Patents

Literature

50results about How to "Well done" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum Therapy Device

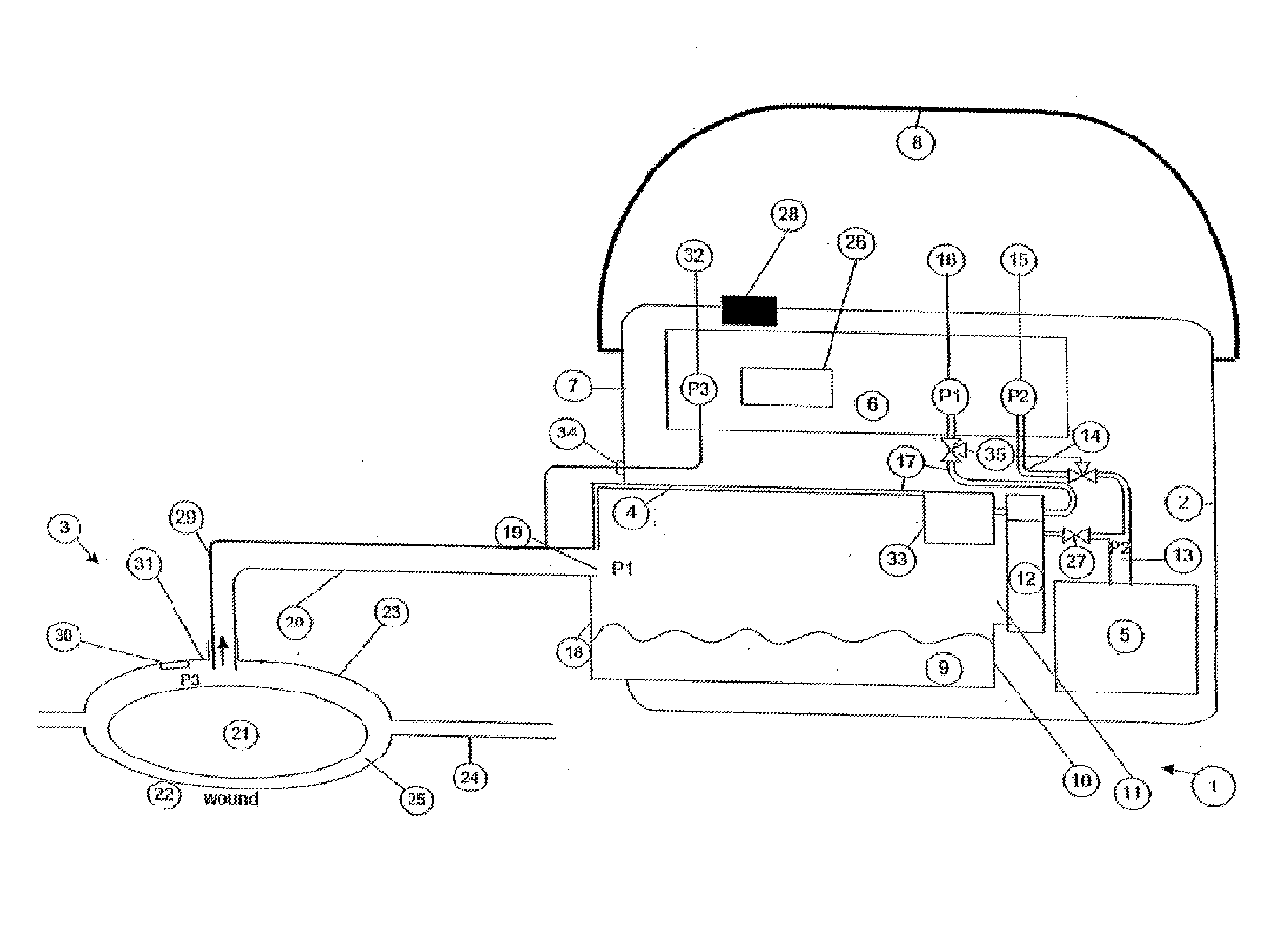

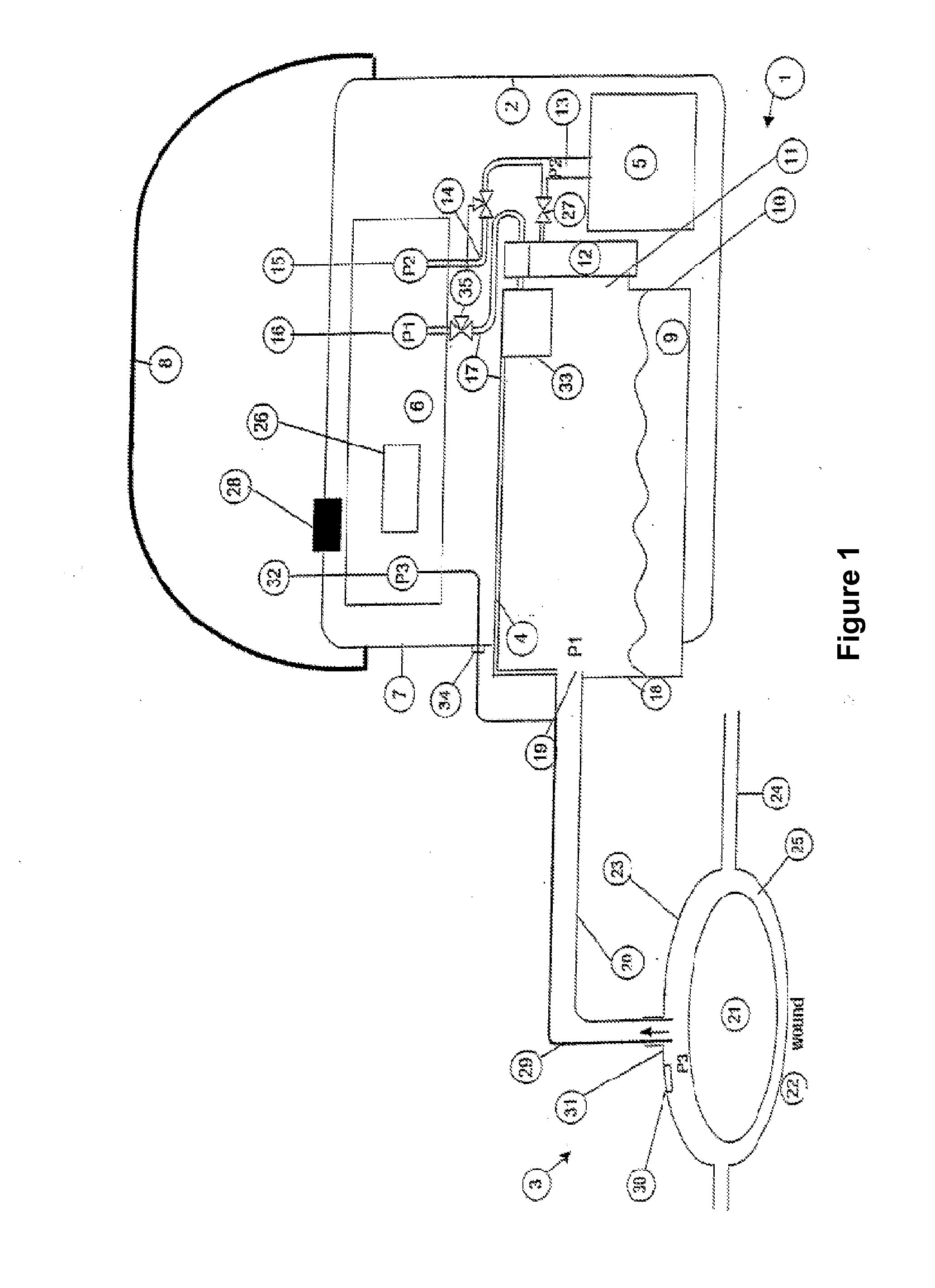

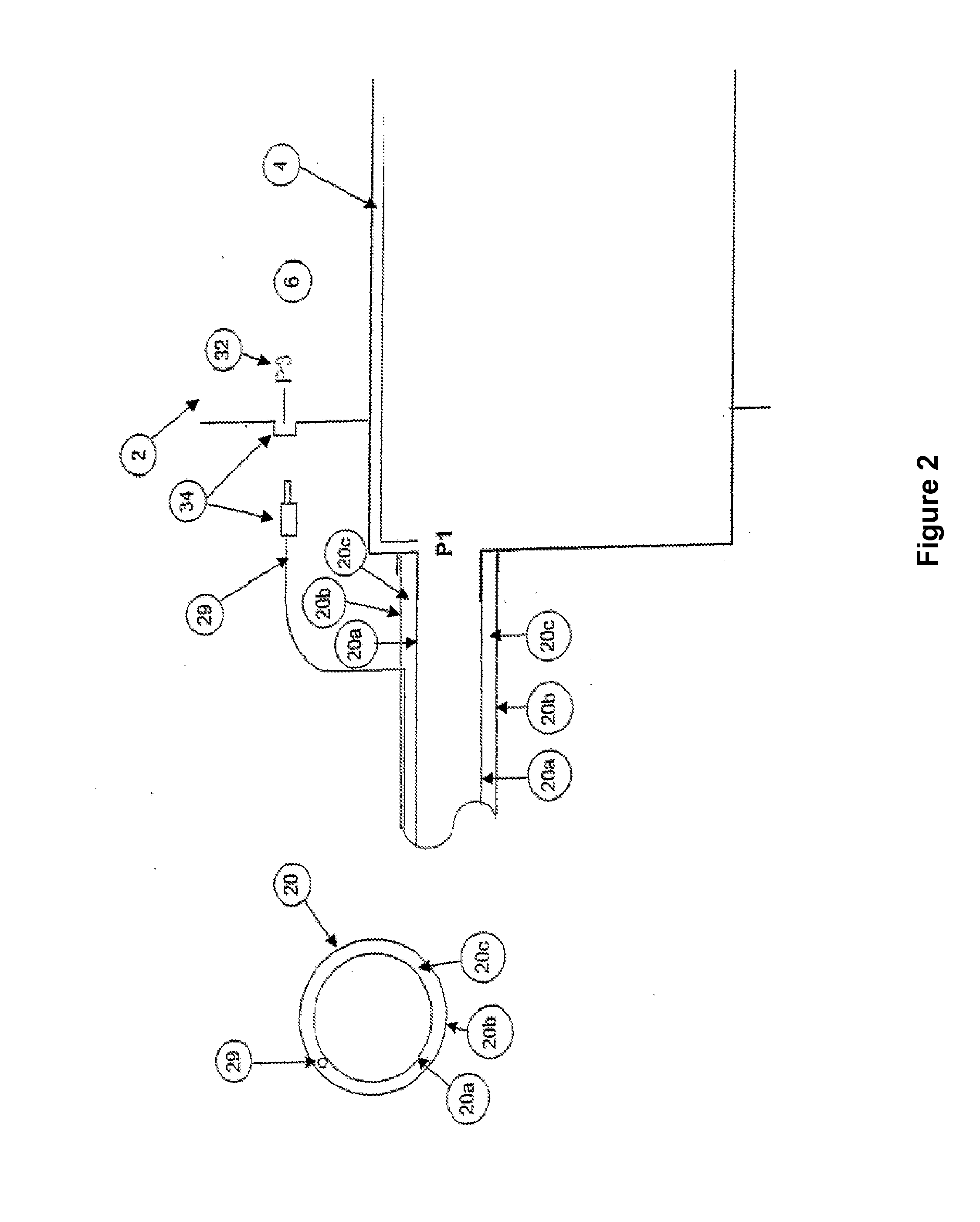

InactiveUS20080281281A1Constrict pressureEasy to useMedical devicesIntravenous devicesLine tubingWound dressing

The invention relates to a therapeutic device to promote the healing of a wound, comprising a porous paid which is permeable for fluids to place on the wound, a bandage to cover the wound and to provide an essentially airtight seal around the wound, a drainage line connecting the pad with a suction pump so that suction can be applied to the wound to draw the fluids away from it, whereby the line is connected to the suction pump via a canister to collect fluid sucked from the wound, a connector to connect the pad to the drainage line, means to determine a prevailing wound pressure basically comprising the wound and this surrounding skin area, as well as a control unit to control the wound pressure. In order to generally improve metrology with the goal of making possible a more reliable and more secure dressing of the wound, and also to design metrology in an especially simple and error-free way, it is proposed that the pad interconnect the suction pump solely via the drainage line.

Owner:VCS MEDICAL TECH

Traditional Chinese medicinal material saving equipment with good ventilation effect

InactiveCN109229792AMobile function is goodSolve the inconvenience of movingContainers preventing decayShock-sensitive articlesEngineeringChinese herbology

The invention discloses traditional Chinese medicinal equipment with a good ventilation effect, and belongs to the technical field of traditional Chinese medicine saving. According to the equipment, the interiors of the left and right side faces of a box body are provided with a micro fan and a ventilation port, wherein the micro fan is electrically connected with a control panel, an instruction is sent by the control panel to switch on the micro fan when temperature reduction ventilation is needed by medicinal materials to ventilate the medicinal materials, drying agent filling layers are arranged on both upper and lower ends of the box body, drying devices or other additives preventing mosquitoes and insects can fill the filling layers to ensure the dryness and completeness of the medicinal materials, the medicinal materials in the box body can be conveniently taken out, a limiting device is not arranged, and therefore the scattering of the medicinal materials caused by the sliding out of frame bodies of medicine drawers in the box body is ensured to be prevented when medicinal materials are taken out.

