Patents

Literature

170results about How to "Adjust the gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

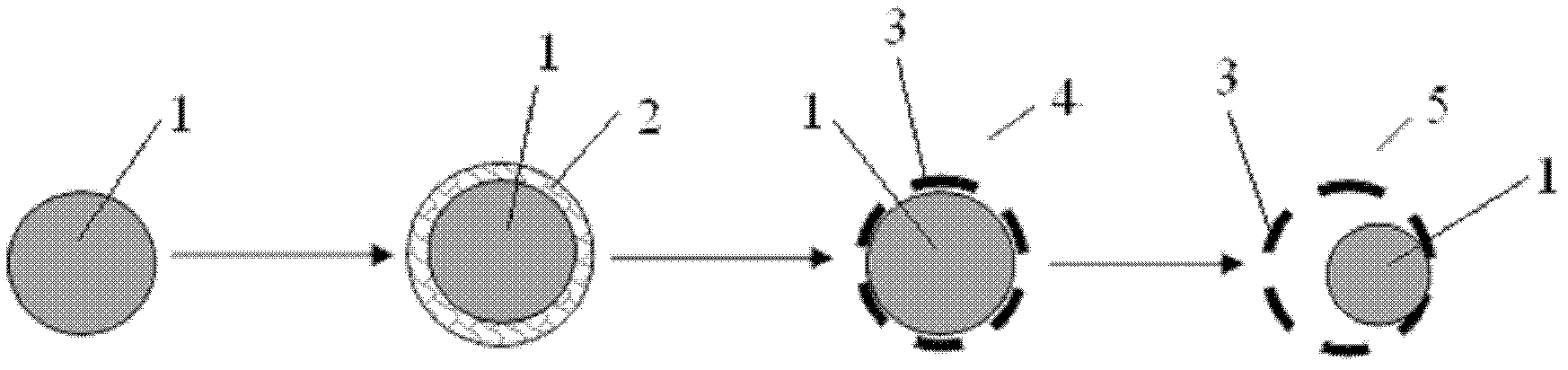

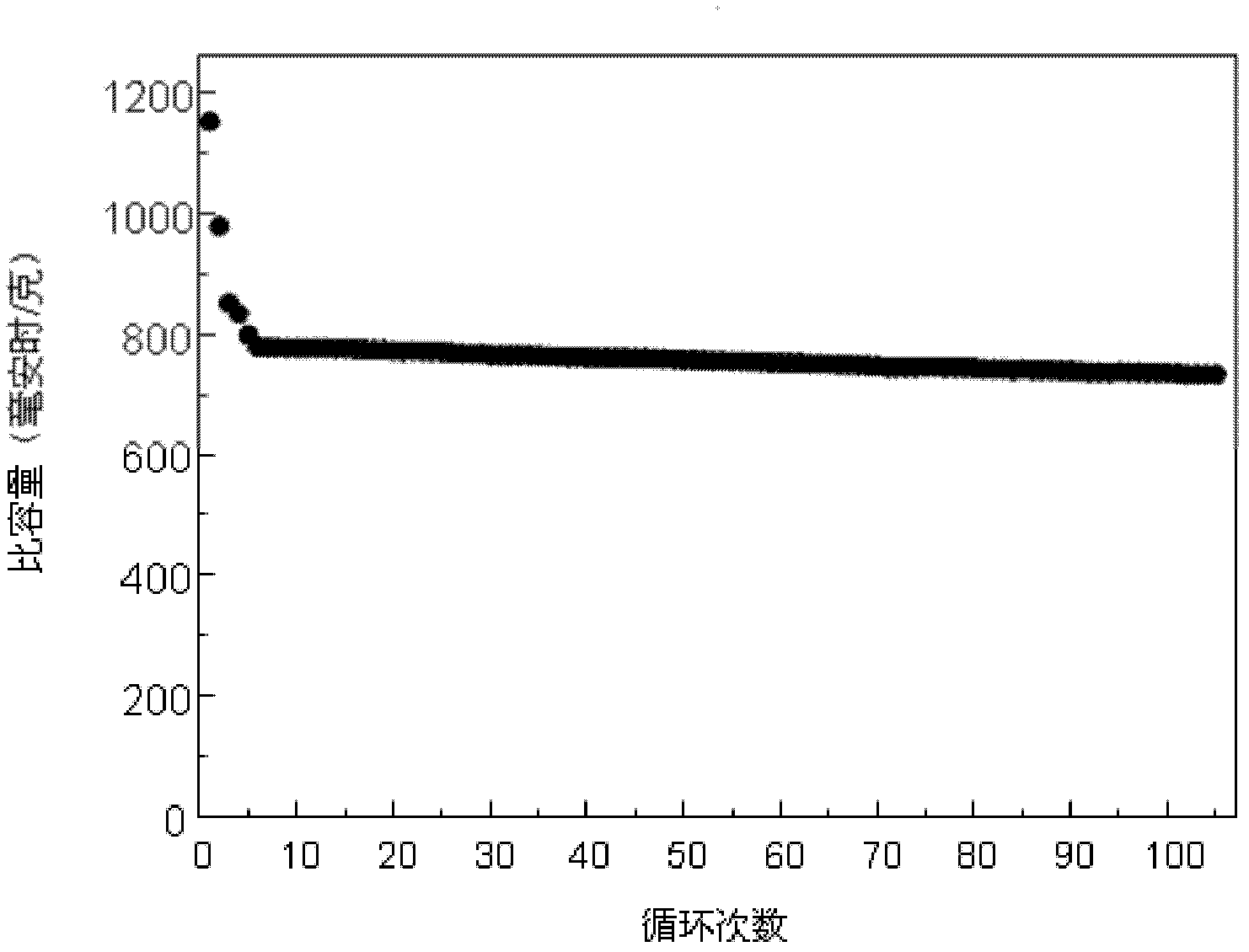

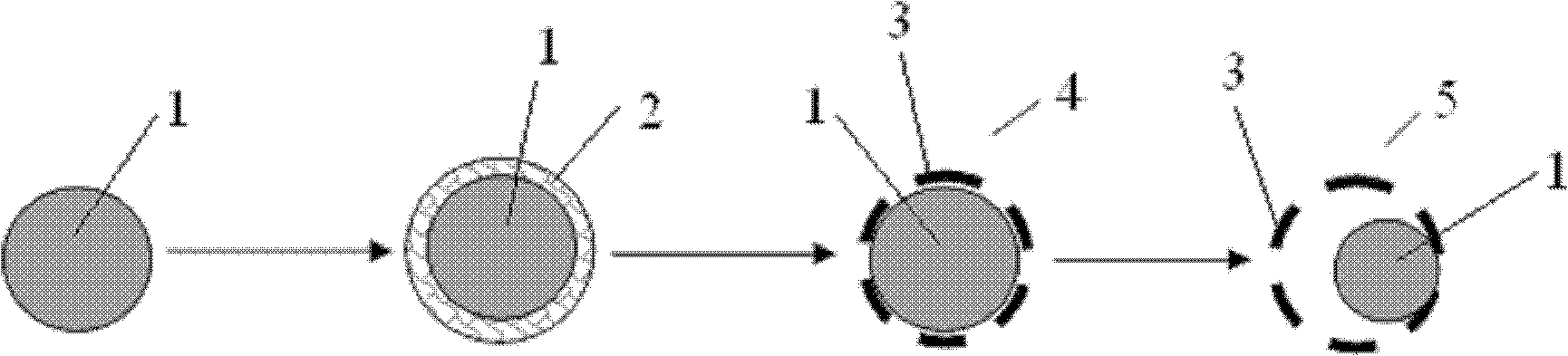

Carbon-silicon composite material, preparation method thereof, and lithium ion battery containing carbon-silicon composite material

InactiveCN102593418AEasy to makeControl silicon contentCell electrodesSecondary cellsPorous carbonLithium-ion battery

The invention discloses a carbon-silicon composite material, a preparation method of the carbon-silicon composite material and a lithium ion battery containing the carbon-silicon composite material. The preparation method comprises the steps of: directly selecting silicon powder as a raw material, wrapping the silicon powder with a precursor of organic carbon to obtain a porous carbon layer wrapping silicon composite material, and using corrosive liquid to remove partial silicon in the porous carbon layer wrapping silicon composite material by corrosion, so as to obtain the carbon-silicon composite material, wherein a gap exists between a carbon shell and the silicon arranged in the carbon shell. The preparation process is simple. The carbon-silicon composite material prepared by the preparation method disclosed by the invention is good in electrochemical property, and the battery prepared from the carbon-silicon composite material is good in cycling performance.

