Patents

Literature

61results about How to "Reduce zinc consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot dip galvanizing method for steel pieces

ActiveCN101092682ALong corrosion lifeImprove uniformityHot-dipping/immersion processesRare-earth elementAlloy

This invention discloses a method for hot-dip galvanizing on steel work piece. The method comprises: checking black work piece, suspending, degreasing, rinsing, washing with acid, rinsing, treating with a galvanizing aid, drying with hot air, hot-dip galvanizing and cooling. During the hot-dip galvanizing process, Al, Ni, Si and rare earth element are added into the galvanizing solution. The galvanizing solution comprises: Al 7-9 wt. %, Ni 3-6 wt. %, Si 0.5-0.8 wt. %, rare earth element 0.5-1.0 wt. %, and Zn as balance. The addition of Si can reduce Fe content in the galvanizing solution, and the formation of Zn-Fe alloy residue. The Zn consumption is lowered by nearly 1%, and the surface quality of galvanized steel is improved.

Owner:南京大吉铁塔制造有限公司

Method and device of refining separating zinc by bismuth method

InactiveCN1869260AAchieve recyclingEasy to operateProcess efficiency improvementToxic gasEconomic benefits

The invention relates to separate zinc from bismuth liquid and distill zinc from silver zinc dregs after taking refining zincification desilverization process. It puts the bismuth liquid into vacuum container and whisking, making zinc vaporize from bismuth liquid to gain zinc vapor. Vacuuming to make the vapor rise to condensing apparatus to condense to solid and adhere at condensing apparatus and gathering. Inducing the tail gas into purification device to take purifying and discharge. The method to distill zinc from silver zinc dregs is almost the same, and adds the process of melting silver zinc dregs. The device includes bismuth fine furnace, vacuum container, condensing device, whisking device, subsidence purifying device and vacuum pump. The invention could lower zinc consumption, and good economic benefit and avoid pollution of toxic gas and chlorine alkali dregs.

Owner:汪立果

Hot-dip galvanizing method for steel products

ActiveCN101280401AReduce take awayTemperature controlHot-dipping/immersion processesHeat lossesHeat energy

The invention relates to a hot dip galvanizing method for the iron and steel product, which belongs to the hot dip plating engineering in the metallurgy field. The invention mainly solves the technical problem that a hot dip galvanizing method for the iron and steel product utilized directly aiming at the faults in the normal hot dip galvanizing process that the excessive consumption of the zinc and the low efficiency utilization of the heating system is provided. The heating method of the dip galvanizing kettle of the invention is side surface heating, thus, the temperature of the liquid zinc can be conveniently controlled, the deposition of the zinc dross can be accelerated, and the zinc quantity taken away by the galvanizing piece can be reduced; because the ferric salt content inside the assistant galvanizing tank is controlled, the zinc dross quantity inside the zinc kettle is reduced; simultaneously, the output rate per hour is controlled to stabilize the heat loss and reduce the added zinc consumption caused by temperature variation. Through the progress of the process, the zinc consumption is reduced, the heat energy is fully utilized, the fault of the excessive zinc consumption caused by normal process and low efficiency utilization coefficient of the heating system are overcome, the quality is ensured, simultaneously, the resources are saved.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

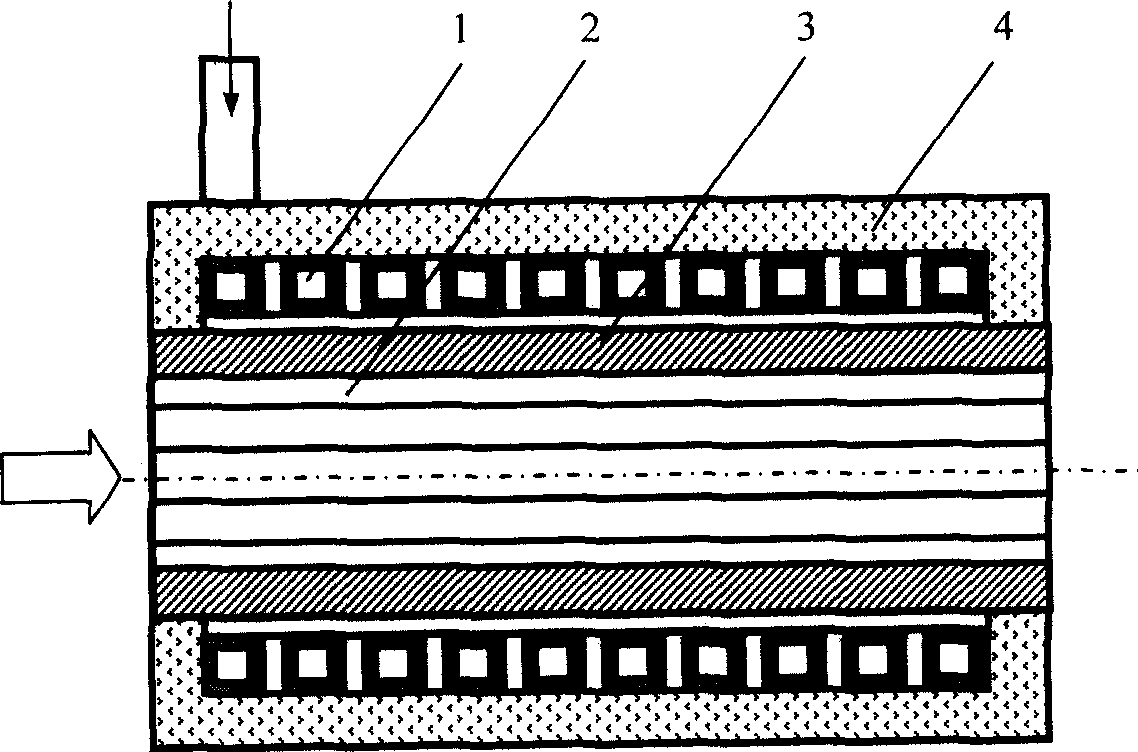

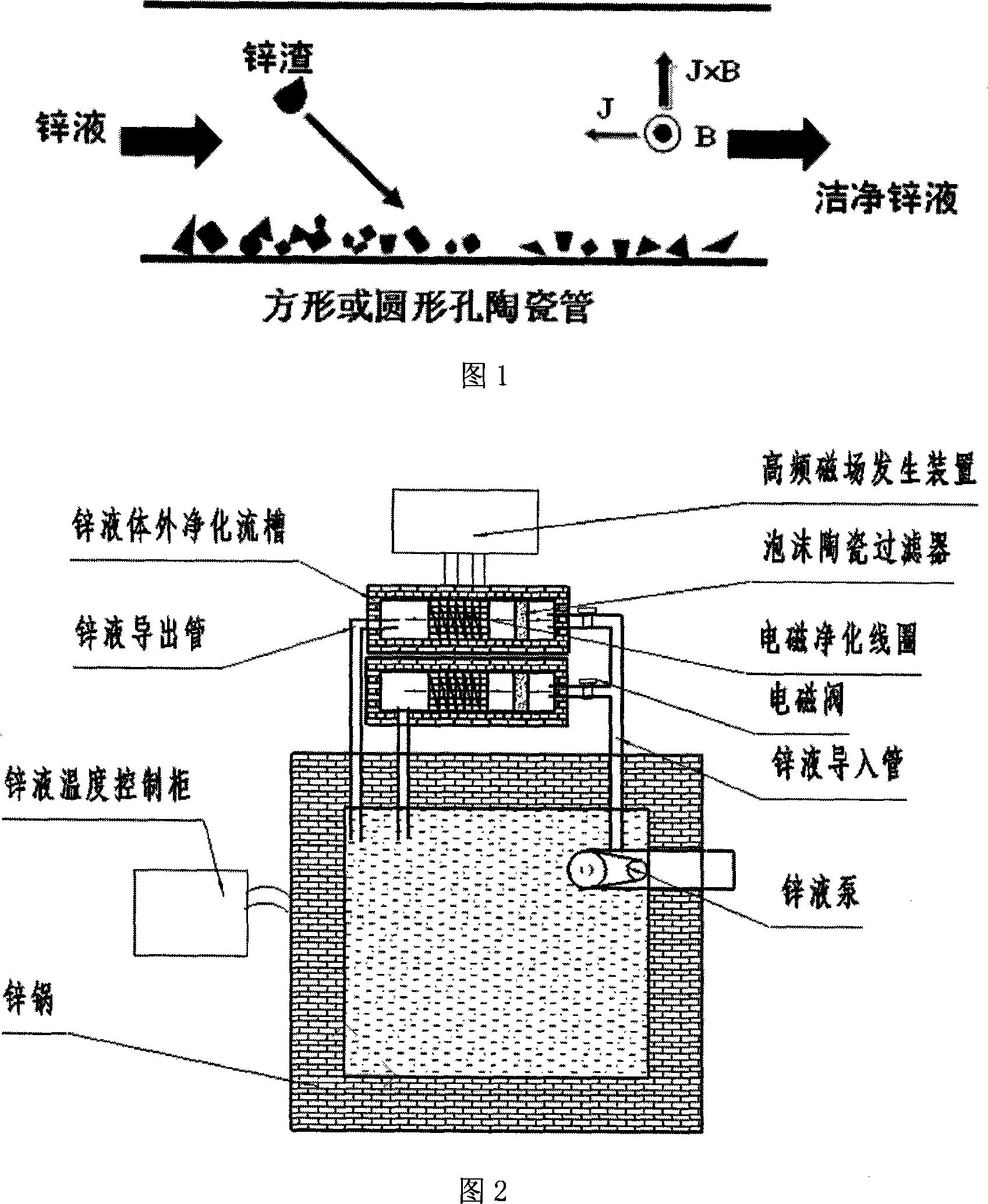

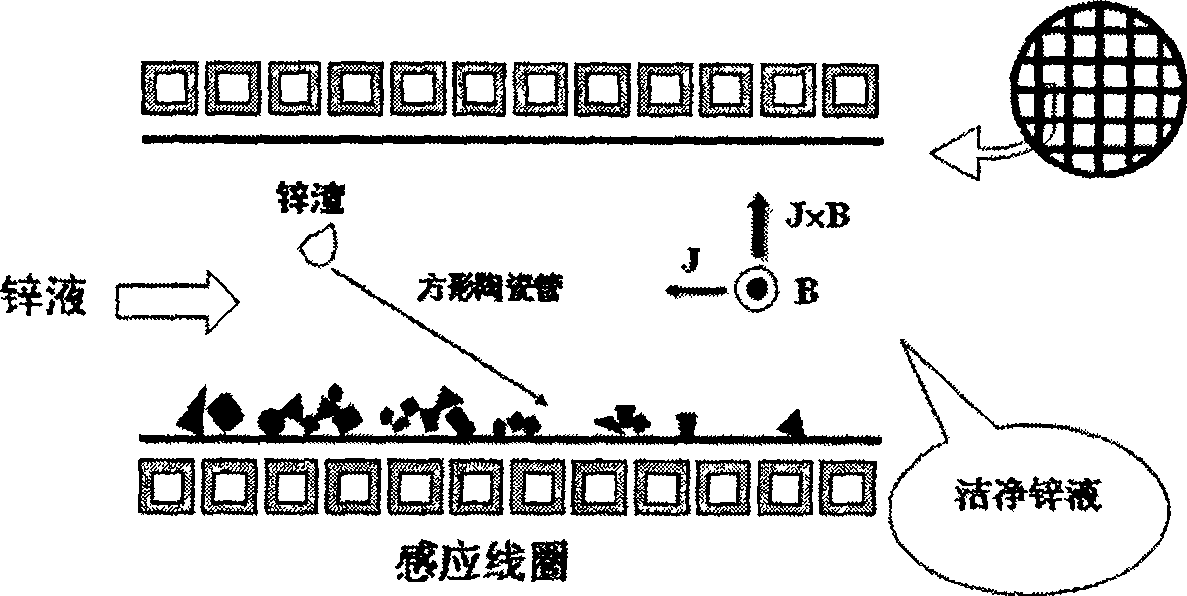

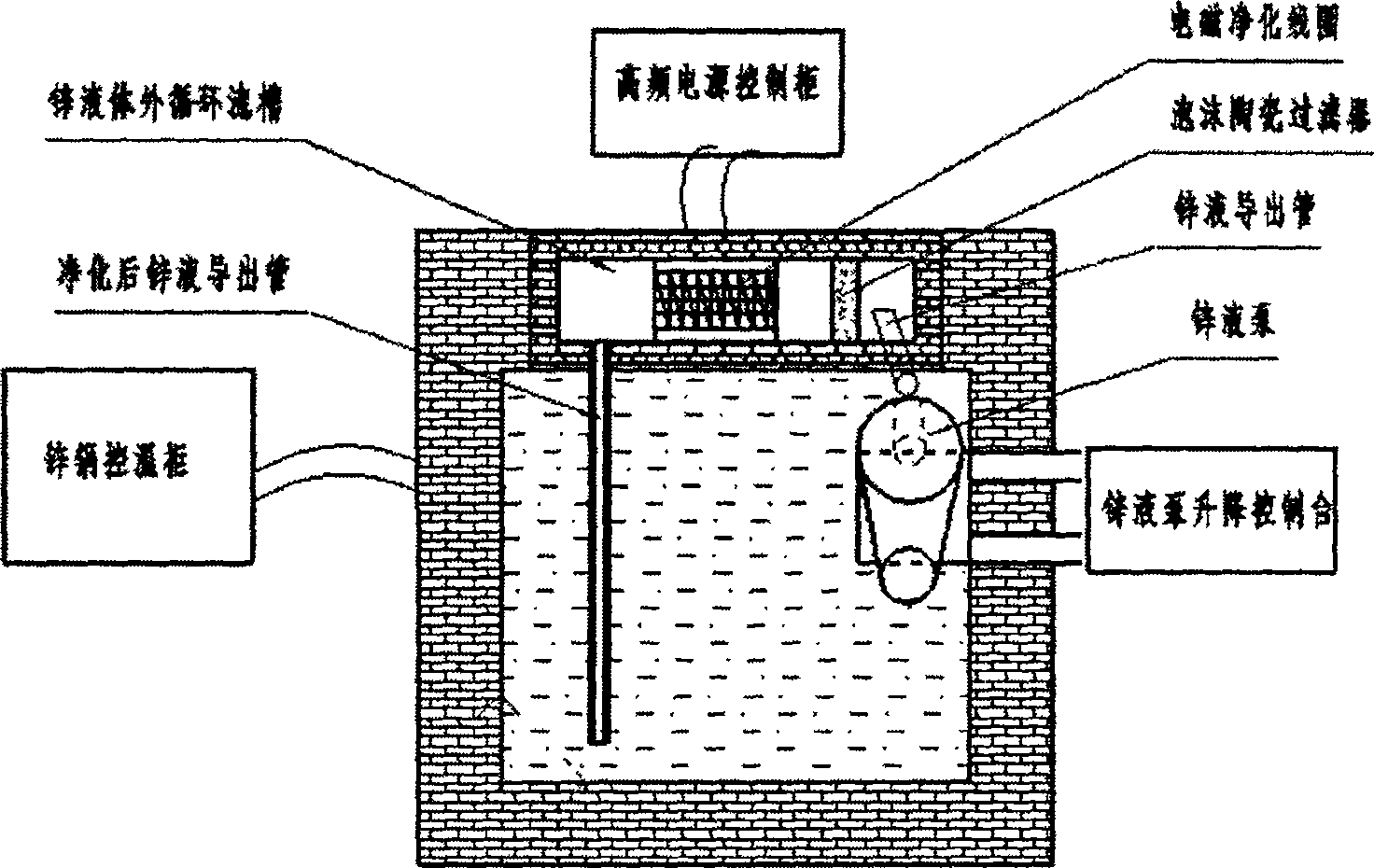

Electromagnetic cleaning means for hot galvanizing liquid

ActiveCN1730682AReduce defectsReduce the amount of drossIncreasing energy efficiencyFlotationHoneycombZinc

Disclosed is an electromagnetic cleaning means for hot galvanizing liquid which comprises an induction coil, a honeycomb shaped square ceramic tube, a heat insulation sleeve and a housing of refractory material, wherein the ceramic tube is arranged inside the induction coil, the heat insulation sleeve is arranged between the induction coil and the ceramic tube. The device is placed in the zinc coating liquid located inner the belt steel for cleaning treatment.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Composite purification device for continuously removing zinc slag in heat zinc coating liquid

InactiveCN101104917AReduce zinc dross defectsThe amount of dross is reducedHot-dipping/immersion processesIncreasing energy efficiencySlagHot-dip galvanization

A combined purification apparatus is provided for continuously removing zinc dross from molten zinc in hot dip galvanization, which belongs to the field of metal smelting technique. The apparatus comprises a molten zinc delivery device, a first-step filter, and a second-step electromagnetic deslagging device. The molten zinc delivery device comprises a molten zinc pump and a molten zinc flow channel. The first-step filter is a ceramic foam filter. A zinc pumping pipe of the molten zinc pump is immersed into a zinc pot. The ceramic foam filter is arranged inside the molten zinc flow channel. The second-step electromagnetic deslagging device is arranged in the middle inside the molten zinc flow channel, and comprises an induction coil, a porous ceramic pipe, a heat-insulating jacket, and a fire-resisting shell, wherein the porous ceramic pipe is arranged inside the induction coil; the heat-insulating jacket is used to isolate the induction coil from the porous ceramic pipe; the induction coil, heat-insulating jacket and porous ceramic pipe are all arranged inside the fire-resisting shell. The invention can efficiently remove zinc dross from molten zinc in hot dip galvanization at the early formation stage, and helps to reduce the zinc slag defect of steel work piece in hot dip galvanization and improve the surface quality.

