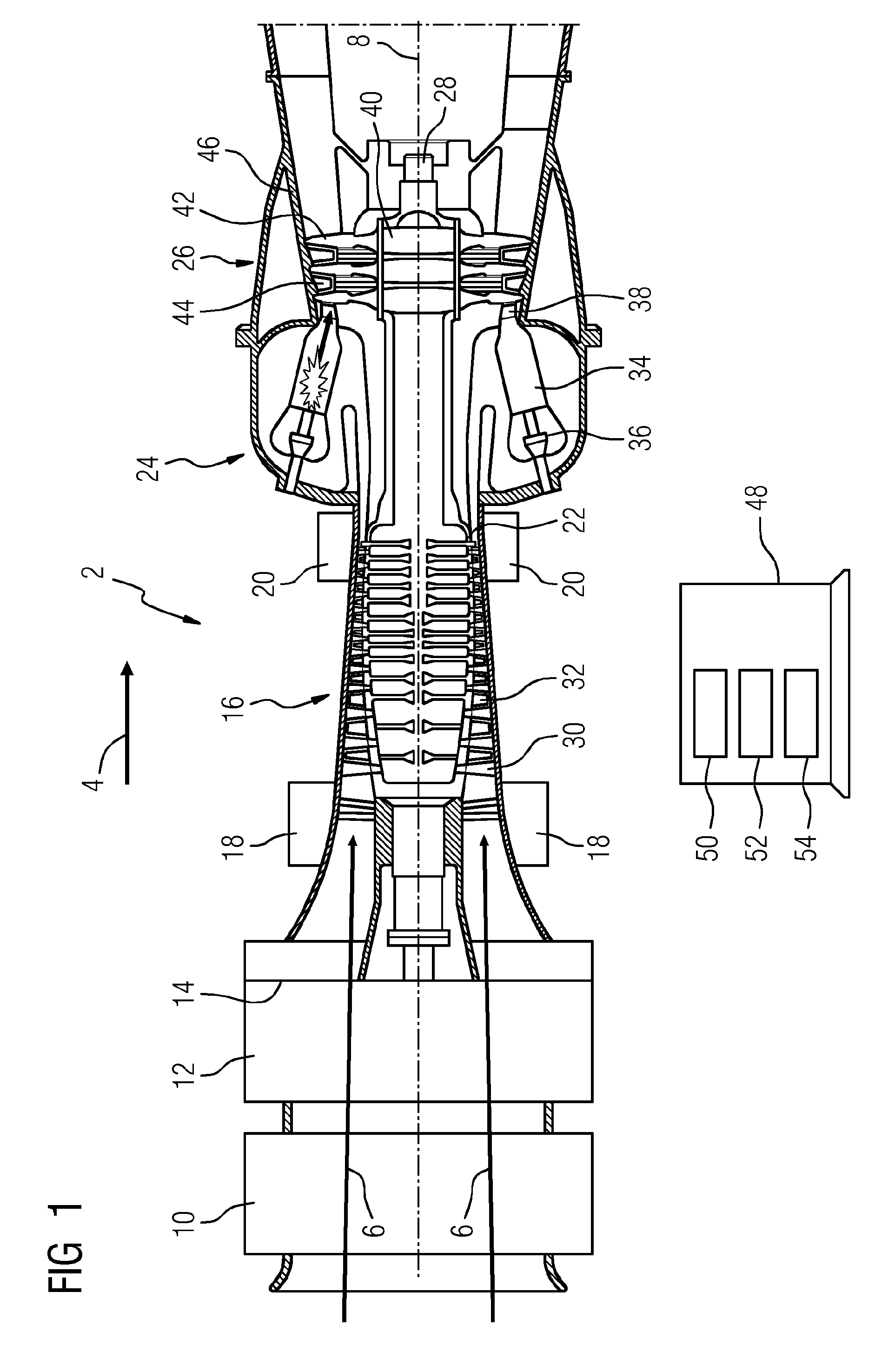

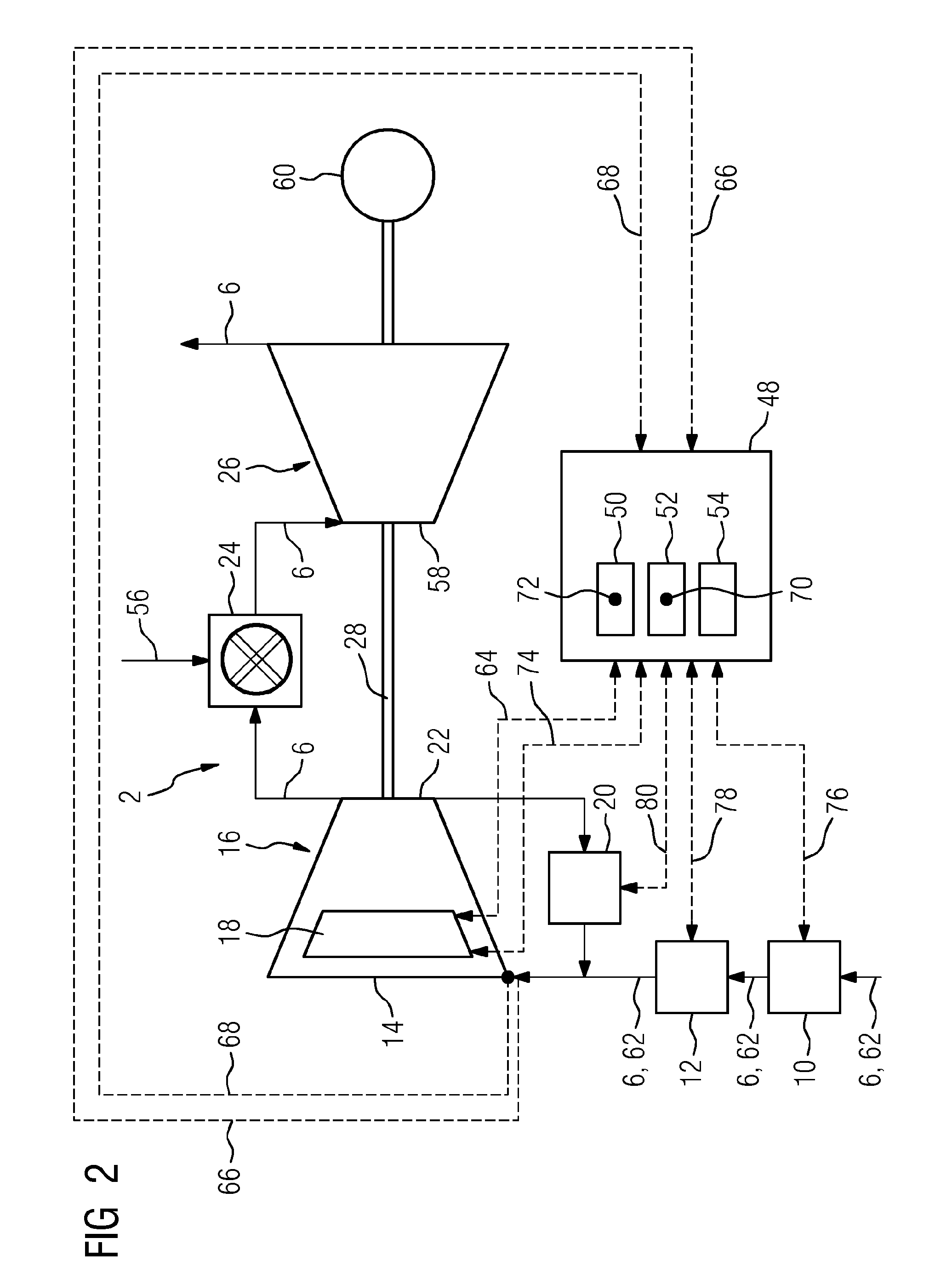

Method and device for compensating variations in fuel composition in a gas turbine system

ActiveUS20070119178A1Accelerate emissionsIncreased fluctuationGas turbine plantsTurbine/propulsion fuel controlCombustorGas turbines

The invention relates to a method for compensating variations in fuel composition in a gas turbine system consisting of at least two parallel-operated burner stages, wherein the fuel supply to at least two of the burner stages is adjusted in response to variations in fuel composition, wherein the fuel split between the burner stages, i.e. the relative increase in speed of the fuel supplied to the burner stages, is adjusted to a target value or maintained at a target value during adjustment of the fuel supply. The target value can, for example be a constant or a function of one or several variables. More particularly, the gas turbine system can comprise a pilot burner stage and a main burner stage. When the fuel supply is adjusted, the fuel split between the pilot burner stage and the main burner stage is adjusted to a target value or maintained at a target value.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

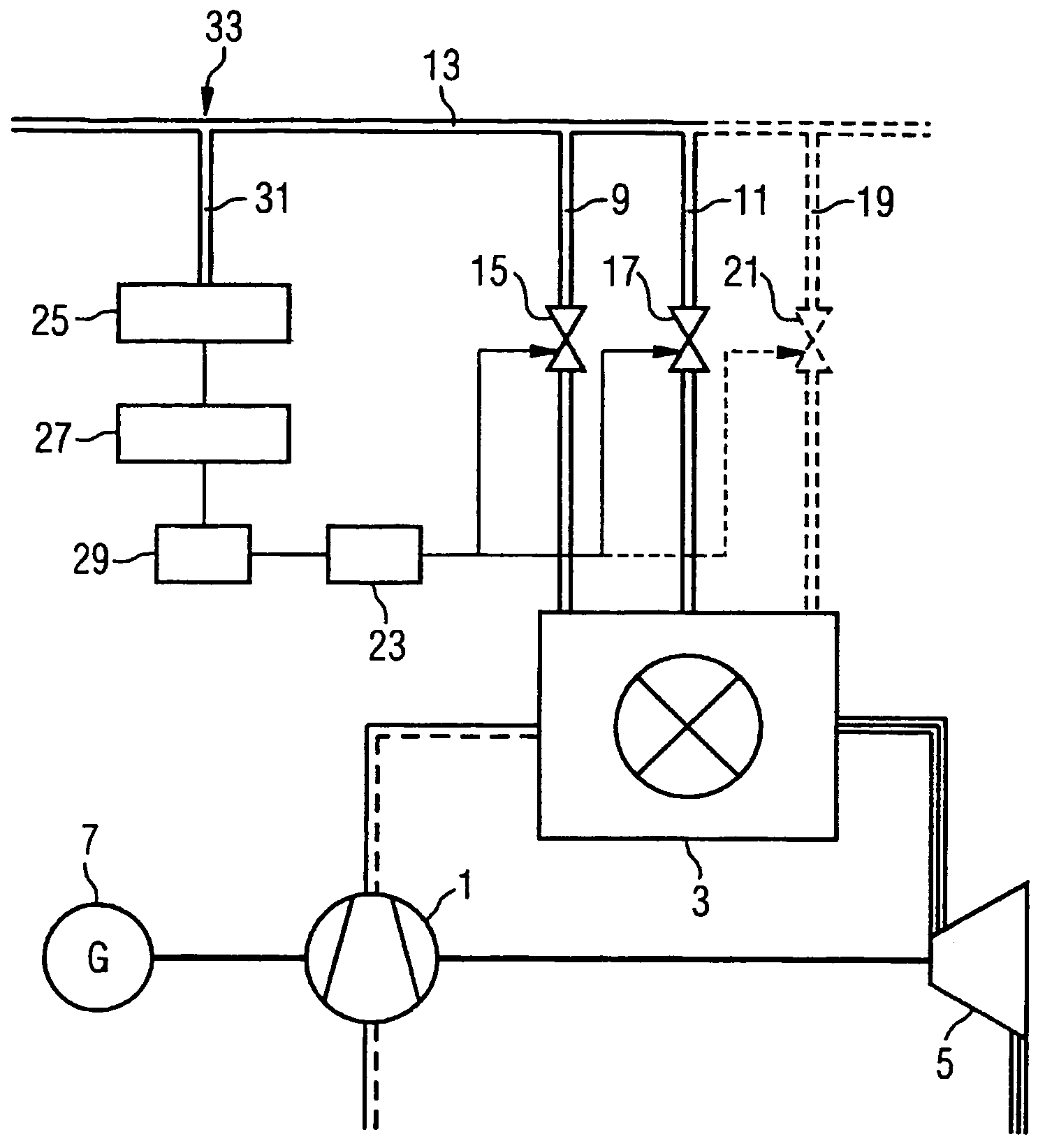

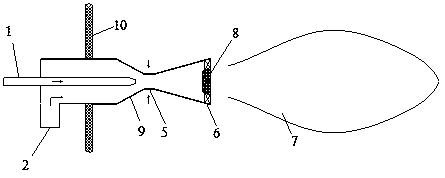

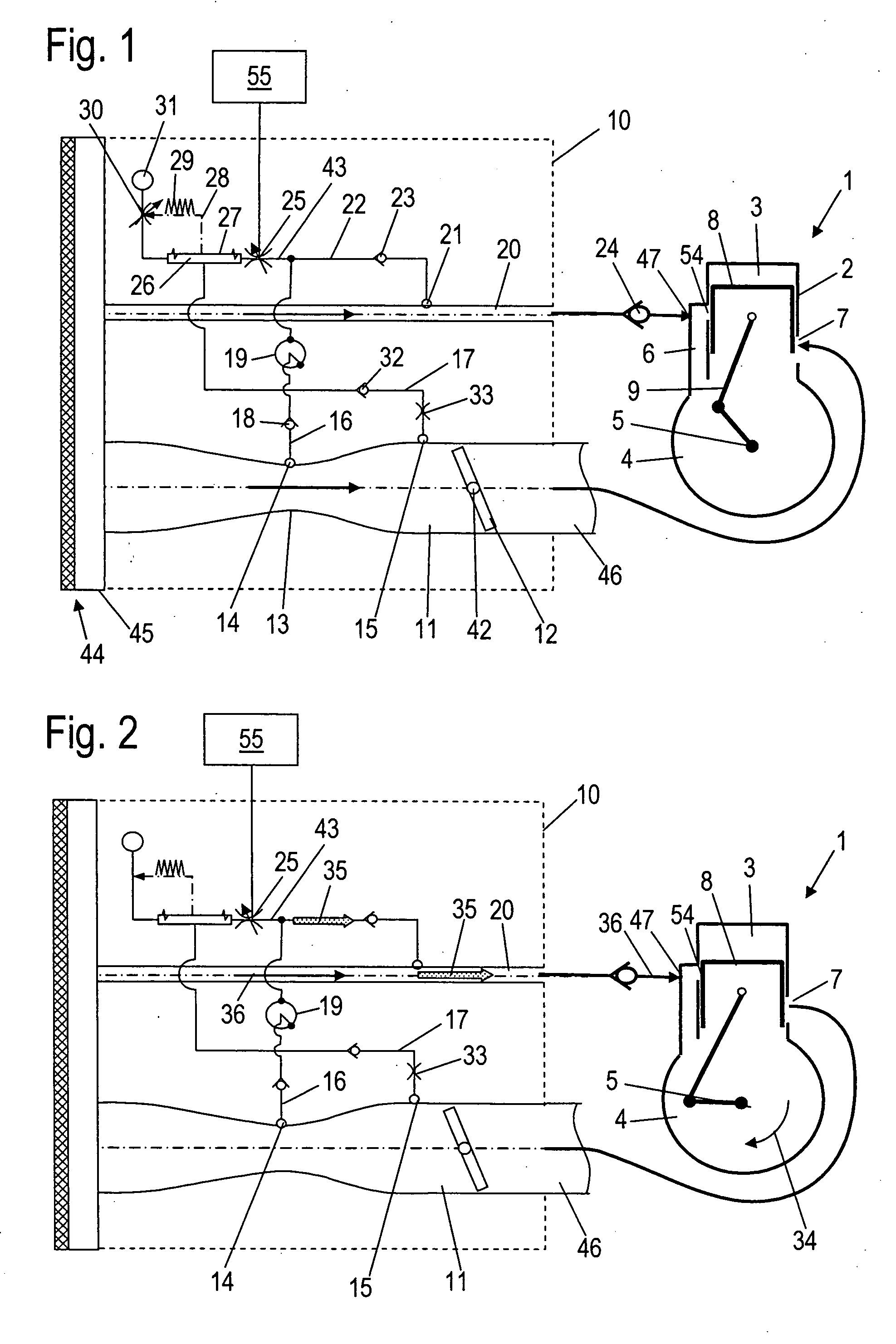

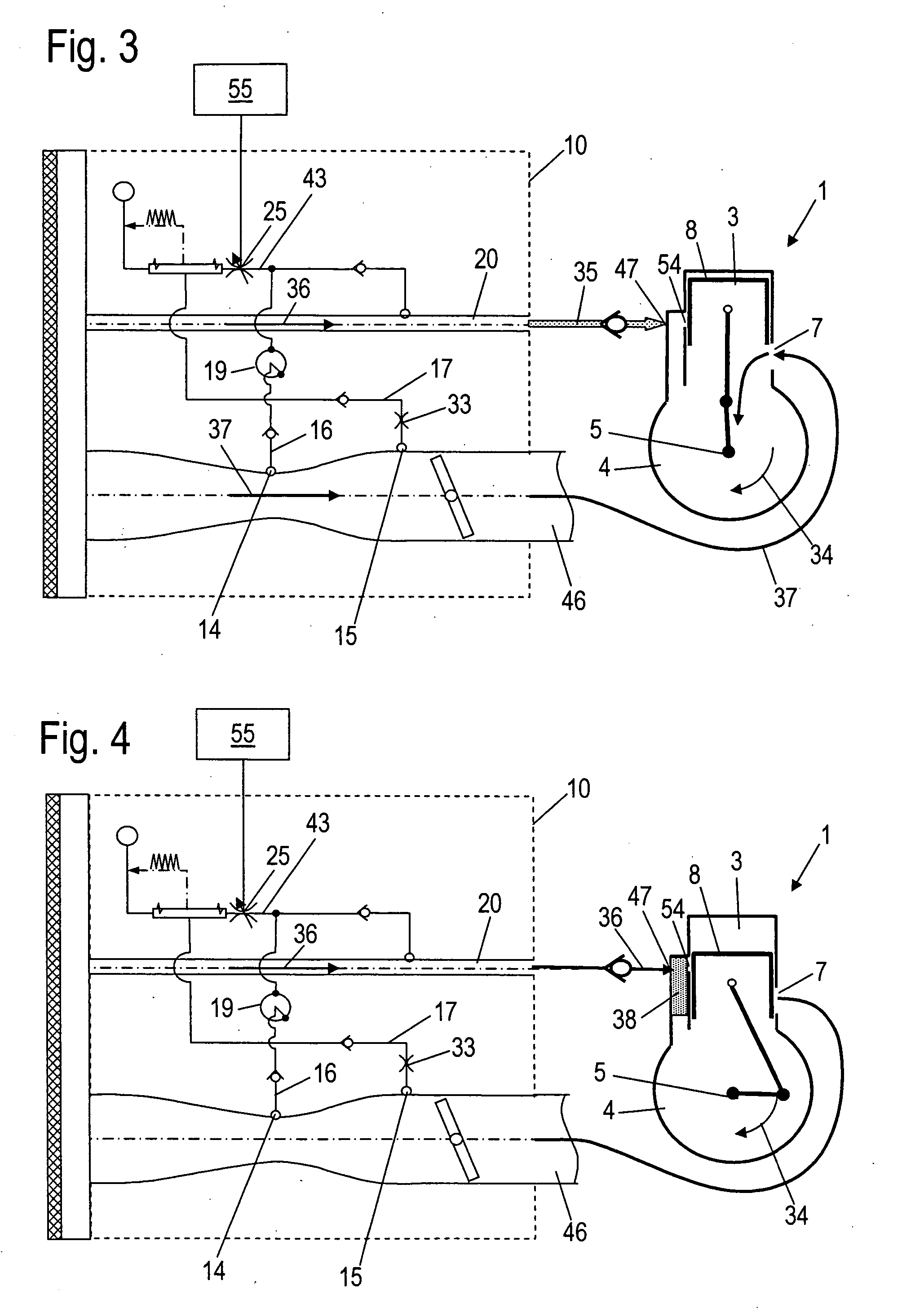

Charge air system and charge air operation method

ActiveUS20110000469A1Chemical emission valueEliminate the problemInternal combustion piston enginesCarburettorsCombustionEngineering

A charge air system for a combustion engine and an operation method are provided. The charge air system includes a first turbocharger stage for intake of combustion air supplied to the engine from a first pressure to a second pressure, a second turbocharger stage for compression of the compressed air to a third pressure, a first heat exchanger being arranged between the first and the second turbocharger stage for cooling the compressed air, a first intake air bypass for modulating the flow of the air through the first heat exchanger and / or a first mass flow control unit for controlling the flow of a cooling medium supplied to the first heat exchanger.

