Device for continuously hot dip galvanizing pipe

A technology of hot-dip galvanizing and equipment, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of non-continuous production, waste of double-sided galvanizing, slow production speed, etc., and improve the degree of automation , reduce production costs, and reduce the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

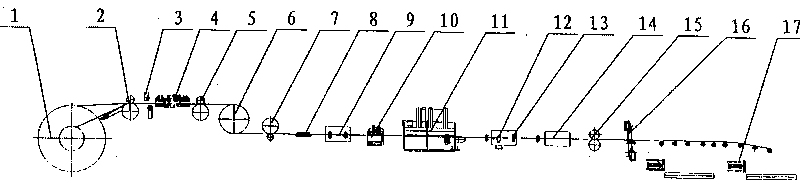

[0011] Entrance section: first place the steel coil on the uncoiler 1 with the steel coil car, cut off the plate head with the head and tail cutter 2, flatten through the first pinch roller 3 and pass through the steel plate welding machine 4, and the previous steel coil Cut the head and tail of the coil 2 to cut off the irregular tails of the steel plates and weld them together, change the position and direction of the steel strip through the pinch roller 5, so that the steel strip enters the disc looper 6 from the horizontal direction to the vertical direction , the steel strip enters the disc looper 6, when the coil is normally uncoiled, the disc looper 6 stores the material, and when the coil is changed and welded, the disc looper 6 discharges the material, which meets the requirements of continuous production of the unit;

[0012] Process section: The steel strip comes out of the disc looper 6 and is turned by the second pinch roller 7, so that the steel strip changes from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com