Patents

Literature

33results about How to "Avoid scuffing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

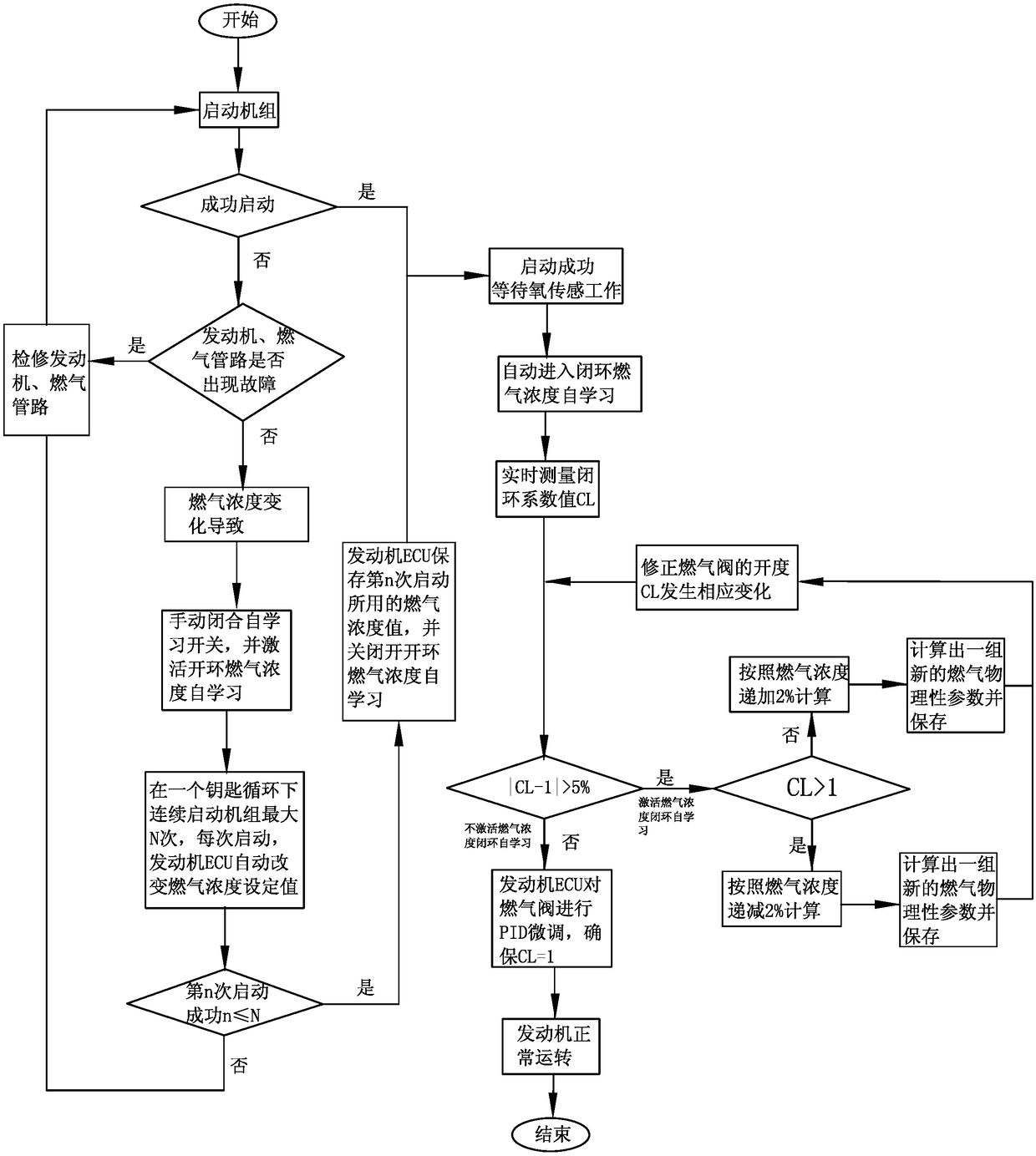

Fuel gas concentration self-adaptive control method for fuel gas generating set

ActiveCN108757194AFor precise controlPrevent knockingElectrical controlInternal combustion piston enginesAutomotive engineeringBiomass

The invention discloses a fuel gas concentration self-adaptive control method for a fuel gas generating set. The fuel gas concentration is the concentration of methane in fuel gas. The method comprises an open-loop fuel gas concentration self-learning starting control step carried out when the fuel gas generating set is not successfully started, wherein an engine ECU performs internal logic fuel gas concentration self-learning to reach the changed fuel gas concentration value, so that the set can be started smoothly; and the method further comprises a closed-loop fuel gas concentration self-learning control step, wherein the engine ECU continuously and finely adjusts the fuel gas methane concentration value repeatedly according to closed-loop data of an oxygen sensor, and finally performsaccurate self-learning to reach the changed fuel gas methane concentration value so that the fuel gas generating set can easily respond to the change of the concentration of the methane in the fuel gas. According to the method, the fuel gas generator set can accurately control the injection amount of a fuel gas valve and the air-fuel ratio better under the condition of fuel gas such as biogas, gasand biomass gas with the methane concentration variable, so that safe and stable operation is realized.

Owner:WEICHAI XIGANG NEW ENERGY POWER

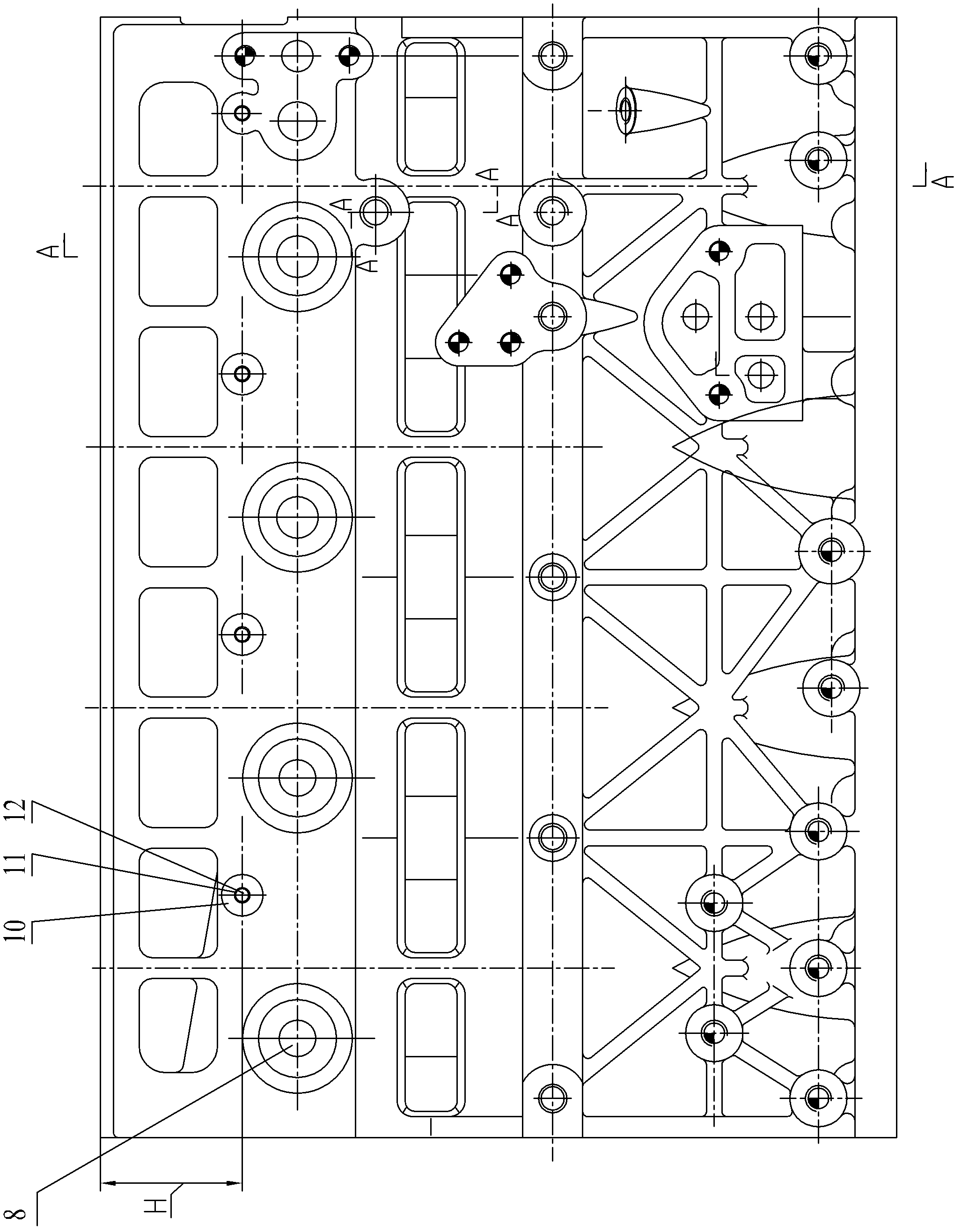

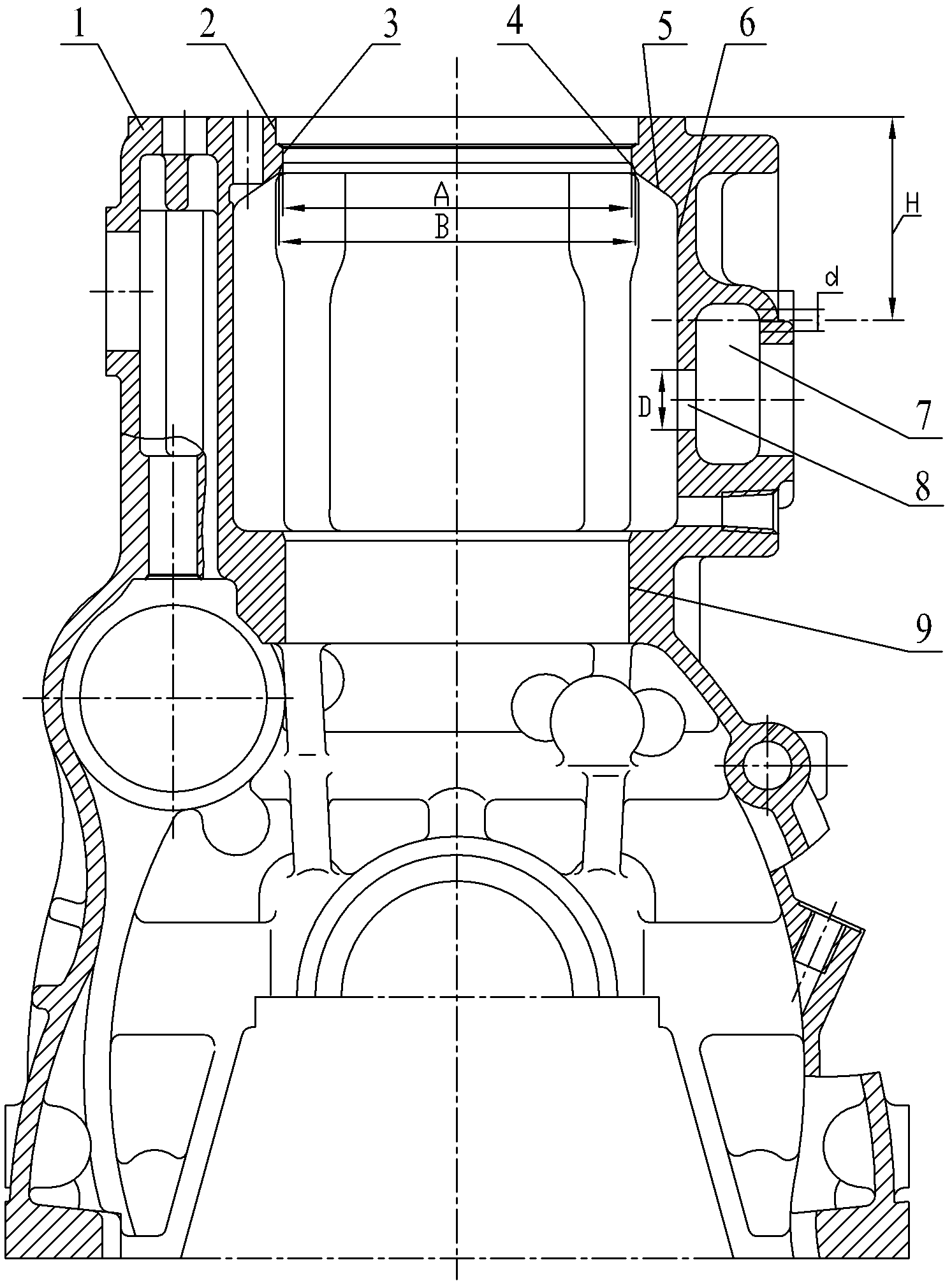

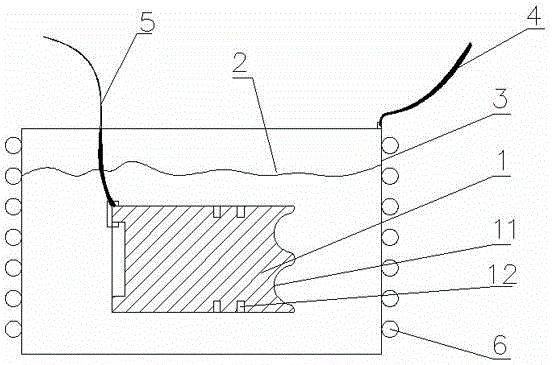

Cooling water jacket structure of diesel engine cylinder body

InactiveCN102536494AReasonable arrangementGuaranteed cooling effectCylinder headsCylindersTop dead centerPiston ring

The invention relates to a cooling water jacket structure of a diesel engine cylinder body. A water inlet channel is disposed at the upper portion of the air inlet side of the cylinder body, a cylinder body water jacket is formed at the middle upper portion of each cylinder of the cylinder body, and the water inlet channel is communicated with the insides of the cylinder body water jackets through water inlet holes. The diesel engine cylinder body cooling water jacket structure is characterized in that the top ends of the cylinder body water jackets upwards extend to be provided with conical cooling water jackets, the conical cooling water jackets are located below cylinder jacket axial location ring support shoulders of cylinders of the cylinder body, the upper ends of the conical cooling water jackets are connected with the cylinder jacket axial location ring support shoulders, and the lower ends of the conical cooling water jackets are connected with water jacket inner cavity inclined planes of the cylinder body water jackets. The height of each conical cooling water jacket should ensure that when a piston is located at a top dead center, the upper ends of the conical cooling water jackets basically align to the top edge of a first piston ring on the piston. The cooling water jacket structure of the diesel engine cylinder body can ensure that when the piston is located at the compression top dead center, the piston, the piston ring and the cylinder jacket can all be cooled effectively, and scuffing of cylinder bore of the cylinder jacket can be prevented.