Owner:SHANGHAI JIAO TONG UNIV +1

On-batch steel hot galvanizing environment-friendly type multi-effect galvanization helping liquid and use method thereof

The invention discloses an on-batch steel hot-galvanizing environment-friendly type multi-effect galvanization helping liquid and a use method thereof. Each liter of the on-batch steel hot galvanizing environment-friendly type multi-effect galvanization helping liquid comprises the following substances: a filming agent, an accelerant, a complexing agent, an anti-explosion zinc agent and water. The invention further provides the use method of the on-batch steel hot galvanizing environment-friendly type multi-effect galvanization helping liquid. The use method requires that the working temperature is 50-60 DEG C, the pH value is 3.5-5, and the galvanization time is 3-6 minutes, and a workpiece can be directly fed to a next zinc immersion procedure after galvanization helping without being dried, so that the time is saved, and the efficiency is improved. In addition to the capability of meeting the common requirements of an on-batch steel hot-galvanizing process, the on-batch steel hot-galvanizing environment-friendly type multi-effect galvanization helping liquid further has the characteristics that the energy consumption for heating the galvanization helping liquid is reduced due to adoption of intermediate temperature galvanization helping, the investment is reduced as no drying is needed after galvanization helping, and the energy consumption for drying is reduced; the increase of Fe<2+> in the galvanization helping liquid is effectively controlled, zinc ash and zinc slag are reduced in zinc immersion, no dust is generated, explosion is effectively avoided, and multiple effects that a galvanization helped film layer is uniform and free of galvanization omission, a zinc layer is bright, and the like, are achieved.

Owner:钱宏彬

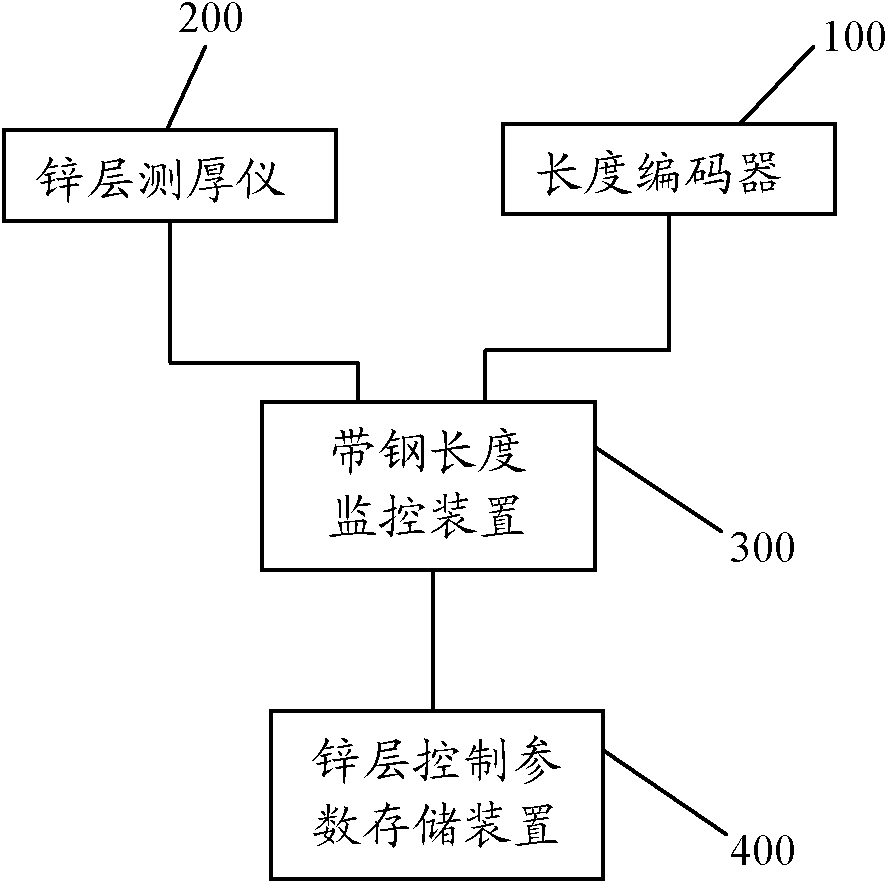

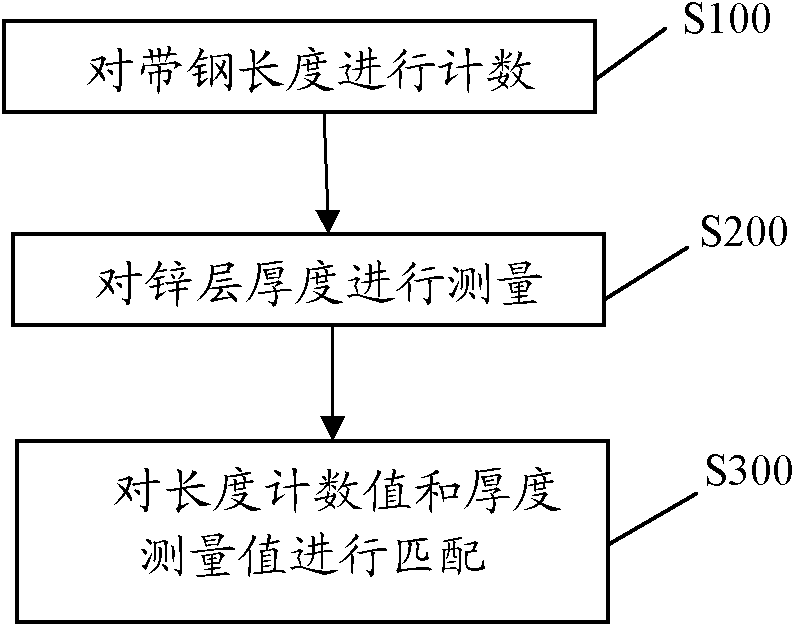

Device and method for measuring thickness of zinc layer in continuous hot galvanizing machine set

ActiveCN102465246AGuarantee the quality of galvanizingEliminate lagHot-dipping/immersion processesEngineeringStrip steel

The invention provides a device for measuring thickness of a zinc layer in a continuous hot galvanizing machine set. The continuous hot galvanizing machine set comprises an air knife, a slewing roller and a tension roller, wherein the air knife is used for performing galvanizing treatment on a steel strip, and the slewing roller and the tension roller are used for outputting the steel strip afterbeing galvanized and cooled. The device for measuring the thickness of the zinc layer comprises a length encoder, a zinc layer thickness gauge, a steel strip length monitoring device and a zinc layercontrol parameter storage device, wherein the length encoder is arranged on the tension roller and is used for counting the length of the steel strip; the zinc layer thickness gauge is arranged behind the slewing roller and is used for measuring the thickness of the zinc layer; the steel strip length monitoring device is respectively connected with the length encoder and the zinc layer thickness gauge; and the zinc layer control parameter storage device is connected with the steel strip length monitoring device. The device and method for measuring the thickness of the zinc layer, provided by the invention, can be used for realizing the accurate correspondence between the thickness of the zinc layer on a specific position of the steel strip and other parameters used for controlling the thickness of the zinc layer on the position.

Owner:BAOSHAN IRON & STEEL CO LTD

Dual channel electromagnetic method for separating zinc dross from hot galvanizing zinc fluid

InactiveCN101092666AReduce the amount of drossReduce zinc consumptionHot-dipping/immersion processesProcess efficiency improvementFiltrationZinc

This invention discloses a double-channel electromagnetic method for separating zinc residue from hot-plating zinc solution. The method comprises: sucking out zinc solution from a kettle with a pump that can continuously run, introducing into a double-channel electromagnetic purification flow groove outside the kettle, performing primary filtration with a foamed ceramic filter, introducing into an electromagnetic purification apparatus, performing secondary filtration via applying an alternate magnetic field, and returning into the kettle via a pipeline. Both the primary and the secondary filtration processes are performed in the double-channel electromagnetic purification flow groove, in which there are an electromagnetic valve, a primary filter and a secondary filtration electromagnetic purification apparatus inside either channel. During the purification process, more and more zinc residues are attached to the ceramic tube wall, so the ceramic tube should be replaced when accumulated zinc residues reach a certain quantity. The ceramic tube is replaced by: tswitching off the electromagnetic valve at the front end of one channel to cut off the communication of the zinc solution, and meanwhile switching on the electromagnetic valve at the front end of the other channel. The method can continuously purify for 6 h, reduce the content of zinc residues suspending in the zinc solution by more than 90%, and decrease zinc consumption by 12%.

Owner:SHANGHAI JIAO TONG UNIV

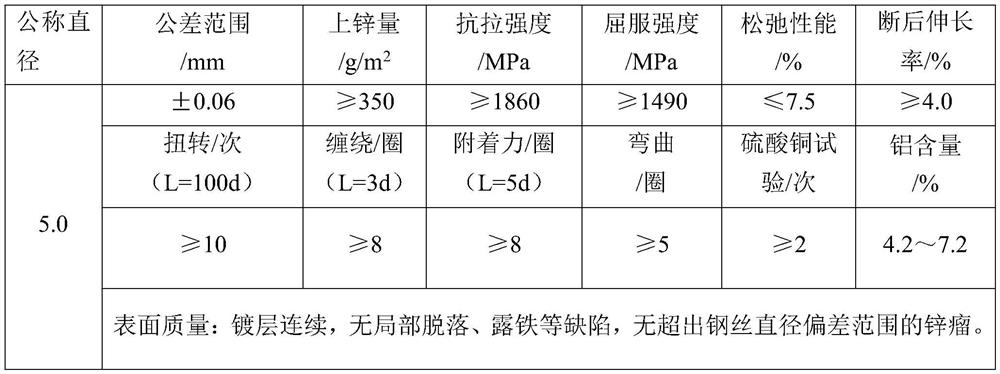

Production technology of high strength galvanized steel wires

The invention relates to a production technology of high strength galvanized steel wires. The high strength galvanized steel wires of which the diameters are 2.0mm are made from wire rods of which the steel grade is 82B and the diameters are 8.0mm, a drawing after medium galvanizing technology is adopted for drawing, a three-segment type linear drawing die is adopted, the angle of a working cone is 6-80 degrees, and the length of the working cone is 2.5-3.5 times the diameter of a drawn wire; the length of a calibrating straight is 0.35-0.55 of the diameter of the wire; low-compressibility multi-time drawing is adopted during a drawing process, the compression ratio of the average drawing part is about 14%, the smooth drawing of the high strength galvanized steel wires can be realized, the problems that in the drawing process of super high strength galvanized steel wires, zinc is easy to scrape and filament breakage is easy to occur, are solved, the comprehensive performance indexes of torsion, curving and the like of the steel wires are favorable, and the purpose that the super high strength galvanized steel wires of which the diameters are 2.0mm and the pressure is 2000MPa can be well produced is realized.