Owner:JILIN UNIV FIRST HOSPITAL

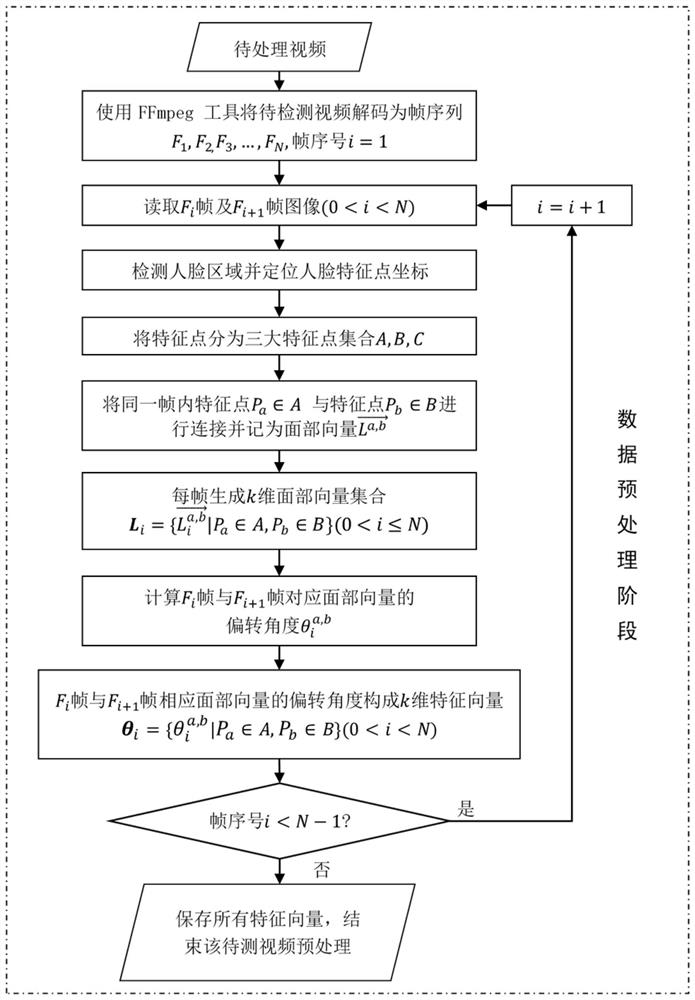

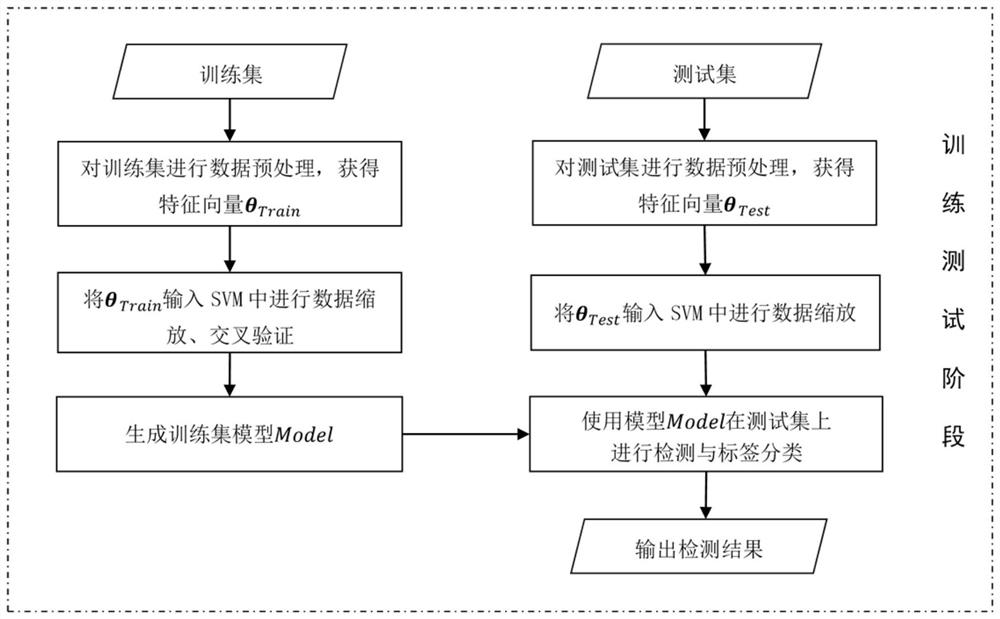

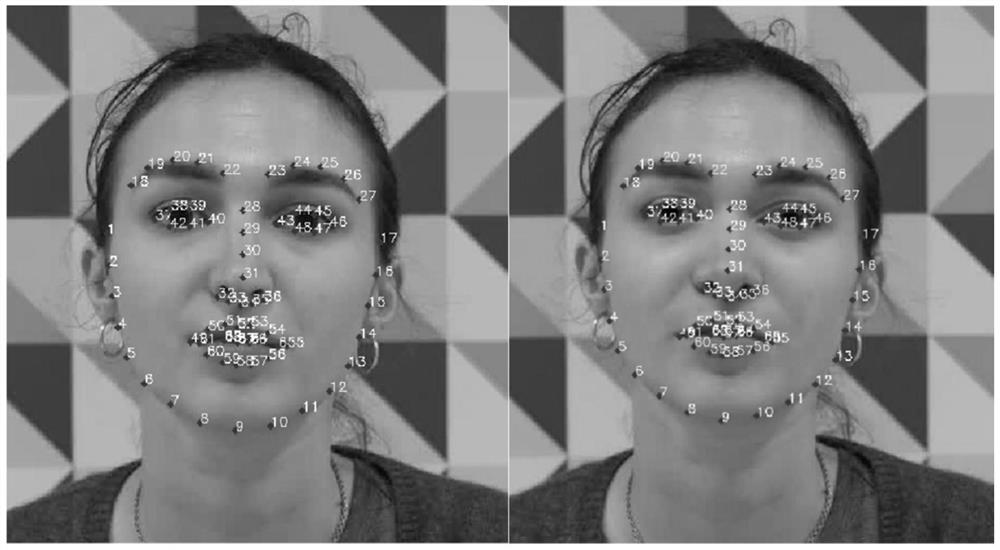

Face-changing video tampering detection method based on face feature time domain stability and application thereof

ActiveCN111914633AEasy to detectWell doneCharacter and pattern recognitionEnergy efficient computingTime domainFeature vector

The invention discloses a face-changing video tampering detection method based on face feature time domain stability and application thereof. The method comprises the steps of decoding a to-be-detected video into a frame sequence and storing the frame sequence frame by frame; detecting a face area of each frame and extracting coordinate values of face feature points; selecting a specific feature point according to the position and activity of the feature points, and calculating a connection vector of the specific paired feature points as a face vector; calculating a deflection angle of a corresponding face vector on an adjacent frame in a spatial position; taking the deflection angle values of all face vectors of two adjacent frames as feature values, and constructing feature vectors; inputting the feature vectors of the training sample into a support vector machine for training to generate a classification model; and classifying to-be-detected video frames by the trained classification model, and judging whether the video is tampered or not. According to the method, detection is carried out by utilizing inherent characteristics of human face biological signals, a relatively good detection effect is achieved, traces of tampered videos are captured by utilizing time domain characteristics of the face vectors, and the method has good universality.