Owner:JIANGSU SIDA POWER MECHANICAL GROUP

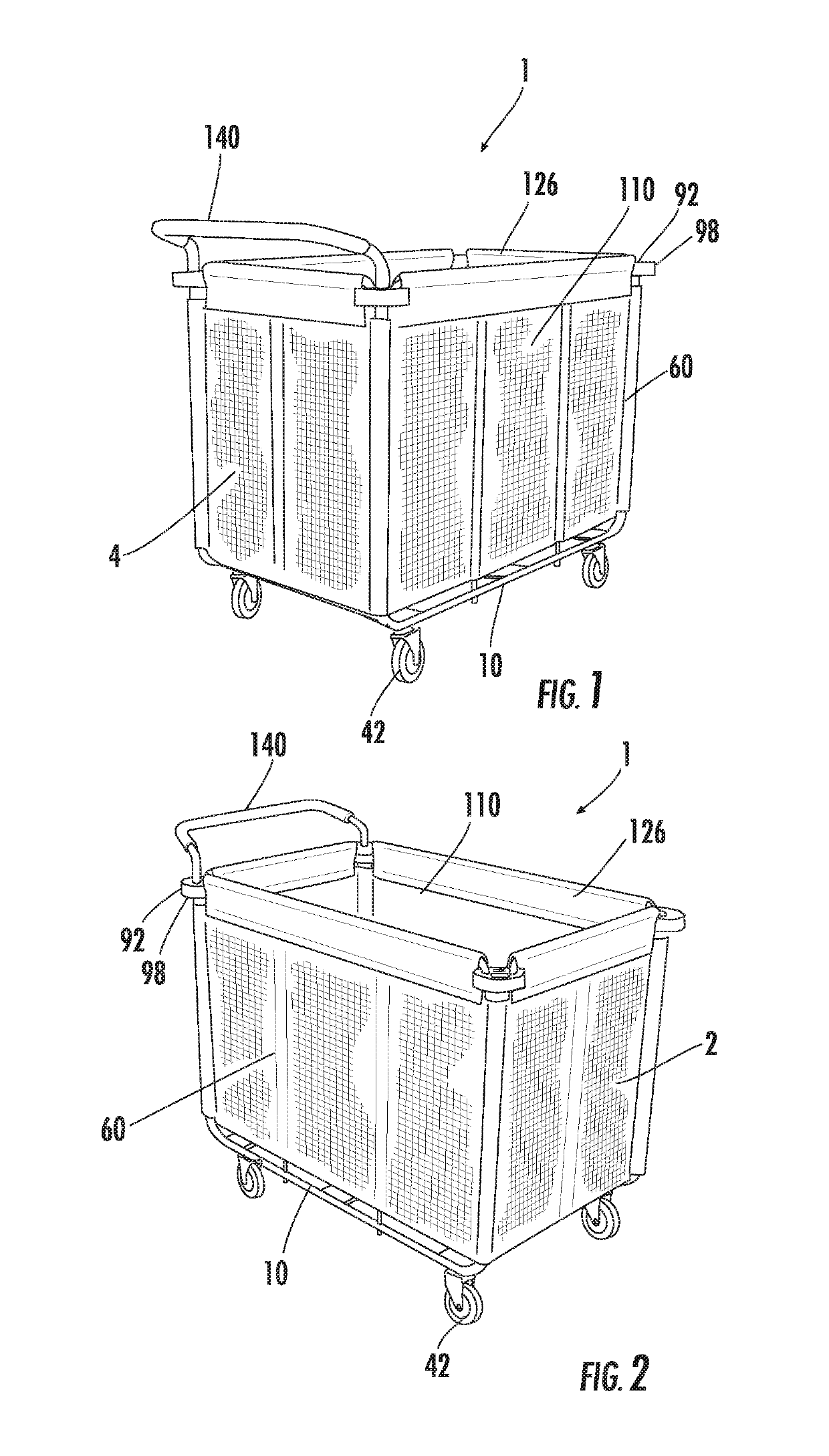

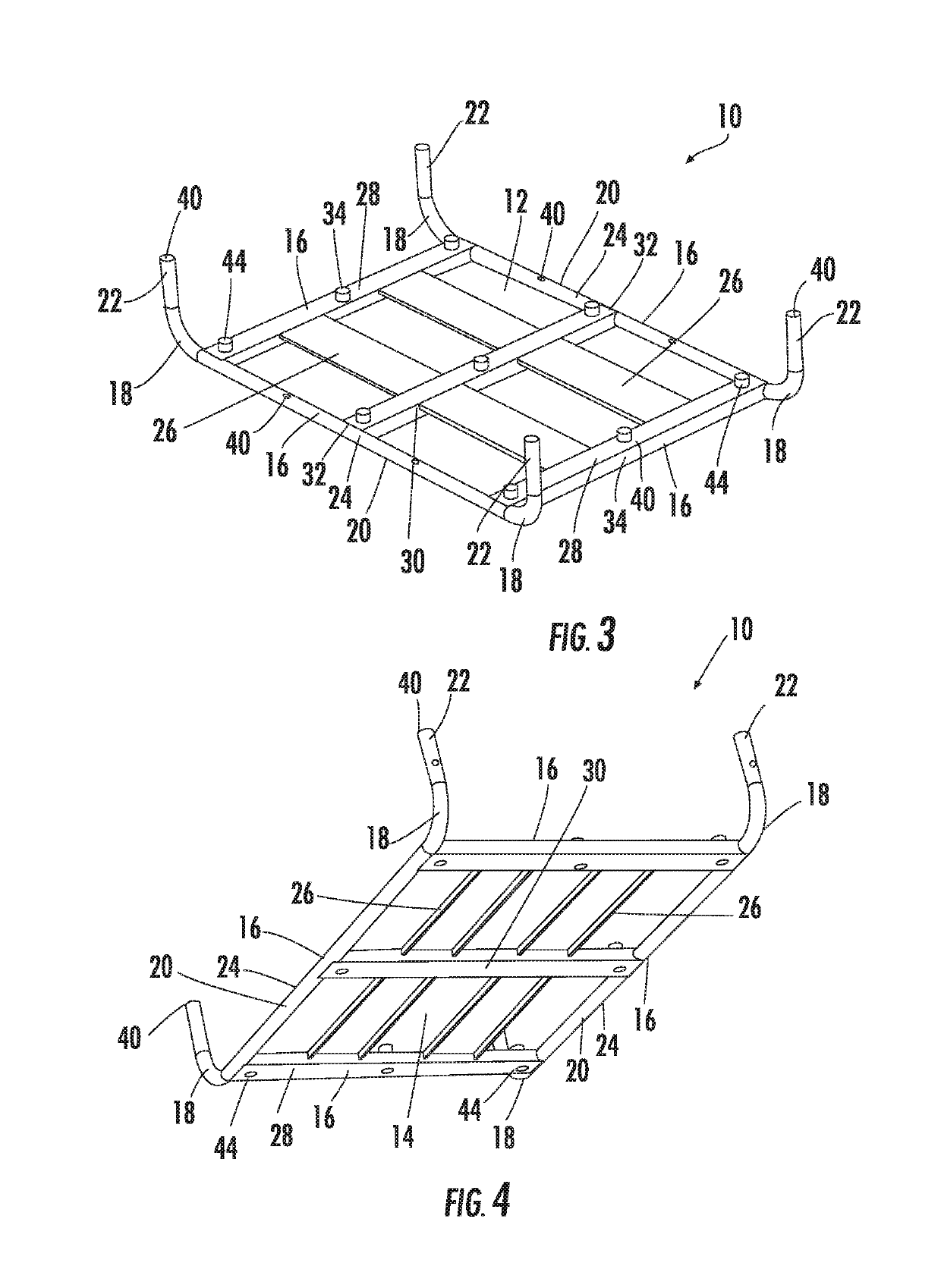

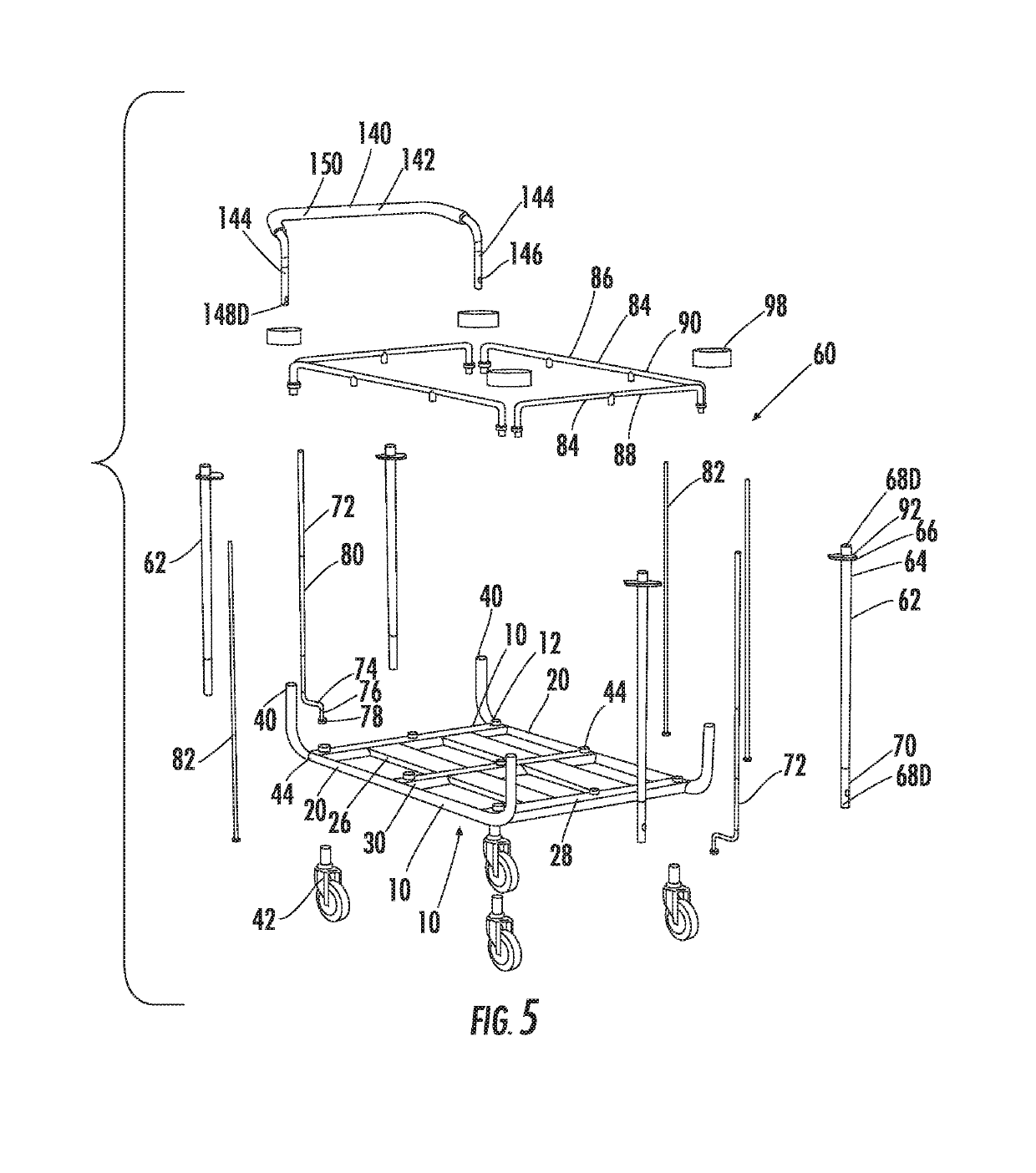

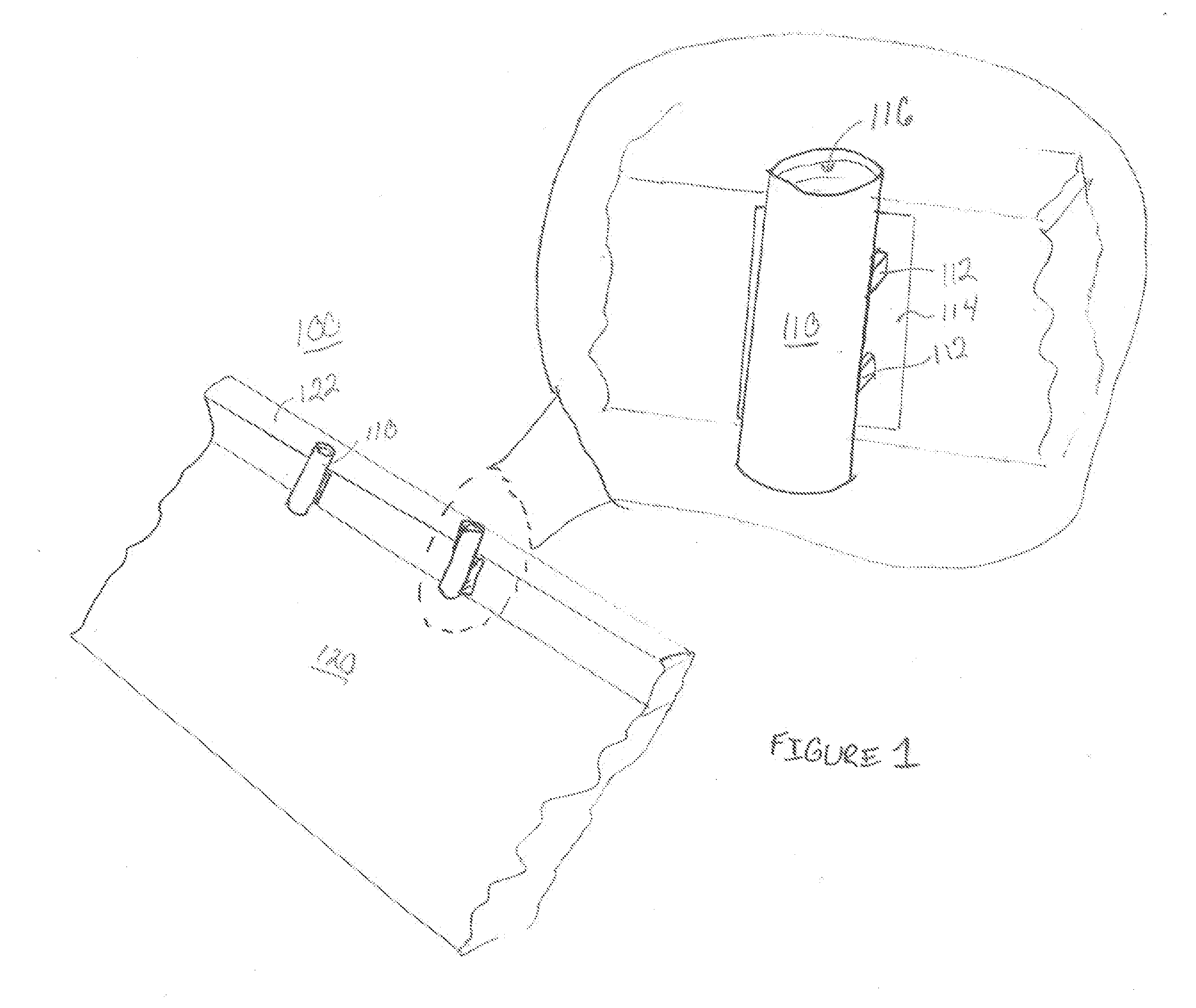

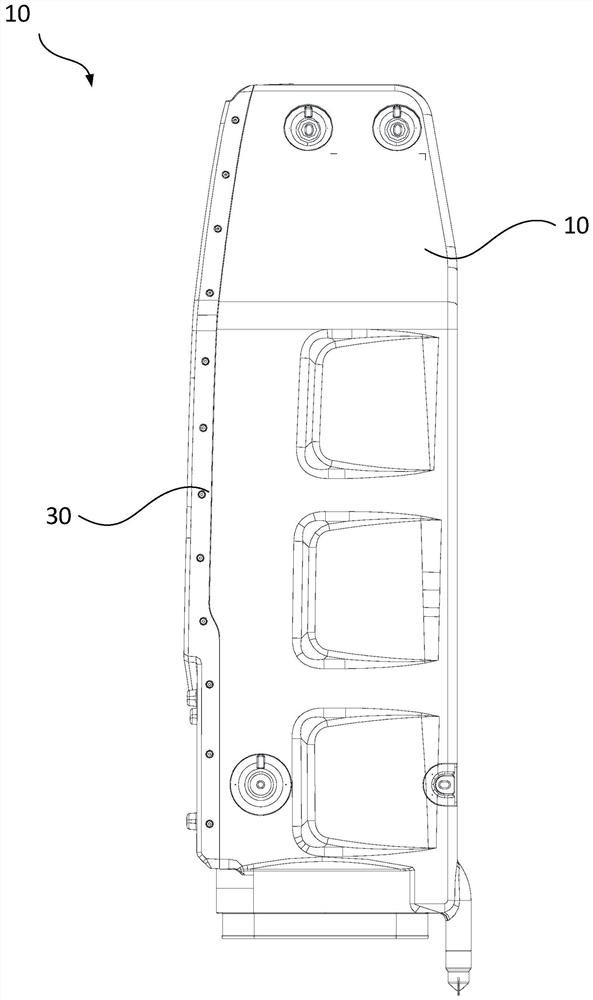

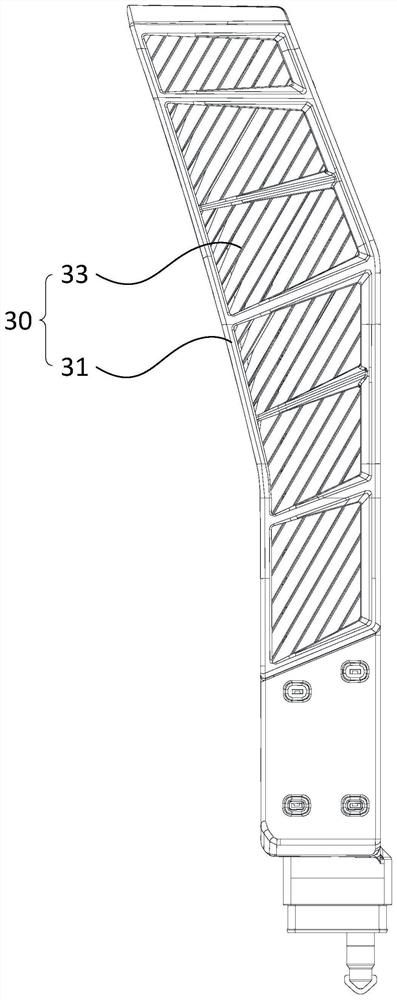

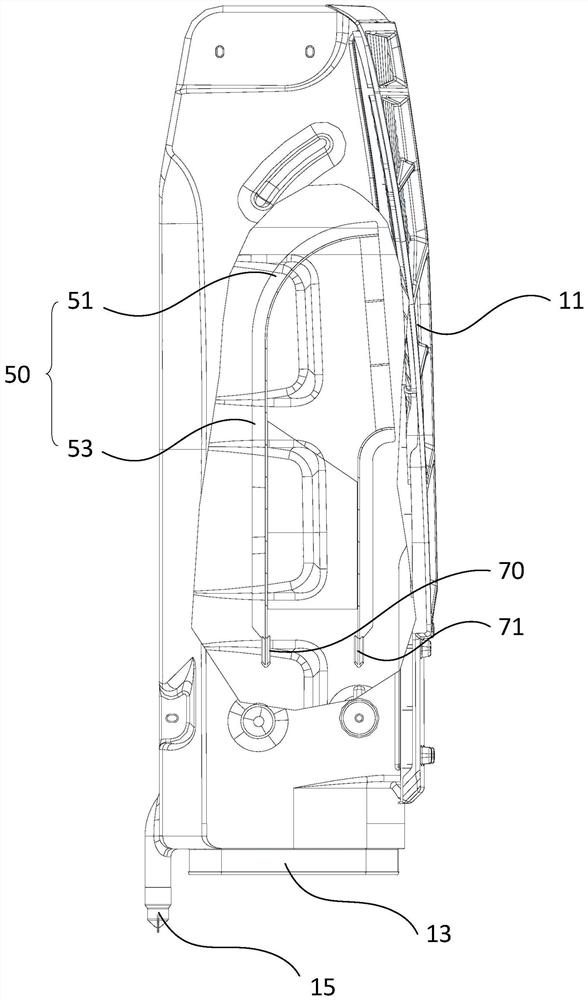

Laundry cart

A laundry cart comprised of a base assembly, casters, steel frame assembly, handle, and fabric hamper body. The quadrilateral base includes a pair of longitudinally spaced U-shaped members interposed between a pair of longitudinal slats and a plurality of transverse slats fixed together in a common lattice fashion. The steel frame assembly is comprised of uprights along the periphery of the base platform, which includes offset uprights and corner uprights. The corner uprights are attached above the base, thereby reducing the shear stress on the laundry cart. The Z-shaped offset uprights allow all the uprights on the short side and long side of the cart to be on the same plane. The hamper body is sized and configured to seat within the uprights and crossmembers. The hamper body includes reinforced trim along the top periphery, which is constructed of a sewn soft rubber to prevent scuffing and damage to walls and doors.