Owner:CHERY AUTOMOBILE CO LTD

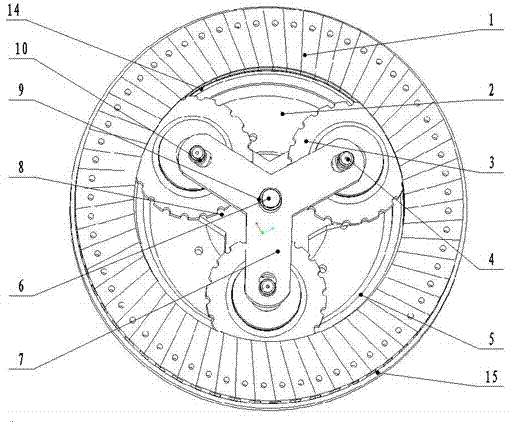

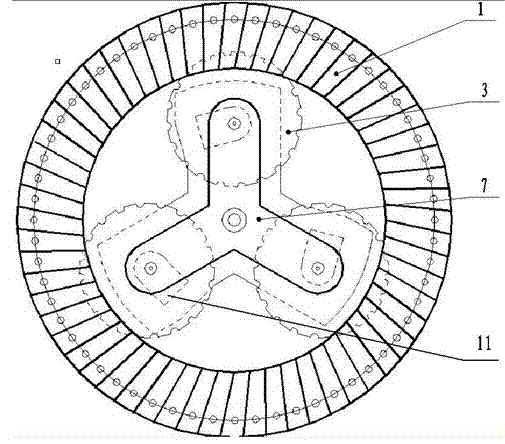

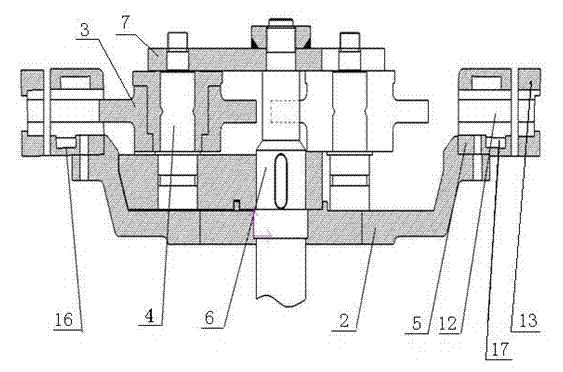

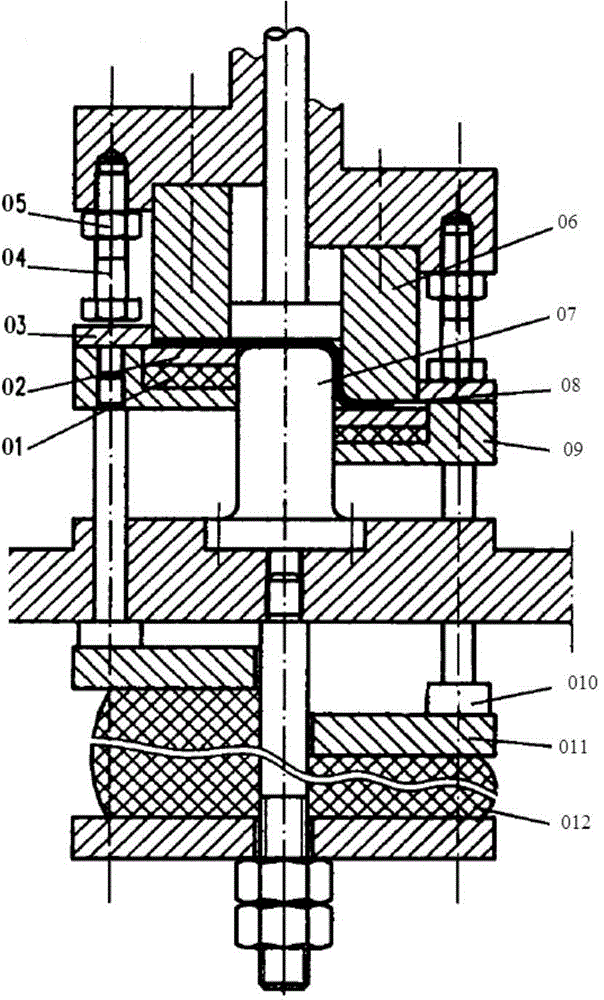

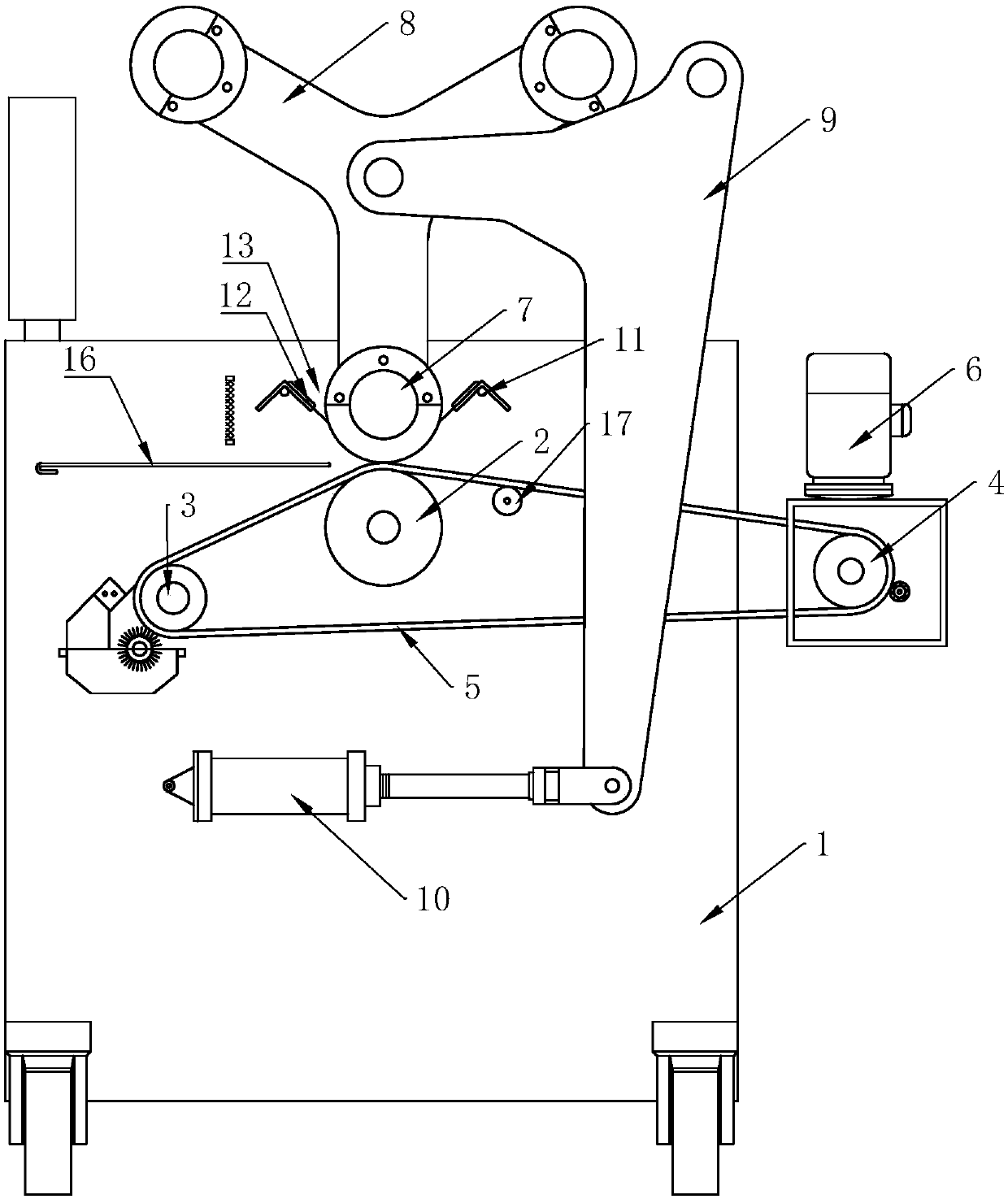

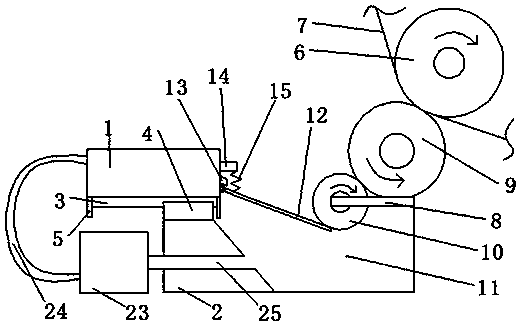

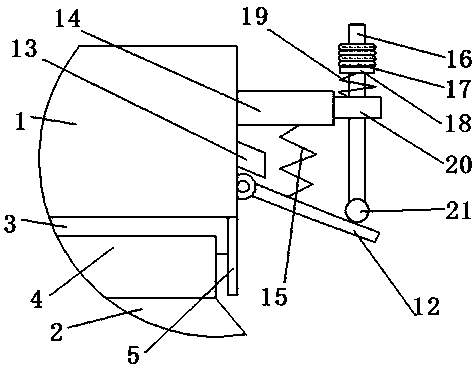

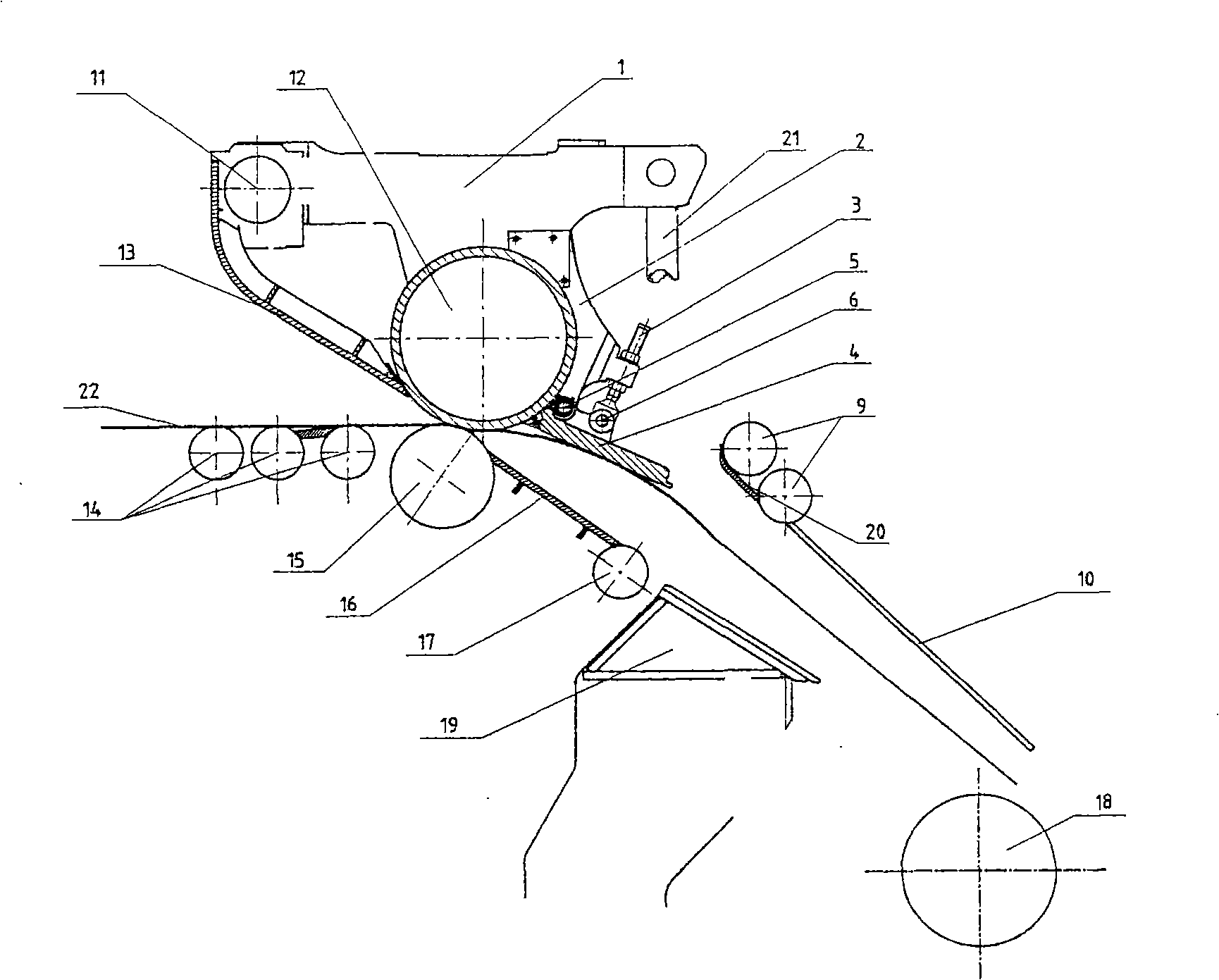

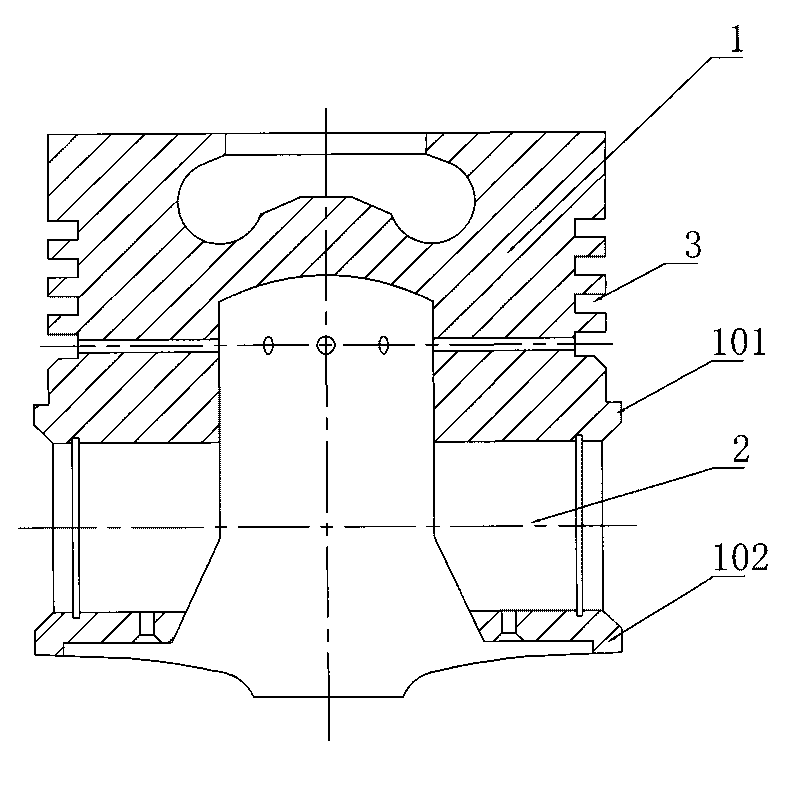

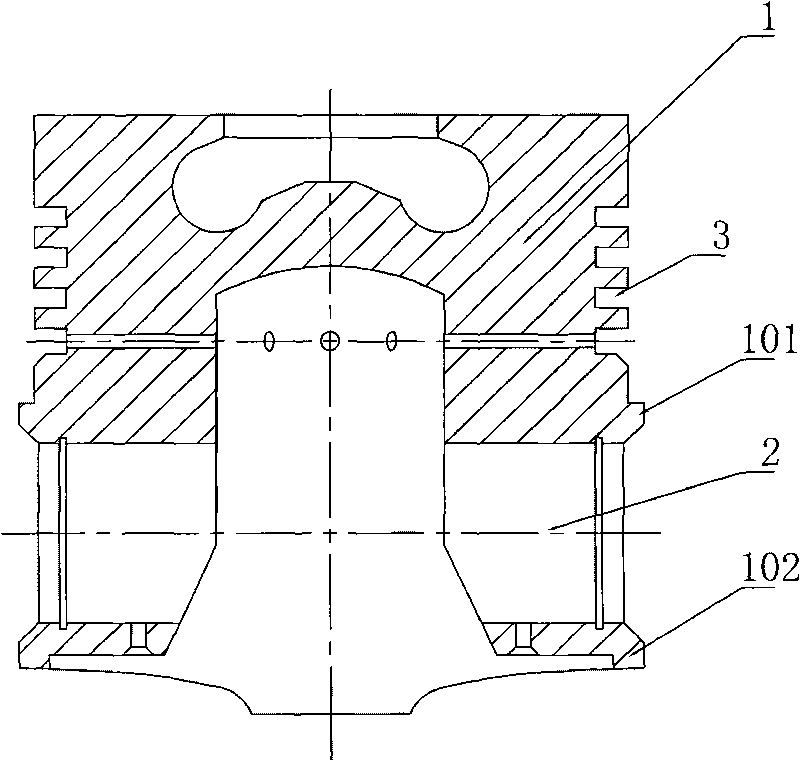

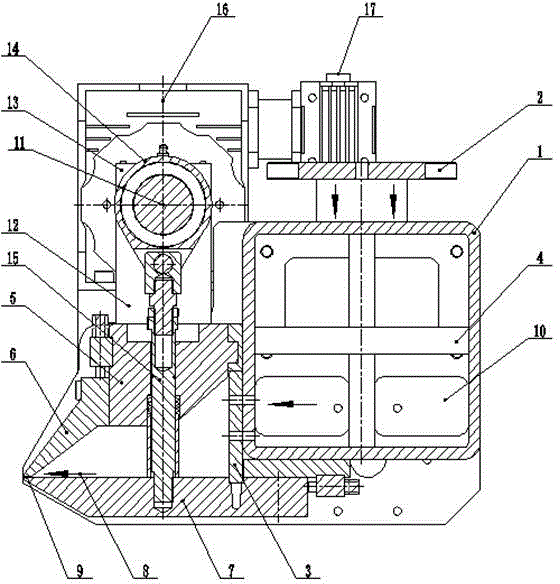

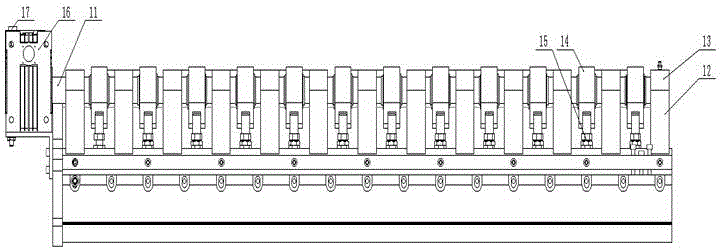

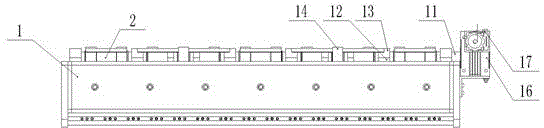

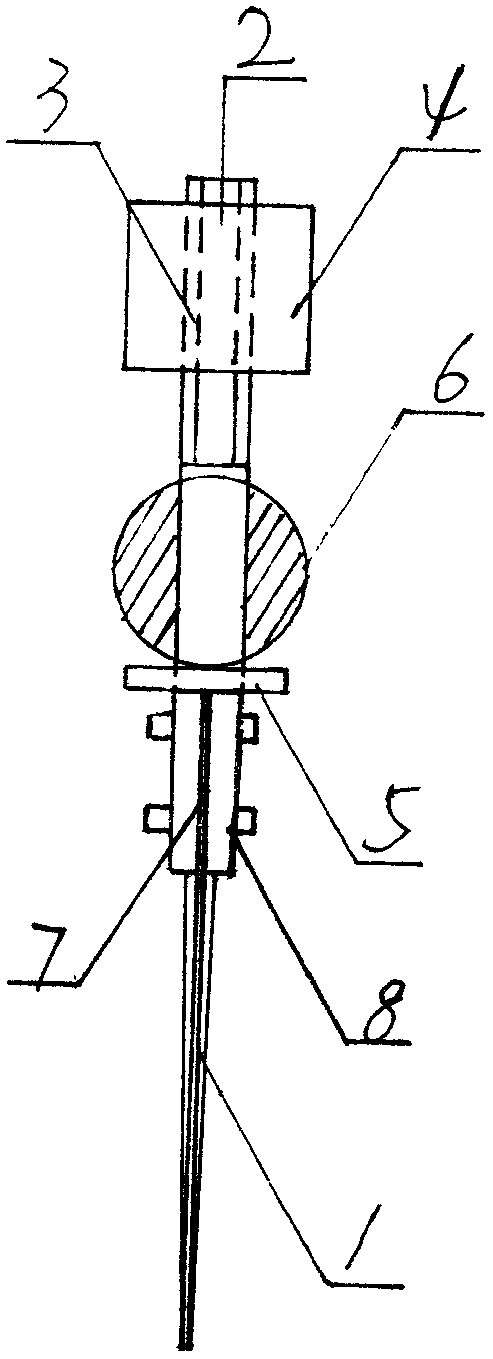

Straw briquetting machine

InactiveCN102873899AIncrease productivityExtended service lifeShaping pressPulp and paper industryBriquette

The invention relates to a straw briquetting machine. The straw briquetting machine comprises a ring die (1), a base (2), a pressing roller (3), an eccentric shaft (4), a pressure cover (5), a main shaft (6), an abrasive disk (8) and an upper pressure plate (13), wherein the central hole of the base (2) is provided with a central main shaft (6); the straw briquetting machine is characterized in that the main shaft (6) drives the abrasive disk (8) to rotate; the abrasive disk (8) drives the eccentric shaft (4) to rotate; and the pressing roller (3) rotates around the main shaft (6) on the eccentric shaft (4). Straw fed from a feeding port (14) of the ring die (1) is continuously compressed in the space of an abrasive cavity and extruded from a discharge port (15) to prepare finished products, and the straw briquettes are formed. By adopting the straw briquetting machine, the production efficiency of the straw briquette is improved, the power consumption is reduced, the production cost is lowered; and a roller is connected with the abrasive disk through the eccentric shaft, so that the gap between the roller and an extrusion die can be adjusted, the production efficiency is improved, the service lives of the extrusion die and the roller are prolonged, and the safety is enhanced.

Owner:JIANGSU YUANTONG AGRI MACHINERY TECH

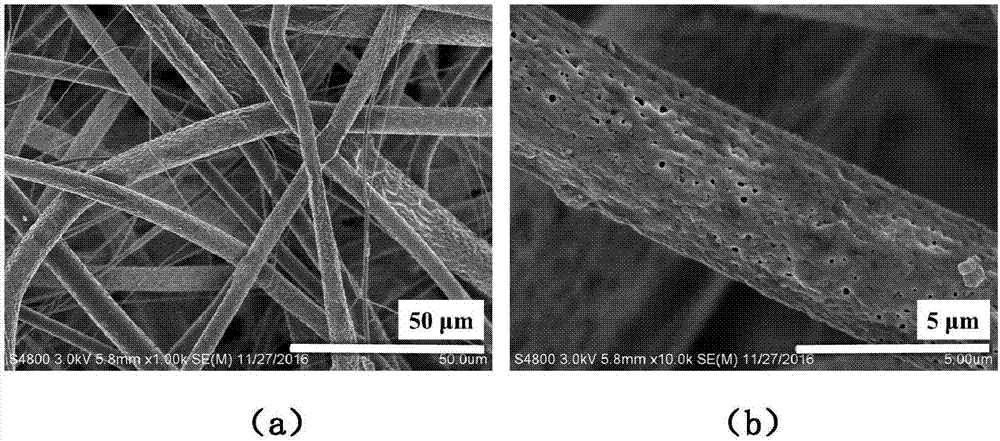

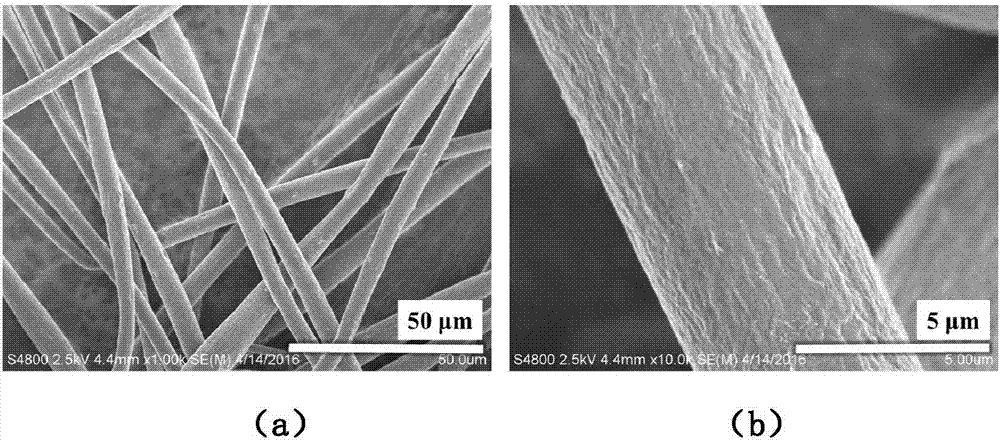

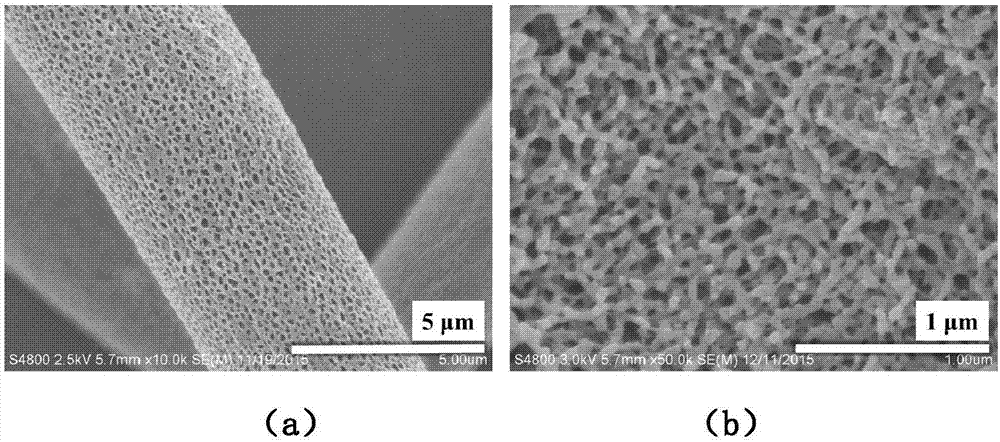

Thin film composed of polylactic acid fibers in nano-continuous porous structure and preparation method thereof

PendingCN106948164AAdjust the gapImprove ductilitySemi-permeable membranesFibre typesPolymer sciencePolyethylene oxide

The invention discloses a thin film composed of polylactic acid fibers in a nano-continuous porous structure and a preparation method thereof. The polylactic acid porous fiber thin film is prepared through two template methods including electrostatic spinning and crystallization-induced phase separation. The preparation method particularly includes the steps of: 1) according to certain weight ratio, dissolving polylactic acid and polyethylene oxide in a co-solvent and stirring the solution for 6 h at normal temperature to prepare a homogenous solution; 2) spinning the polymer solution into polylactic acid / polyethylene oxide composite fibers through a high voltage electrostatic technology; 3) soaking the composite fibers in a water solution, performing etching to remove the polyethylene oxide phase in the composite fibers, and dehydrating the composite fibers in a drying box to obtain an environment-friendly polylactic acid porous fiber cloth. The polylactic acid porous fiber cloth has high specific surface area due to micro and nano hierarchical pore structures therein. The fiber cloth has high fluid flux and excellent mechanical performance, and can be applied to the membrane separation fields, such as water treatment, air treatment, etc.

Owner:杭州安诺过滤器材有限公司

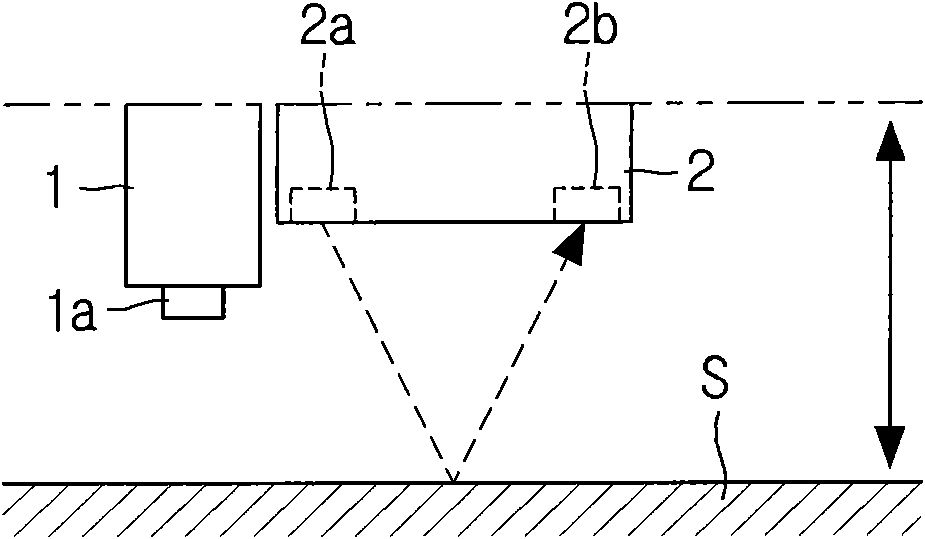

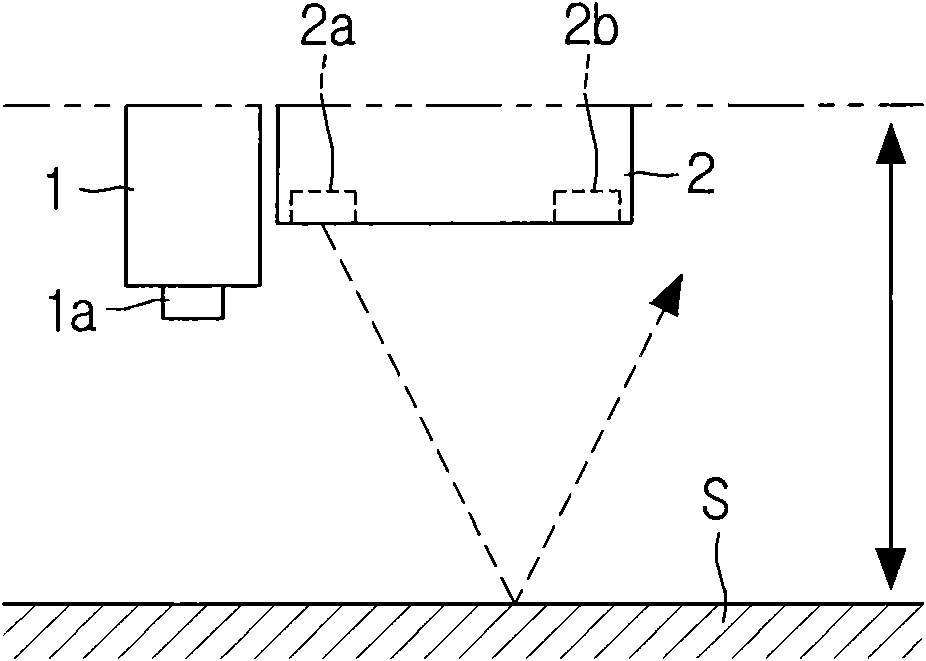

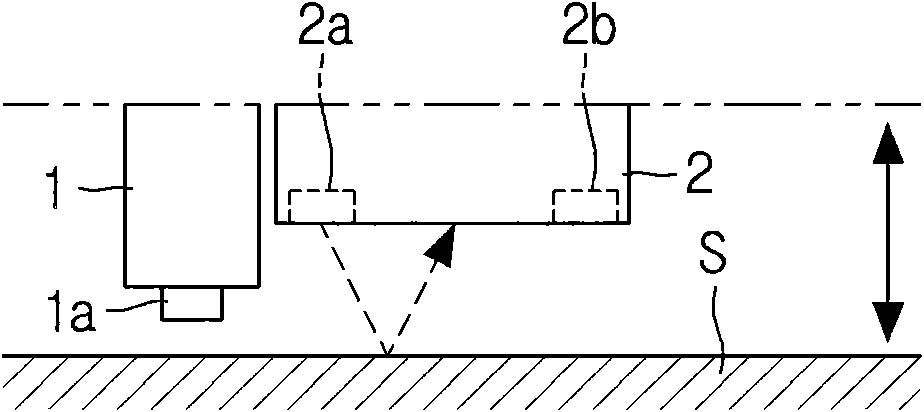

Paste dispenser and method for controlling the same

The invention discloses a paste dispenser and a method for controlling the same. A nozzle can be moved vertically and independently from a laser distance sensor. When the interval between an outlet hole of the nozzle and a substrate can be adjusted to adjust the cross-sectional area of the paste pattern, the vertical position of the nozzle relative to the substrate can be adjusted, when the position of the laser distance sensor is fixed, thereby the laser distance sensor can be disposed at the best position relatively to the interval between the outlet hole of the nozzle and the substrate.

Owner:TOP ENG CO LTD

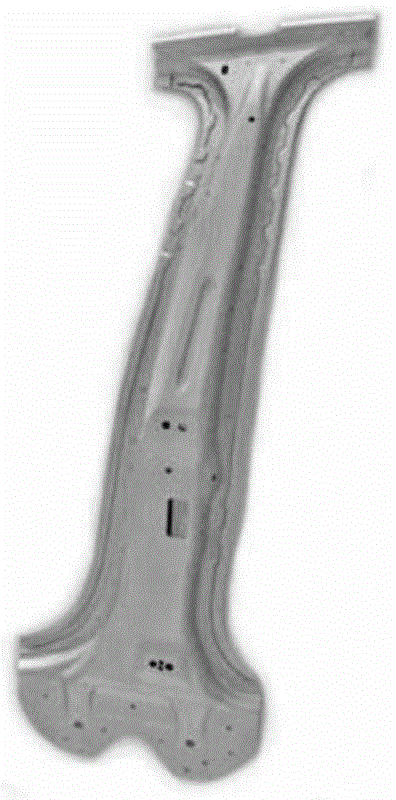

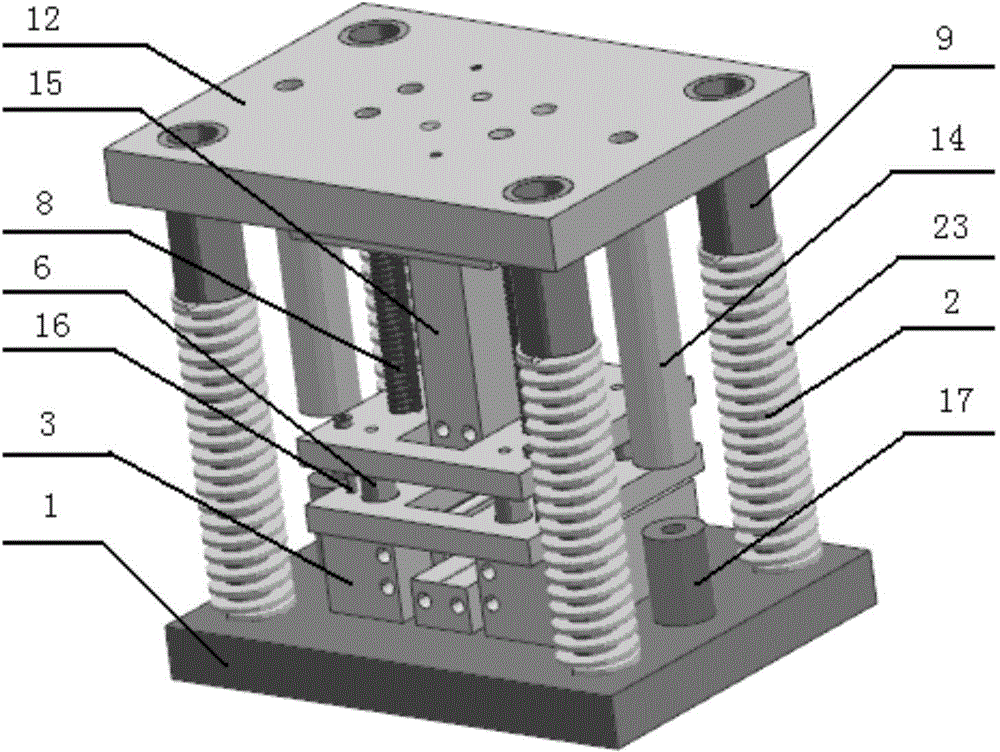

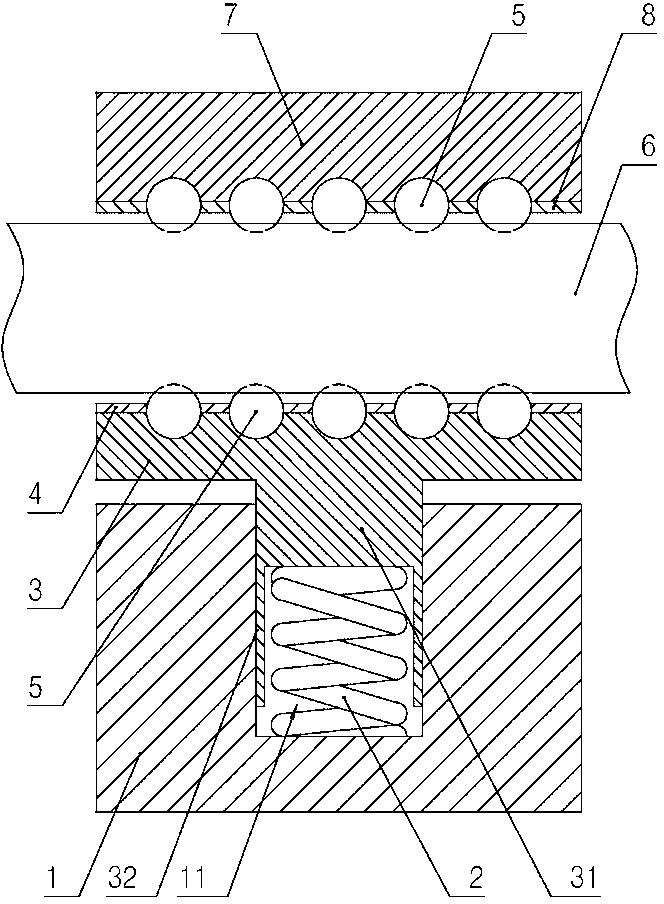

Punching device and method for automotive aluminum plate

ActiveCN104858283AAccurate Design CalculationsEasy to adjustShaping toolsVehicle componentsConstant forcePunching

The invention provides a punching device for an automotive aluminum plate. The punching device comprises an upper die assembly and a lower die assembly. The upper die assembly comprises a platy upper die holder, an upper clamping plate, a columnar male die, upper die limiting columns, guide sleeves and a constant-force edge pressing assembly. The upper die holder is arranged at the topmost end of the device and is horizontally arranged. The upper clamping plate is arranged on the lower surface of the upper die holder. One end of each columnar male die is fixedly arranged on the upper die holder, and the free end of each columnar male die faces downwards. One end of each upper die limiting column is fixedly arranged on the upper die holder, and the free end of each upper die limiting column faces downwards. One end of each guide sleeve is fixedly arranged on the upper die holder, and the free end of each guide sleeve faces downwards. The constant-force edge pressing assembly is arranged below the upper clamping plate. According to the forward punching device, the male dies are arranged on the upper portion, female dies are arranged on the lower portion, the design that constant-force edge pressing is achieved through two stages of springs, and the punching experiment can be conducted on a single-acting hydraulic machine.