Owner:SOUTH CHINA UNIV OF TECH +1

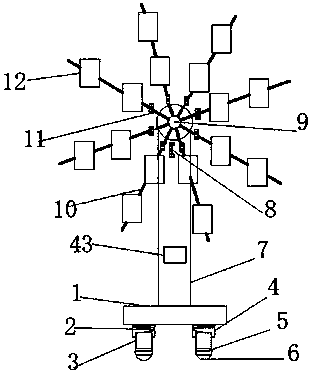

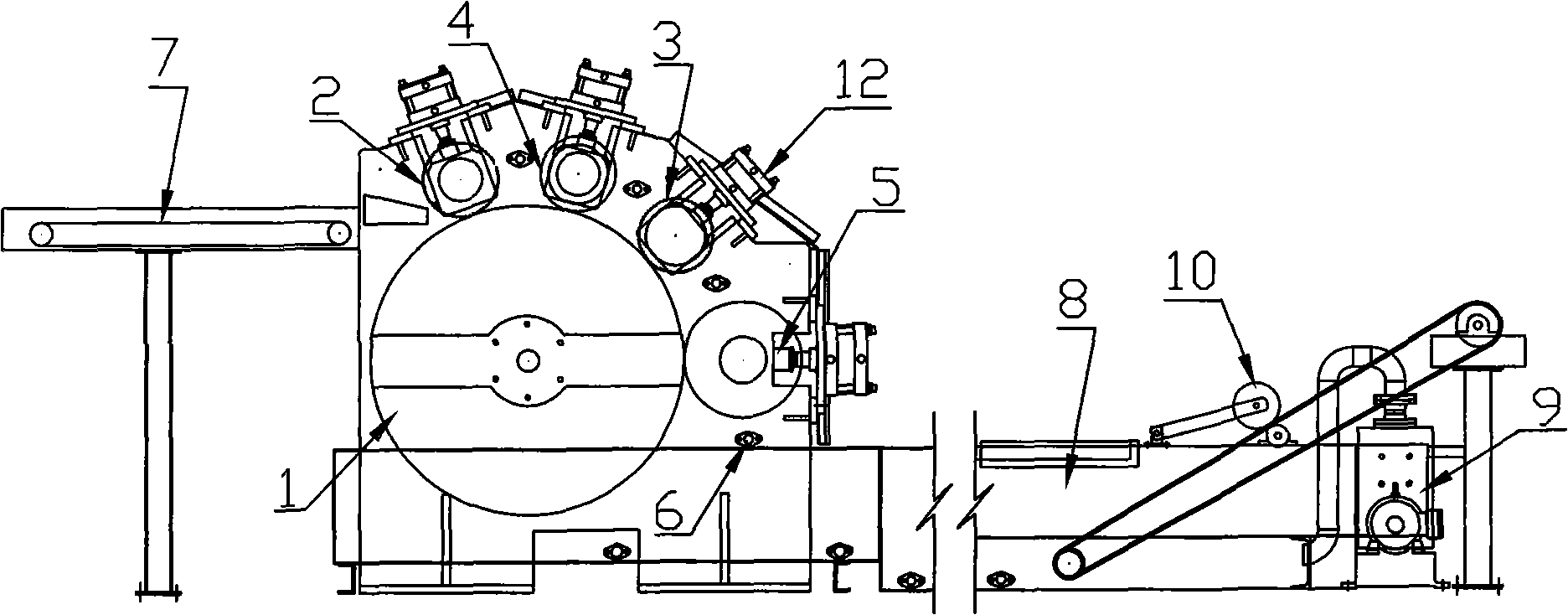

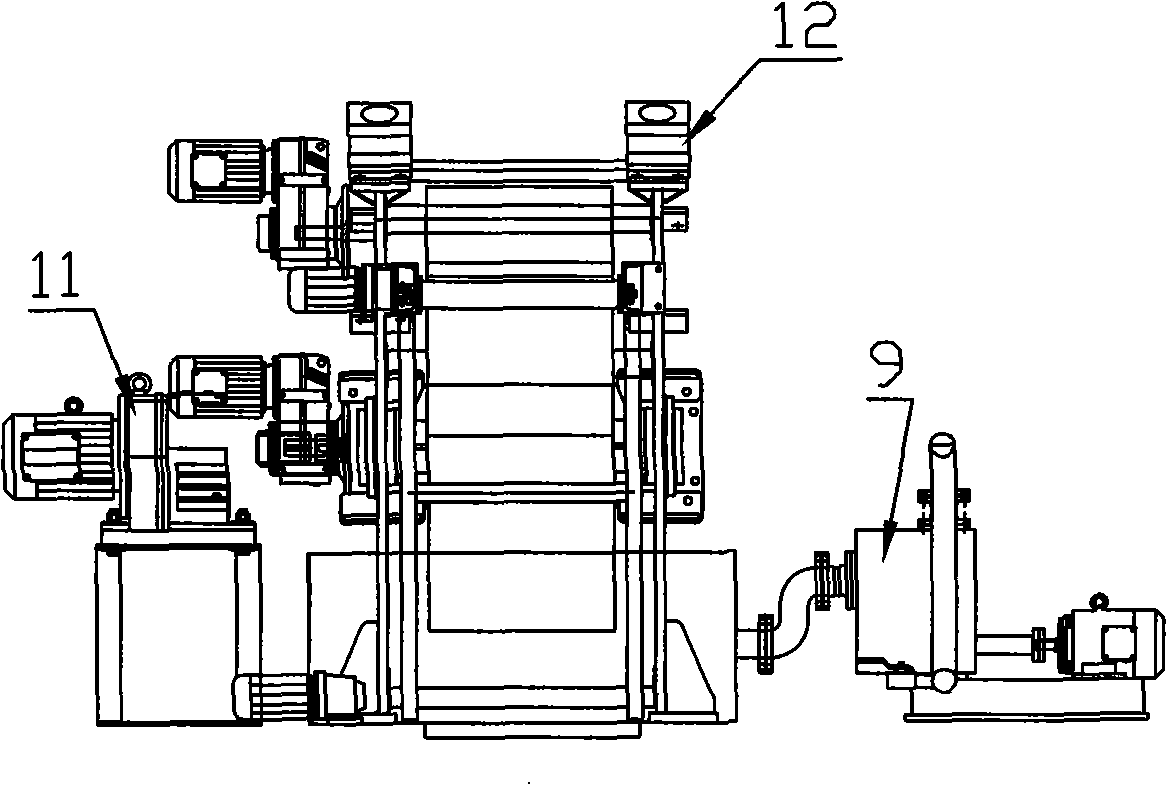

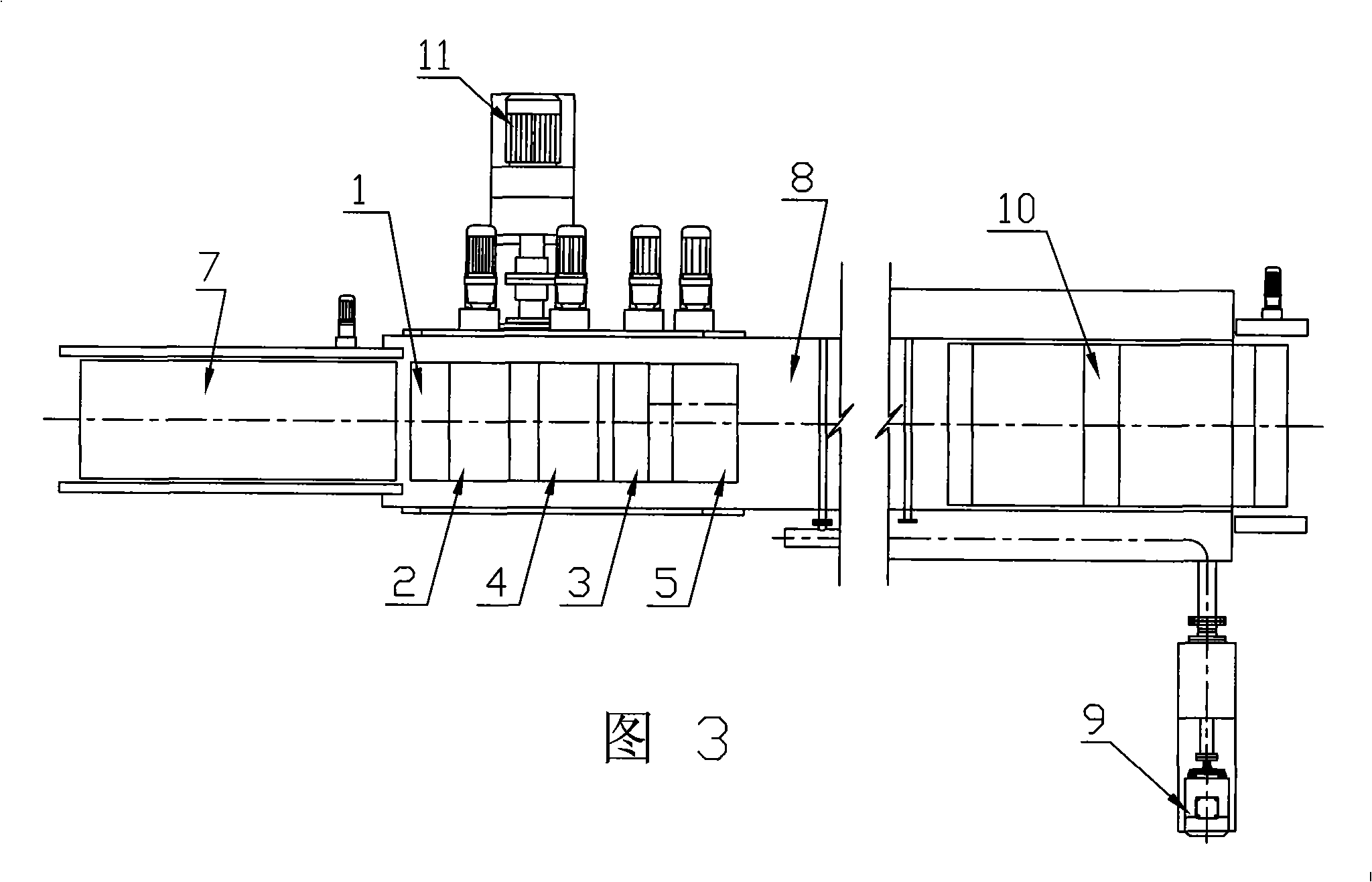

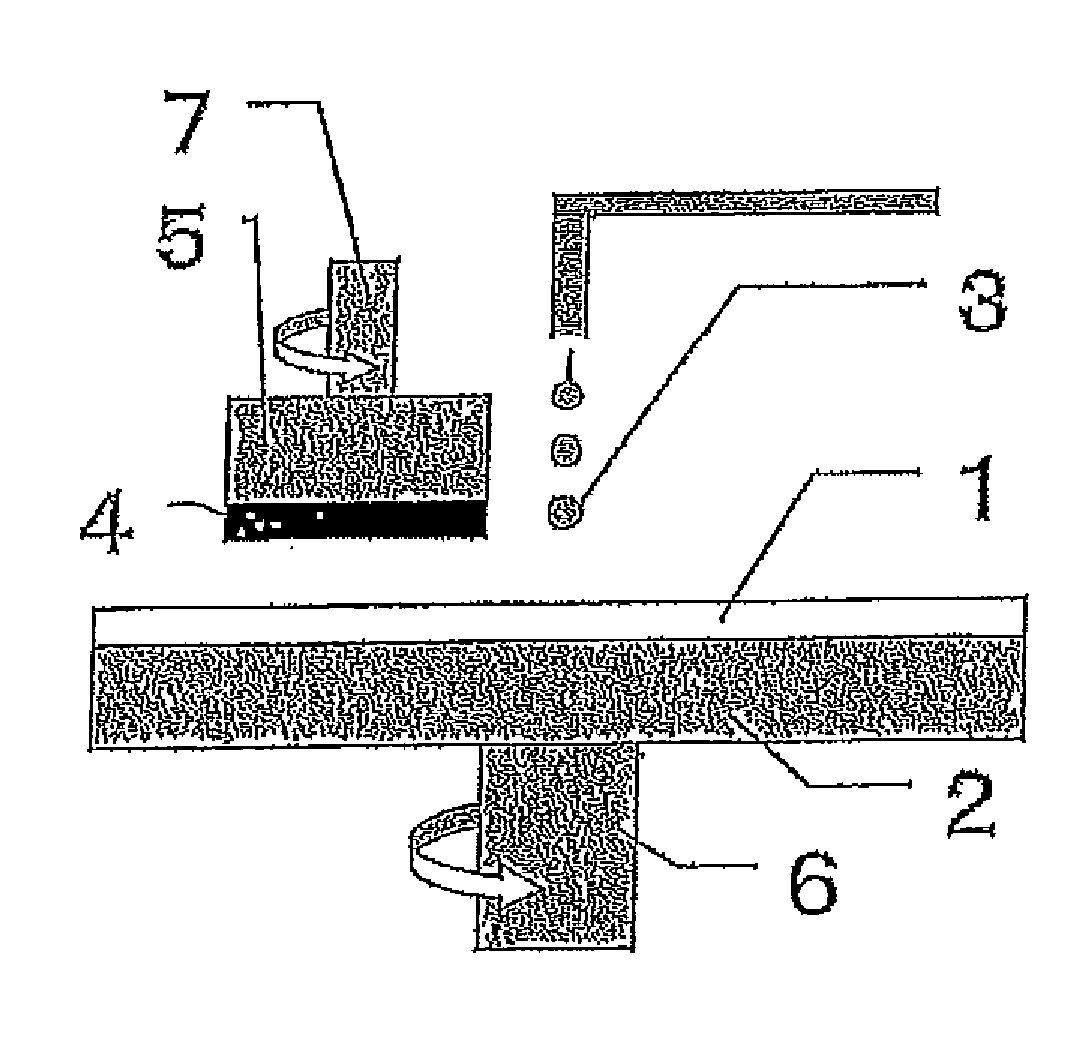

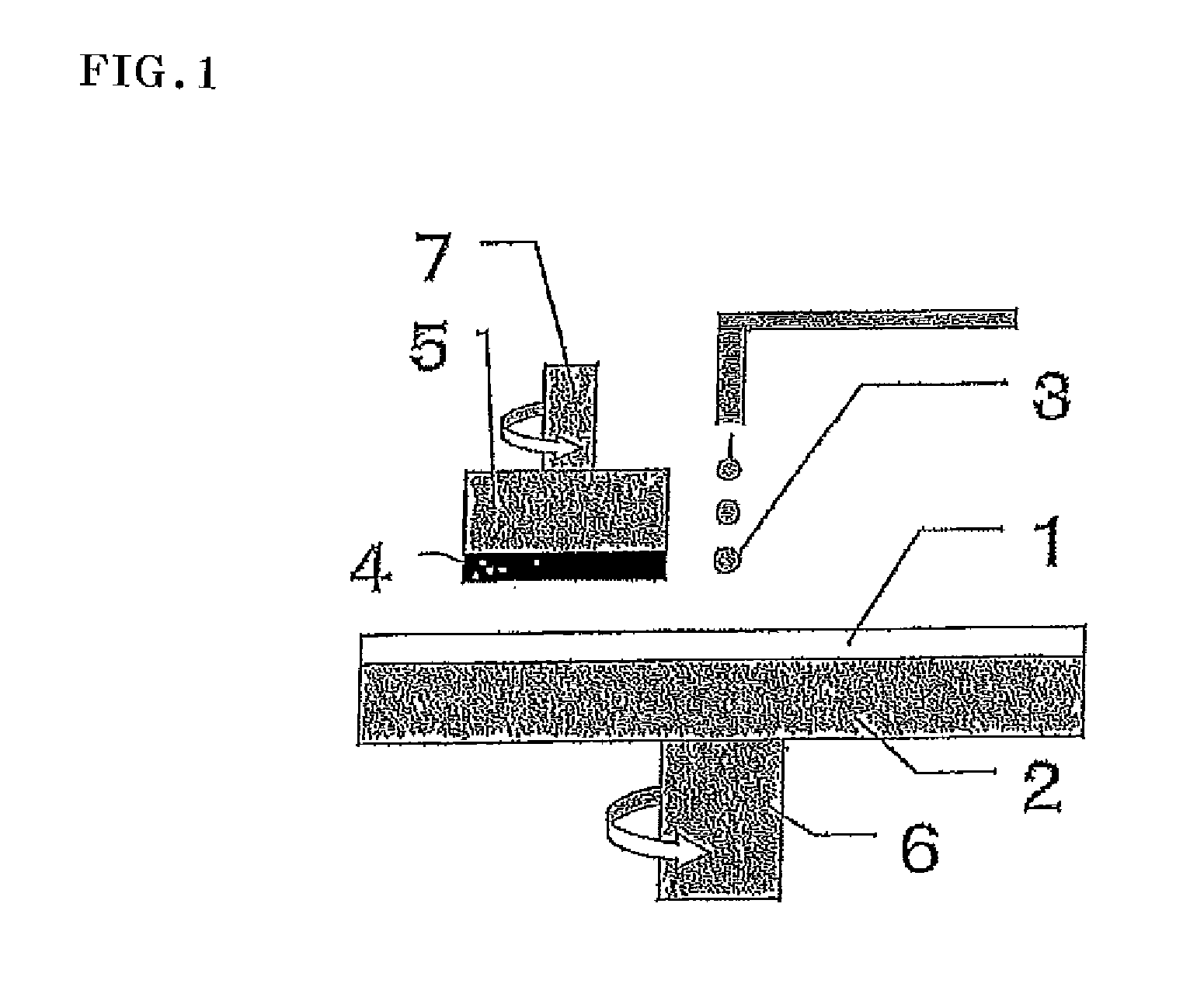

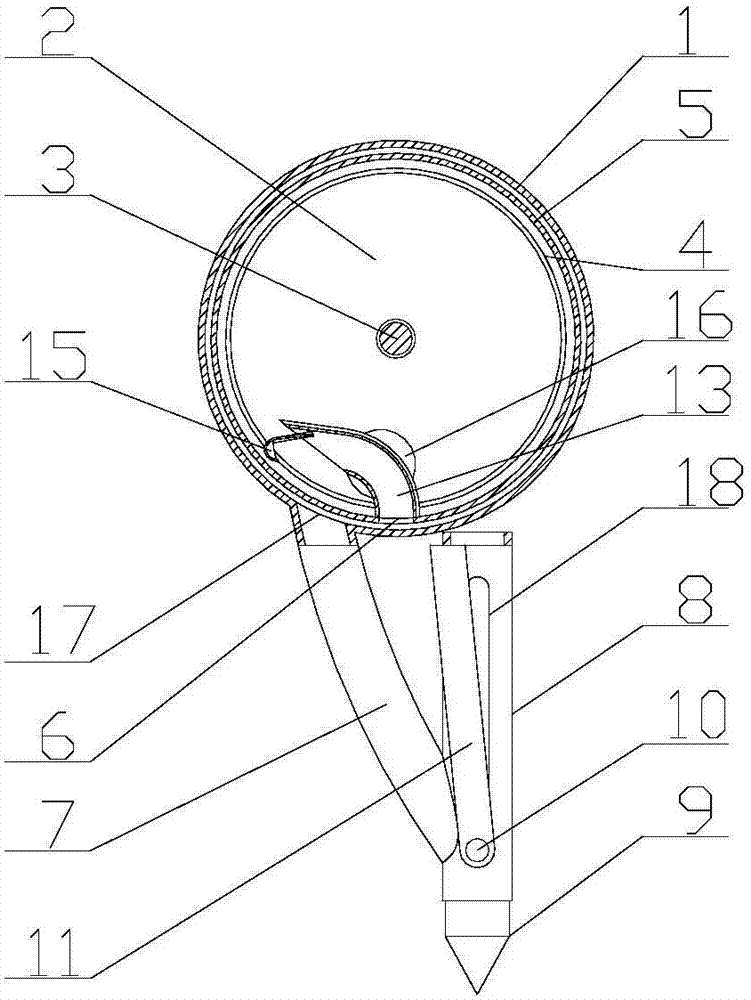

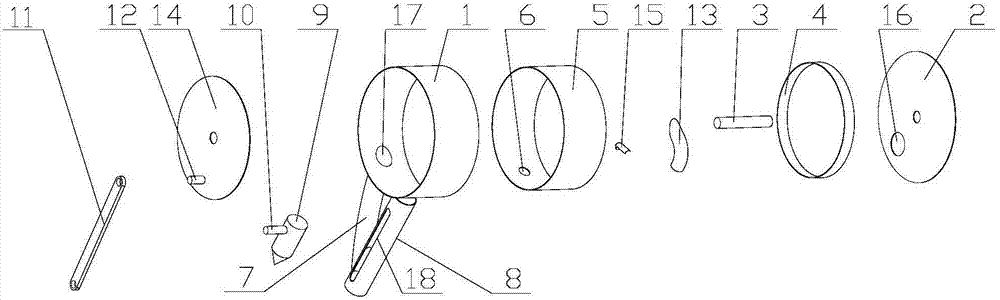

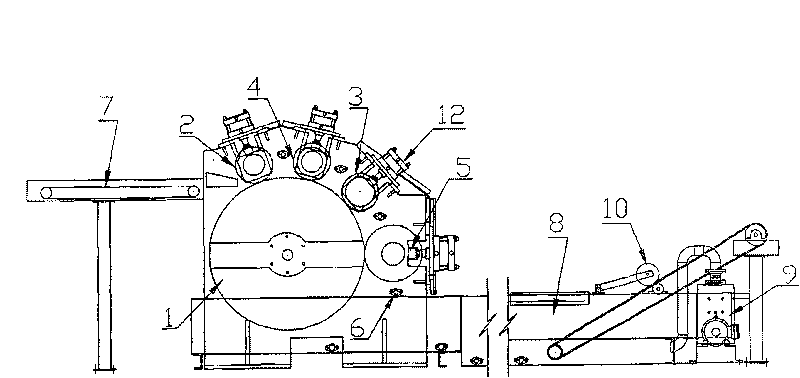

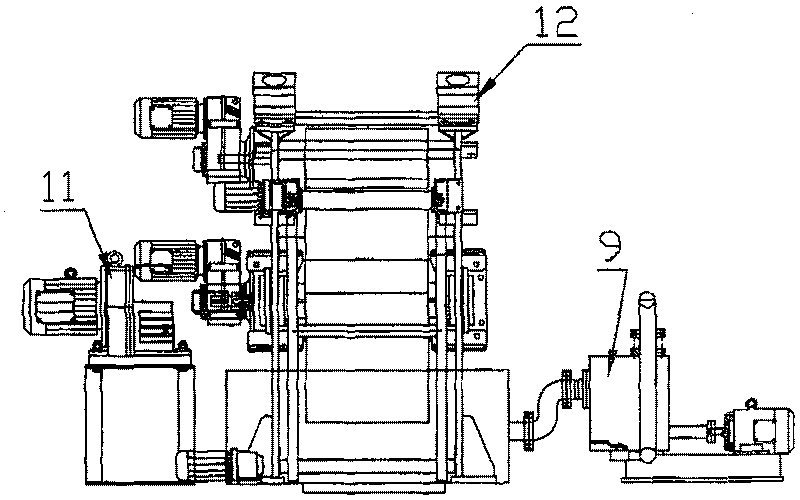

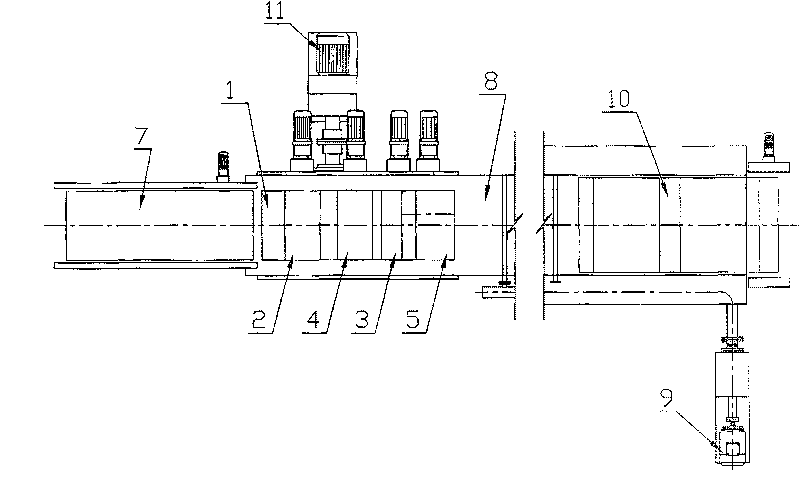

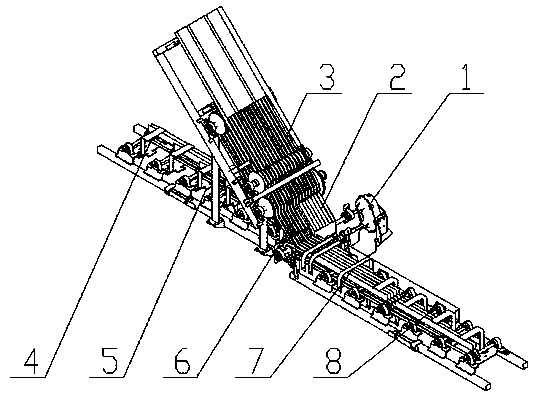