Owner:SUNCAST TECH

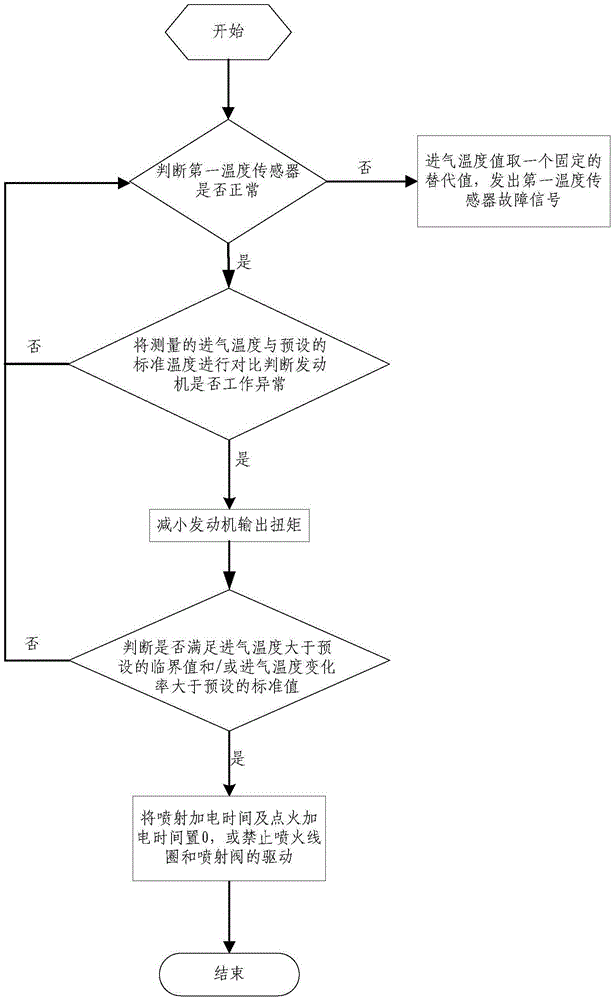

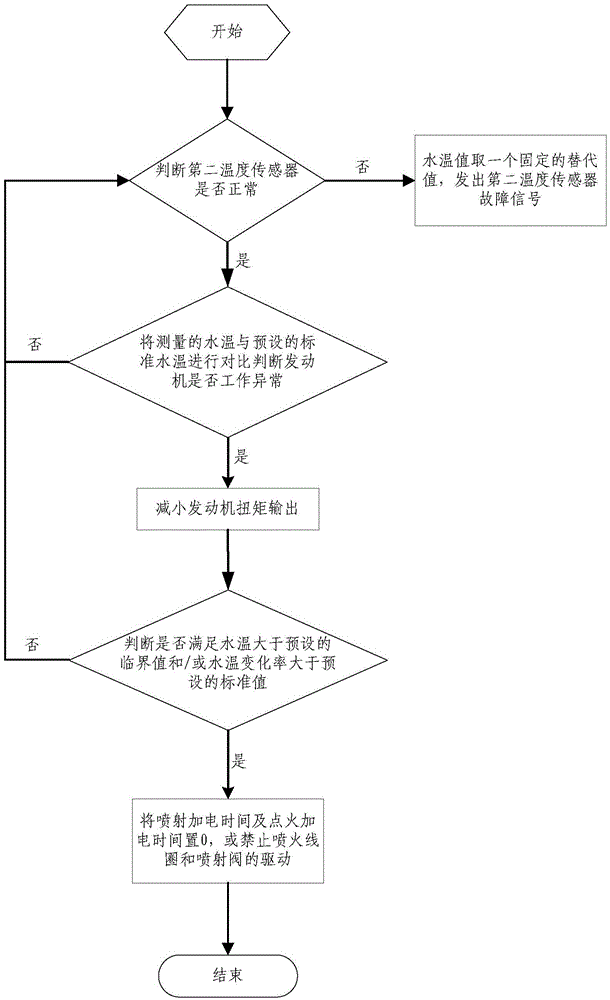

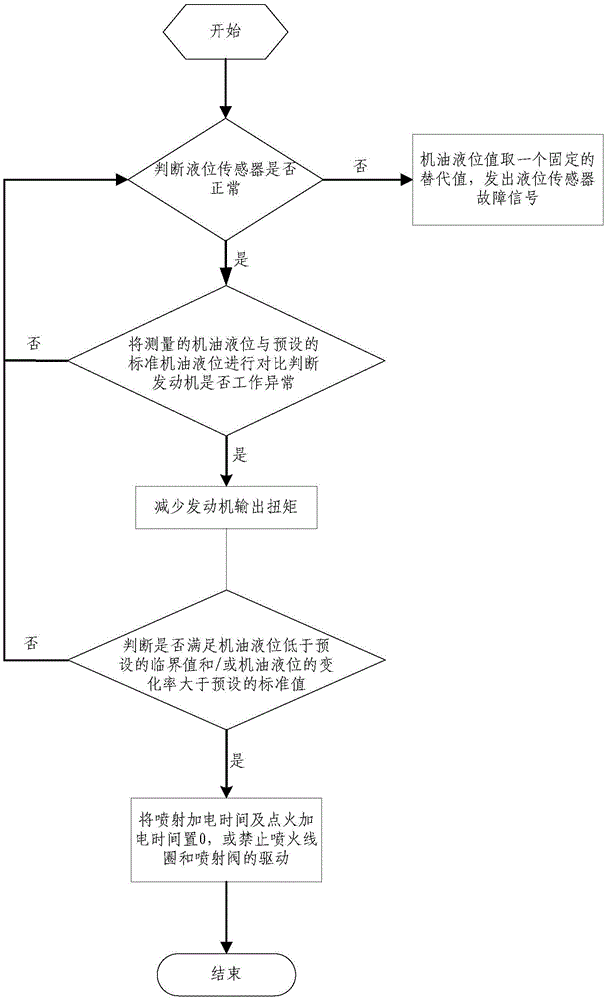

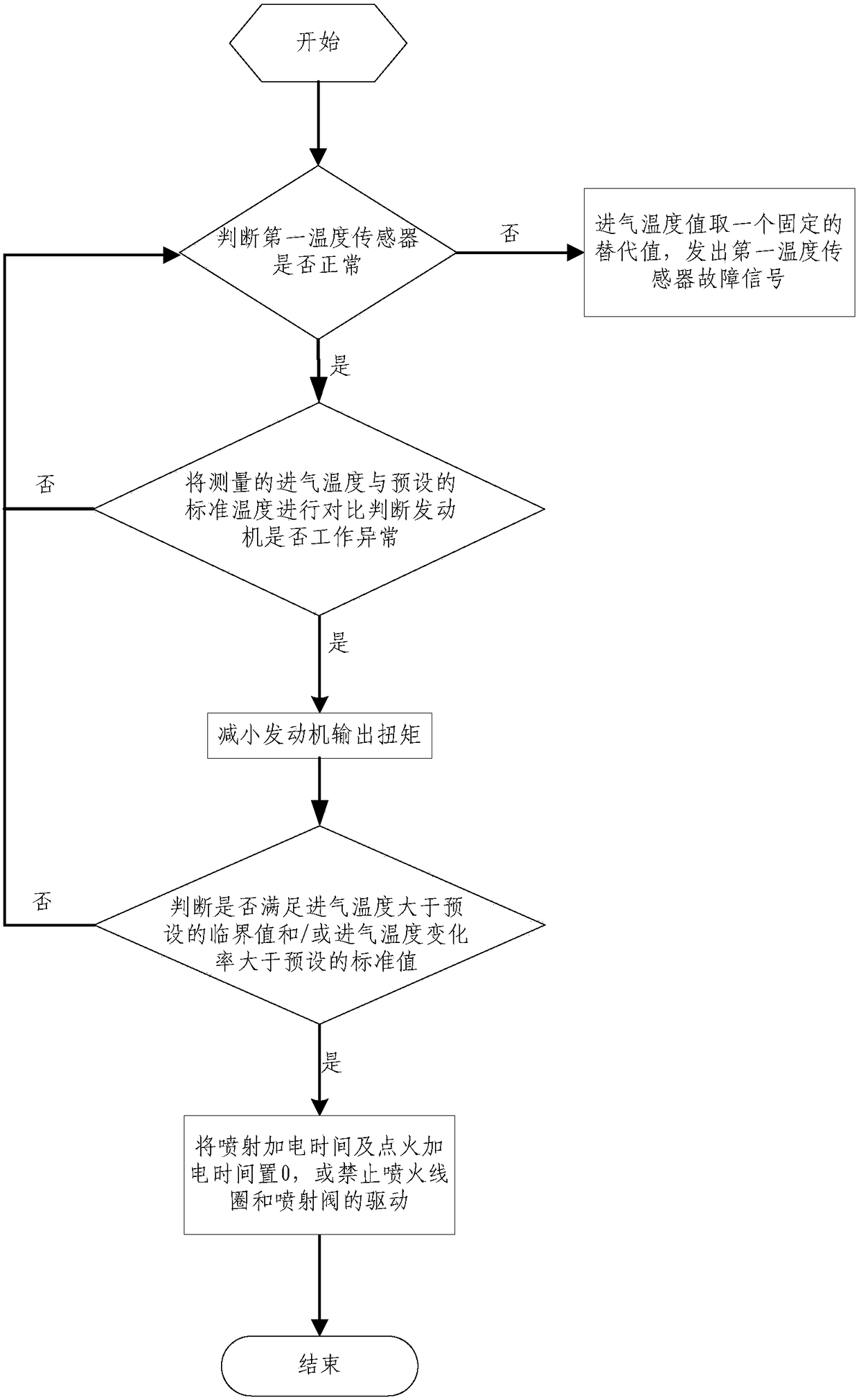

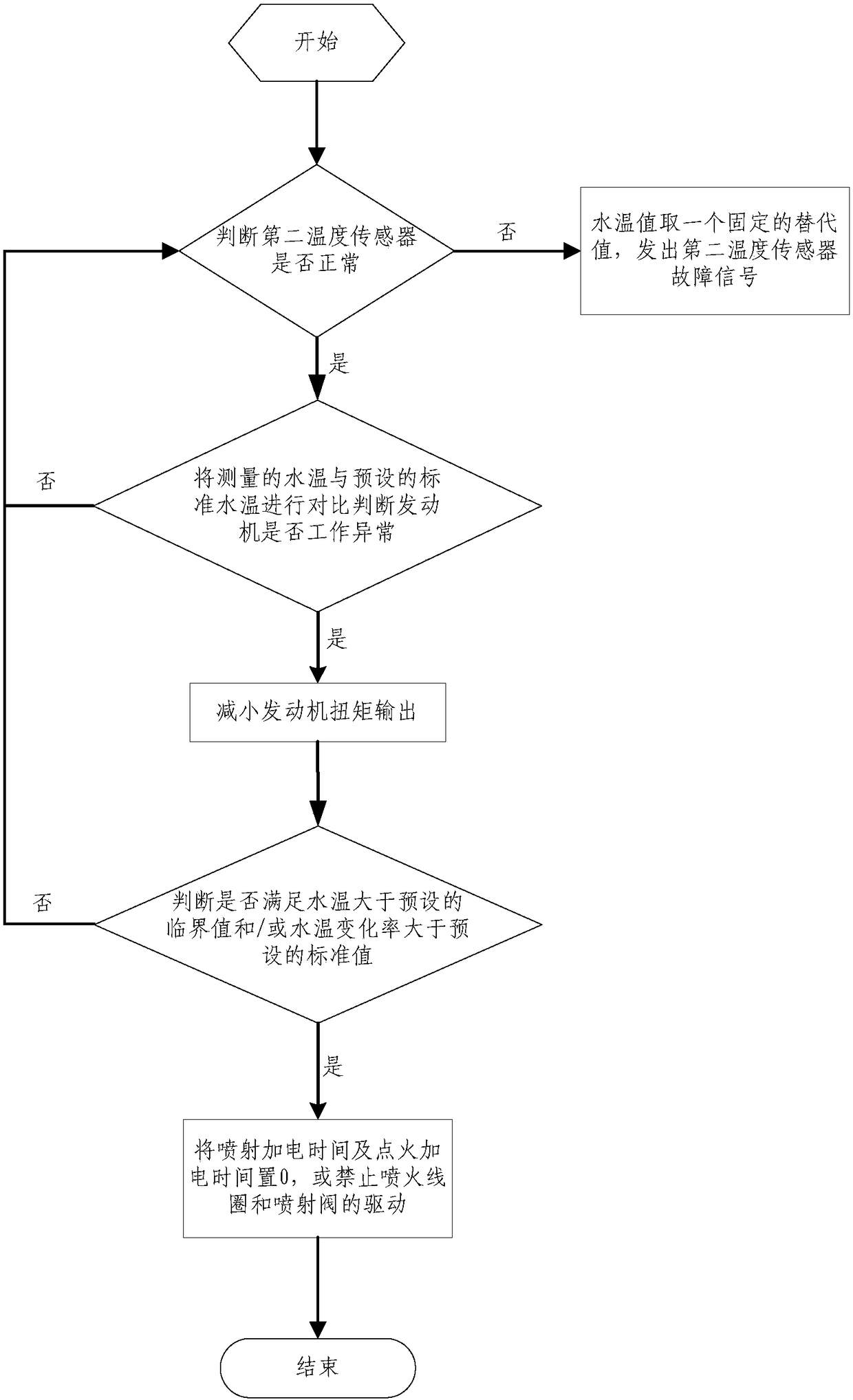

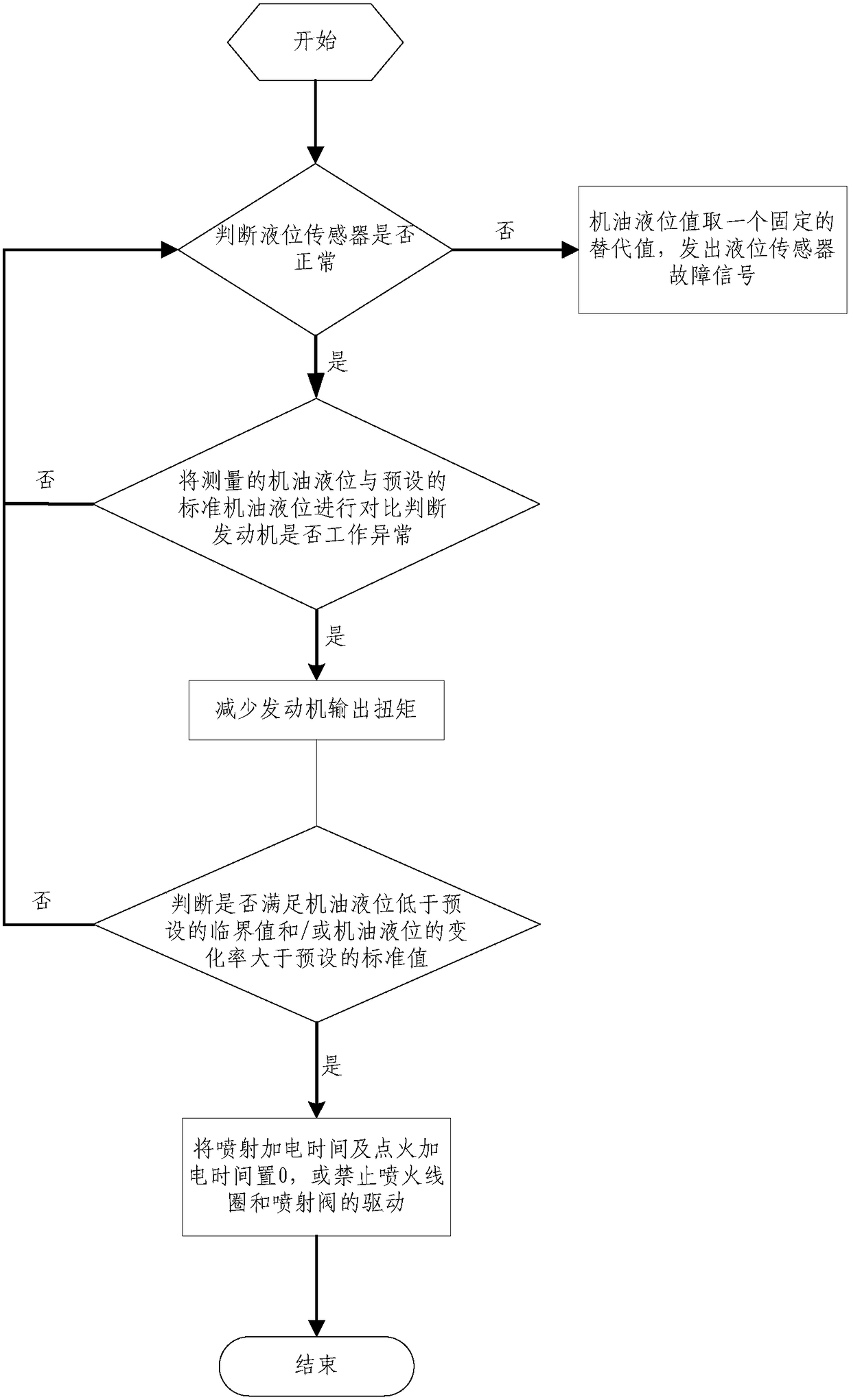

Method for preventing engine cylinder scoring

The invention relates to the technical field of automobiles, in particular to a method for preventing engine cylinder scoring. According to the method for preventing engine cylinder scoring, whether an engine fails or not is judged by measuring performance parameters of the engine; when it is judged that the engine fails according to the performance parameters of the engine, the output torque of the engine is limited first; and after the output torque of the engine is reduced, when the abnormal situation of the engine is still not improved or eliminated, the engine is directly turned off. According to the method, the situation that the gas inlet temperature, water temperature and lubrication situations of the engine become abnormal within a short period of time due to burst problems such as intercooler and throttle valve blockage, fan faults and engine oil leakage is considered, and it is effectively avoided that cylinder scoring happens when this type of situations happen to the engine.

Owner:WEICHAI POWER CO LTD

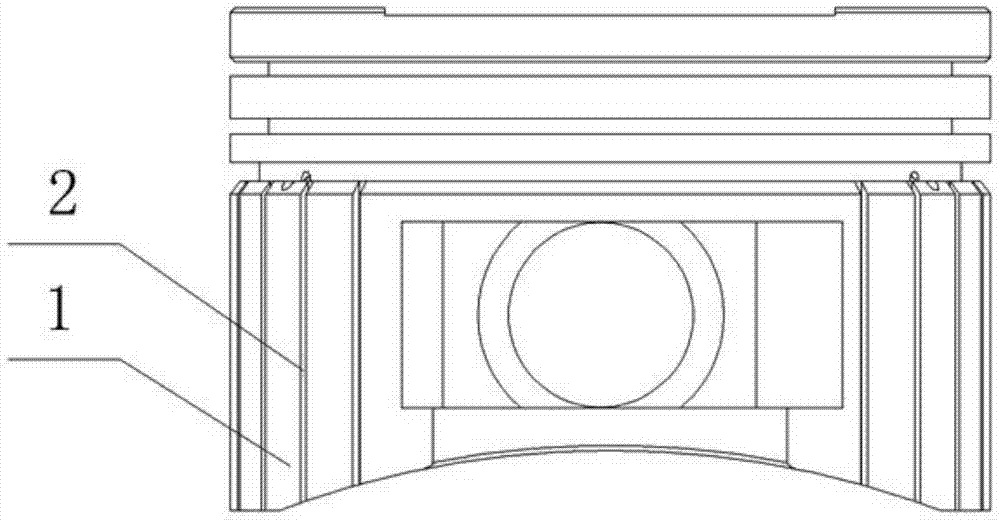

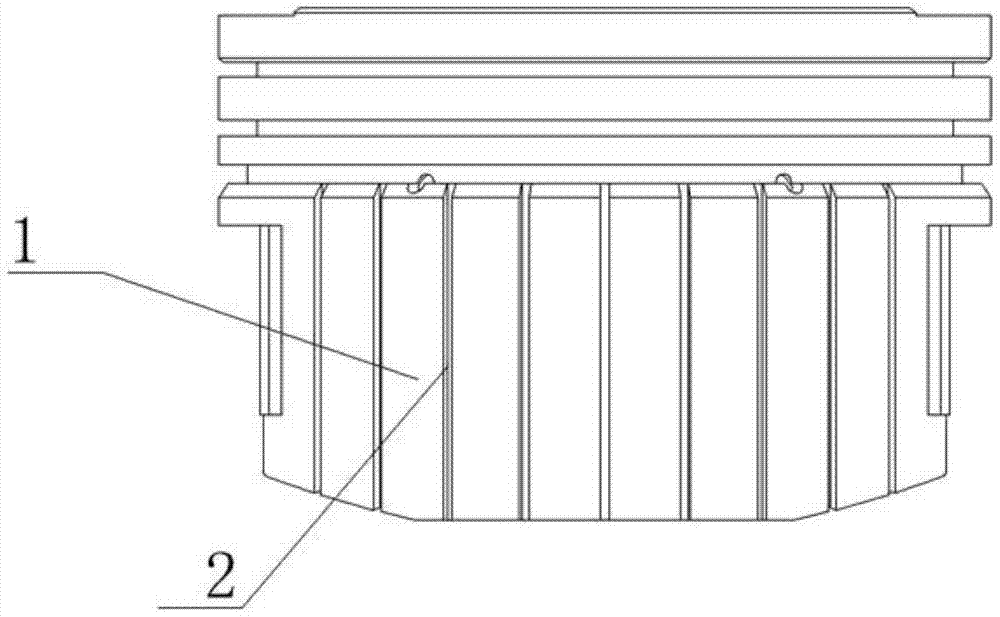

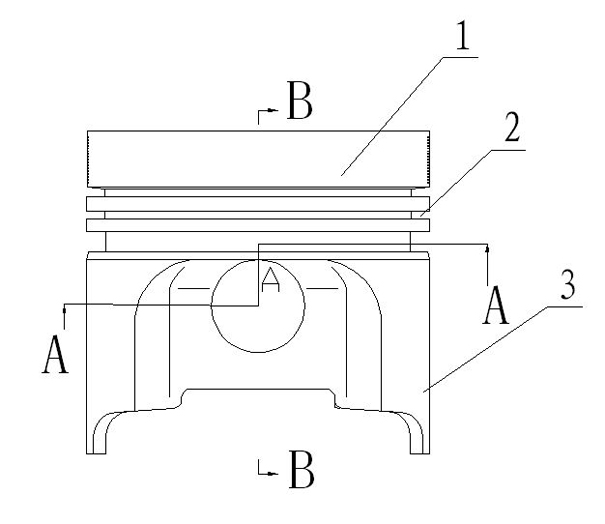

Wear-resistant piston head

The invention discloses a wear-resistant piston head used in the technical field of internal combustion engines. A pin shaft hole transversely penetrating the piston head is formed on the piston head, a plurality of piston ring grooves are formed above the pin shaft hole, a piston skirt part is arranged below the pin shaft hole, a radially raised step is arranged between the upper part of the pin shaft hole and the piston ring groove at the bottom, and the diameter at the step is equal to that of the piston skirt part. When the piston head is used, the inner diameter of the corresponding air cylinder is fitted with the diameter at the step, therefore, the diameter at the upper part of the piston is far smaller than the inner diameter of the air cylinder, the purposes of balancing the piston and adjusting the gap are achieved through a piston ring, simultaneously, the upper part of the piston is not in contact with the inner wall of the air cylinder during the working process, even if the operating conditions are bad and the piston is worn, the upper part of the piston can still keep a certain distance with the inner wall of the air cylinder to avoid the phenomenon of scuffing of cylinder bore and eccentric wear, and simultaneously, the piston head is not easily worn.

Owner:JIANGSU YANGGONG POWER MACHINERY

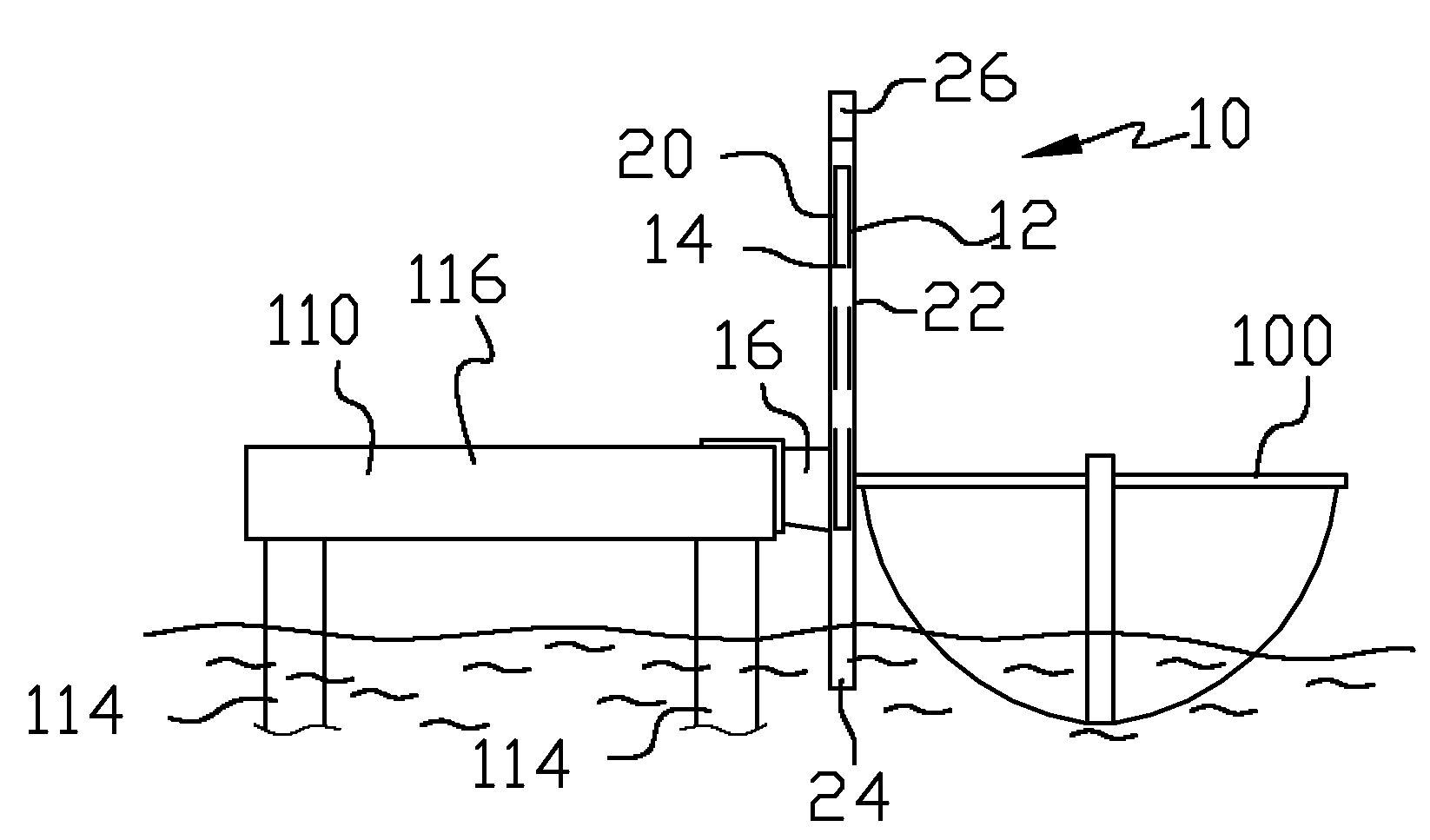

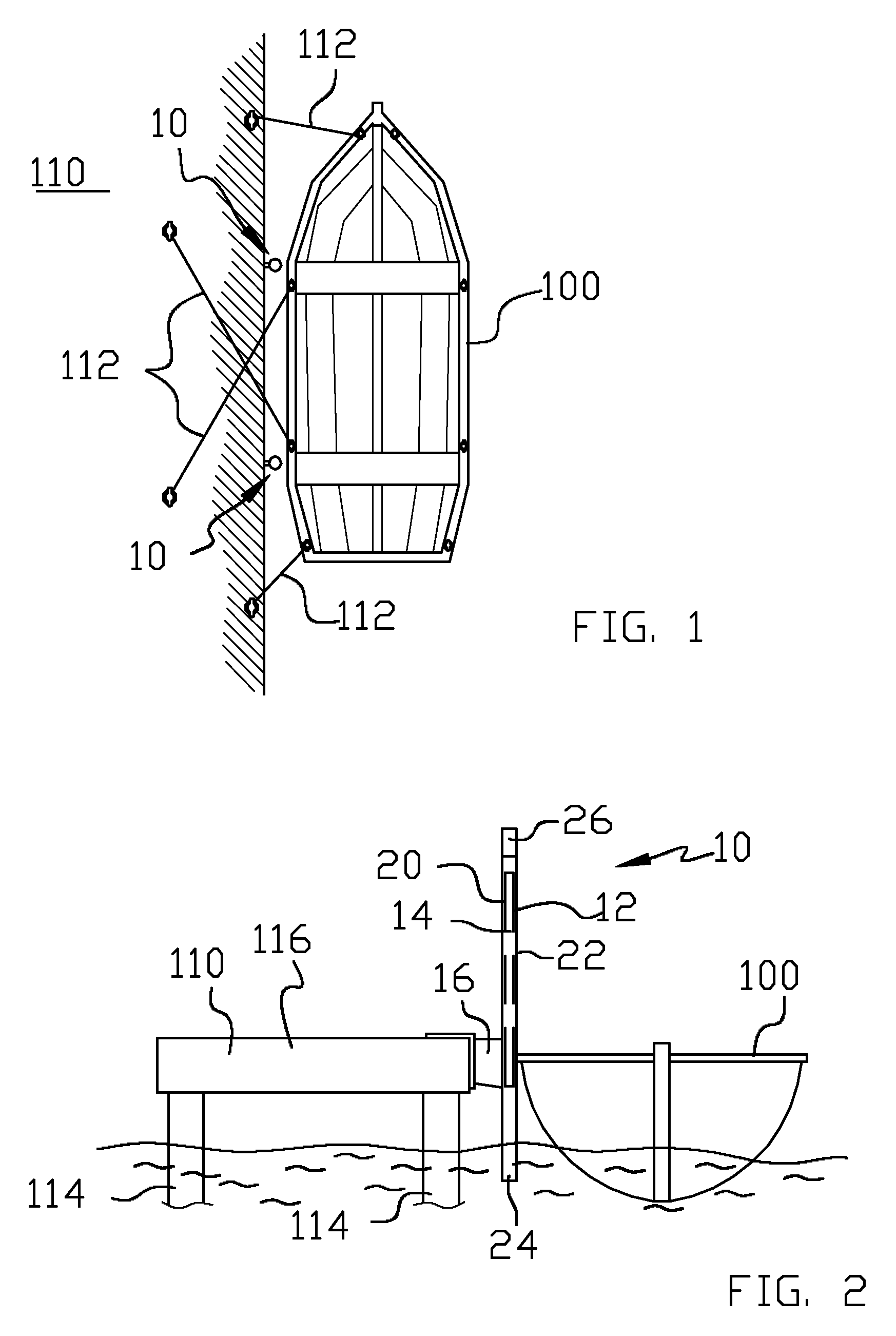

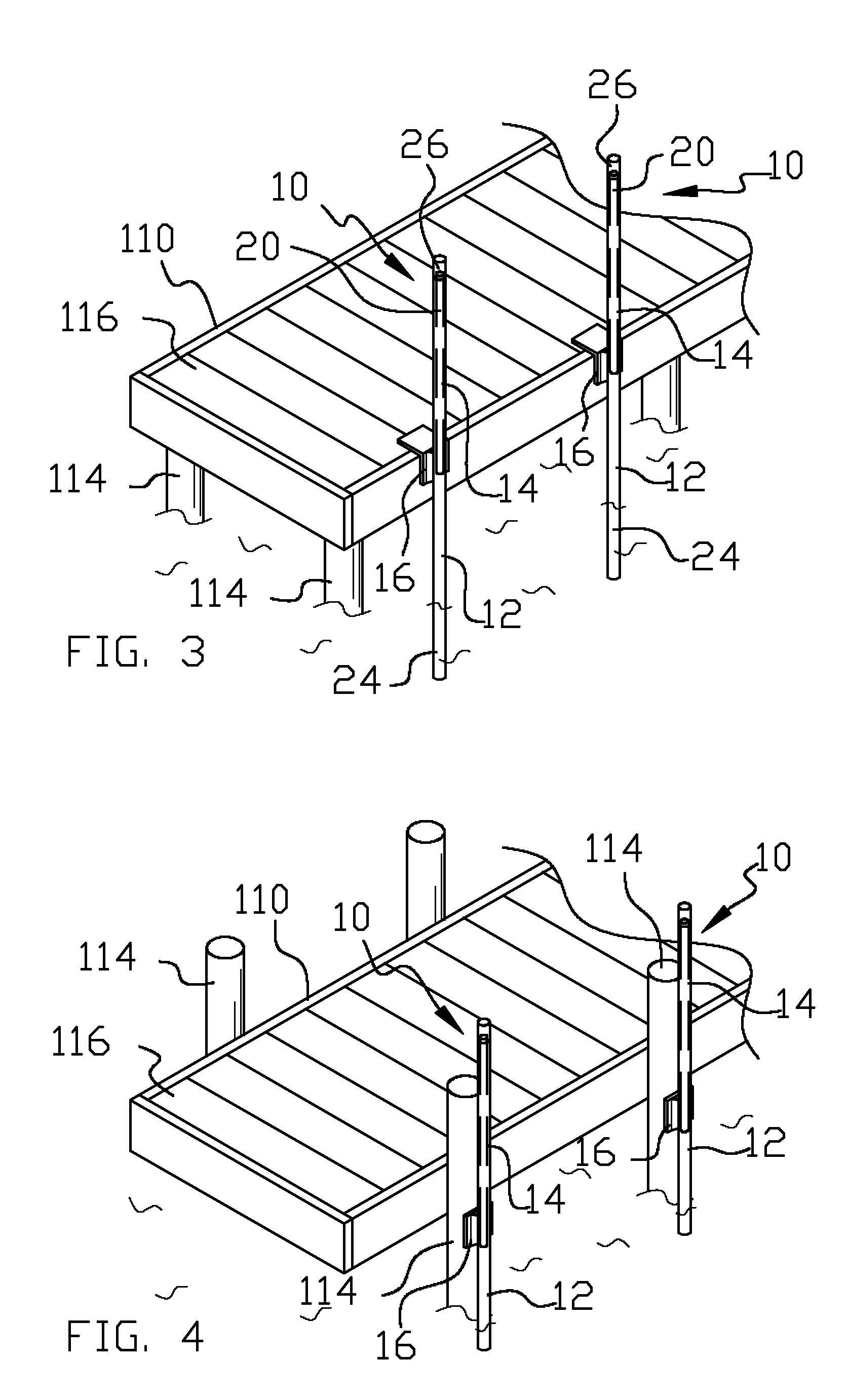

Watercraft hull and gunwale mooring guard

A watercraft hull and gunwale mooring guard for attachment to a mooring structure to prevent abrasion damage to the contact surfaces of a moored watercraft. The mooring guard includes a stationary vertical guide rod that is attached at one end to a mooring structure at an spaced horizontal distance therefrom and extends vertically upward above the mooring structure. A traveler member is slidable attached to the guide rod which when movement of the water causes the watercraft to move up and down, the traveler in contact with the watercraft will correspondingly move up and down and thus prevent hull and gunwale abrasion, scuffing and damage to the watercraft.