Owner:CENT SOUTH UNIV

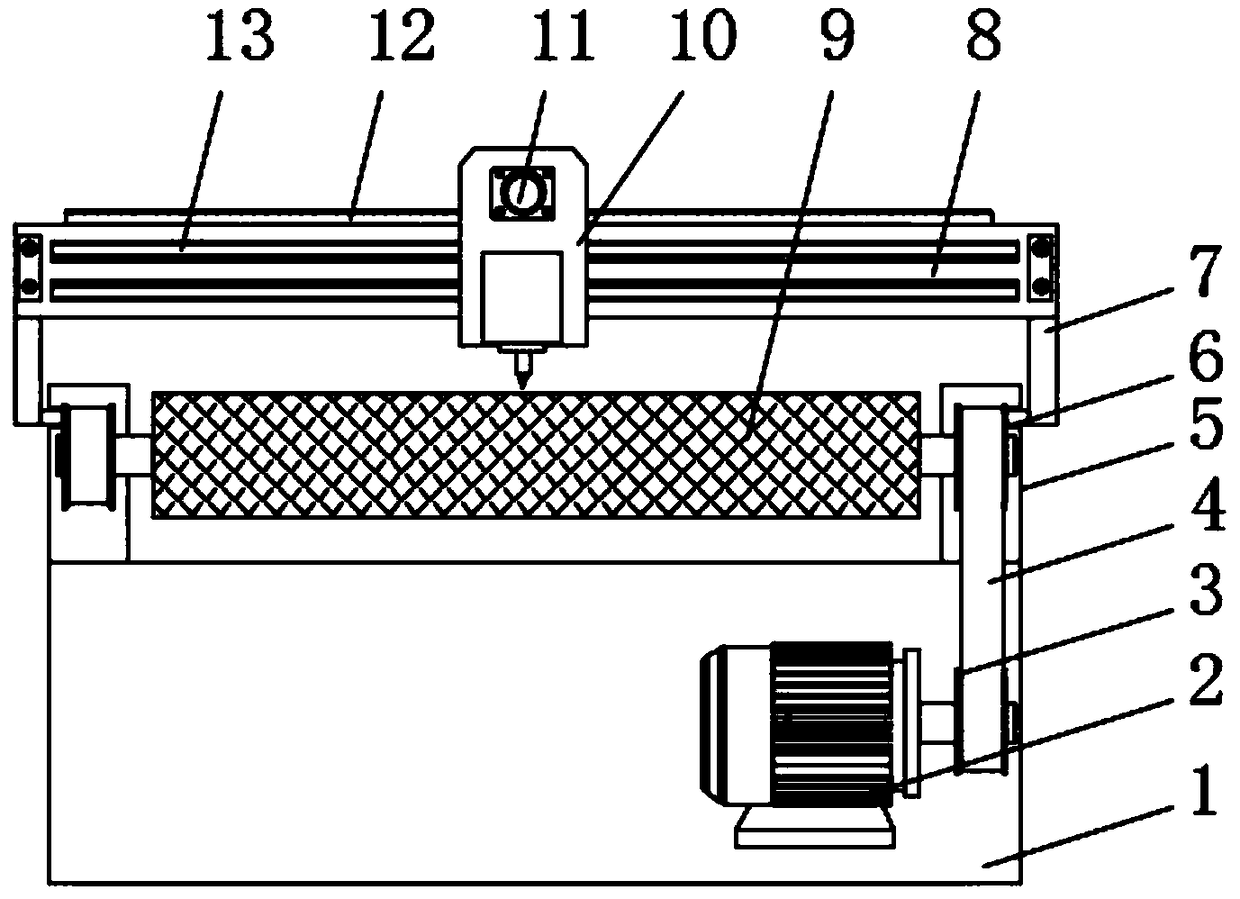

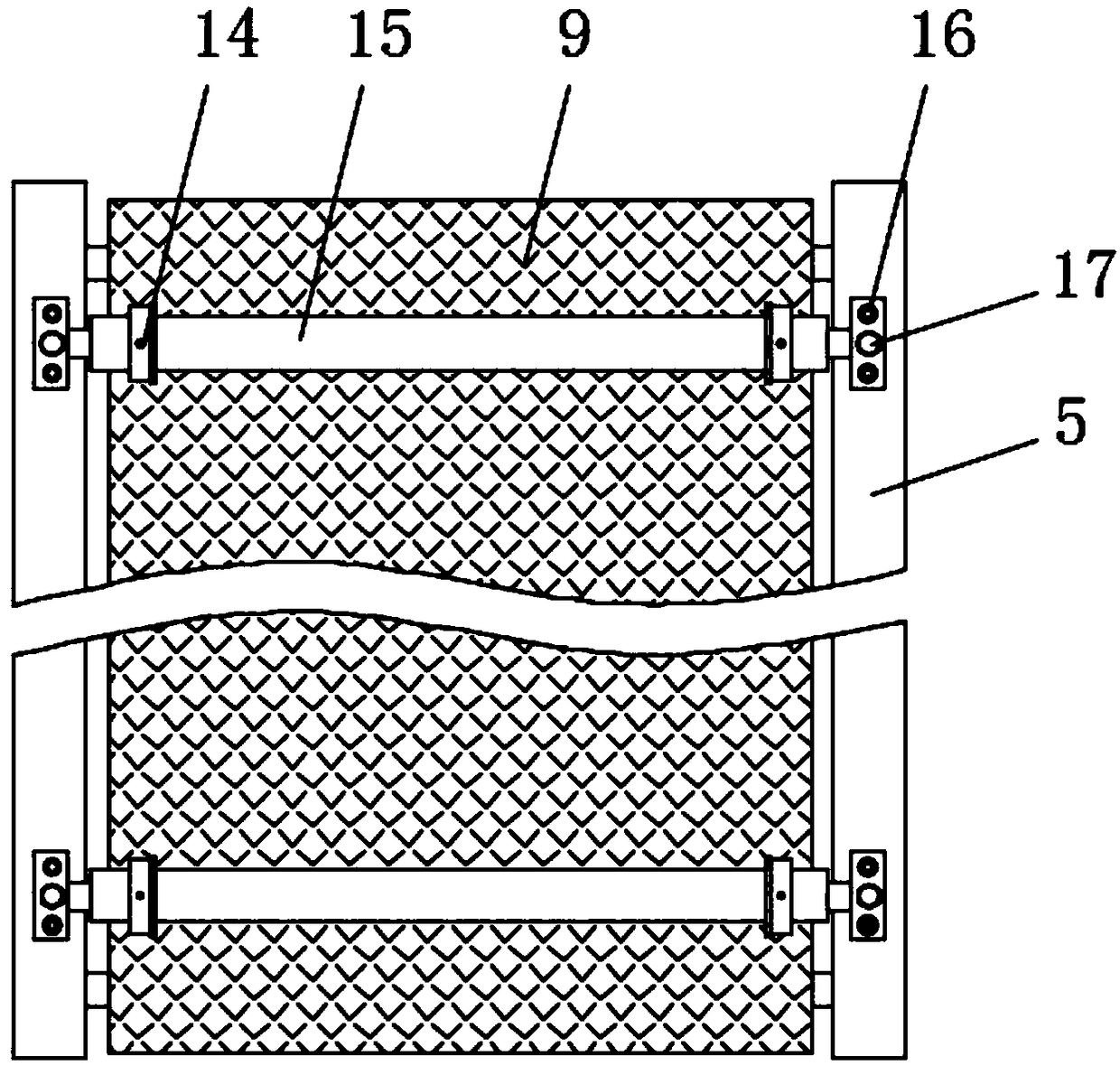

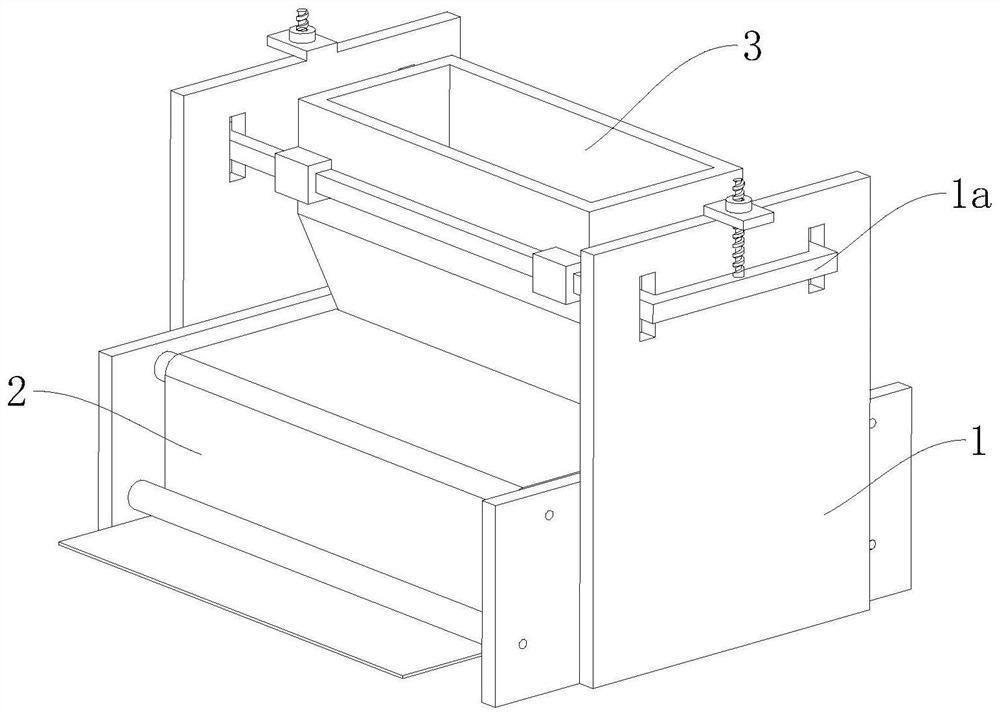

Bottom material pre-coating machine for leather waterborne finishing agent and leather surface processing equipment and technology

InactiveCN108774653AMeet the needs of regular replacementImprove replacement efficiencyLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringSlurry

The invention provides a bottom material pre-coating machine for a leather waterborne finishing agent and leather surface processing equipment and technology. The bottom material pre-coating machine comprises a rack, wherein the rack is provided with a pressing roller, a tensioning roller and an adhesive tape transmission roller, wherein a conveyer belt for conveying leather to be covered sleeve among the pressing roller, the tensioning roller and the adhesive tape transmission roller; the adhesive tape transmission roller is in power connection with a driving mechanism; the rack is further provided with a finishing roller; the finishing roller is provided with a finishing roller rapid replacement mechanism; the leather surface processing equipment comprises the bottom material pre-coatingmachine; a leather buffing machine is arranged at the upstream of the equipment, and an ironing machine, a roller printing finishing machine, an ironing embossing machine and a slurry spraying machine are arranged at the downstream of the equipment in sequence; the leather surface processing technology comprises the steps of carrying out leather blank buffing, pre-coating a bottom material, ironing a leather blank, rolling a waterborne wet-process material, embossing and carrying out color spraying. According to the bottom material pre-coating machine for the leather waterborne finishing agent and the leather surface processing equipment and technology, the coating quality and efficiency of the bottom material of a waterborne polyurethane leather finishing agent are improved, and the problems that leather easily has an uneven surface and the edge is not ordered when the exsisting equipment utilizes the waterborne polyurethane leather finishing agent to treat leather are solved.

Owner:山东莱福特皮革制品有限公司

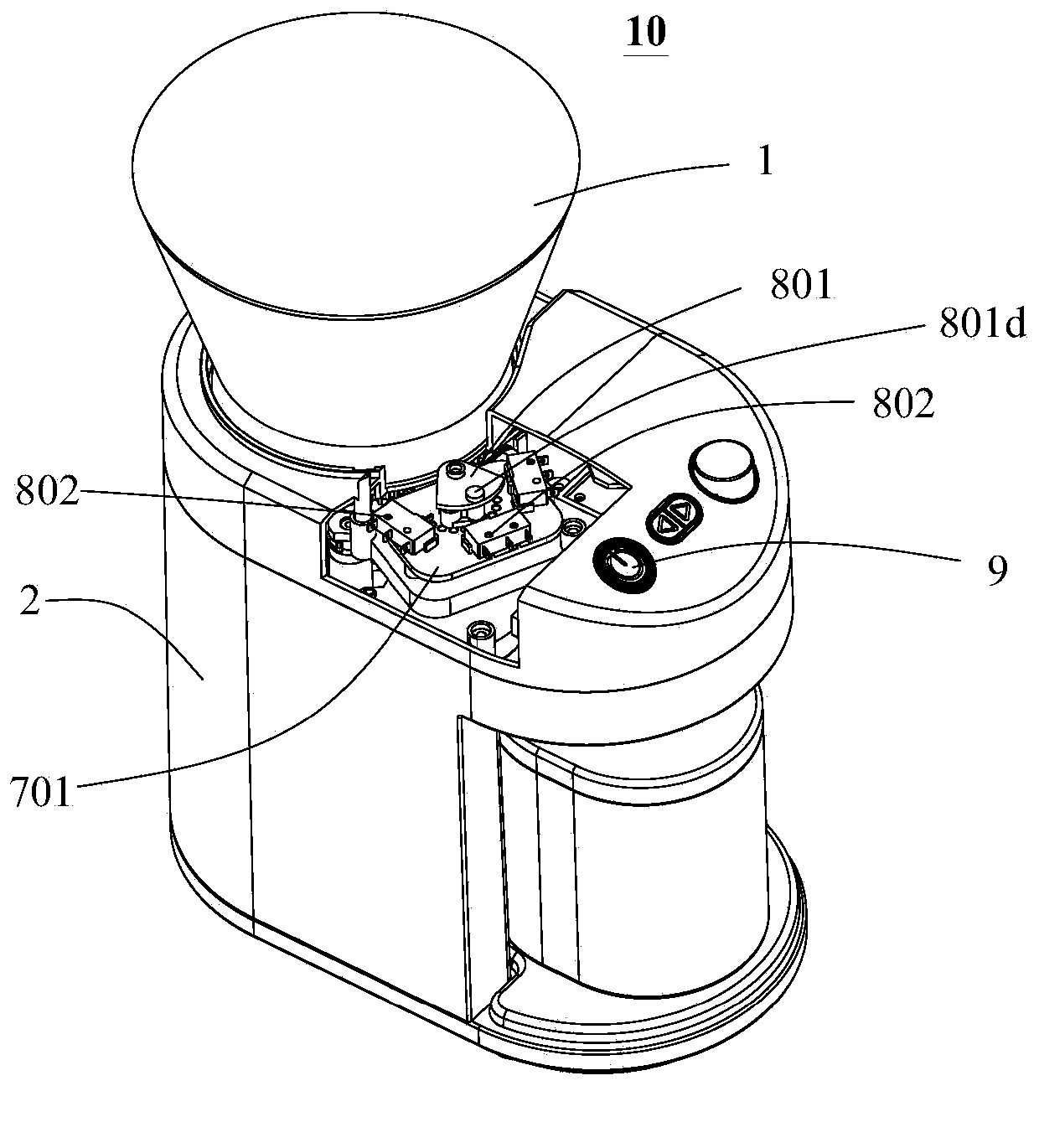

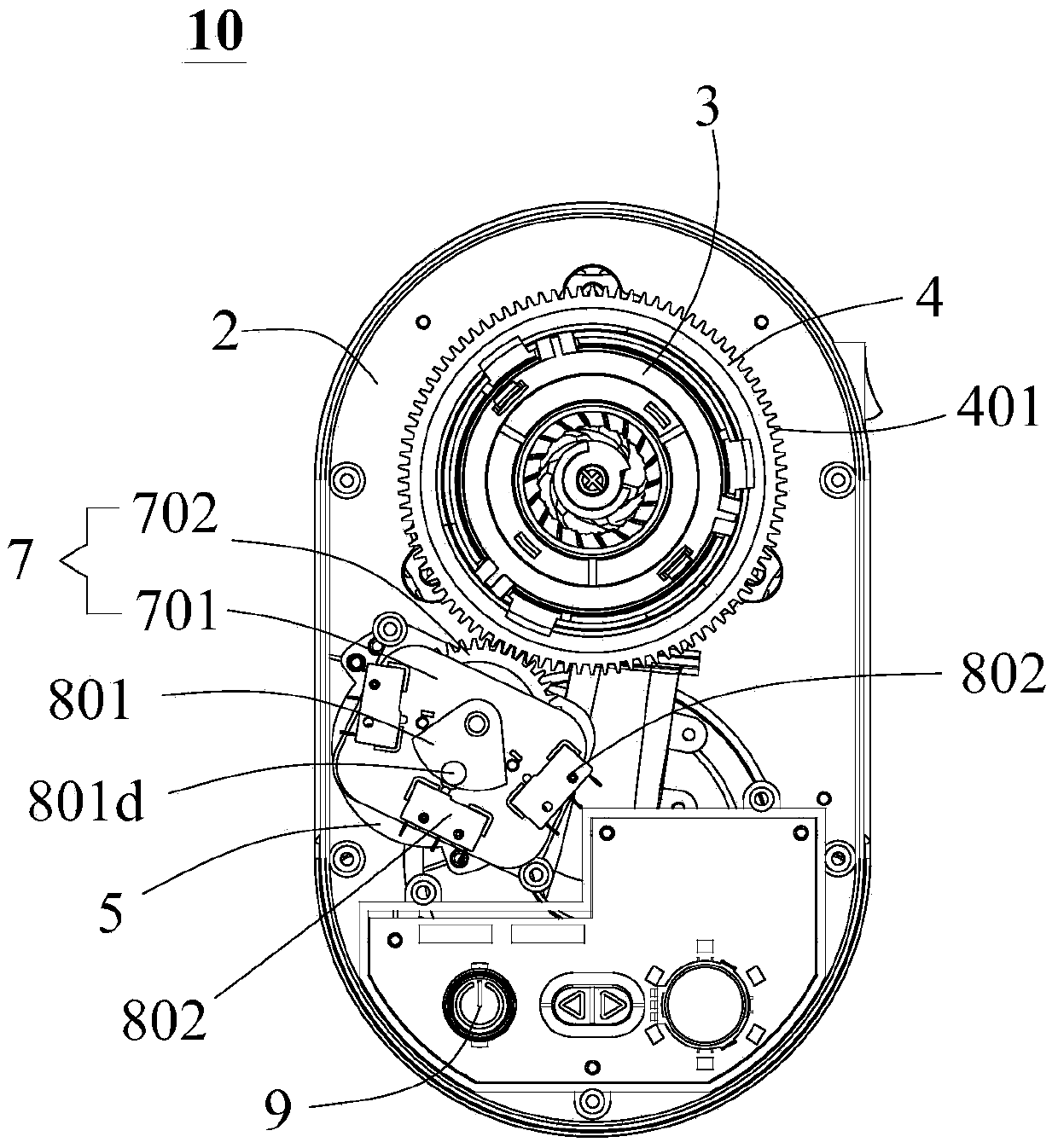

Powder grinding device

ActiveCN104172946AEasy to useControl rotation angleCoffee millsSpice millsEngineeringElectric control

The invention relates to a powder grinding device which comprises a main body, an abrasive wheel assembly arranged in the main body, a rotary adjusting ring arranged on the abrasive wheel assembly and used for adjusting crudeness and fineness of powder ground by the abrasive wheel assembly, a power source arranged on the main body and used for promoting rotation of the rotary adjusting ring, and an angle controller arranged on the main body and used for controlling the rotation angle of the rotary adjusting ring. According to the powder grinding device, the crudeness and fineness of the ground powder are adjusted by the adoption of an electric control mode, so that the use of the powder grinding device is simple, and the level in people's heart is improved.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