Owner:GUIZHOU WIRE ROPE

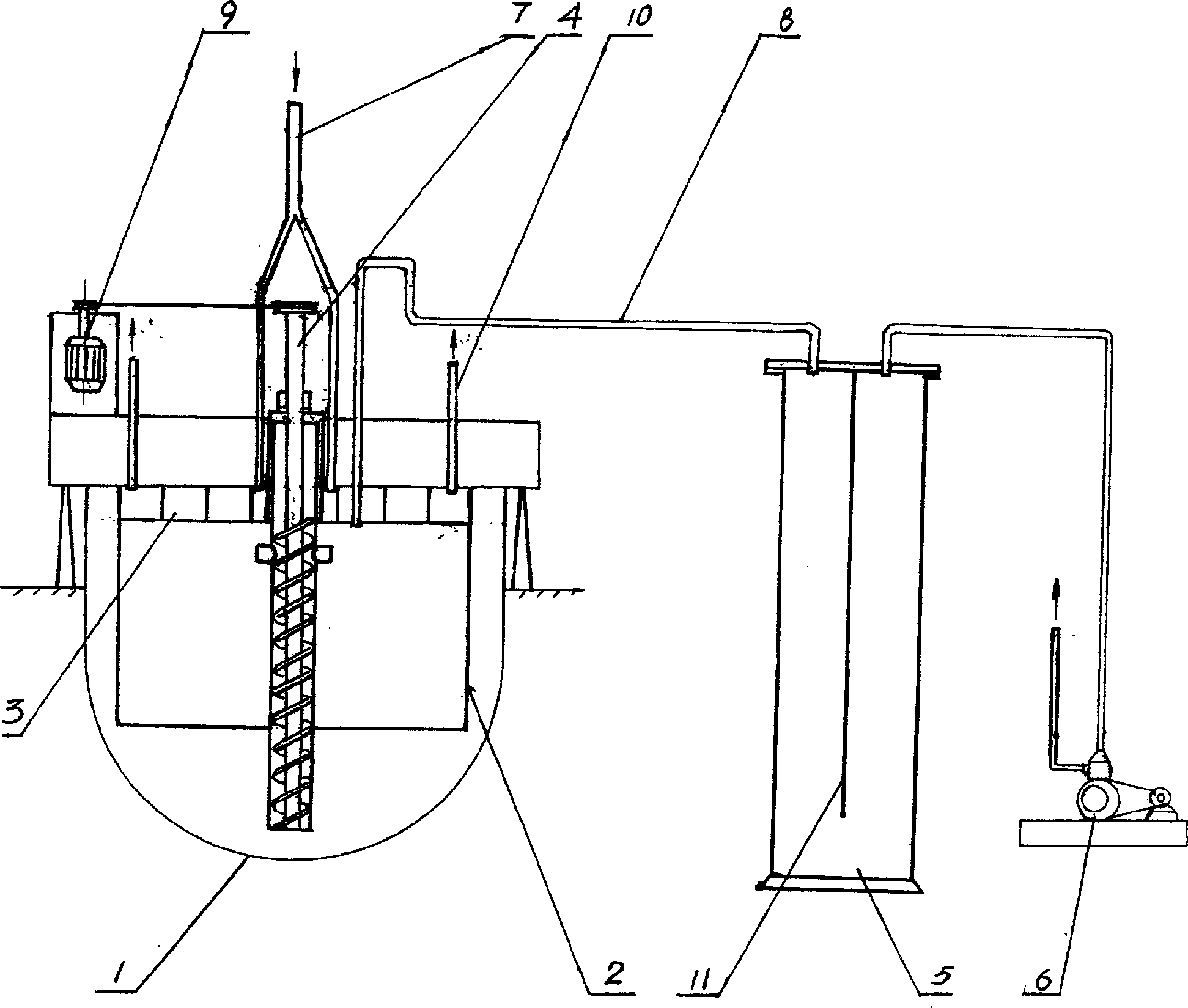

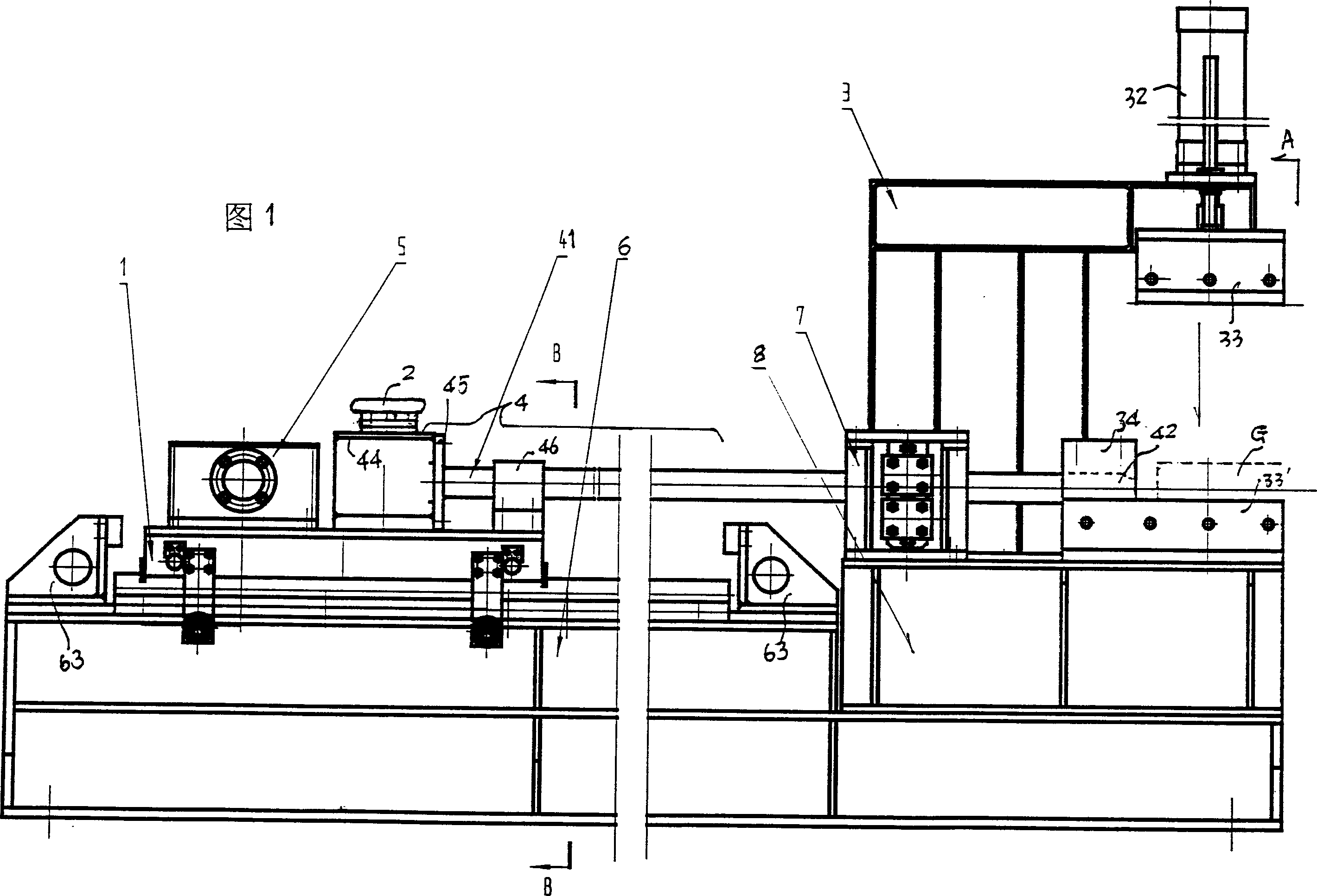

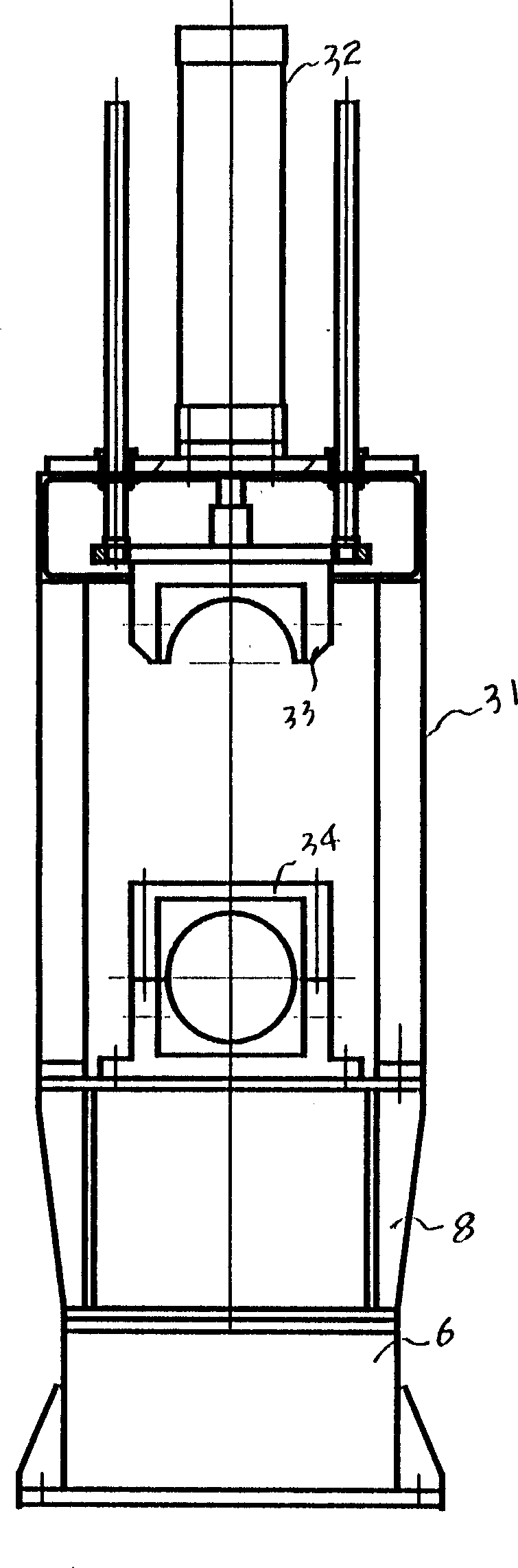

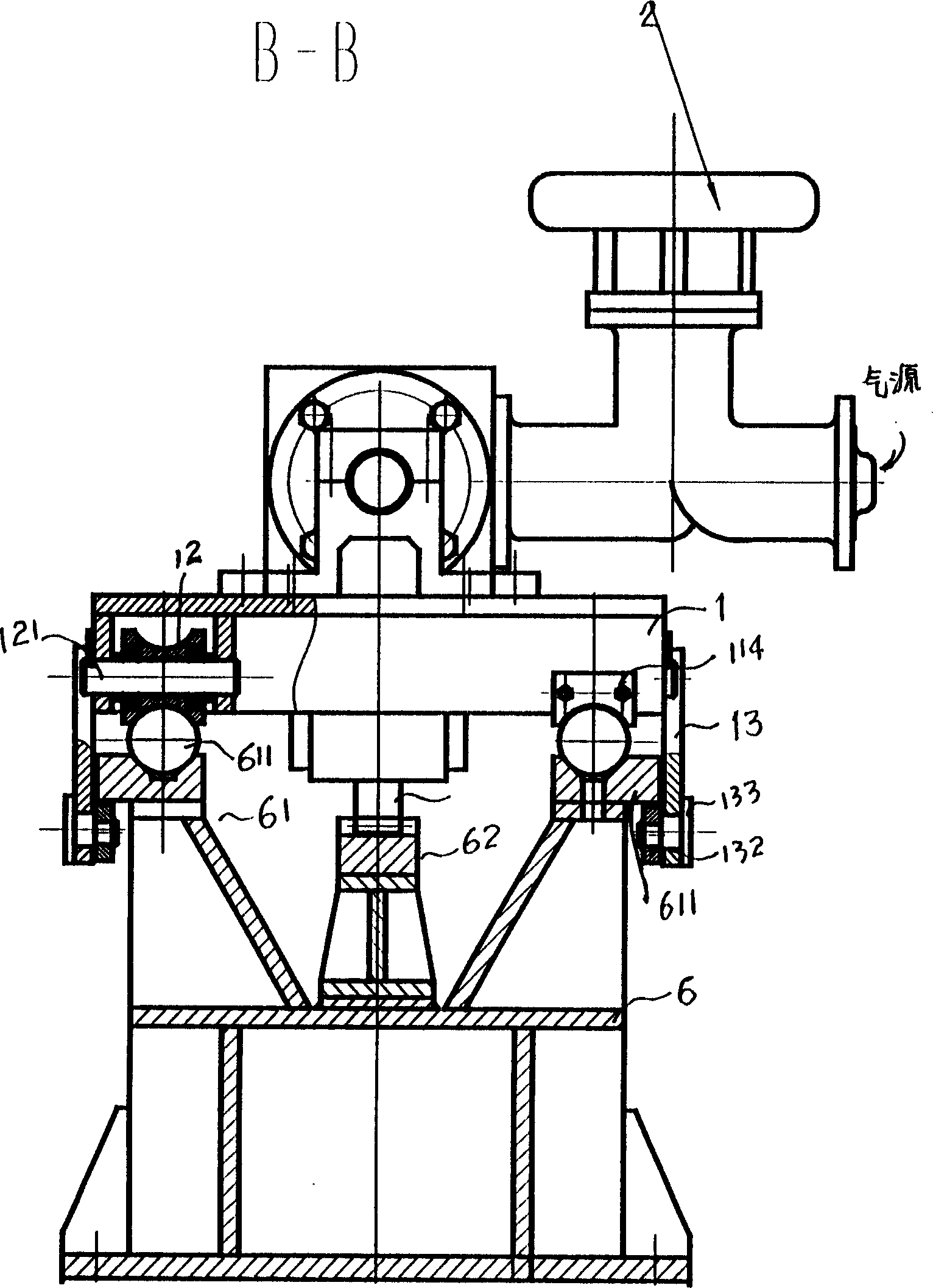

Blowing tube type inner blower

InactiveCN1458295AReduce zinc consumptionImprove working environmentHot-dipping/immersion processesBogieWorking environment

The blowing tube type inner blower has servo motor for driving, inner blowing bogie mounted on the track on the bed and comprising driving mechansm, inner blowing valve and blowing nozzle-blowing pipe unit, clamping guide seat and guide unit. The inner blowing gas is compressed air, heated or unheated, and the blowing nozzle is extended into hot galvanized steel pipe to eliminate unsolidified zinc liquid. Using to steam boiler, dedusting apparatus and other auxiliary apparatus, no zinc dust is produced and the blow out matter is basically pure zinc, rather than zinc oxide, so that zinc consumption is greatly lowered and the work environment is improved.