Owner:AHLQUIST BRAD

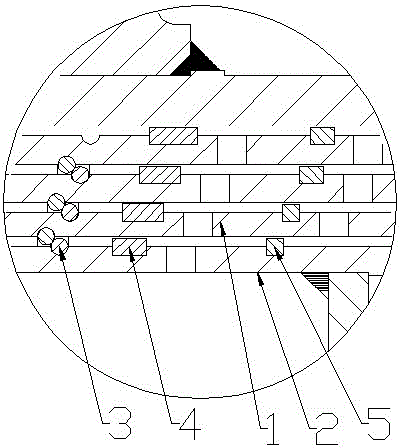

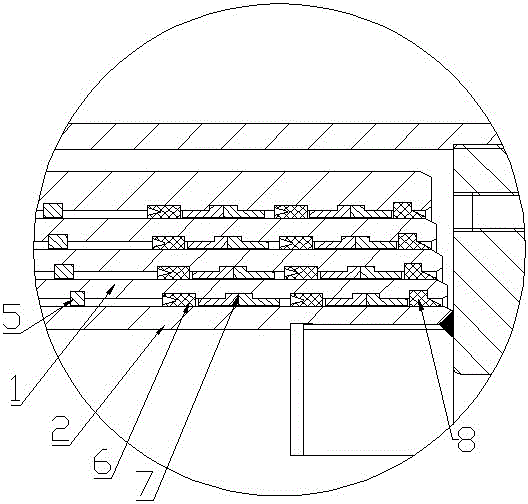

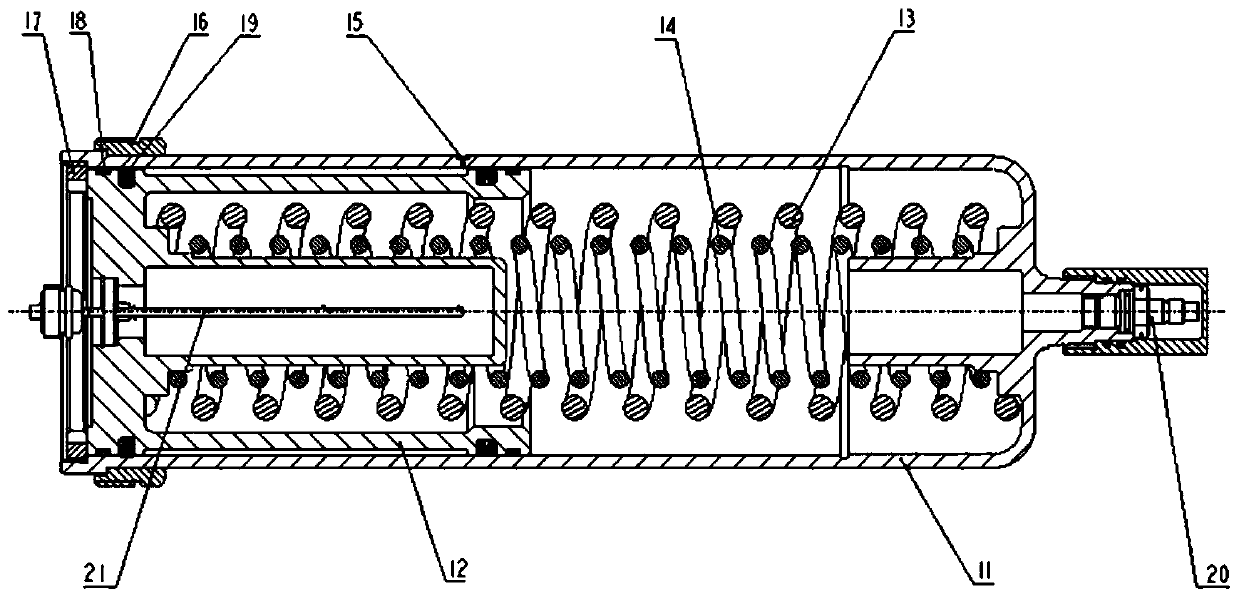

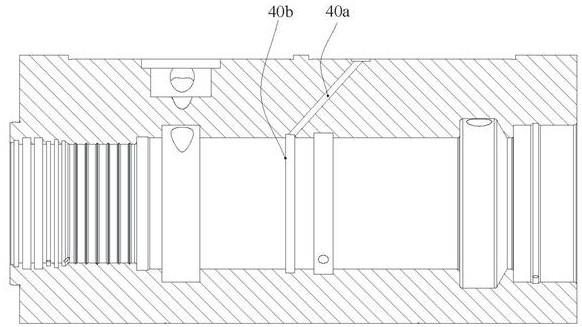

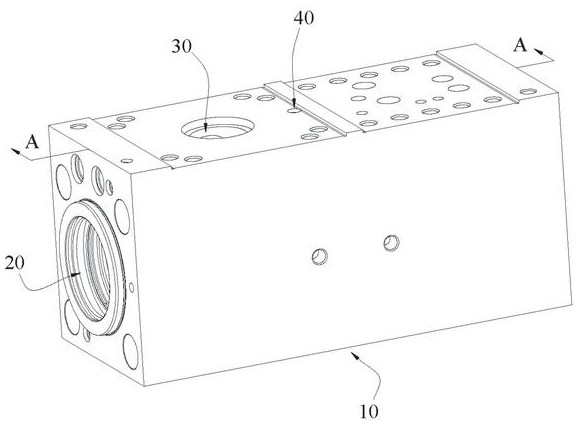

Hydraulic hammer cylinder part

PendingCN110067277AStable supportFit closelySoil-shifting machines/dredgersFluid-pressure actuatorsAxial compressionPiston ring

The invention discloses a hydraulic hammer cylinder part. The hydraulic hammer cylinder part comprises a cylinder body, a piston, a piston ring, sealing parts and a reversing valve. According to the hydraulic hammer cylinder part, a left side piston ring cylindrical section of a leftmost sealing part groove of a piston ring inner hole is lengthened by L1, meanwhile, an oil feeding groove is additionally formed in the lengthened part, and a gap sealing section D is formed on the left side of the oil feeding groove, or one or two sealing part grooves are additionally formed in the left side of the oil feeding groove; and in the working process, high-pressure oil is always introduced into the gap sealing section D or the added sealing part grooves, so that the sealing parts in the sealing part grooves are simultaneously subjected to axial compression force and radial compression force under the action of the high-pressure oil, the sealing parts in the grooves are more tightly matched witha to-be-sealed surface, the great supporting effect is achieved on a postmedian section in the piston, so that the severe loss caused by scoring of the piston and the inner hole due to contact of thepiston and the inner hole of the cylinder is effectively avoided.

Owner:MAANSHAN KAMET HYDRAULIC MASCH MFG CO LTD

Energy-saving and environmentally-friendly piston of internal combustion engine

InactiveCN104763550ASufficient supplyEvenly distributedMachines/enginesPistonsReciprocating motionExternal combustion engine

The invention discloses an energy-saving and environmentally-friendly piston of an internal combustion engine. The piston is that a vertical groove which passes through the whole skirt part is axially formed in the surface of a piston skirt; lubricating oil and grinding chippings can be stored in the groove; lubricating oil can be fully supplied to the piston while moving in a cylinder sleeve by reciprocating, the lubricating oil can be uniformly distributed, so that the frictional heat can be dispersed, the lubricating effect can be improved, the frictional resistance can be reduced, the cylinder can be prevented from pulling and knocking, and as a result, the service lives of the piston and a cylinder can be prolonged; the groove and the piston move in the same direction; the piston skirt part is arranged by a passing manner, so that the piston can be uniformly stressed during moving; meanwhile, stress concentrated at an oil returning hole in a third ring groove of the piston can be unloaded through the groove, and thus the fatigue life of the piston can be prolonged.

Owner:CHANGCHUN INST OF TECH

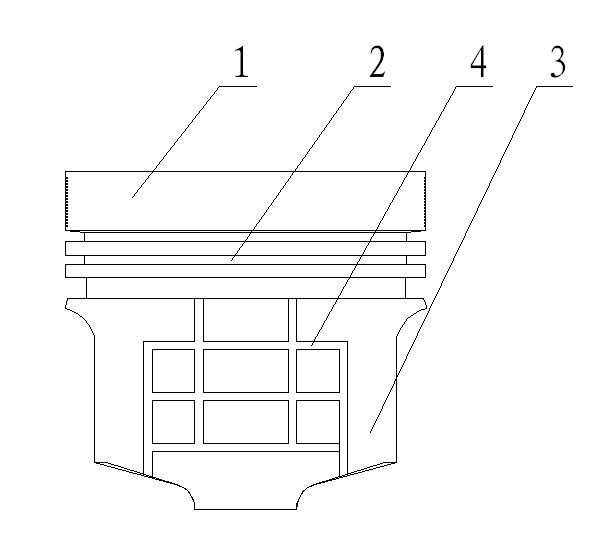

Engine piston capable of saving energy and prolonging service life

ActiveCN106677917AImprove lubrication conditionsAvoid scuffingInternal combustion piston enginesPistonsPistonLubrication

The invention relates to an engine piston, in particular to an engine piston capable of saving energy and prolonging service life based on lubrication improvement, wear resistance and service life prolonging functions. A skirt portion of the piston is divided into a main stress bearing area and a secondary stress bearing area. Parallel vertical indent stripes are evenly distributed on the outer surface of the skirt portion of the piston at equal intervals. The vertical indent stripes comprise first vertical indent stripes and second vertical indent stripes, the first vertical indent stripes are located in the secondary stress bearing area and are of an equally-wide equally-deep groove structure, the second vertical indent stripes are located in the main stress bearing area and are of an equally-wide unequally-deep groove structure, the depths of the second vertical indent stripes are linearly and progressively decreased from the upper portion to the lower portion of the skirt portion of the piston, the vertical indent stripes can store lubrication oil and abrasive dust, lubrication oil can be sufficiently supplied when the piston does reciprocating motion in a cylinder sleeve, distribution is uniform, friction heat is dispersed, the lubrication effect is improved, friction resistance is reduced, piston scraping and piston slap are prevented, and the service life of the piston and the service life of an air cylinder are prolonged.

Owner:CHANGCHUN INST OF TECH +1

Composite surface treatment piston and preparation method thereof

InactiveCN105909418AReduce frictionImprove corrosion resistanceMachines/enginesLiquid/solution decomposition chemical coatingFailure ratePiston ring

The invention belongs to the field of piston processing and relates to piston surface processing, in particular to a composite surface treatment piston and a preparation method thereof. The preparation method comprises two links namely printing an antifriction coating on the piston skirt and tinning the overall piston surface, the composite surface treatment method of printing the antifriction coating on the piston skirt and tinning the overall piston surface is adopted; printing a graphitic layer or a MoS2 layer on the piston skirt effectively prevents piston skirt friction, and tinning the overall piston surface effectively prevents friction between a piston ring groove and a piston ring and friction between a piston land and an air cylinder, so that the corrosion resistance and the anti-attrition lubricity of the piston are enhanced, the anti-seizure property of the air cylinder and the piston is greatly improved, early damage is prevented, the cylinder scoring phenomenon is avoided, a complete machine operates steadily, the failure rate is reduced, and the service life of the complete machine is prolonged.

Owner:QUFU JINHUANG PISTON

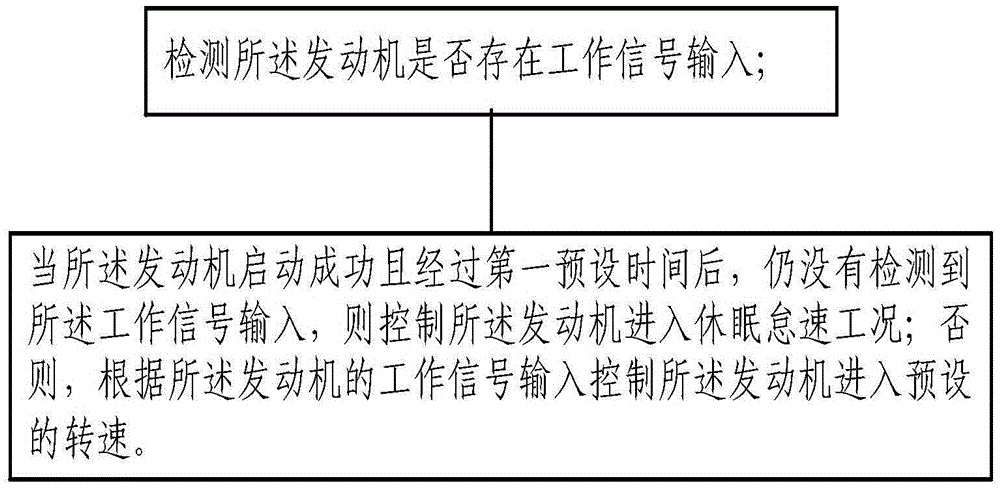

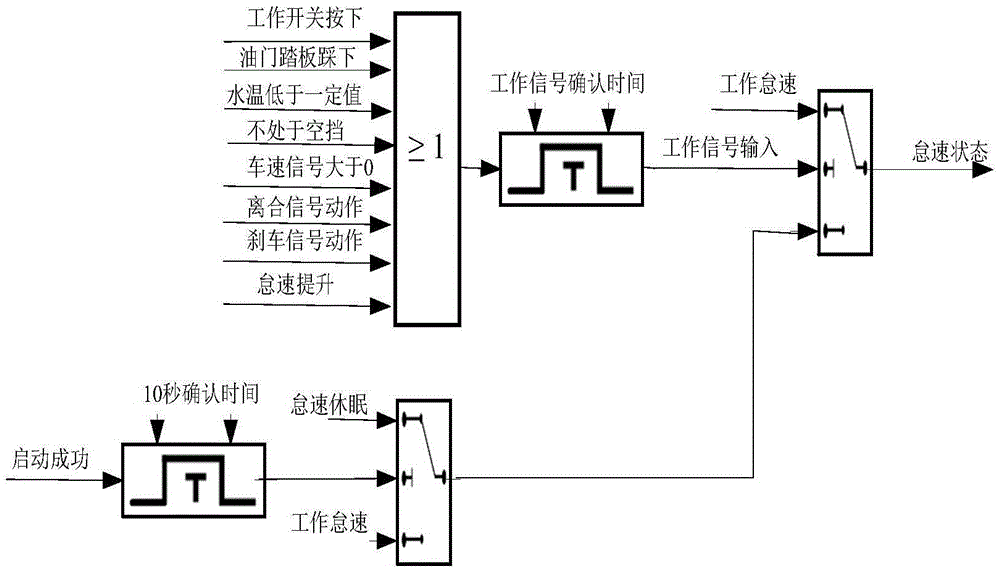

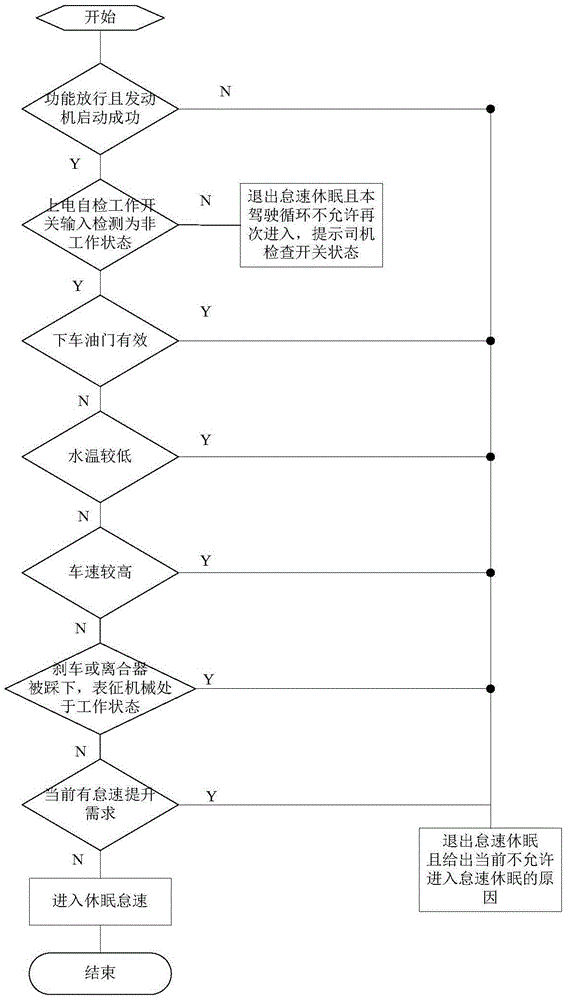

Idling dormancy control method and system for engine

InactiveCN105673230AImprove securitySave footing resourcesElectrical controlMachines/enginesIdle speedDormancy

The invention relates to an idling dormancy control method and system for an engine. The method comprises the steps that whether working signal input of the engine exists or not is detected; if working signal input is still not detected after the engine is successfully started and after a first preset period of time, the engine is controlled to enter a dormancy idling working condition; and otherwise, the engine is controlled to operate at a preset rotation speed according to the working signal input of the engine. By the adoption of the idling dormancy control method and system for the engine, whether the engine is under the working condition or not can be judged by judging whether working signal input exists or not, and accordingly whether an idling dormancy function is achieved or not is judged automatically; and the situation that the idling dormancy function is achieved only through triggering by pressing a switch manually is avoided, so that array position resources of a controller are saved, and an intelligent automatic triggering judgment mechanism is achieved.

Owner:WEICHAI POWER CO LTD

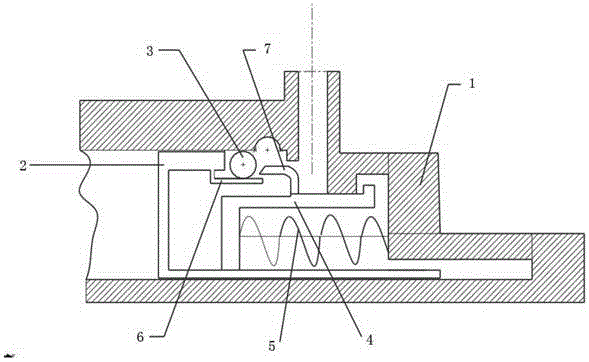

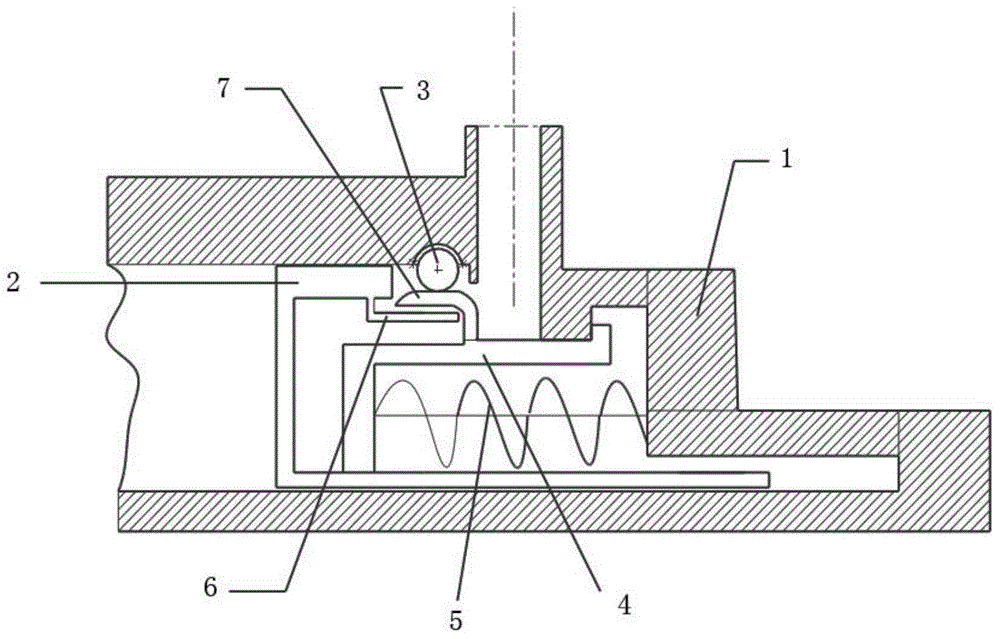

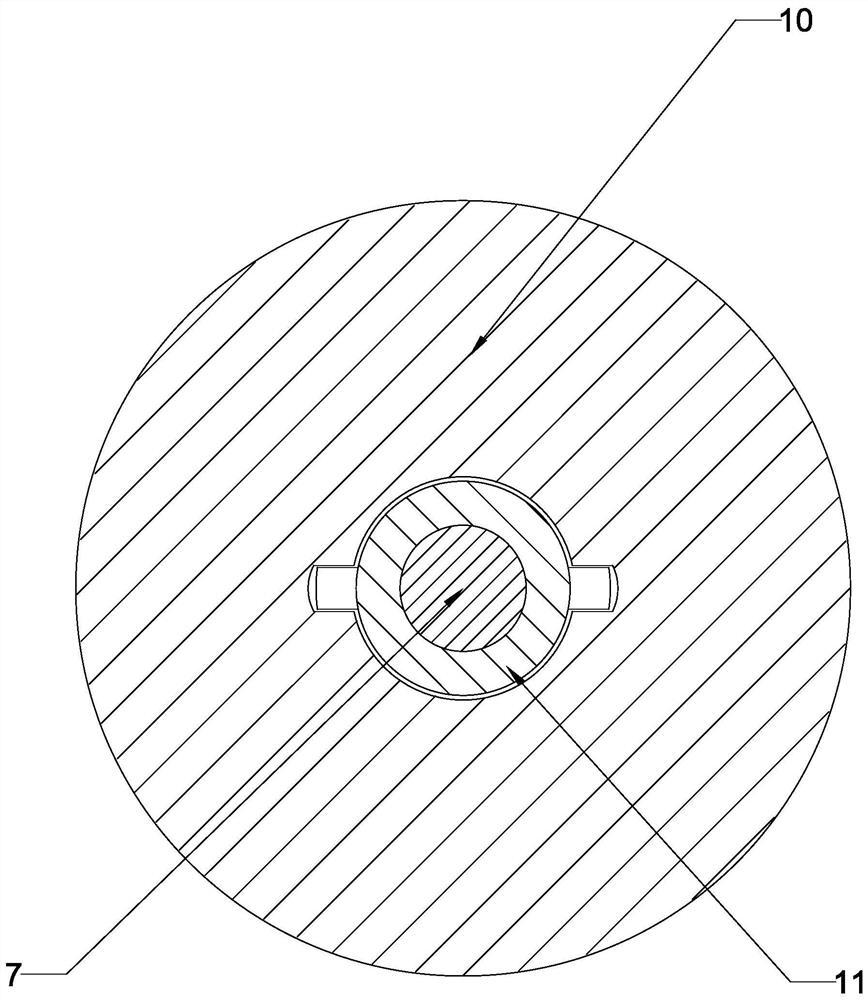

Hydraulic steel-ball locking device for automobile chassis

InactiveCN104553658ASimple structureEasy to operateResilient suspensionsLocking mechanismPiston ring

The invention provides a hydraulic steel-ball locking device for an automobile chassis. The hydraulic steel-ball locking device comprises a piston cylinder with an oil filling hole, a piston, a steel ball, a plunger and a compression spring, wherein a groove is formed in the piston cylinder, the shape of the groove is matched with that of the steel ball, the piston is U-shaped and consists of a piston long segment, a piston short segment and a piston sealing face, a ball placement block is arranged on the piston short segment, the plunger is L-shaped and consists of a plunger long segment and a plunger short segment, the plunger short segment is in sliding connection with the piston long segment, the plunger long segment is in sliding connection with the piston cylinder, a curved face body is arranged on the plunger long segment, a curved face is 1-2cm higher than the ball placement block, one end of the compression spring is connected into the piston cylinder, the other end of the compression spring is connected into the plunger short segment, the elastic force of the compression spring is smaller than the frictional force between the piston and the piston cylinder, and a piston ring and an oil scraping ring are arranged on the piston. The hydraulic steel-ball locking device has the advantage that the problem of the existing locking mechanisms that the structure is complicated or the manufacturing cost is high is solved.

Owner:CHONGQING QUANHAI MACHINERY

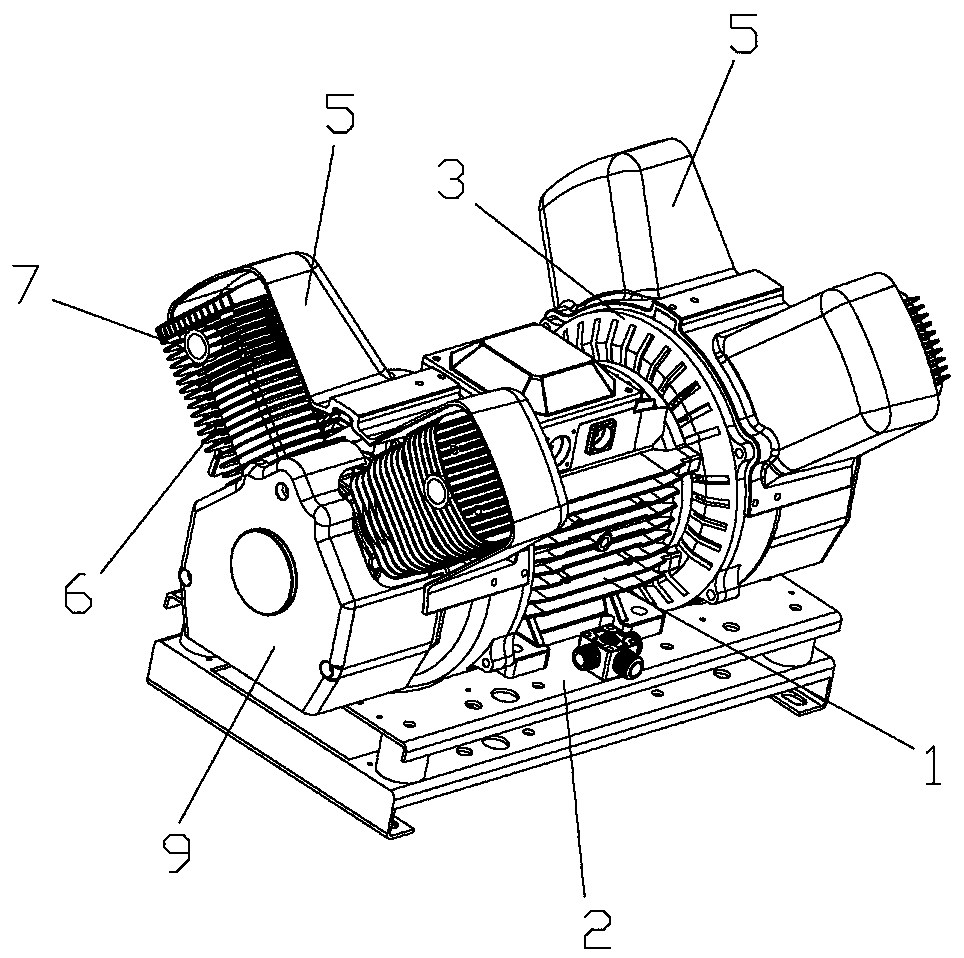

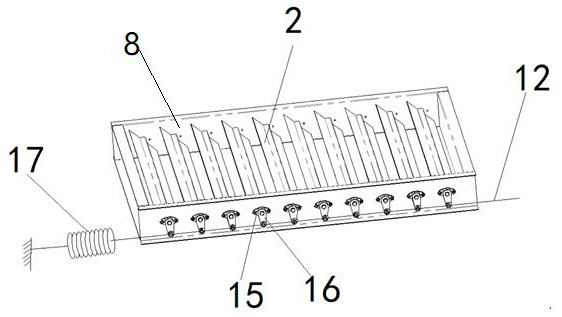

an air compressor

ActiveCN107313923BReduce shakingStable supportPositive displacement pump componentsPiston pumpsPiston ringElectric machinery

The invention relates to an air compressor. Flaky heat dissipation fins are arranged on the surfaces of air cylinders and cylinder covers, and the output end of a motor is connected with a heat dissipation fan. Guide covers are arranged between the heat dissipation fan and the air cylinders and the cylinder covers. The output of the motor drives the fan to conduct heat dissipation on the air cylinders and the cylinder covers meanwhile pressurizing is conducted. According to the air compressor, the heat dissipation efficiency of the air compressor is greatly improved, the exhaust gas temperature can be effectively lowered, thus, the temperature of a piston and a piston ring is also lowered, and the life of the piston ring is prolonged; and in addition, waterproof and dustproof treatment is conducted on the motor, a box body, the air cylinders and the cylinder covers, so that the air compressor has a good waterproof and dustproof grade.