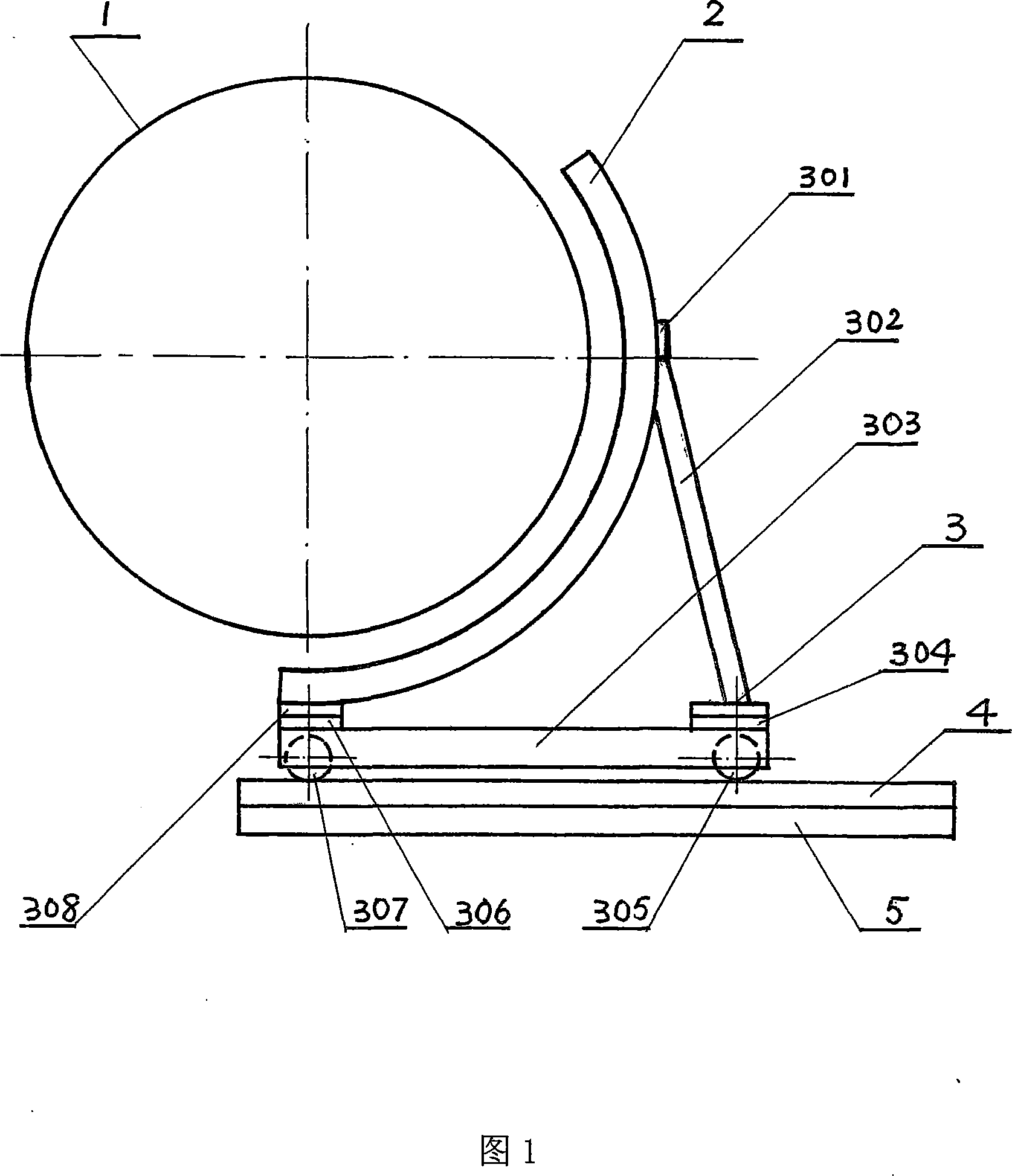

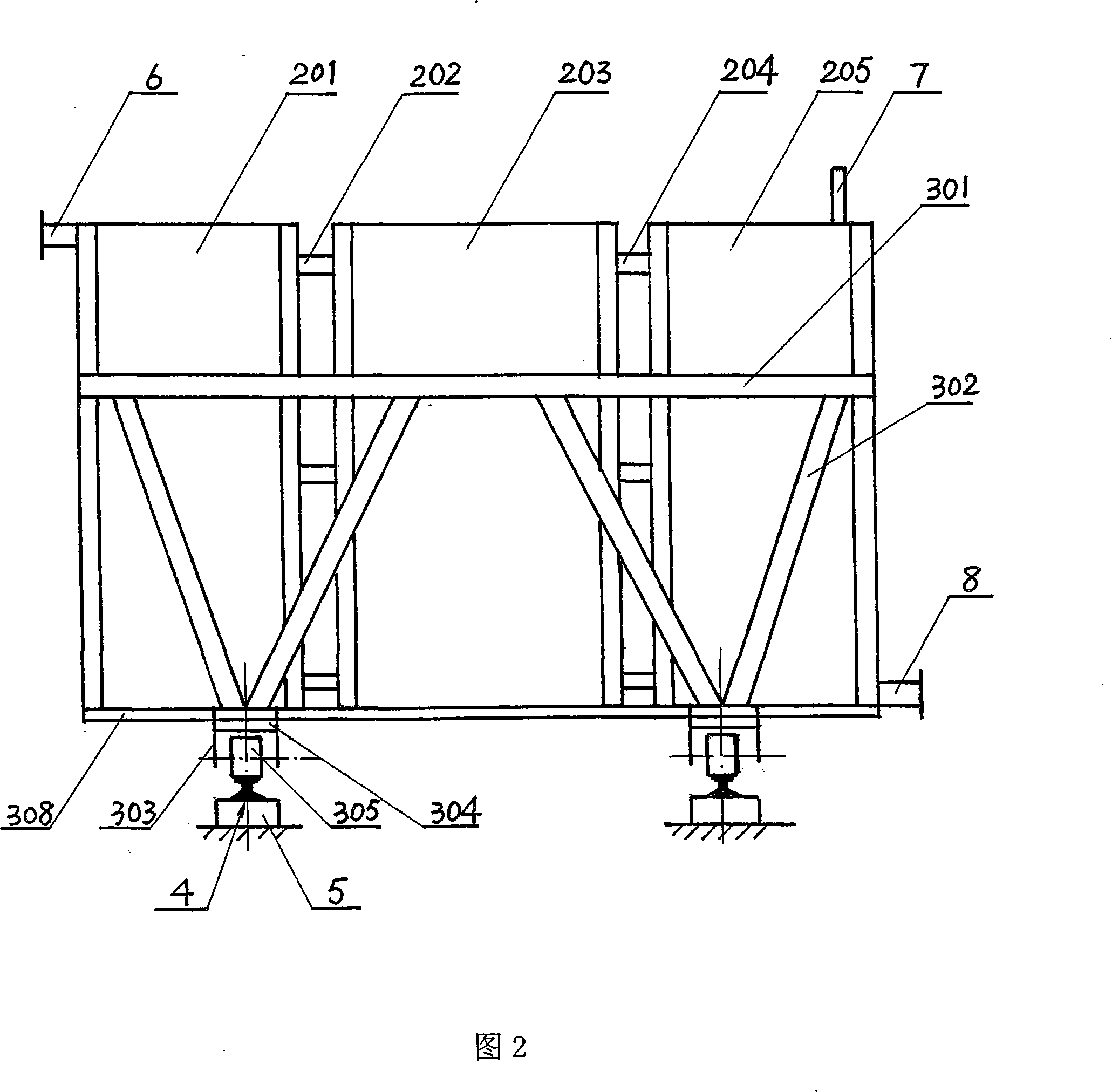

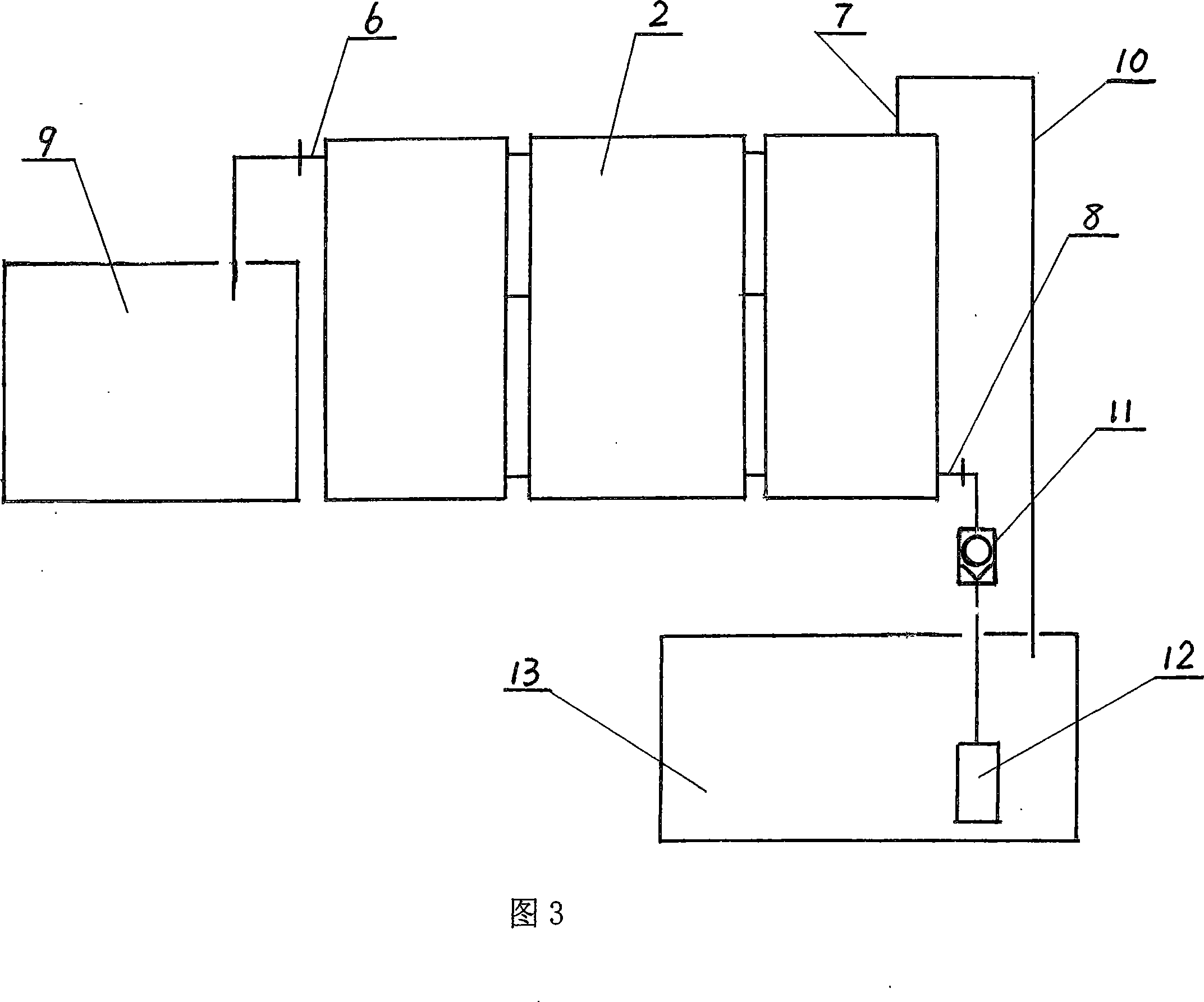

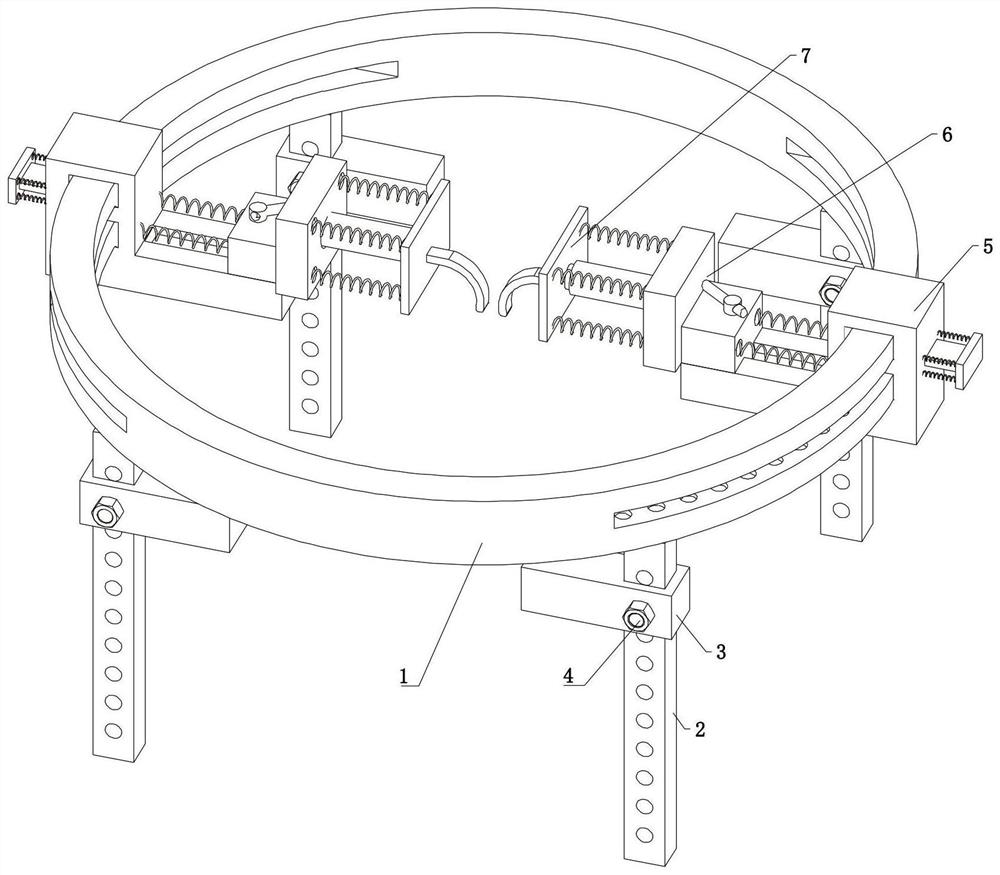

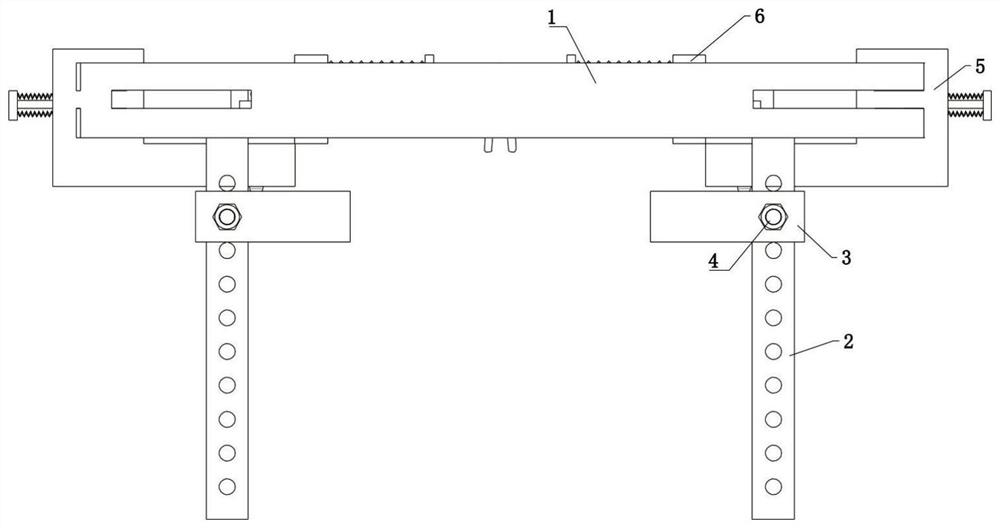

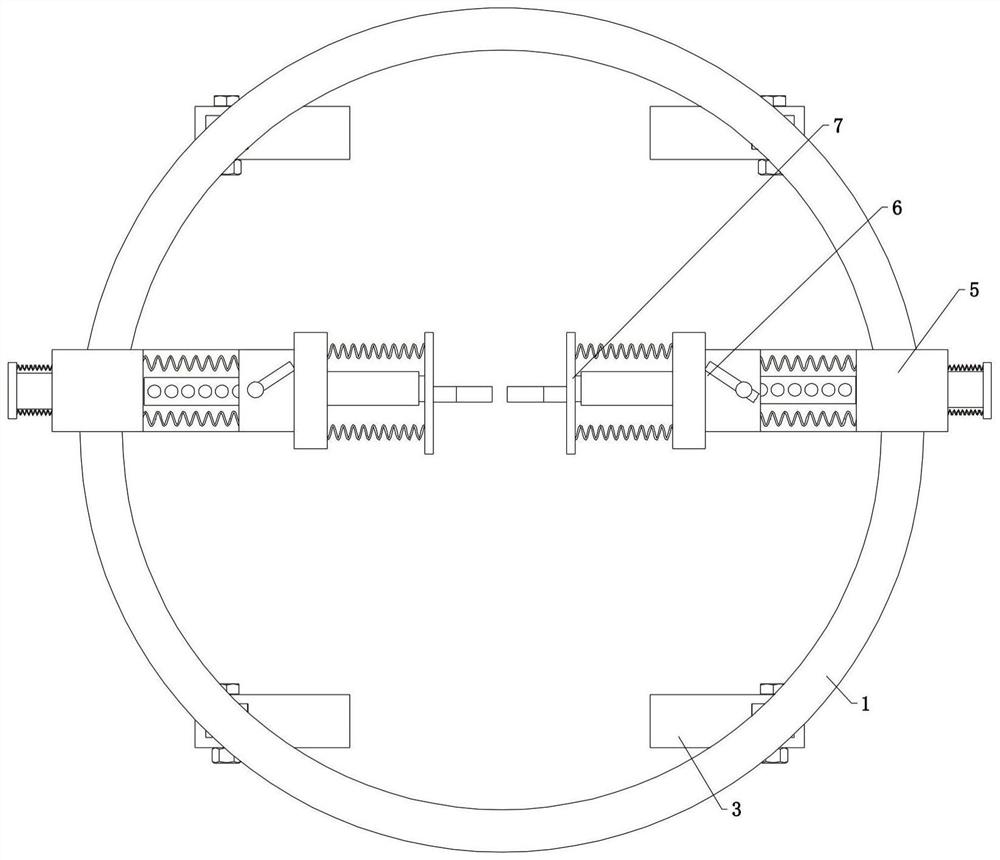

Rotary kiln surface residual heat utilization device

InactiveCN101187532AStable temperatureEffective absorptionIncreasing energy efficiencyStationary tubular conduit assembliesAutomatic controlEngineering

The invention discloses a residual heat utilizing device for the surface of a rotary kiln, which mainly solves the problem that residual heat resources of the surface of the rotary kiln can not be effectively utilized. The residual heat utilizing device for the surface of the rotary kiln comprises a heat exchanger which is arranged on the outer surface of the rotary kiln, the heat exchanger is provided with a heat-absorbing surface which is corresponded to the shape of the surface of the rotary kiln, the heat exchanger is fixed on a supporting stand, a relative position between the heat-absorbing surface of the heat exchanger and the surface of the rotary kiln is kept being stabled through the supporting stand, and the heat exchanger is provided with a water inlet and a water outlet. The heat exchanger is provided with a plurality of heat exchanger units, and each heat exchanger unit is connected through a communicating pipe. The heat exchanger adopts a curl plate type multilayered structure or a curl pipe range type structure, the water inlet of the heat exchanger is connected to a water outlet of a water pump, and the water outlet of the heat exchanger is connected to a hot-water tank. An electronic temperature controller can automatically measure water temperature and automatically control running the water pump according to a setting temperature. The invention can effectively absorb heat which is given off from the surface of the rotary kiln, and provide hot water with stable temperature.

Owner:山东长泰机械制造有限公司

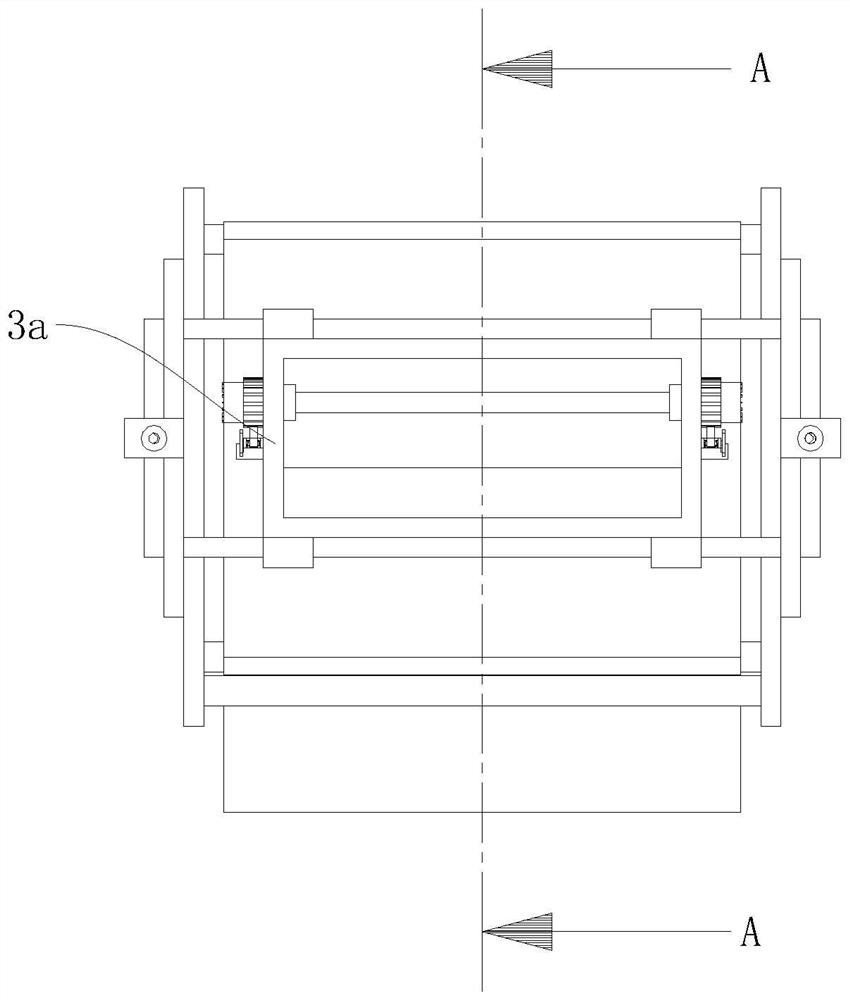

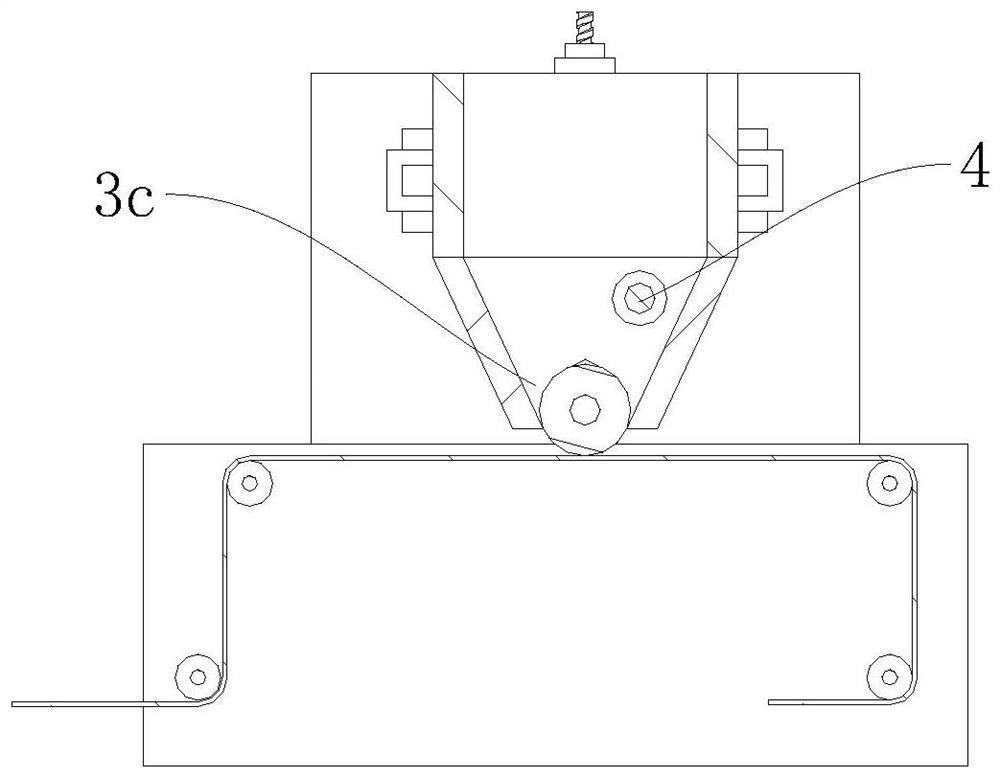

Base paper coating and printing all-in-one machine and production method thereof

ActiveCN108749302AReduce areaImprove rate consistencyLiquid surface applicatorsRotary pressesPulp and paper industrySlip ring

The invention discloses a base paper coating and printing all-in-one machine which comprises a compression roller, a feeding roller, a second coating groove, a fixed seat and a sliding chute, whereina sliding rail is movably connected onto the sliding chute; a first coating groove is fixedly connected with the top of the sliding rail; the other side of the second coating groove is fixedly connected with a sponge roller through a first bracket; the sponge roller is in contact with the bottom of the feeding roller; a discharging hole is formed in the inner side of the first coating groove; a second bracket is fixedly connected with the inner side of the first coating groove; the inner side of the first coating groove is hinged to a trapezoidal flow guiding plate; the flow guiding plate is positioned below the discharging hole; the second bracket is positioned above the discharging hole; two first springs are connected between the second bracket and the flow guiding plate; the position above the flow guiding plate is contact with the sponge roller; a slip ring is connected with the outer side of the second bracket; an inserted rod is movably inserted on the slip ring; and a scraper is fixedly connected with the bottom of the inserted rod. The base paper coating and printing all-in-one machine can improve the defects in the prior art and can reduce the coating area according to the demand of a carbon-free paper printed matter.

Owner:得力高控股有限公司

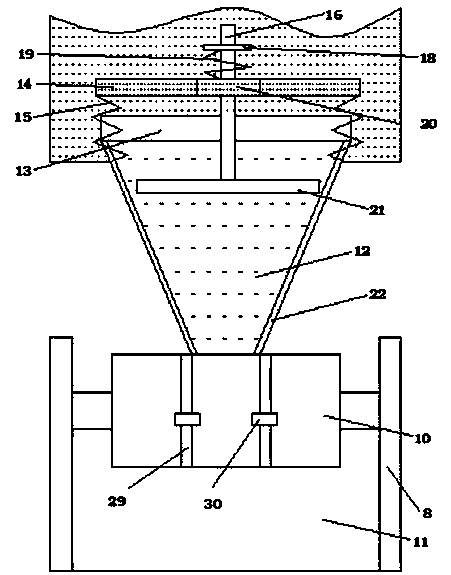

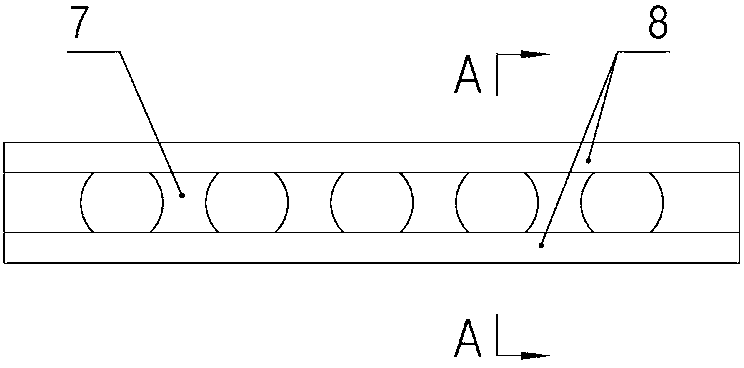

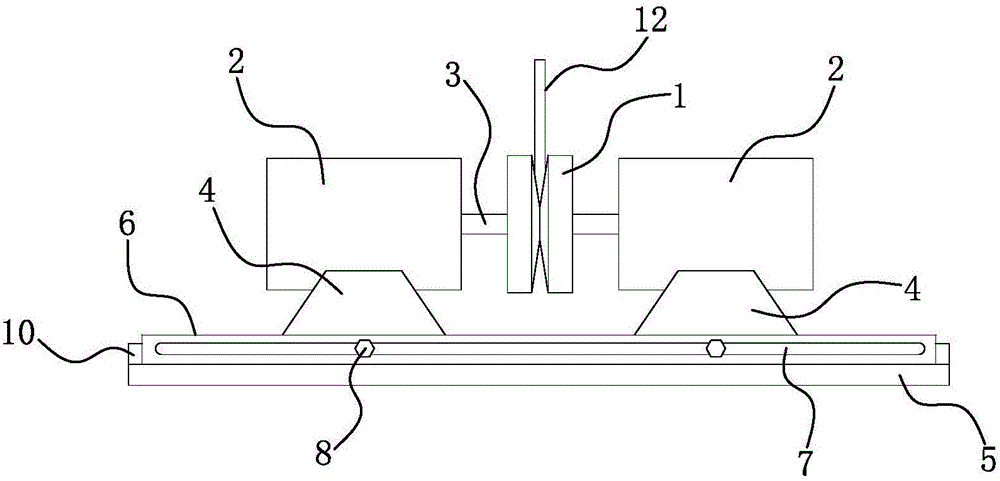

Linear guideway assembly

InactiveCN103100859AReduce frictional resistanceEasy to installLarge fixed membersEngineeringMachine tool

The invention discloses a linear guideway assembly which is convenient to install, capable of reducing frictional resistance, and capable of automatically adjusting gaps. The linear guideway assembly comprises a slide bar, one side of the slide bar is provided with a fixed guide body, and the other side of the slide bar is provided with a guide seat and a movable guide body arranged in the guide seat. The top end of the guide seat is provided with a guide hole, the bottom of the movable guide body is provided with a guide post matched with the guide hole, and the guide post is arranged in the guide hole. A pre-tightening spring is arranged between the guide post and the bottom wall of the guide hole and arranged in the guide hole. Respective guide faces of the fixed guide body and the movable guide body are respectively provided with a plurality of placing holes, and steel balls are arranged in the placing holes, and the respective guide faces of the fixed guide body and the movable guide body are respectively provided with a baffle for preventing the steel balls from sliping off. All the steel balls are extended from corresponding baffles. The linear guideway assembly is mainly used for all kinds of machine tools.