Owner:李广辉

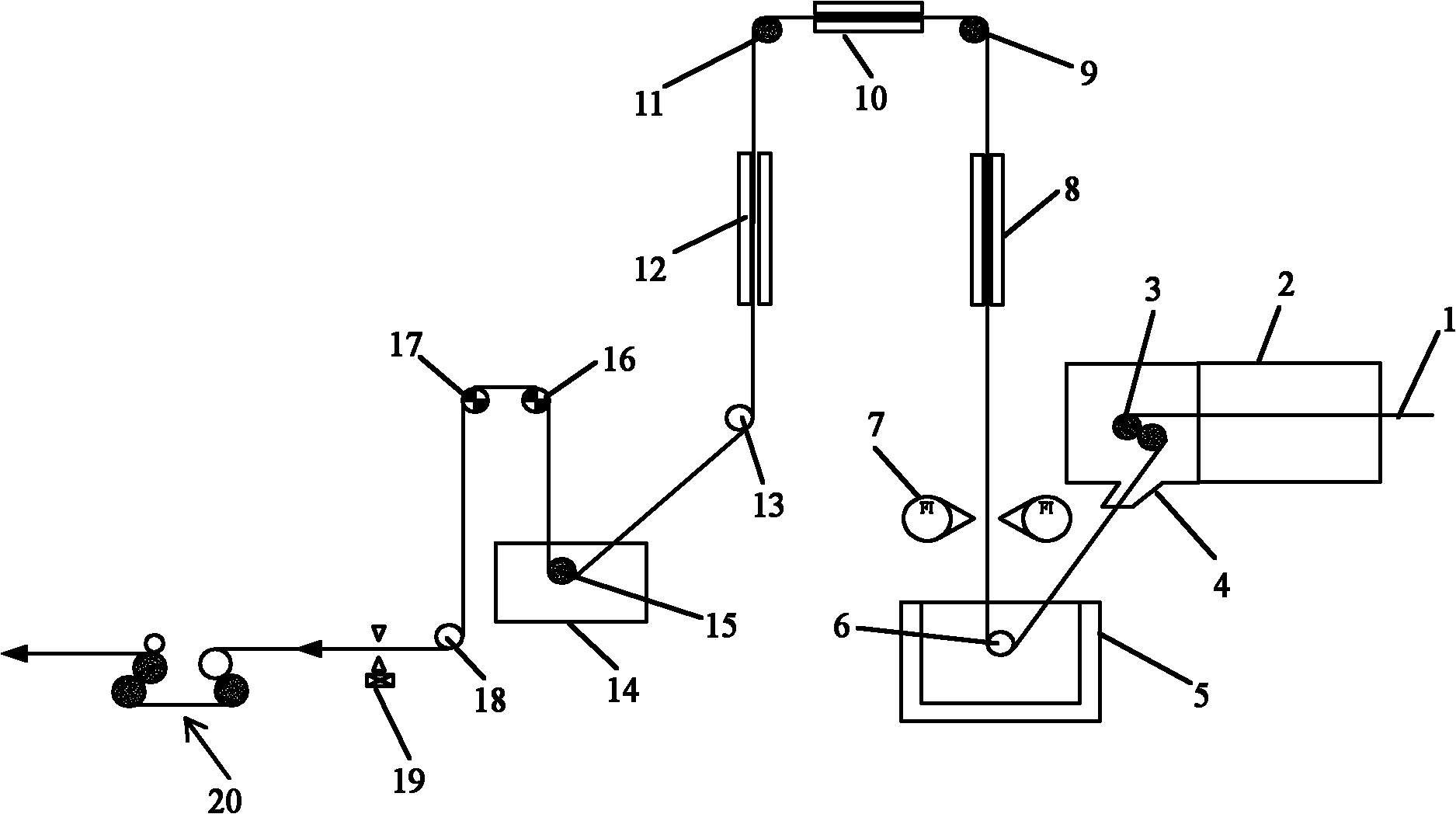

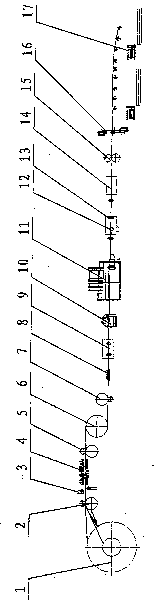

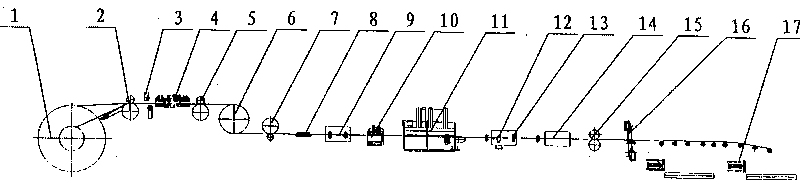

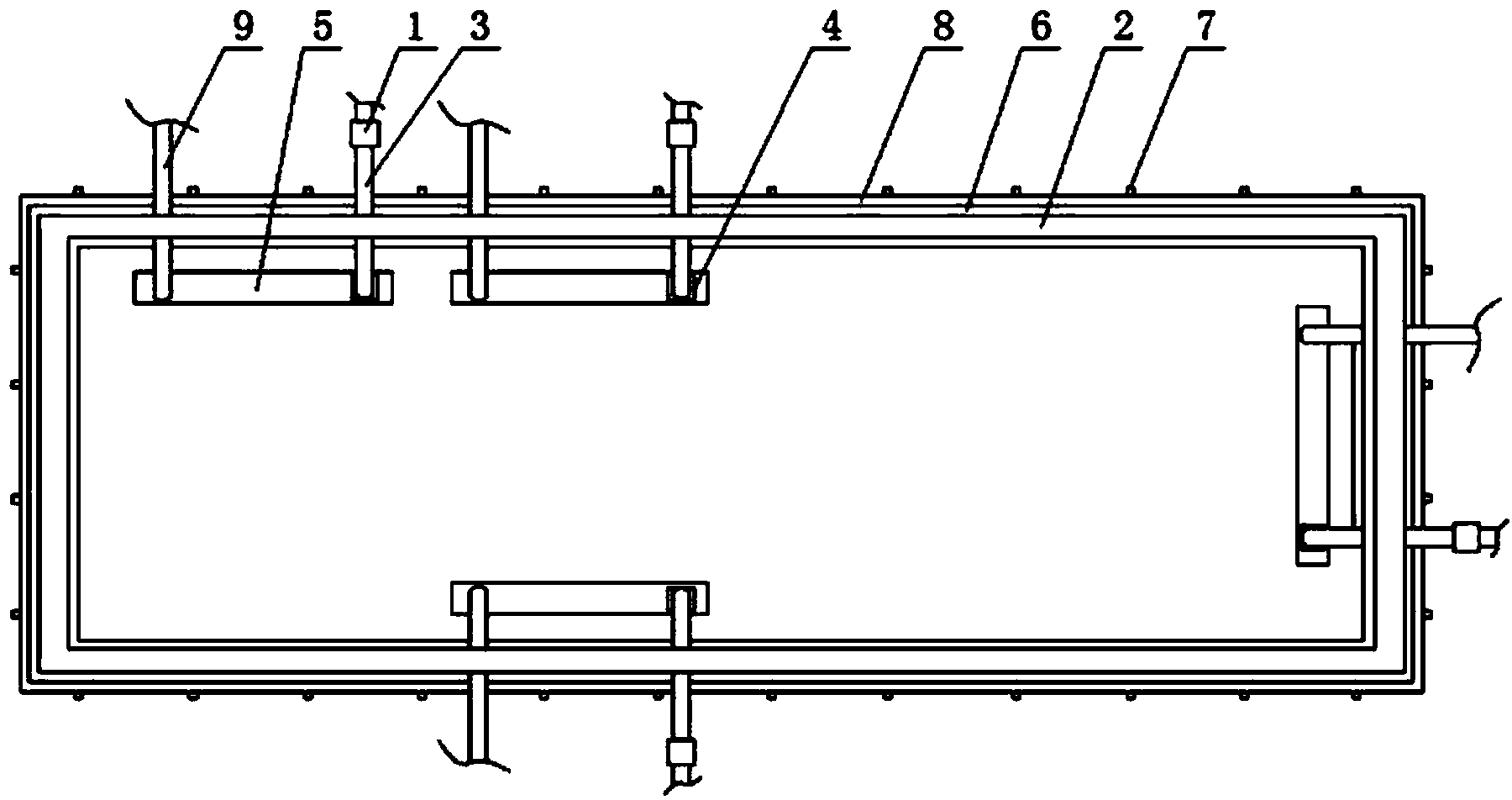

Device for continuously hot dip galvanizing pipe

InactiveCN101705463AQuality improvementRealize online full continuous productionHot-dipping/immersion processesCold airMolding machine

The invention provides a device for continuously hot dip galvanizing a pipe. A continuous production line device is adopted to solve the problem that a steel pipe cannot be continuously galvanized in the prior art. The device for continuously hot dip galvanizing the pipe comprises an uncoiling machine 1, cropping tail scissors 2, a first withdrawal roll 3, a steel plate welder 4, a withdrawal roll 5, a disc-type loop 6, a second withdrawal roll 7, a straightening device 8, a rolling molding machine 9, a straight welding machine 10, a pre-heating cleaner 11, a zinc groove 12, an annular air knife 13, a cold air blower 14, a steel pipe clamping and delivering device 15, fixed-length rear scissors 16 and a stacking apparatus. The stacking apparatus is provided with two stackers, one of which is put into operation while the other is for later use. The device for continuously hot dip galvanizing the pipe improves the production efficiency and saves cost.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Method for comprehensive treatment of ferrous ions in hot galvanizing assistant liquid

ActiveCN104004983AAvoid the pH value being low again, failing to meet the requirements of 5-6Avoid being too low again, failing to meet the requirements of 5-6Hot-dipping/immersion processesFiltrationFerrous

The invention provides a method for comprehensive treatment of ferrous ions in a hot galvanizing assistant liquid, which relates to a method for removal and treatment of ferrous ions in a hot galvanizing assistant liquid during batch production of galvanization products. The method comprises the following steps: (1) preparing raw materials consisting of hydrogen peroxide and potassium permanganate according to a ratio, oxidizing iron ions and combinedly adding hydrogen peroxide and potassium permanganate; (2) changing a hydrogen peroxide hot galvanizing assistant liquid liquid-level feeding manner into a hot galvanizing assistant liquid tank-bottom feeding manner, namely, pumping hydrogen peroxide into the bottom of a plating assistant tank with a water pump so as to reduce decomposition of hydrogen peroxide and release of oxygen; (3) starting an aeration pipe to stir the hot galvanizing assistant liquid, then adding potassium permanganate and carrying out a secondary reaction; (4) measuring a pH value after completion of the reaction, adding corresponding ammonia water according to obtained data and carrying out full adjusting and stirring so as to allow the pH value to be 5 to 6; and (5) adding a flocculating agent to accelerate precipitation when the pH value is 5 to 6, pumping out a supernatant, i.e., the treated hot galvanizing assistant liquid, in the plating assistant tank, carrying out recovering, pumping a precipitate into a filter press for press filtration and recovering a filtrate to the plating assistant tank.

Owner:CHIEFNEW NANTONG HEAVY IND

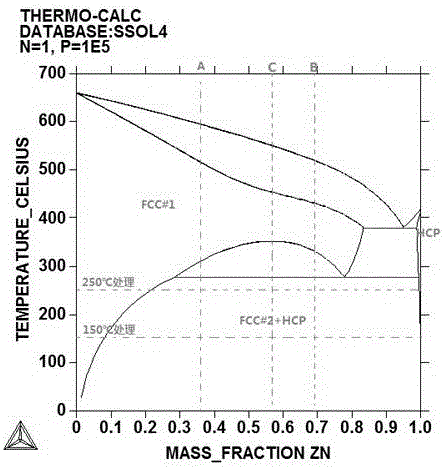

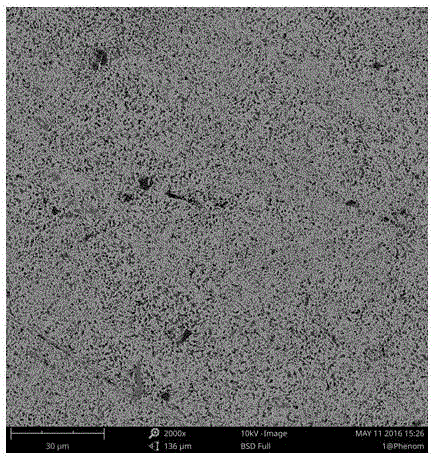

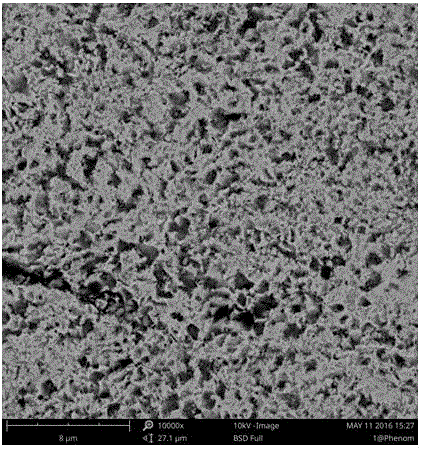

Component design and preparation method for zinc-aluminum alloy pipe

The invention discloses a component design and preparation method for a zinc-aluminum alloy pipe. The zinc-aluminum alloy pipe comprises, by weight, 36.00%-69.00% of zinc, 31.00%-64.00% of aluminum, 0.01%-1.00% of copper, 0.01%-1.00% of magnesium, 0.01%-1.0% of tin, 0.01%-1.00% of silver, 0.01%-2.00% of titanium, 0.01%-0.50% of boron, 0.01%-0.70% of cerium and 0.01%-0.20% of praseodymium, and the sum of the weight percentage is 100%. The obtained zinc-aluminum alloy pipe can be used for manufacturing a mold and a pipe fitting in a complex shape and used for manufacturing a delay element in the civil explosive industry according to the component and performance differences, so that an existing lead-antimony alloy pipe which is severe in environmental pollution and toxicity is replaced; and meanwhile, zinc-aluminum alloy is light in proportion and cheaper than a copper alloy material, the cost can be obviously reduced, and the zinc-aluminum alloy pipe can be widely used in metallurgy, mines, light industry, food, chemical industry, printing, mechanical equipment and other fields.

Owner:FUZHOU UNIVERSITY

Aqueous fusion agent used for flux method hot dip coating low aluminium zinc alloy and its application method

InactiveCN1442503AImprove activation abilityImprove solubilityHot-dipping/immersion processesCeriumZinc alloys

An aqueous flux for hot dip coating of low-Al Zn alloy by flux method is prepared from zinc chloride (70-80 mass%), ammonium chloride (8-10 mass%) and cerium chloride (4-10 mass%). Said hot dip coating process includes such steps as removing oil and rust from the iron or steel workpiece, immersing it in said aqueous flux for a certain time, baking at 120-160 deg.c, and immersing in molten Zn-Al alloy.