Owner:浙江盛源空压机制造有限公司

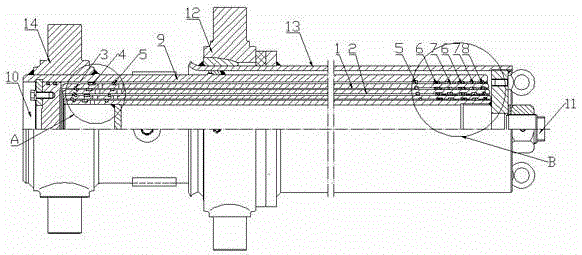

Multi-stage hydraulic oil cylinder with improved structure

InactiveCN105020196AAvoid scuffingAvoid malfunctioningEngine sealsFluid-pressure actuatorsWork performancePolycaprolactone

A multi-stage hydraulic oil cylinder with an improved structure comprises oil cylinder retraction and limiting components, oil cylinder tail end guide rings, oil cylinder lifting limiting components, oil cylinder sealing rings, oil cylinder front end guide rings and dustproof rings. The oil cylinder retraction and limiting components, the oil cylinder tail end guide rings, the oil cylinder lifting limiting components, the oil cylinder sealing rings, the oil cylinder front end guide rings and the dustproof rings are arranged between outer circles of outer oil cylinder bodies and outer circles of oil cylinder bodies of next stages. Each oil cylinder retraction and limiting component is composed of two steel wire check rings, one steel wire check ring of each oil cylinder retraction and limiting component is fixed in an inner annular groove in the tail end of the corresponding outer oil cylinder body, and the other steel wire check ring of each oil cylinder retraction and limiting component is fixed in an outer annular groove in the tail end of the oil cylinder body of the next stage. When the oil cylinder bodies retract and are limited, the two corresponding steel wire check rings are in contact for limiting, and the steel wire check rings are made of 65Mn materials. The oil cylinder tail end guide rings and the oil cylinder front end guide rings are made of polyurethane materials. The oil cylinder sealing rings are double-lip sealing rings made of polycaprolactone materials. The dustproof rings are double-lip dustproof rings made of polyurethane materials. The limiting, guiding and sealing structure of the multi-stage hydraulic oil cylinder is improved, and the work performance of the multi-stage hydraulic oil cylinder is superior to that of an existing multi-stage hydraulic oil cylinder.

Owner:SHIYAN JIEDING CYLINDER MFG

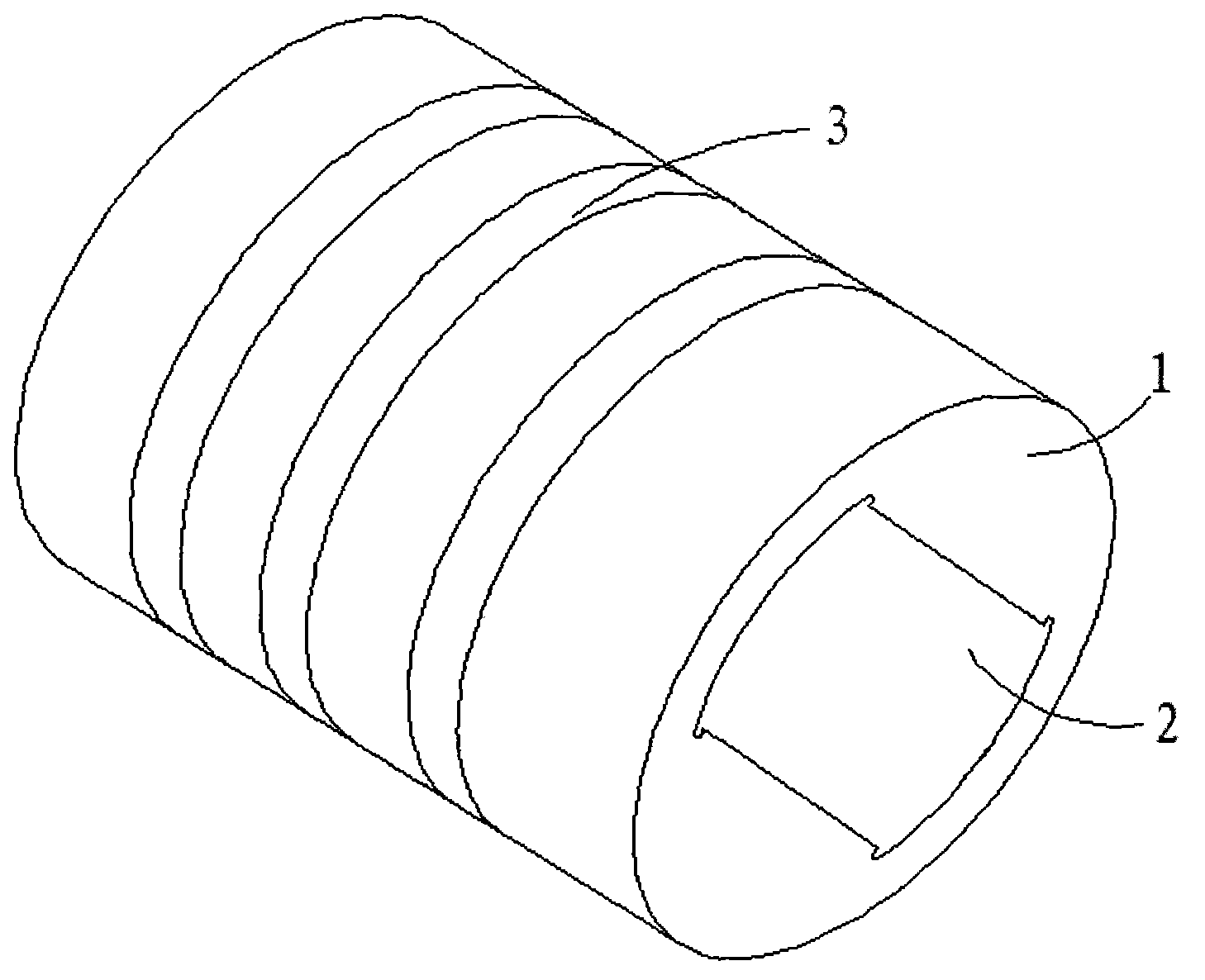

Piston

InactiveCN101846013AAvoid re-injuryAvoid large contact with each otherMachines/enginesPistonsFriction reductionPiston ring

The invention discloses a piston, comprising a main body (1). The main body (1) is provided with a piston ring slot (2) and a skirt section (3), and oil return holes (5) are arranged in the main body (1). The piston is characterized in that the excircle surface of the skirt section (3) is provided with a labyrinth-shaped groove (4) so that the excircle surface of the skirt section (3) forms a plurality of curved surfaces. After the labyrinth-shaped slot is arranged on the excircle surface of the skirt section, when the piston and a cylinder sleeve rub mutually in the movement, a thicker layer of oil film is formed between base kinematic pairs so as to reduce the friction contact surface. The large-area mutual contact of slight convex bodies on metal surfaces can be avoided, and the functions of abrasion resistance and cylinder scraping prevention can be achieved in the maximum degree.

Owner:浙江博瑞车业有限公司

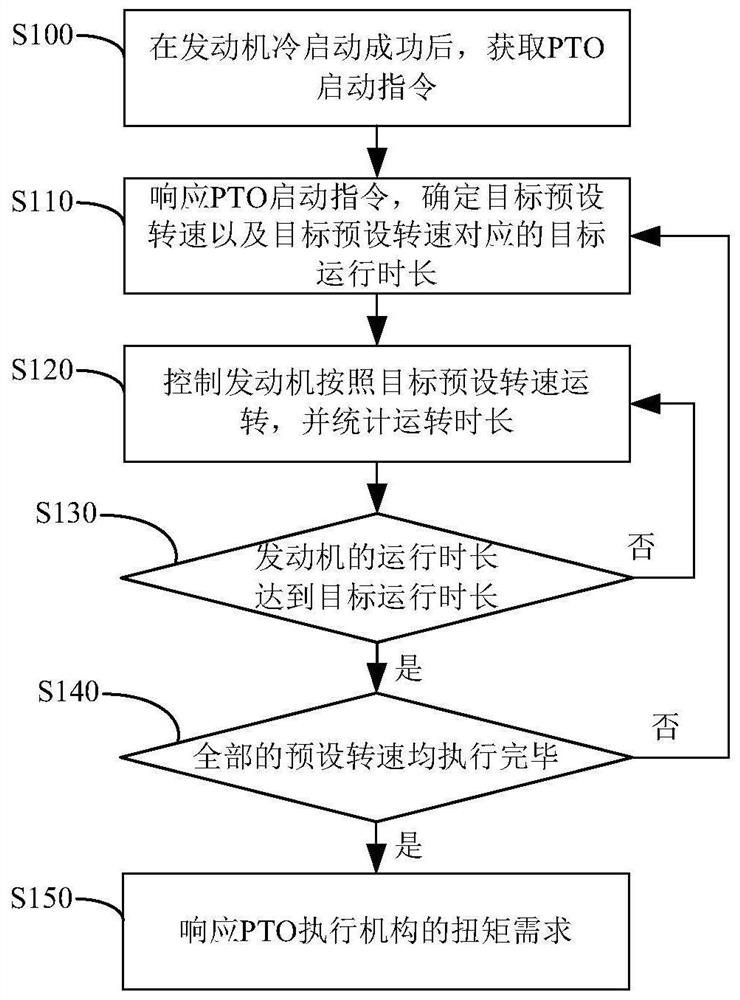

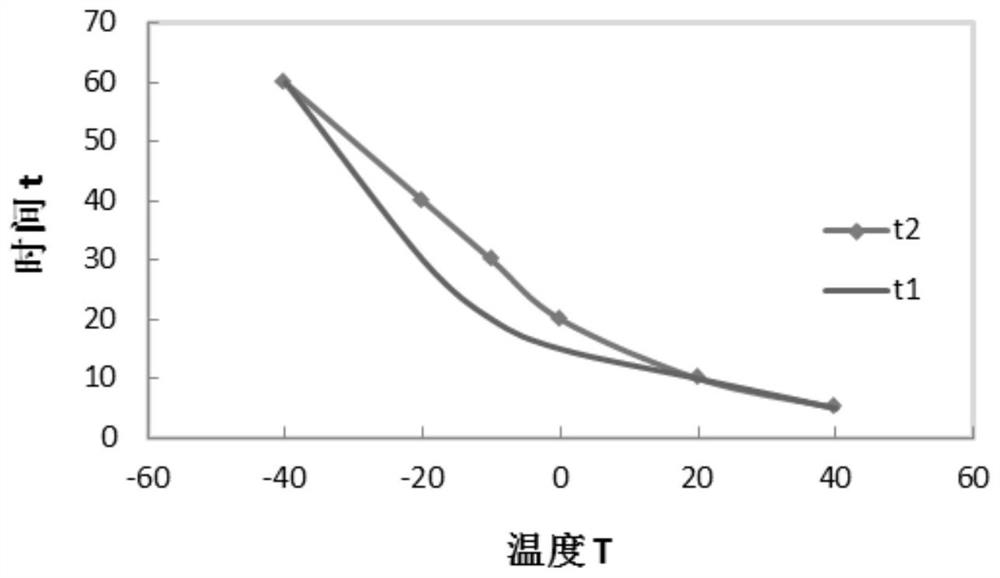

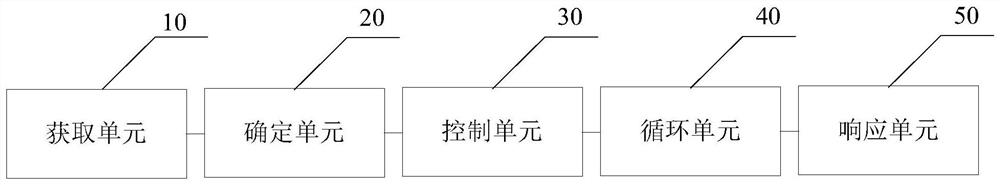

An engine control method and device

ActiveCN110905673BThere will be no problem of rapid increase in speed in a short period of timeAvoid scuffingSpeed sensing governorsMachines/enginesLow speedControl theory

The engine control method and device provided by the present invention are applied in the field of automobile technology. After obtaining the PTO start command, the method controls the engine to run according to the target preset speed, and reaches the target operation corresponding to the target preset speed when the engine is running. After a long period of time, the engine is again controlled to run at the next target preset speed until all preset speeds are executed. Since the target preset speed selected each time is the lowest speed among all preset speeds to be executed at present, it can ensure that the engine speed gradually increases during the entire execution process, and the sum of the running time corresponding to each preset speed is The lubricating system gradually builds up the time corresponding to the oil pressure. Therefore, the problem of rapid increase in engine speed in a short period of time in the prior art will not occur. At the same time, it also allows the lubricating system to have enough time to build up the oil pressure, effectively avoiding engine scuffing. Ensure safe operation of the engine.

Owner:WEICHAI POWER CO LTD

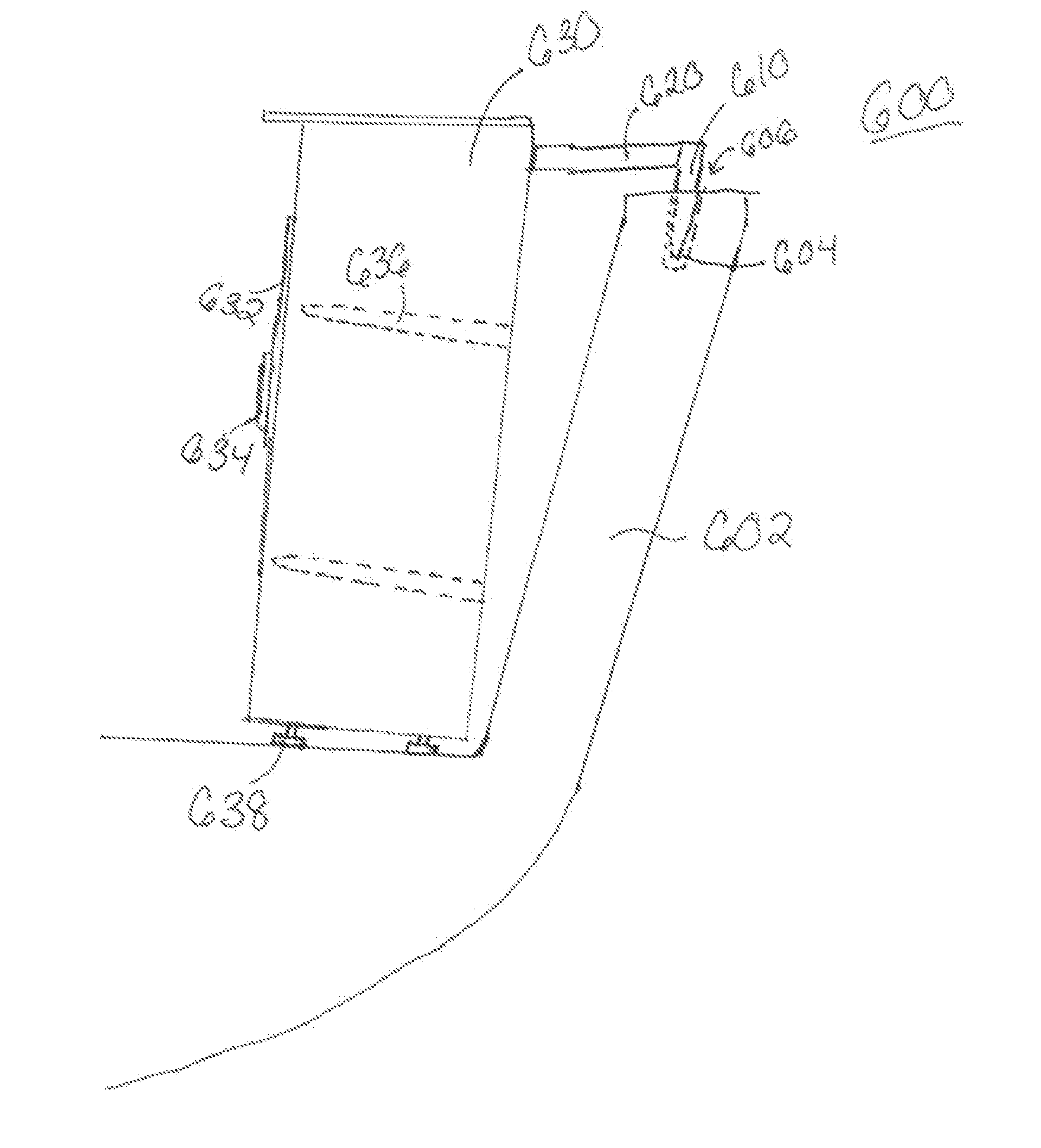

Piston of oil cylinder

InactiveCN104214001AReduce contact surfaceAvoid large contact with each otherMachines/enginesPistonsFriction reductionMechanical engineering

The invention discloses a piston of an oil cylinder. The piston comprises a hollow and cylindrical piston body, one end face of the piston body is closed, a connecting opening connected with a piston rod is formed in the other end face of the piston body, a plurality of annular grooves are formed in the outer circumferential face of the piston body, and the central lines of the grooves coincide with the central line of the piston body. When the piston and a cylinder sleeve rub in the movement process, oil films can be formed in the grooves of the piston so that the friction contact face can be reduced, the piston and the cylinder sleeve can be prevented from being in large-area contact, and therefore the function of resisting abrasion and preventing cylinder scuffing is achieved to the maximum extent.

Owner:WUXI HENGTELI METAL PROD

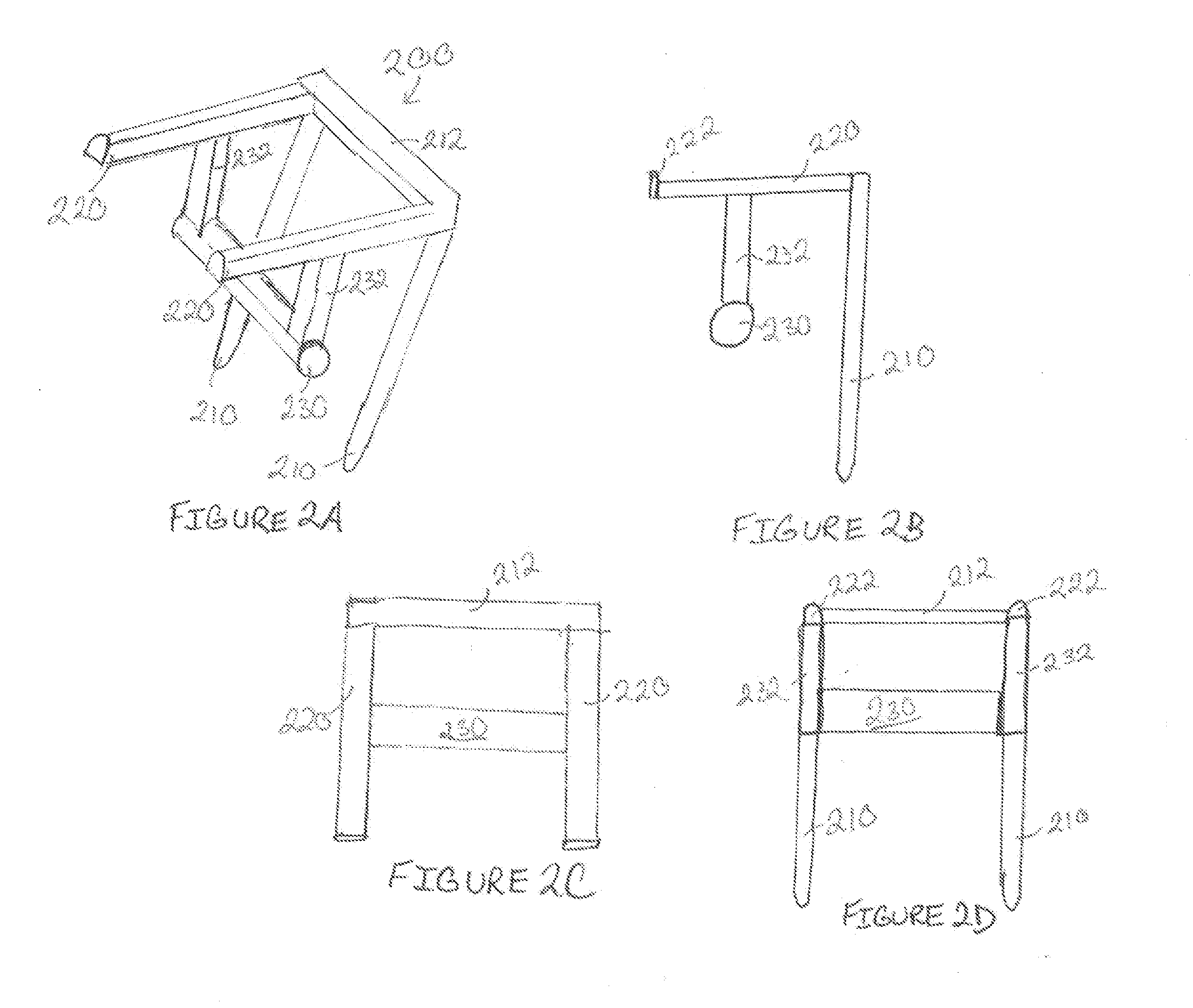

Adaptable rack for aquatic transport of articles

InactiveUS20110303713A1Increase storage capacityAvoid scuffingAccommodation for deck loadsStowing appliancesRocketMechanical engineering

Owner:GRASSO MICHAEL

Air inlet channel assembly

InactiveCN113187633AImprove gas-water separation rateIncrease chance of contactMachines/enginesAir cleaners for fuelInlet channelEnvironmental engineering

The invention relates to an air inlet channel assembly. The air inlet channel assembly is characterized by comprising an air inlet channel body, an air inlet grille and at east one flow guide piece; the air inlet channel body comprises an air inlet and an air outlet; the air inlet grille is arranged at the air inlet; the at least one flow guide piece is arranged in the air inlet channel body and is constructed to be capable of dividing the interior of the air inlet channel body into at least two independent air inlet flow channels; the air inlet end of each air inlet flow channel communicates with the air inlet, and the air outlet end of each air inlet flow channel communicates with the air outlet; each flow guide piece is at least located on a flowing path of airflow flowing in from the air inlet end of the air inlet flow channel where the flow guide piece is located; a water draining opening is further arranged in the air inlet channel body, and the air inlet channel assembly further comprises a drainage piece; and the drainage piece communicates between the air outlet ends of the multiple air inlet flow channels and the water draining opening and located in the gravity direction of water in airflow in the multiple air inlet flow channels. According to the air inlet channel assembly, the contact probability of water in airflow and the wall faces of the flow guide pieces is increased through the flow guide pieces, and the water is drained to the water draining opening through the drainage piece to be drained. Therefore, the water removal efficiency of the air inlet channel assembly is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

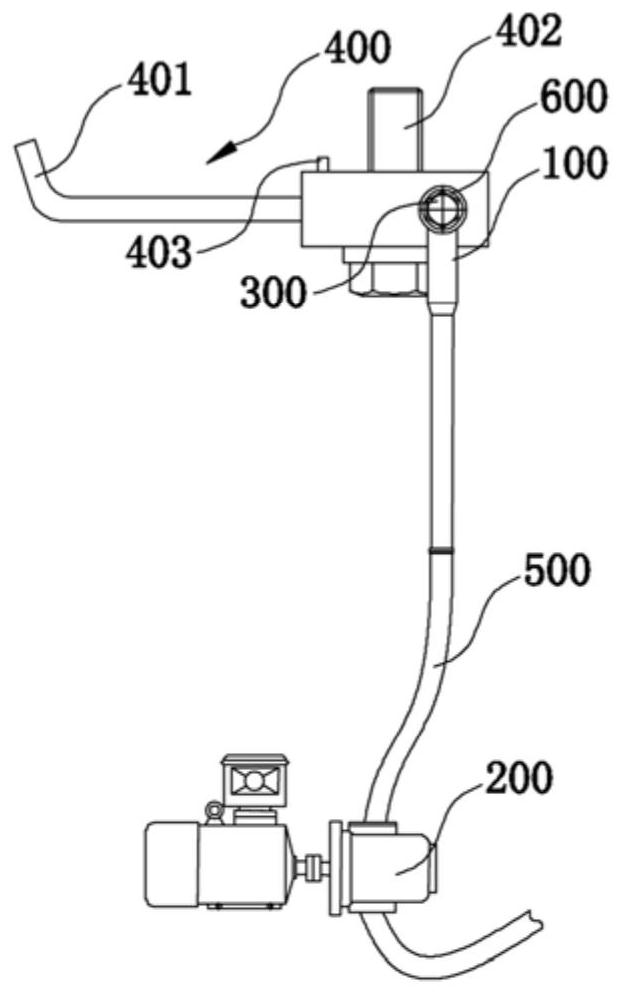

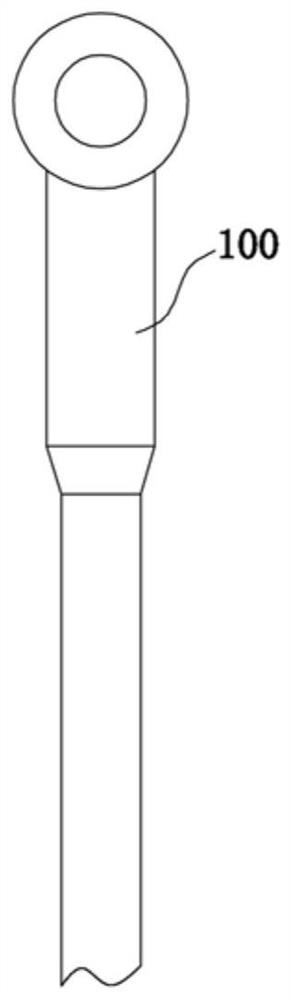

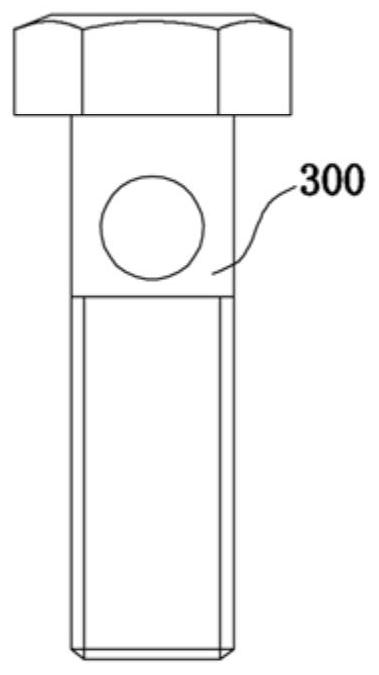

Device and method for inspecting fuel injection status of fuel injector in generator set target shooting test

ActiveCN110848064BGuaranteed uptimeTimely inspectionEngine testingFuel injection apparatusInjector nozzleControl theory

The invention relates to the technical field of generator set testing, in particular to a device for checking the fuel injection status of a fuel injector in a generator set target test, including a high-pressure ball head oil pipe and an oil pump, and one end of the high-pressure ball head oil pipe is connected to the fuel injector through a hollow oil pipe bolt The position of the oil plug; the oil outlet end of the oil pump is connected to the other end of the high-pressure ball head oil pipe, and the pipeline at the oil inlet end of the oil pump leads into the machine oil. A method for inspecting the fuel injection status of a fuel injector in the target shooting test of a generator set, using the aforementioned device for checking the fuel injection status of the fuel injector in the target shooting test of a generator set. This patent can conveniently check the fuel injection status of the fuel injector when the machine is not turned on, which can greatly avoid the problem of the fuel injector causing the unit to pull cylinders, and greatly promote the comprehensiveness of maintenance and the reliability of the equipment.