Owner:JIANGSU TONGSU TRAFFIC FITTINGS

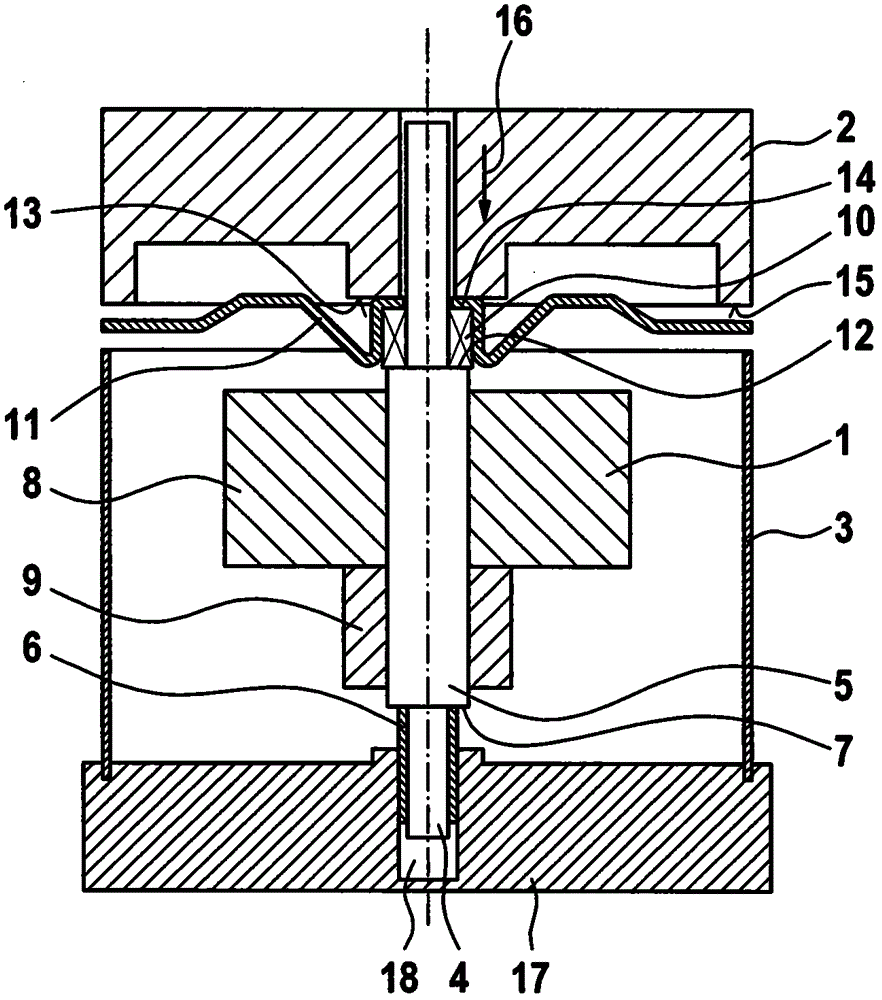

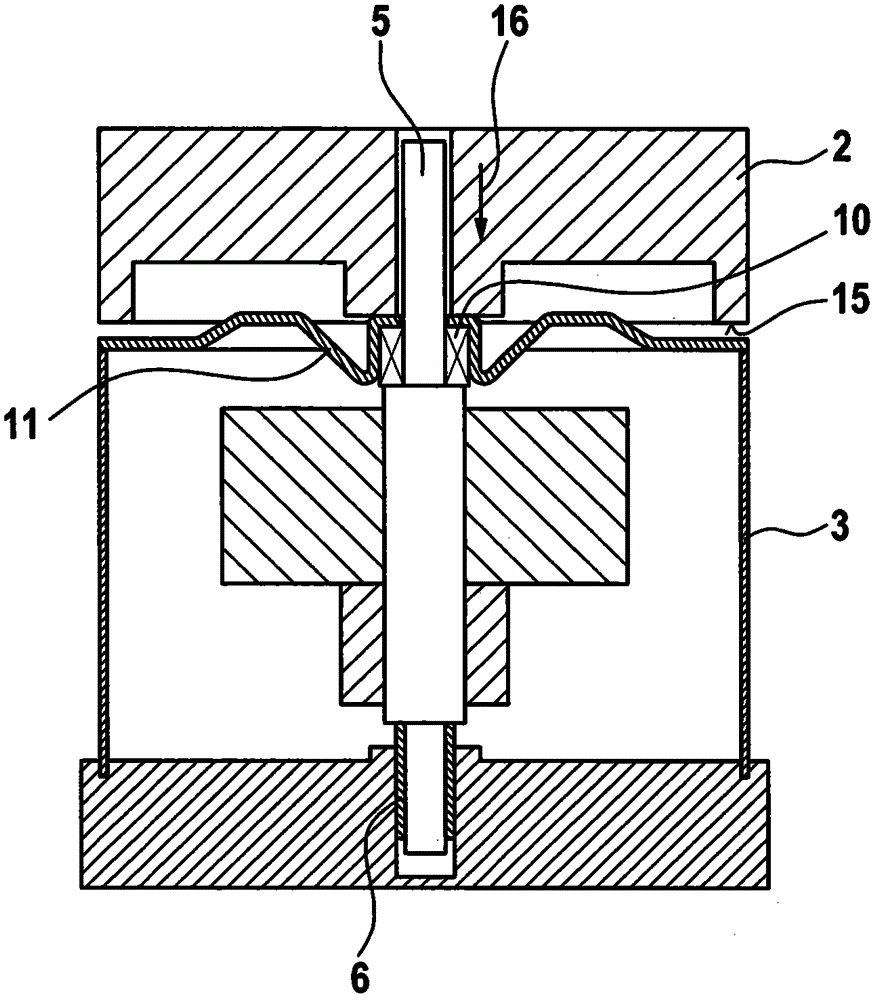

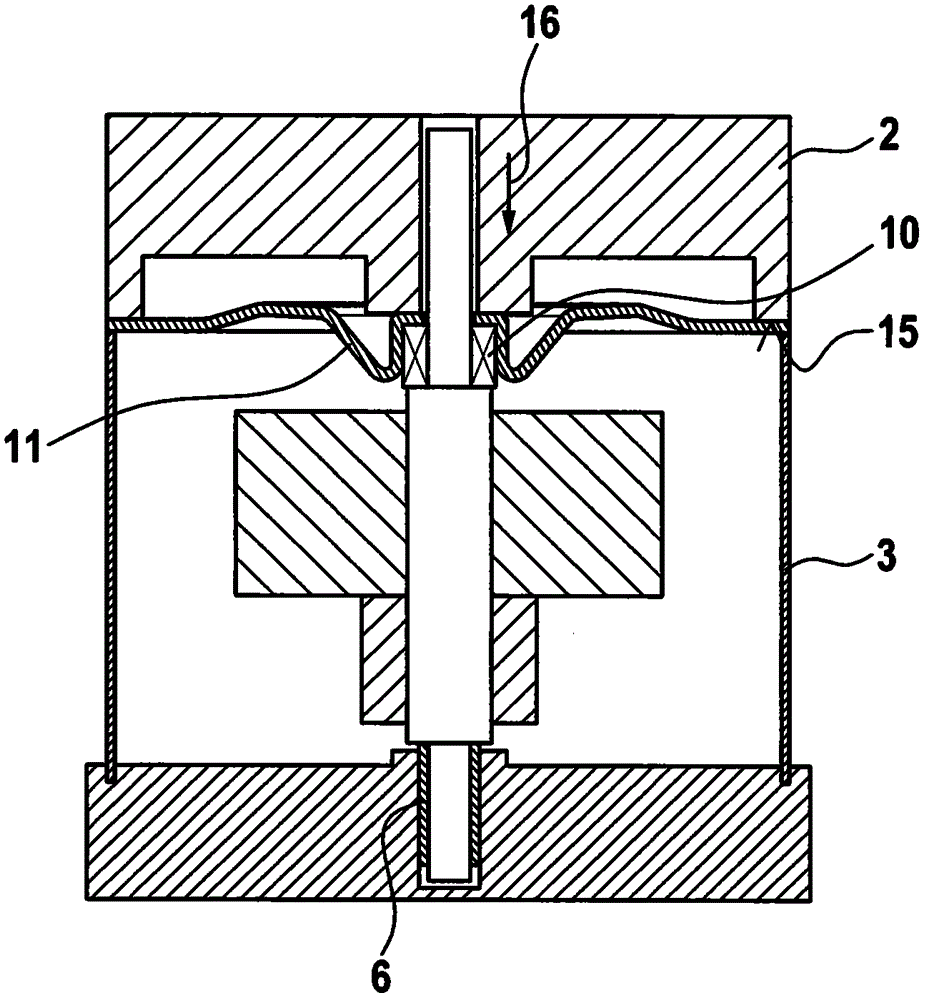

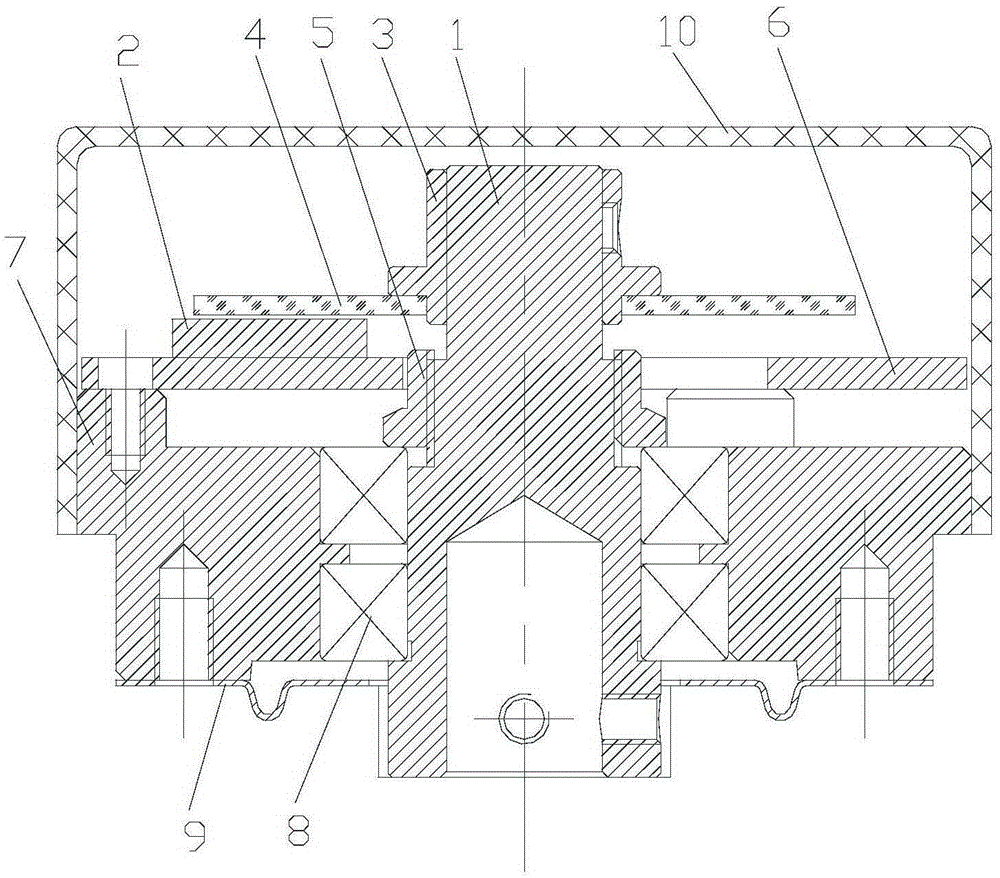

An electric machine and a method for adjusting the axial bearing clearance

InactiveCN104578541AAvoid offsetEasy to implementManufacturing dynamo-electric machinesSupports/enclosures/casingsAxial displacementElectric machine

The invention relates to an electrical machine and a method for adjustment of the axial bearing clearance (LS) between two bearings (6, 10) for mounting a rotor shaft (5) and provided on both sides of a rotor (1) of an electrical machine, wherein the rotor shaft (5) is at least supported axially displaceably in a bearing (6). The axial bearing clearance is adjusted by an axial displacement of the rotor shaft (5) adjoining the bearing (6) with an annular shoulder (7) in its axial position of a slidable first bearing (6), by the deflection movement, compared to a basic position without axial bearing clearancethe, the movable first bearing (6) moves to a final position with a predetermined axial clearance (LS).

Owner:SEG AUTOMOTIVE GERMANY GMBH

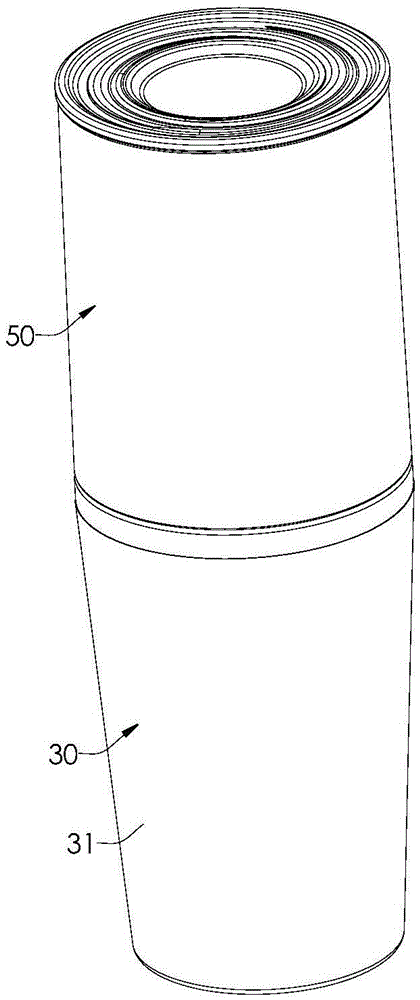

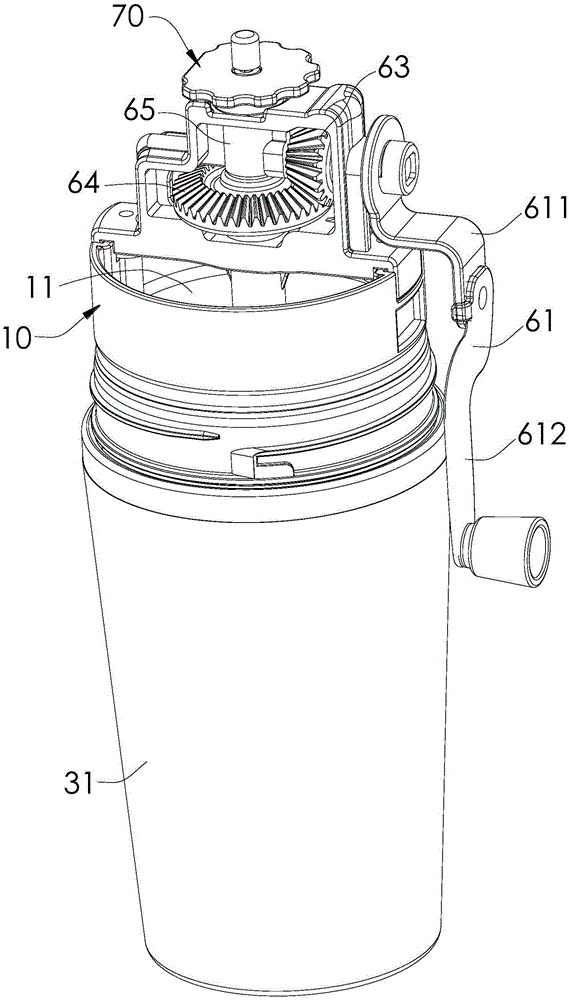

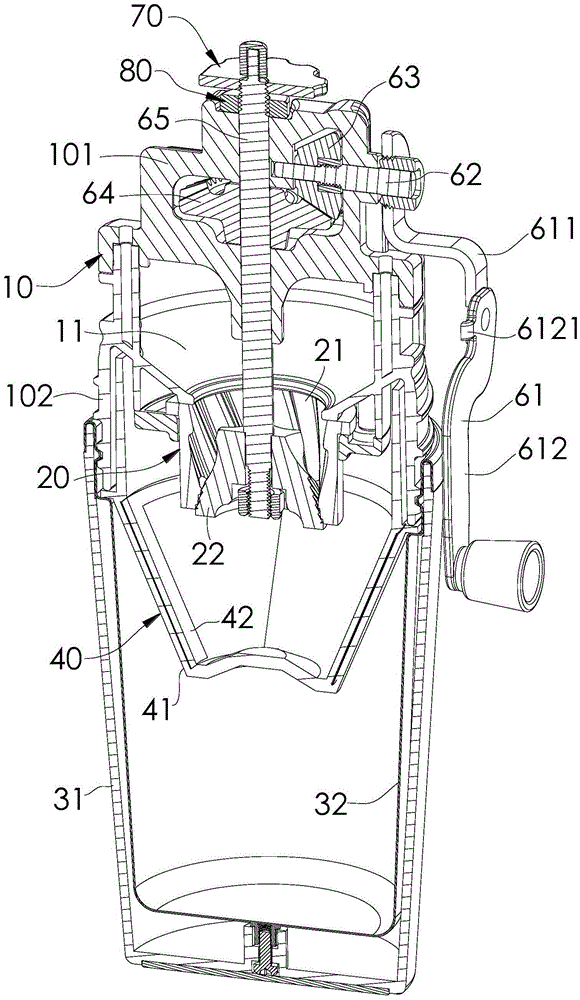

Coffee all-in-one cup machine

InactiveCN105581655AEasy to adjustEasy and Easy GrindingCoffee millsSpice millsEngineeringMechanical engineering

A coffee all-in-one cup machine comprises a support, a grinding assembly, a driving assembly and an adjustment sheet. A material cavity is formed in the support, the grinding assembly comprises a grinding barrel and a grinding core, the grinding barrel is fixedly arranged at the lower end of the support, the upper portion of the grinding barrel is communicated to the material cavity, the grinding core is movably arranged at the lower end of the interior of the grinding barrel, and a grinding gap is formed between the grinding core and the grinding barrel; the driving assembly comprises a main shaft, a first bevel gear, a second bevel gear, a rocking bar shaft and a rocking bar, the lower end of the main shaft penetrates through the inner side of the grinding barrel and is fixedly connected with the grinding core, the first bevel gear is installed on the main shaft in a sleeving mode and can rotate along with the main shaft and vertically move relative to the main shaft, the rocking bar is located outside one side of the support, one end of the rocking bar is fixed on the rocking bar shaft, and the first bevel gear and the second bevel gear are meshed with each other; the adjustment sheet is rotatably arranged on the support and is in threaded connection with the upper end of the main shaft. According to the coffee all-in-one cup machine, the size of ground beans can be conveniently adjusted.

Owner:陈志刚

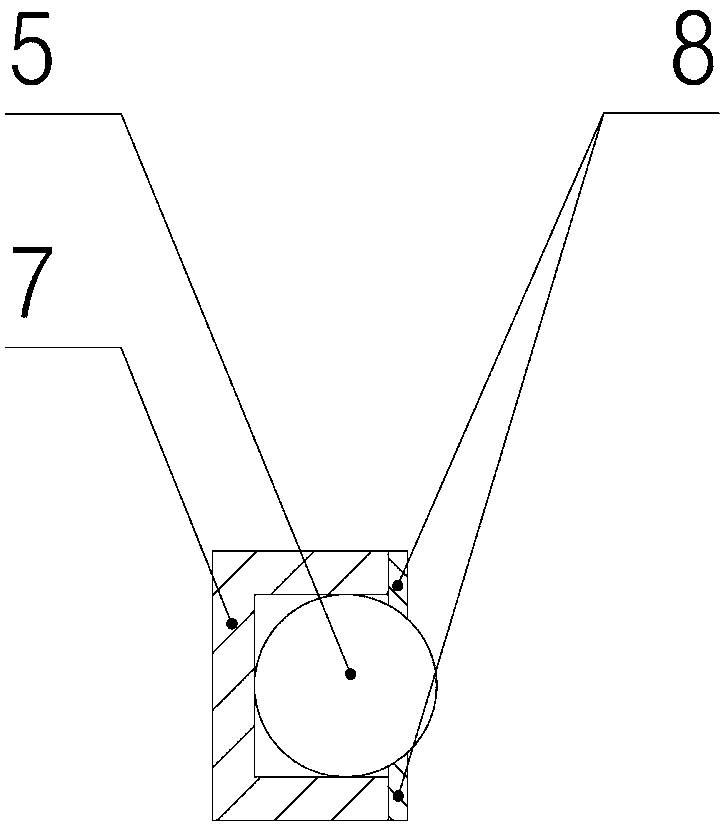

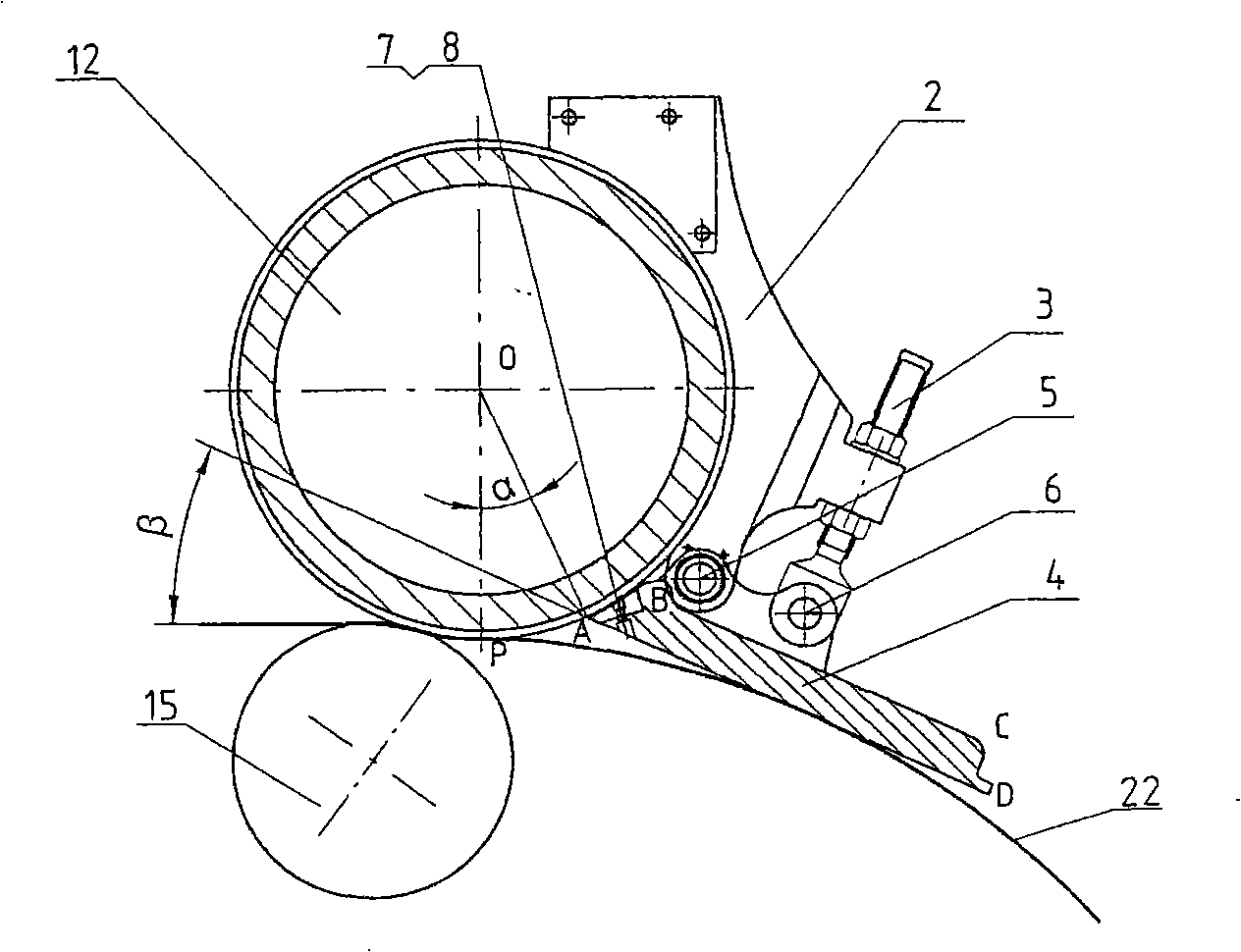

Swinging strip steel guiding conveying device

InactiveCN101264486AAvoid Folding Stack Steel FailuresAvoid fireGuiding/positioning/aligning arrangementsFlexible work arrangmentsHydraulic cylinderThin slab

The invention relates to a rotary guidance and transport device for band steel, belonging to the technical field of guidance and transport device for flexible workpiece, in particular to the device for guiding and transporting the band steel made by continuous casting and continuous rolling to a thin slab to a coiler. The device is characterized in that: an upper pinch roll is fixedly arranged on a swing arm, while the swing arm and a lower pinch roll are fixedly arranged in a housing window; the rotary guidance device is aslant arranged in the lower right part of the upper pinch roll, a gap is arranged on the cylindrical concave arc surface for enclosing a part of the upper pinch roll, the gap moves back Alpha angles from the gap of the upper pinch roll in relation to the biting line of the band steel, far away from the biting line; and the bottom of the rotary guidance device is a surface which is inclined Beta angles around the surface in relation to a rolling line. After use, the head of the band steel avoids the gap and runs to the bottom surface of the guidance device directly and refractably, guiding smoothly. The device has the advantages of simple and reasonable structure, reliable operation, avoidance for rolling or folding the heaping steel, convenience for reducing waste product, improving operating rate, saving energy and reducing consumption; less spare parts, easy implementation and maintenance, low running cost, and ability to avoid fire accidents of the hydraulic cylinder.