Owner:UNIV OF SCI & TECH BEIJING

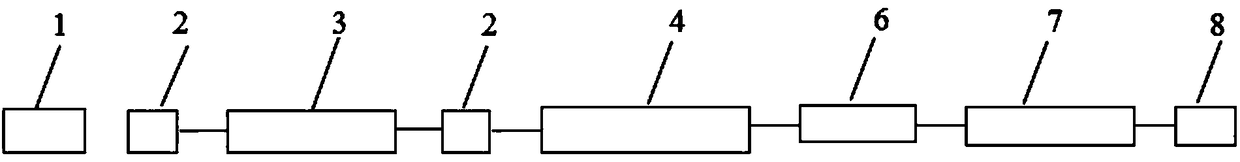

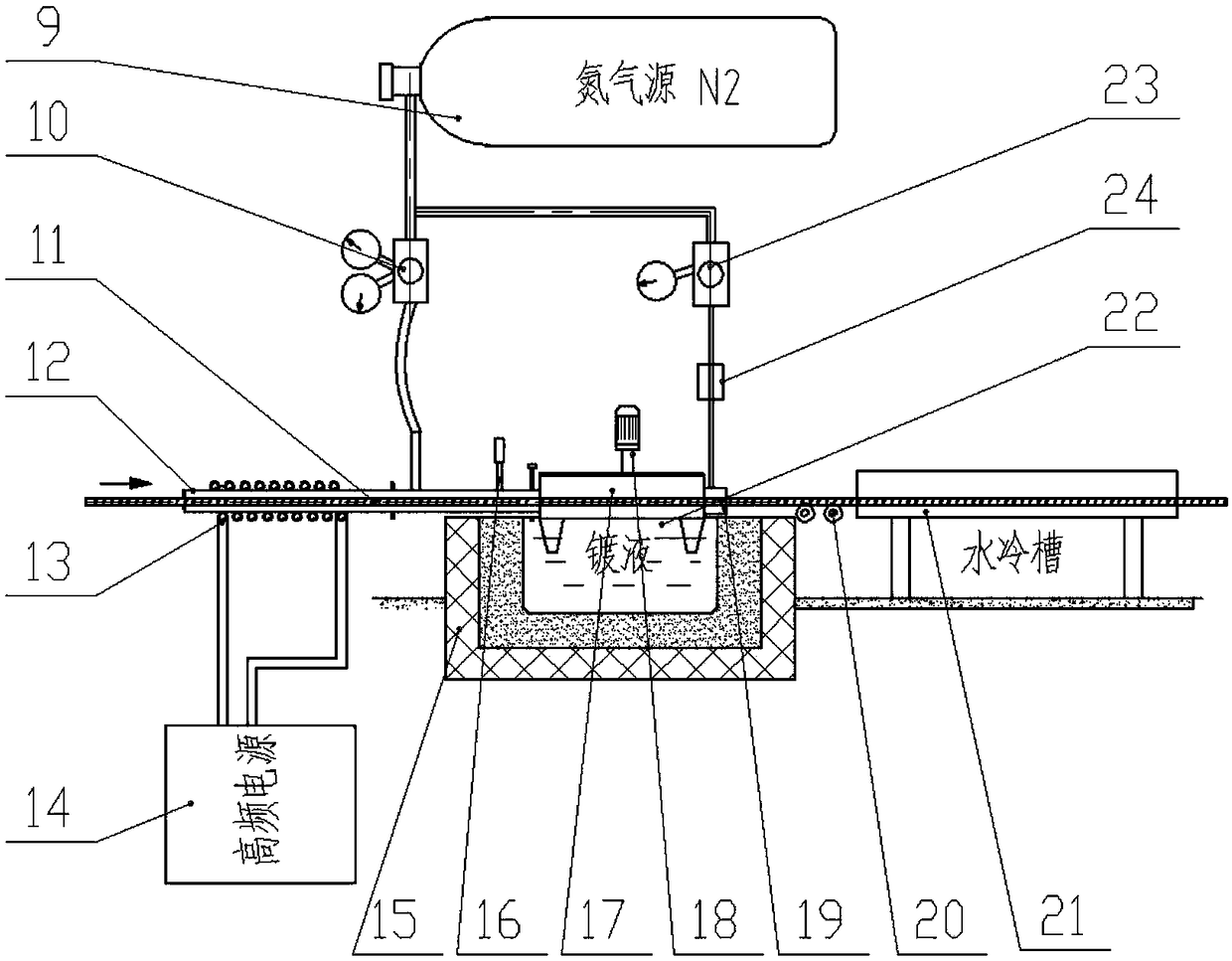

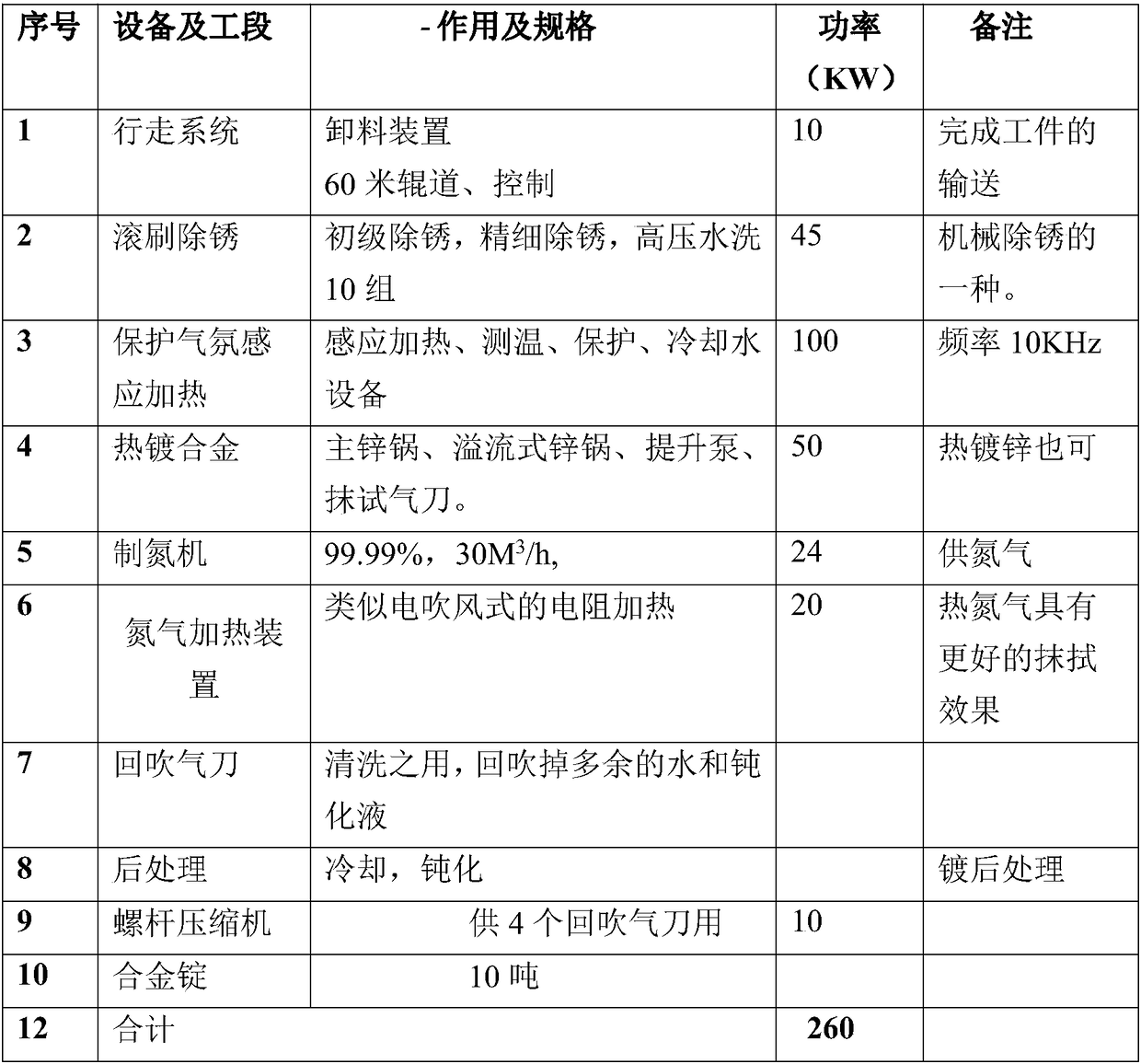

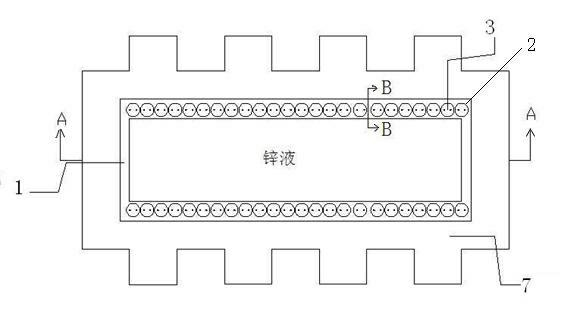

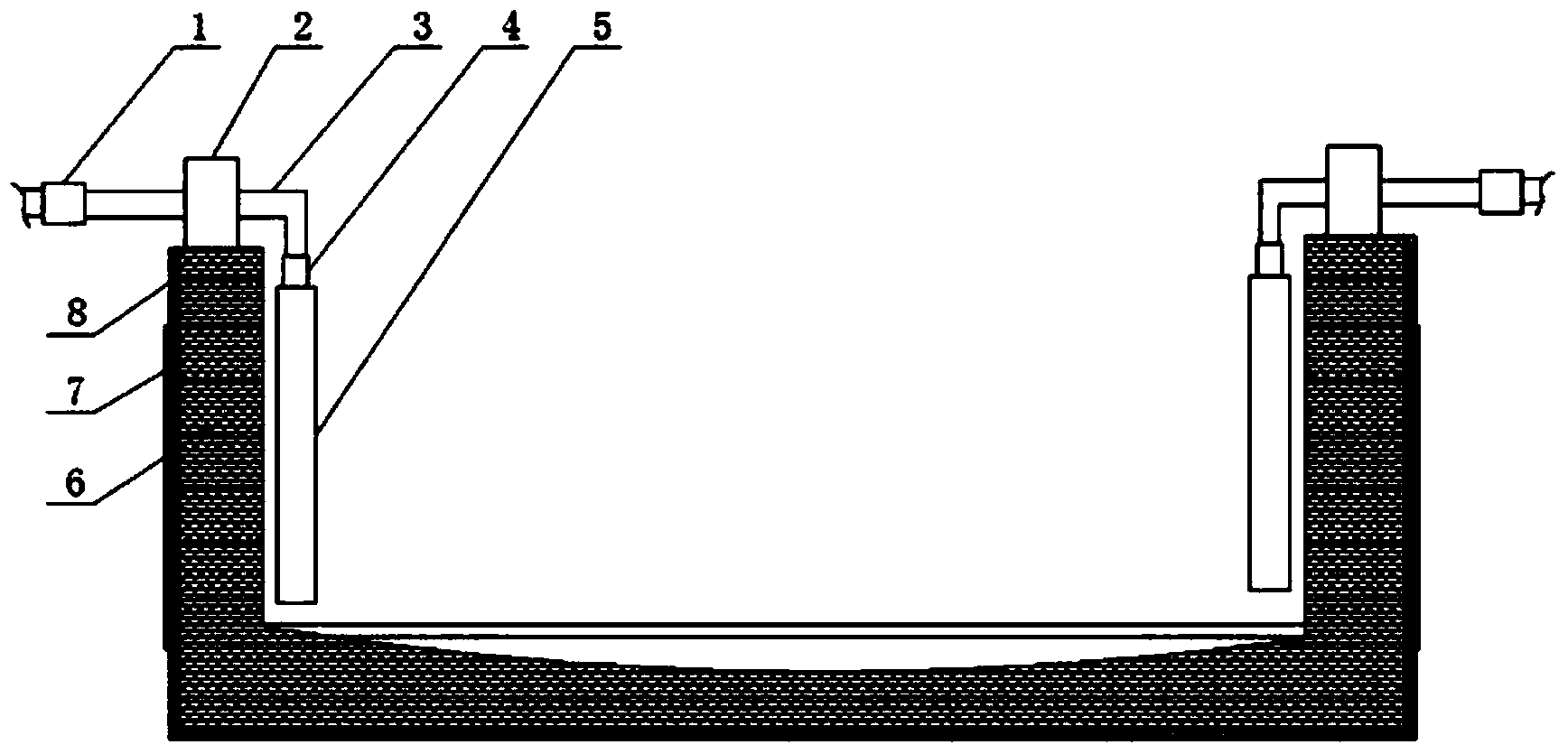

Long material horizontal hot plating equipment and hot plating method

ActiveCN108220854AWalk fastReduce zinc capacityHot-dipping/immersion processesHigh frequency powerShielding gas

The invention relates to long material horizontal hot plating equipment and a hot plating method. The hot plating equipment comprises a horizontal overflow hot plating device; the horizontal overflowhot plating device comprises a high-temperature resisting pipe, a high-frequency power supply, a main zinc pot, an overflow zinc pot and a protective gas source; the main zinc pot holds a hot platingmaterial; the upper parts of the main zinc pot and the overflow hot plating zinc pot are both sealed; a branch pipe for introducing a protective atmosphere is arranged at the middle part of the high-temperature resisting pipe; a high-frequency induction coil sleeves the front part of the high-temperature resisting pipe, and is connected with a high-frequency induction power supply; the tail end ofthe high-temperature resisting pipe is tightly connected with a workpiece inlet of the overflow zinc pot; a temperature measuring gauge is arranged near the tail end of the high-temperature resistingpipe; the overflow zinc pot is positioned above the main zinc pot; long material workpieces transversely penetrate through the overflow zinc pot; a lifting pump is arranged on the overflow zinc pot;and an overflow port is arranged above the overflow zinc pot. The equipment can provide a closed protective gas system to long materials, and finishes continuous hot plating process for the long materials.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

Rare-earth multi-element alloy coating and hot-dip galvanizing method thereof

The invention discloses a rare-earth multi-element alloy coating and a hot-dip galvanizing method thereof. The rare-earth multi-element alloy coating comprises the following main components: rare earth, aluminum, nickel, magnesium and zinc. The hot-dip galvanizing method comprises the following steps: (1) mix-melting intermediate alloys, namely Al-RE-Mg and Zn-Ni; (2) mix-melting a multi-element rare-earth alloy; (3) dredging slag; (4) casting; and (5) applying. The rare-earth multi-element alloy coating and the hot-dip galvanizing method thereof have the advantages that: firstly, difficulty of directly adding multiple elements with different melting points into a zinc liquid to melt and the impossibility problem of adding high-melting-point elemental metal elements into the zinc liquid to melt are solved; secondly, the multiple elements can be completely and quickly molten and dispersed, so that the hot-dop galvanizing method is easy to operate and control in a practical production process; thirdly, the dilution capability, the dispersive capacity, the mobility and the uniformity of the zinc liquid are strengthened, so that the zinc consumption is reduced by 5%-15%, the cost is reduced and the benefits are increased; and fourthly, the corrosion resistance of the rare-earth multi-element alloy coating is doubled in comparison with that of a conventional hot dip galvanized coating.