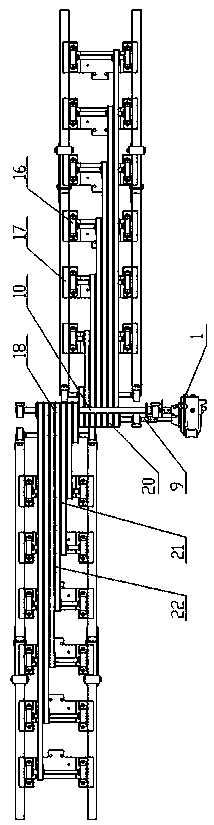

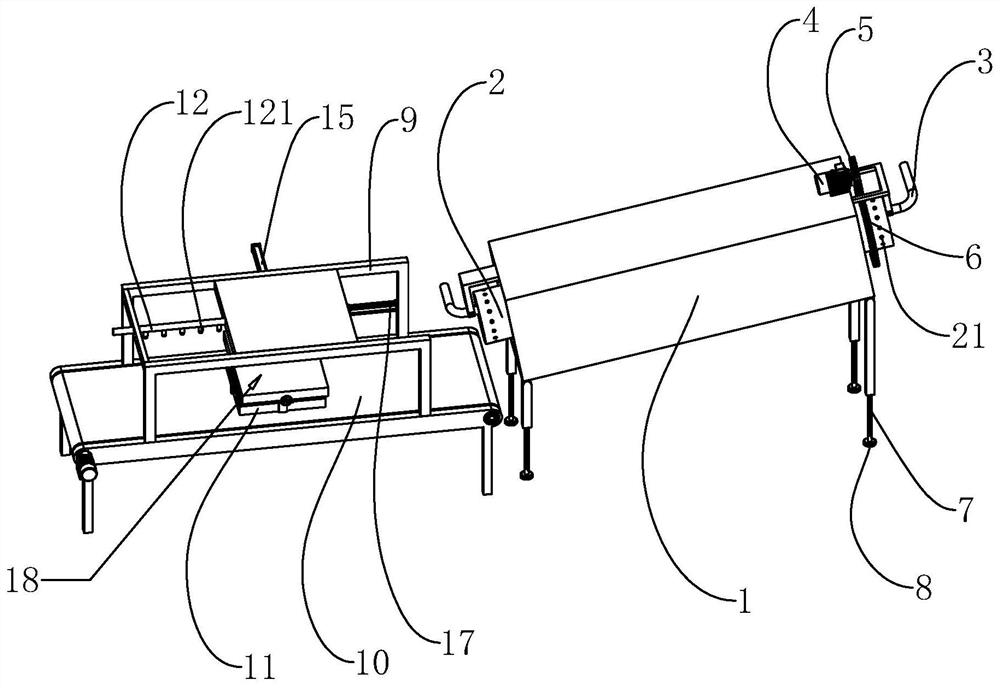

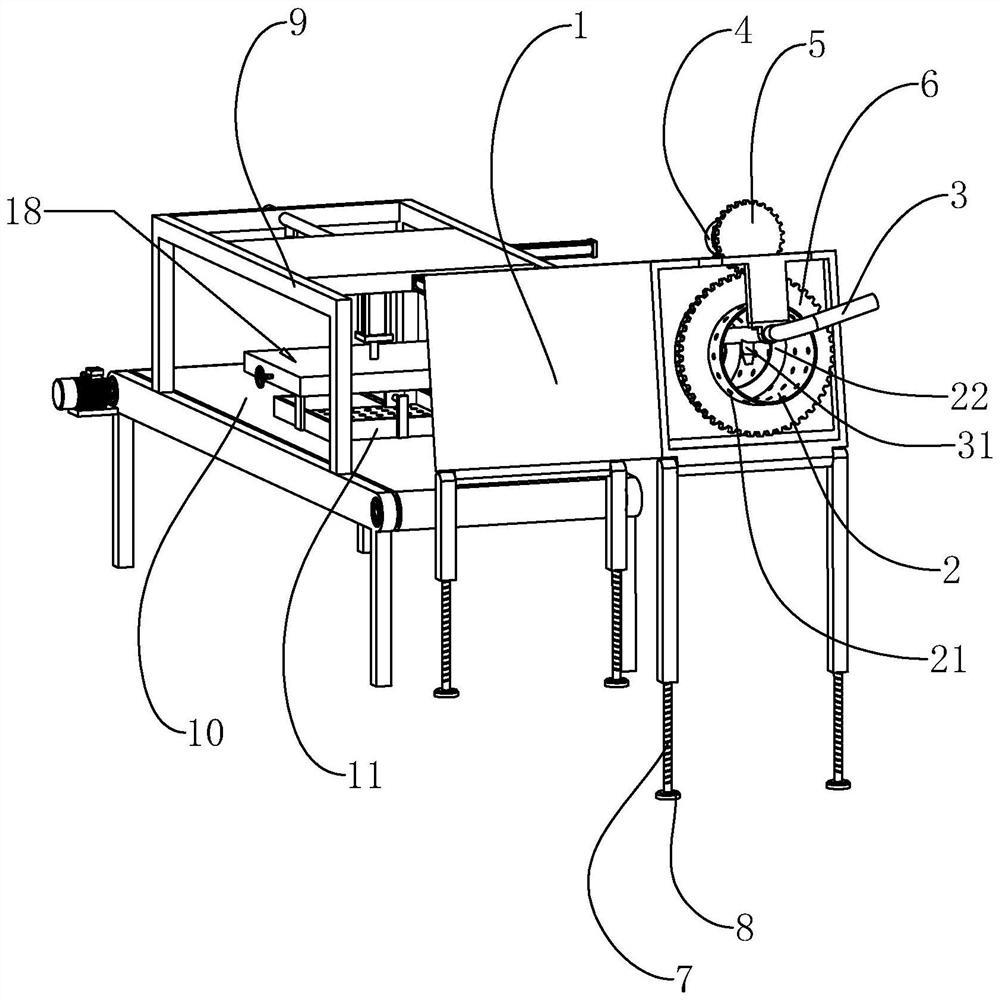

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499AHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extruding unit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

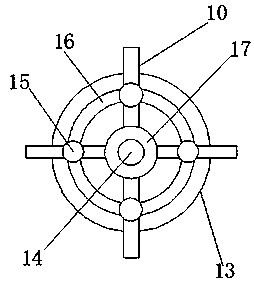

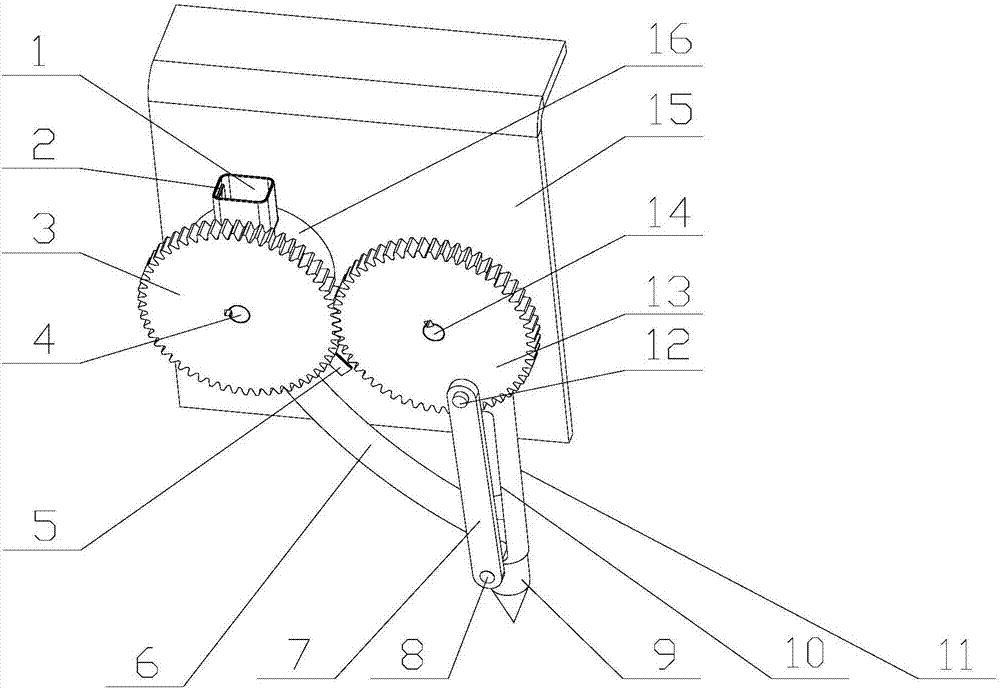

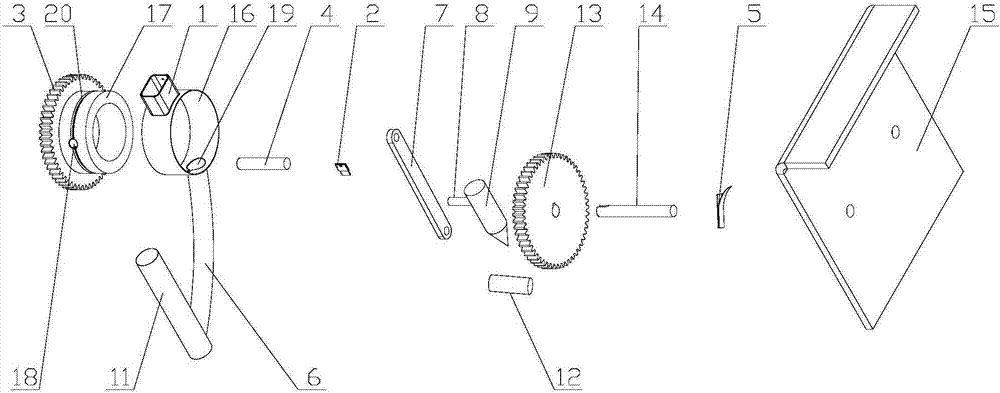

Gear-driven hole-pricking and seed-discharging mechanism of mold-hole type seed meter