Owner:HENAN BCCY IND

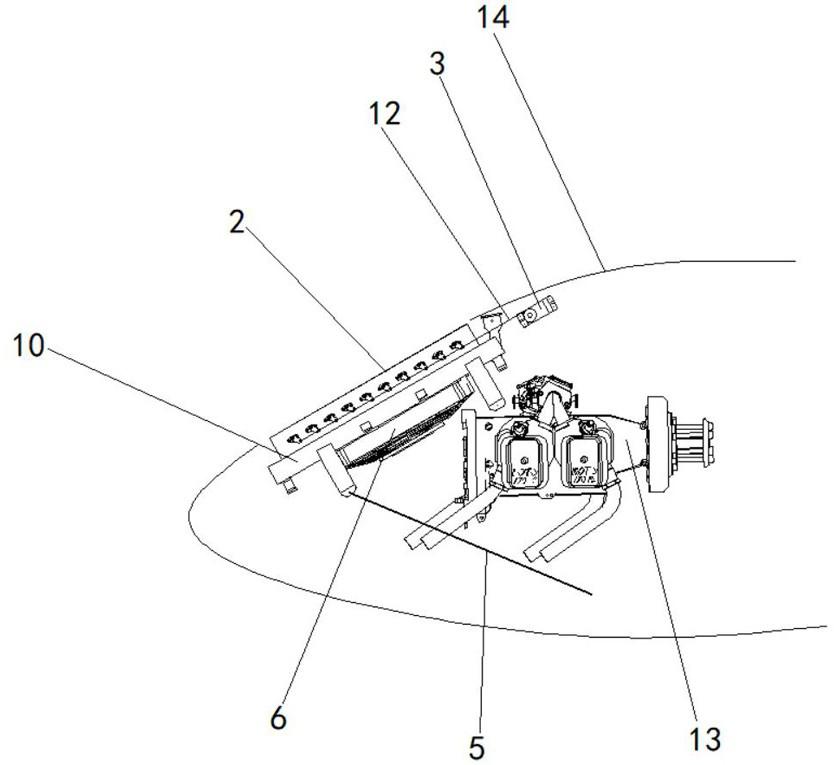

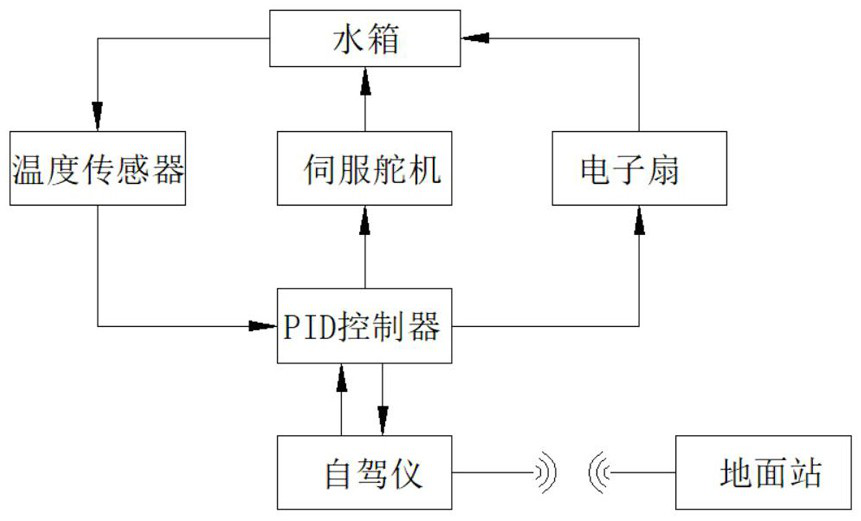

Intelligent temperature control system of UAV engine and its realization method

ActiveCN110318856BReduce loadImprove cooling efficiencyPower plant cooling arrangmentsCoolant flow controlCooling effectHeater Rod

The invention discloses an intelligent temperature control system of an unmanned aerial vehicle engine and an implementation method of the intelligent temperature control system, relates to the technical field of unmanned aerial vehicle engines, and in particular to an unmanned aerial vehicle engine liquid cooling (water cooling and oil cooling) temperature control system and an implementation method thereof. The intelligent temperature control system comprises an intelligent water tank assembly installed on a machine head portion of an unmanned aerial vehicle and a PID controller integrated in an unmanned aerial vehicle self-driving instrument, wherein the intelligent water tank assembly comprises a water tank, a shutter movable assembly arranged at the top of the water tank and an electronic fan arranged at the bottom of the water tank, the water tank is arranged above the engine and is connected with the engine, a temperature sensor is arranged at the water inlet of the water tank,a heating rod is arranged at the water outlet of the water tank, a servo motor in the heating rod, the temperature sensor, the shutter movable assembly and an electronic fan are connected with the PIDcontroller, and the PID controller completes real-time data transmission communication with the ground end through a radio station inside the unmanned aerial vehicle self-driving instrument. The system has the positive effect on improving the cooling effect of the unmanned aerial vehicle engine.

Owner:青岛未来创新高新技术有限公司

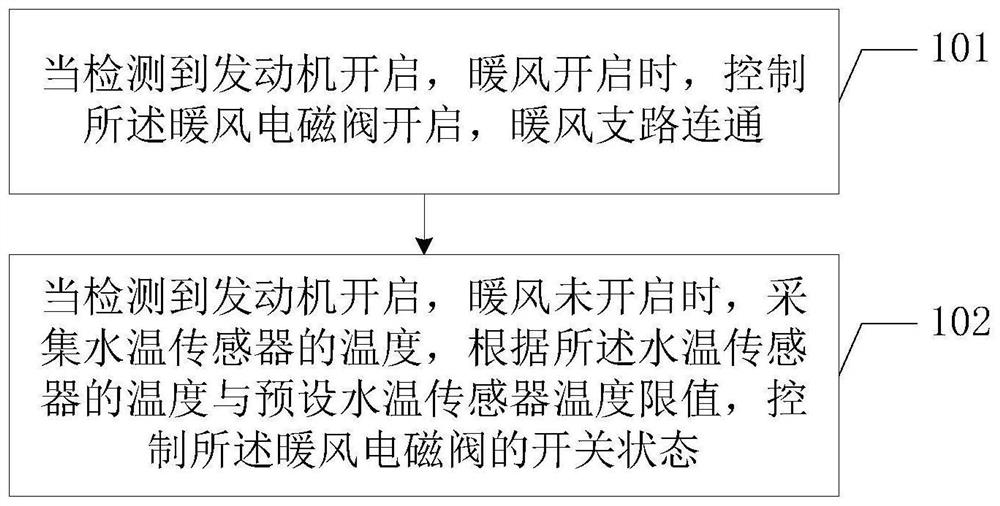

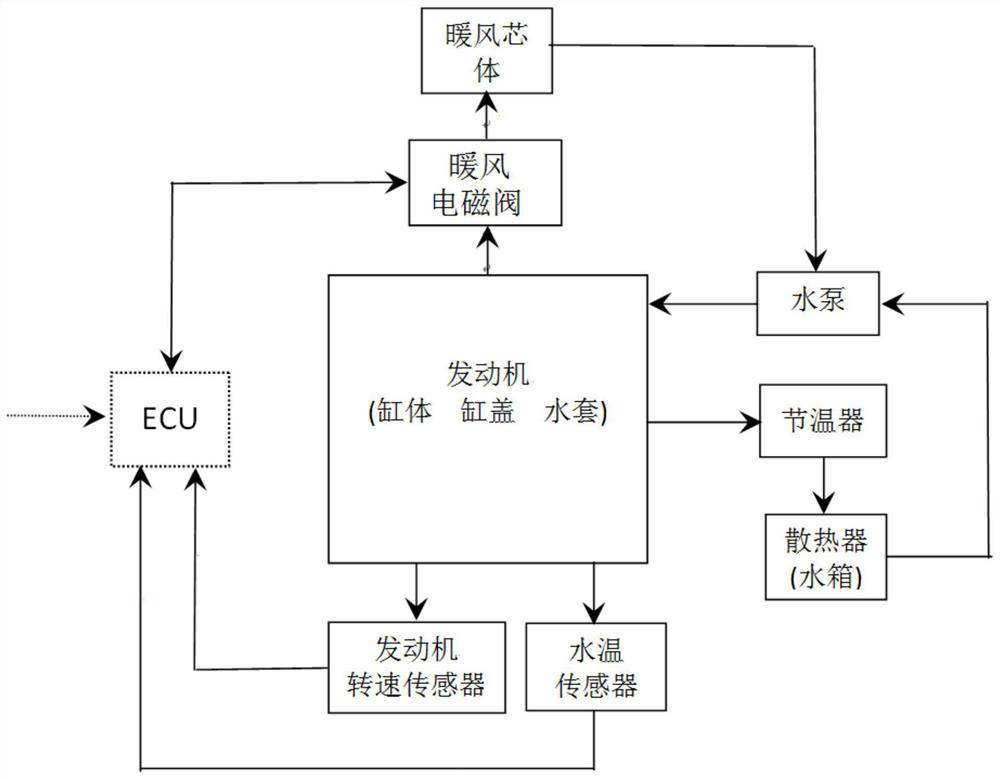

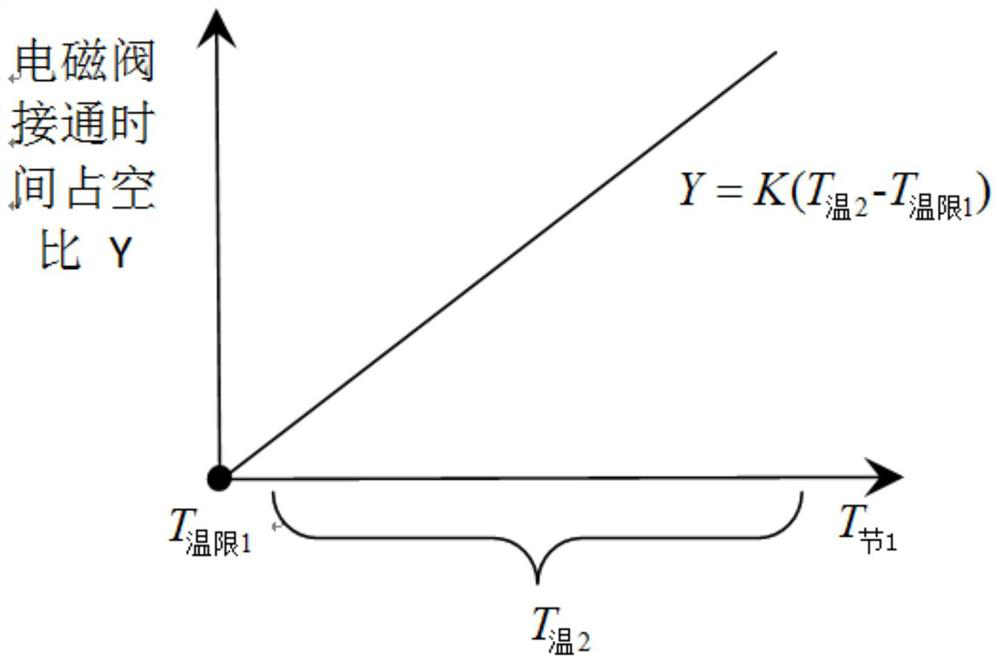

Control method of vehicle heating system and terminal equipment

PendingCN114763050ARapid coolingAvoid scuffingAir-treating devicesVehicle heating/cooling devicesCooling effectTerminal equipment

The invention is suitable for the technical field of vehicle warm air control, and provides a control method of a vehicle warm air system and terminal device.The method comprises the steps that when it is detected that an engine is started and warm air is started, a warm air electromagnetic valve is controlled to be started, a warm air branch is controlled to be communicated, rapid warm-up is achieved, and fuel consumption is reduced; when it is detected that the engine is started and the warm air is not started, the temperature detected by the water temperature sensor is collected, and the on-off state of the warm air electromagnetic valve is controlled according to the temperature of the water temperature sensor and the preset temperature limit value of the water temperature sensor, so that cooling water in the engine of the vehicle is intelligently controlled to flow under different working conditions of the engine, and the cooling effect is improved. The engine can be quickly warmed or cooled, faults such as cylinder scoring or scrapping of the engine are prevented, the service life of the engine is prolonged, and user experience is improved.