Owner:江苏中远稀土新材料有限公司

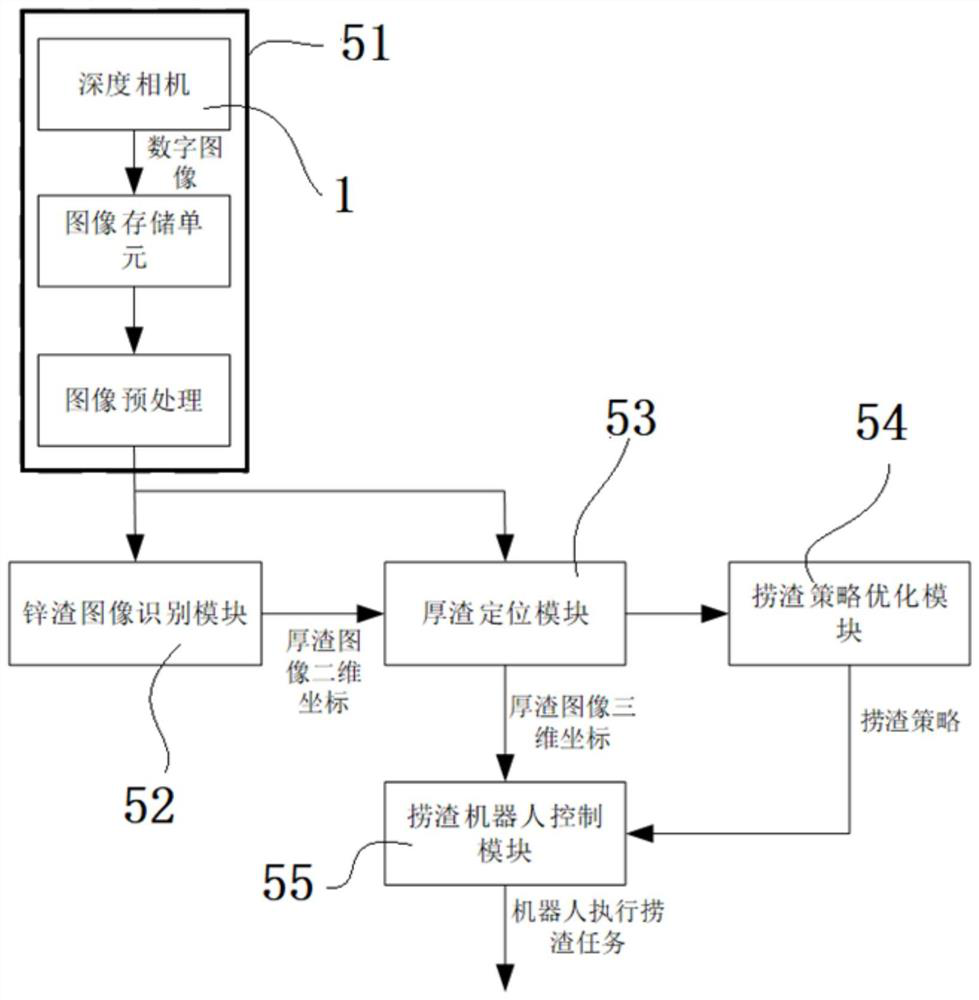

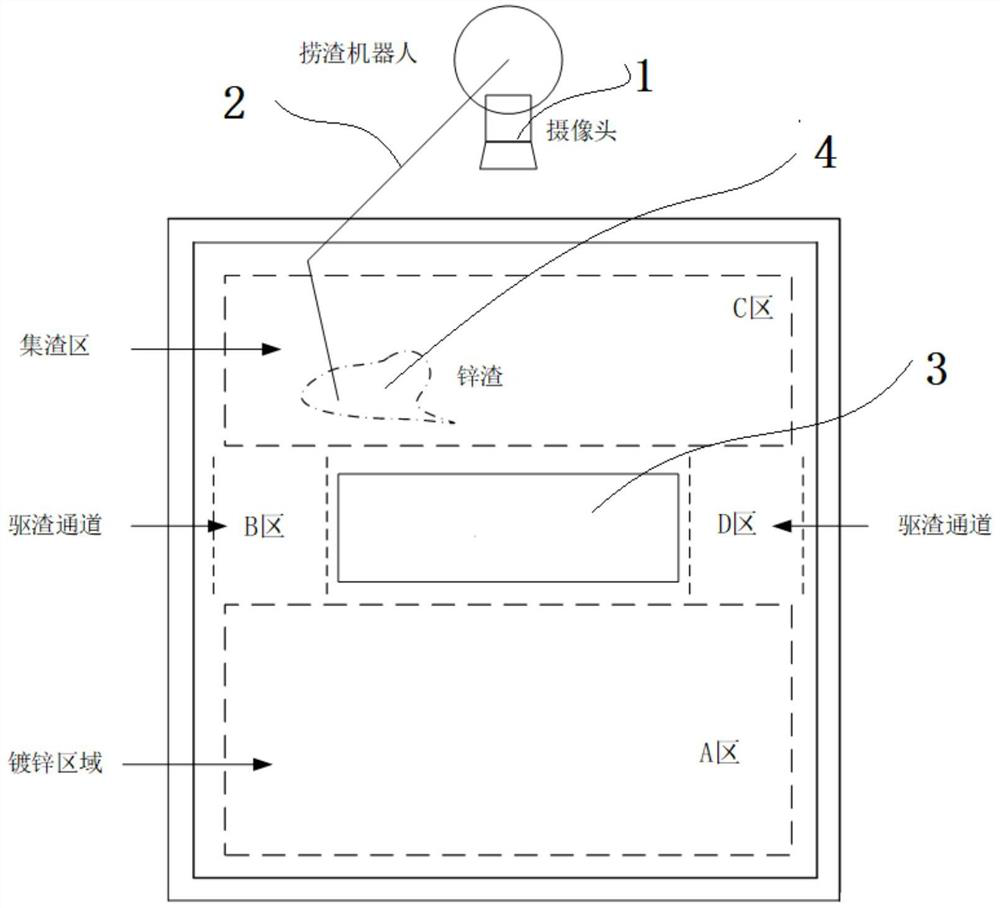

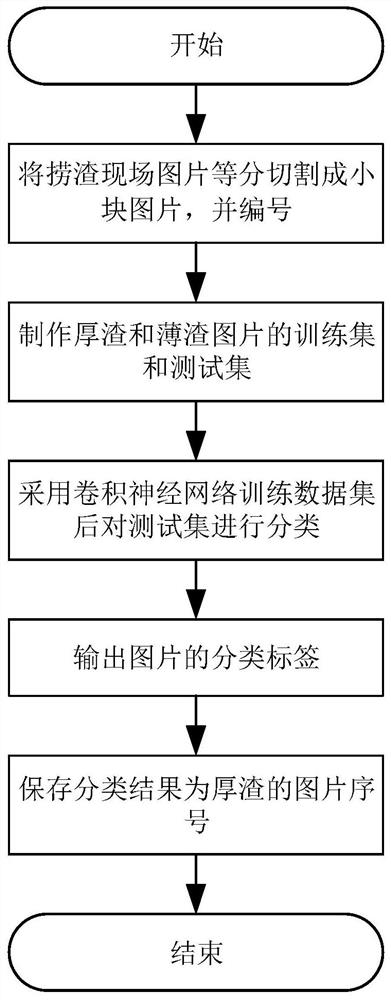

Machine vision-based slag salvaging method and robot system

ActiveCN112011750AIncrease autonomyReduce fishing frequencyHot-dipping/immersion processesProgramme-controlled manipulatorRobotic systemsMachine vision

The invention discloses a machine vision-based slag salvaging method and robot system. A thick slag area influencing the quality of a galvanized plate is identified and positioned through a vision technology, then, a slag salvaging sequence is obtained according to a slag salvaging area priority rule, and finally, a slag salvaging robot is controlled to salvage all thick slag and pour the thick slag into a nearby slag hopper. Compared with a traditional robot slag salvaging system, the machine vision-based slag salvaging scheme is provided, the optimal slag salvaging sequence is optimized anddetermined according to zinc slag distribution characteristics and a slag salvaging strategy, zinc consumption and power consumption caused by unnecessary slag salvaging times are reduced, the autonomy of the slag salvaging robot is remarkably improved, and the operation efficiency is improved.

Owner:WUHAN UNIV OF SCI & TECH

Aqueous fusion agent used for flux method hot dip coating low aluminium zinc alloy and its application method

InactiveCN1186473CImprove activation abilityImprove solubilityHot-dipping/immersion processesCeriumZinc alloys

An aqueous flux for hot dip coating of low-Al Zn alloy by flux method is prepared from zinc chloride (70-80 mass%), ammonium chloride (8-10 mass%) and cerium chloride (4-10 mass%). Said hot dip coating process includes such steps as removing oil and rust from the iron or steel workpiece, immersing it in said aqueous flux for a certain time, baking at 120-160 deg.c, and immersing in molten Zn-Al alloy.

Owner:UNIV OF SCI & TECH BEIJING

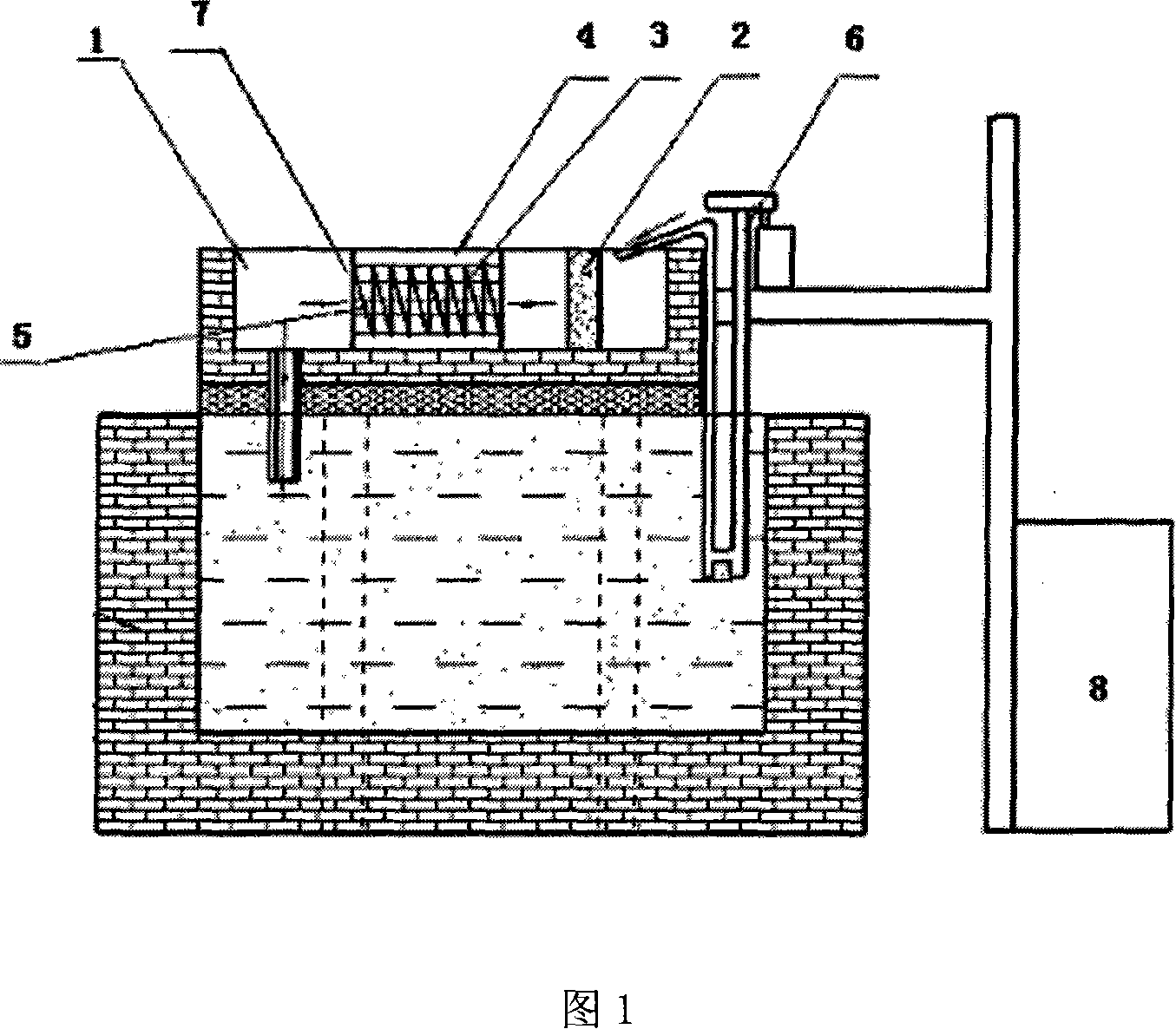

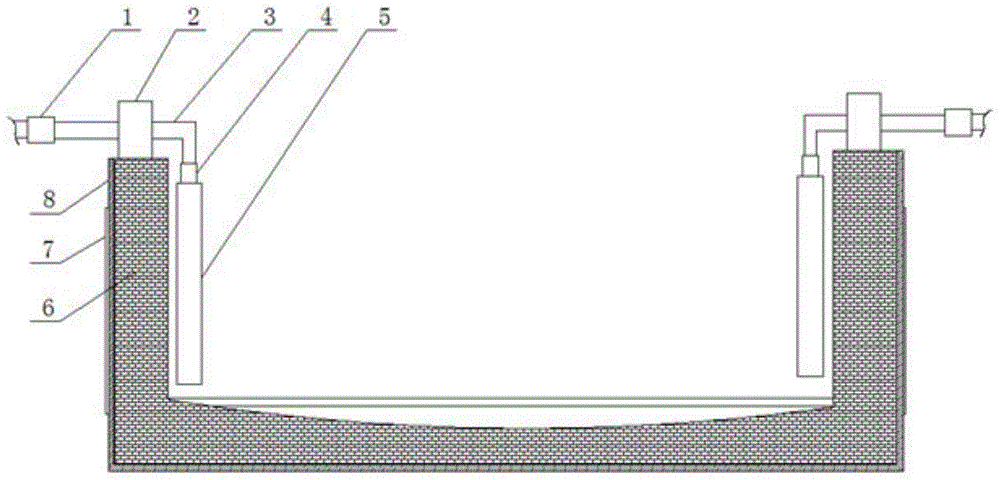

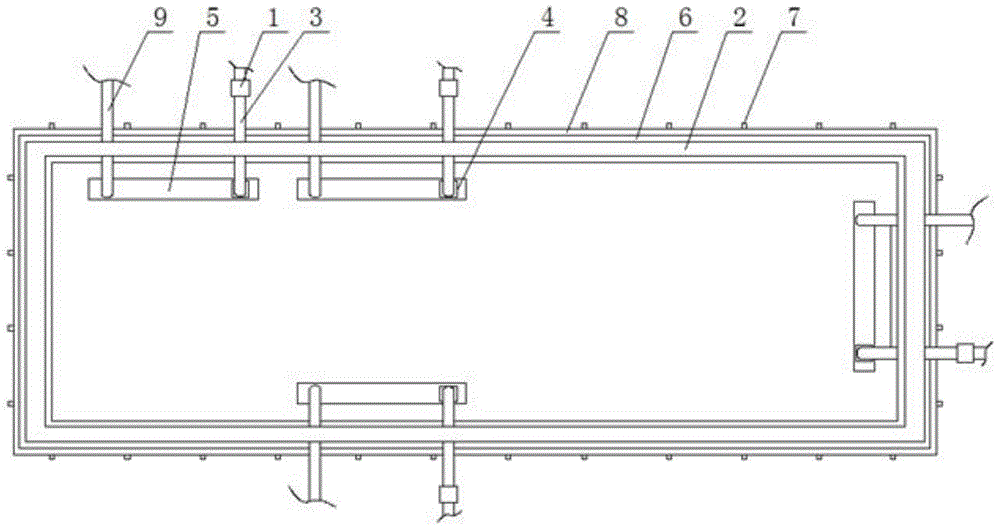

An internal heating galvanized pot

ActiveCN104233145BAvoid direct contactExtended service lifeHot-dipping/immersion processesFlue gasEngineering

The invention relates to an internal-heating galvanized pot which comprises a pot body and a heating mechanism, wherein the pot body is composed of a pot body casing and a pot body inner core, and the pot body casing covers the external part of the pot body inner core; the heating mechanism is arranged on the inner wall of the pot body inner core and composed of a rectangular casing, a corrosion prevention layer, a radiant tube, a flue gas pipeline, a burner, a regulating valve and an exhaust pipeline; the corrosion prevention layer is arranged on the outer surface of the rectangular casing, and the radiant tube is arranged in the rectangular casing; a mounting plate is arranged on the pot body inner core, and the burner is mounted at the inlet of the rectangular casing; the gas inlet end of the burner is connected with the flue gas pipeline penetrating the mounting plate, and the regulating valve is mounted on the flue gas pipeline; the exhaust pipeline communicated with the outlet of the rectangular casing penetrates the mounting plate. The internal-heating galvanized pot has the advantages of long service life, low loss, good zinc melting effect, pollution reduction, high thermal efficiency, galvanization cost reduction and the like and is easy to realize.

Owner:TIANJIN YIRUNDING METAL PROD

Method for resisting fused zinc corrosion of steel and iron product

InactiveCN1804126AExtended service lifePrevent hard particlesHot-dipping/immersion processesSheet steelZinc

The method to resist Zinc solution corrosion comprises: cover a piece of soft fabric that resists to Zinc solution corrosion and 480-960Deg and composes a plurality of oxides on the steel product surface to insulate the product from Zinc solution. This invention overcomes defects in prior art, reduces difficulty and cost, and benefit to Zn cooker and inner-dip heater.

Owner:ZHEJIANG UNIV

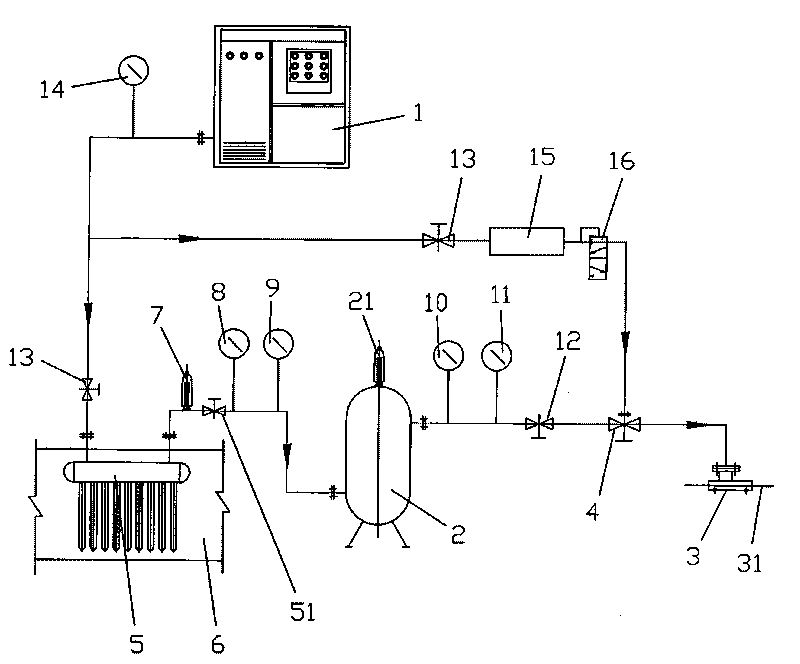

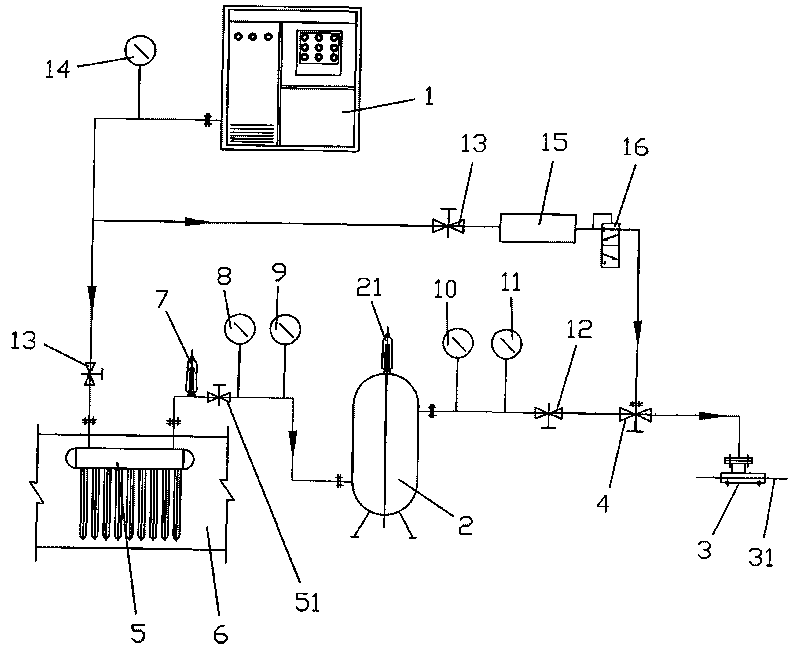

System for replacing steam internally blowing hot-dip galvanized steel pipe equipment

InactiveCN101713058ALow running costWill not oxidizeHot-dipping/immersion processesAir preheaterEngineering

The invention discloses a system for replacing steam internally blowing hot-dip galvanized steel pipe equipment, which comprises an air compressor, a steam drum and an internally blowing device communicated with the steam drum, wherein a pneumatic control membrane valve is communicated with the steam drum and the internally blowing device; a control end of the pneumatic control membrane valve is communicated with an air channel of the air compressor; the steam drum is communicated with an air channel of an air preheater; the air preheater is communicated with the air channel of the air compressor; and the air preheater is arranged in a flue of a heating furnace of a galvanized pot. A safety valve, a temperature meter and a pressure gauge are arranged between the steam drum and the air preheater. The system is easy to be put on a new project; the equipment cost, the production cost and the maintenance cost are lower; and the system can save more energy and the consumption of zinc, is safer and more environmentally-friendly, is simpler and more convenient to operate, and reduces the total cost of the input of a galvanized steel pipe project.