InactiveCN106941817ANovel structureReasonable structurePlantingSeed depositing seeder partsGear driveDrive shaft

A gear-driven hole-pricking and seed-discharging mechanism of a mold-hole type seed meter belonging to the field of agricultural machinery. The mechanism is assembled from a fixing frame, a driven shaft, a driving shaft, a driven gear, a driving gear, a mold hole wheel, a cylindrical outer cylinder, a seed inlet cylinder, a seed transportation tube, a hole-pricking piston cylinder, a hole-pricking piston, a seed cleaning brush, a piston pin, a gear pin, a connecting rod and a seed cleaning blade. A mold hole and a seed cleaning blade annular groove are formed in a cylindrical outer surface of the mold hole wheel. A seed inlet and a seed discharge outlet are formed on the wall of the cylindrical outer cylinder. A vertical bar-shaped gap is formed in the wall of the hole-pricking piston cylinder. The driving gear is engaged with the driven gear with transmission ratio being 1. In the mechanism, coordination between the mold hole wheel and the hole-pricking piston is controlled and matched in a gear driving manner, so as to complete the hole-pricking and seeding operation. The mechanism has novel and reasonable structure, has good synchronicity in the hole-pricking and seed-discharging operations, is high in hole sowing quality and has good reliability and less malfunction.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Rare-earth multi-element alloy coating and hot-dip galvanizing method thereof

The invention discloses a rare-earth multi-element alloy coating and a hot-dip galvanizing method thereof. The rare-earth multi-element alloy coating comprises the following main components: rare earth, aluminum, nickel, magnesium and zinc. The hot-dip galvanizing method comprises the following steps: (1) mix-melting intermediate alloys, namely Al-RE-Mg and Zn-Ni; (2) mix-melting a multi-element rare-earth alloy; (3) dredging slag; (4) casting; and (5) applying. The rare-earth multi-element alloy coating and the hot-dip galvanizing method thereof have the advantages that: firstly, difficulty of directly adding multiple elements with different melting points into a zinc liquid to melt and the impossibility problem of adding high-melting-point elemental metal elements into the zinc liquid to melt are solved; secondly, the multiple elements can be completely and quickly molten and dispersed, so that the hot-dop galvanizing method is easy to operate and control in a practical production process; thirdly, the dilution capability, the dispersive capacity, the mobility and the uniformity of the zinc liquid are strengthened, so that the zinc consumption is reduced by 5%-15%, the cost is reduced and the benefits are increased; and fourthly, the corrosion resistance of the rare-earth multi-element alloy coating is doubled in comparison with that of a conventional hot dip galvanized coating.

Owner:江苏中远稀土新材料有限公司

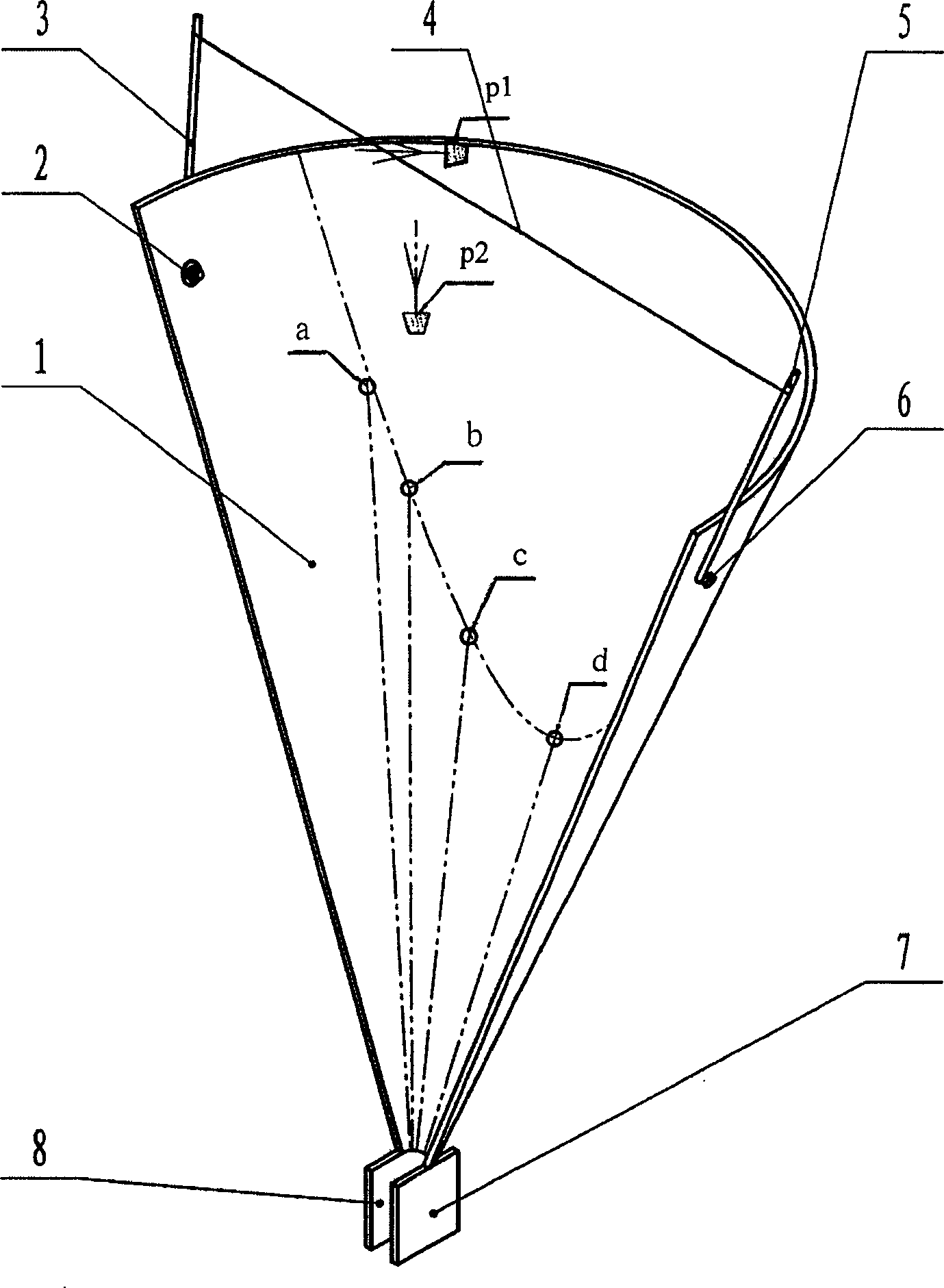

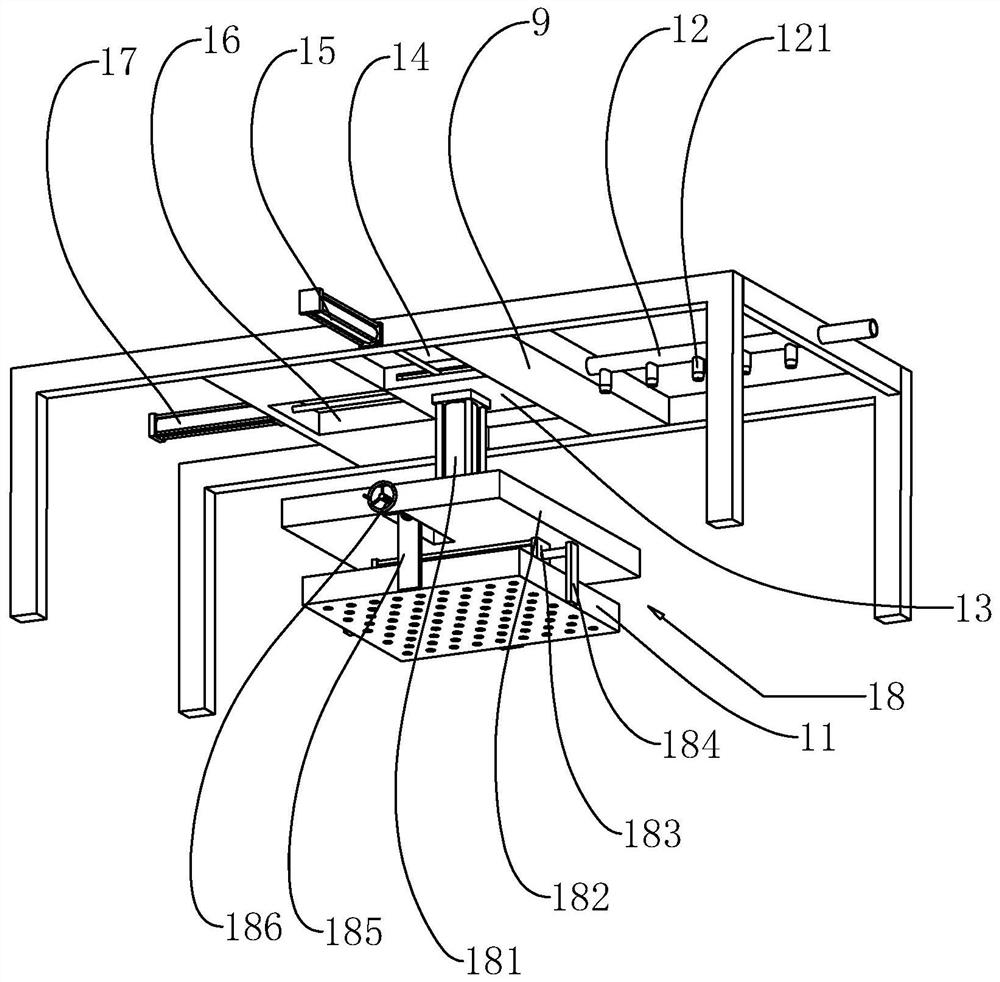

Ordered seedling-ejection guiding device

InactiveCN1742534AAccumulation-orientedAdjust the height positionTransplantingAgricultural engineeringGuide tube

The present invention discloses an orderly seedling-throwing and seedling-guiding device. It includes the following components: an inverted conical seedling-guiding tube, left and right rope bars and left and right rubber baffle plates. Said invention also provides their connection mode and concrete action of the above-mentioned every component. Said invention also provides its operation method.