Owner:VOLVO LASTVAGNAR AB

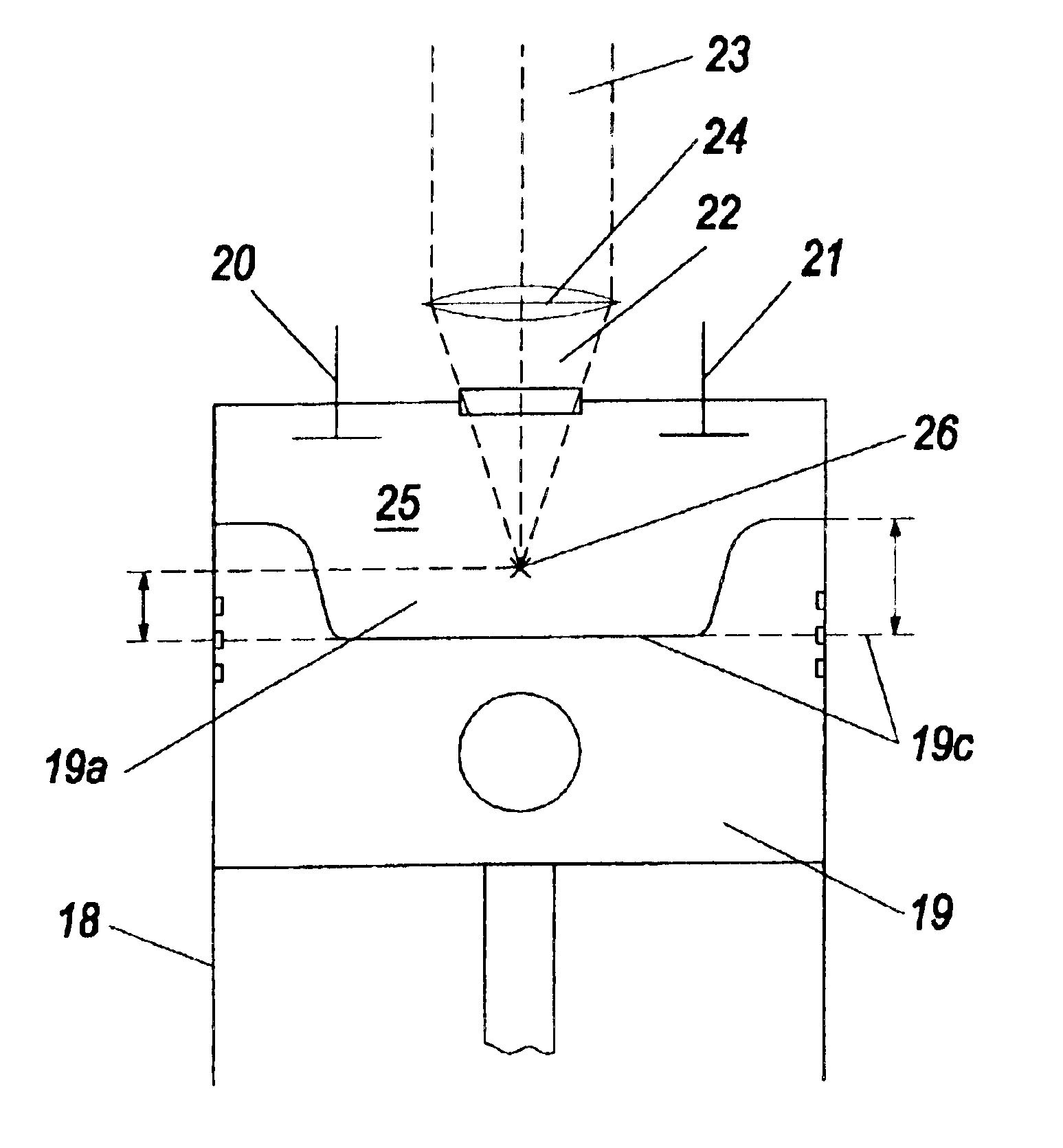

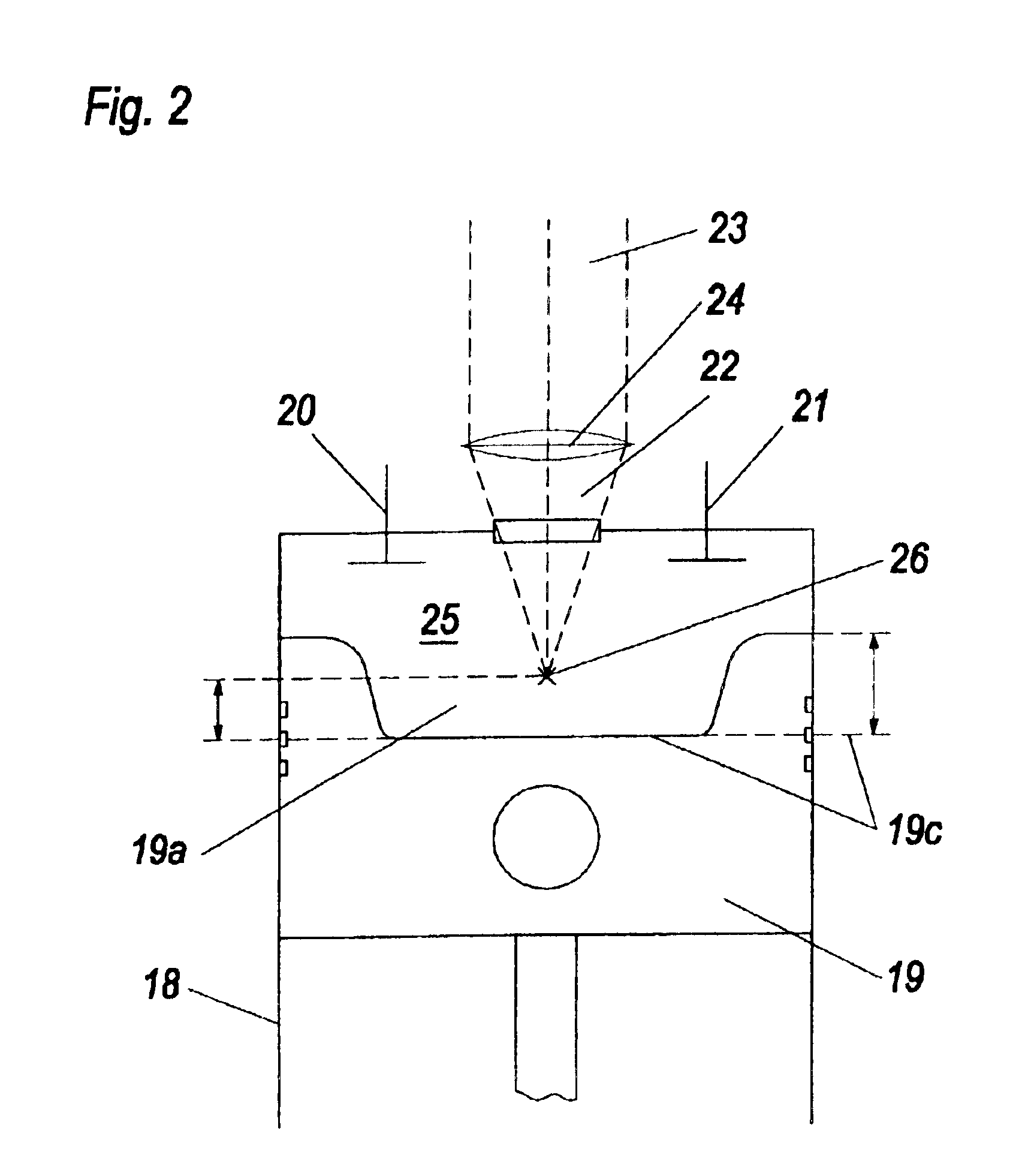

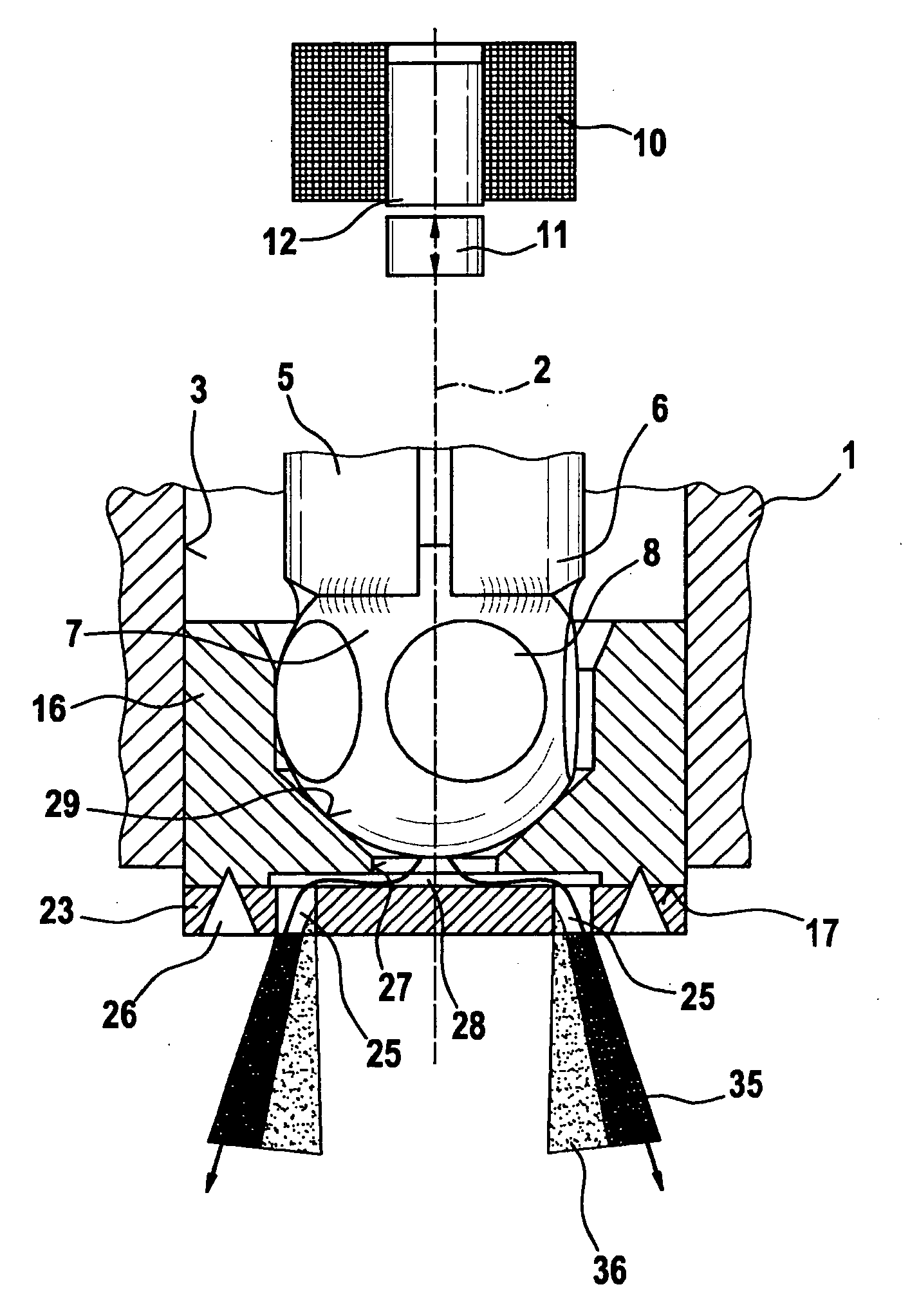

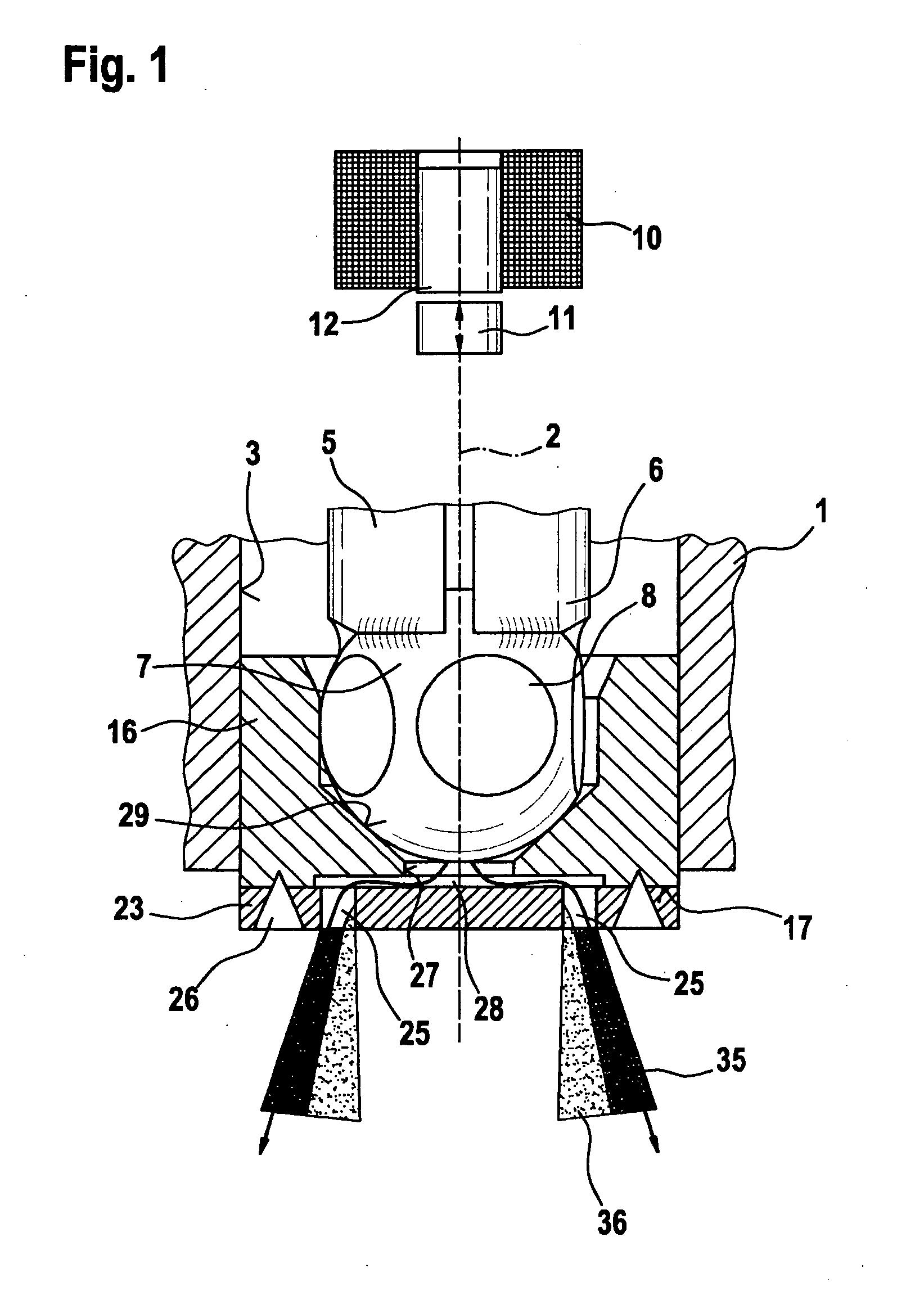

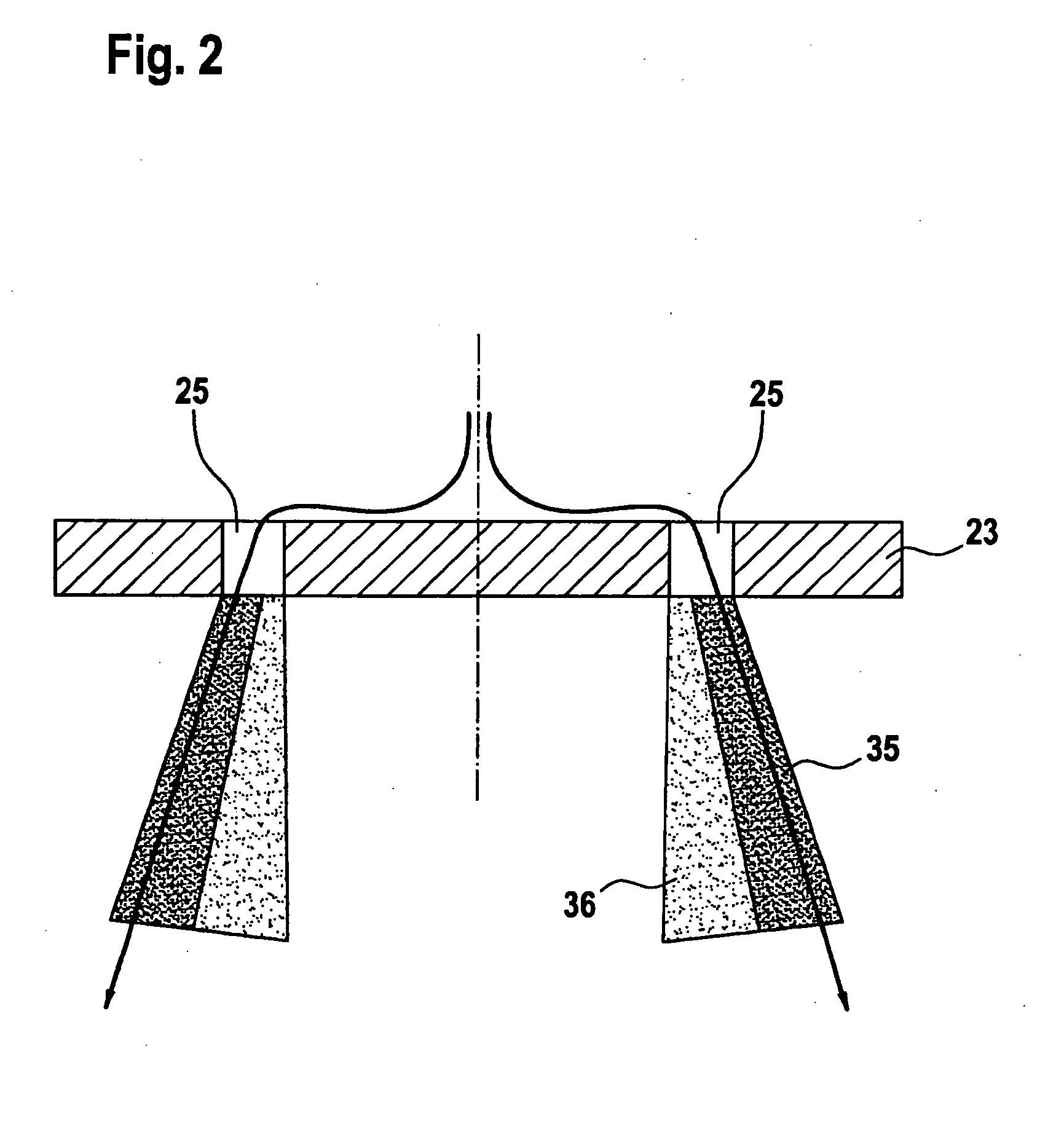

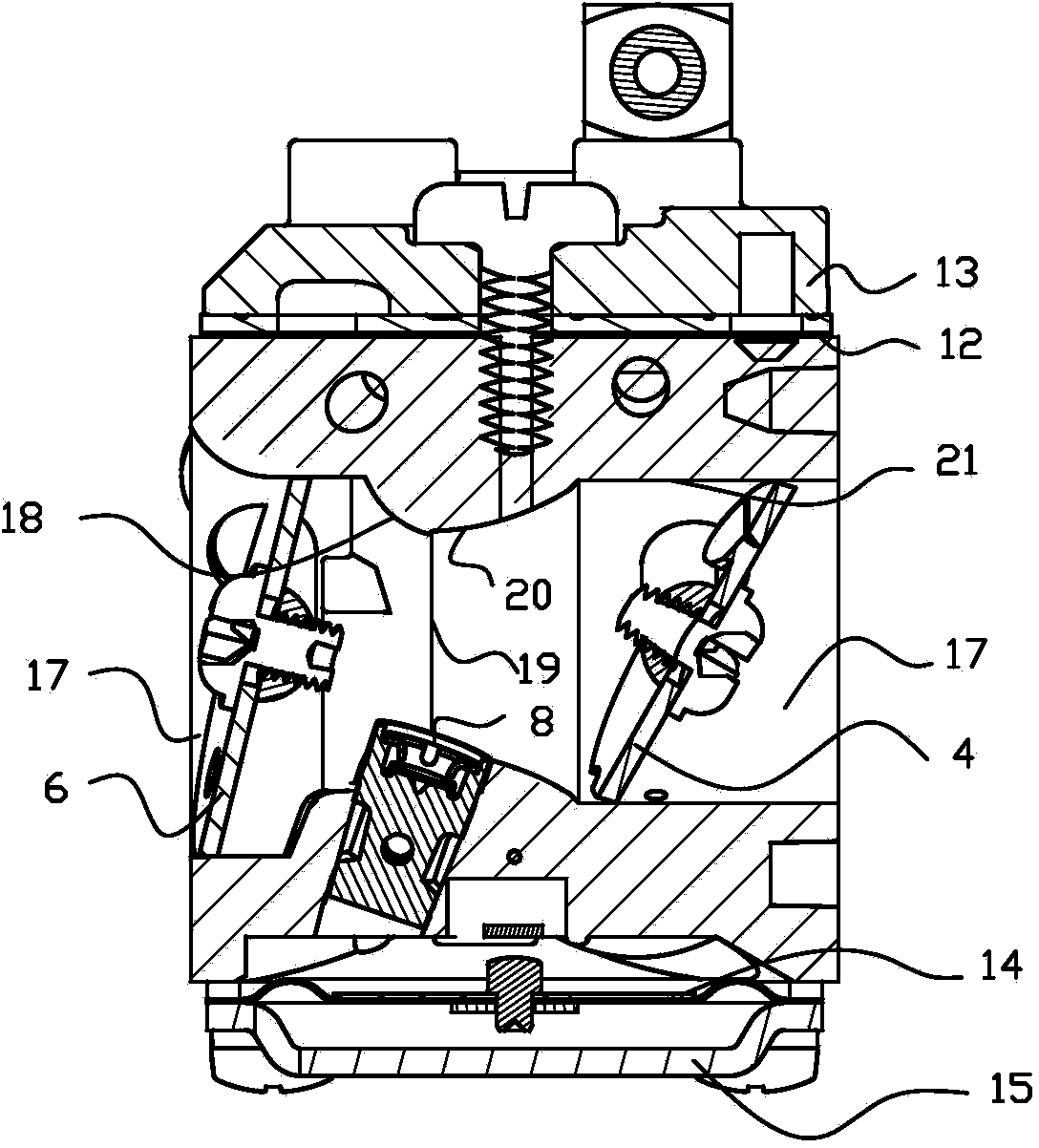

Internal combustion engine

InactiveUS7040270B2High spatial energy densityReliable ignitionLaser detailsElectrical controlCombustion chamberLaser light

Internal combustion engine with at least one cylinder, in which the combustion of a homogeneous air / fuel mixture compressed in the cylinder by a piston is initiated by a time-controlled external ignition, the air / fuel ratio of the air / fuel mixture in the combustion chamber (25) being greater than 1.9 and, for the time-controlled external ignition, at least one laser light source (10), at least one optical transmission apparatus (11) and at least one coupling optic (12) for the focussing of laser light into a combustion chamber (25) being provided.

Owner:GE JENBACHER

Method and device for compensating variations in fuel composition in a gas turbine system

ActiveUS7472540B2Accelerate emissionsIncreased fluctuationGas turbine plantsTurbine/propulsion fuel controlCombustorEngineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

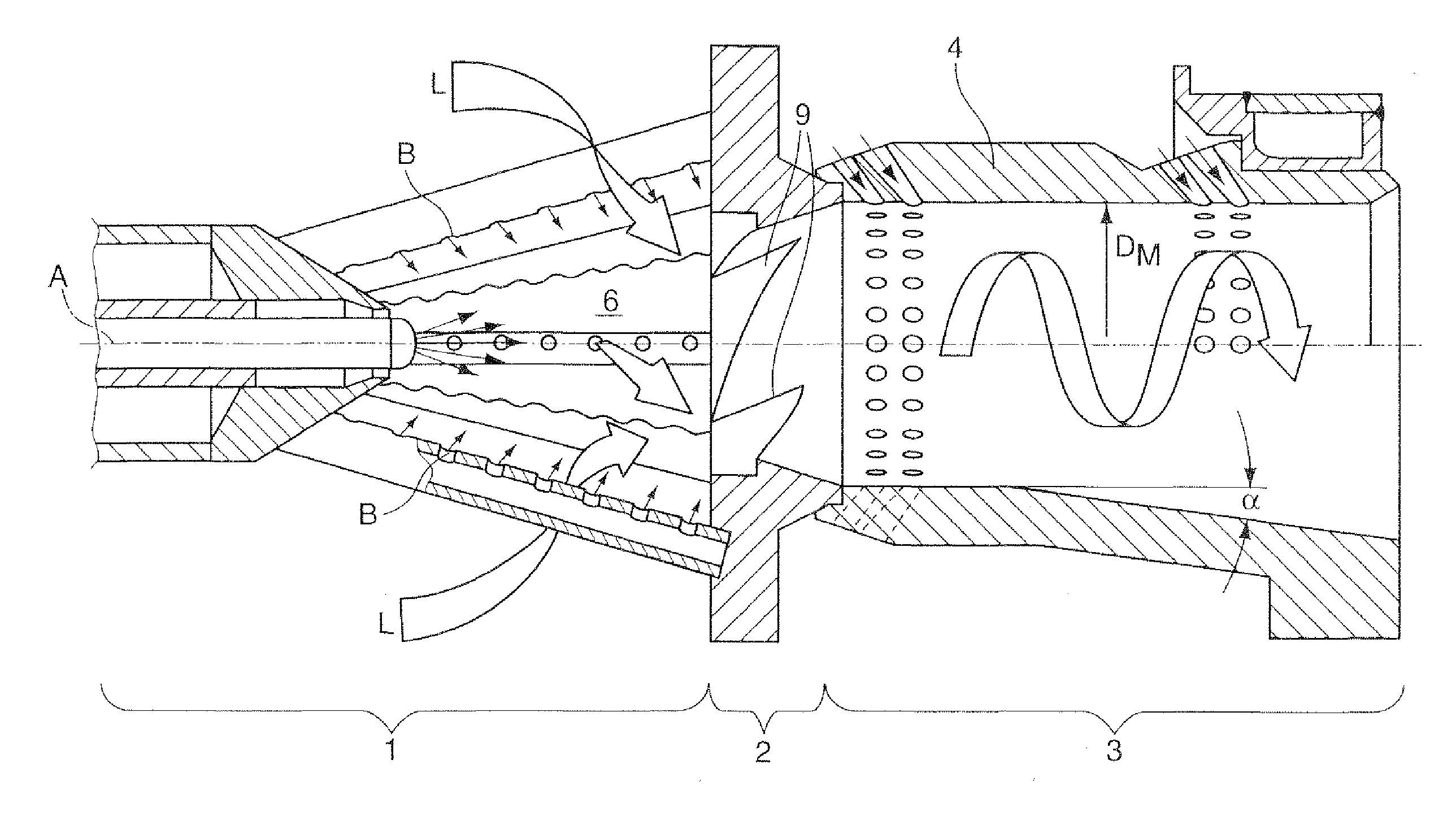

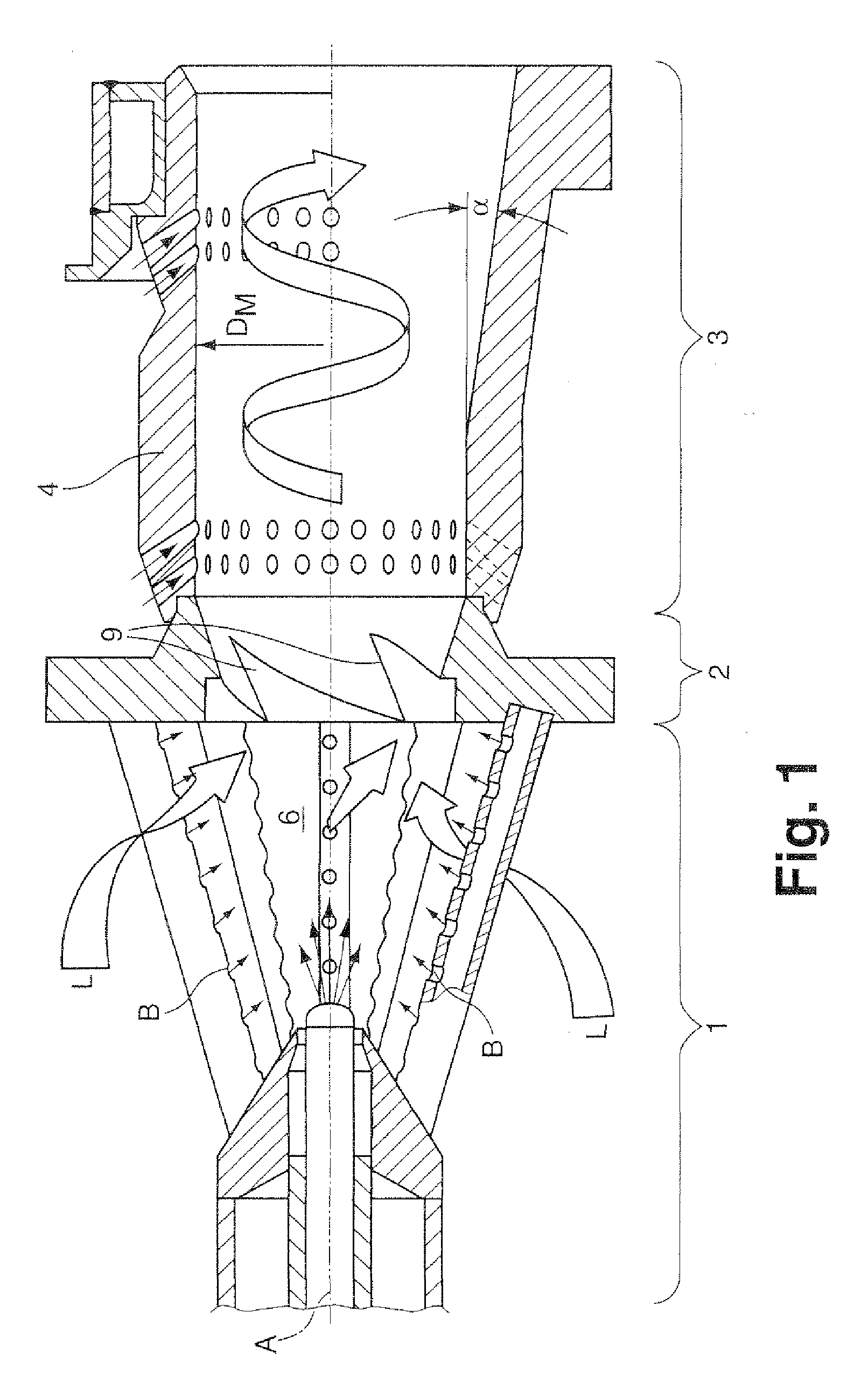

Premix Burner

InactiveUS20070202453A1Reduce riskIncrease capacityGaseous fuel burnerCombustion chambersCombustorLiquid fuel

A premix burner for a heat generator has partial cone shells (5) which make up a vortex generator, and which encompass a conically widening vortex chamber (6) and mutually define tangential air inlet slots (7), and also with feeds for gaseous and / or liquid fuel, of which at least one is arranged along the air inlet slots (7) on the partial cone shells (5), and at least one other is arranged along a burner axis (A) which centrally passes through the vortex chamber (6). At least n partial cone shells (5) encompass the vortex chamber (6), and define n air inlet slots (7), with n≧3, preferably n≧5, the n air inlet slots (7) each have at least a maximum slot width (10) which is equal to or larger than that slot width (10) which a generic type premix burner (1) of the same size and dimensioning with m≦2 partial cone shells (5) and m air inlet slots (7) has.

Owner:ANSALDO ENERGIA IP UK LTD

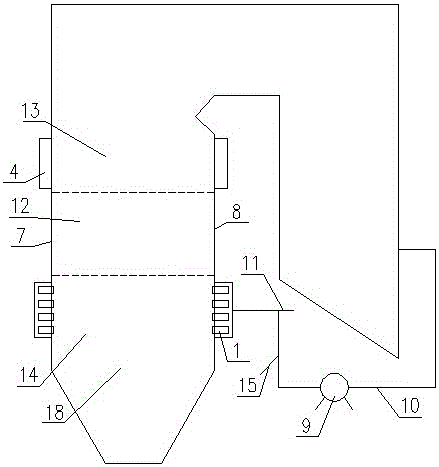

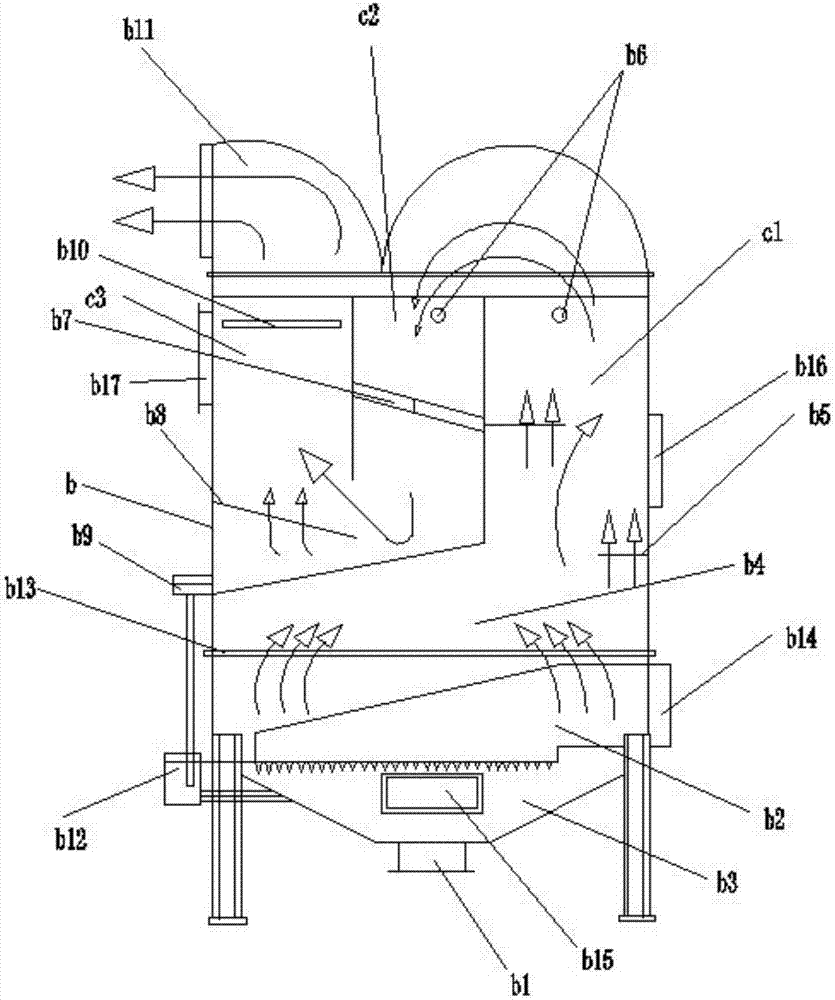

Face-fired boiler advanced denitration burning method

ActiveCN106247320AReduce concentrationLower emission valueCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFlue gasHearth

The invention discloses a face-fired boiler advanced denitration burning method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of turbulent burners in each of layers of turbulent burners arranged on a front wall and a rear wall and is burnt, secondary air is introduced through secondary air nozzles of the turbulent burners, over fire air is introduced through one or more layers of over fire air nozzles on the front wall and the rear wall, the primary air and the secondary air on the front wall and the rear wall are oppositely introduced, the excess air coefficient range of the main burning area of the turbulent burners is 0.5-1.05, and the fire coal undergoes low oxygen burning; the excess air coefficient range of the over fire area of the over fire air nozzles is 1.05-1.3, and oxygen rich burning is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over fire layer to reduce nitrogen oxides in flue gas in high temperature environment in the hearth and inhibit generation of new nitrogen oxides. The face-fired boiler advanced denitration burning method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

W-firing boiler advanced denitration combustion method

ActiveCN106247321AReduce concentrationLower emission valueFluegas recirculationIndirect carbon-dioxide mitigationHearthEngineering

The invention discloses a W-firing boiler advanced denitration combustion method. The method comprises the following steps: fire coal is sent to a hearth through primary air in the primary air nozzles of a plurality of main combustors on boiler arches of a front wall and a rear wall and is combusted, secondary air and under-arch secondary air are respectively introduced through secondary air nozzles and under-arch secondary air nozzles, exhaust gas wind is introduced through exhaust gas wind nozzles on the front wall and the rear wall, one or two layers of over-fire air are introduced through over-fire air nozzles, the excess air coefficient range of a main combustion area is 0.7-1.05, and the fire coal undergoes low oxygen combustion; the excess air coefficient range of an over-fire area is 1.05-1.3, and oxygen rich combustion is carried out; and one or more layers of an amino reduction inhibitor are injected to the hearth under the uppermost over-fire air layer to reduce nitrogen oxides in flue gas and inhibit generation of new nitrogen oxides. The W-firing boiler advanced denitration combustion method has the advantages of substantial reduction of the nitrogen oxide discharge value of the outlet of the hearth, realization of ultralow discharge, no strict temperature window or catalyst, great reduction of the denitration cost, and prevention of high temperature corrosion of water screens in the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP +1