Owner:符邠怀

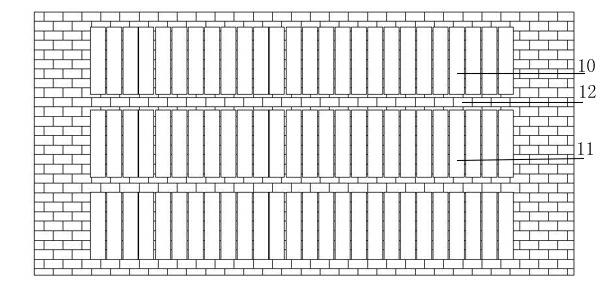

Novel ceramic zinc pot and electrical heating arrangement method

InactiveCN102154603AMeet the needs of modern galvanizingMeet the requirements for plating other workpiecesHot-dipping/immersion processesHeater elementsElectricityBrick

The invention discloses a novel ceramic zinc pot which comprises a zinc pot body consisting of refractory ceramic bricks, wherein a plurality of placing positions which are perpendicular to the bottom surface of the zinc pot body are arranged on the side wall of the zinc pot body and extend sequentially along the length of the side wall, and heating units are arranged on the placing positions; the heating units comprise quartz glass tubes fixed inside the placing positions; and electrical heating wires are arranged in the quartz glass tubes, and sheaths are arranged outside the quartz glass tubes. Due to the adoption of a new electrical heating arrangement mode, the size of the zinc pot can meet the requirement of modern galvanization, the problem of plating large-scale workpieces is solved, and the invention has the advantages that the novel ceramic zinc pot is easy to operate, safe in use, and saves energy and zinc. Simultaneously, the invention also discloses an electrical heating arrangement method for the novel ceramic zinc pot.

Owner:CHONGQING GUANGREN TOWER MFG

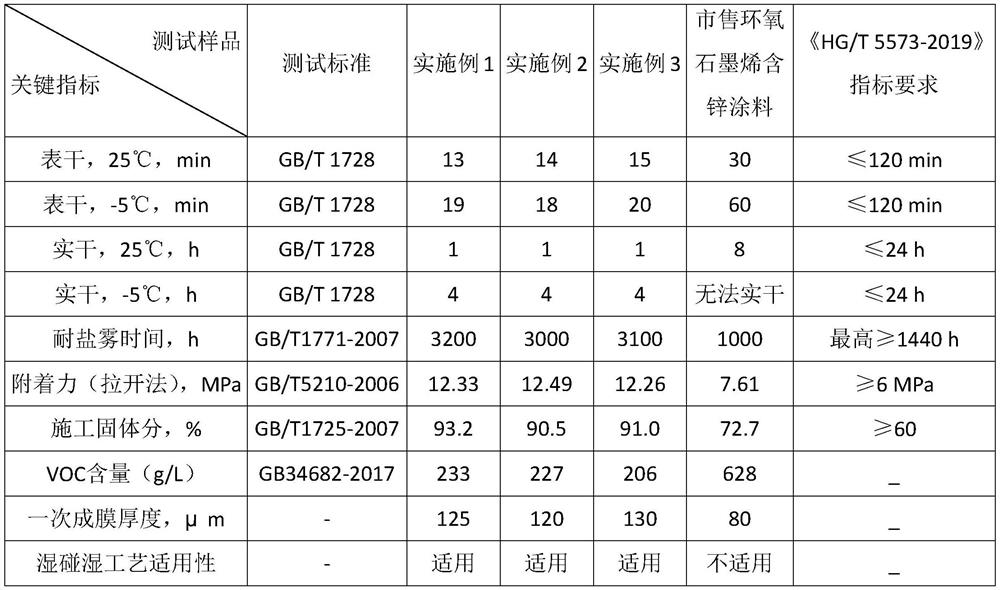

Graphene modified polyaspartic acid ester zinc-containing coating and preparation method thereof

InactiveCN112143360AImprove performanceEasy to dryAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidOrganosolv

The invention relates to a graphene modified polyaspartic acid ester zinc-containing coating and a preparation method thereof. The coating comprises a component A capable of curing to form a film anda component B containing a curing agent, the component A comprises high solid content low viscosity polyaspartic acid ester resin, an organic solvent, a dispersant, graphene, zinc powder, an antirustpigment, a leveling agent and an anti-settling agent; and the component B is isocyanate or a mixture of isocyanate and an organic solvent. The graphene modified polyaspartic acid ester zinc-containingcoating belongs to an environment-friendly green product, is higher in drying speed compared with an existing common epoxy zinc powder coating, and can meet the wet-to-wet spraying process requirements, and the one-time film forming thickness can reach 120 [mu]m or above, so that the construction efficiency is greatly improved; the salt spray resistance is better, and the adhesive force is good;the method provided by the invention is environment-friendly in production process, simple in process, free of sanding process, low in cost and beneficial to industrial large-scale production.

Owner:湘江涂料科技有限公司

Continuous and electromagnetic separating method for zinc slag in heat galvanizing liquid

InactiveCN100503875CReduce the amount of drossReduce zinc consumptionHot-dipping/immersion processesProcess efficiency improvementSlagFiltration

This invention relates to a method for separating Zn dregs in galvanized fluid continuously by electromagnetism including: applying a Zn fluid pump to extract Zn fluid from a Zn boiler to flow into a clarifier launder, in which, dregs are separated in the launder from the fluid in the separation process, the first stage filter uses a foam ceramic filter, and hot galvanized fluid after the first stage filtration flows into a magnetic scummer, which exerts an alternating magnetic field by a coaxial solenoid coil to let Zn fluid in the ceramic tubebe acted by electromagnetic force vertical to the ceramic tube wall, and Zn dregs move along the direction opposite to the magnetic force born by the Zn fluid under the magnetic field to be captured till moving to the wall of the ceramic pipe, the Zn fluid flows from the scummer device t oflow back to a Zn boiler via a pipeline connected with the boiler to finish a continuous clarification process out of the boiler to remove dregs.

