Cooling water jacket structure of diesel engine cylinder body

A technology for cooling water jackets and cylinder blocks, applied to cylinders, cylinder heads, mechanical equipment, etc. Problems such as temperature unevenness, achieve the effect of reducing particle emission value, simple structure, and enhancing cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

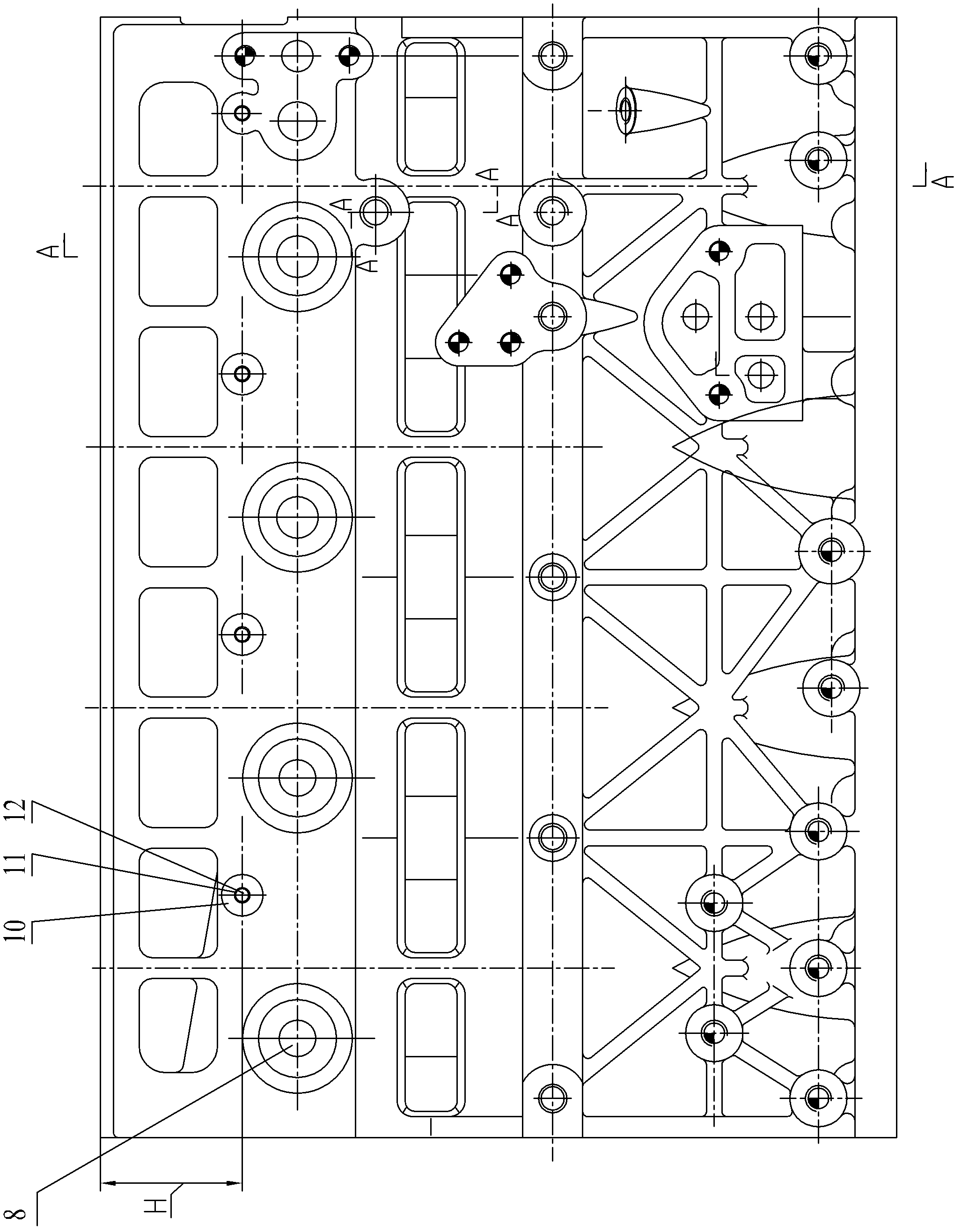

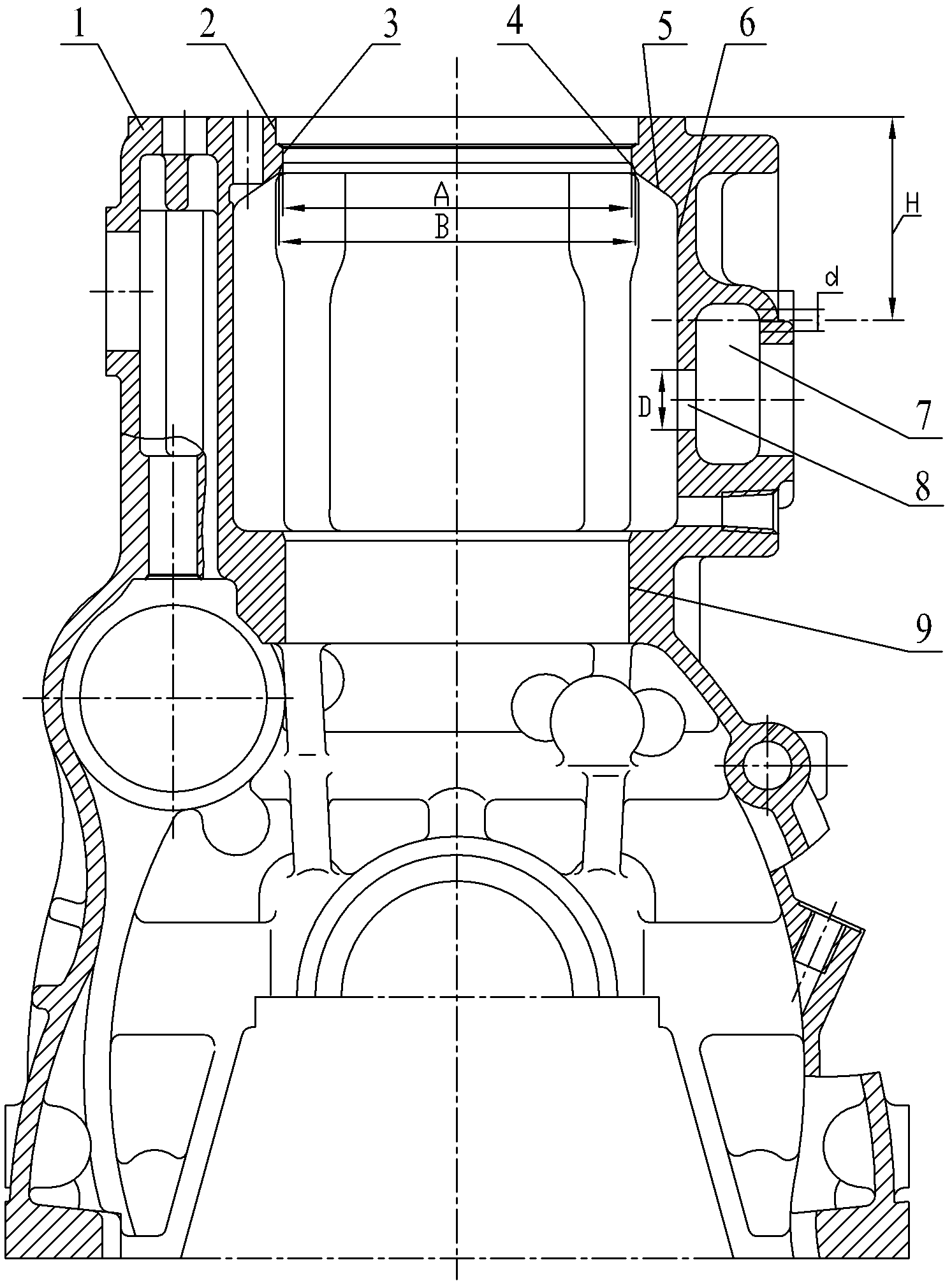