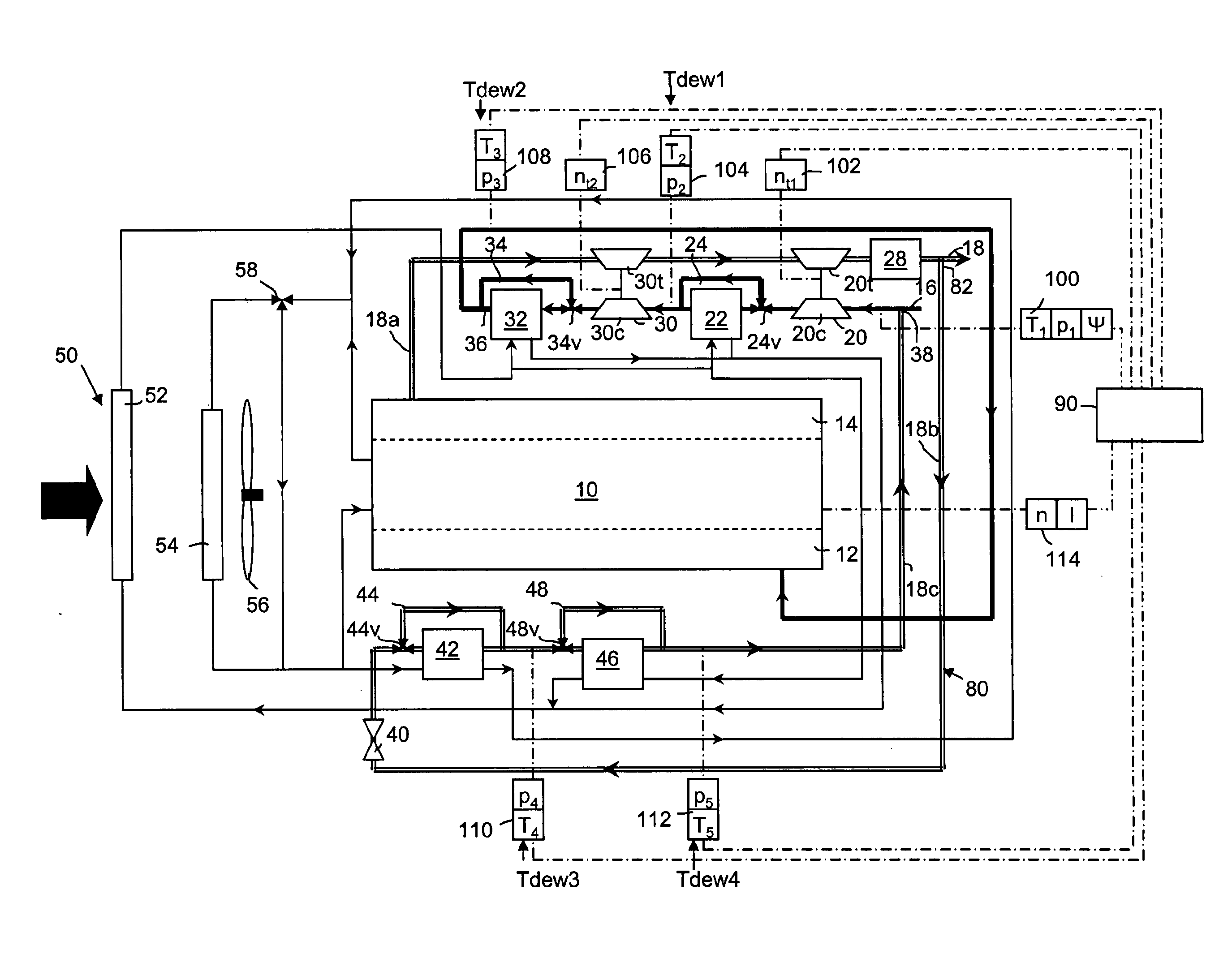

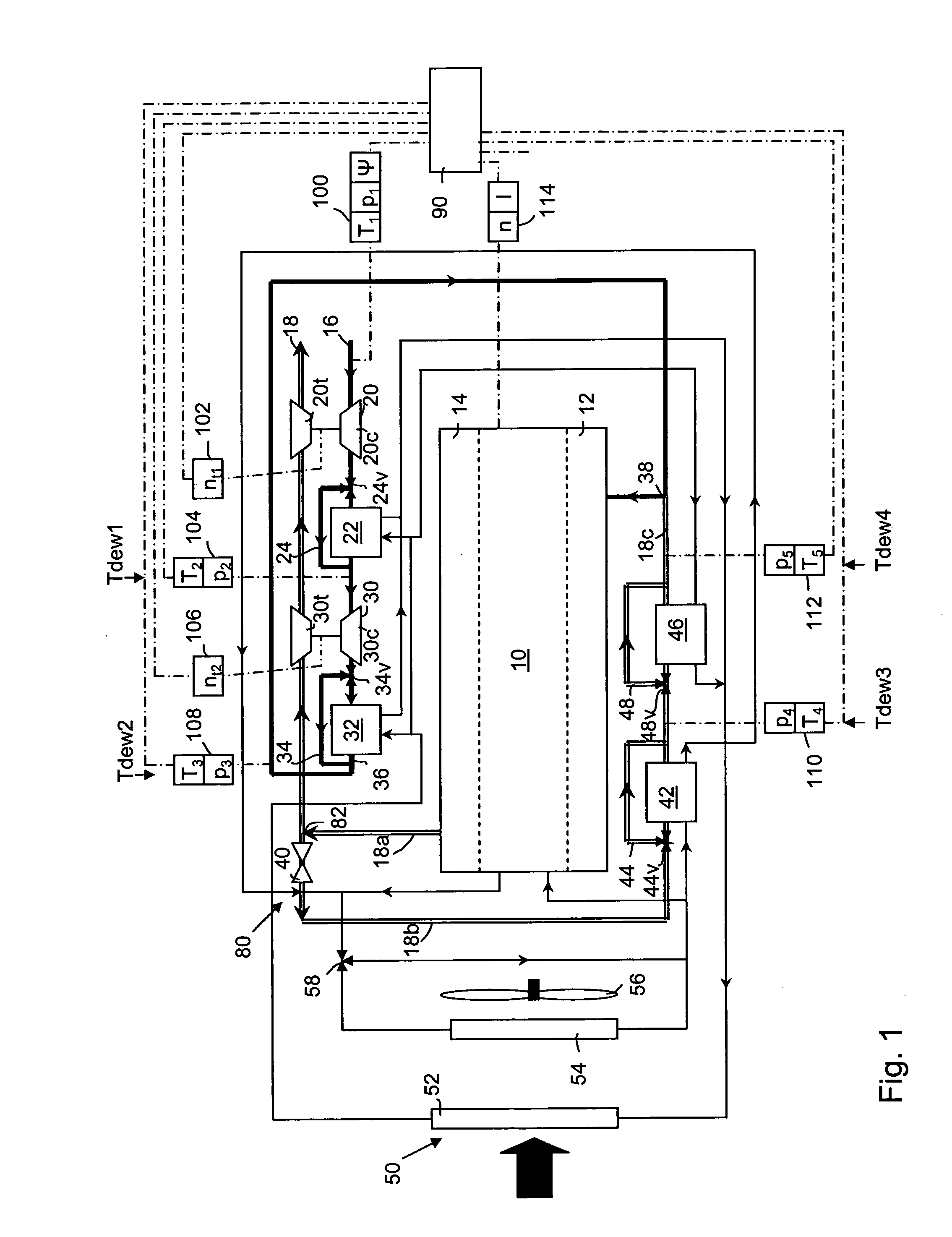

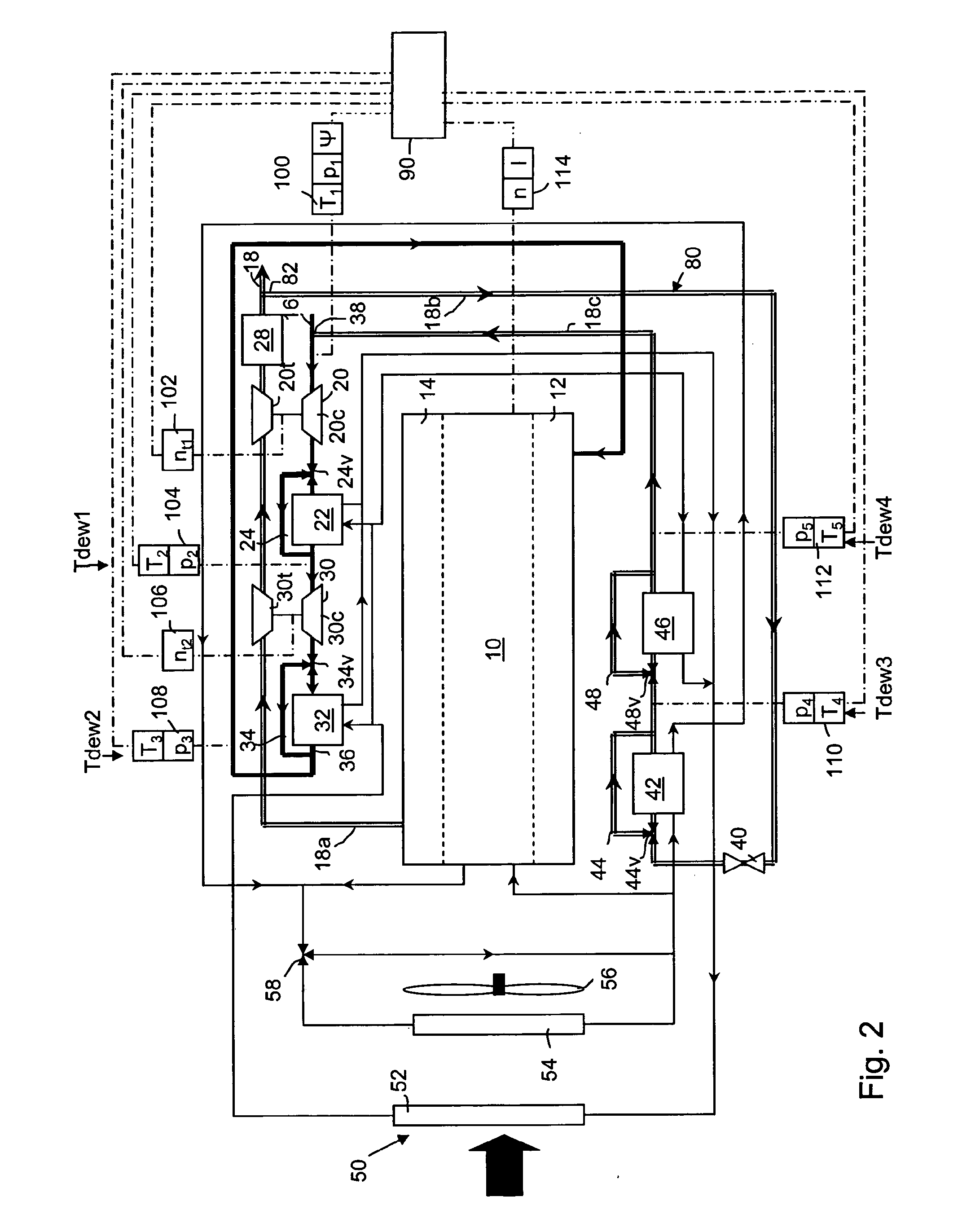

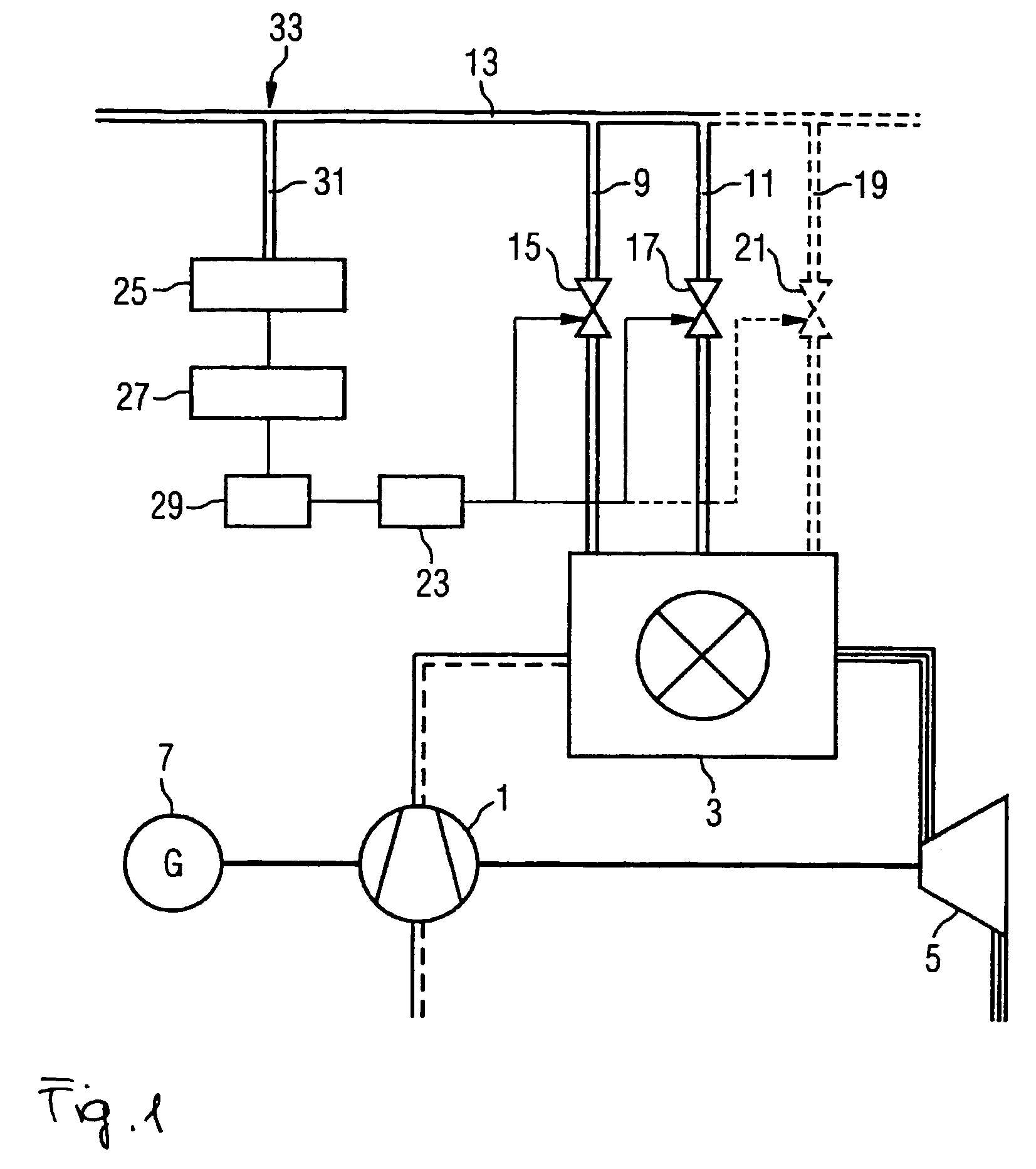

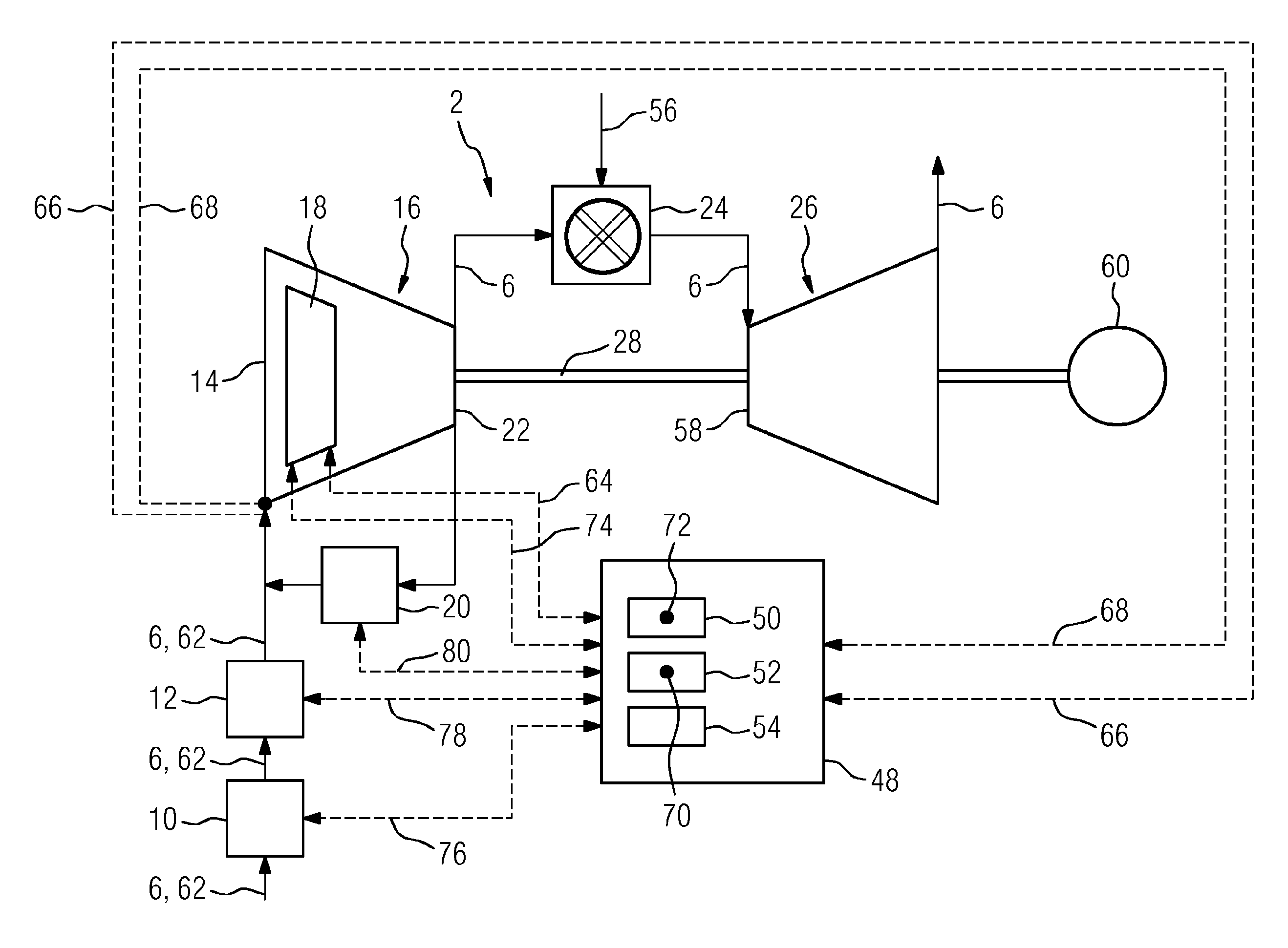

Operation of a gas turbine system in part load operation

InactiveUS20160348690A1Simple controllabilityReduce the total massPump componentsGas turbine plantsLimit valueGas turbines

A method for operating a gas turbine system in part load operation wherein a compressor pre-guide blade adjustment for part load operation is initiated in case of a given state of a flow medium which flows into a compressor, a value of the initiated compressor pre-guide blade adjustment is compared with a compressor pre-guide blade adjustment limit value which is determined depending on the state of the flow medium, and, if the value of the initiated compressor pre-guide blade adjustment meets a predefined condition with regard to the compressor pre-guide blade adjustment limit value, at least one measure is initiated for changing the state of the flow medium which flows into the compressor in part load operation. An arrangement has an actuating device, determining device and control unit to carry out the method. The gas turbine system has an anti-icing device and / or an intake air heating device and the arrangement.

Owner:SIEMENS AG

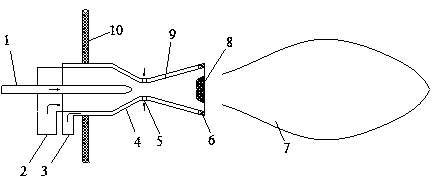

Fuel Injector

InactiveUS20090321540A1Lower emission valueShorten the overall cycleDust removalFire preventionVena contracta diameterEngineering

A fuel injector has an orifice plate including a plurality of spray-discharge orifices, which orifice plate is situated downstream from a valve seat member having a fixed valve seat. An inflow opening, which is provided directly upstream from the spray-discharge orifices as incident-flow cavity, is designed in such a way that an incident flow to the spray-discharge orifices takes place largely at a right angle to the longitudinal extension of the spray-discharge orifices. The spray-discharge orifices are placed and oriented in such a way that at least one fuel spray in the form of a hollow cone lamella or full cone lamella is able to be spray-discharged, in which a radially outer region is made up of larger droplets than a radially inner region of the spray.