Owner:ZHEJIANG SCI-TECH UNIV

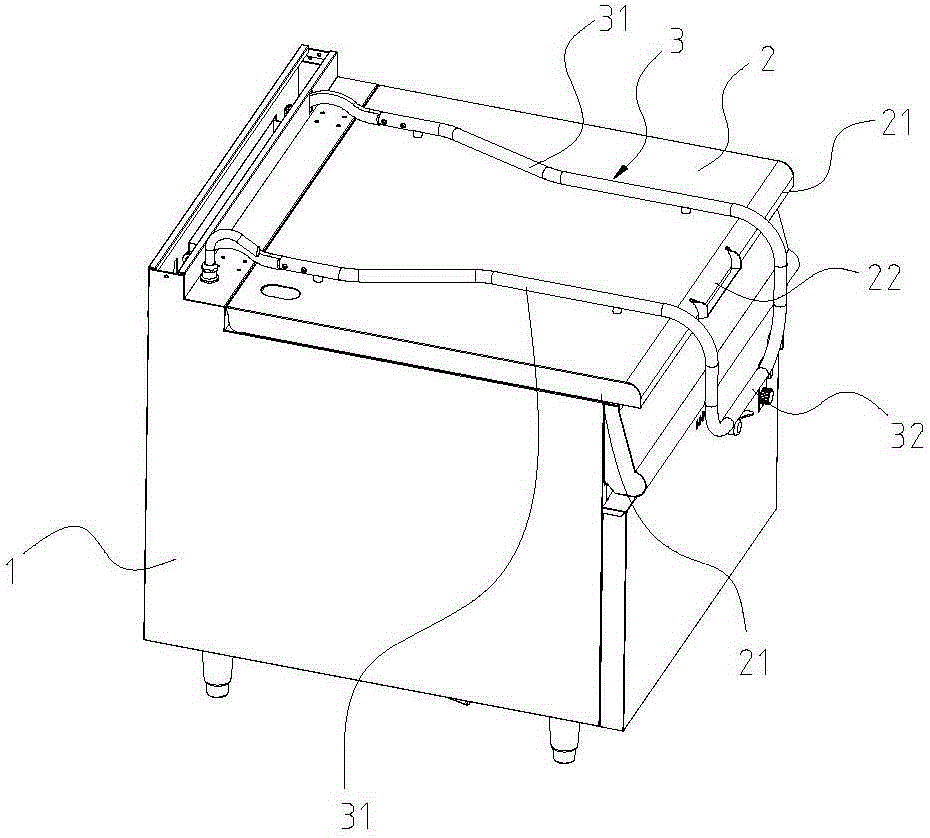

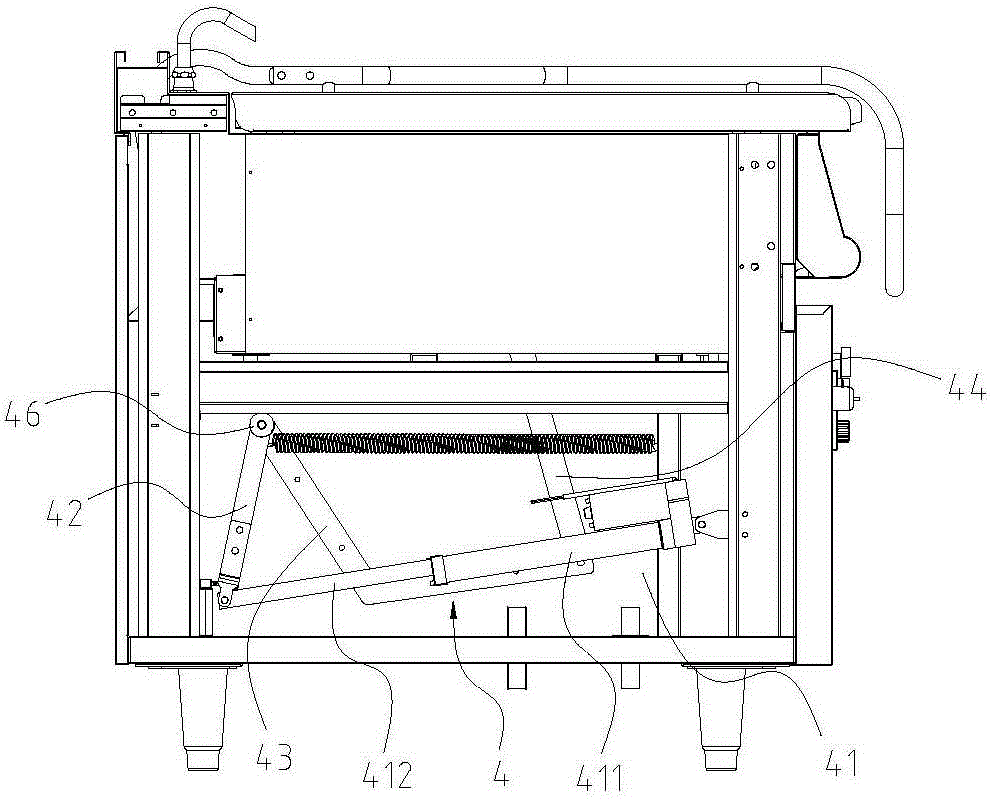

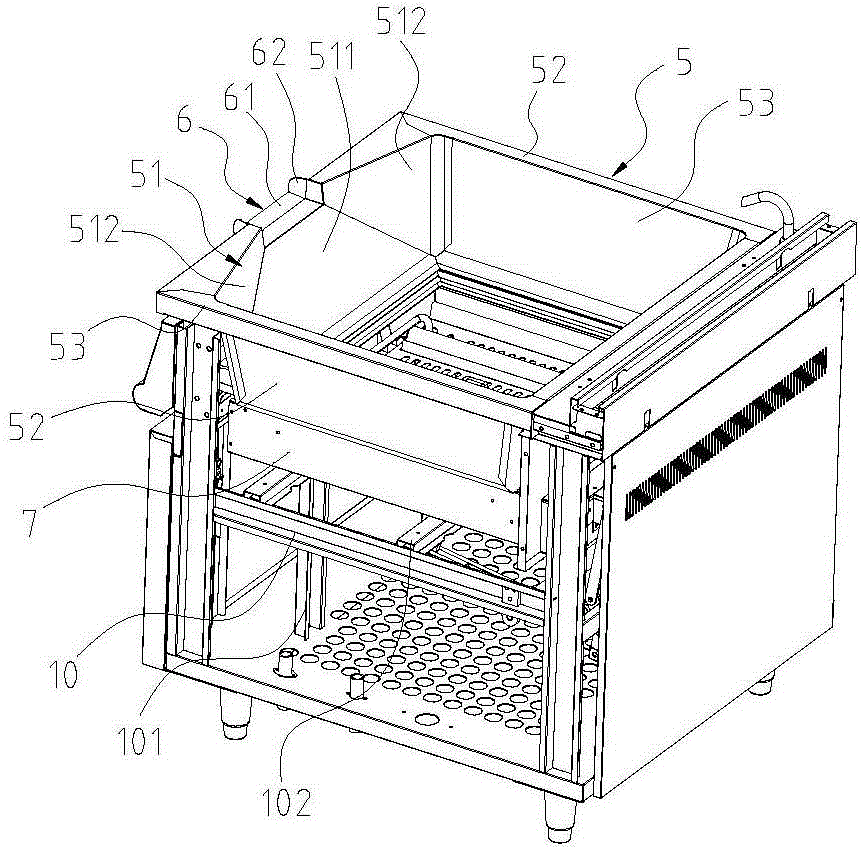

Vertical fuel gas inclinable frying pan

A vertical fuel gas inclinable frying pan comprises a pan body, a pan cover matched with the pan body, a rack used for supporting the pan body, a lifting mechanism used for lifting the pan body, and a heating assembly. The lifting mechanism is arranged below the pan body and comprises a cylinder, a rotating shaft, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod. A cylinder base of the cylinder is hinged to a supporting frame, a telescopic rod of the cylinder is hinged to one end of the first connecting rod, and the other end of the first connecting rod is fixedly connected with one end of the rotating shaft; the second connecting rod is in the shape of V, one end of the second connecting rod is fixed to the middle of the rotating shaft, the other end of the second connecting rod is hinged to one end of the third connecting rod, the other end of the third connecting rod stretches out of a travel hole in a tray bottom panel and is hinged to one end of the fourth connecting rod, and the other end of the fourth connecting rod is fixedly connected with a bottom plate. The frying pan can be electrically lifted, and manpower and time are saved.

Owner:广州煌子西厨设备制造有限公司

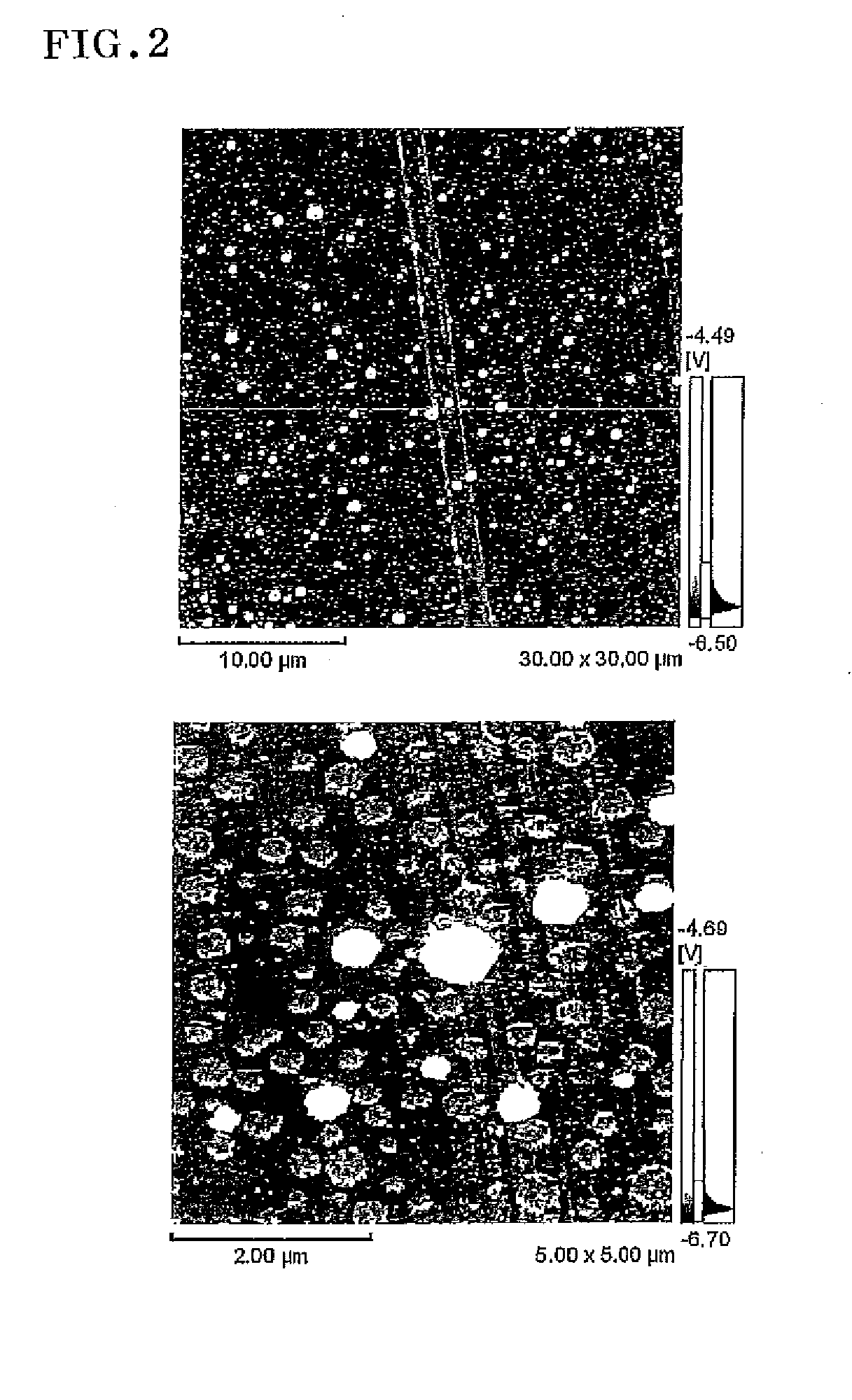

Polishing pad

InactiveUS20150360342A1Reducing life of padReduced wear resistance requirementsOther chemical processesSemiconductor/solid-state device manufacturingPolyesterPolymer science

A polishing pad includes a polishing layer, and the polishing layer is formed of a reaction cured body of a polyurethane-forming raw material composition that contains: an isocyanate-terminated prepolymer (A) which is obtained by reacting a prepolymer-forming raw material composition (a) that contains an isocyanate component and a polyester polyol; an isocyanate-terminated prepolymer (B) which is obtained by reacting a prepolymer-forming raw material composition (b) that contains an isocyanate component and a polyether polyol; and a chain extender. The polyether polyol contains a polyether polyol (C) that has a number average molecular weight of 1000 or less and a polyether polyol (D) that has a number average molecular weight of 1900 or more. The reaction cured body has a triple phase separation structure.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