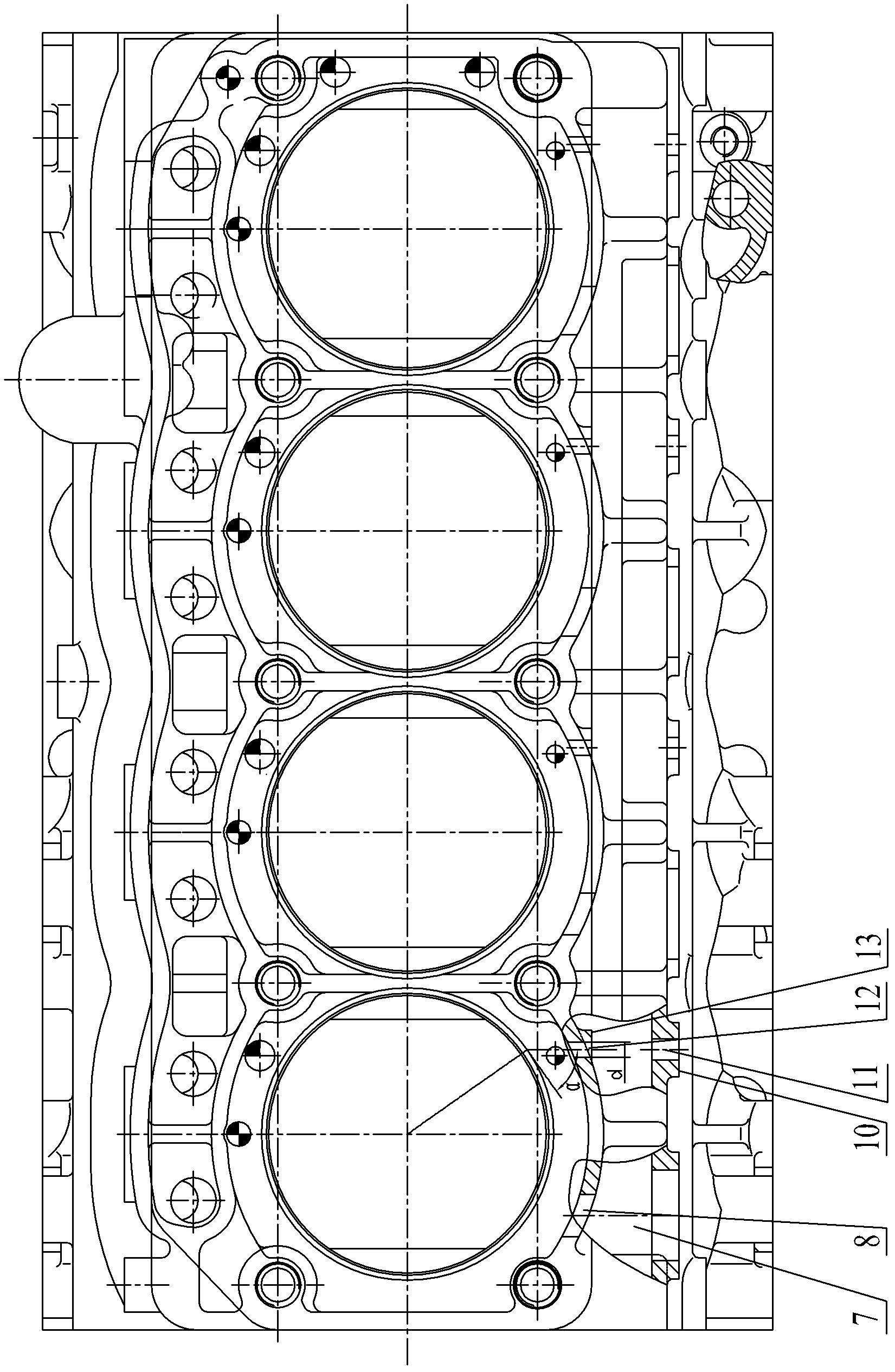

[0024] Such as Figure 1~Figure 5 As shown, the upper part of the intake side of the cylinder block 1 is provided with a transverse water inlet 7, and one end of the water inlet 7 is connected to a water pump; the middle and upper parts of each cylinder of the cylinder block 1 are formed with a cylinder block water jacket 6, and the cylinder block water The sleeve 6 is provided with a water inlet 8 and a drain hole. The water inlet 8 is located on the intake side of the cylinder block 1, and the water inlet 7 communicates with the inside of the cylinder block water jacket 6 through the water inlet 8; A conical cooling water jacket 4 is arranged at the top of the body water jacket 6 extending upward. The conical cooling water jacket 4 is located under the axial positioning annular support shoulder 3 of each cylinder of the cylinder block 1. The conical cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com