Method for operating a hybrid drive

A drive and operating mode technology, applied in the layout of multiple different prime movers of hybrid vehicles, general power plants, motor vehicles, etc., can solve problems such as inability to perform zero calibration, and achieve improved calculation/matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

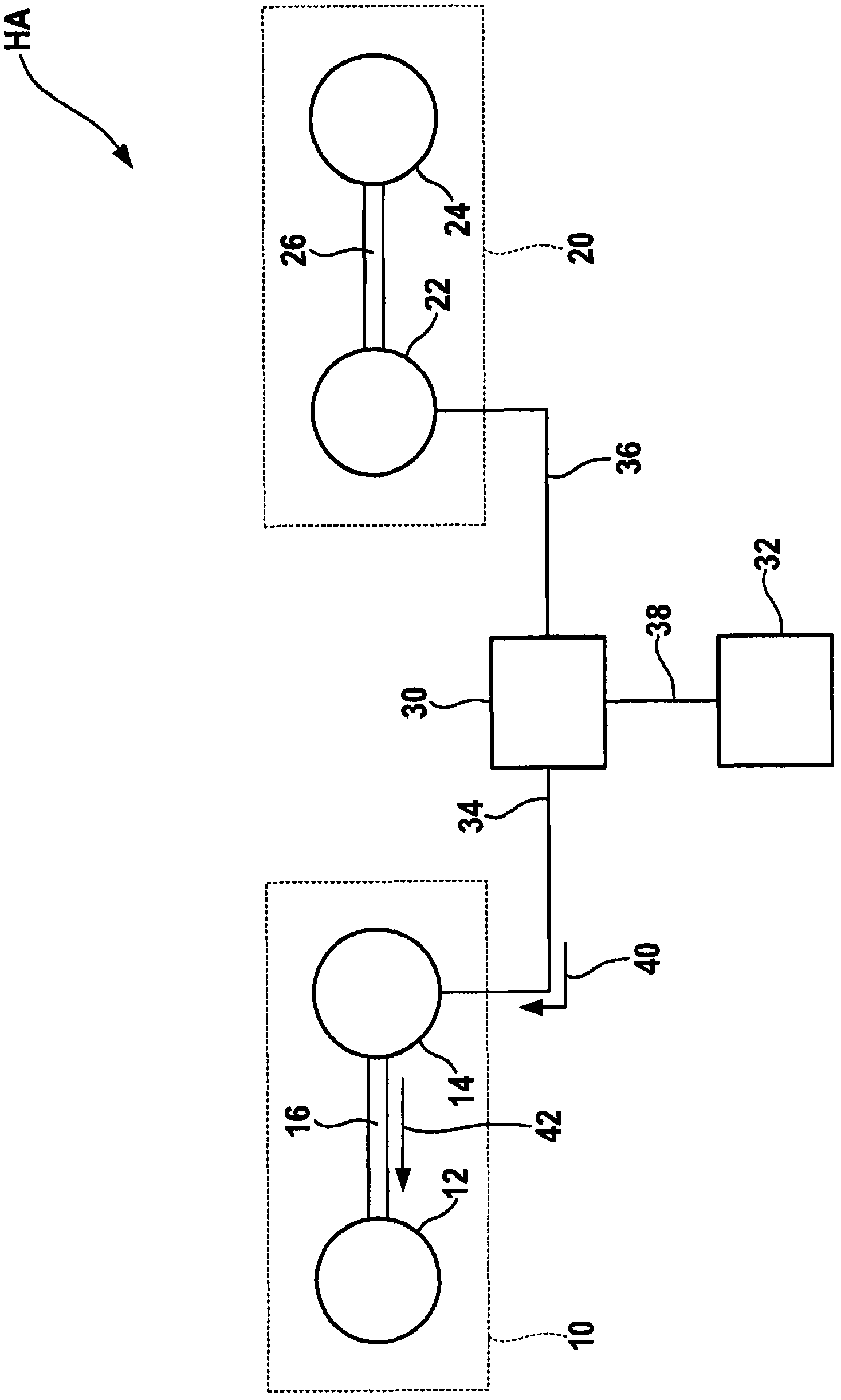

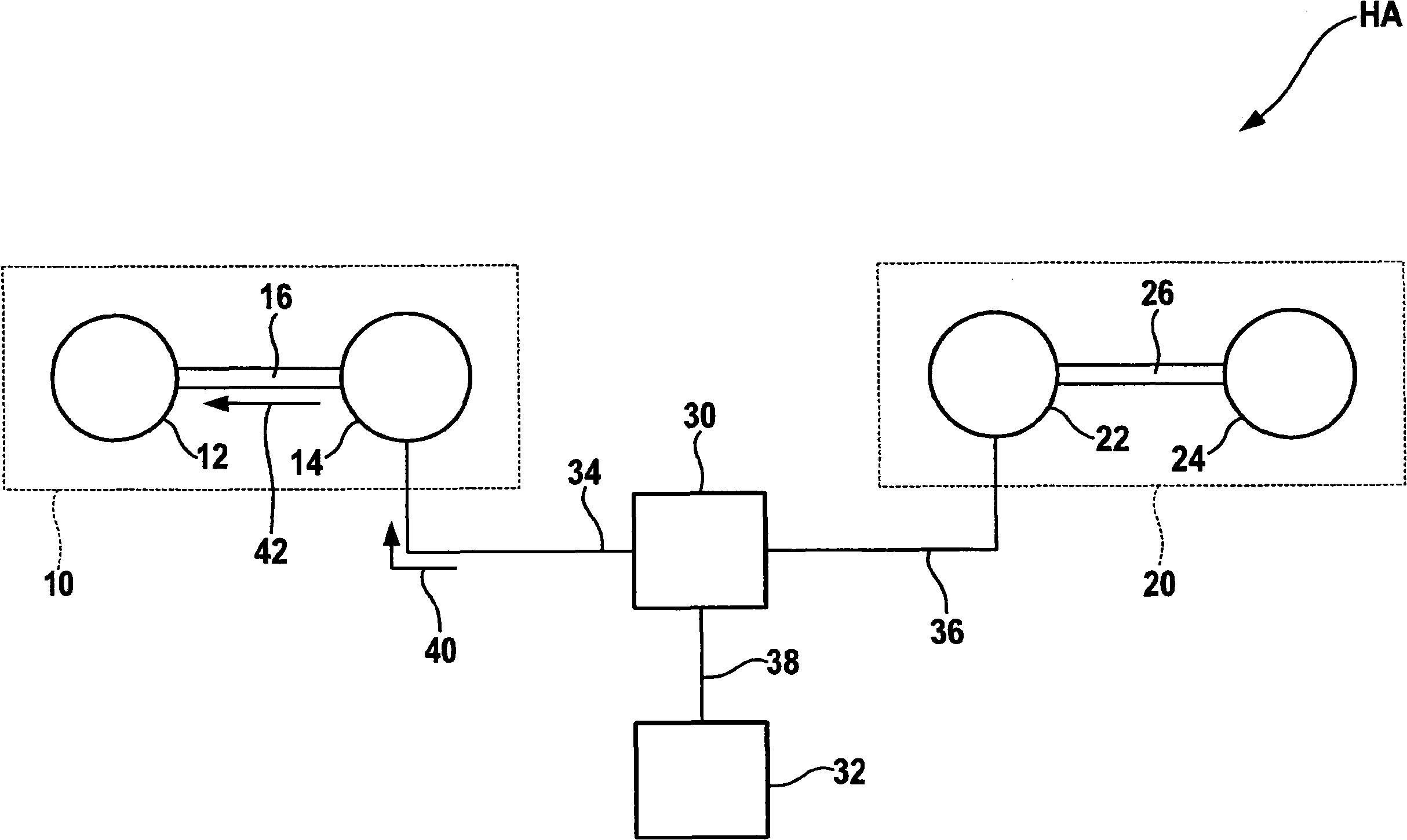

[0016] figure 1 The hybrid drive HA of the series basically includes a supply unit 10 and a drive unit 20 . The supply unit 10 consists of an internal combustion engine 12 and a generator 14 . Internal combustion engine 12 and generator 14 are coupled via a power transmission connection 16 . The drive unit 20 is composed of an electric motor 22 and a drive train 24 . The electric motor 22 and the drive train 24 are coupled via a force-transfer connection 26 .

[0017] Energy transfer unit 30 is connected to generator 14 , electric motor 22 and battery 32 by means of lines 34 , 36 and 38 . The generator 14 , the electric motor 22 and the battery 32 can be operated as energy sources or as energy reducers.

[0018] The supply unit 10 serves the purpose of supplying electrical energy to a vehicle unit, for example a drive unit 20 . For this purpose, the generator 14 is driven by the internal combustion engine 12 . The generator 14 converts the mechanical energy emitted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com