Owner:ROBERT BOSCH GMBH

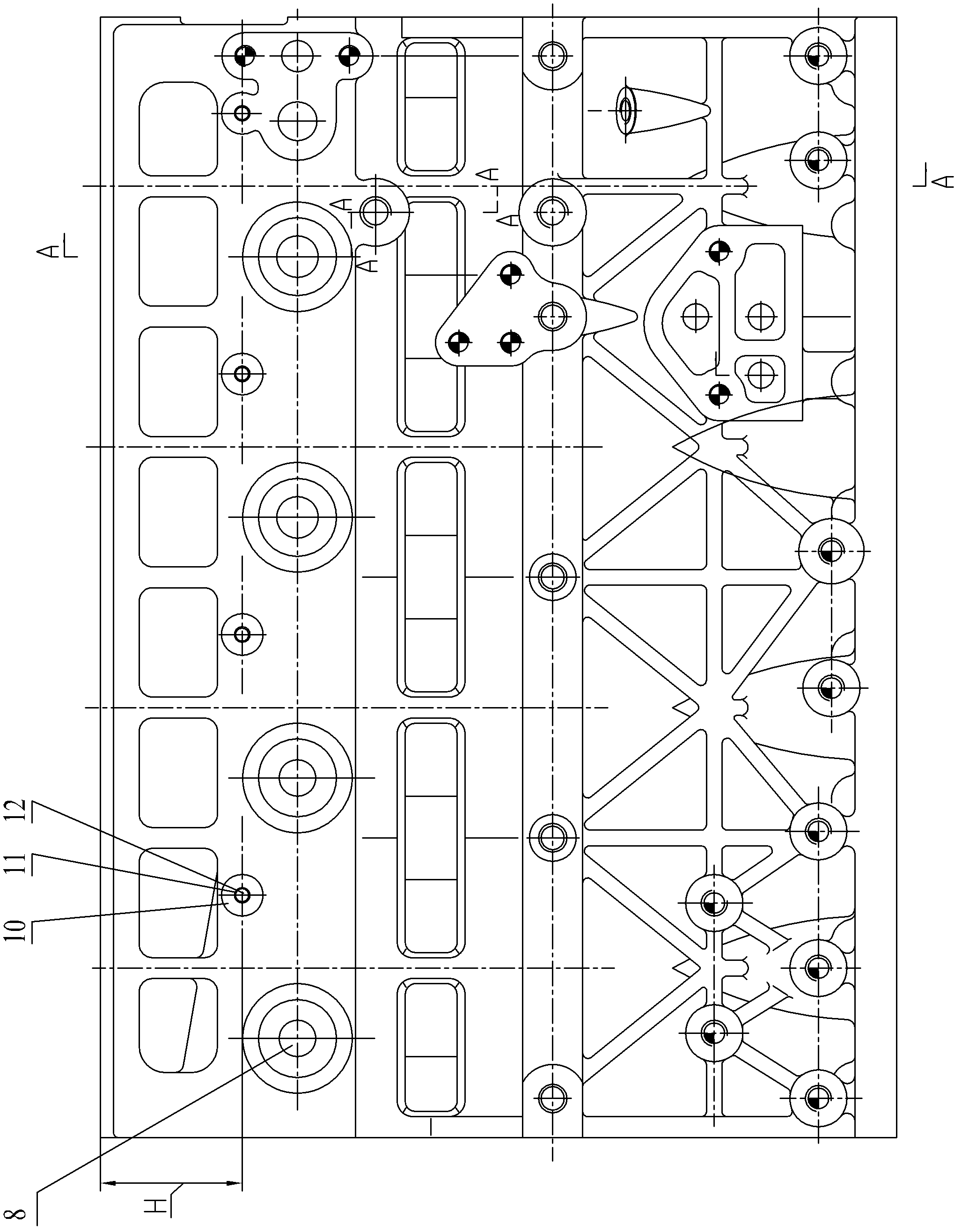

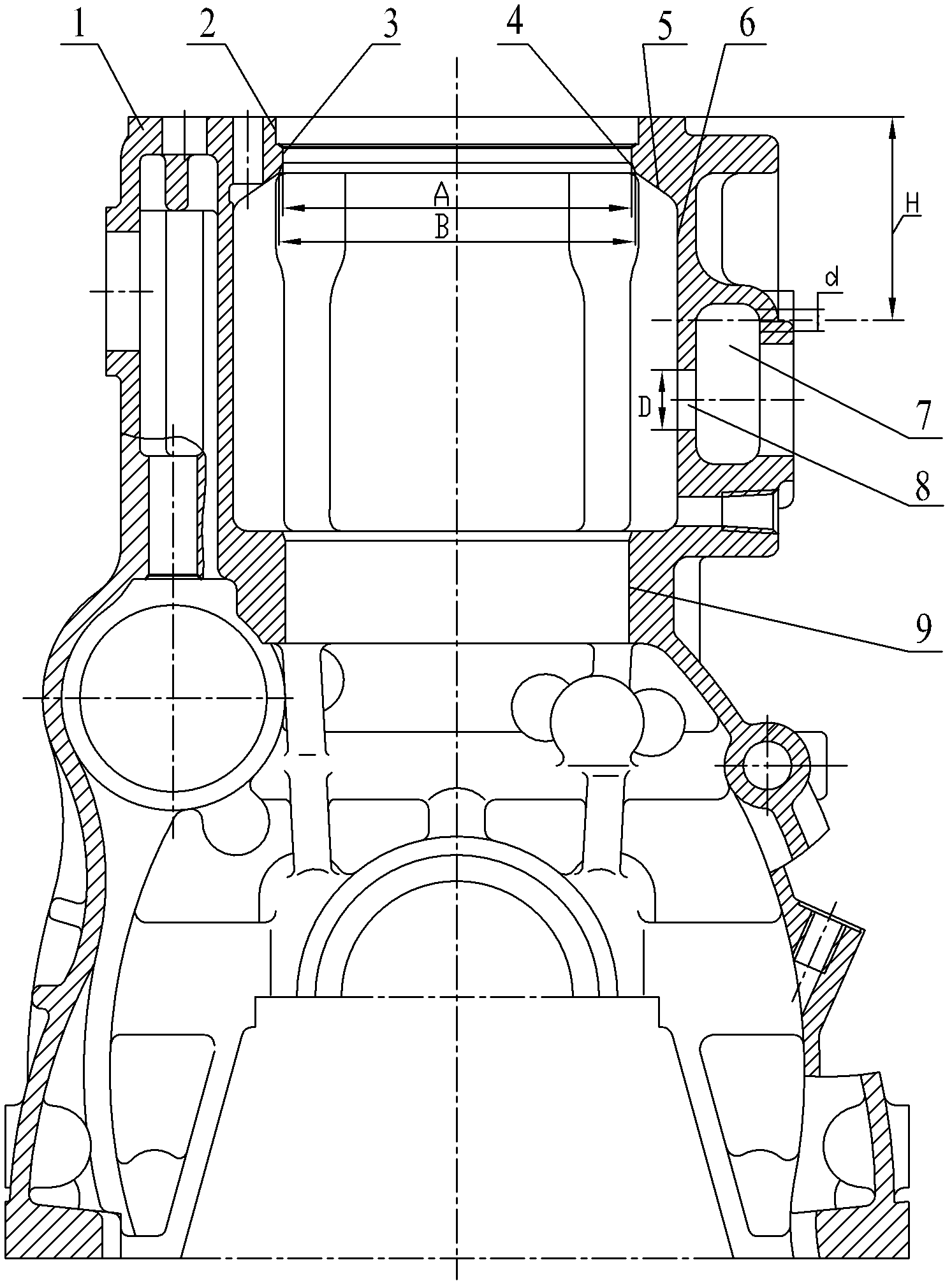

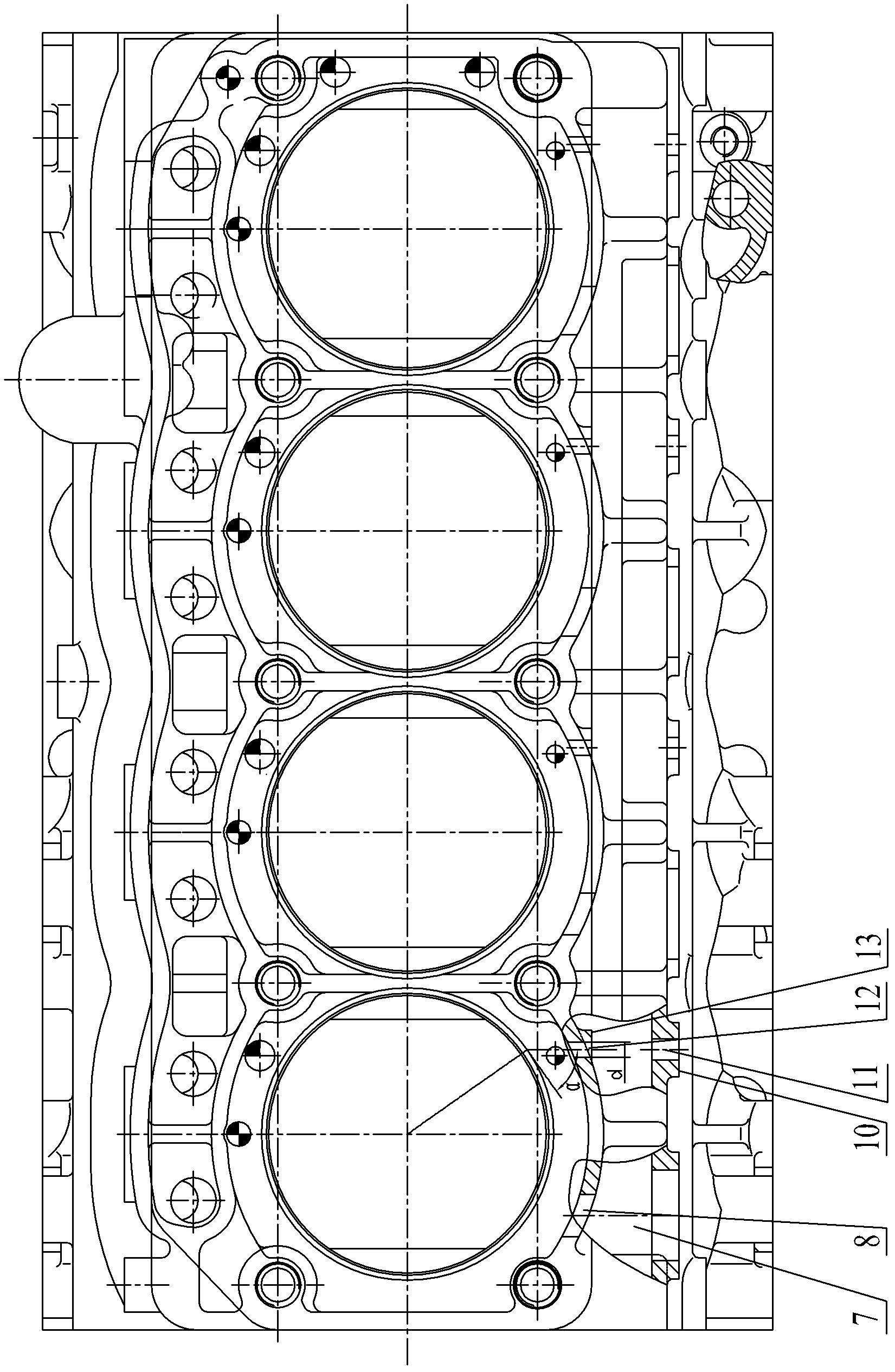

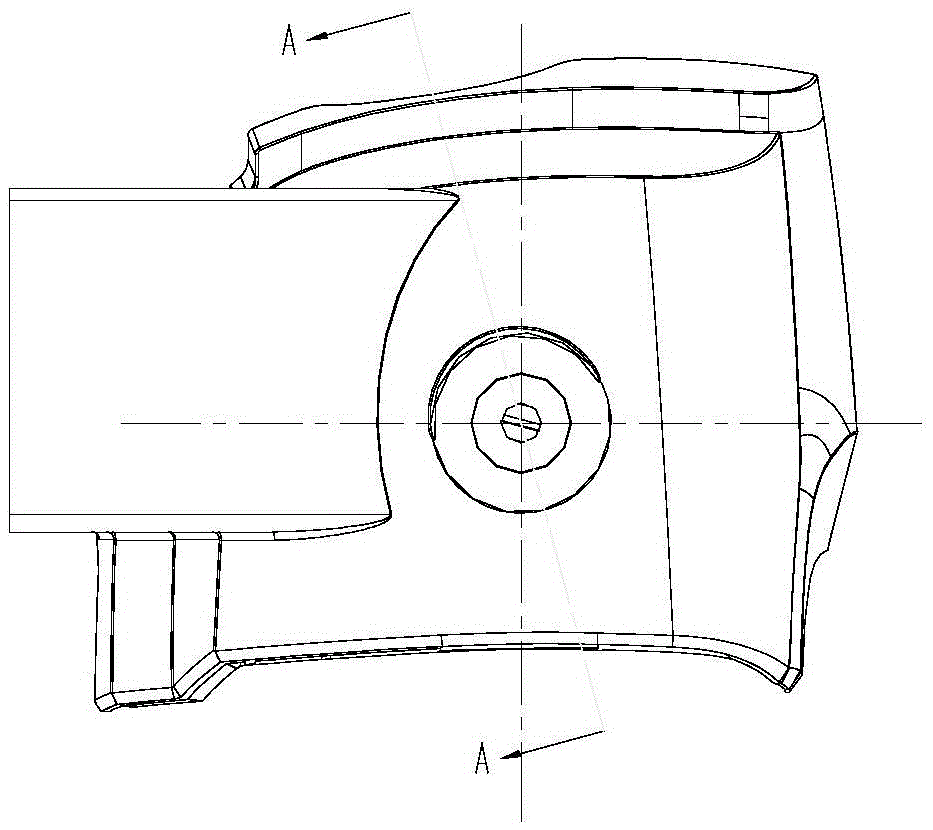

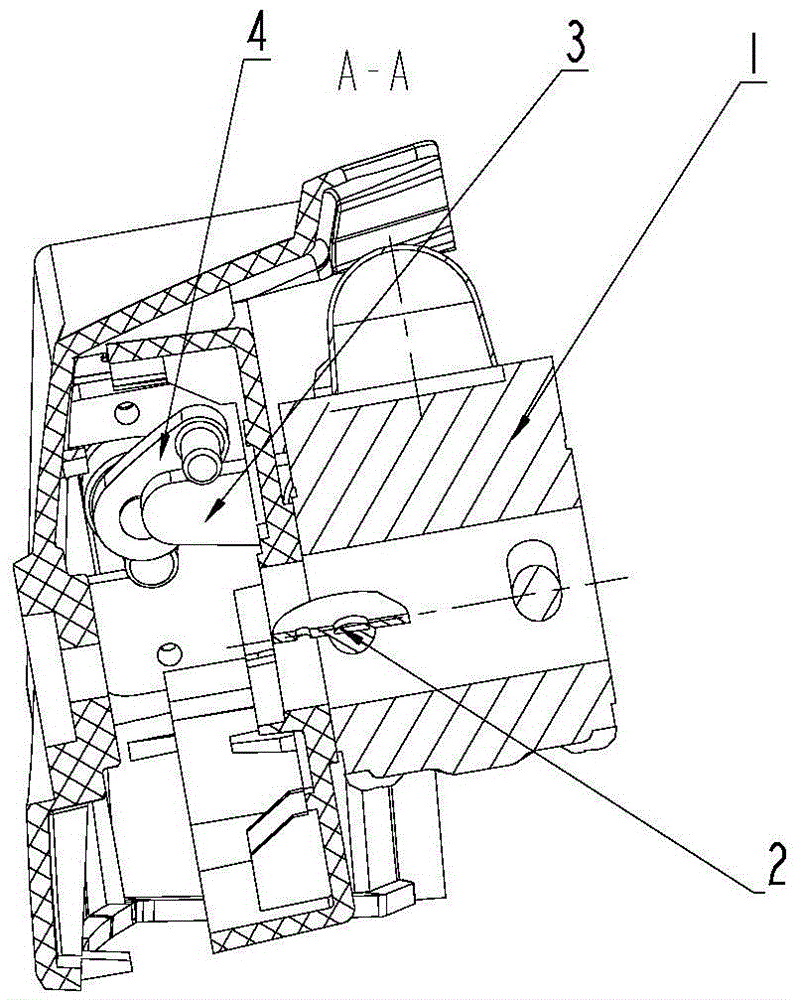

Cooling water jacket structure of diesel engine cylinder body

InactiveCN102536494AReasonable arrangementGuaranteed cooling effectCylinder headsCylindersTop dead centerPiston ring

The invention relates to a cooling water jacket structure of a diesel engine cylinder body. A water inlet channel is disposed at the upper portion of the air inlet side of the cylinder body, a cylinder body water jacket is formed at the middle upper portion of each cylinder of the cylinder body, and the water inlet channel is communicated with the insides of the cylinder body water jackets through water inlet holes. The diesel engine cylinder body cooling water jacket structure is characterized in that the top ends of the cylinder body water jackets upwards extend to be provided with conical cooling water jackets, the conical cooling water jackets are located below cylinder jacket axial location ring support shoulders of cylinders of the cylinder body, the upper ends of the conical cooling water jackets are connected with the cylinder jacket axial location ring support shoulders, and the lower ends of the conical cooling water jackets are connected with water jacket inner cavity inclined planes of the cylinder body water jackets. The height of each conical cooling water jacket should ensure that when a piston is located at a top dead center, the upper ends of the conical cooling water jackets basically align to the top edge of a first piston ring on the piston. The cooling water jacket structure of the diesel engine cylinder body can ensure that when the piston is located at the compression top dead center, the piston, the piston ring and the cylinder jacket can all be cooled effectively, and scuffing of cylinder bore of the cylinder jacket can be prevented.

Owner:JIANGSU SIDA POWER MECHANICAL GROUP

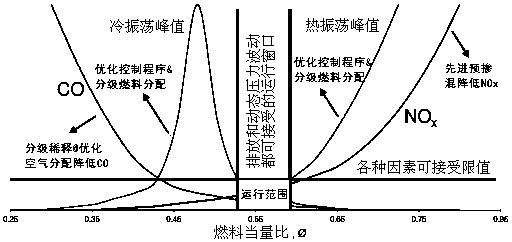

System and method for adjusting optimum control on combustion of gas turbine

PendingCN108506098AWide range of applicationsImprove gas turbine operating efficiencyTurbine/propulsion fuel valvesTurbine/propulsion fuel controlOptimum controlGas turbines

The invention relates to a system and a method for adjusting optimum control on combustion of a gas turbine, which aim at solving the current urgent problem of providing a method, with common suitability, for adjusting optimum control on combustion of a gas turbine. The method comprises the following steps of firstly, judging whether the gas turbine requires the combustion optimum control adjustment or not; after determining that the gas turbine requires the combustion optimum control adjustment, determining the effective running boundary range of combustion parameters of the gas turbine; then, collecting the parameter values of the gas turbine when entering the temperature-control full load state at different environment temperatures, comparing the effective running boundary ranges of thecombustion parameters of the gas turbine, analyzing the cause of combustion offset, determining the adjusting types of fuel adjusting values, and adjusting the equivalent ratio of fuel to air on linein real time; finally, increasing and decreasing the load of the gas turbine, adjusting and correcting the opening degree of each fuel adjusting valve on line, and repeating the steps until the gas turbine runs at the optimum state under the current environment condition. The method has the advantages that the optimum control on the combustion of various types of gas turbines can be adjusted, andthe application range is broad.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

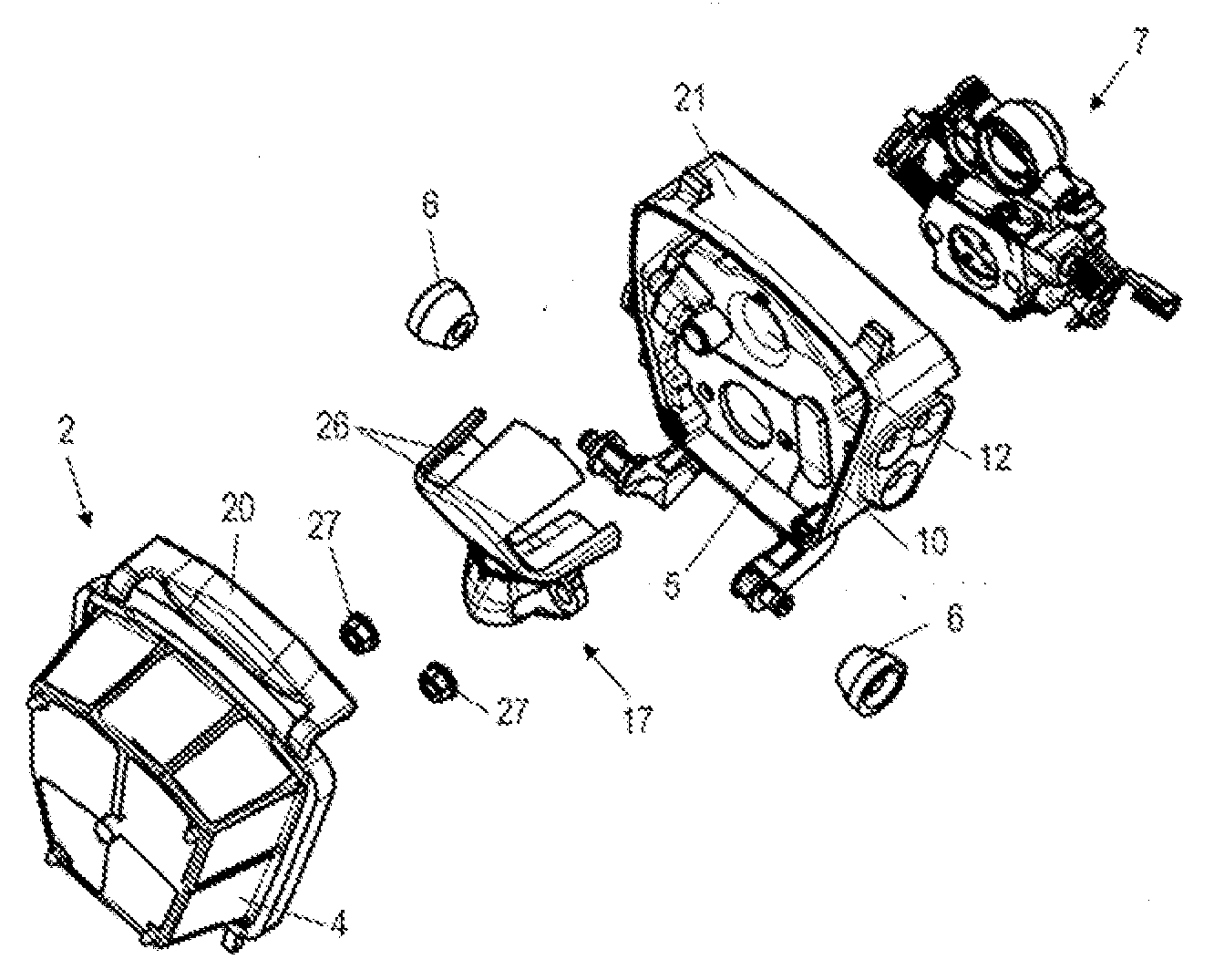

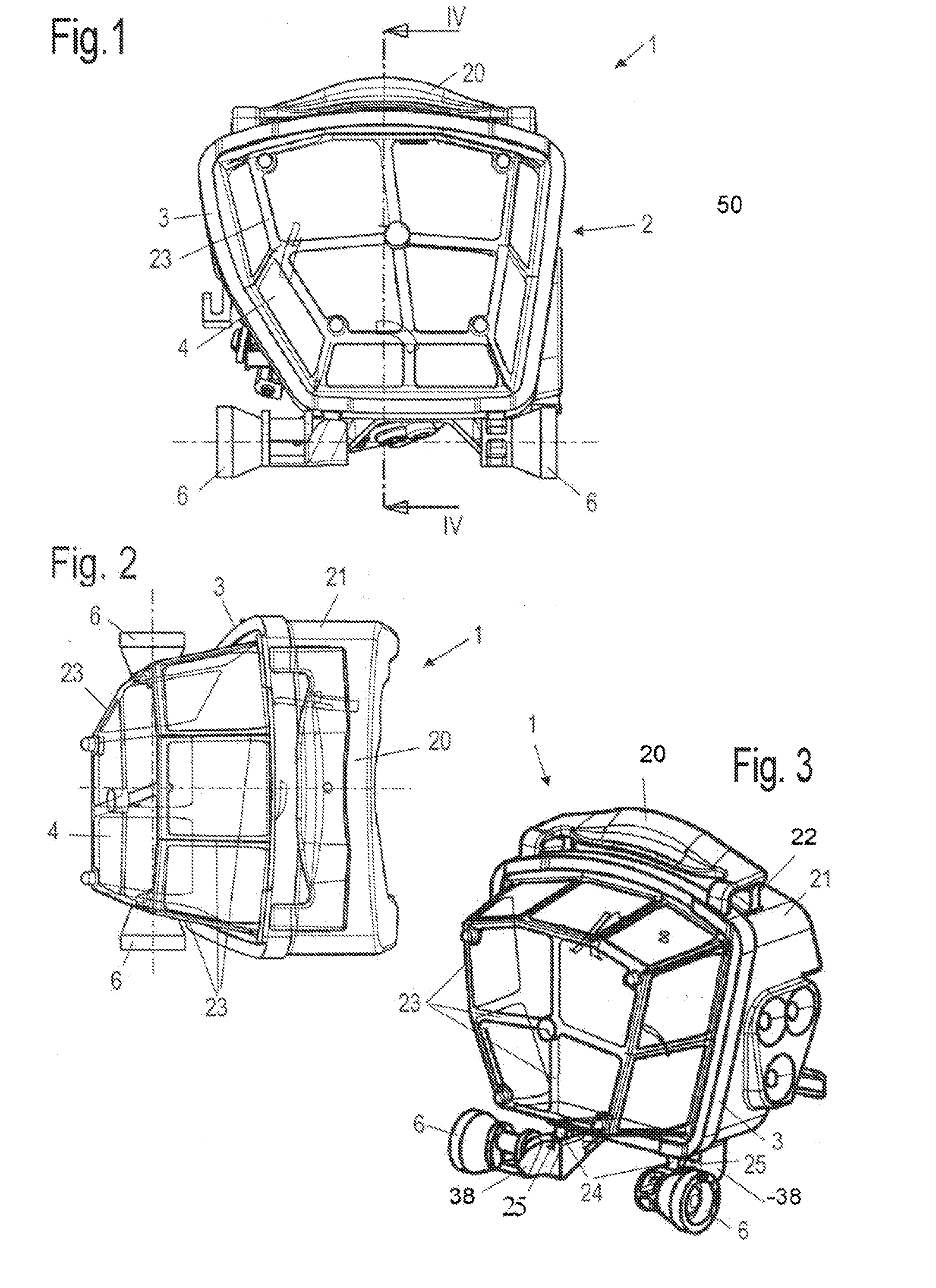

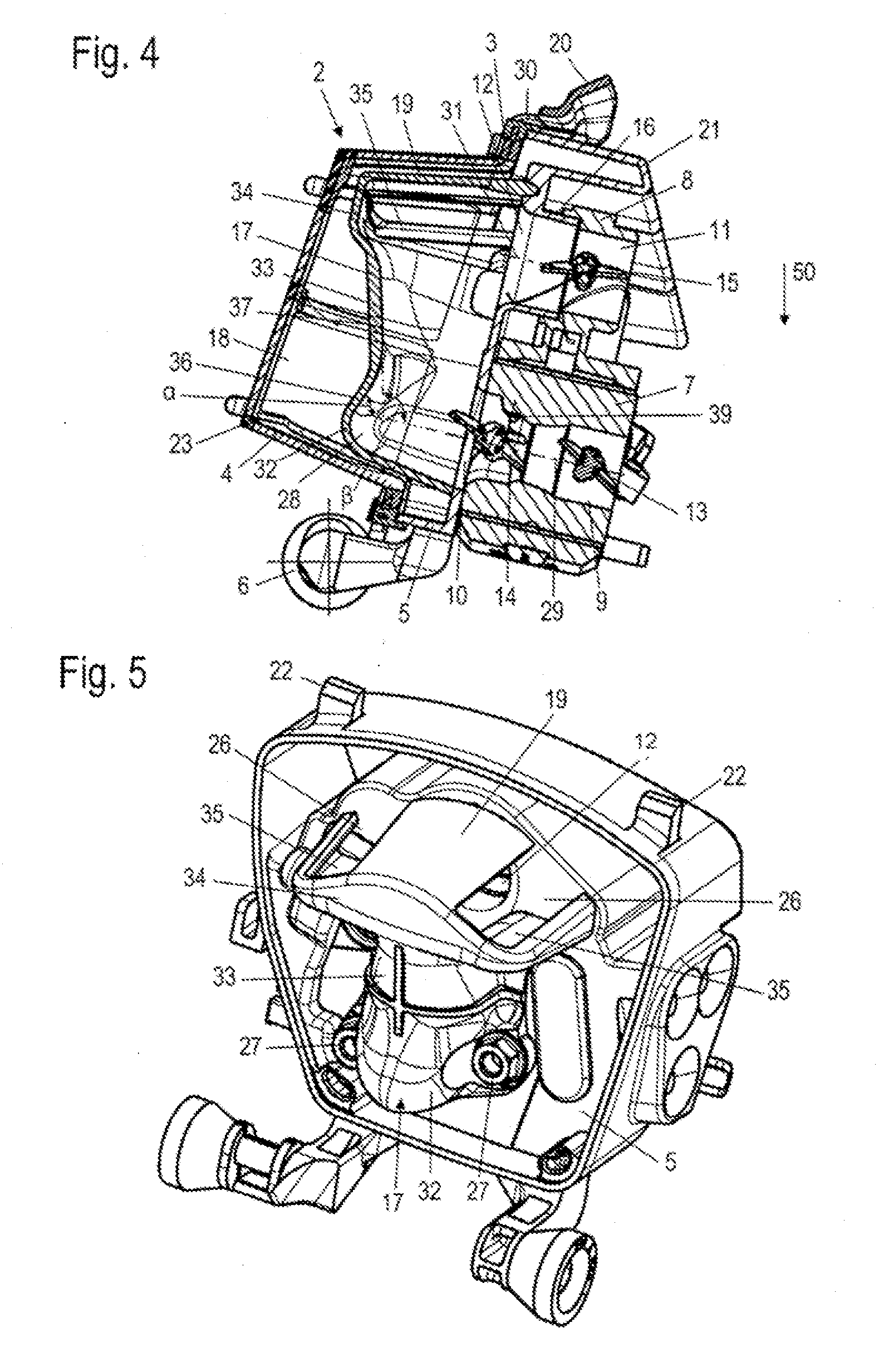

Air filter arrangement for an internal combustion engine

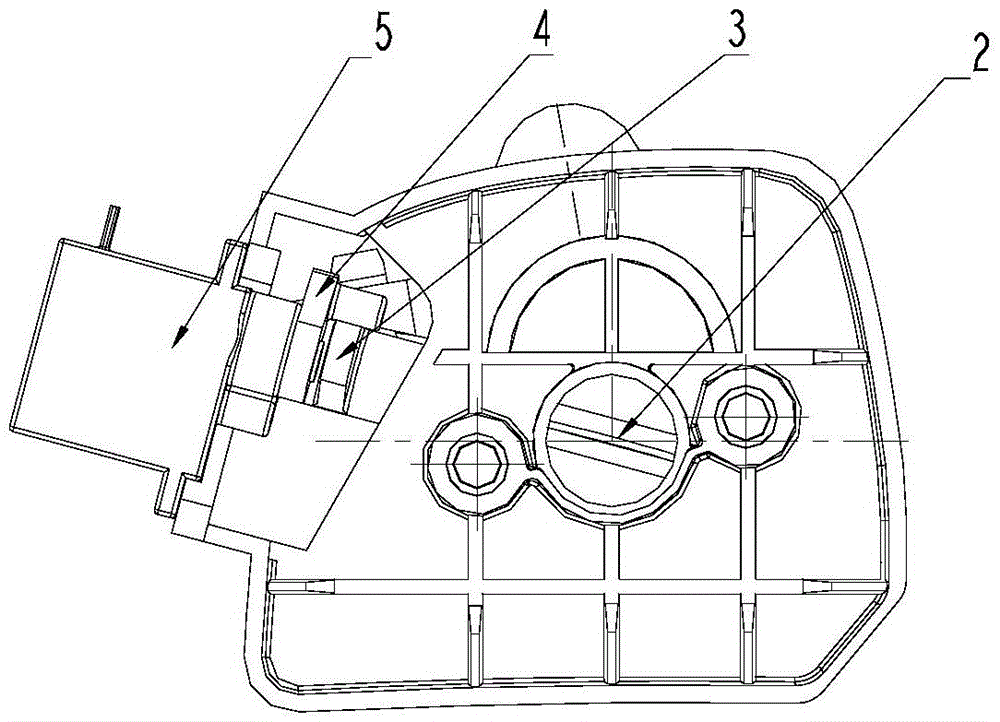

ActiveUS20070220848A1Easy to fillGood degree of fillingCombination devicesCombustion-air/fuel-air treatmentAir filterInternal combustion engine

An air filter arrangement for an internal combustion engine, especially for a two-cycle engine in a manually guided implement such as a power saw, a cut-off machine, etc., and including an air filter element that delimits a first clean chamber. The air filter arrangement has an inlet opening for an air channel and an inlet opening for a mixture channel. A shield is provided for shielding the air filter element relative to the mixture channel. The inlet opening of the air channel and the inlet opening of the mixture channel are interconnected via the shield.

Owner:ANDREAS STIHL AG & CO KG

Nano emulsified fuel addtiive and its perparing method

InactiveCN1587357ALower emission valueReduce concentrationLiquid carbonaceous fuelsPolyethylene glycolAlkylphenol

The present invention discloses nanometer emulsified fuel additive and its preparation process, and belongs to the field of liquid fuel additive technology. The fuel additive is prepared with the components including triethyl tetramine, diethyl ethanolamine, AE03 or AE04, alkylphenol ethoxylate, polyethylene glycol lauryl ether, ethylene glycol monomethyl ether, sorbitan oleate, fatty acid ester, isopropyl nitrate, cobalt naphthenate, acetone and ferrocene. It has an oil saving rate of 7-12 % and obvious pollution reducing effect.

