On-line adjustment method of air knife used for production of hot galvanized plate and air knife body

A technology of hot-dip galvanized sheet and cutter body, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problems of difficult zinc layer control, affecting output, wasting zinc consumption, etc., to save production shutdown The effect of adjusting time, improving equipment operation rate and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

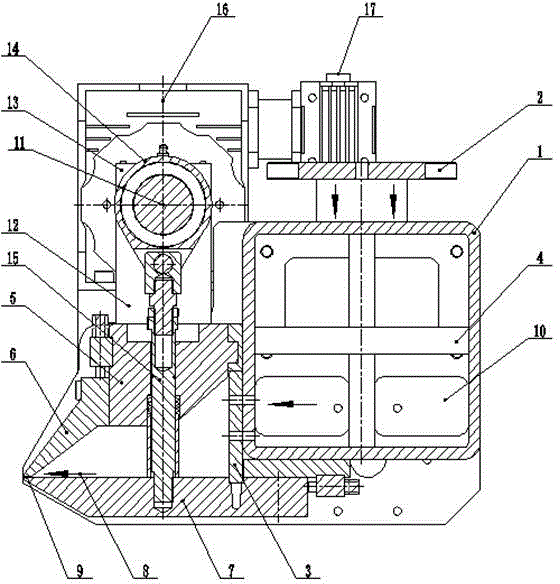

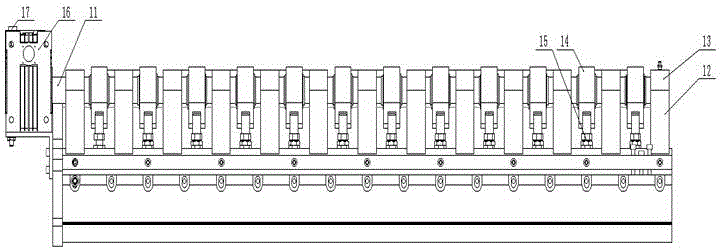

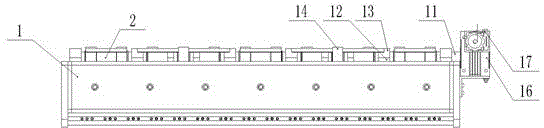

[0024] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0025] An online adjustment air knife body for hot-dip galvanized sheet production, which is composed of an air knife body and an adjustment mechanism; , the upper knife lip 6, the lower knife lip 7, the lower knife seat, the air outlet channel 8, the upper and lower knife lip gap 9 and the cavity 10; the knife body 1 is provided with a cavity 10, and the cavity 10 is provided with an air inlet 2 and The air outlet is provided with a hole-shaped air outlet regulating plate 3, which is connected with the air outlet channel 8; the upper knife seat 5 and the upper knife lip 6 are on the air outlet channel 8, and the lower knife seat and the lower knife lip 7, and the upper knife lip 6 are located below. One end is fixed on the upper knife seat 5, and the other end protrudes; one end of the lower knife lip 7 is fixed on the lower knife seat, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com