Owner:GREAT WALL MOTOR CO LTD

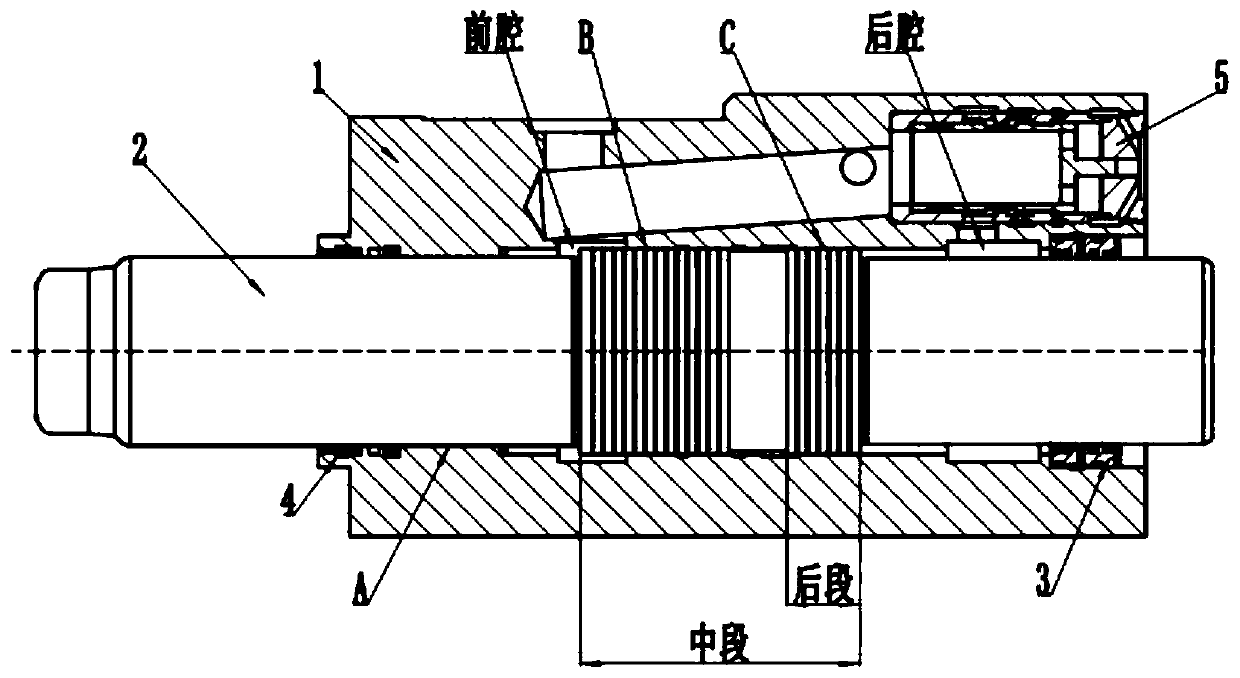

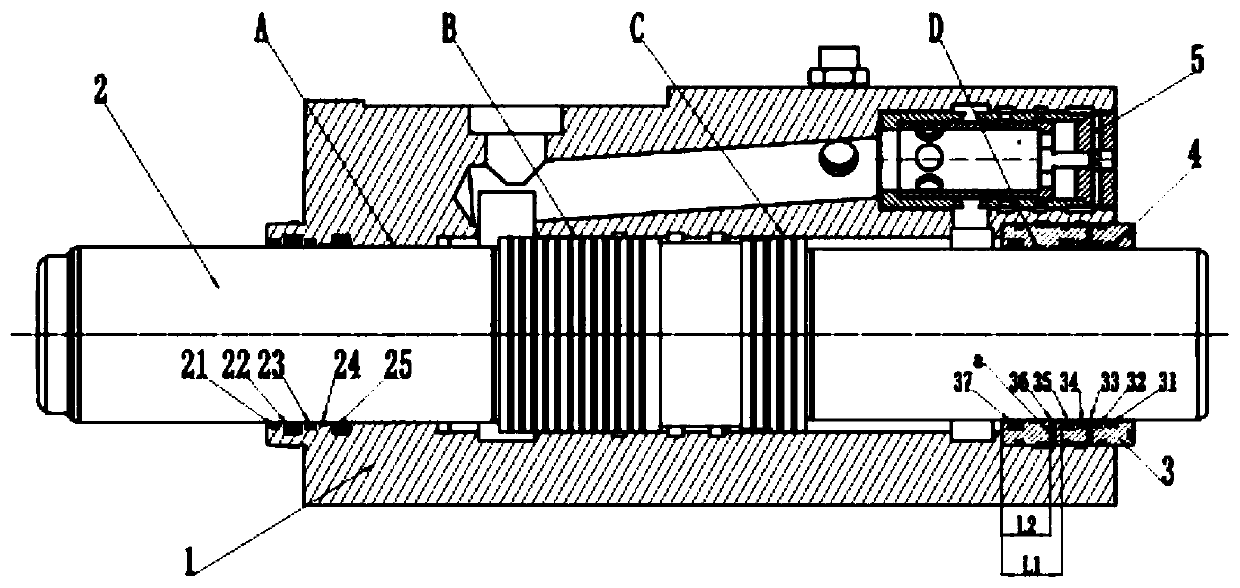

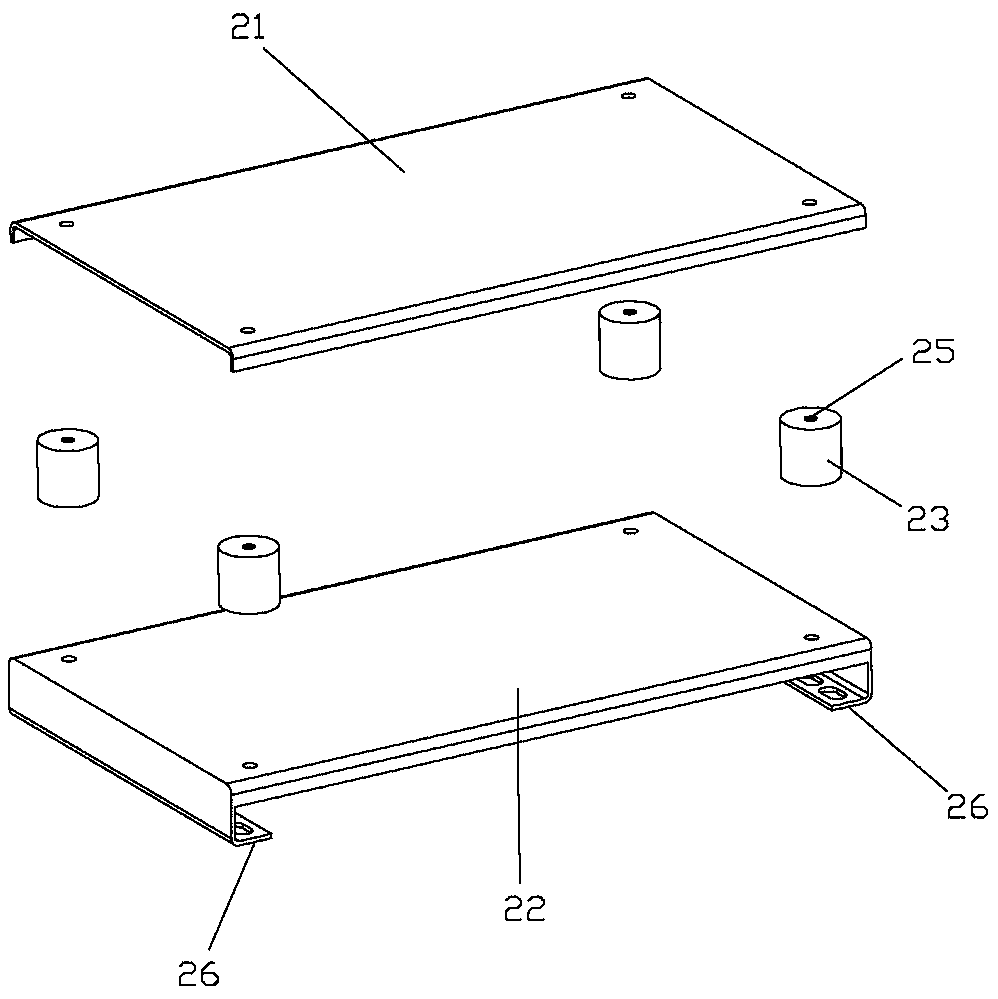

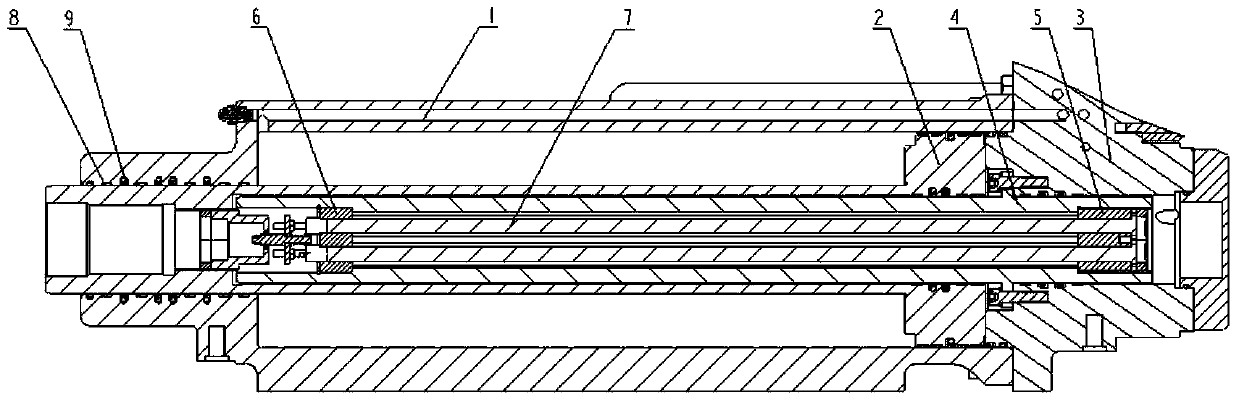

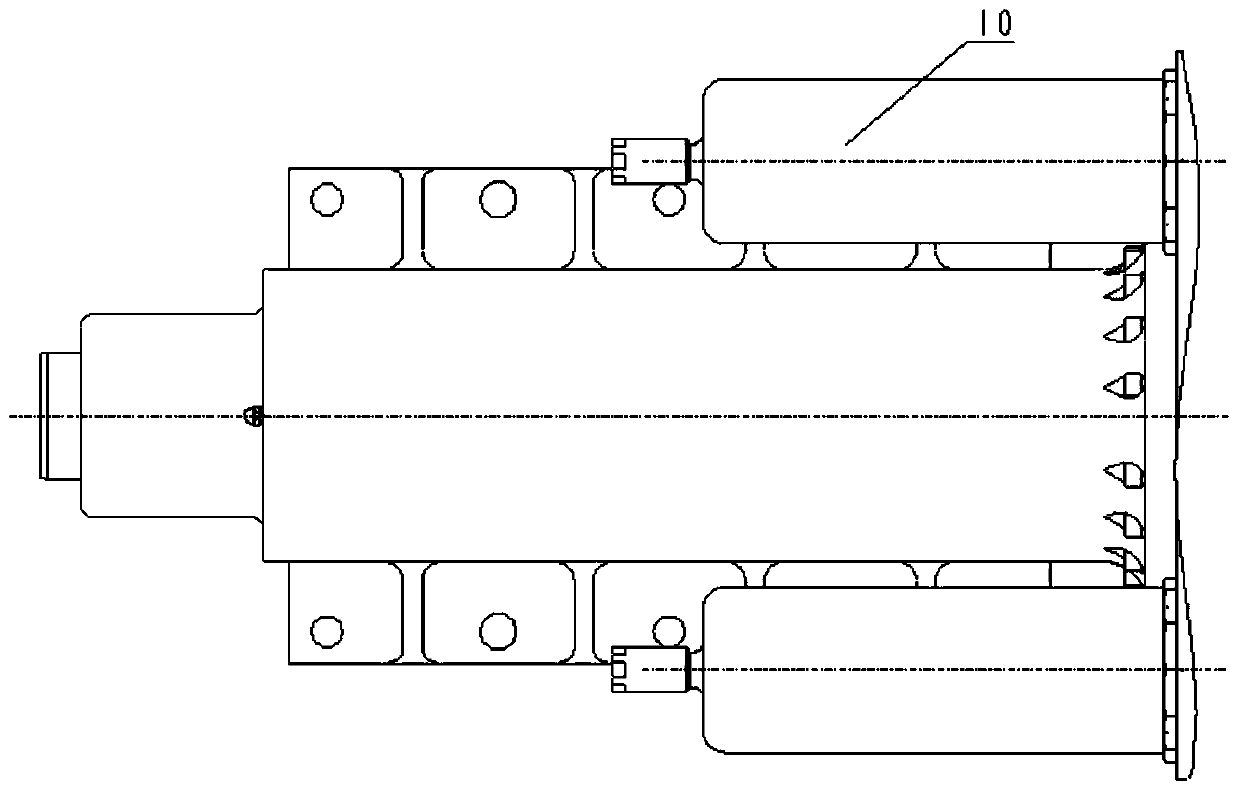

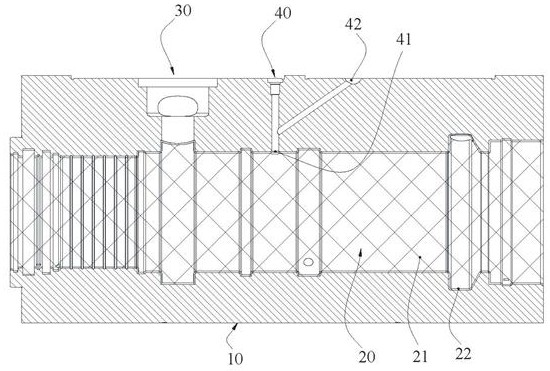

A Highly Compact "Micro Differential" Closed Servo Mechanism with Single Rod

ActiveCN105626605BReduce demandImprove utilization efficiencySteering ruddersServomotorsEngineeringActuator

The invention belongs to the technical field of large ship steering mechanisms, and relates to a single-rod highly compact micro-differential closed type servo mechanism which realizes a micro differential of two cavities, lowers the demand of a system for the hydraulic energy flow amount and improves energy utilization efficiency of the system. The single-rod highly compact micro-differential closed type servo mechanism comprises a servo mechanism body and two self-pressurization oil tanks (10) with the dual actions of mechanical springs and air pressure. The servo mechanism body comprises an actuator cylinder (1), a piston rod (2), a shell (3), a supporting rod (4), a rear support (5), a front support (6), a displacement sensor (7), a supporting ring A (8) and a combined seal A (9). The demand of the system for the hydraulic energy flow amount is lowered, the energy utilization efficiency of the system is improved, a compact type closed type system design is realized, the radial component force of a load can be effectively borne, cylinder scoring is avoided, and the structural compactness and anti-jamming capability of the servo mechanism are increased.

Owner:北京实验工厂有限责任公司 +2

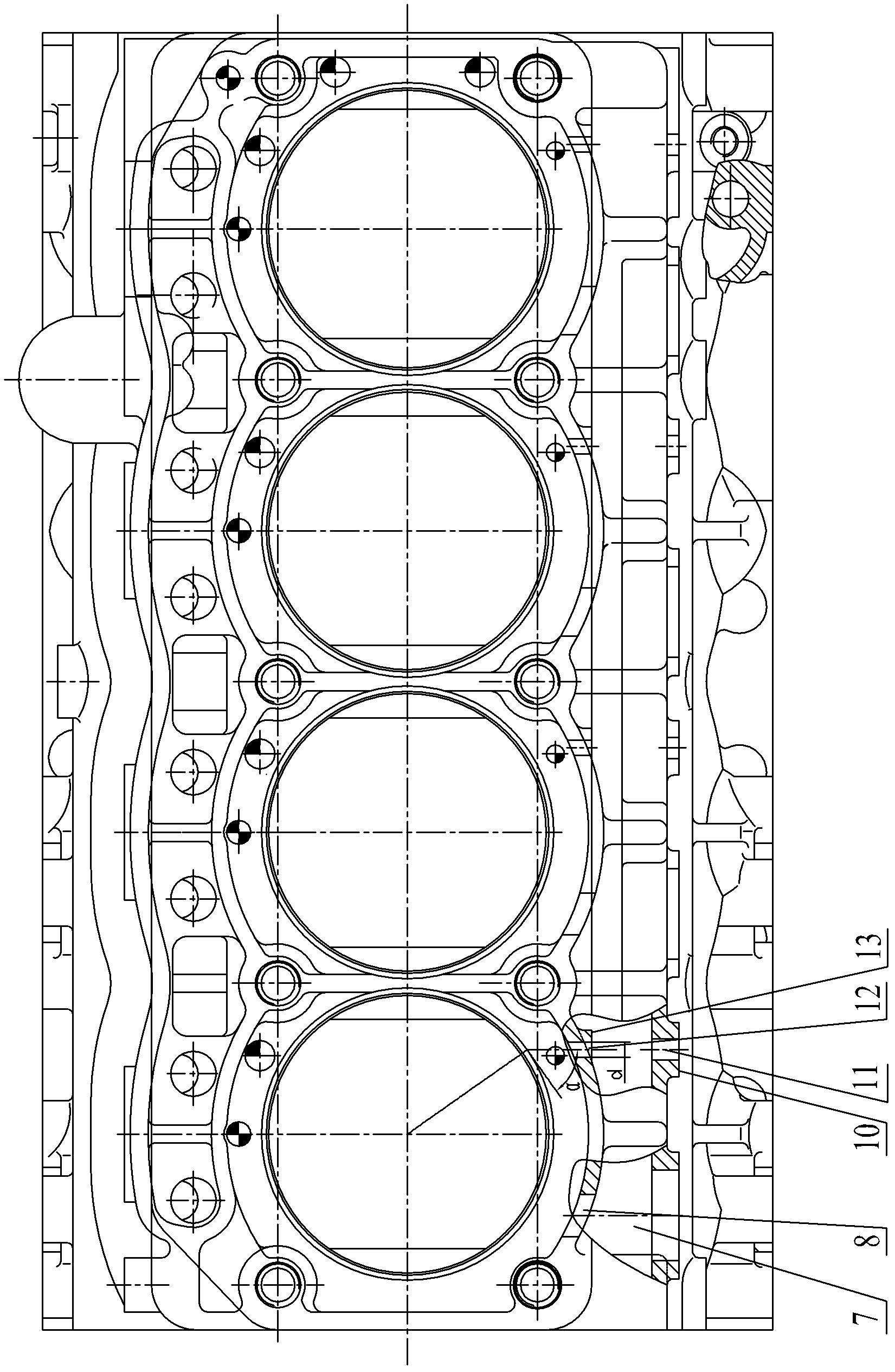

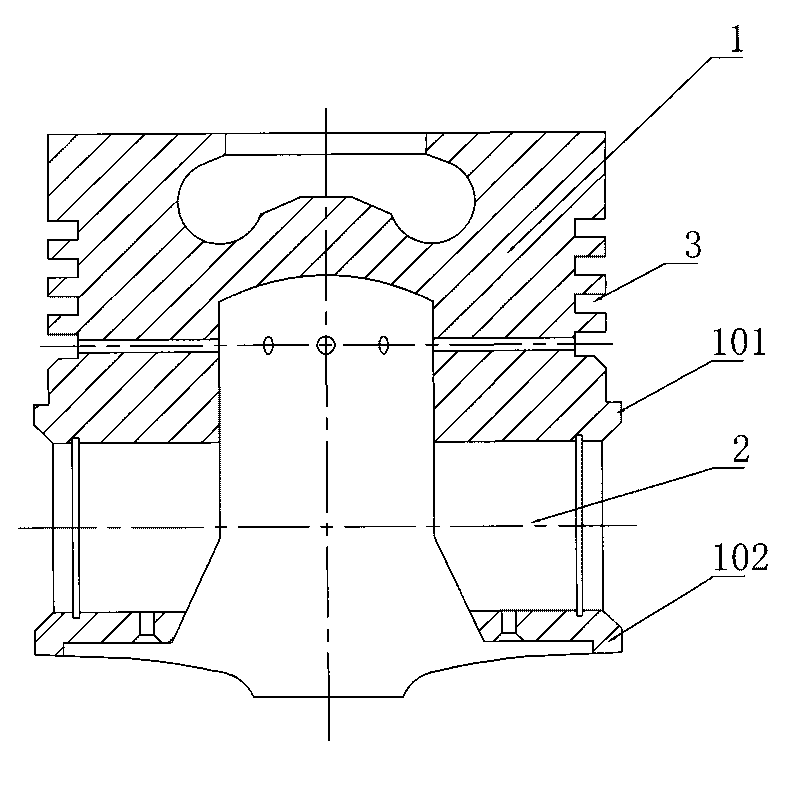

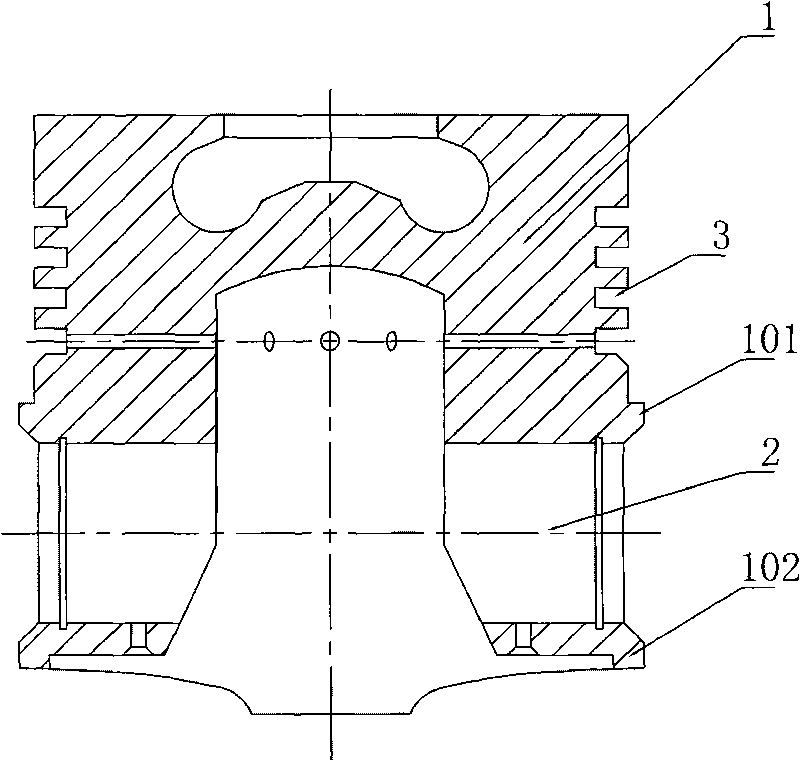

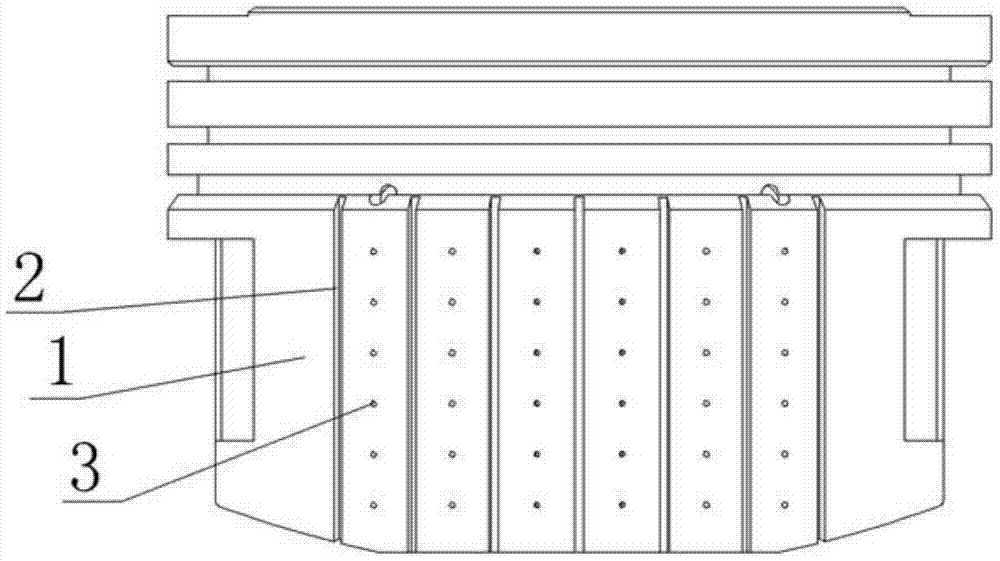

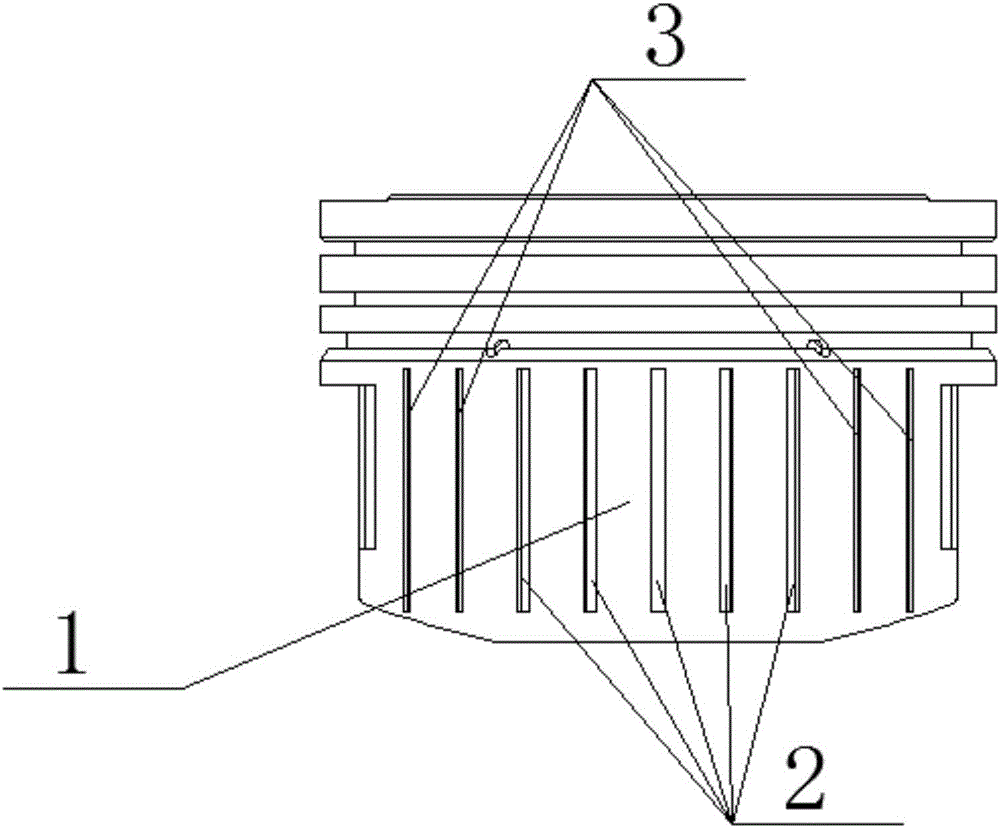

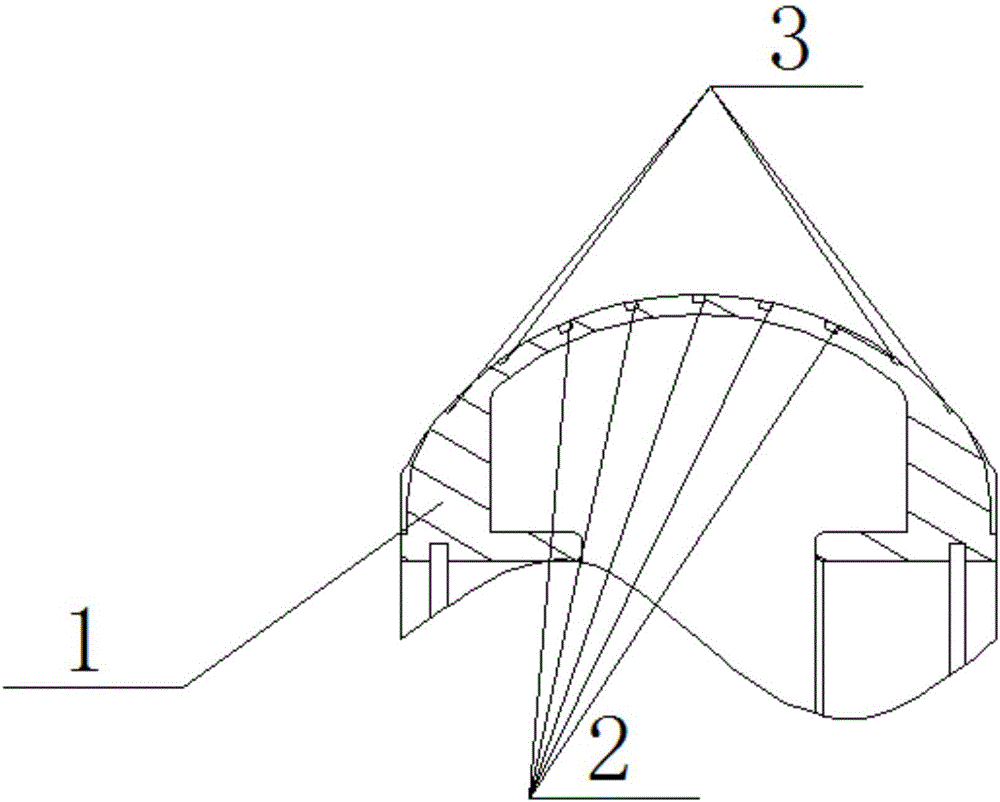

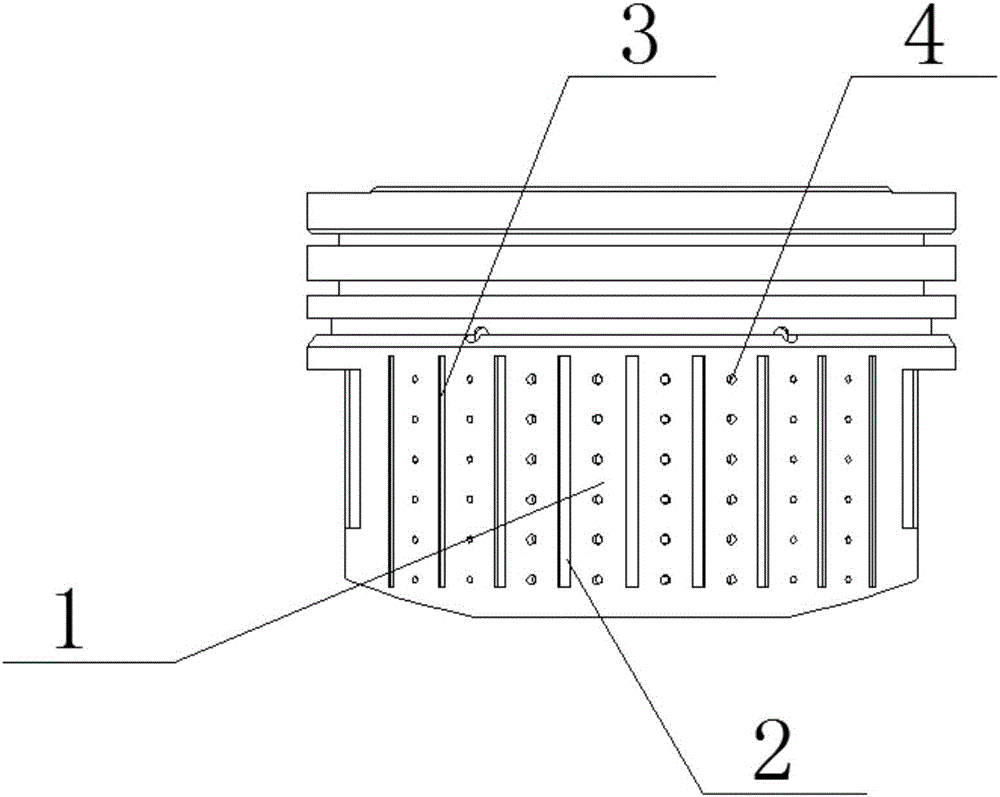

Die structure and manufacturing process of bimetallic cylinder liner

The invention belongs to the technical field of engine dies, and particular discloses a die structure of a bimetal cylinder liner and a processing technology thereof. The die structure of the bimetal cylinder liner comprises a die body, an upper pressing die, an inner core and a lower ejection die, wherein the die body, the upper pressing die and the lower ejection die are respectively of a hollow structure; the upper pressing die is arranged above the die body; the inner core and the lower ejection die are arranged in the die body; the inner core is positioned above the lower ejection die; a die cavity is formed among the die body, the inner core and the lower ejection die; the inner diameter of the lower ejection die and the upper pressing die are corresponding to the outer diameter of the inner core; the outer diameter of the lower ejection die and the upper pressing die are corresponding to the die cavity; the lower ejection die and the upper pressing die can perform up and down movements along the die cavity; an inner induction coil is arranged in the inner core; an outer induction coil is arranged outside the die body. The die structure of the bimetal cylinder liner and the processing technology thereof, provided by the invention, have the advantages that thermal ablation resistance of the engine cylinder liner is good, the heat insulation effect is good, the wear resistance is high, and the service life is long.

Owner:长治恒久磁性材料有限公司

A method for preventing engine from scuffing

The invention relates to the technical field of automobiles, in particular to a method for preventing engine cylinder scoring. According to the method for preventing engine cylinder scoring, whether an engine fails or not is judged by measuring performance parameters of the engine; when it is judged that the engine fails according to the performance parameters of the engine, the output torque of the engine is limited first; and after the output torque of the engine is reduced, when the abnormal situation of the engine is still not improved or eliminated, the engine is directly turned off. According to the method, the situation that the gas inlet temperature, water temperature and lubrication situations of the engine become abnormal within a short period of time due to burst problems such as intercooler and throttle valve blockage, fan faults and engine oil leakage is considered, and it is effectively avoided that cylinder scoring happens when this type of situations happen to the engine.