Owner:谢学秀

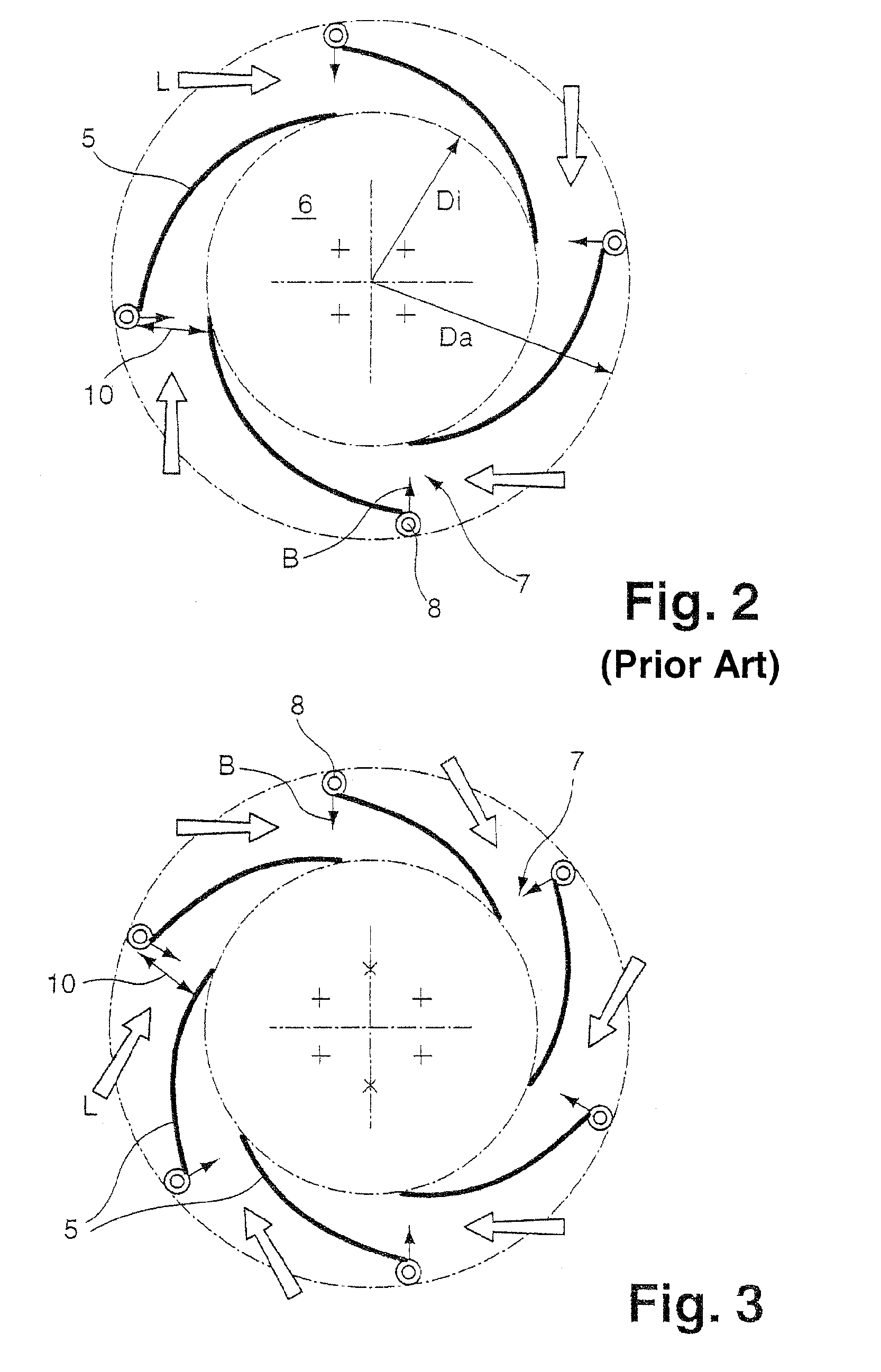

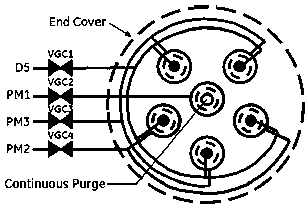

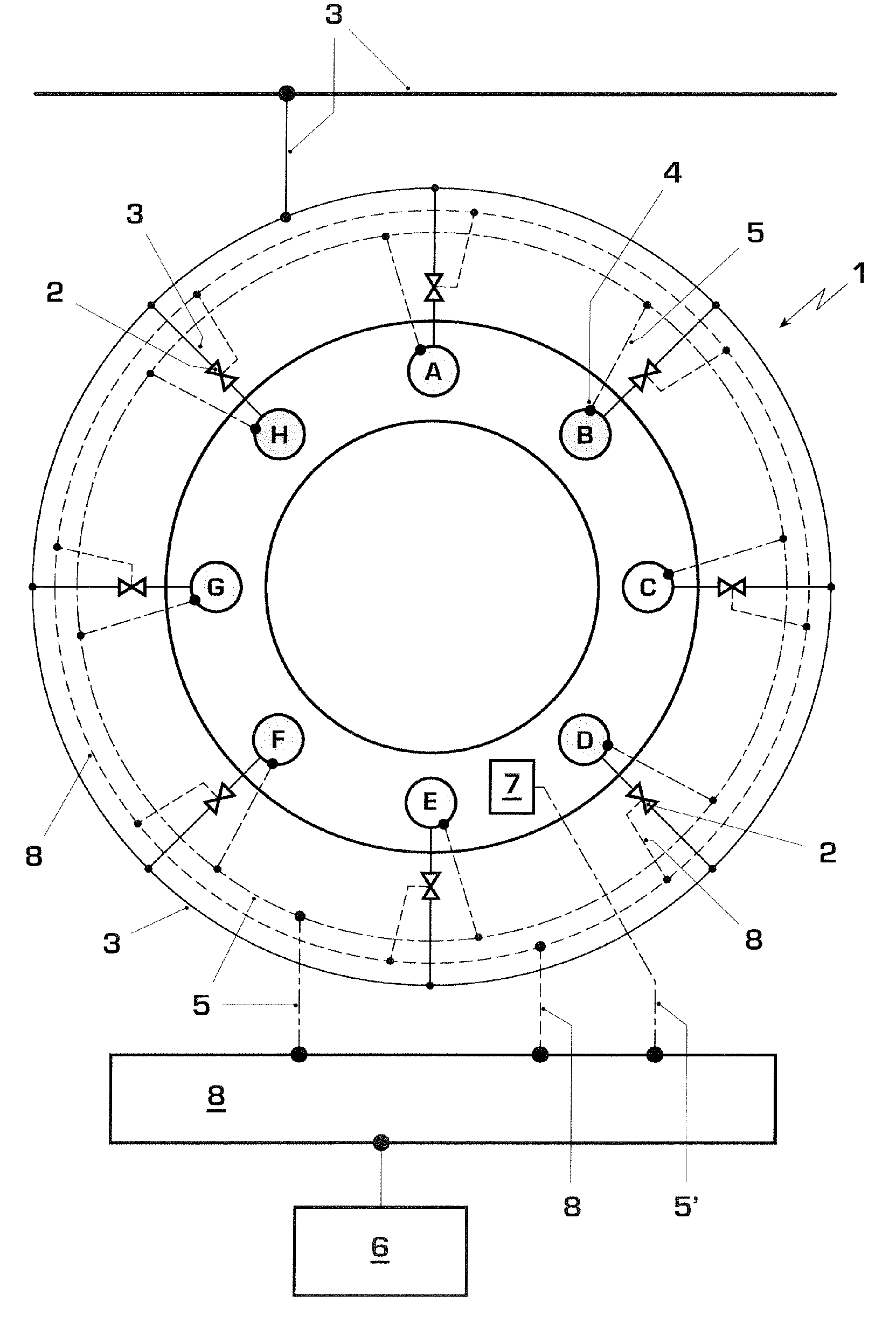

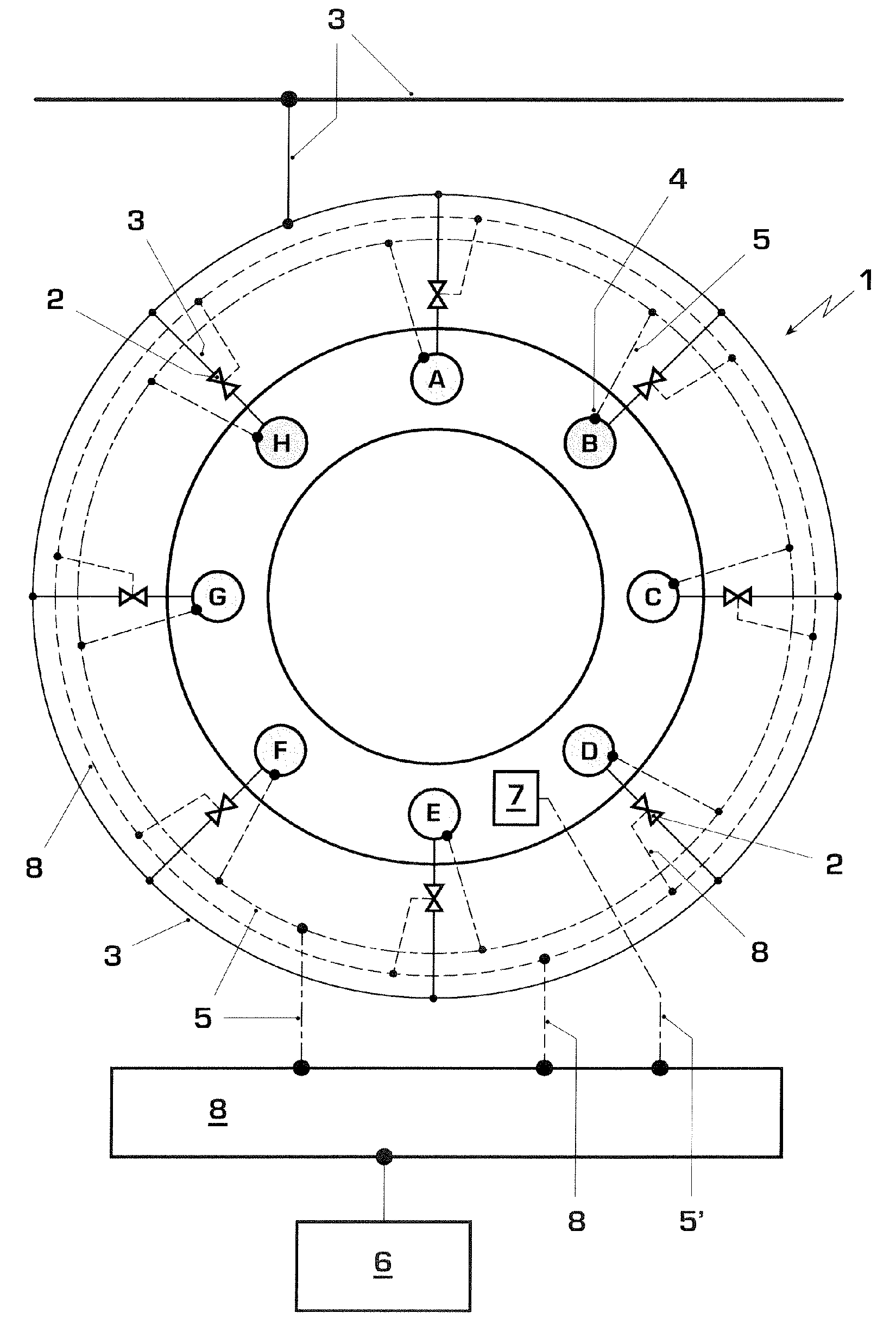

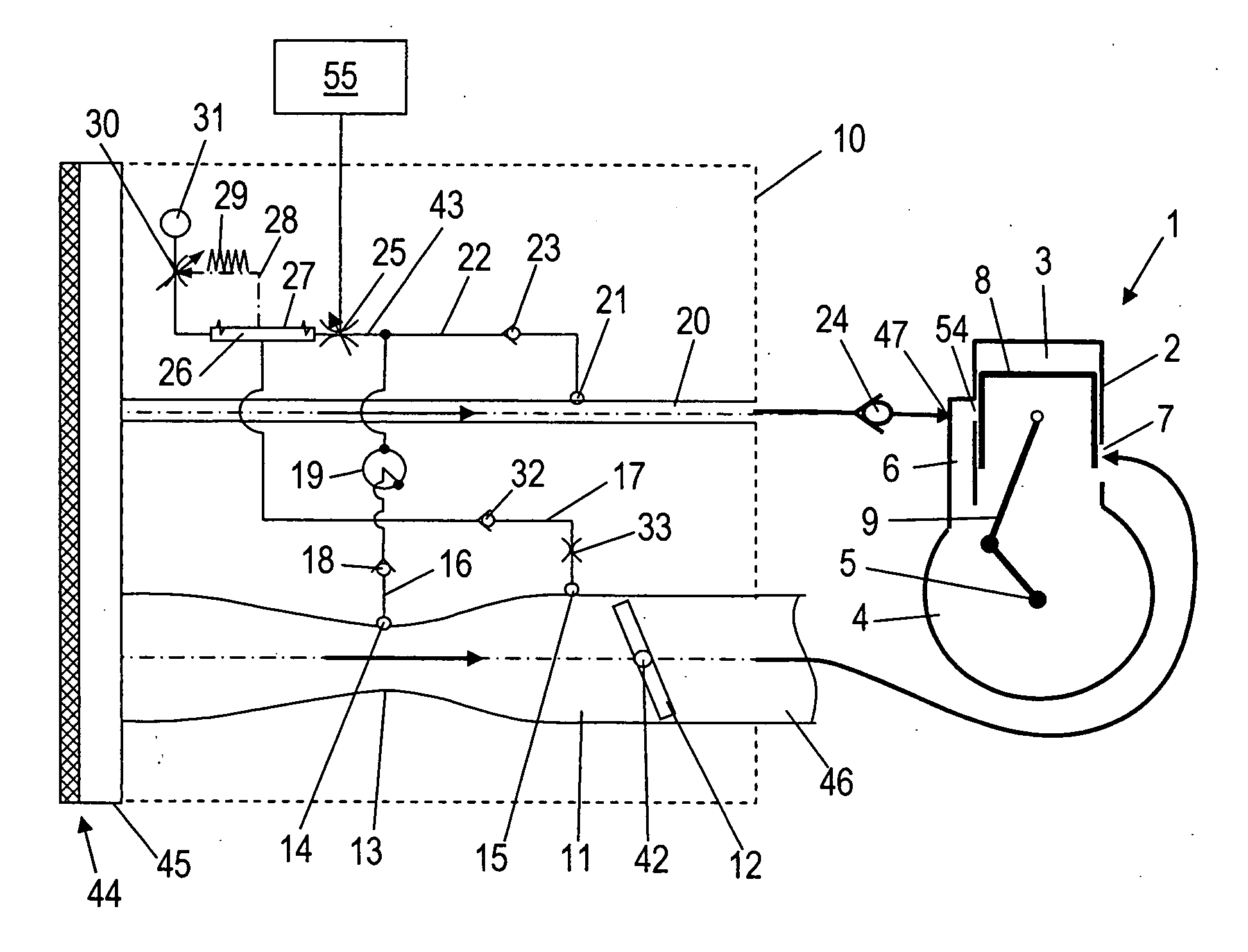

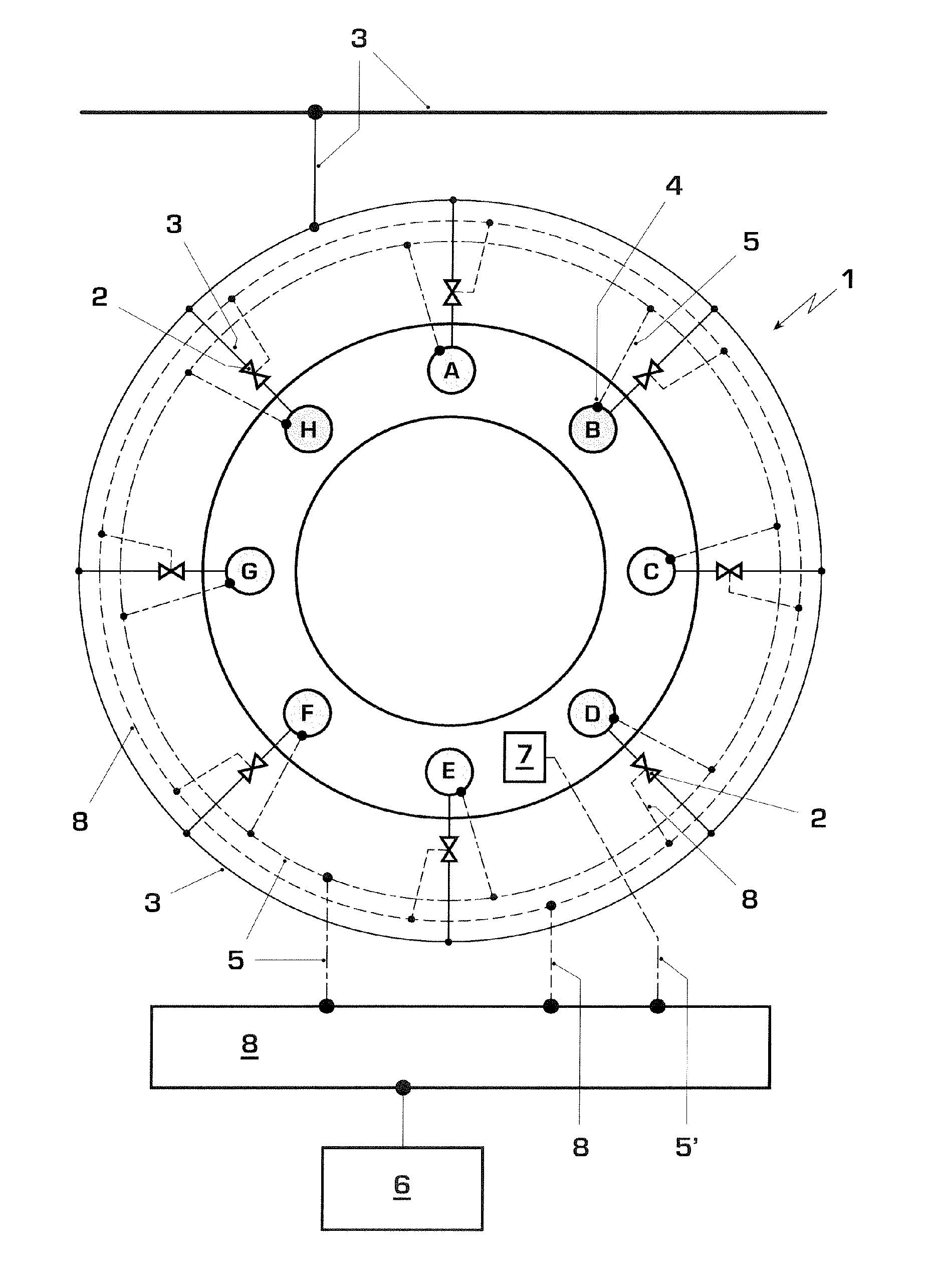

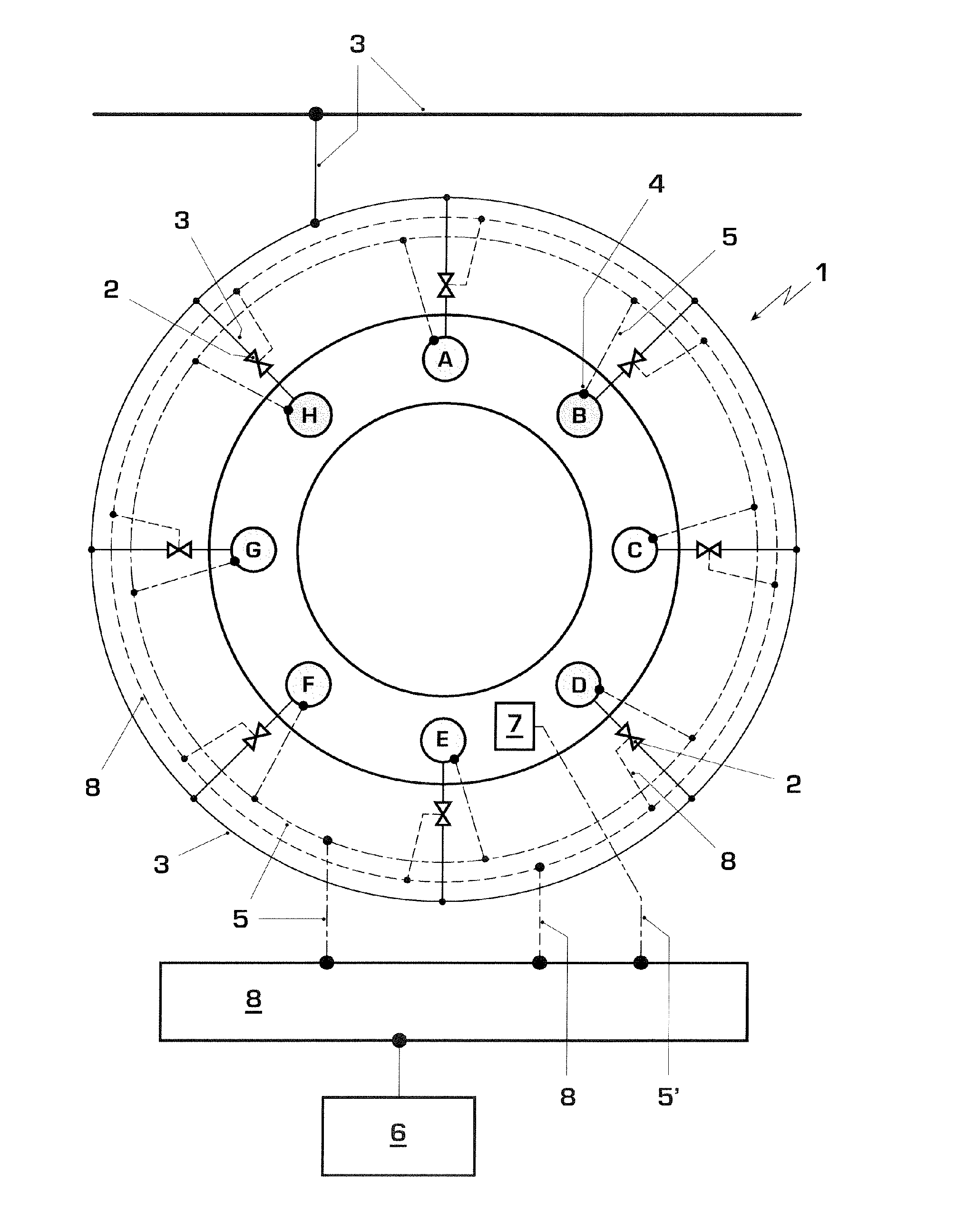

Combustion chamber

InactiveUS7901203B2Improve efficiencyReduce riskFuel supply regulationContinuous combustion chamberCombustorCombustion chamber

A combustion chamber (1), in particular in a gas turbine, has at least two burners (A-H) that are connected to a fuel supply (3) via controllable fuel valves (2′ and 2). Each burner (A to H) is assigned at least one optical measuring device (4) for detecting chemiluminescent radiation, and the combustion chamber (1) is assigned a pressure sensor (7) for detecting a combustion chamber pressure. The optical measuring device (4) and the pressure sensor (7) are connected to a computing and control device, which calculates a correlation value from the incoming measured values. A high correlation value signifies that the associated burner is prone to pulsation. The computing and control device (6) is designed in such a way that it determines the burner or a burner group with the highest correlation and controls the associated fuel valve(s) in such a way that more fuel is fed to the respective burner or the respective burner group, and the pulsation tendency thereof is thereby reduced.

Owner:ANSALDO ENERGIA SWITZERLAND AG

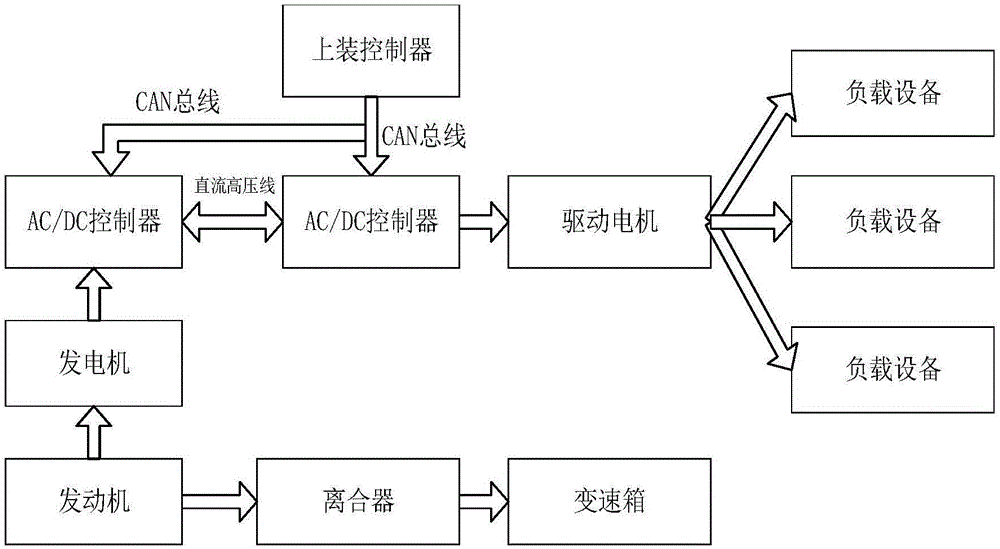

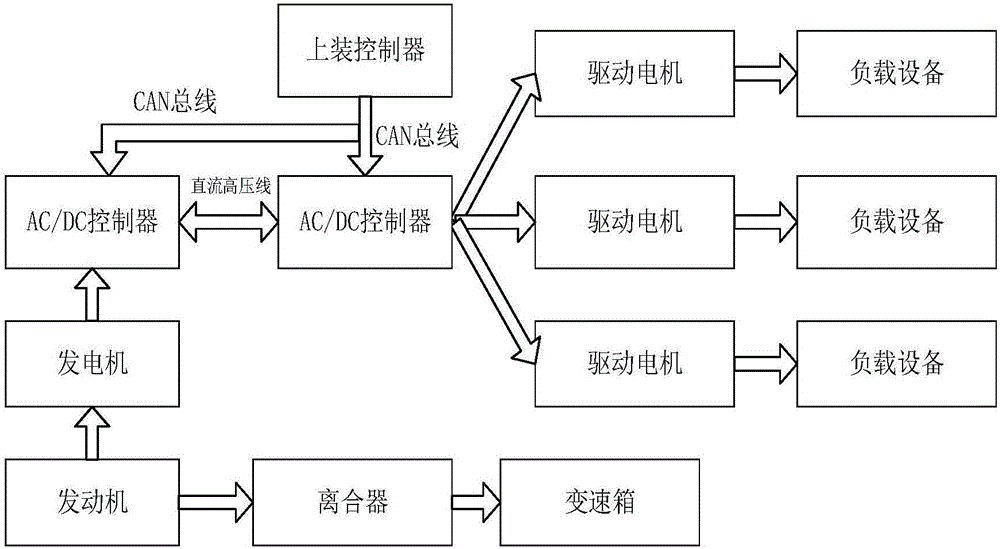

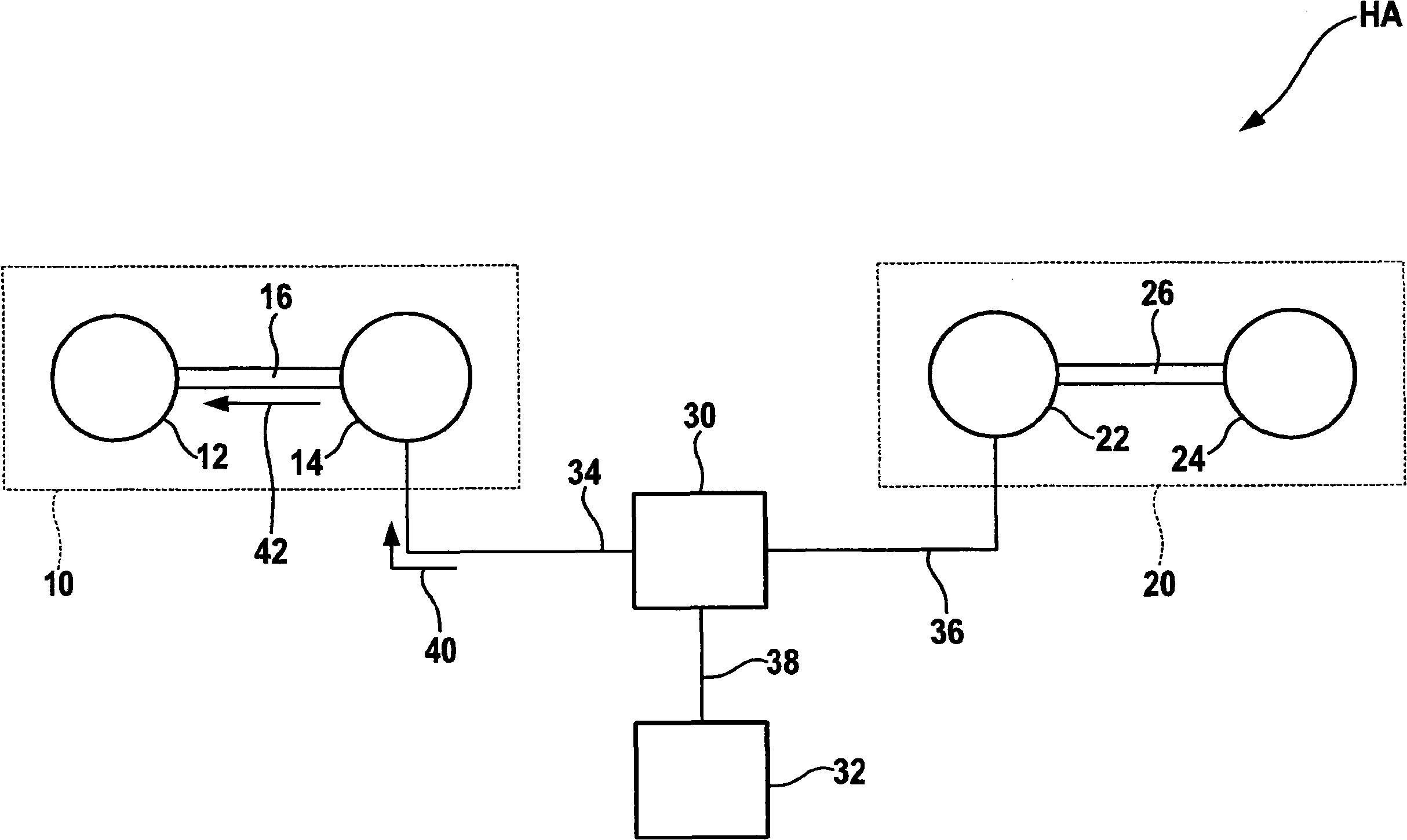

Cleaning car single-engine system and cleaning car thereof

The invention discloses a cleaning car single-engine system and a cleaning car thereof. The cleaning car single-engine system comprises an engine, a generator, an AC / DC controller, a DC / AC controller, an upper loading controller, a driving motor, a clutch and a transmission; the generator and the clutch coat an output shaft of the engine in sequence; the engine drives the generator to generate electricity; the output shaft of the engine is connected with the transmission through the clutch; an output end of the generator is connected with the AC / DC controller; the AC / DC controller is connected with the DC / AC controller through a direct-current high-voltage wire; an output end of the DC / AC controller is connected with the driving motor through a three-phase wire; an output end of the driving motor is connected with loading equipment; and the upper loading controller is respectively connected with the AC / DC controller and the DC / AC controller through CAN buses. The invention adopts the single-engine system, so that the whole car oil consumption is reduced, and the emission is reduced; and an upper loading system has a relatively independent and stable power source, so that the safety is high.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