Owner:MAANSHAN IRON & STEEL CO LTD

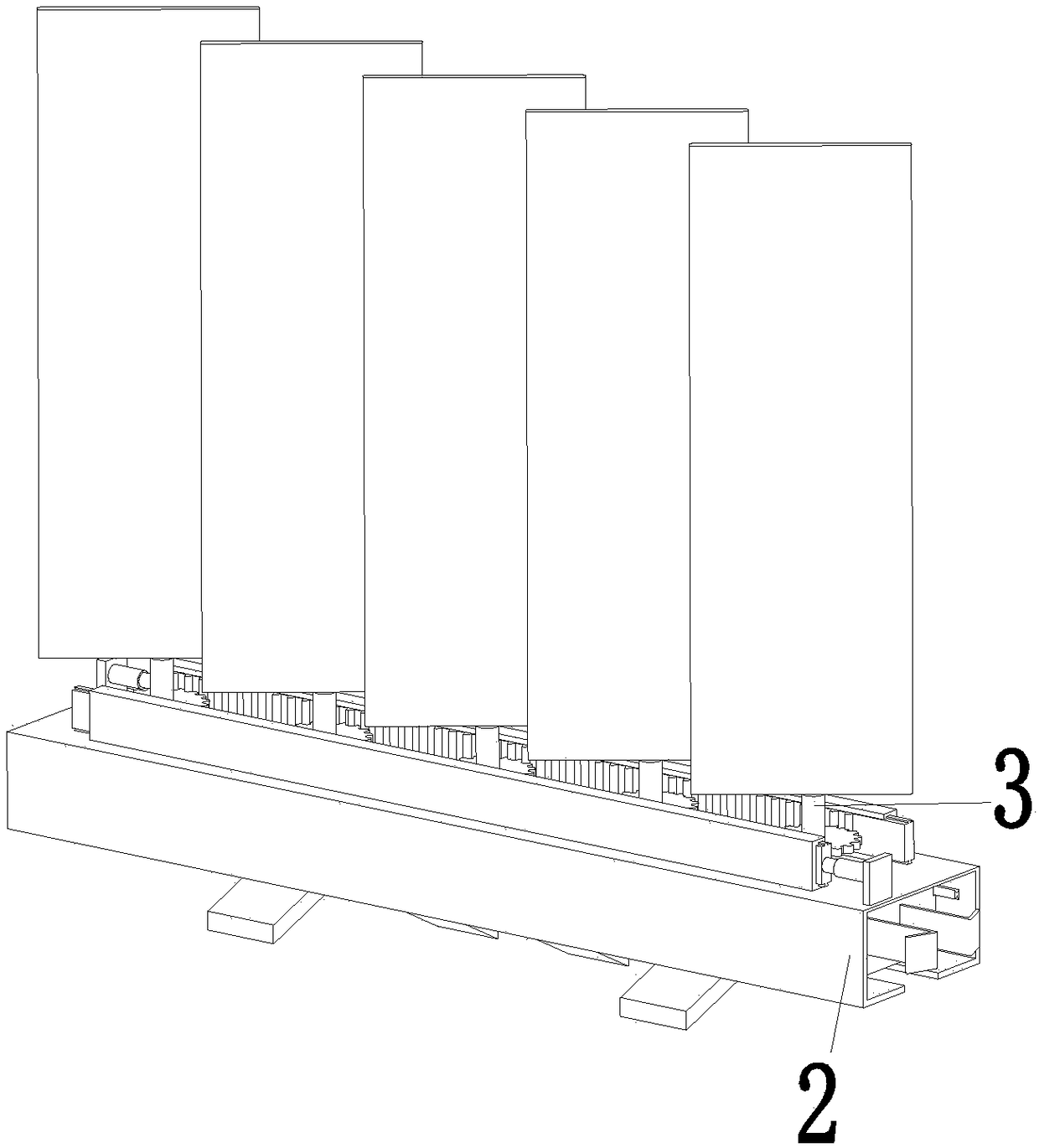

Novel architectural glass enclosing wall

ActiveCN109083499ANot easy to moveQuick fixFencingBuilding constructionsArchitectural glassEngineering

The invention relates to a novel architectural glass enclosing wall. The architectural glass enclosing wall comprises a moving device, a fast fixing device and a rotating device. The moving device ismounted on the inner side face of the fast fixing device, and the rotating device is mounted on the upper end face of the fast fixing device. The architectural glass enclosing wall can solve the problems that time and labor are wasted when existing glass enclosing walls are installed and fixed, the glass enclosing walls cannot be fast spliced and folded, and the air permeability cannot be adjustedunder the condition of ensuring an anti-theft effect; the glass enclosing wall can achieve the functions of fast installation and foldability.

Owner:SUZHOU HUAJIAN GLASS

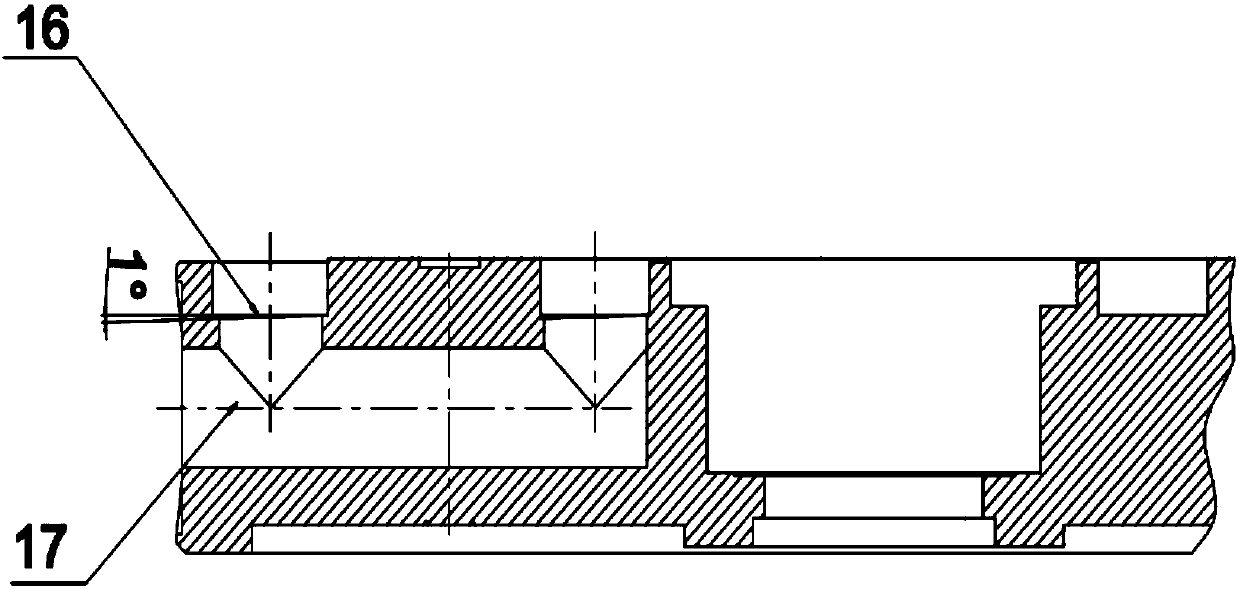

Wear-resistant piston head

The invention discloses a wear-resistant piston head used in the technical field of internal combustion engines. A pin shaft hole transversely penetrating the piston head is formed on the piston head, a plurality of piston ring grooves are formed above the pin shaft hole, a piston skirt part is arranged below the pin shaft hole, a radially raised step is arranged between the upper part of the pin shaft hole and the piston ring groove at the bottom, and the diameter at the step is equal to that of the piston skirt part. When the piston head is used, the inner diameter of the corresponding air cylinder is fitted with the diameter at the step, therefore, the diameter at the upper part of the piston is far smaller than the inner diameter of the air cylinder, the purposes of balancing the piston and adjusting the gap are achieved through a piston ring, simultaneously, the upper part of the piston is not in contact with the inner wall of the air cylinder during the working process, even if the operating conditions are bad and the piston is worn, the upper part of the piston can still keep a certain distance with the inner wall of the air cylinder to avoid the phenomenon of scuffing of cylinder bore and eccentric wear, and simultaneously, the piston head is not easily worn.

Owner:JIANGSU YANGGONG POWER MACHINERY

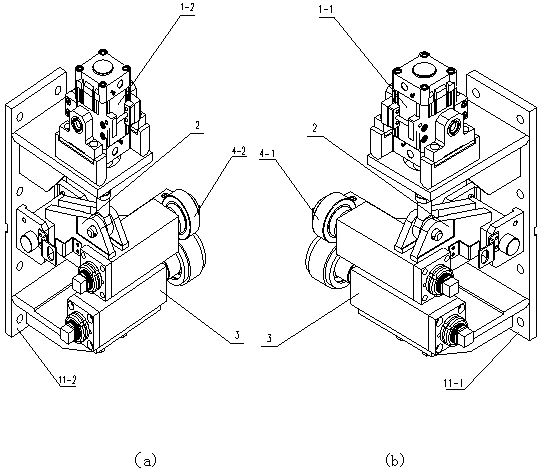

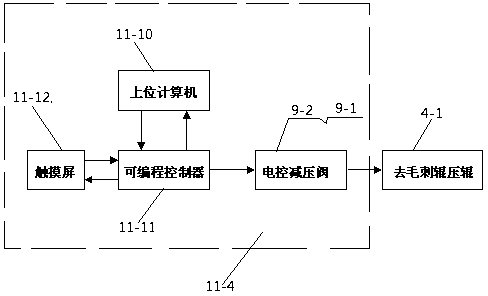

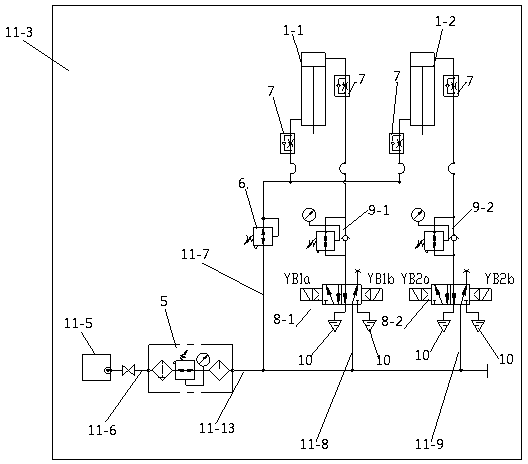

Automatic control system used for rolling force of burring roller and control method thereof

InactiveCN104070071AAdjust the gapAutomatic adjustment of rolling forceRoll force/gap control deviceAutomatic controlControl manner

The invention provides an automatic control system used for a rolling force of a burring roller and a control method thereof. The automatic control system comprises a left burring device and a right burring device, wherein the right burring device comprise a second cylinder; the left burring device comprises a first cylinder; a pneumatic control unit is connected with the first cylinder and the second cylinder in a controlling manner; an electric control unit is connected with the pneumatic control unit in the controlling manner. The automatic control method comprises the following steps of: A, obtaining and recording thickness, yield strength, size, plastic deformation coefficient and hardness of a processed work-piece; B, inputting results obtained in the step A into the electric control unit; C, starting up the automatic control system, and starting controlling the automatic control unit after an electrical control reducing valve receives an electric control signal; D, adjusting the size of the rolling force between a movable pressing roller of the debugging device and a processing belt material based on the control result obtained in the step B, and displaying in a display screen. According to the scheme, the adjusted rolling force of the burring device is high in precision, the processing materials to be used are wide in range, and the rate of finished products in the processing process is extremely high; the automatic control system used for the rolling force of the burring roller and the control method thereof can be widely applied to the belt material processing field.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

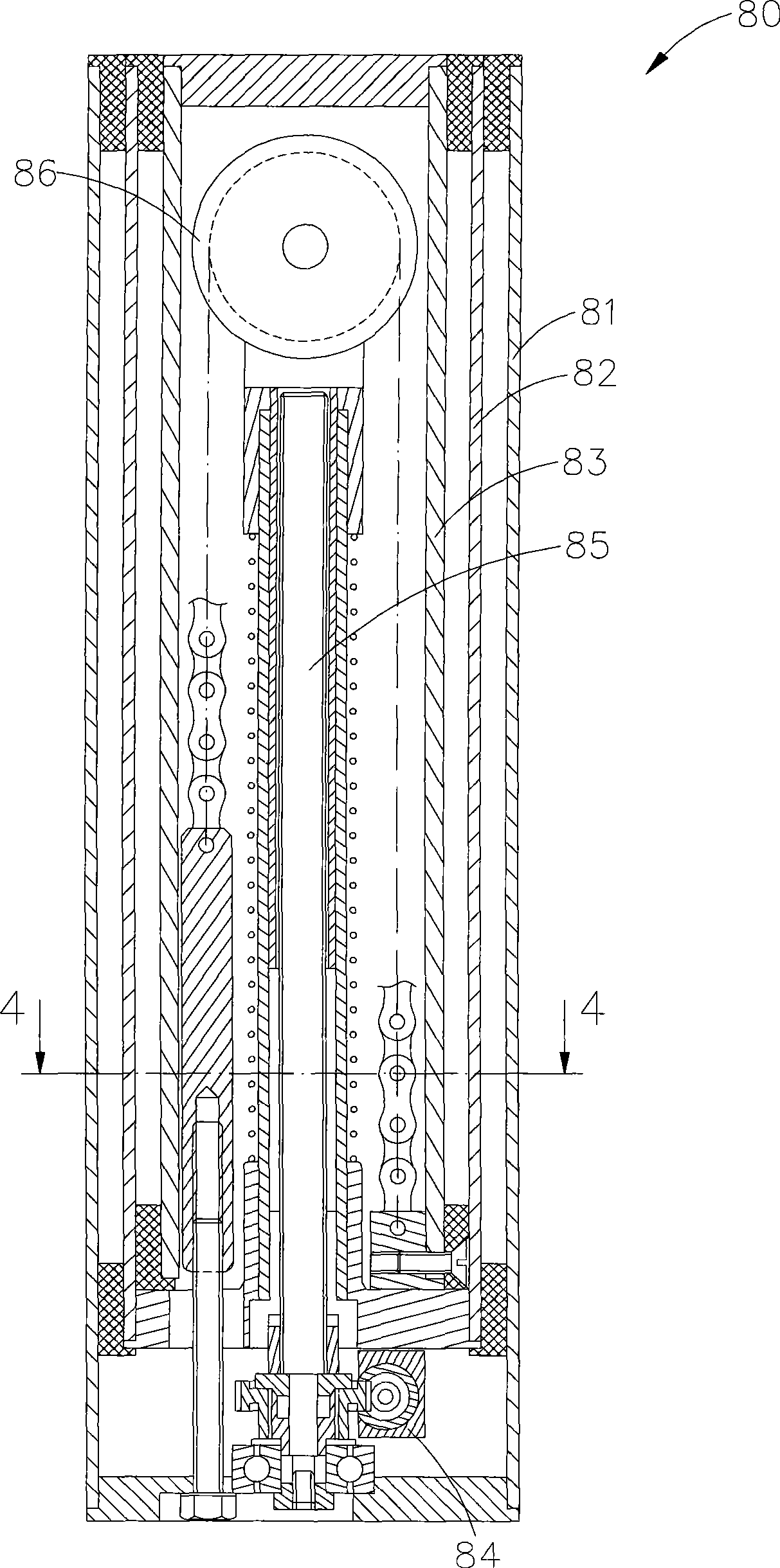

Linear actuator

The invention discloses a linear actuator, comprising an outer tube structure, a medium tube structure and an inner tube structure which are all of hollow polygonal tubular shapes. The outer tube is used for the medium tube and the inner tube to penetrate and clamp each other by spacing and is internally provided with a thrust gear and at least a tension adjusting device; the thrust gear is provided with a screw rod and a floating nut matching each other by a screw; the floating nut is combined with a pushing post and is pushed by the screw rod; a pulley is arranged at the top of the pushing post to support a drawing-supporting component by pushing; both ends of the drawing-supporting component are fixedly connected between the inner tube and the outer tube; another drawing-supporting component is arranged between the medium tube and the inner tube; the drawing-supporting component crosses the pulley; the tension of the drawing-supporting component is changed after being drawn by the tension adjustment device so that axial expansion and movement among tubes are stabler and more reliable.

Owner:HIWIN MIKROSYST

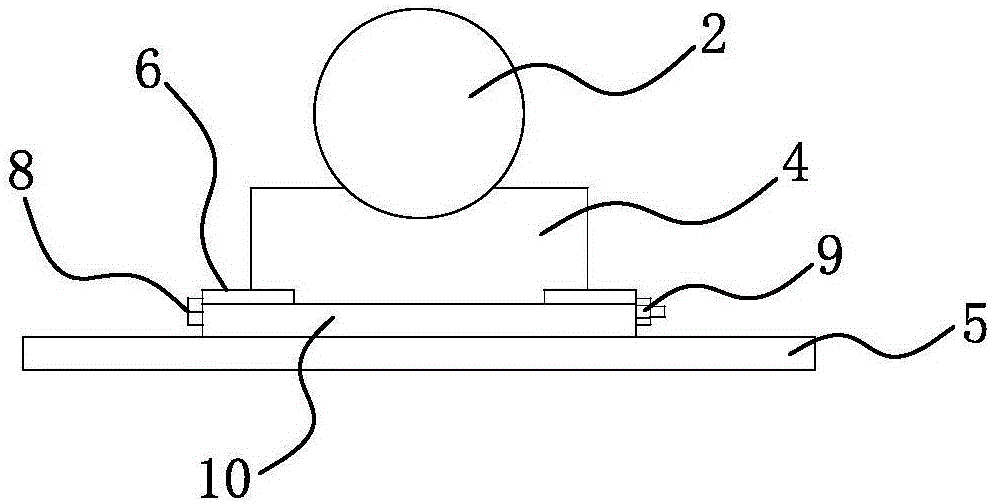

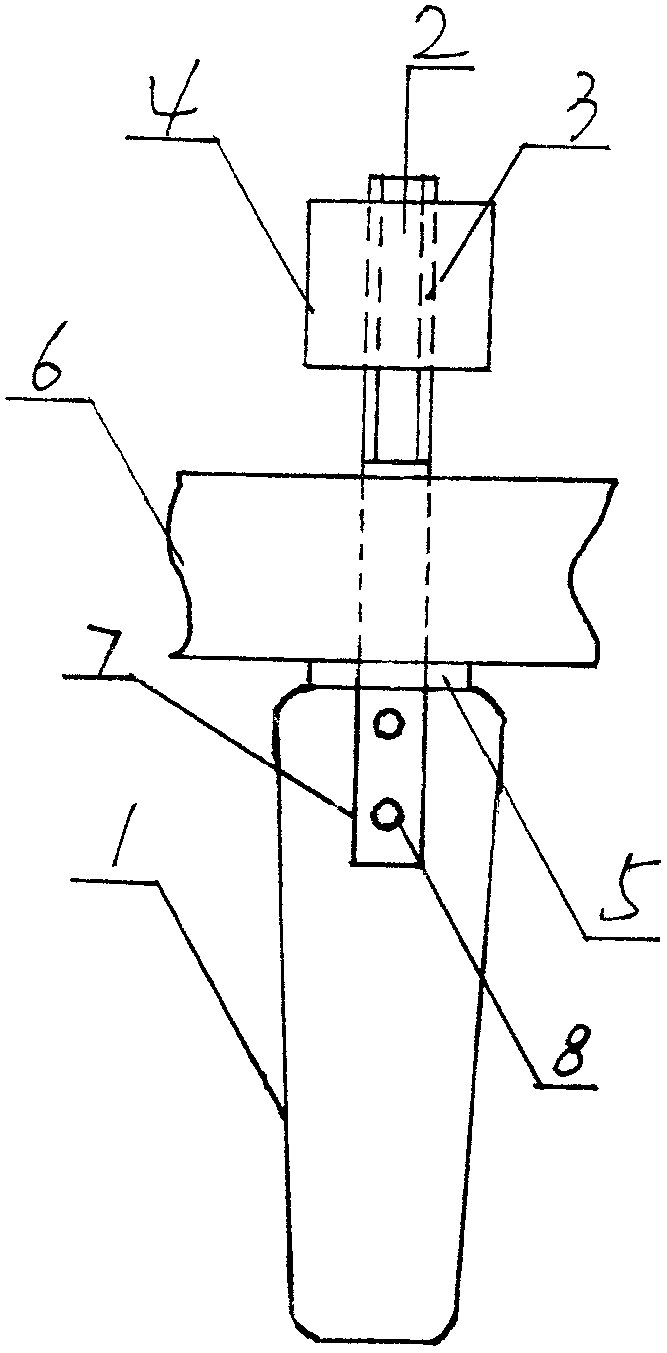

Photoelectric encoder

InactiveCN105258715AAdjust the gapQuality assuranceConverting sensor outputMechanical engineeringEncoder

The invention discloses a photoelectric encoder. The photoelectric encoder comprises a rotating shaft (1), a code disk assembly which sleeves the rotating shaft (1) in a sliding mode, and a photoelectric detection assembly (2) which is fixedly arranged on the rotating shaft (1). The code disk assembly is equipped with a locking member used for locking the axial position of the code disk assembly on the rotating shaft (1). According to the photoelectric encoder of the invention, the problem that the gap between the code disk and the photoelectric detection assembly of the photoelectric encoder in the prior art cannot be adjusted is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

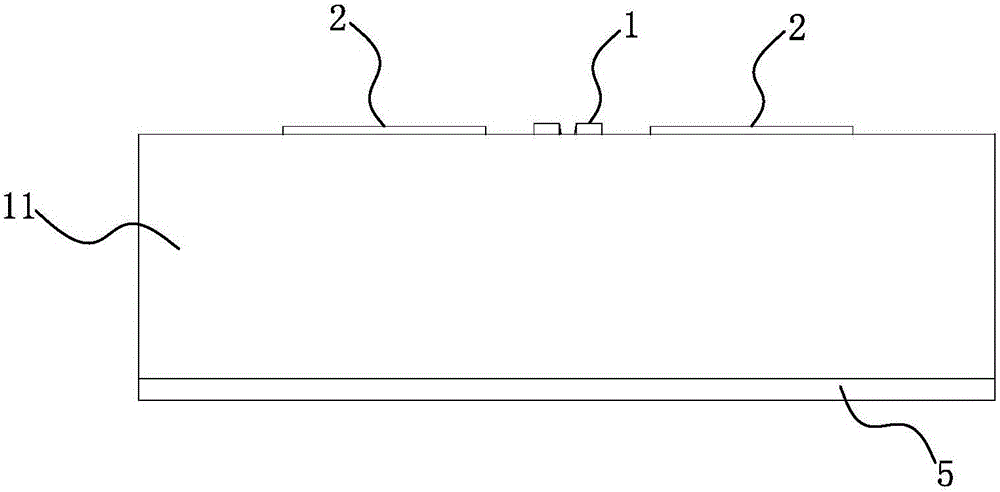

Tool sharpener

InactiveCN105904293ASimple and fast operationSimple structureOther manufacturing equipments/toolsGrinding/polishing safety devicesStructural engineeringGrinding wheel

The invention relates to a grinder for grinding tools, in particular to a tool sharpener which is simple in structure and easy and convenient to operate. The tool sharpener comprises two oppositely arranged grinding wheels (1) with opposite wheel surfaces being conical. The two grinding wheels (1) are driven by motors (2) correspondingly, and when the motors (2) drive the grinding wheels (1) to rotate, the two grinding wheels (1) are opposite in rotation direction.