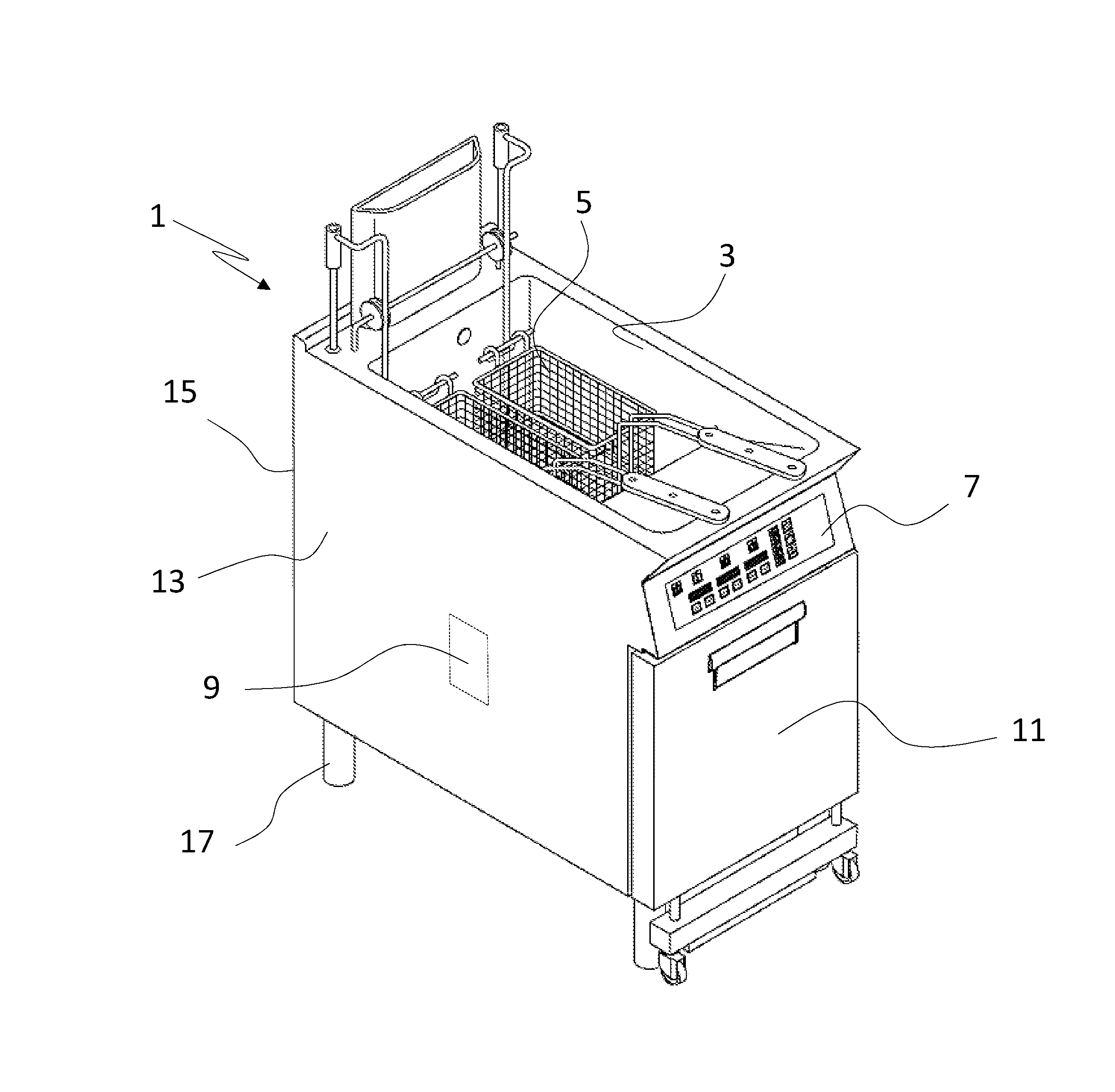

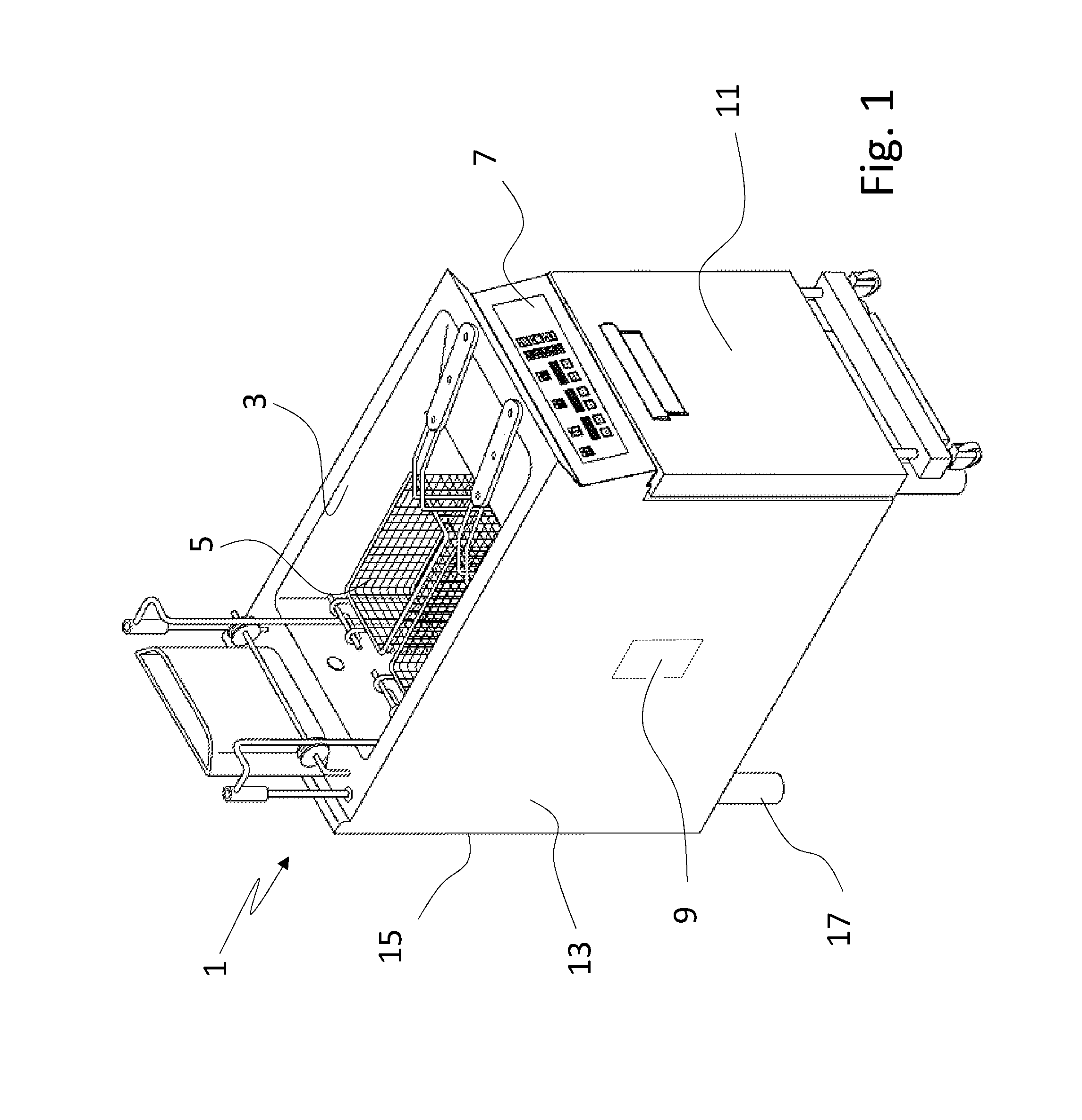

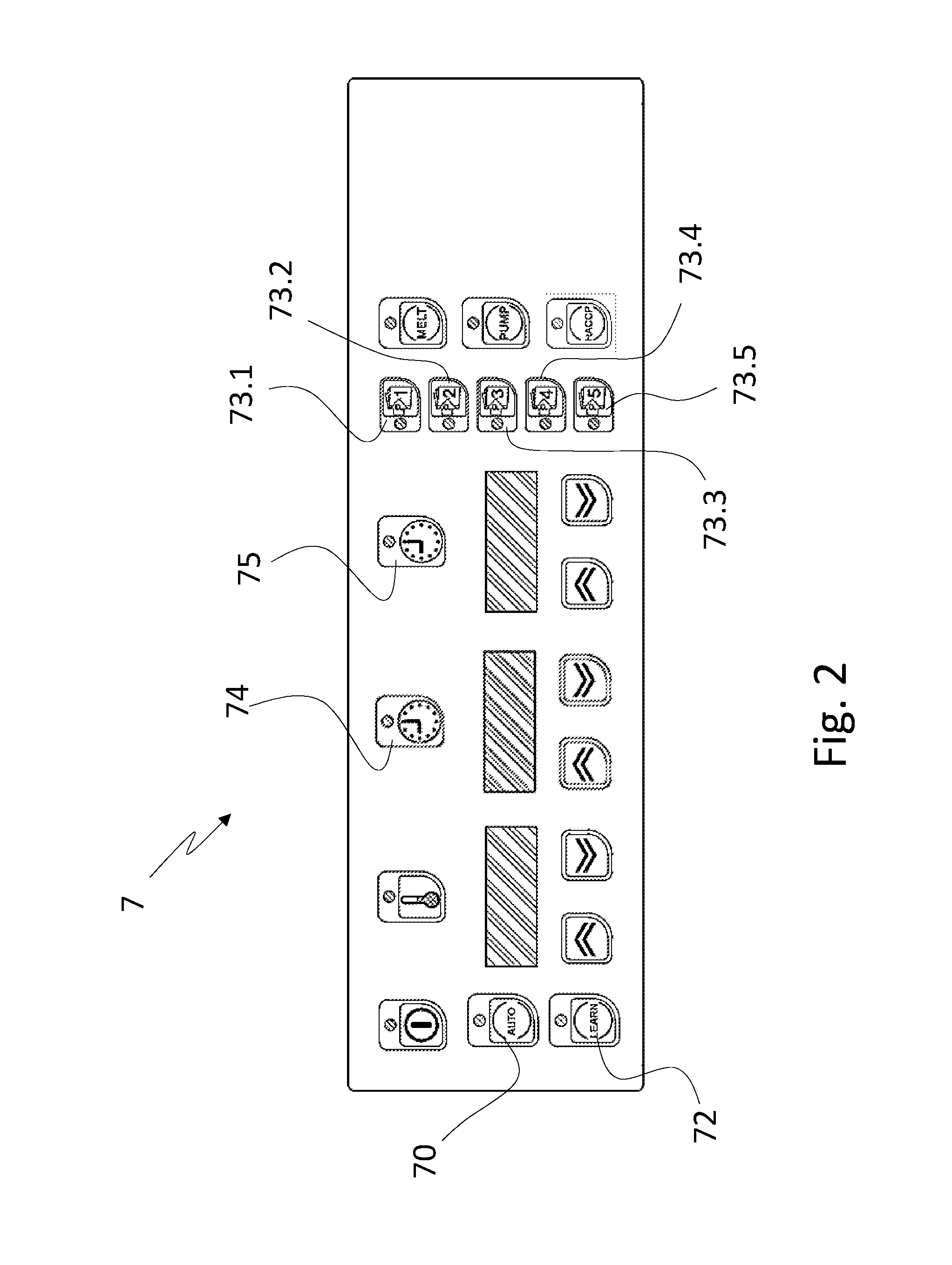

Method and computer program for controlling a fryer, and fryer arranged for carrying out such method

InactiveUS20170027385A1Easy to useWell doneInput/output for user-computer interactionElectric heatingLogic cellProcess engineering

The present invention is related to a method for controlling a fryer (1) comprising a vat (3), a logic unit (9) and a manual validation interface (70, 72), the method comprising the following steps: S.1) carrying out a learning frying run, in its turn 1 0 comprising the following steps: S.1.1) placing a first batch of food to be fried in a cooking medium contained in the vat (3), the food to be fried being of a predetermined kind; S.1.2) when the food to be fried reaches a desired frying condition, communicating to the logic unit (9) through the manual validation interface (70, 72) that the food has reached said desired frying condition; S.2) carrying out a successive frying run comprising the following steps: S.2.1) placing a second batch of food to be fried in the cooking medium contained in the vat (3), the food of the second batch being substantially of the same kind as of the food of the first batch; S.2.2) frying the second batch of food for a frying time determined by the logic unit (9) depending on the desired frying condition signalled through the manual validation interface (70, 72) during the learning frying run. The invention is also related to a fryer (1) programmed or however arranged for carrying out the method and comprising a vat (3), a logic unit (9) and a manual validation interface (70, 72), and to a computer program arranged for enabling the fryer (1) to carry out the method

Owner:ELECTROLUX PROFESSIONAL

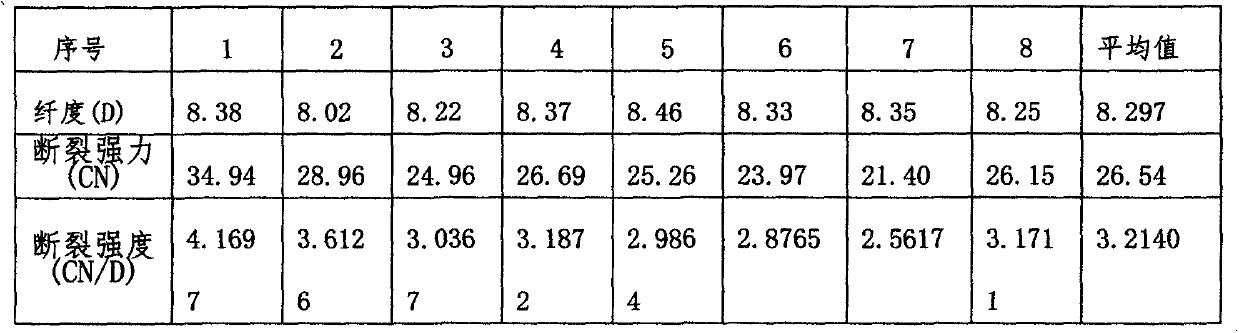

Friction and weighting agent and its preparation and application in improving kapok fiber spinning performance

InactiveCN102277731AImprove spin performanceEase of industrial productionVegetal fibresCardingKapok fiber

The invention relates to a friction-increasing and weighting agent and its preparation method and use in improvement of kapok fiber spinning performances. The friction-increasing and weighting agent is a mixed solution of raw materials comprising an acrylate derivative, sodium alginate, an emulsifier, a softener, an organic metal salt, an anionic surfactant and a nonionic surfactant. The preparation method comprises that the friction-increasing and weighting agent is prepared from the raw materials through emulsification and stirring. The use of the friction-increasing and weighting agent in improvement of kapok fiber spinning performances comprises the following steps of treating kapok fibers by the friction-increasing and weighting agent at a temperature of 20 to 30 DEG C and balancing the treated kapok fibers under the constant-temperature and constant-humidity conditions for 12 to 48 hours to obtain kapok fibers with improved performances. The preparation method of the friction-increasing and weighting agent has the advantages of simple operation, low cost, environmentally friendly characteristics and good applicability for industrialized production in textile industries. Through the use of the friction-increasing and weighting agent, kapok fibers have good performances of cotton carding, ribbon forming and spinning and thus a spinning bottleneck of kapok fibers in a spinning field is opened.