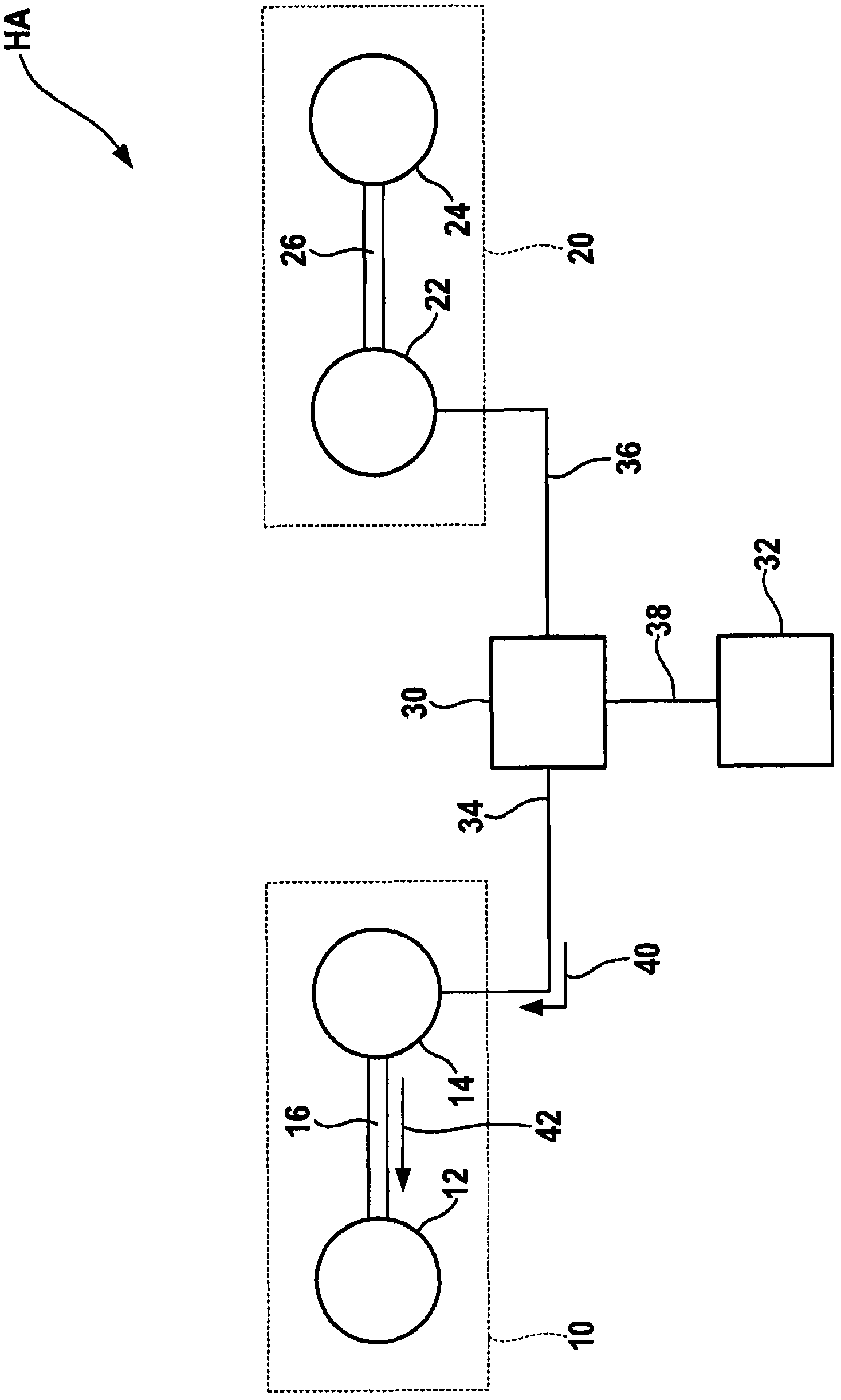

Method for operating a hybrid drive

ActiveCN102060017AImprove find/matchImprove efficiencyElectrical controlMachines/enginesElectric generatorHybrid drive

The invention relates to a method for operating a hybrid drive. The method for operating the hybrid drive of a motor vehicle in particular. An internal combustion engine is connected to a generator via a force-conducting connection. In a learning mode, the generator is operated as a motor and drives the internal combustion engine. In this learning mode, a so-called zero quantity calibration is performed.

Owner:ROBERT BOSCH GMBH

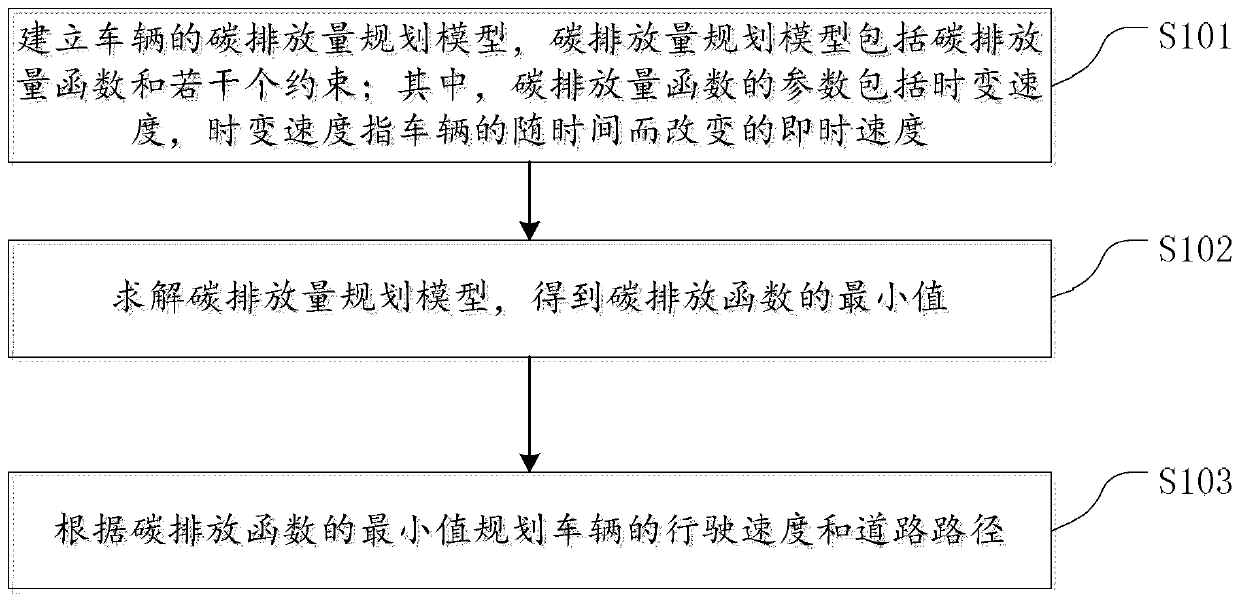

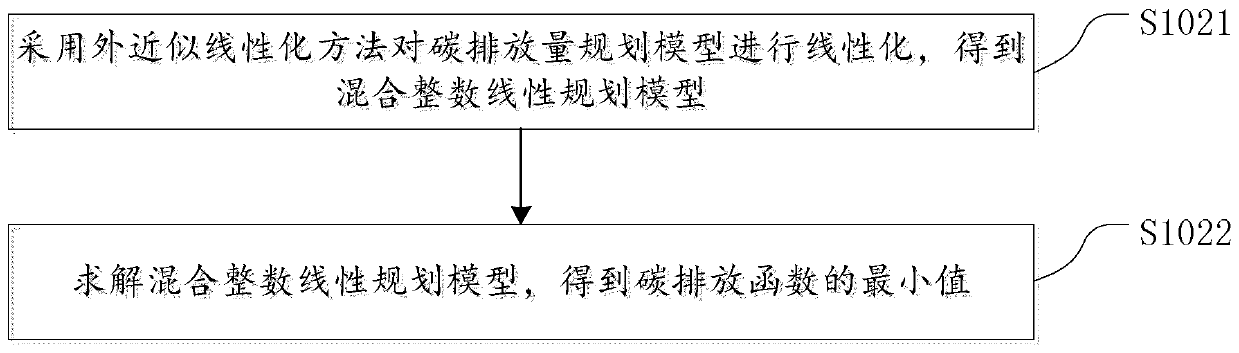

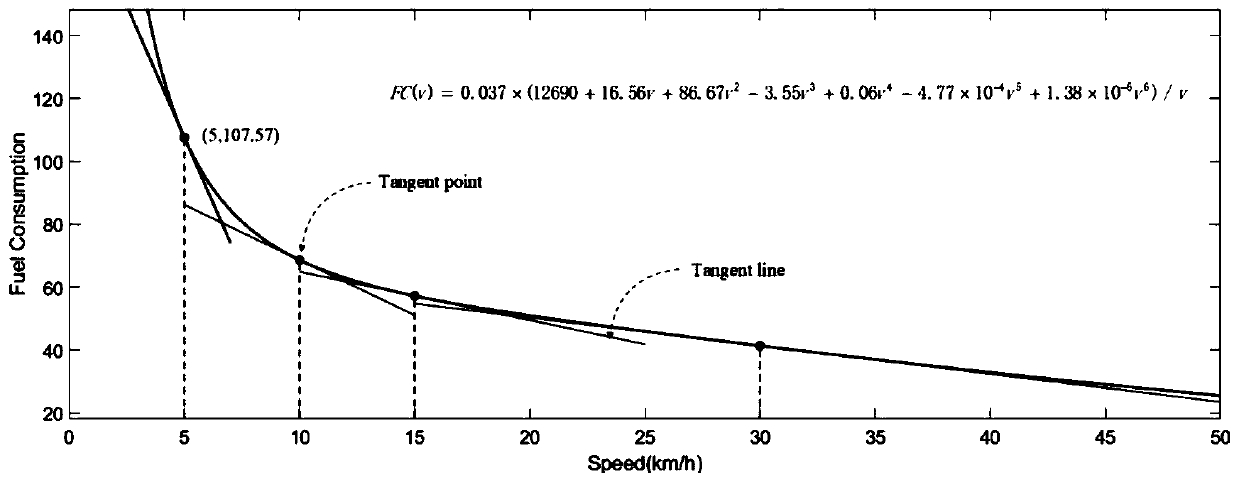

Vehicle carbon emission planning method and device, electronic equipment and storage medium

PendingCN110378506AEmission reductionLower emission valueForecastingResourcesLogistics managementEngineering

The embodiment of the invention relates to the field of logistics, and discloses a vehicle carbon emission planning method, which comprises the following steps of: establishing a carbon emission planning model of a vehicle, the carbon emission planning model comprising a carbon emission function and a plurality of constraints; solving the carbon emission planning model to obtain the minimum valueof the carbon emission function; planning the driving speed and the road path of the vehicle according to the minimum value of the carbon emission function, wherein the parameters of the carbon emission function comprise the time-varying speed, and the time-varying speed refers to the real-time speed, changing along with time, of the vehicle. According to the method, the time-varying speed of thevehicle is regarded as the decision variable of vehicle carbon emission planning, and the minimum carbon emission value is obtained, so that the optimal planning scheme of the vehicle driving path andthe driving speed is provided, and the carbon emission in logistics activities is reduced to the maximum extent.

Owner:SHANGHAI UNIV

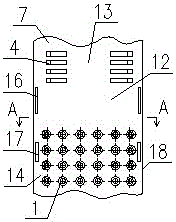

Deep denitration combustion method for tangential boiler

ActiveCN106287674ALower emission valueReduce concentrationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNitric oxideEngineering

The invention discloses a deep denitration combustion method for a tangential boiler. The hearth of the tangential boiler comprises a main combustion zone, a reduction zone and a burning-out zone; fuel coal is fed into the main combustion zone of the hearth for combustion through primary air in one or more layers of primary air nozzles; one or more layers of secondary air is introduced through secondary air nozzles in the main combustion zone; and one or more layers of burning-out air is introduced through burning-out air nozzles in the burning-out zone. The deep denitration combustion method is characterized in that an excess air coefficient in the main combustion zone ranges from 0.5 to 1.05, and the fuel coal is subjected to low oxygen combustion; an excess air coefficient in the burning-out zone ranges from 1.05 to 1.3, and the fuel coal is subjected to oxygen-enriched combustion; an amidogen reduction inhibitor is sprayed in through one or more layers of reduction inhibitor nozzles in the hearth below the burning-out air on the uppermost layer; the reduction inhibitor nozzles on the same layer are located on the same plane; and nitric oxides in smoke are reduced in a high-temperature environment in the furnace, and generation of new nitric oxides is inhibited. By adopting the deep denitration combustion method, a nitric oxide emission value at the outlet of the hearth can be obviously lowered, and ultra-low emission is realized; strict temperature windows and analysts are not needed; denitration cost is greatly lowered; combustion efficiency can also be ensured; economic benefit is obvious; and the deep denitration combustion method has wide applicability.