Owner:江浩

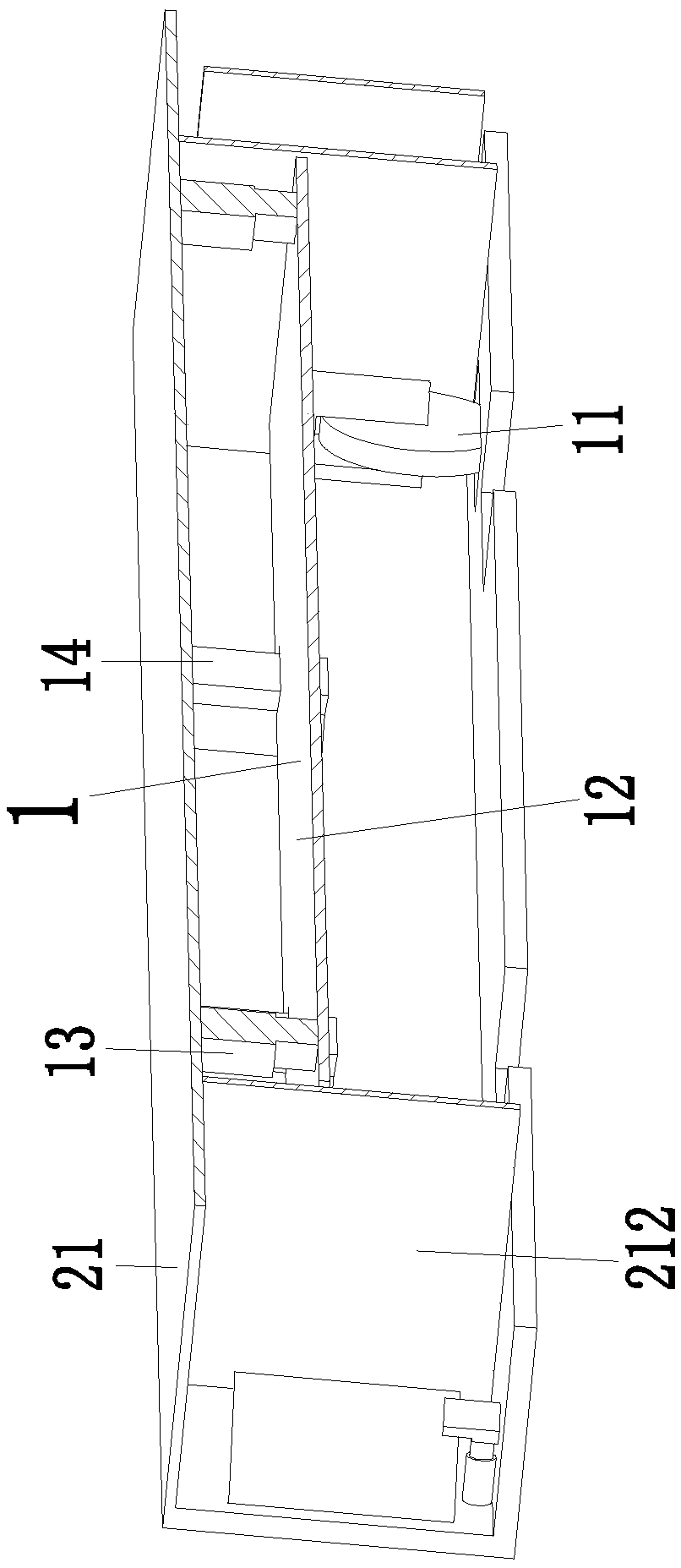

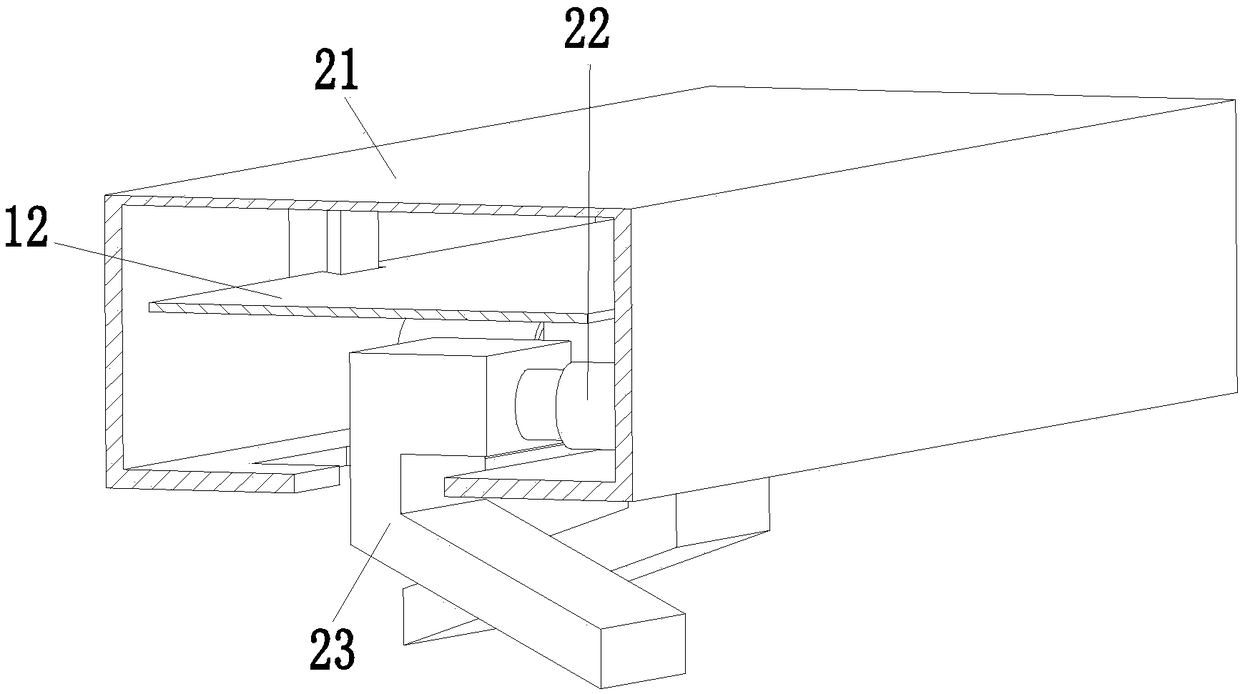

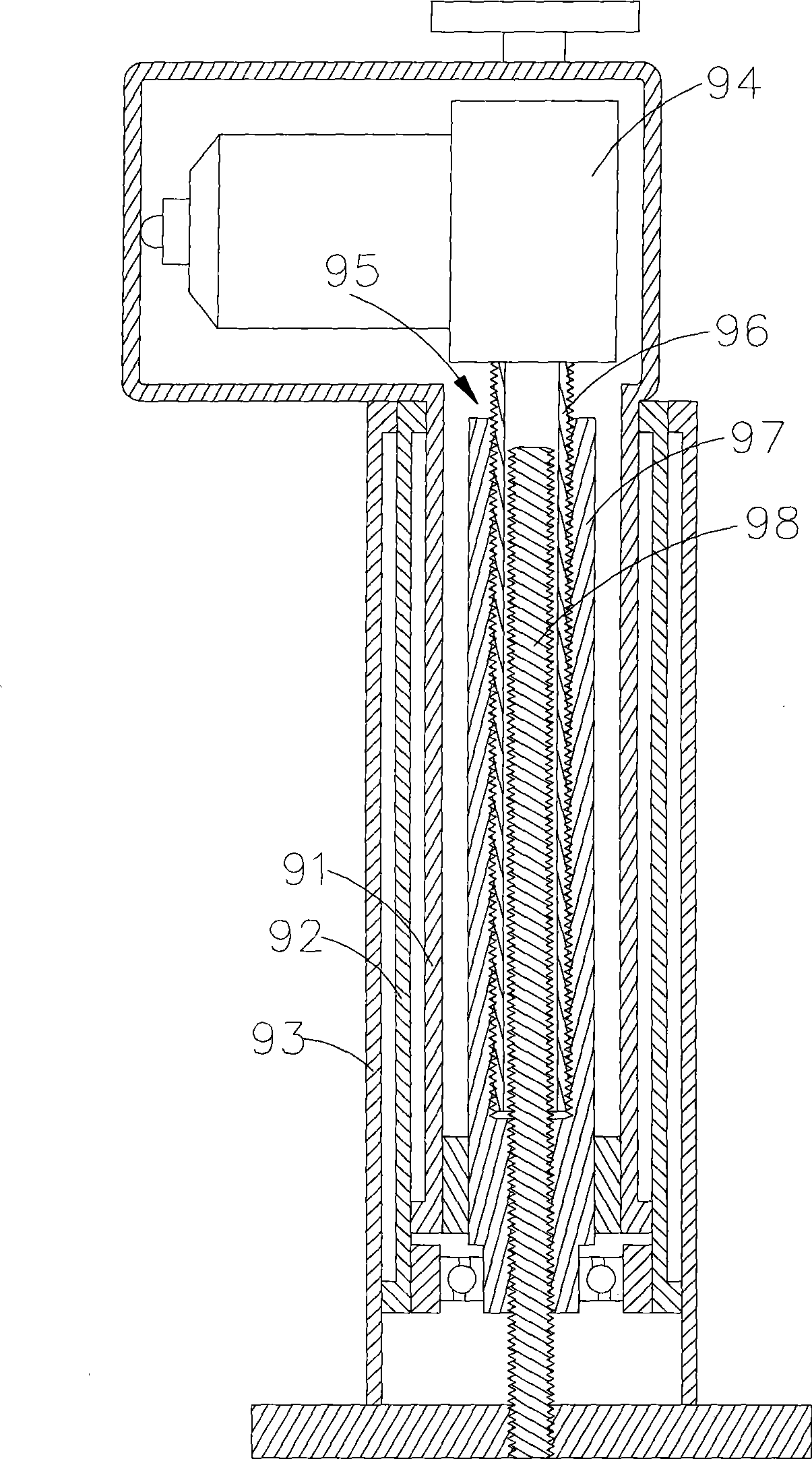

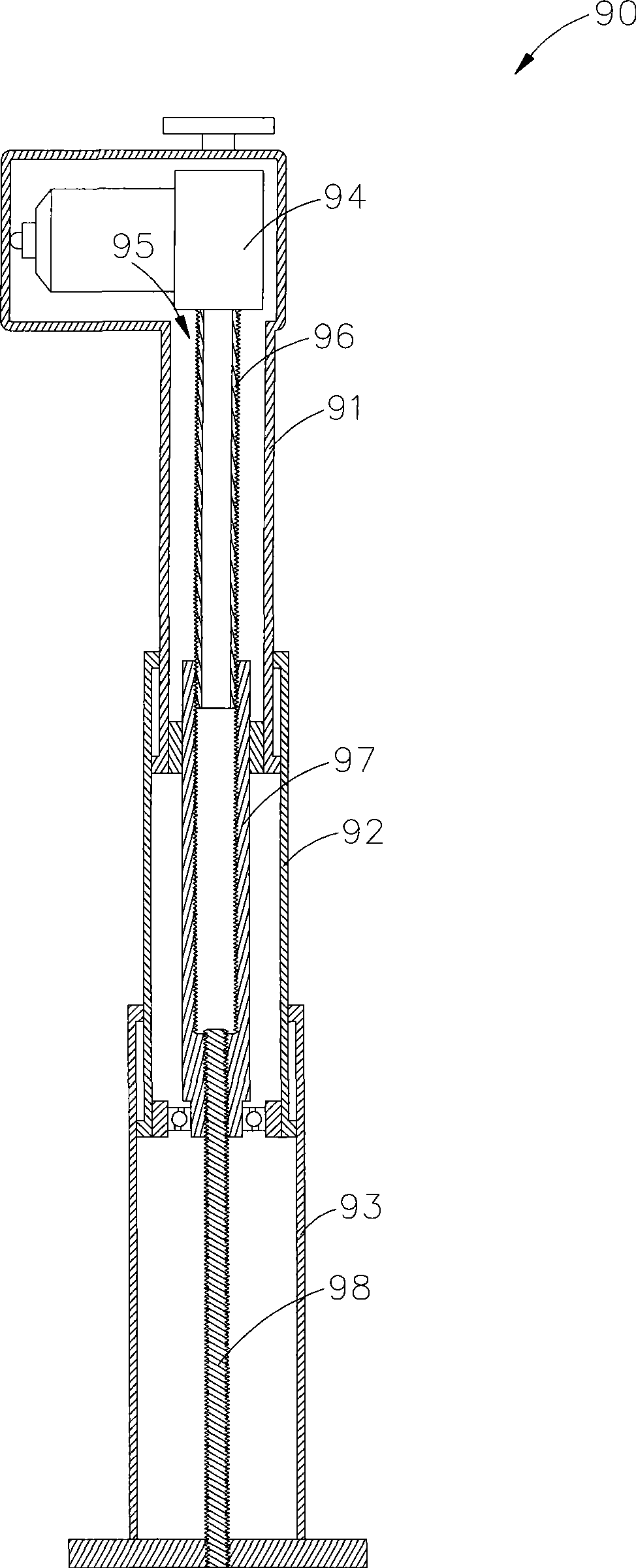

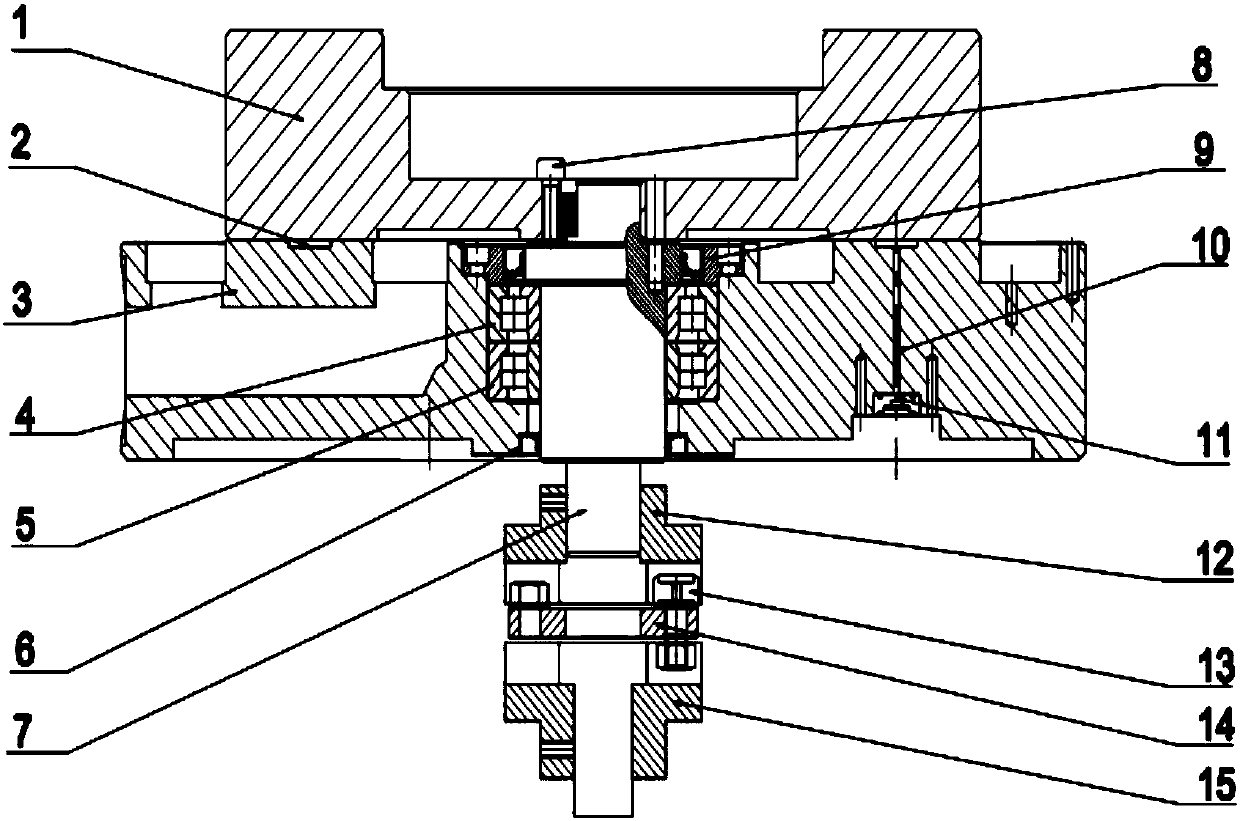

On-line adjustment method of air knife used for production of hot galvanized plate and air knife body

ActiveCN104911524ASolve technically difficult and demanding problemsGuaranteed smoothHot-dipping/immersion processesReducerEngineering

The invention relates to an on-line adjustment method of an air knife used for production of a hot galvanized plate and an air knife body, belonging to the technical field of hot galvanized plate production in the metallurgical industry. The technical scheme is that: the air knife consists of the air knife body and an adjusting mechanism; the adjusting mechanism comprises a long multi-segment bent axle (11), a bent axle fixing and supporting seat (12), a bent axle connecting rod bearing (14), bent axle connecting rod supporting iron (15), an assembled speed reducer (15), an operating rod connecting hole (17) and an electric controller. The gap between upper and lower knife lips is timely adjusted by the on-line adjustment method; stopping production to disassemble the whole air knife and make the air knife leave a zinc pot through lifting is not required, the time for stopping production to adjust is saved, and the operation rate is improved; the manual adjustment is replaced by the electric control adjustment, the problem that adjusting the work is great in technical difficulty and high in requirement is solved, and the gap between the upper and lower knife lips is kept in the optimum state; the smooth zinc surface is guaranteed, the controllable and adjustable zinc surface is realized, and the zinc consumption is reduced.

Owner:TANGSHAN JIAGUAN INDAL

Pervious concrete and preparation method thereof

The invention provides pervious concrete and a preparation method thereof. The content of each component in raw materials is as follows: 21-34 parts of ore coarse aggregates, 23-27 parts of fine sand,17-24 parts of Portland cement, 16-23 parts of diatomite, 13-17 parts of a polymer cementing material, 2-4 parts of phosphorus slag fine powder, 1-3 parts of iron powder, 8-13 parts of phenolic fibers and 6-15 parts of polypropylene fibers. Through the preparation by using the preparation method, the adhesion degree of all the components in the raw materials can be enhanced; gaps are generated between the phenolic fibers and the polypropylene fibers, and facilitate water permeation; and the pervious concrete can be further promoted in the actual building industry.

Owner:山东鲁盛新能源有限公司

Novel hydrostatic pressure thrust bearing device

ActiveCN110230642AEliminate misalignment errorsGuaranteed rotation accuracyLiquid cushion bearingsCouplingThrust bearing

The invention belongs to the field of bearings, and particularly discloses a novel hydrostatic pressure thrust bearing device. The novel hydrostatic pressure thrust bearing device comprises a rotary workbench, a thrust bearing and a main shaft mechanism, wherein the rotary workbench is horizontally arranged on the upper surface of the thrust bearing and fixedly connected with a main shaft; the thrust bearing is provided with an annular oil cavity, an oil return groove, an oil supply hole which is in communication with the annular oil cavity, and an oil return hole which is in communication with the oil return groove; the main shaft mechanism comprises the main shaft and a cross rolling coupling; the main shaft penetrates the thrust bearing and is matched with the thrust bearing through twoparallel cylindrical roller bearings; the upper end of the main shaft is connected with the rotary workbench, and the lower end of the main shaft is connected with the cross rolling coupling; the cross rolling coupling comprises an upper transmission seat, a lower transmission seat and a transmission disc positioned between the upper transmission seat and the lower transmission seat; and the transmission disc is in sliding fit with the upper transmission seat and the lower transmission seat through four roller cam guide apparatuses which are distributed on the upper surface and the lower surface of the transmission disc in a cross manner. The novel hydrostatic pressure thrust bearing device has the advantages of being high in rotation precision, small in friction coefficient and good in stability.