Owner:WEICHAI POWER CO LTD

Formula and process of crystal ceramic fluid for high-silicon aluminum alloy piston surface treatment of engine

InactiveCN103992098BLow thermal conductivityExtend your lifeMetallic material coating processesCombustion chamberCleansing Agents

The invention discloses piston surface treatment of a high-power engine and particularly discloses a crystal porcelain liquid formula and process for treatment of a surface layer of a high-silicon aluminum alloy piston of an engine. The process comprises the following steps: 1) cleaning a piston workpiece by using a metal cleaning agent; 2) adding well prepared crystal porcelain liquid into a treatment liquid tank, applying a positive electrode to the crystal porcelain liquid and applying a negative electrode to the piston workpiece; 3) mounting a circulating cooling water pipe outside the treatment liquid tank for controlling the temperature of the crystal porcelain liquid, wherein the temperature of the crystal porcelain liquid is below 60 DEG C; 4) keeping the conditions as follows: the voltage of a power supply is 120V, the current is 150A, the alternating frequency is 500Hz and the crystal porcelain time is 50min; 5) taking out the piston workpiece, drying and polishing a combustion chamber of the piston workpiece and a piston ring groove. The crystal porcelain liquid formula and process for treatment of the surface layer of the high-silicon aluminum alloy piston of the engine can directly perform crystal porcelain treatment on the combustion chamber of the high-silicon aluminum alloy piston and the piston ring groove once after processing so as to increase the hardness and the resistance to hot corrosion.

Owner:常州天泰表面技术有限公司

Cylinder body of a hydraulic breaker and its manufacturing method

ActiveCN113550375BReduce demandImprove structural strengthSoil-shifting machines/dredgersForging/hammering/pressing machinesEngineeringControl valves

Owner:江苏玖润机械工业科技有限公司

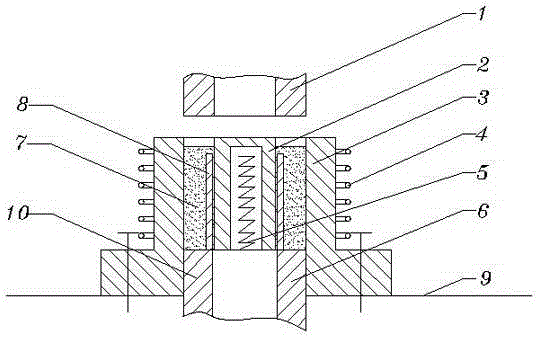

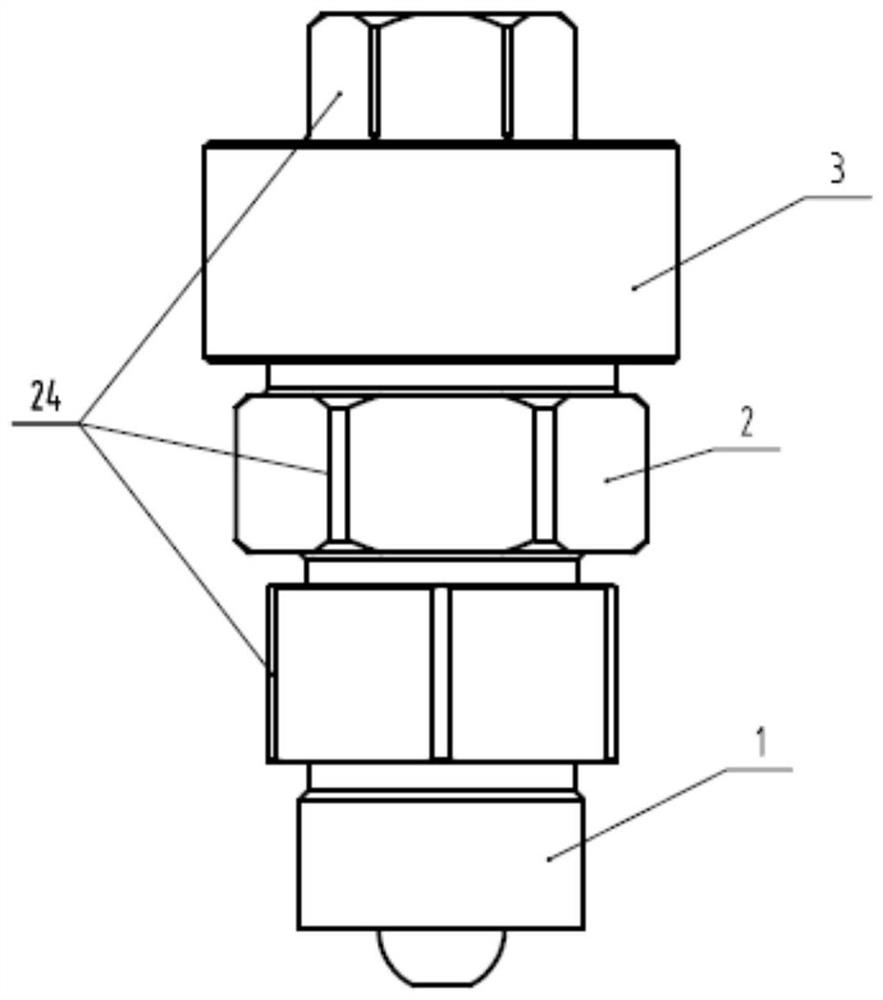

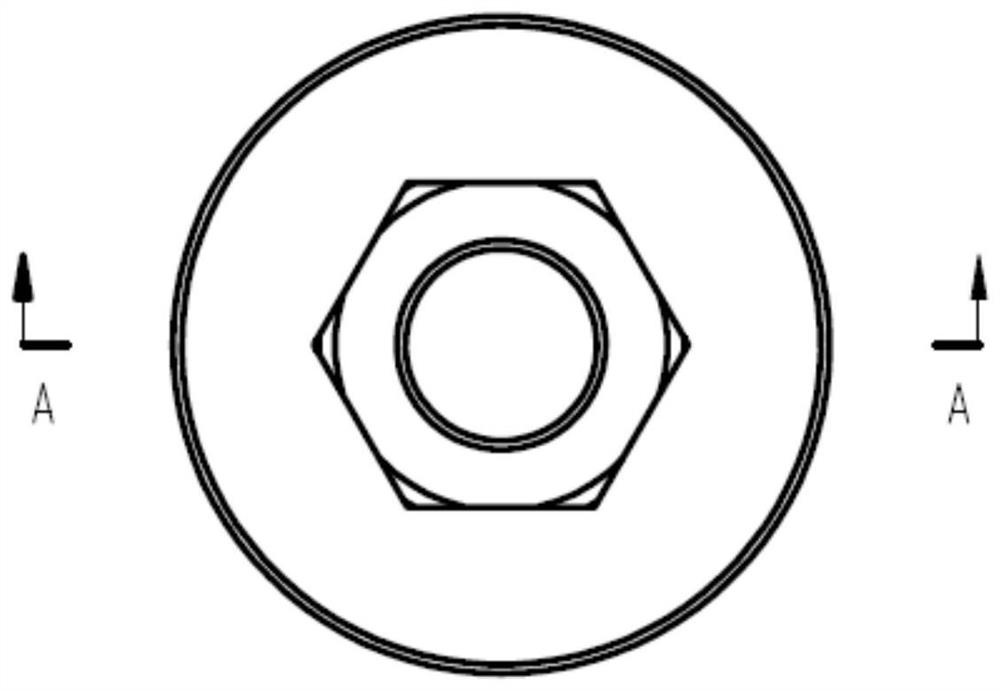

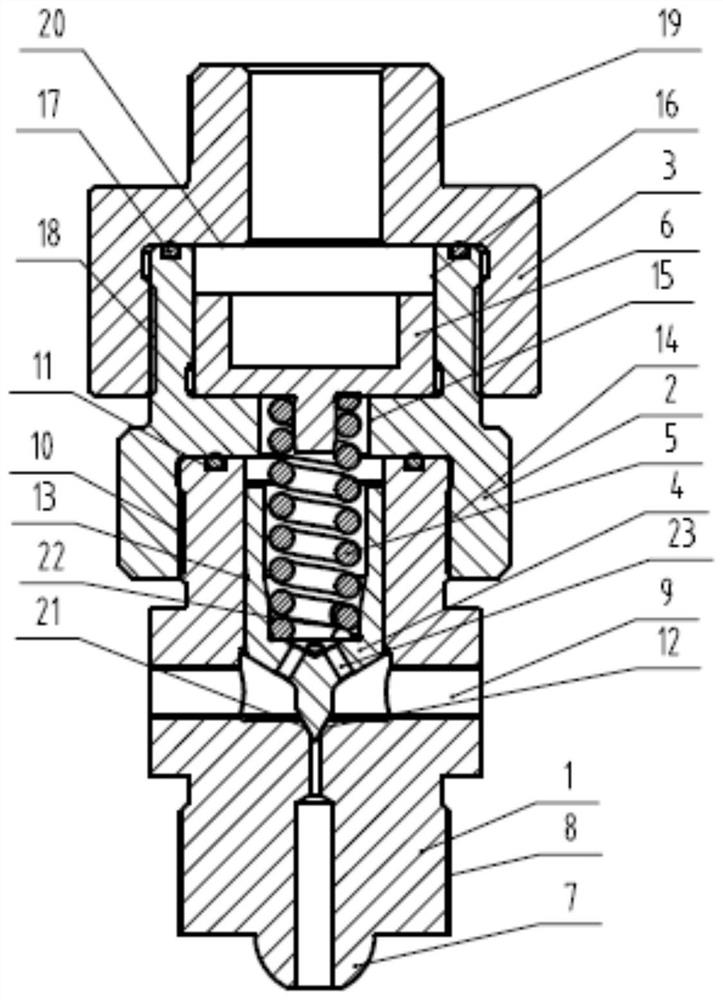

Mechanical lubricating oil control safety valve assembly

ActiveCN112555474AAvoid scuffingFragile or even brokenOperating means/releasing devices for valvesEqualizing valvesEngineeringSafety valve

The invention discloses a mechanical lubricating oil control safety valve assembly which comprises a lower connector, a valve body, an upper connector, a valve element, a spring and a control piston.The lower end part of the lower connector is a ball head, threads are arranged above the ball head and at the upper end part of the lower connector; a transverse through threaded hole is formed in themiddle of the lower connector and is an oil outflow hole; a sealing ring groove is formed in the upper end surface, and an oil passage is formed in the center of the lower connector in a penetratingmode; a through hole is formed in the center of the valve body in a penetrating mode; a lower hole is a threaded hole and is connected with the lower connector; an upper hole is a guide hole, and a sealing ring groove is formed in the upper end face; the oil passage is formed in center of the upper connector in a penetrating mode; the upper and lower holes are both threaded holes; the lower hole is connected with the valve body; the upper hole is connected with a lubricating oil pipe; a cone body is at the lower end part of the valve element and is placed on the lower connector, and the upperend part is provided with an inner hole for placing the spring; and the control piston is placed on the spring. By the mechanical lubricating oil control safety valve assembly, whether a system operates or not can be controlled according to the lubricating oil pressure, and the problem of friction failure, caused by insufficient lubricating oil, of bearing bush journal sticking, piston cylinder score and the like when the lubricating oil pressure is too low is solved.

Owner:CHONGQING HONGJIANG MACHINERY

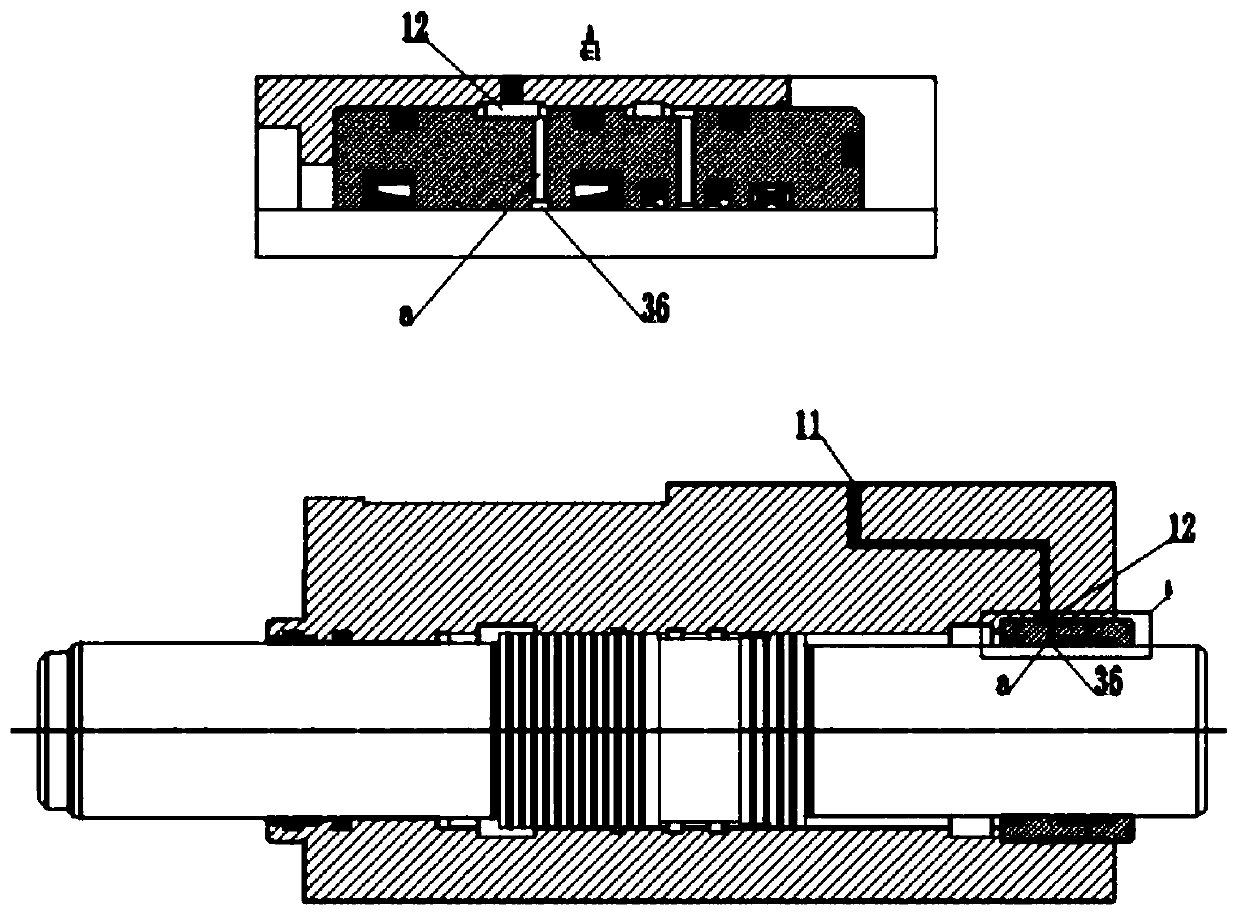

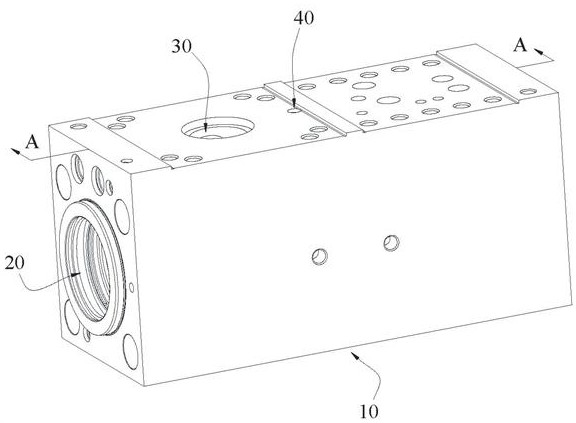

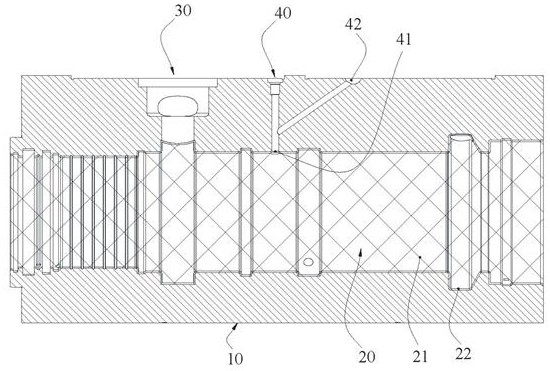

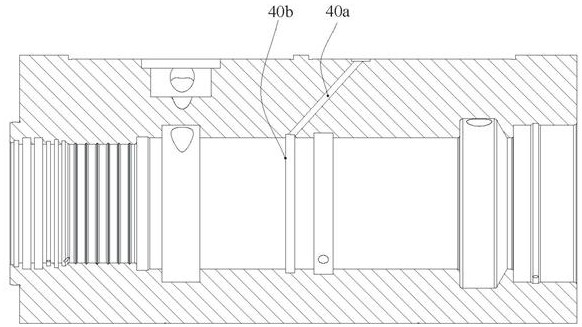

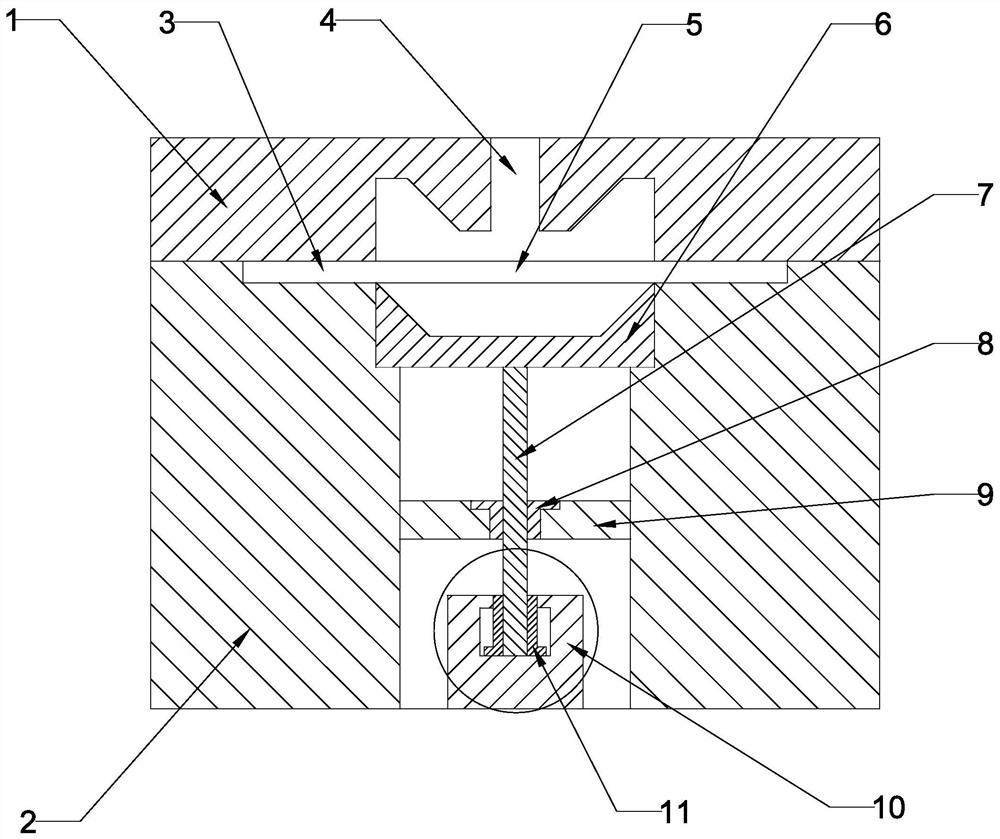

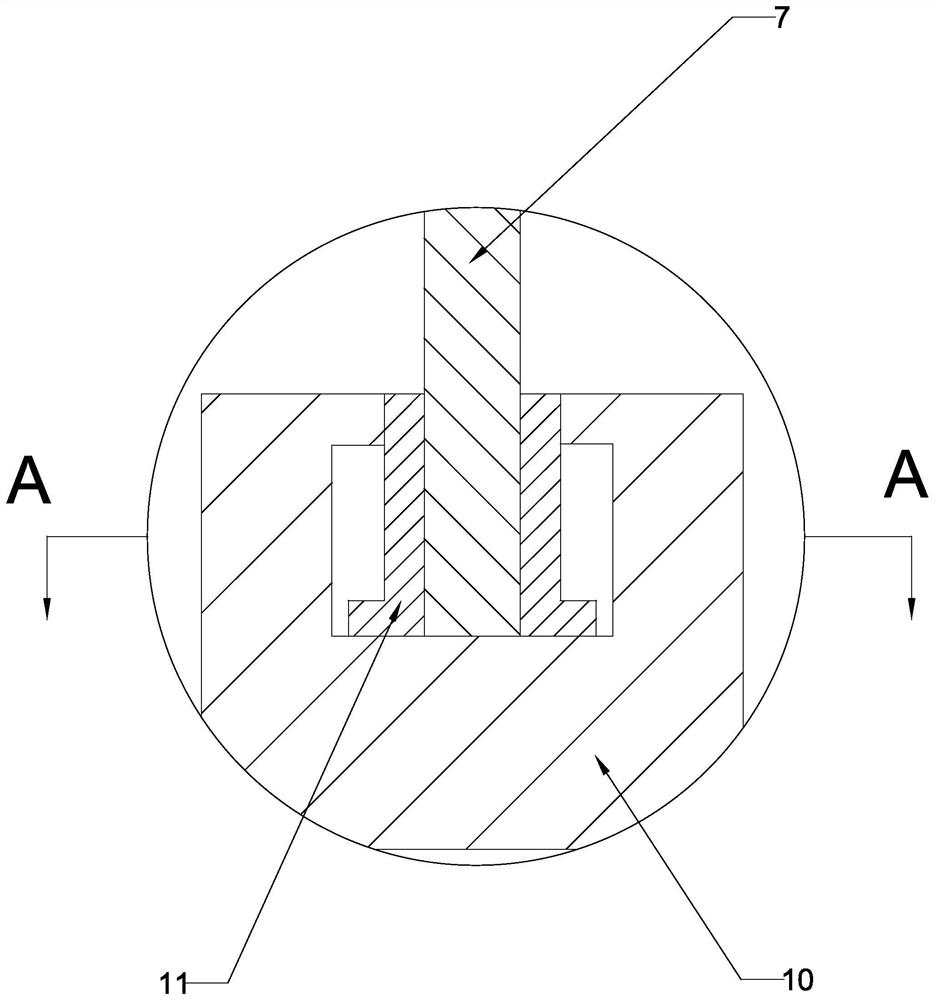

Middle cylinder block of hydraulic breaking hammer and manufacturing method of middle cylinder block

ActiveCN113550375AReduce demandImprove structural strengthSoil-shifting machines/dredgersForging/hammering/pressing machinesEngineeringControl valves

The invention relates to the technical field of hydraulic breaking hammers, in particular to a manufacturing method of a middle cylinder block of a hydraulic breaking hammer. The middle cylinder block comprises a middle cylinder block body, wherein a piston cavity is longitudinally formed in the middle cylinder block body; an energy accumulator cavity and a control valve signal channel which communicate with the piston cavity are also formed in the middle cylinder block body; a reticulate pattern structure is uniformly distributed on the inner wall of the piston cavity and uniformly distributed in a whole inner cavity; the outer layer of the reticulate pattern structure is coated with a soft film; and the soft film covers the inner wall of the piston cavity. An original signal slot is eliminated, so that the amount, demanded by the signal slot, of hydraulic oil can be reduced, the structural strength of the middle cylinder block body can be enhanced, and the effect of preventing internal leakage can be achieved; the soft film has certain resilience, so that hard friction strain can be prevented; through the reticulate pattern structure, the adhesion of the soft film can be stronger; meanwhile, the soft film has the functions of adsorbing the hydraulic oil and increasing the timeliness of an oil film staying on the inner wall of the cylinder block; and due to the fact that the oil film is regarded as a main factor for supporting a piston in a vacuum environment of the inner cavity, the occurrence probability of cylinder scoring can be effectively prevented.

Owner:江苏玖润机械工业科技有限公司

In-mold cutting injection mold

The invention discloses an in-mold cutting injection mold. The in-mold cutting injection mold comprises an upper mold core and a lower mold core, and is characterized by further comprising a cutter, and the cutter comprises a cylindrical cutter body. The cylindrical cutter can directly form a product with a round hole while cutting off a water gap, the technological process of hole digging is omitted, meanwhile, the water gap can be completely hidden, and the appearance is more attractive.

Owner:ZHEJIANG KAIHUA MOLDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com