Owner:SHANGHAI JIAO TONG UNIV +1

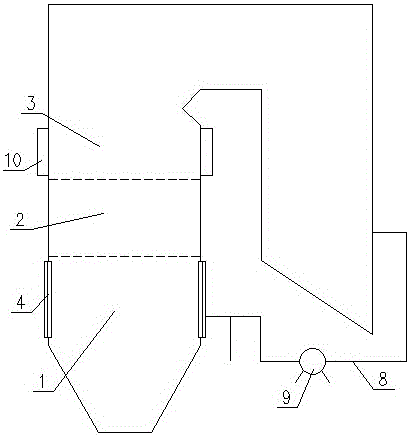

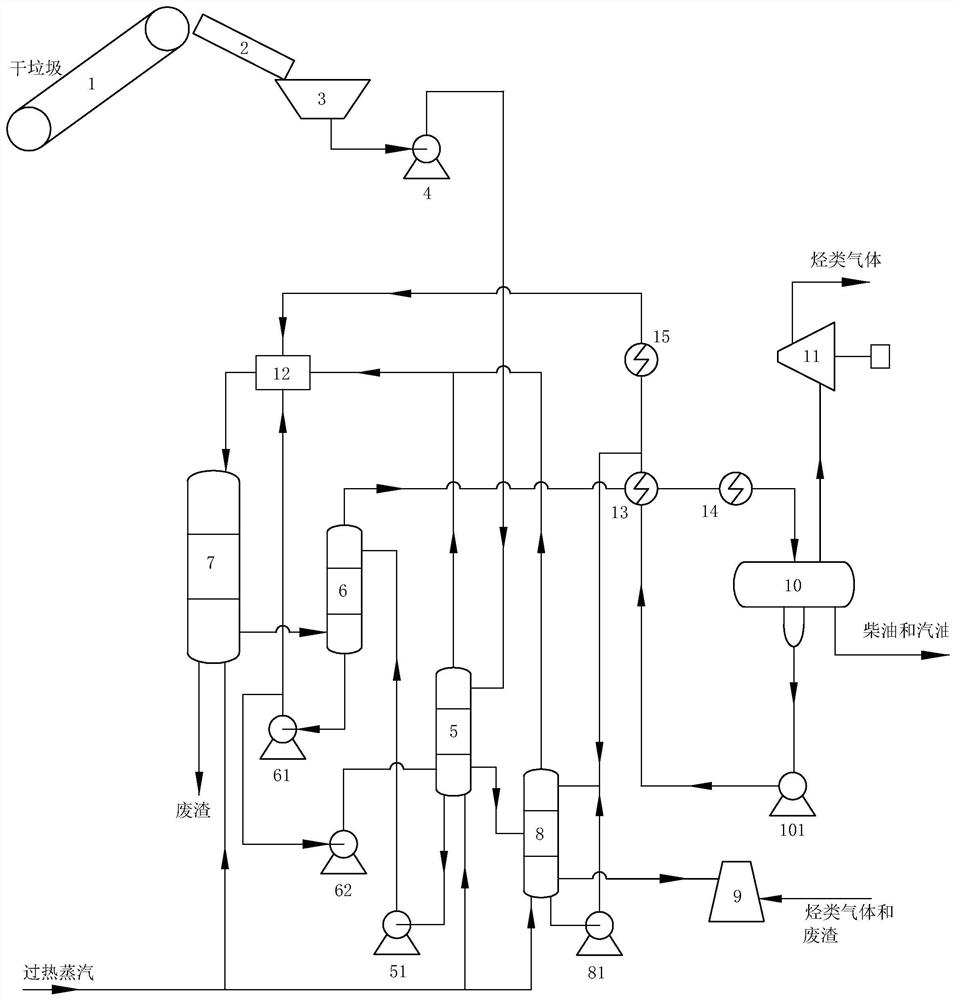

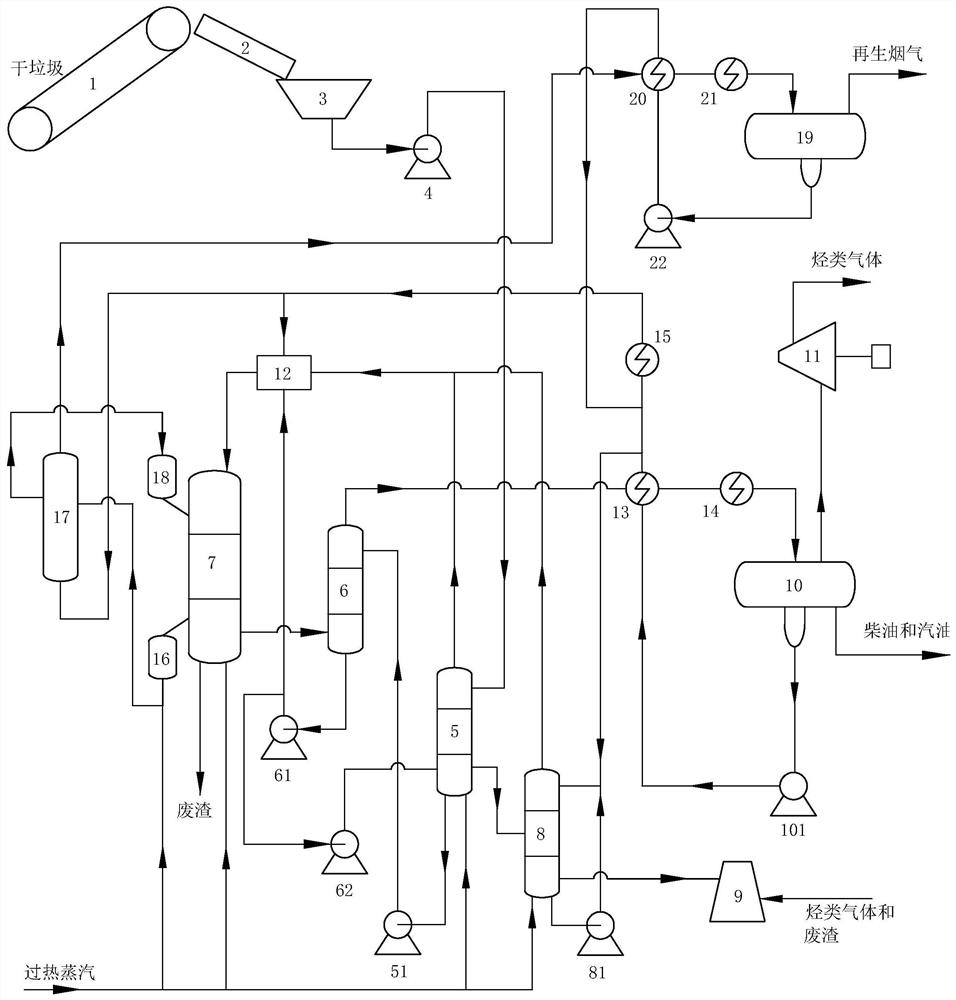

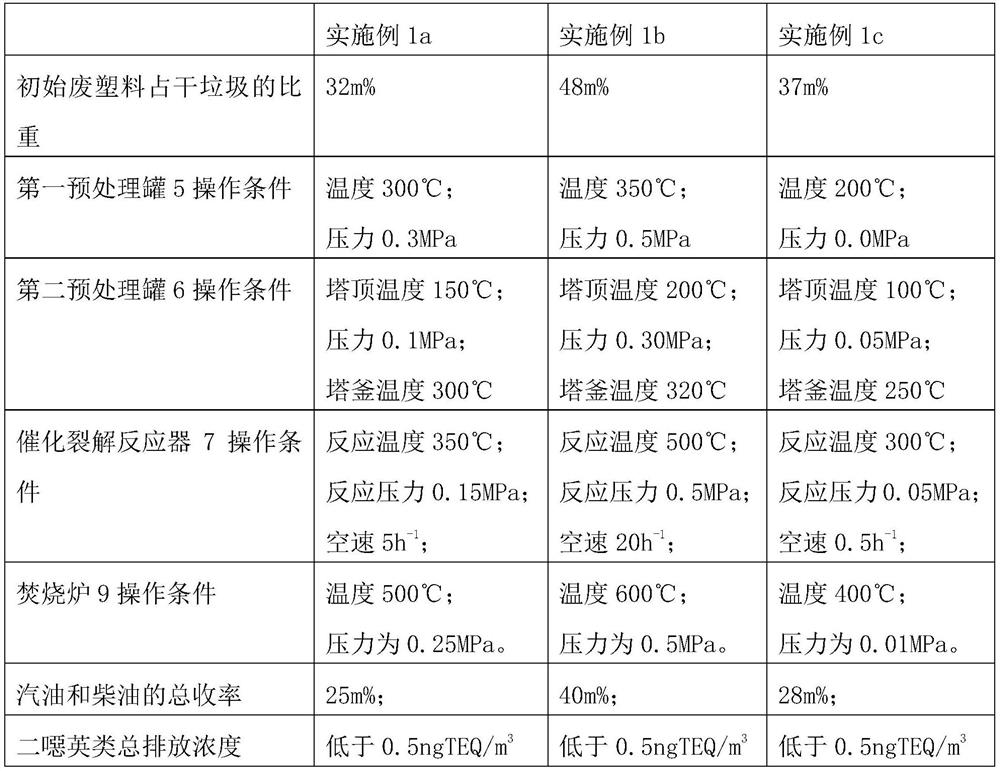

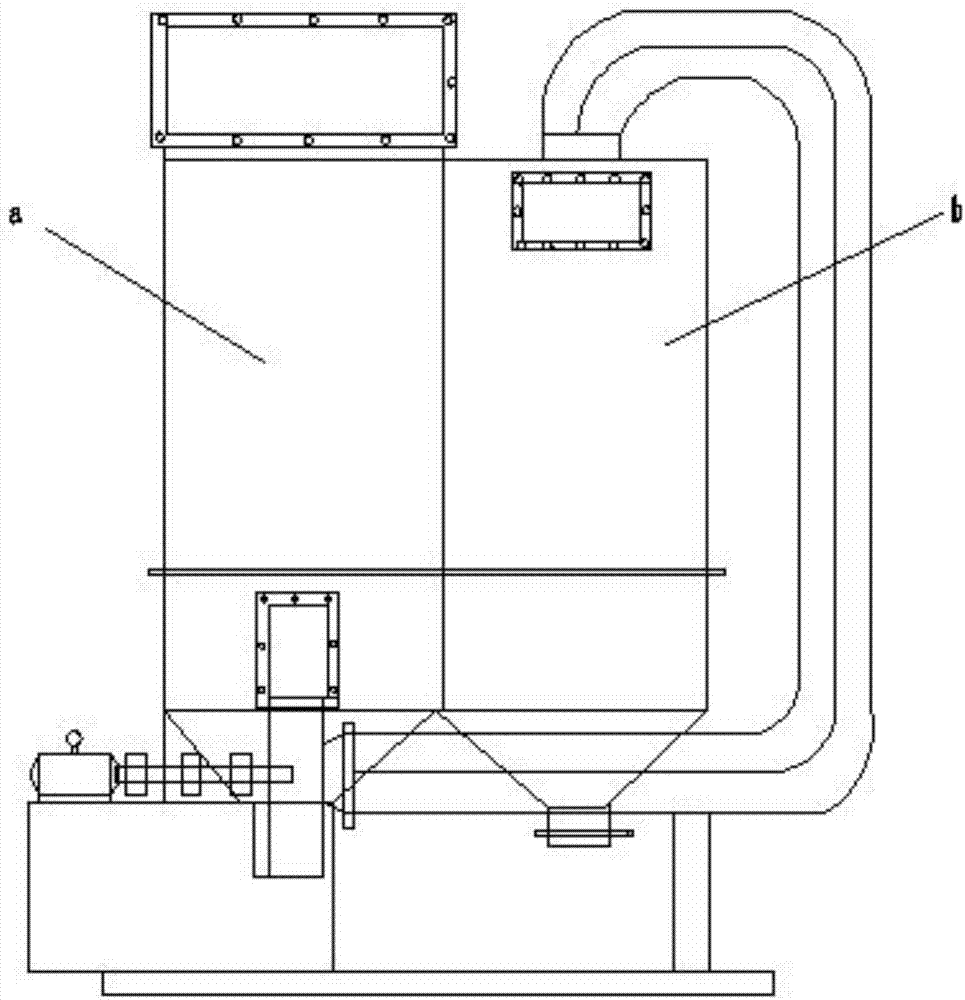

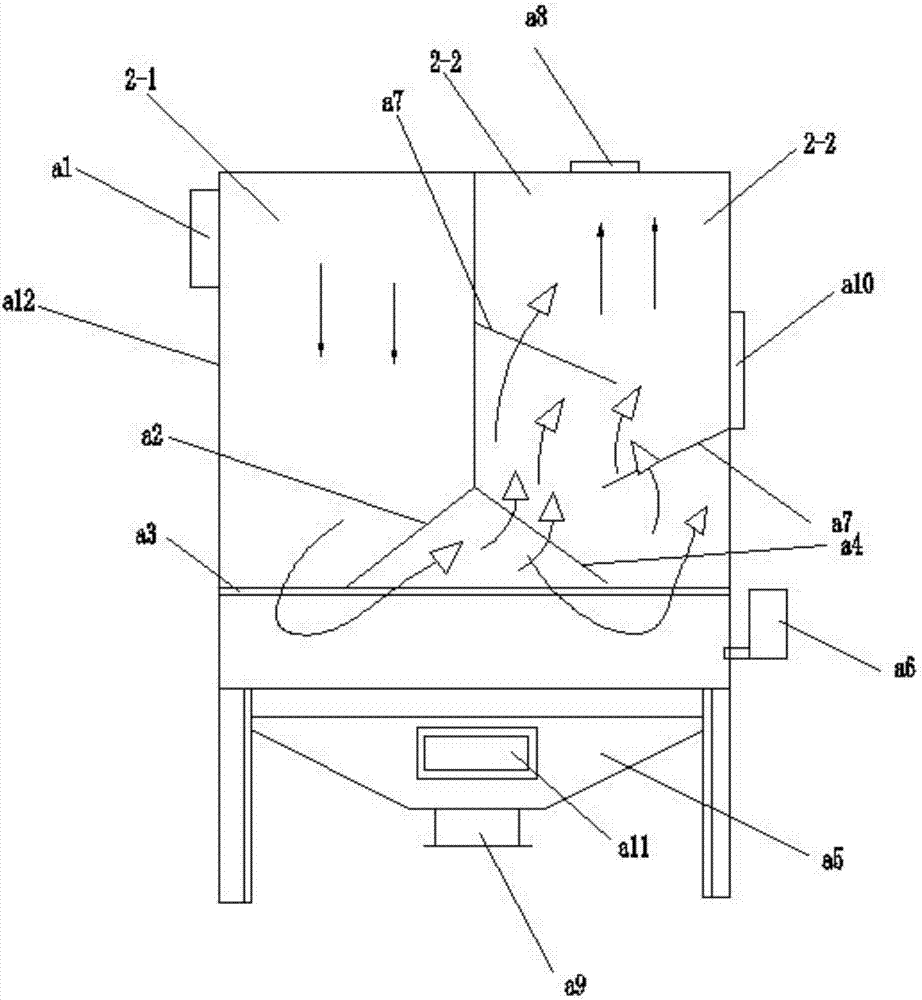

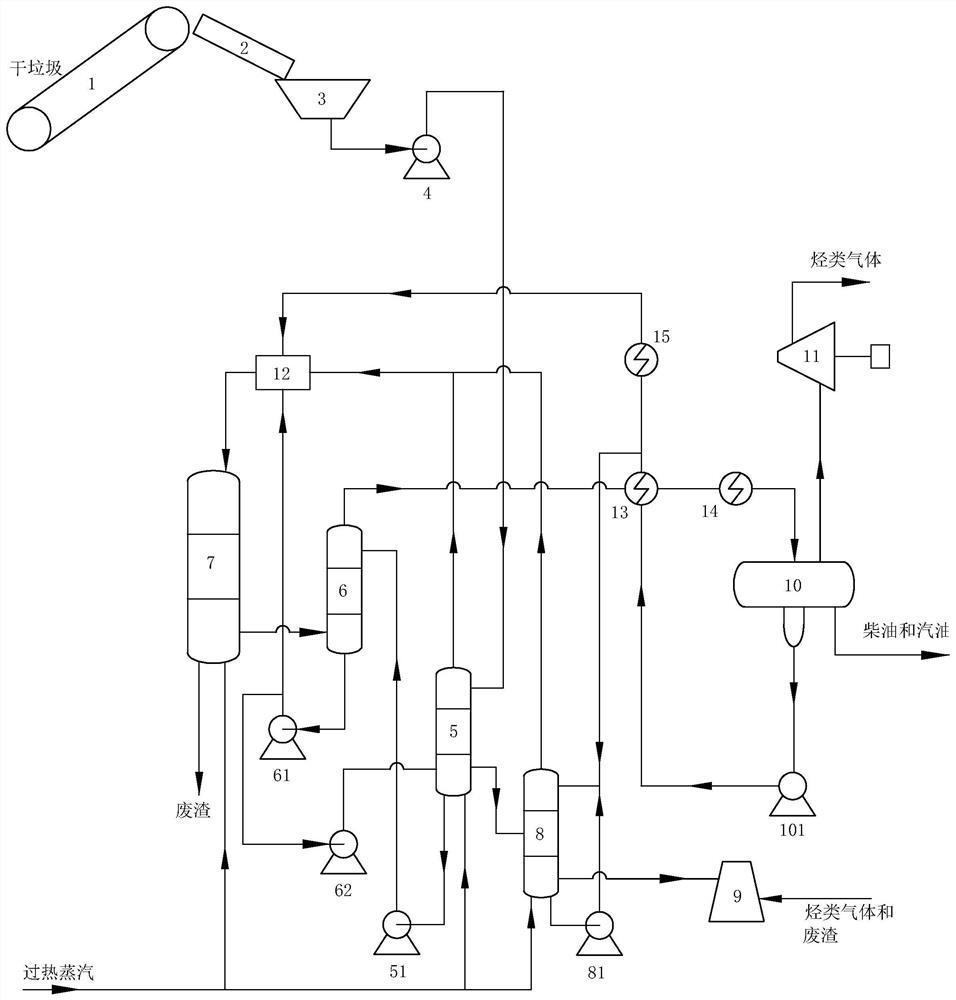

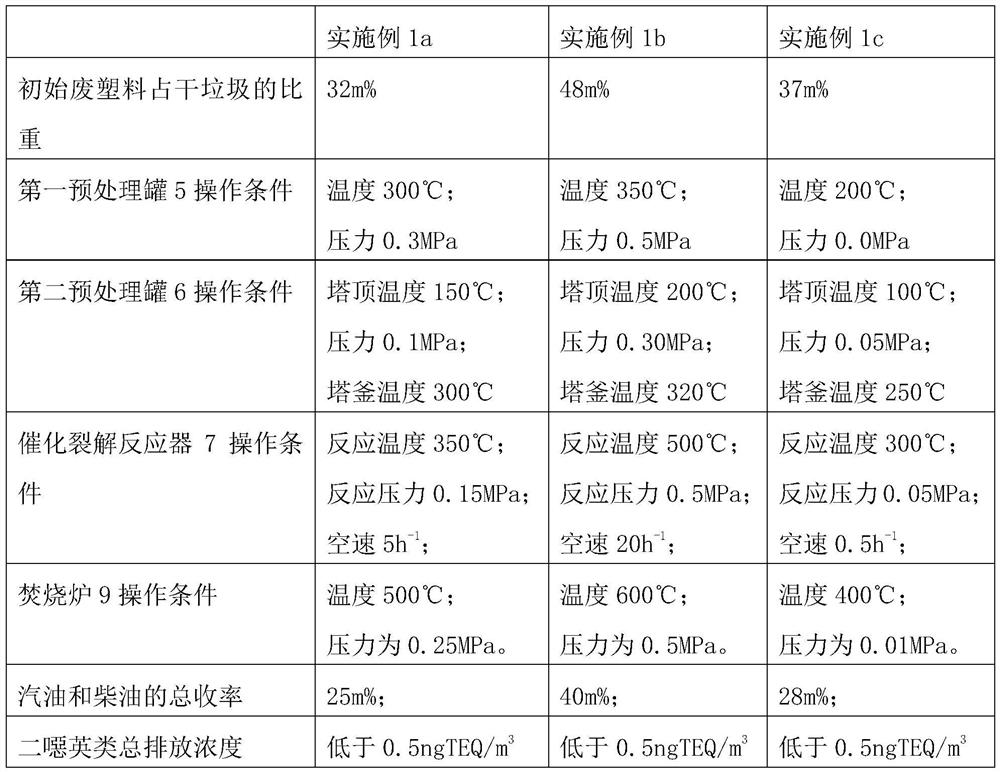

Method for embedding waste plastic green oiling technology into garbage incineration

ActiveCN111750358ALower emission valueMeet incineration requirementsCatalytic crackingGaseous fuelsSocial benefitsCombustion

The invention discloses a method for embedding a waste plastic green oiling technology into garbage incineration. The method comprises the following steps that firstly, dry-wet separation is carried out on garbage, and dry garbage is fed into a pretreatment unit of a waste plastic green oiling device; the pretreatment unit liquefies waste plastic in the dry garbage, and the non-plastic garbage isseparated after being treated by liquid-solid separation equipment; and secondly, the liquefied waste plastic is fed into a cracking unit to produce products such as gasoline and diesel oil; the non-plastic garbage is still discharged into an incinerator to be incinerated, wherein the dioxin emission in the process is much lower than the standard value. According to the method for embedding the waste plastic green oiling technology into garbage incineration, waste plastic garbage is improved from the value of coal to the value of fuel oil, waste plastic garbage is not incinerated in the incinerator any more, the production amount of dioxin is quite small, the combustion temperature of the incinerator is greatly reduced, the equipment investment and the operation cost can be greatly saved,and remarkable economic and social benefits are achieved.

Owner:ZHEJIANG COMY ENVIRONMENT TECH CO LTD

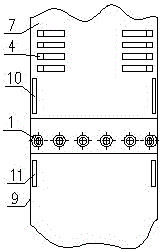

Efficient wet multistage desulfurization dust remover

InactiveCN107158919AImprove efficiencyNo emission pollutionCombination devicesVena contracta diameterFlue gas

The invention discloses an efficient wet multistage desulfurization dust remover, and relates to the technical field of dust removers. The efficient wet multistage desulfurization dust remover comprises a primary desulfurization dust removal device and a secondary and tertiary desulfurization dust removal device. The primary desulfurization dust removal device is separated from the secondary and tertiary desulfurization dust removal device by sealing partition plates, the upper portion of a primary desulfurization dust removal tank is divided into a first flue chamber and a second flue chamber, a Y-shaped flue flat plate is arranged on the lower side of the first flue chamber, a Y-shaped flue orifice plate is arranged on the lower side of the second flue chamber, an alkali liquor sedimentation pond is arranged at the bottom of the primary desulfurization dust removal tank, a blow-down opening is formed in the bottom of the alkali liquor sedimentation pond, a second dust cleaning inspection opening is formed in a side wall of the alkali liquor sedimentation pond, an automatic water replenishing tank is connected with a side edge of the alkali liquor sedimentation pond, and two layers of turbulence dehydration plates are oppositely mounted on the upper side and the lower side of the inside of the second flue chamber. The efficient wet multistage desulfurization dust remover has the advantages that the efficient wet multistage desulfurization dust remover has efficient desulfurization and dust removal double-effect functions and is small in occupied area and convenient to mount; flue gas pollutant emission values of the efficient wet multistage desulfurization dust remover are lower than pollutant emission limit values in national environmental protection standards for important regions.

Owner:叶宏

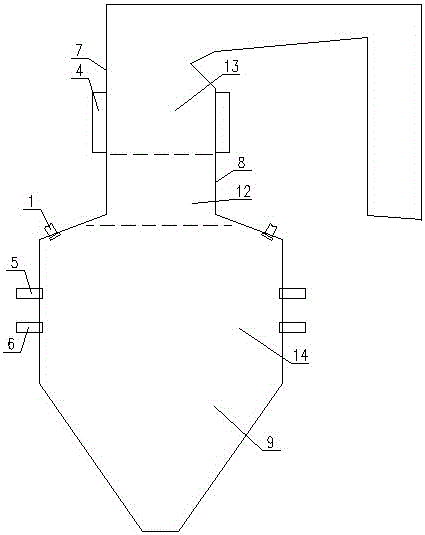

Low NOx gas burner based on internal recycle of gas and method of reducing emission

PendingCN108506935ALower emission valueEmission reductionGaseous fuel burnerFlue gasProcess engineering

The invention discloses a low NOx gas burner based on an internal recycle of gas and a method of reducing emission and belongs to the technical field of gas fuel burning. The low NOx gas burner comprises a gas pipe and a secondary air channel, wherein a combustion stabilization disc is arranged at the outlet of the secondary air channel, and the secondary air channel is composed of a secondary airinlet pipe section and a Venturi reducing pipe section; and an internal circulation flue gas inlet is formed in the throat of the Venturi reducing pipe section in a hearth of a boiler. A flue gas recycle fan and a flue gas pipeline are not needed. The proportion of circular flue gas is 5-20% by way of internal circulation mode of flue gas, and reaches the flue gas circulation proportion of an external circulation method, so that the NOx emission value of a burner or the boiler is low.

Owner:HANGZHOU ZHEDA TIANYUAN SCI & TECH

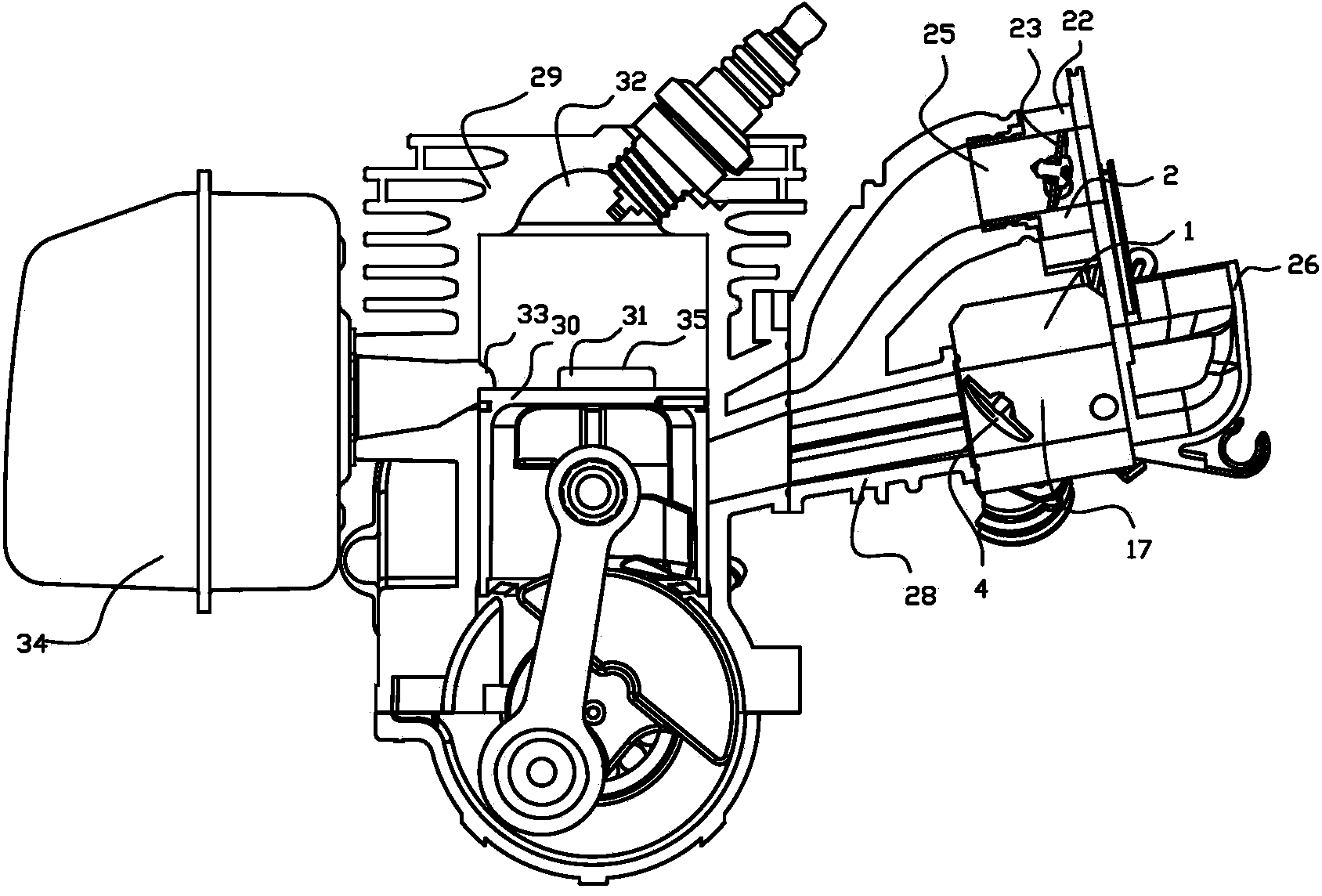

Internal combustion engine and method of operating same

ActiveUS20070034180A1Reduce fuel consumptionLower emission valueCombustion enginesIdling devicesCombustion chamberCrankcase

An internal combustion engine having an intake channel that opens into a crankcase. A first fuel channel opens into the intake channel to supply fuel thereto as a function of underpressure in the intake channel. An auxiliary channel opens into a transfer channel that fluidically connects a crankcase to the combustion chamber. A second fuel channel opens into the auxiliary channel and is connected to a storage reservoir for fuel. At least one valve controls the quantity of fuel to be supplied to the engine via the auxiliary channel. Largely fuel-free air is supplied to the engine via the intake channel during idling. During a first revolution of the crankshaft, fuel is supplied via the auxiliary channel, so that a combustible mixture can form in the combustion chamber. During a second revolution, largely fuel-free air is supplied via the auxiliary channel and the combustion chamber is scavenged with largely fuel-free air.

Owner:ANDREAS STIHL AG & CO KG

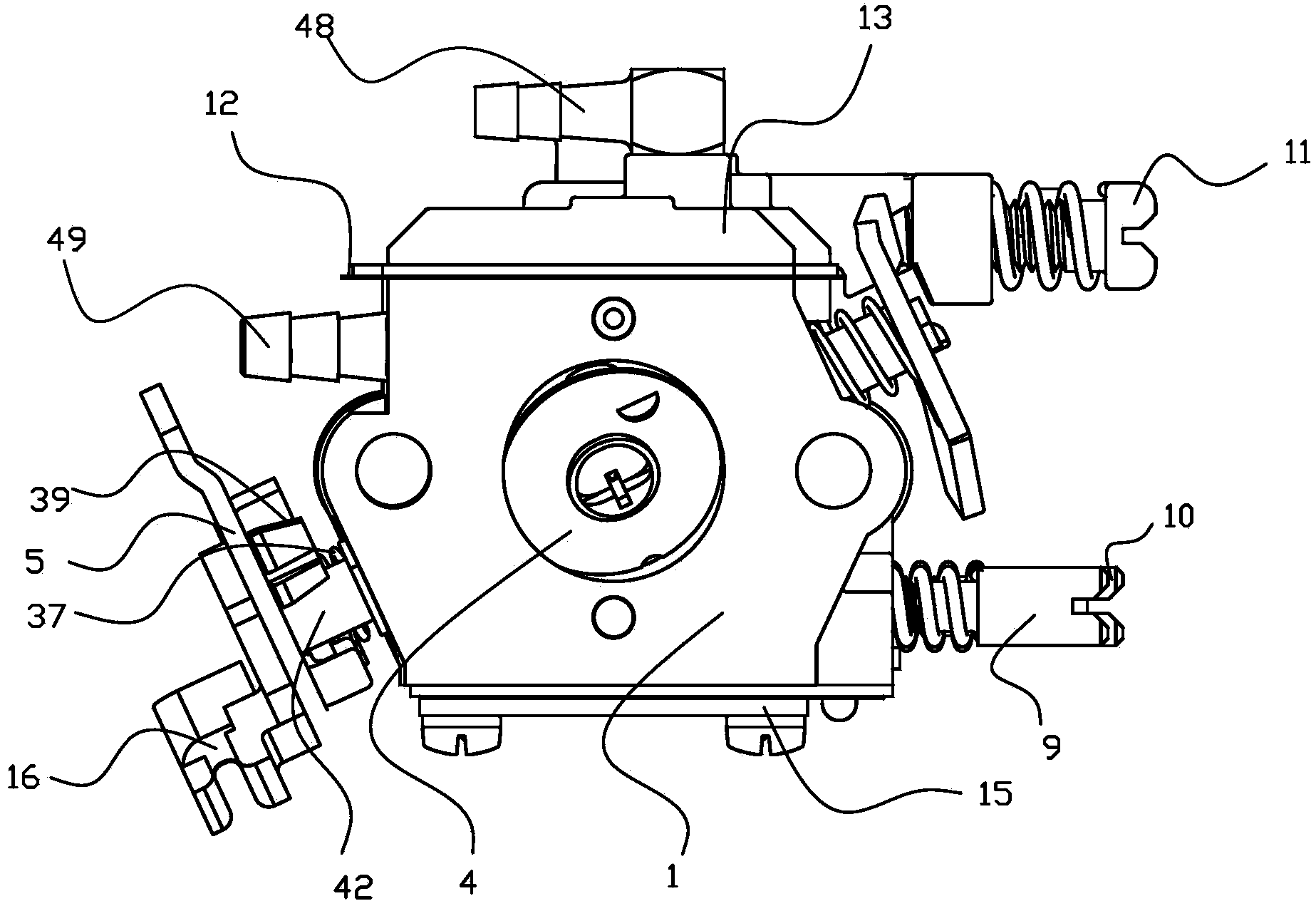

Portable gasoline engine and automatic air door control system thereof

ActiveCN105484899AEasy to openImprove economyMachines/enginesCarburettorsInlet channelAutomatic train control

The invention discloses a portable gasoline engine and an automatic air door control system thereof. The gasoline engine comprises a carburetor. The carburetor is provided with a gas inlet channel with a gas inlet. The automatic air door control system comprises a choke valve and a power unit for driving the choke valve. The gas inlet is opened or closed by the choke valve. The automatic air door control system further comprises a transmission unit and a controller. The transmission unit and a rotary shaft are matched and connected. The controller is provided with a circuit drive module for driving the transmission unit to move so that the choke valve can be controlled to be closed and opened. Automatic closing or opening of the choke valve can be achieved, operation is easy and convenient, no requirement for the skill or experience of an operator exists, and product popularization is facilitated.

Owner:SUZHOU CLEVA PRECISION MACHINERY & TECH

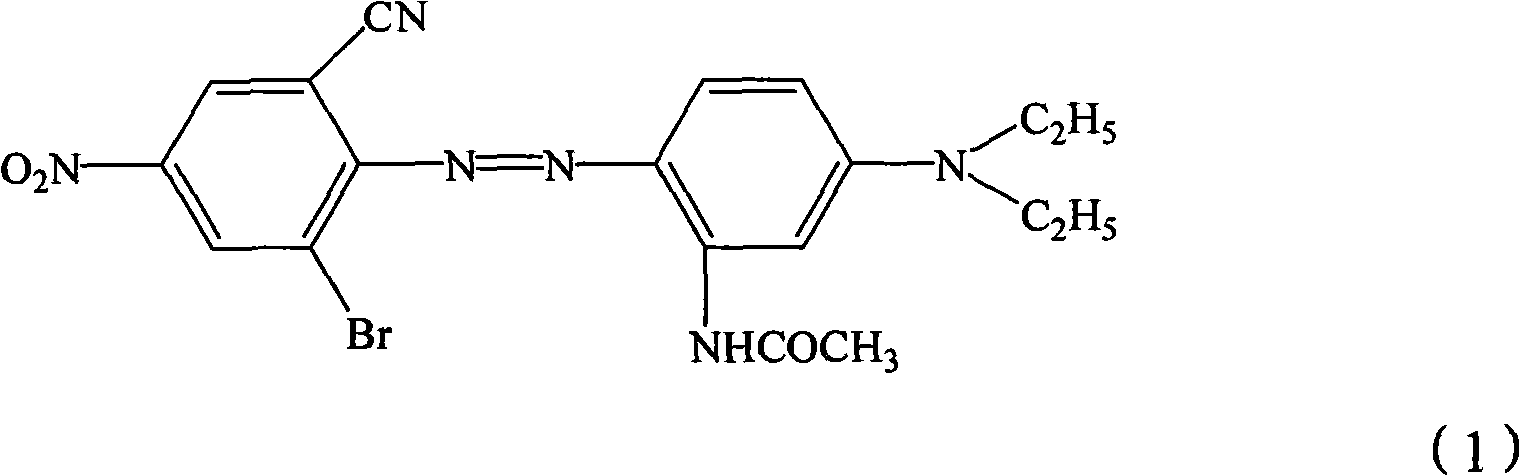

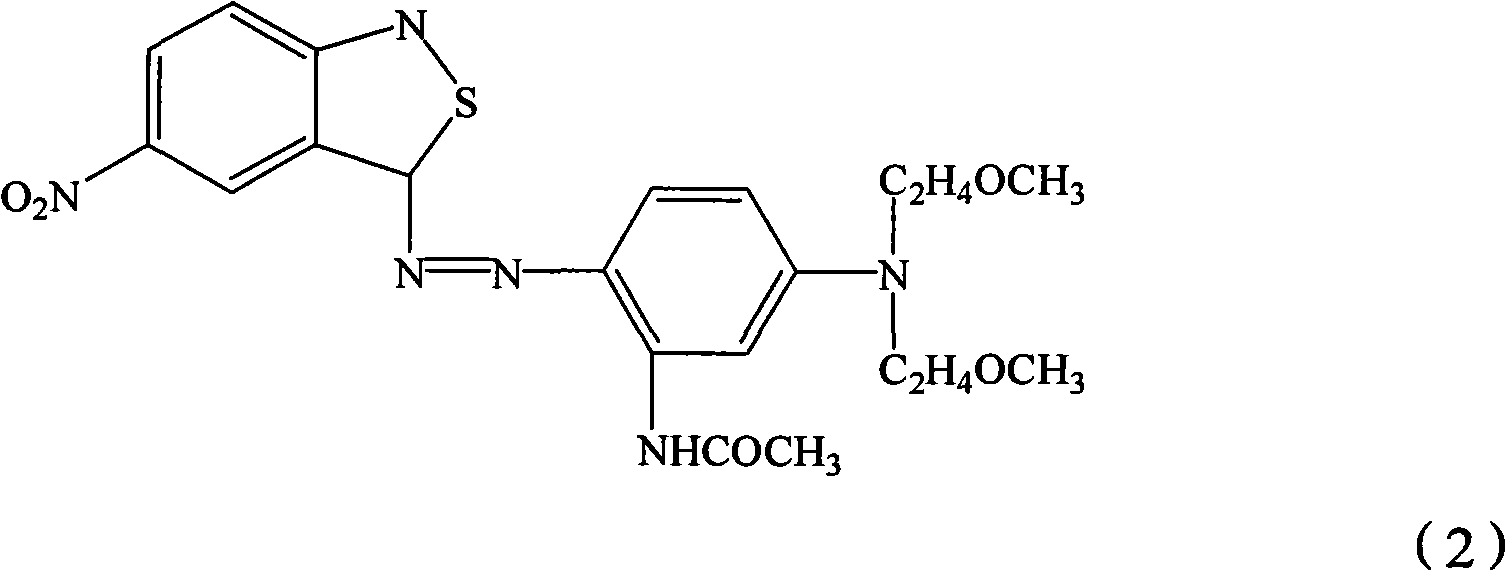

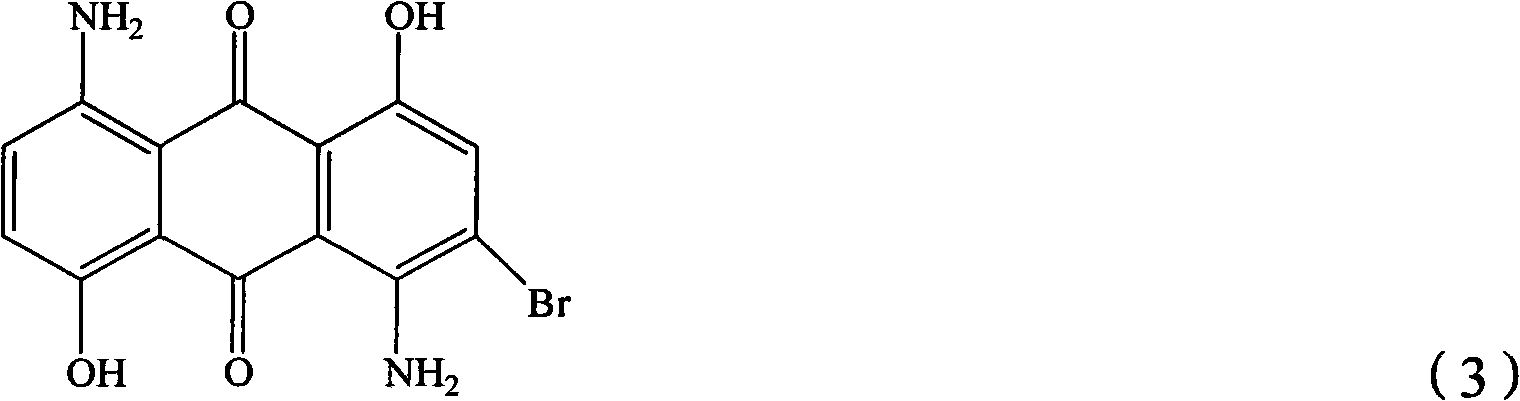

Compound disperse blue dye for direct printing

The invention relates to a compound disperse blue dye for direct printing, comprising the following components by weight: 30-82% of dye monomer A, 10-50% of dye monomer B, 1-22% of dye monomer C and the balance auxiliary agent. The dye can be applied to directly printing pure polyester fiber fabrics or other blend fabrics and ensure the fabrics to have bright-colored, full and layered hues, has low sensitivity to change of direct printing process parameters, has good printing levelling property and high color yield percentage and can obtain optimal color fastness and simultaneously reduce COD discharge value of printing and dyeing wastewater and environmental pollution.

