Energy-saving and environmentally-friendly piston of internal combustion engine

An energy-saving and environment-friendly internal combustion engine technology, applied to pistons, mechanical equipment, engine components, etc., can solve problems such as high prices and imperfect supporting facilities, and achieve the effects of prolonging service life, uniform force, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

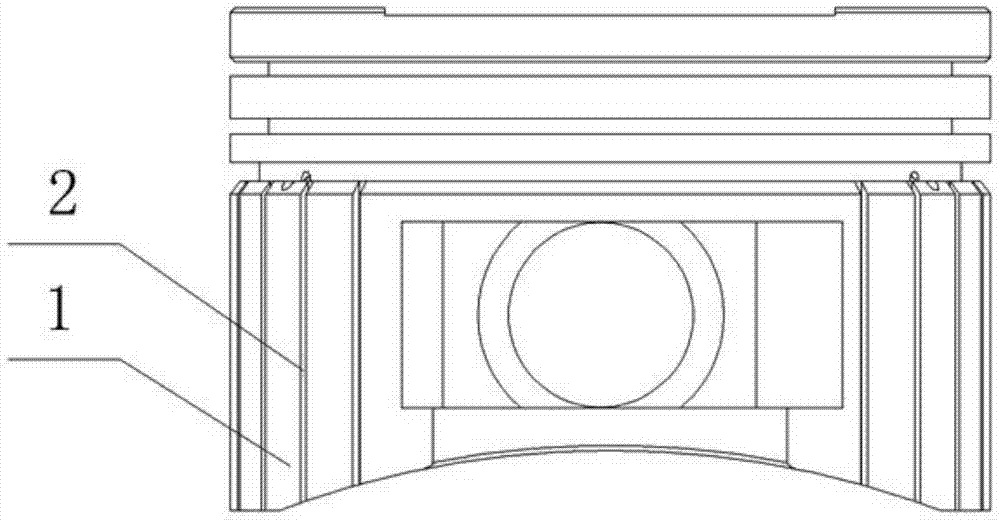

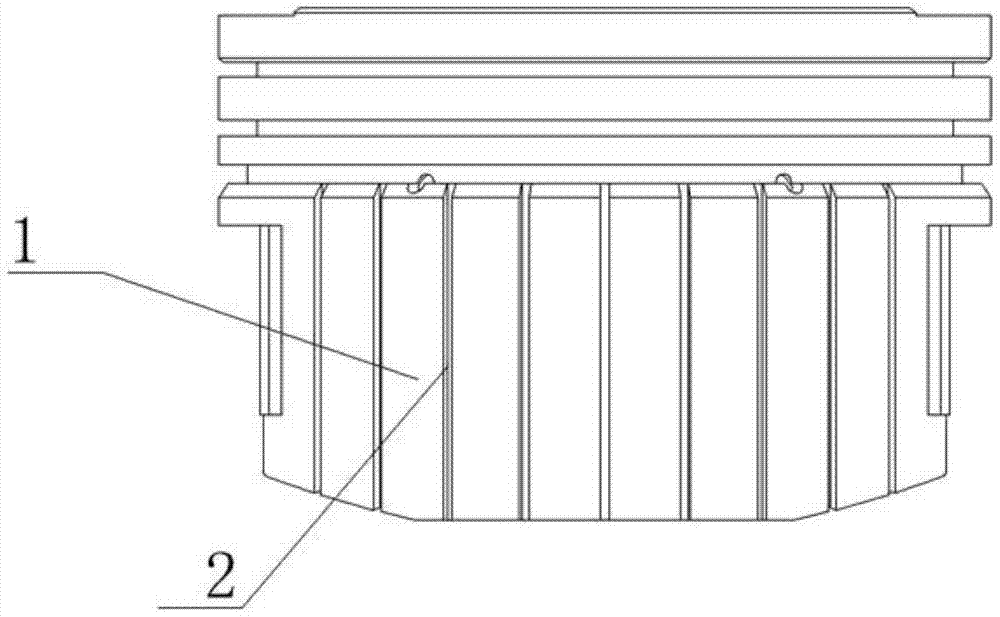

[0032] Such as figure 1 , figure 2 and Figure 5 As shown, in the present invention, a vertical groove 2 that runs through the entire piston skirt 1 is provided on the surface of the piston skirt 1 along the axial direction.

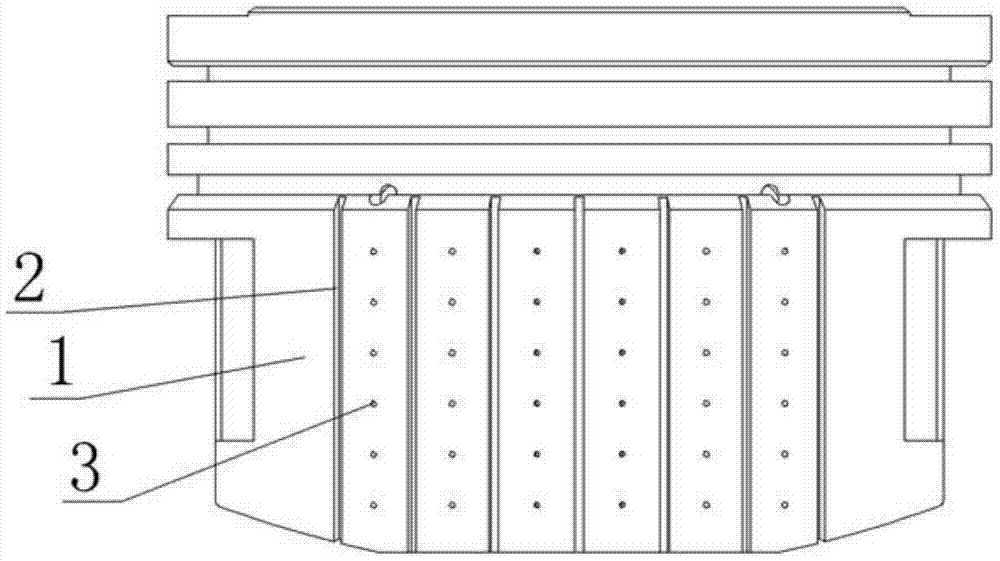

[0033] Such as figure 2 and Figure 6 As shown, in the present invention, the surface of the piston skirt 1 is provided with vertical grooves 2 running through the entire piston skirt 1 along the axial direction, and the piston skirt 1 between the vertical grooves 2 is provided with through holes 3 .

[0034] Such as Figure 4 and Figure 7 As shown, in the present invention, the surface of the piston skirt 1 is provided with a vertical wide groove 4 that runs through the entire piston skirt 1 along the axial direction, and the surface of the piston skirt 1 between the vertical wide grooves 4 is provided with a penetrating groove 4 along the axial direction. Vertical narrow groove 5 on the entire piston skirt 1.

[0035] Such as Figure 5 , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com