Owner:HUAZHONG UNIV OF SCI & TECH

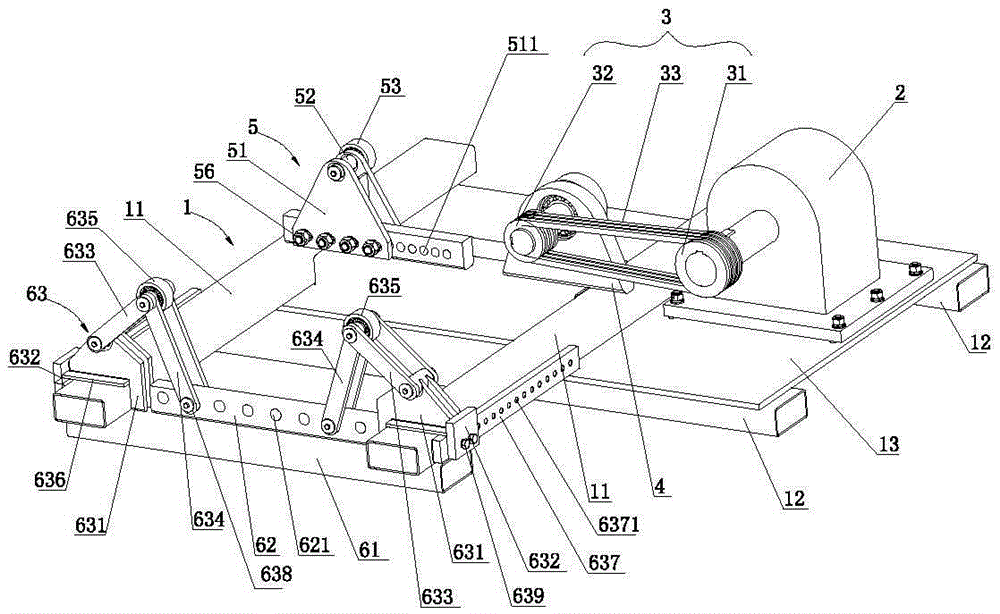

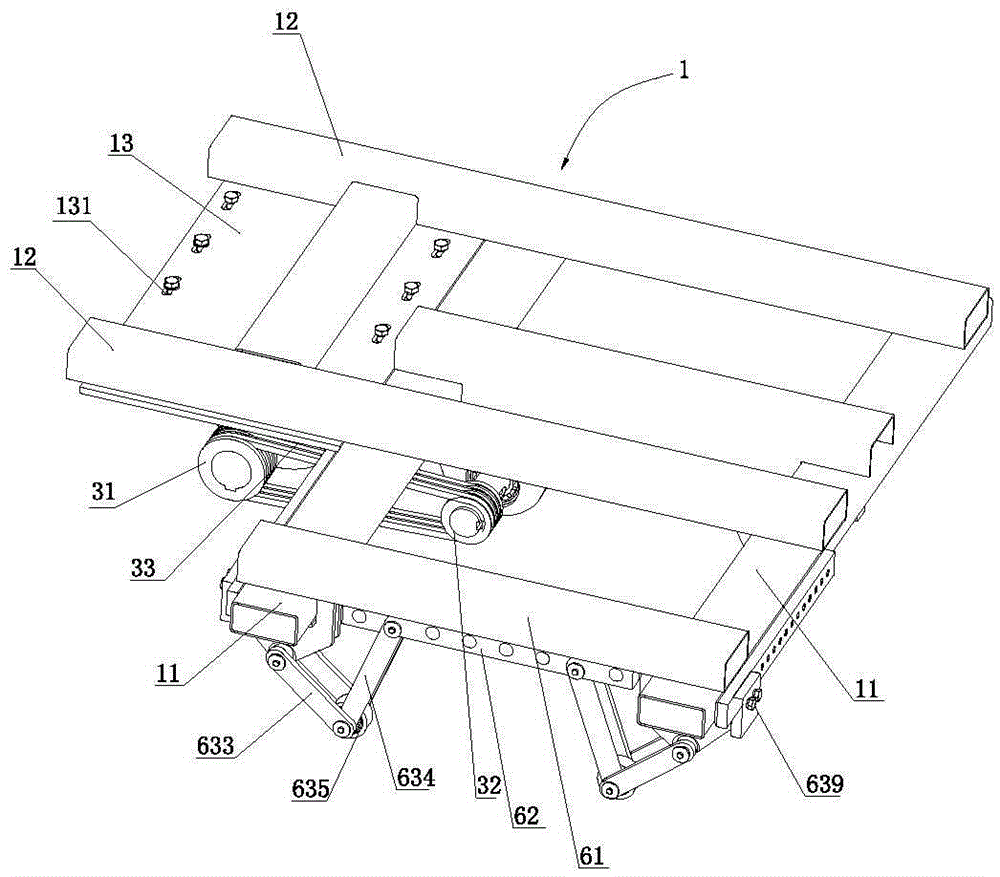

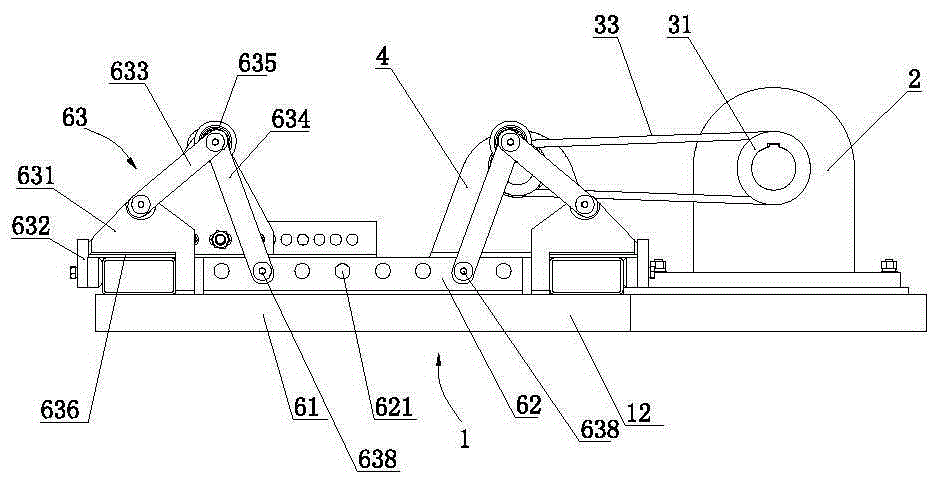

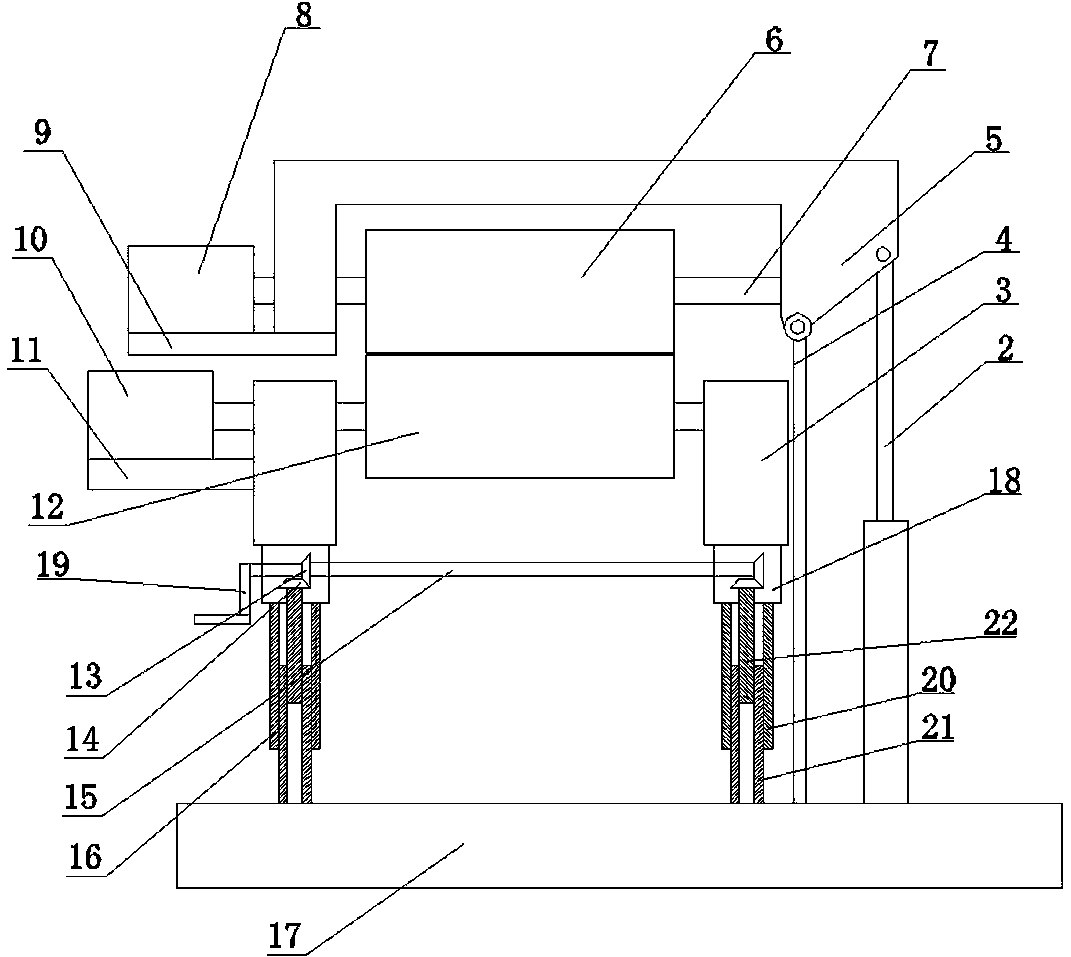

Electric wheel assembly tool and assembly method

ActiveCN105345444AImprove assembly efficiencySimple structureMetal working apparatusReduction driveCoupling

The invention discloses an electric wheel assembly tool and an assembly method. The electric wheel assembly tool comprises an underframe, a driving device, a transmission system, a fixing seat, a first adjusting device and a second adjusting device. The assembly method comprises the following steps: performing position adjustment by adjusting the first adjusting device and the second adjusting device, then placing a speed reducer on the assembly tool, driving the reducer to rotate through the driving device, making a motor correspond to a coupler of the speed reducer in position, and finally assembling the motor and the speed reducer. The tool and the method can realize the purpose of quickly assembling an electric wheel, has high efficiency and is not toilsome.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

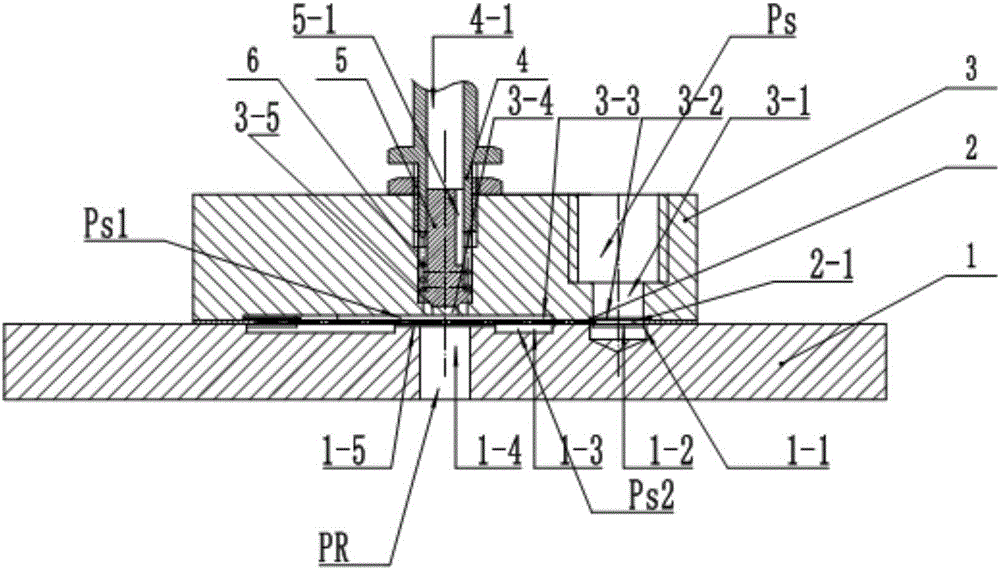

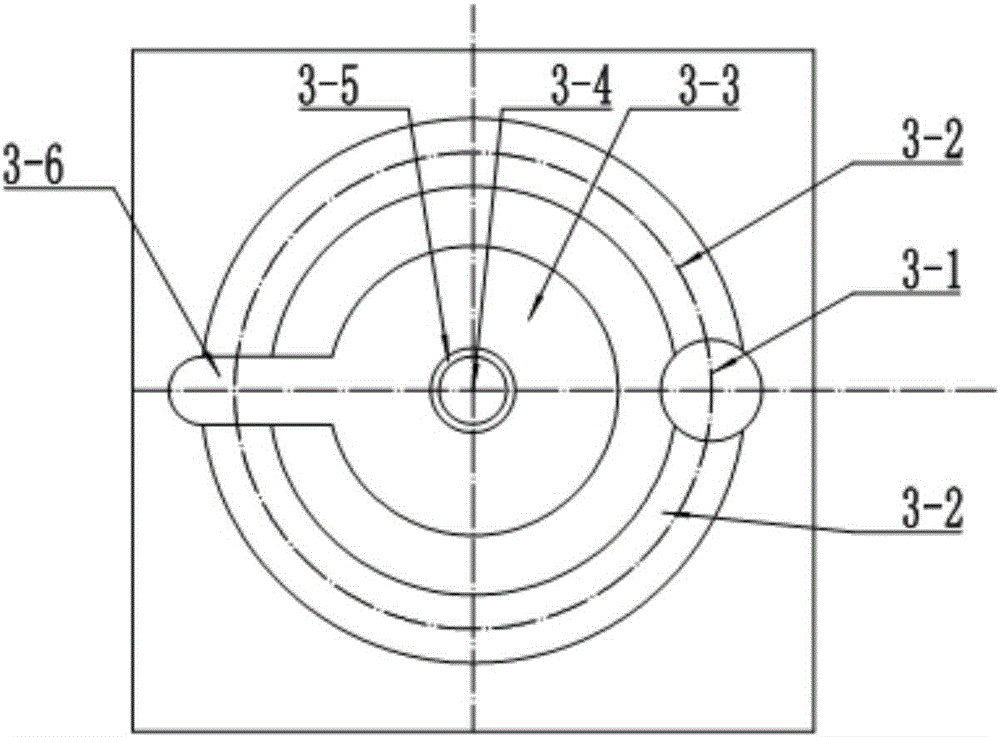

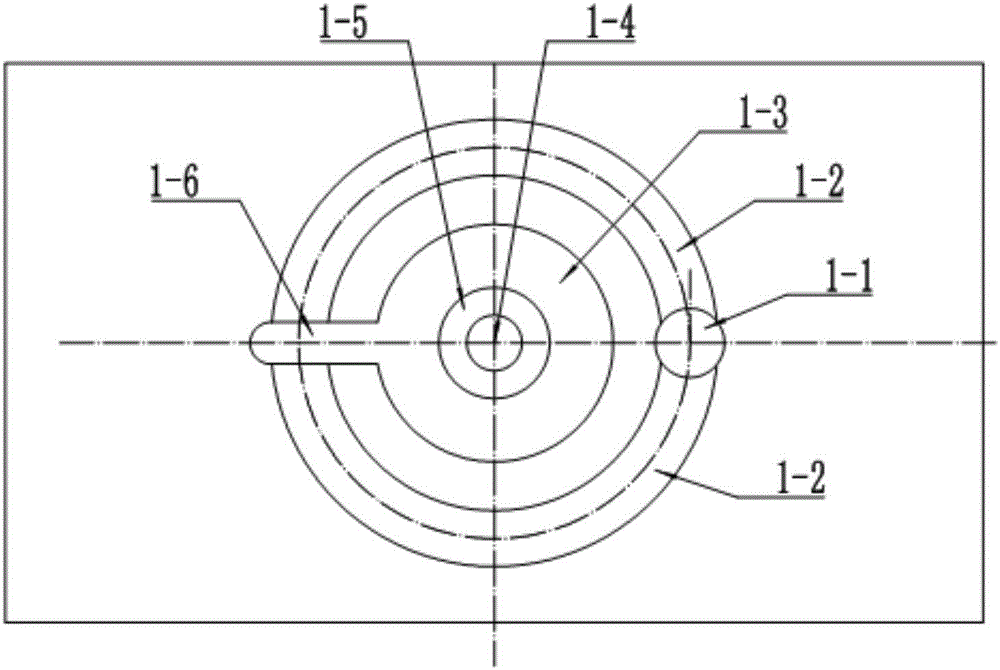

Self-stabilization single-face thin film restrictor with prepressure adjusting function

InactiveCN106641353AAdjust the amount of compressionAdjust the gapEqualizing valvesSafety valvesSelf-stabilizationEngineering

Owner:QILU UNIV OF TECH +1

Blade of mud stirring machine

The invention discloses a blade of a mud stirring machine. The blade structurally comprises a blade surface, a blade handle and nuts, wherein the front surface of the blade surface is shaped like a isosceles trapezoid with round angles; the blade surface is made of elastic steel plate; the blade surface and the blade handle are connected into a whole body; the other end of the blade handle is provided with a section of thread; the blade handle penetrates into a hole of the stirring shaft and then is fastened on the stirring shaft by using the nuts.

Owner:薛梅

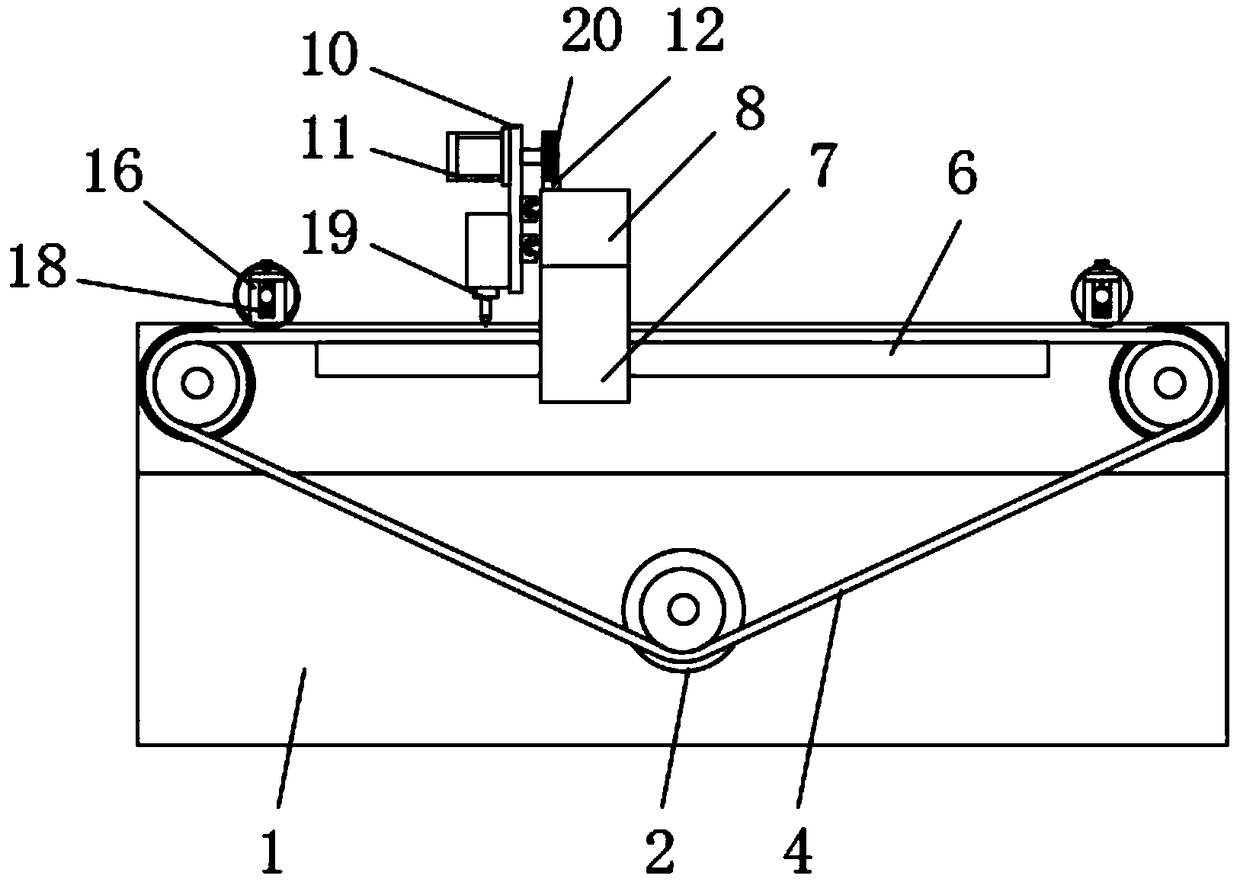

Cutting device convenient to fix for processing microfiber leather

The invention discloses a cutting device convenient to fix for processing microfiber leather. The cutting device comprises a base and a driving motor, the driving motor is mounted on one side of the interior of the base, and a synchronous belt pulley is mounted at one end of the driving motor; a synchronous belt is transmission connection with the surface of the synchronous belt pulley, and a conveyor net is arranged on one side of the upper portion of the synchronous belt; a supporting sectional material is arranged on one side of the upper portion of the base, a sliding slot is formed in oneside of the upper portion of the supporting sectional material, and a supporting leg is slidingly connected to one side of the sliding slot. According to the cutting device for processing the leather, an arranged cutting knife can achieve linkage of two axes and cut the leather in any shape, the driving motor drives the synchronous belt in transmission connection with the surface of the synchronous belt pulley to rotate, a cross beam on the supporting leg moves along the sliding slot, and the cutter can be moved in a Y-axis direction; at the same time, a moving motor drives a gear to rotate on a rack, so that the cutting knife below a mounting plate moves along a linear guide in an X-axis direction.

Owner:YANGZHOU XIANGBEI MACHINERY

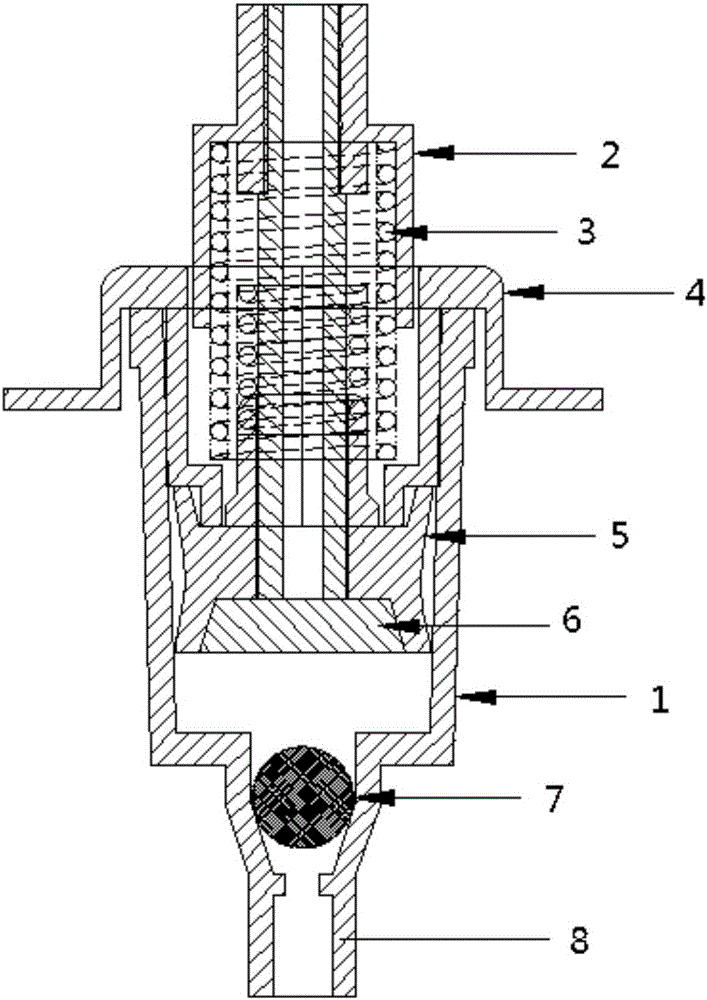

Novel daily use chemical sprayer nozzle

The invention discloses a novel daily use chemical sprayer nozzle. The nozzle is characterized by comprising a pump, a valve rod is connected with the upper end of the pump, the lower end of the valve rod is connected with a matched valve rod spring, the lower end of the valve rod spring is connected with a valve ring, the lower end of the valve ring is connected with a valve element, a bottle cap is connected between the valve rod and the valve ring, the valve rod spring penetrates through the middle of the bottle cap, the lower end of the valve element is connected with a sprayer, and a steel ball is installed in the sprayer. The nozzle is compact in structure, is vertically integrated in an injection molding mode and is good in sealing performance in a cavity. The valve ring prevents liquid or gas in the nozzle from leaking, an extrusion spring can adjust the gap between the steel ball and the sprayer, and accordingly atomization density is adjusted.

Owner:张家港市昕烨日化喷雾器有限公司

A sticker surface glue coating device for label production

ActiveCN110385230BAdjust the gapAdjustable distanceLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

Owner:安徽融优新材料科技有限公司

Intelligent abdominal operation retractor

The invention discloses an intelligent abdominal operation retractor, which comprises a first sliding mechanism, a second sliding mechanism and a retracting mechanism and a plurality of stand columnsfixedly installed at the lower end of a frame, wherein the first sliding mechanism, the second sliding mechanism and the retracting mechanism are installed on the two opposite sides of the frame in asliding mode and connected in sequence, and the stand columns are provided with a plurality of through holes with equal distances and equal diameters; the stand column is inserted into a rectangular hole formed in the fixing rod and is connected and kept fixed through a bolt, and the fixing rod is fixed to an external operating table. According to the retractor, the elastic force of the spring isadopted for retracting a wound, the operation time can be effectively saved; meanwhile, the multiple sliding mechanisms are additionally arranged, the retracting gap can be adjusted according to the size of the wound, after an operation is completed, the retractor can be rapidly retracted, and a doctor can sew the wound conveniently. The height of the retractor can be adjusted according to the body type of a patient, and the stretching length of the retractor can be properly adjusted according to the size of an incision wound during an operation.

Owner:THE PEOPLES HOSPITAL SHAANXI PROV

Efficient double-roller film rolling machine

InactiveCN107617642AAdjust the gapMeet the needs of pressing to different sizesBatteries circuit arrangementsMetal rolling stand detailsArchitectural engineeringScrew thread

The invention discloses an efficient double-roller film rolling machine which comprises a bottom plate, wherein two telescopic mechanisms are arranged on the bottom plate; each of the telescopic mechanisms comprises a mounting box; a guide cylinder is arranged at the lower end of the mounting box; a hollow fixed column in sliding fit with the guide cylinder is arranged in the guide cylinder and isfixedly connected with the bottom plate; an internal thread is formed in the inner circle surface of the hollow fixed column; the hollow fixed column is provided with a screw rod in screw-thread fitwith the hollow fixed column; an upper roller is provided with a second motor for driving the upper roller to rotate; a support rod is arranged on the bottom plate; the upper end of the support rod ishinged to one end of an inverted U-shaped mounting rack; and an air cylinder capable of driving the inverted U-shaped mounting rack to rotate around a hinge joint point on the support rod is arrangedon the bottom plate. The efficient double-roller film rolling machine facilitates popularization and application.

Owner:宜宾金原复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com