Owner:JIANGSU YABANG DYE

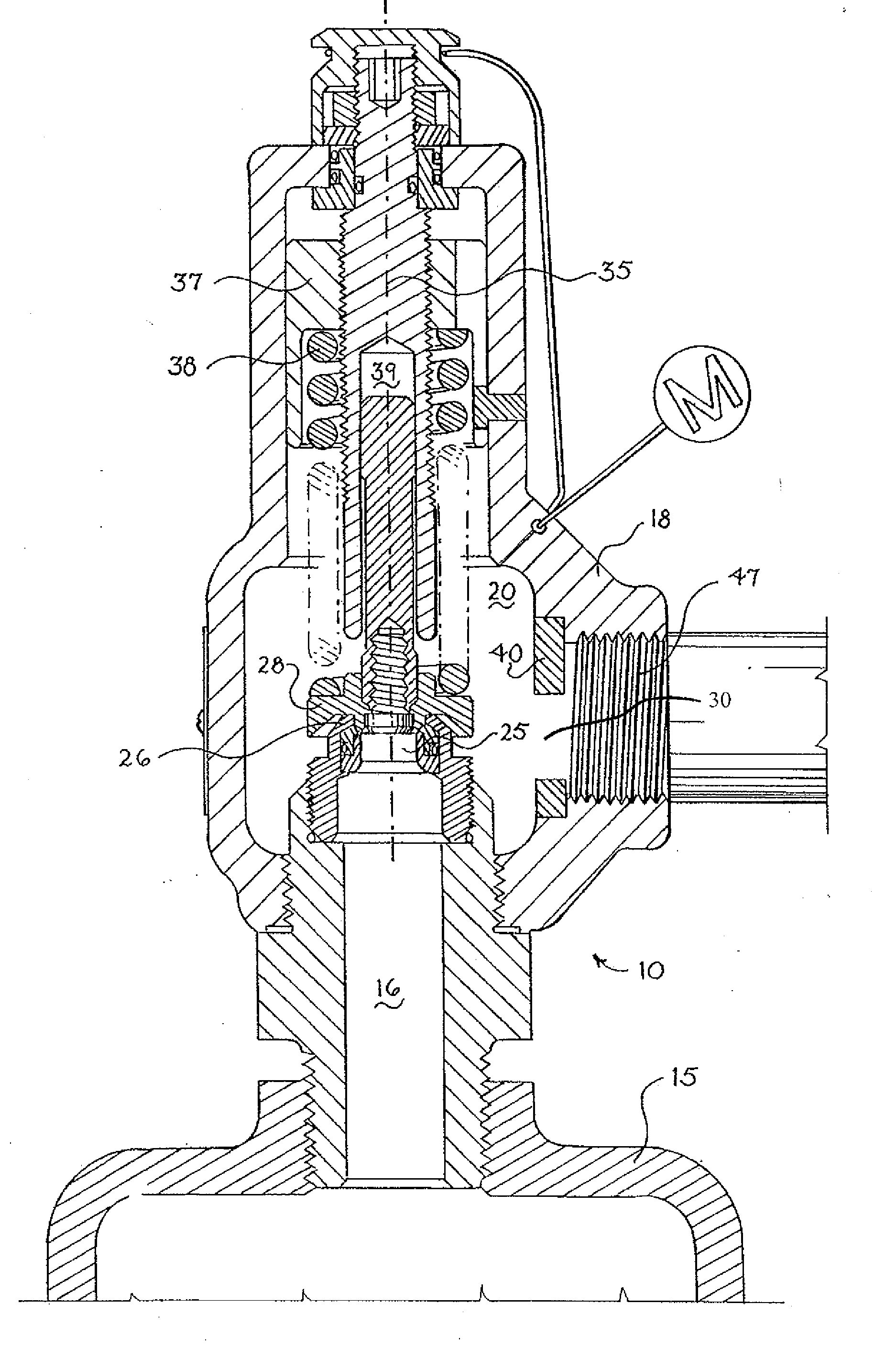

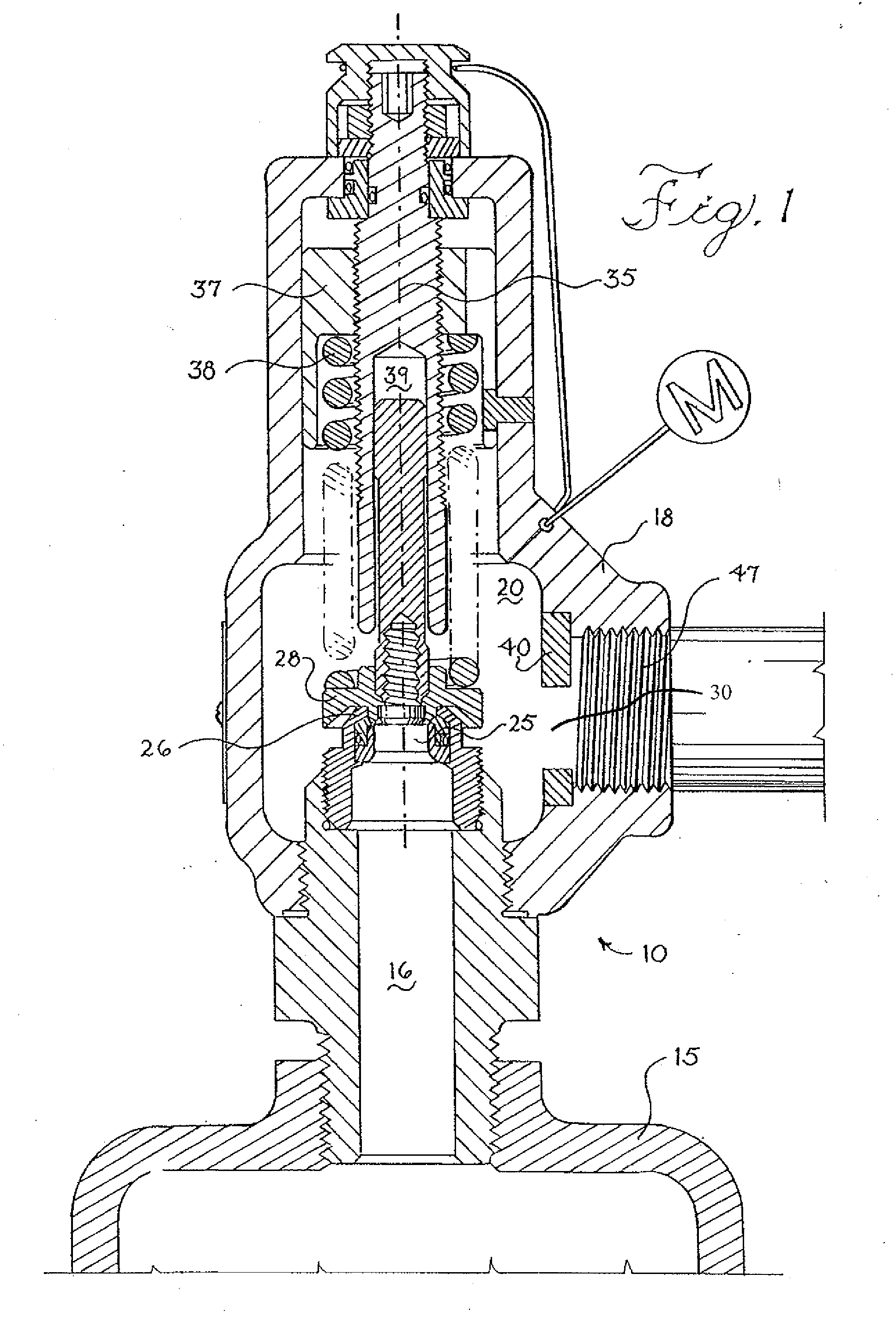

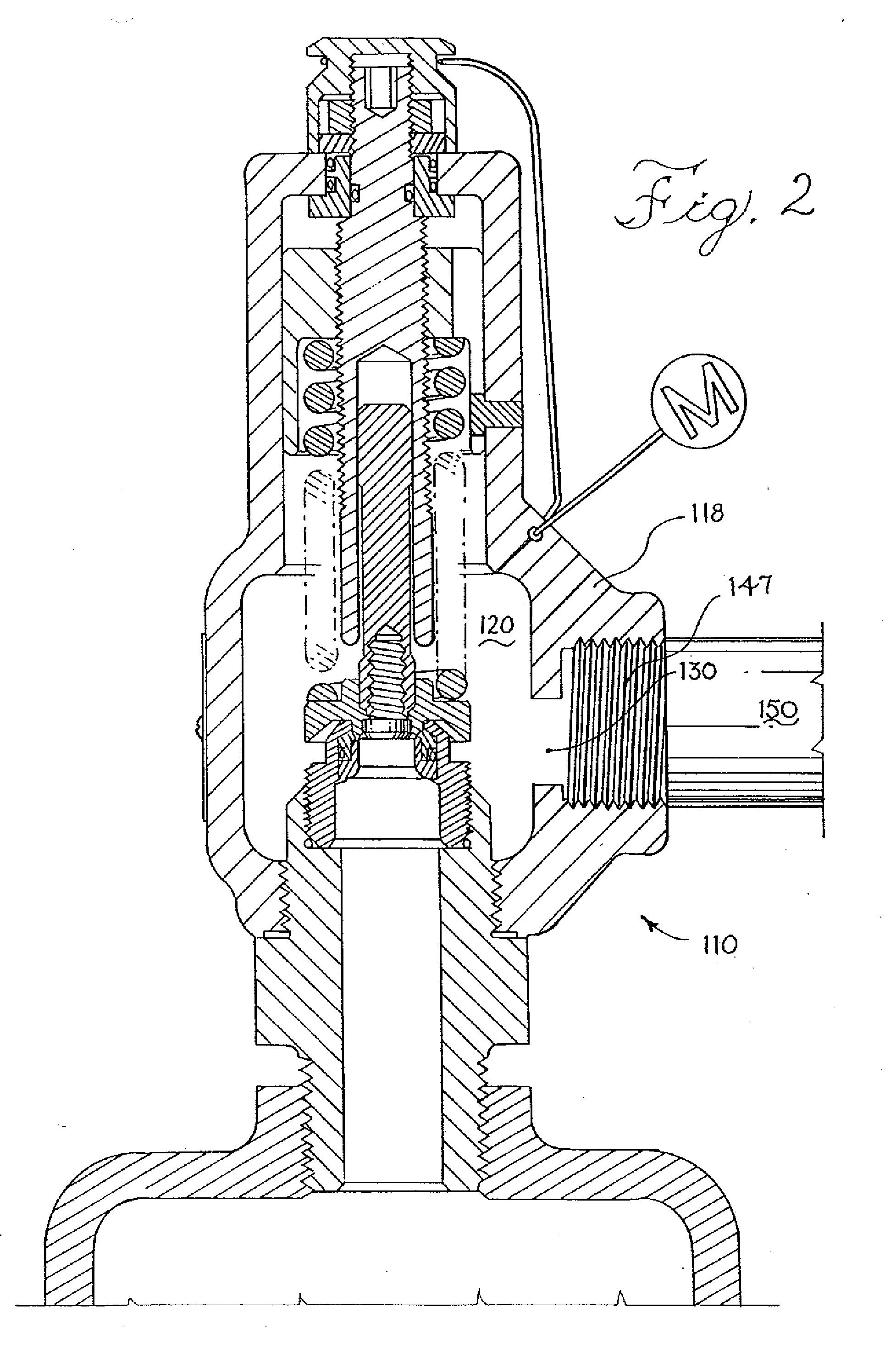

Safety relief valve having a low blow-down value and spring therefore

InactiveUS20080017257A1Lower emission valueImprove flow coefficientCheck valvesValve members for absorbing fluid energyCircular discInlet valve

A safety relief valve is provided that comprises a body comprising a chamber therein and an inlet and an outlet, the inlet comprising an inlet valve seat; a disk member closable on the inlet valve seat; and a mechanism in the body biasing the disk member to rest on the inlet valve seat with a set force such that when the pressure in the inlet exceeds a set pressure resulting from the set force, the disk member is lifted from the inlet valve seat, the mechanism comprising a combination of a coil spring and one or more disk springs stacked in series with the coil spring. A method of preparing a coil spring for use in a pressure relief valve comprises measuring the spring rate of the coil spring and; modifying the spring so as to modify its spring rate to be within ±2% of a desired spring rate.

Owner:MERCER VALVE

Carburetor with air channel

ActiveCN104074630AMeet the requirements of pollution discharge limitsReduce consumptionMachines/enginesCarburettorsCombustionMain channel

The invention relates to a carburetor with an air channel. A carburetor body is provided with a carburetor main channel penetrating the front and rear side walls of the carburetor body, two ends of the carburetor main channel are respectively provided with a throttle valve butterfly valve and a choke valve butterfly valve, the left side wall of the carburetor body is respectively provided with a throttle valve rocker and a choke valve rocker, the throttle valve rocker is connected with the throttle valve butterfly valve, the choke valve rocker is connected with the choke valve butterfly valve, and the throttle valve rocker is arranged on one side of the choke valve rocker. An air inlet bent pipe is fixed on the front side of the carburetor body, the carburetor body and the air channel device are installed on the air inlet bent pipe, the air channel device is connected with the throttle valve rocker through a linkage rod, and the throttle valve rocker drives the air channel device to be started and shut down through the linkage rod during rotation. The carburetor with the air channel has the advantages that engine fuel mixed gas is fully combusted, waste gas produced during combustion is completely discharged, the discharging amount of the non-combusted mixed gas can be decreased, the fuel consumption rate is low, the machine using cost is low, and the non-combusted mixed gas is prevented from being leaked due to the fact the mixed gas is fully combusted.

Owner:ZHEJIANG ZOMAX GARDEN MACHINERY

Combustion Chamber

InactiveUS20070224559A1Lower emission valueImprove efficiencyFuel supply regulationContinuous combustion chamberCombustorCombustion chamber

A combustion chamber (1), in particular in a gas turbine, has at least two burners (A-H) that are connected to a fuel supply (3) via controllable fuel valves (2′ and 2). Each burner (A to H) is assigned at least one optical measuring device (4) for detecting chemiluminescent radiation, and the combustion chamber (1) is assigned a pressure sensor (7) for detecting a combustion chamber pressure. The optical measuring device (4) and the pressure sensor (7) are connected to a computing and control device, which calculates a correlation value from the incoming measured values. A high correlation value signifies that the associated burner is prone to pulsation. The computing and control device (6) is designed in such a way that it determines the burner or a burner group with the highest correlation and controls the associated fuel valve(s) in such a way that more fuel is fed to the respective burner or the respective burner group, and the pulsation tendency thereof is thereby reduced.

Owner:ANSALDO ENERGIA SWITZERLAND AG

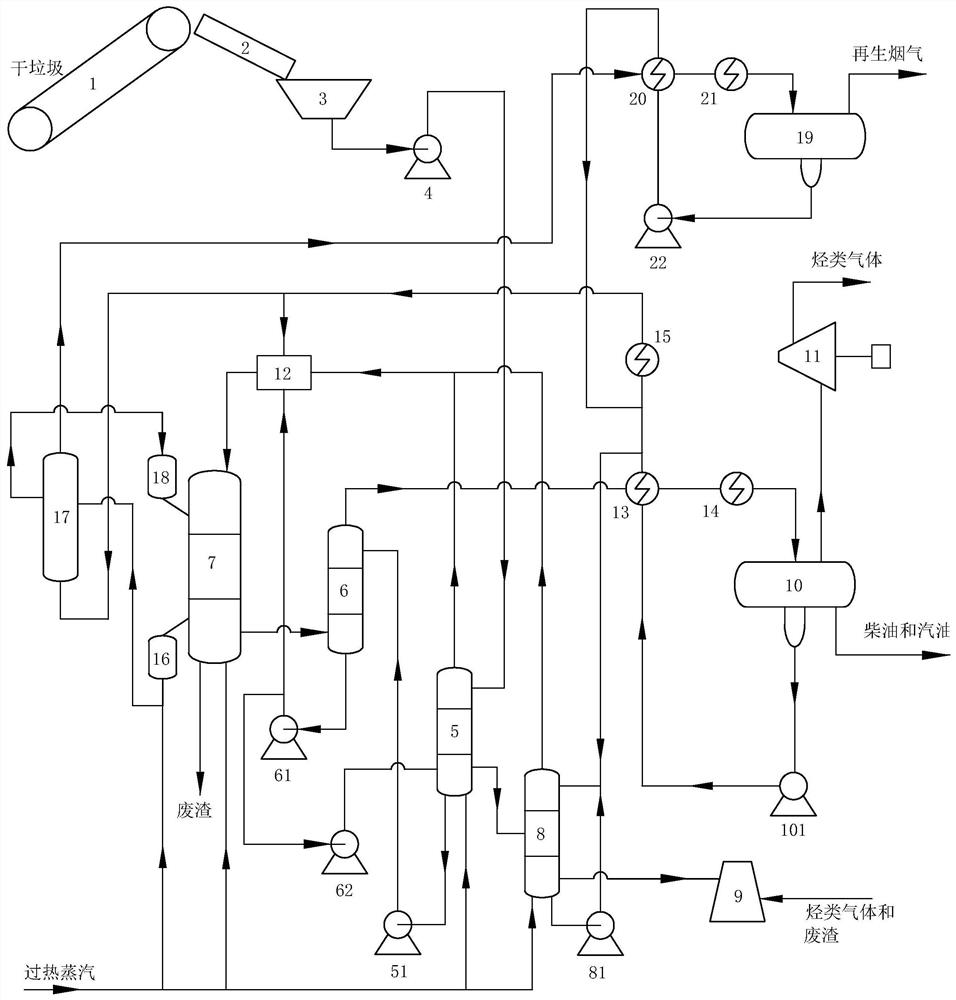

A method of embedding waste plastic green oily technology into garbage incineration

ActiveCN111750358BLower emission valueMeet incineration requirementsCatalytic crackingGaseous fuelsCombustionPlastic waste

The invention discloses a method for embedding waste plastic green oilization technology into garbage incineration, which comprises the following steps: firstly, the garbage is separated from dry and wet, and the dry garbage enters the pretreatment unit of the waste plastic green oilification device; the pretreatment unit converts the waste in the dry garbage Plastic liquefaction, non-plastic waste is separated after being treated by liquid-solid separation equipment; secondly, waste plastic after liquefaction is sent to a cracking unit to produce products such as gasoline and diesel; non-plastic waste is still discharged into an incinerator for incineration; this process Dioxin emissions are far below the standard value. The waste plastic green oilization technology of the present invention is embedded in the garbage incineration method. First, the value of waste plastic garbage is increased from "coal" to "fuel oil". The amount is negligible, and the combustion temperature of the incinerator is greatly reduced, which can greatly save equipment investment and operating costs, and has significant economic and social benefits.

Owner:ZHEJIANG COMY ENVIRONMENT TECH CO LTD

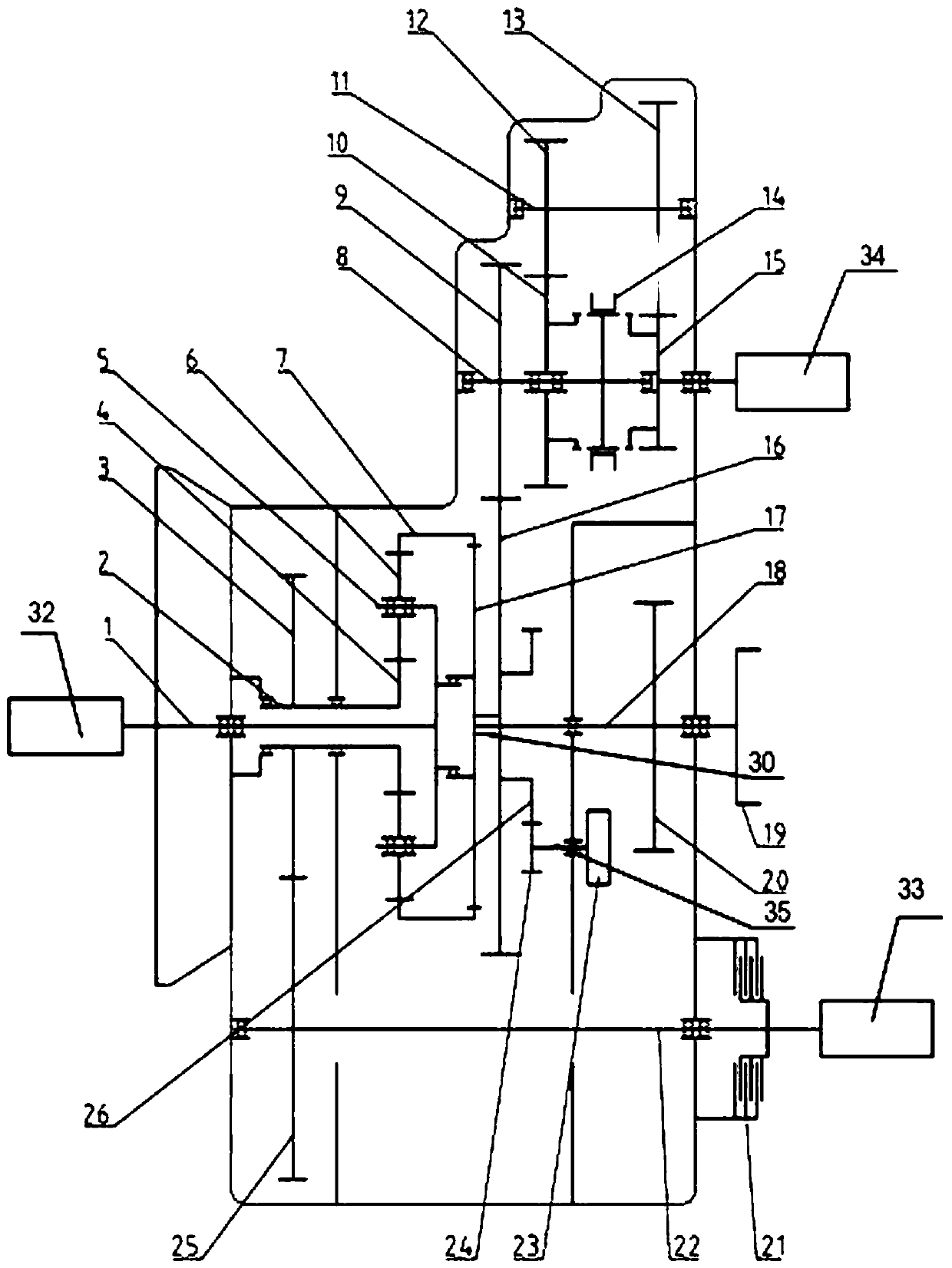

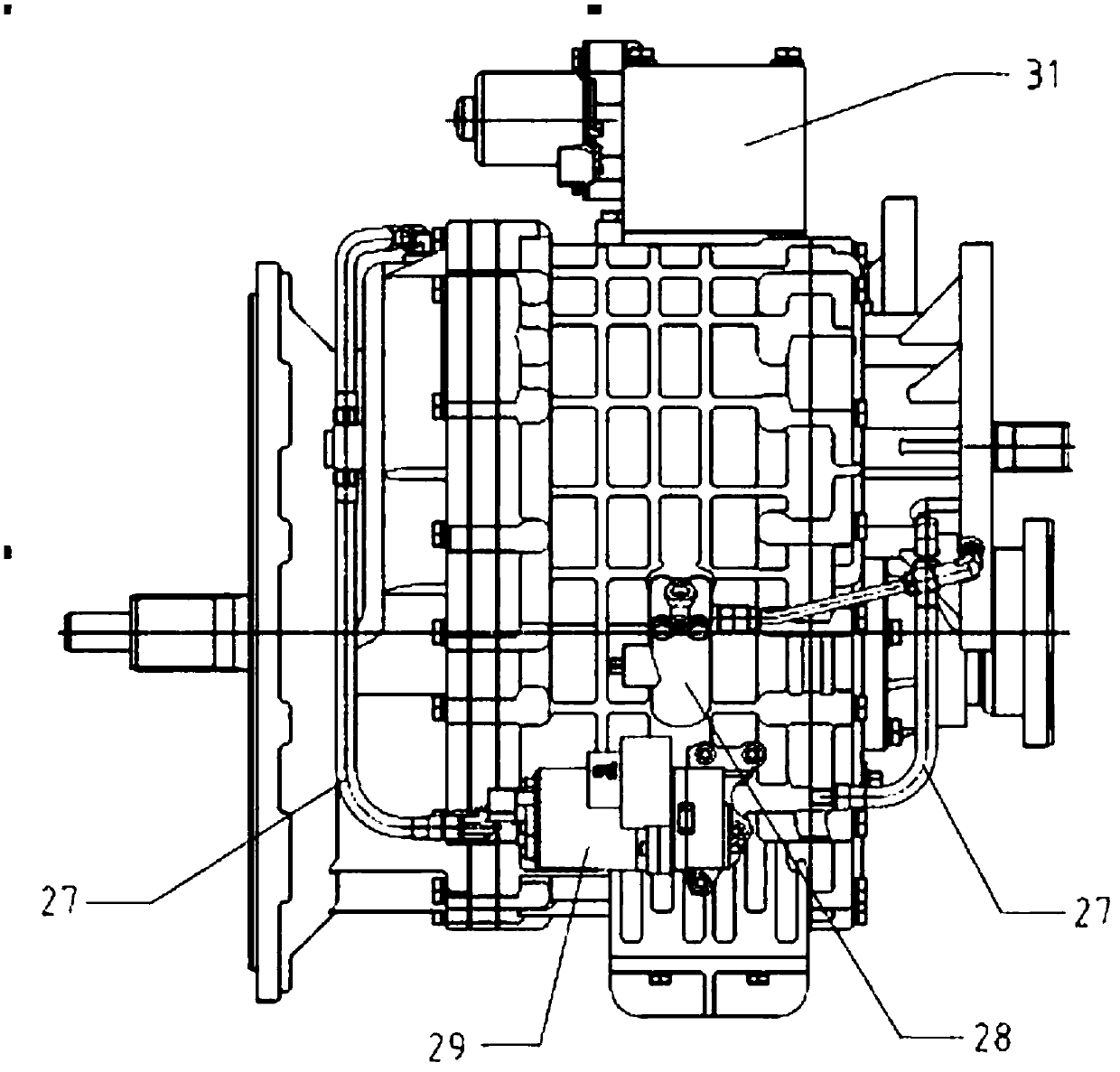

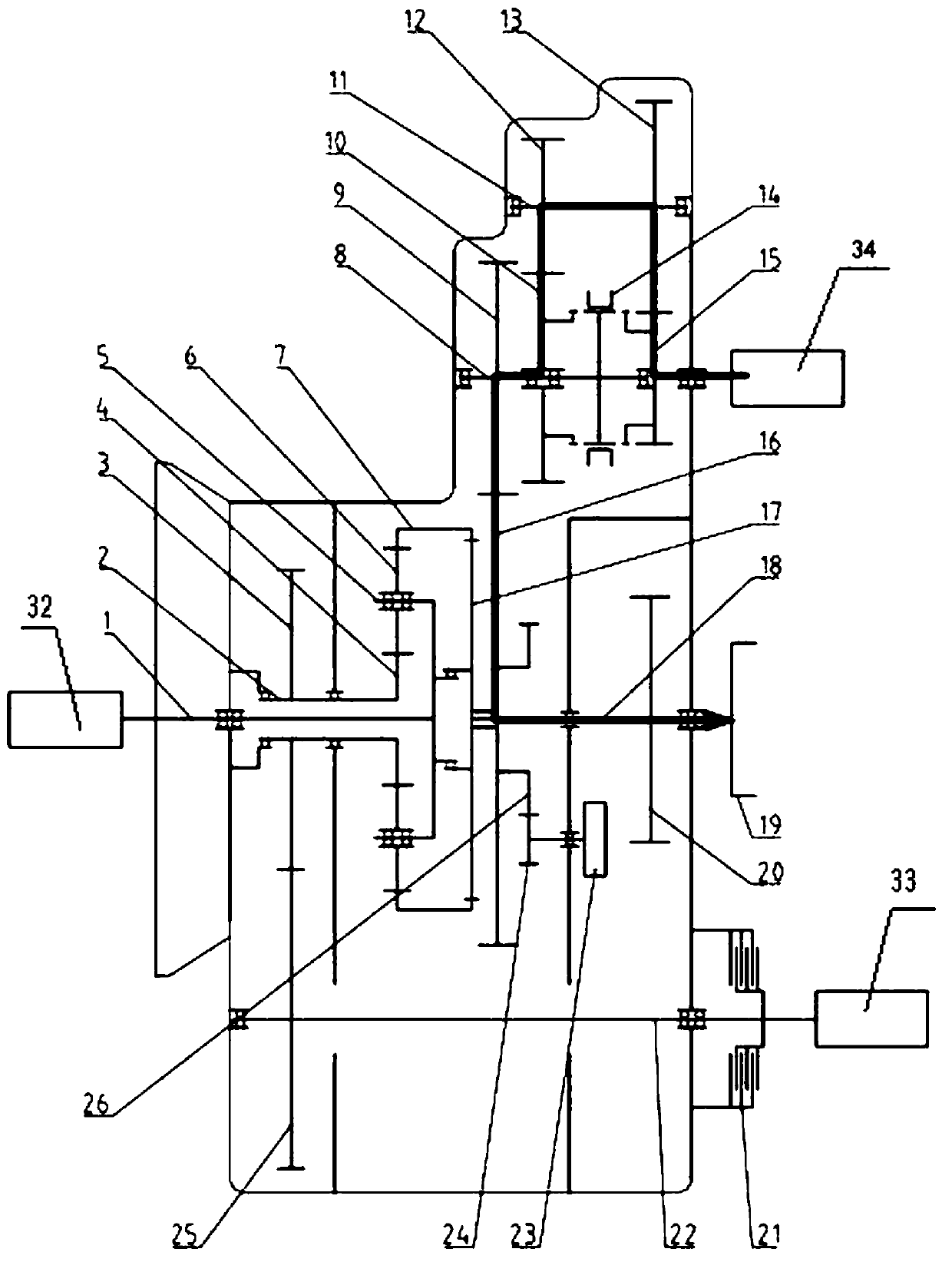

Two-shift hybrid power transmission

InactiveCN108674170ALower emission valueImplement hybrid driveGas pressure propulsion mountingGear lubrication/coolingElectric machineClutch

The invention discloses a two-shift hybrid power transmission. The two-shift hybrid power transmission comprises a planet row transmission mechanism, a two-shift variable-speed transmission mechanism,a power generation transmission mechanism and a power output mechanism. The two-shift variable-speed transmission mechanism transmits the power of a motor to the power output mechanism, the planet row transmission mechanism transmits the power of an engine to the power output mechanism, and the motor and the engine can drive in a separate mode or in a hybrid mode. The transmission replaces a clutch, the motor is used for starting, the starting torque is large, the starting performance is improved, and the emission value is reduced to zero. The transmission can achieve hybrid drive of the engine and the motor, the engine can work in a high efficiency area, the emission value is greatly reduced, and the needs of large driving force can be met. Through reasonable structure and parameter designs, the transmission enables the engine to be in an efficient working area, and thus the goal of energy saving and emission reduction is achieved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com