Owner:SHANGHAI JIAOTONG UNIV

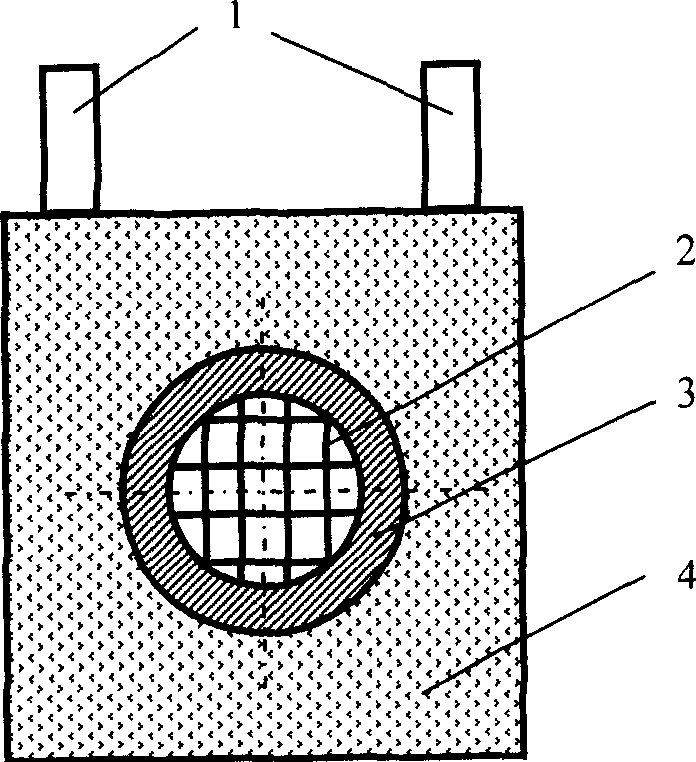

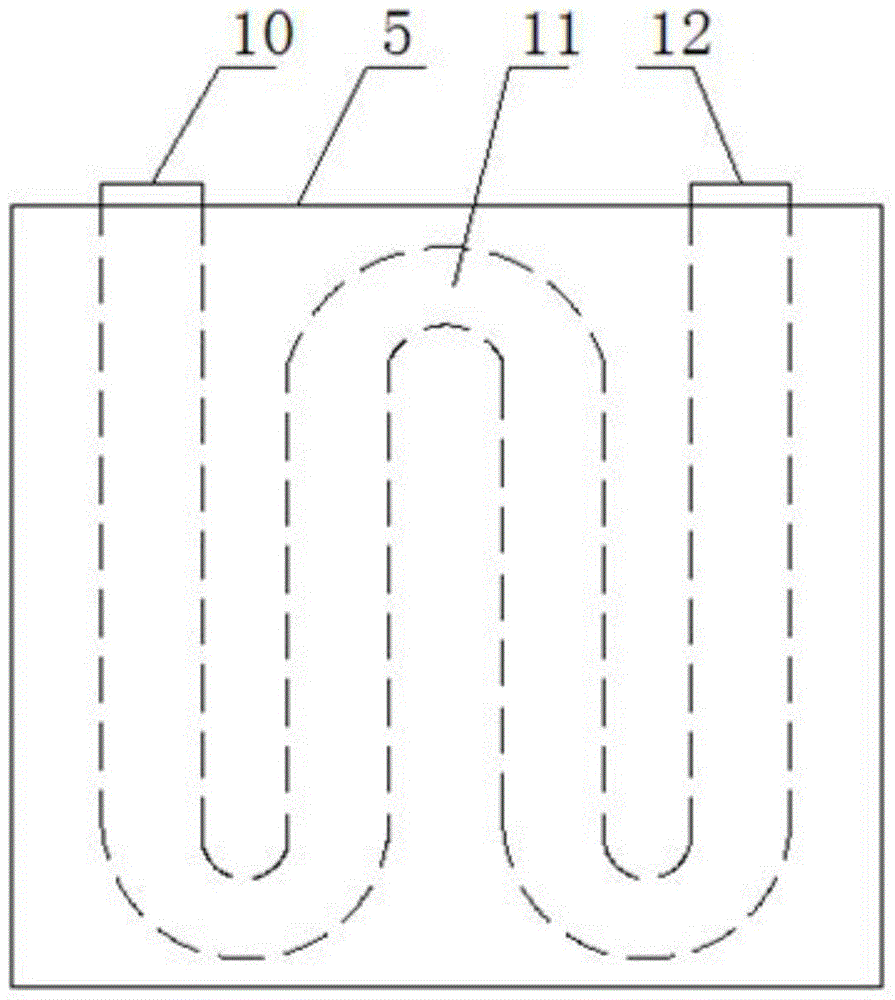

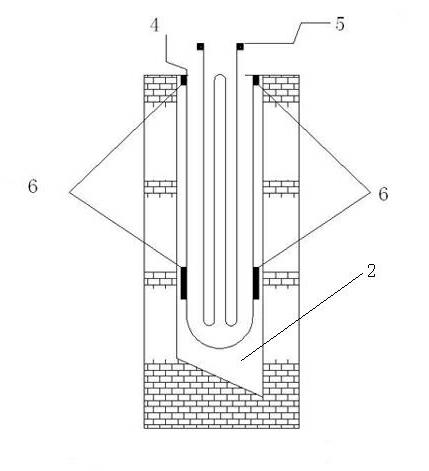

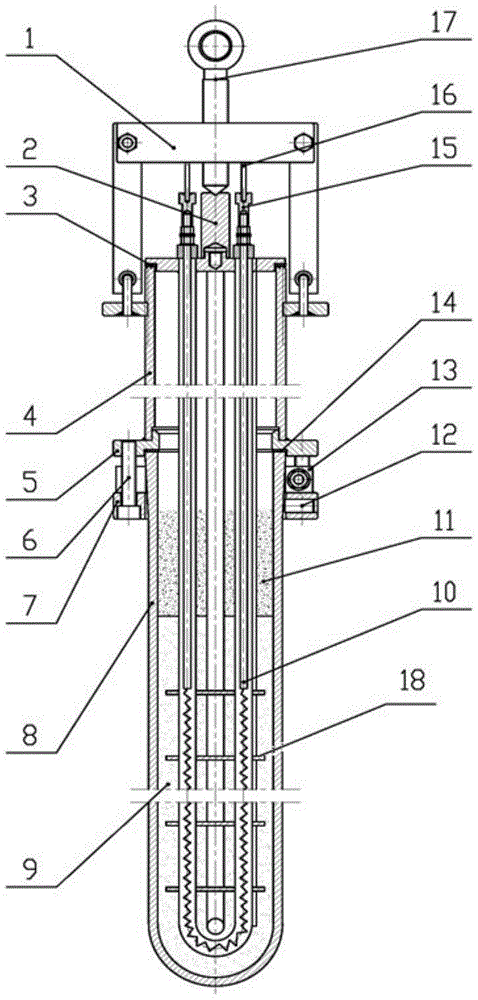

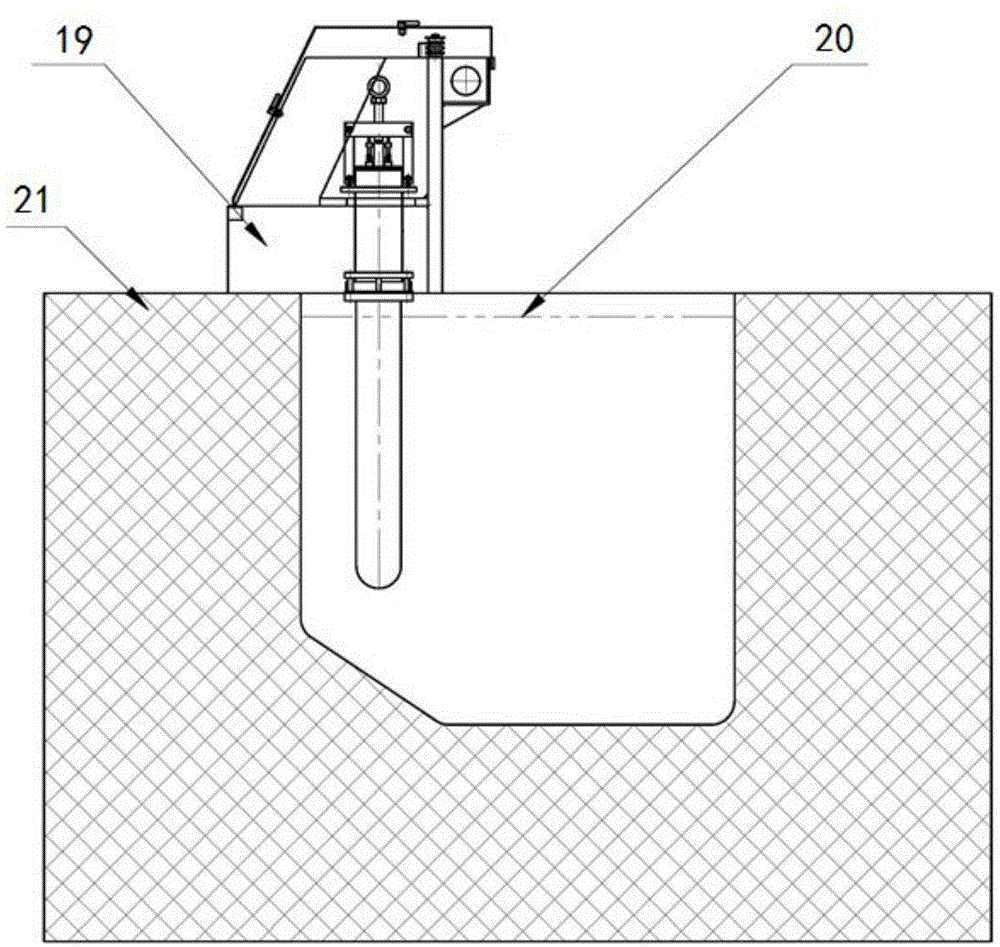

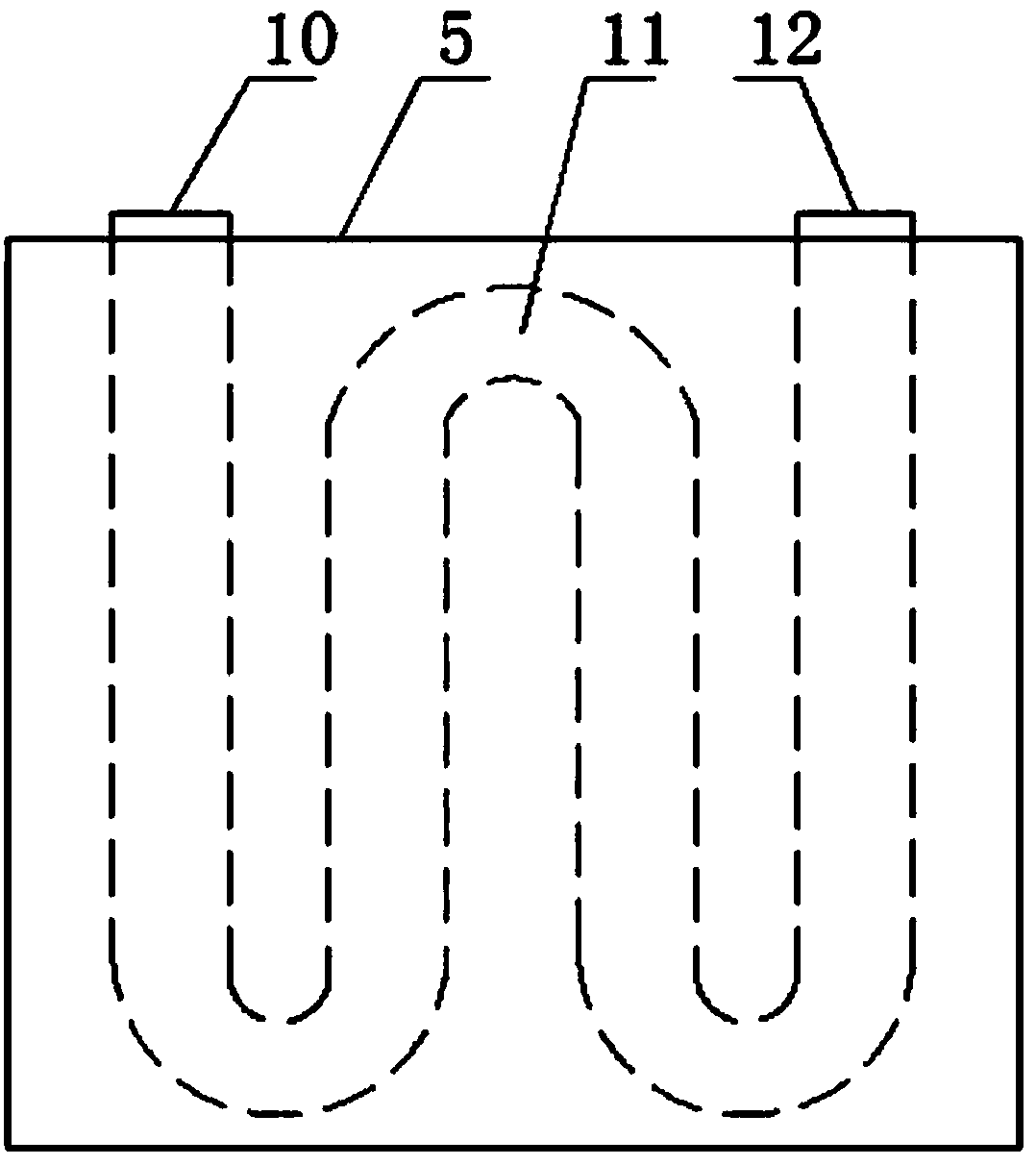

Inner heater of liquid zinc corrosion resistance alloy

ActiveCN104363671ALongitudinal temperature uniformityReduce heat lossHot-dipping/immersion processesHeating element shapesCircular discAlloy

The invention relates to an inner heater of liquid zinc corrosion resistance alloy. The inner heater of the liquid zinc corrosion resistance alloy is characterized by comprising a compression seal device, an additional pipe, a first connecting flange, a second connecting flange, an outer sleeve, a heat conductor, an electrical heating core, a top pillar, an antioxidant and two extraction electrodes, wherein the electrical heating core is a U-shaped electrical heating pipe, and comprises a heating area and a connection electrode area, a designed number of metal plates are evenly distributed along the length direction of the heating area of the electrical heating core, a disk is welded at the top of the connection electrode area of the electrical heating core, the top of the U-shaped electrical heating pipe and the disk are welded into a whole, the two extraction electrodes are respectively extracted from two ends of the U-shaped electrical heating pipe, the two extraction electrodes are connected with a power source through lead wires, a connection blind hole is formed in the disk, the lower end of the top pillar is connected with the connection blind hole, the upper end of the top pillar is connected with a compression bolt, the additional pipe is a cylinder with two ends open, and the upper end of the additional pipe is connected with the disk.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

Special zinc with purification function for hot dip

The invention provides a special zinc with a purification function for hot dip. The special zinc with the purification function for the hot dip is characterized in that a zinc ingot is taken as a benchmark, wherein at least two elements among 0.001%-1.00% of mixed rare earth (La-Ce), 0.001%-2.00% of tin (Sn), 0.001%-1.00% of bismuth (Bi), and 0.12% nickel (Ni) are added into the zinc ingot, and the balance is intrinsic impurities of the zinc ingot. According to the special zinc with the purification function for the hot dip, the added metal elements in the zinc ingot can preferentially react with a nonmetal generated in a zinc plating solution to be discharged, and the special zinc with the purification function for the hot dip has the beneficial effects that 1, the reaction between the nonmetal and the zinc is prevented, the zinc consumption is reduced, the fluidity is improved, and the zinc plating quality is ensured, and the cost is reduced; and 2, the problem of the nonmetal impurity purification is solved, the non-suspend production purification are realized, and the productivity is improved.

Owner:上海灿诺锌合金研究所

Hot-dip galvanizing method for steel products

ActiveCN101280401BReduce take awayTemperature controlHot-dipping/immersion processesHeat lossesDross

The invention relates to a hot dip galvanizing method for the steel product, which belongs to the hot dip galvanizing engineering in the metallurgy field. The invention mainly solves the technical problem that the hot dip galvanizing method which is utilized for the steel product for directly aiming at the faults of excessive consumption of the zinc and low efficiency utilization of the heating system in the normal hot dip galvanizing process is provided. The heating way of the dip galvanizing kettle of the invention is side surface heating, thus, the temperature of the liquid zinc can be conveniently controlled, the deposition of the zinc dross can be accelerated, and the zinc quantity taken away by the galvanizing piece can be reduced; because the ferric salt content inside the assistant galvanizing tank is controlled, the zinc dross quantity inside the zinc kettle is reduced; simultaneously, the output per hour is controlled to stabilize the heat loss and reduce the increased zinc consumption caused by temperature variation. Through the progress of the process, the zinc consumption is reduced, the heat energy is fully utilized, the faults of excessive zinc consumption and low efficiency utilization coefficient of the heating system caused by normal process are overcome, the quality is ensured, simultaneously, the resources are saved.

Owner:SHANGHAI YONGFENG HOT DIP GALVANIZING

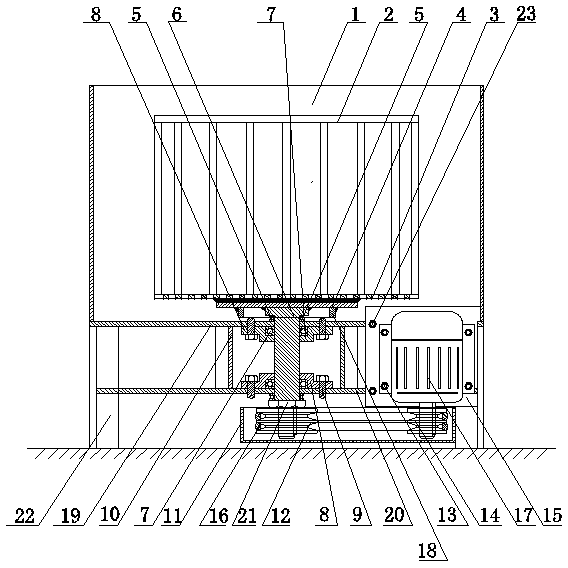

Centrifugal dezincification device used for hot galvanizing

ActiveCN102703847AImprove surface qualityReduce zinc consumptionHot-dipping/immersion processesPulley

The invention relates to a centrifugal dezincification device used for hot galvanizing, which belongs to a hot galvanizing device and is characterized in that the hot galvanizing device mainly comprises a bracket, a protective barrel, a dezincification basket, a lower bearing mounting plate, a main shaft, a main nut, a supporting plate, an upper bearing seat, a lower bearing seat, a big belt pulley, a small belt pulley, a belt, a motor base plate, a motor and an adjusting screw rod, wherein a top plate is welded on the top of each vertical rod, a barrel wall is welded on the top plate to form the protective barrel, and the lower bearing mounting plate is horizontally welded between the middle sections of the vertical rods. The upper bearing seat is fixedly arranged on the bottom surface of a base plate of the protective barrel, the lower bearing seat is fixedly arranged on the lower bearing mounting plate, the main shaft is arranged in the upper bearing seat and the lower bearing seat in a penetrating mode, the disc-shaped supporting plate is welded on the upper end surface of a shaft shoulder of the main shaft, the grid-shaped dezincification basket is fixedly arranged on the supporting plate, the motor base plate and the motor are hinged on the base plate and the front right surface of the lower bearing mounting plate, the dezincification basket is driven to rotate by the driving of the belt, a workpiece is dezincified, the quality is high, and the consumption of zinc is low.

Owner:安徽恒兴装备材料有限公司

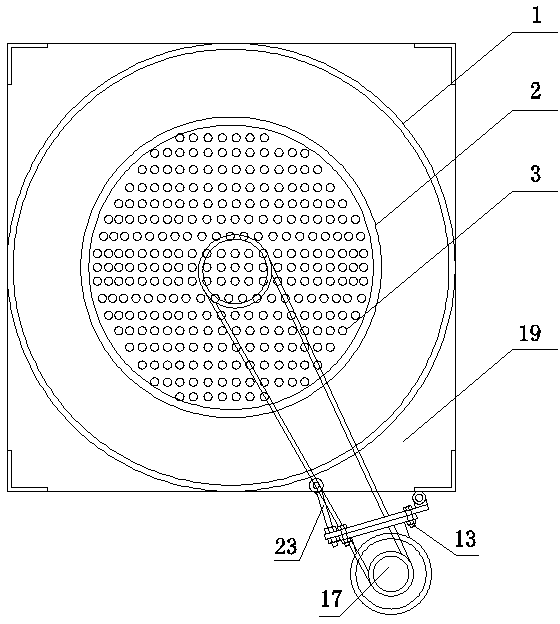

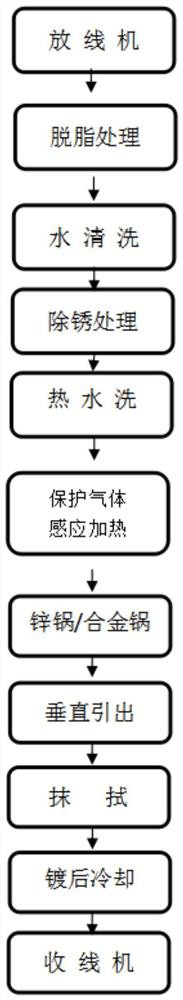

Process method for obtaining steel wire hot galvanizing and alloy thick plating layer

PendingCN112921261AMeet production requirementsGuaranteed binding requirementsHot-dipping/immersion processesFurnace typesShielding gasAlloy

The invention relates to a process method for obtaining a steel wire hot galvanizing and alloy thick plating layer. The process method comprises the following steps: performing oil and rust removal treatment on the surface of a steel wire at a wiring speed in a range of 150-500 m / min, putting the treated steel wire into an induction heating furnace, and performing induction heating on the steel wire under the action of protective gas at the induction heating temperature 0-70 DEG C lower than a plating solution temperature, wherein the plating solution temperature is 420-520 DEG C, and the induction heating time is 0.5-2 seconds; and discharging the steel wire out of the induction heating furnace, entering a zinc pot from a closed steel pipe, vertically leading out a plating solution through a ceramic wire pressing shaft, entering a wiping device, and finally cooling to obtain the thick-plated steel wire. According to the method, the steel wire subjected to surface treatment can enter the zinc pot after being subjected to induction heating by protective gas of which the temperature is equal to or lower than the hot plating temperature at a relatively high wiring speed, namely in a range of 150-500 m / min, and then is vertically led out of a liquid surface to be wiped, so that a high-binding-force thick plating layer meeting the strength requirement is obtained.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

Internal-heating galvanized pot

ActiveCN104233145AAvoid direct contactExtended service lifeHot-dipping/immersion processesFlue gasEngineering

The invention relates to an internal-heating galvanized pot which comprises a pot body and a heating mechanism, wherein the pot body is composed of a pot body casing and a pot body inner core, and the pot body casing covers the external part of the pot body inner core; the heating mechanism is arranged on the inner wall of the pot body inner core and composed of a rectangular casing, a corrosion prevention layer, a radiant tube, a flue gas pipeline, a burner, a regulating valve and an exhaust pipeline; the corrosion prevention layer is arranged on the outer surface of the rectangular casing, and the radiant tube is arranged in the rectangular casing; a mounting plate is arranged on the pot body inner core, and the burner is mounted at the inlet of the rectangular casing; the gas inlet end of the burner is connected with the flue gas pipeline penetrating the mounting plate, and the regulating valve is mounted on the flue gas pipeline; the exhaust pipeline communicated with the outlet of the rectangular casing penetrates the mounting plate. The internal-heating galvanized pot has the advantages of long service life, low loss, good zinc melting effect, pollution reduction, high thermal efficiency, galvanization cost reduction and the like and is easy to realize.

Owner:TIANJIN YIRUNDING METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com