Owner:DONGHUA UNIV

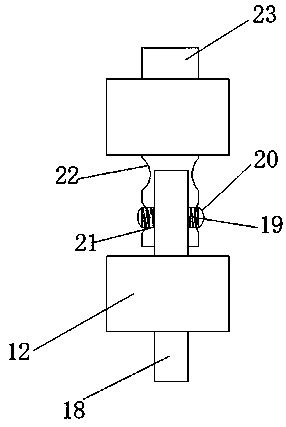

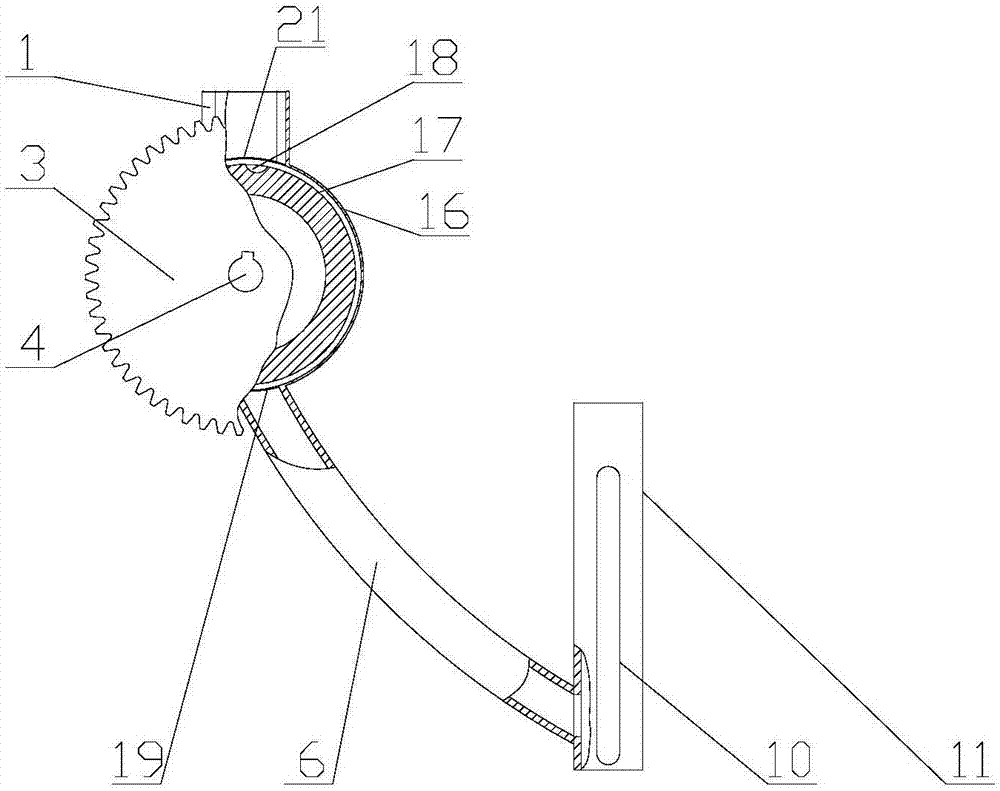

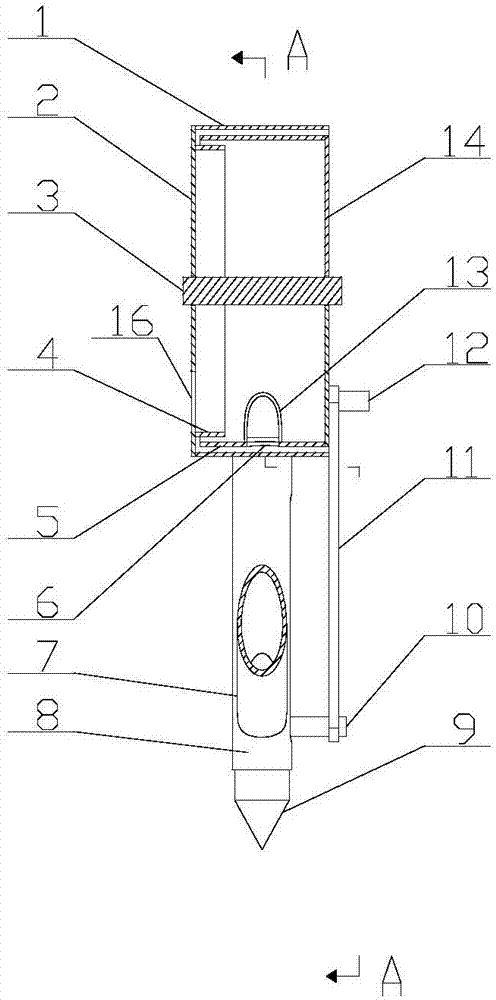

Seed sowing device combining scoop-type seed extraction and piston hole pricking

InactiveCN106900223ANovel structureSimple structureDibble seedersSeed depositing seeder partsDrive shaftAgricultural engineering

The invention discloses a seed sowing device combining scoop-type seed extraction and piston hole pricking, and belongs to agricultural machinery. The seed sowing device comprises a cylindrical inner cylinder, a cylindrical outer cylinder, a left end cover, a right end cover, a driving shaft, a seed taking scoop, a seed containing pipe, a seed delivery pipe, a hole pricking piston cylinder, a hole pricking piston, a connecting rod, a connecting rod pin and a piston pin, a seed inlet is formed in a left cover plate, a seed sowing port is formed in the cylindrical outer cylinder, a seed outlet is formed in the cylindrical inner cylinder, and a vertical strip-shaped notch is formed in the hole pricking piston cylinder. According to the seed sowing device, seeds are taken by the aid of a scoop, holes are pricked by the aid of a piston, continuous operations of seed taking, hole pricking and seed sowing are achieved, the seed sowing device is novel, reasonable and simple in structure and good in hole pricking quality and hole pricking and seed sowing synchronism, high in hole sowing quality, reliable to use and less in fault.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

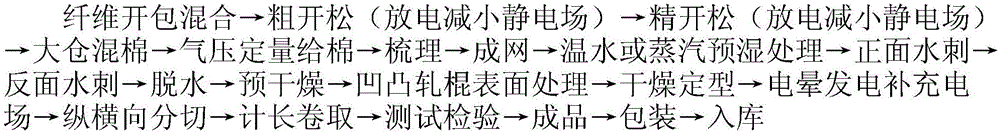

Manufacturing method of odorless electrostatic adsorption multifunctional spunlaced industrial wiping rag

InactiveCN106757769AImprove adsorption capacityReduce electrostatic fieldPattern makingHeating/cooling textile fabricsMachine partsWarm water

The invention discloses a manufacturing method of an odorless electrostatic multifunctional spunlaced industrial wiping rag, and belongs to the technical field of preparation of novel industrial materials. An odorless electrostatic polypropylene short fiber is taken as a raw material, the length of the odorless electrostatic polypropylene short fiber is 38 mm to 45 mm, the fiber fineness of the odorless electrostatic polypropylene short fiber is 1.67 dtex to 2.78 dtex, the spunlaced production process is adopted, a special process condition is used in the process of pre-wetted treatment, warm water or steam at the temperature of 45 DEG C to 55 DEG C is used to conduct pre-wetted treatment on a fiber web; the surface of a spunlaced cloth is treated through a 5-mesh concave-convex pattern roller, a method of increasing the clearance of a rotary drum roller is used in the drying process, and the multifunctional industrial wiping rag having an electrostatic function, having a concave-convex surface, and being strong in adsorption capacity and oil absorbency is manufactured. The manufactured wiping rag has the function of the spunlaced wiping rag in the automobile industry, also has the electrostatic function, is quite effective when used to adsorb dust and machining chips on a machining part, and has a wide market development space.

Owner:JILIN PROVINCE HUAFANG ELECTROSTATIC MATERIAL TECH CO LTD

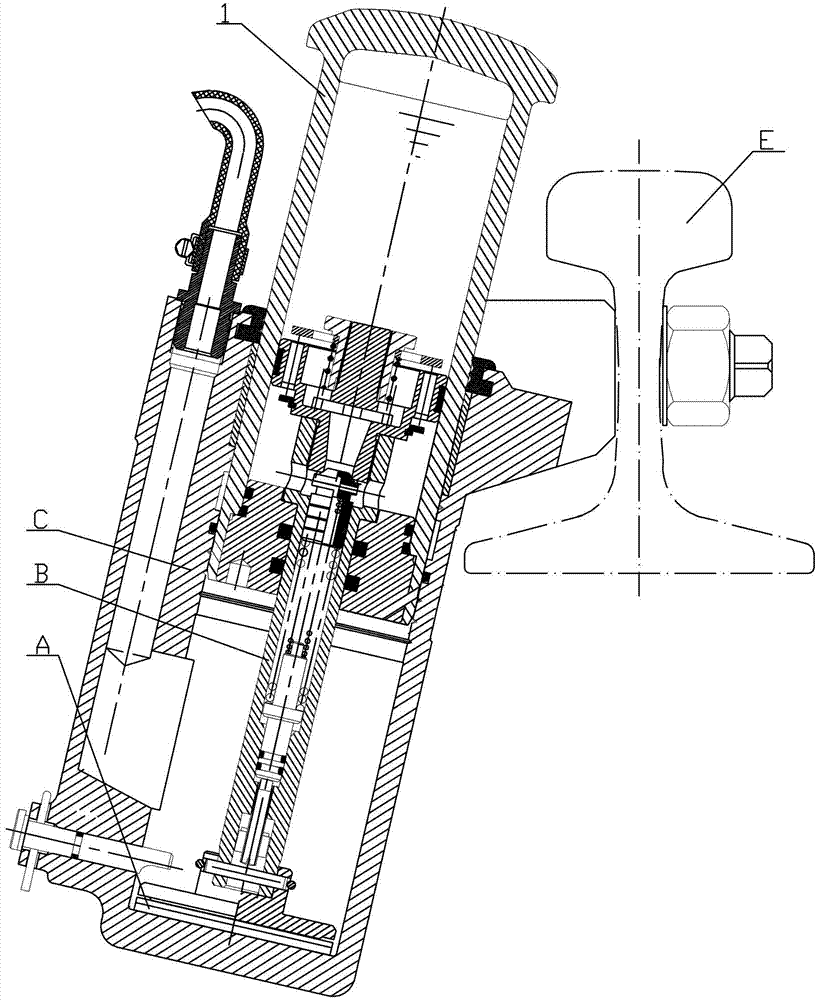

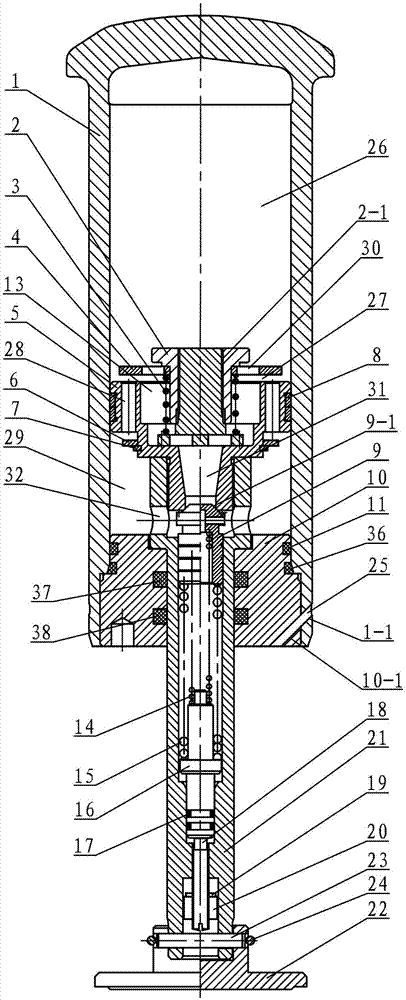

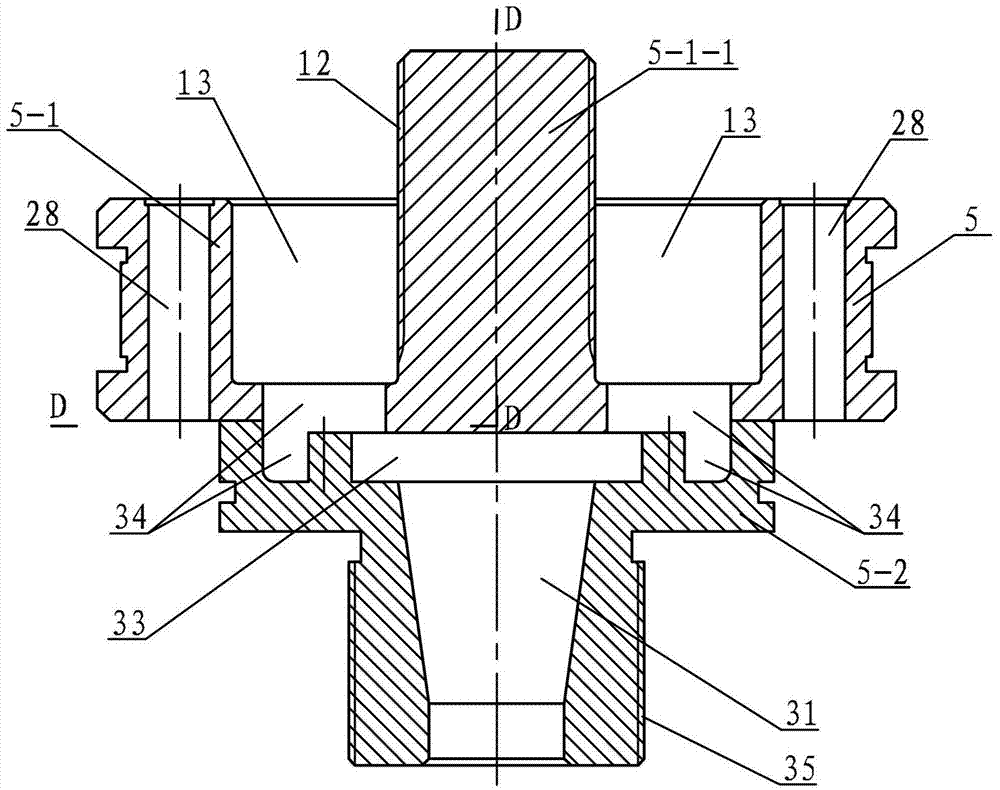

High-load retarder with welding type piston

InactiveCN103192847ASmall overcurrent damping forceRealize speed judgmentTrack brakesHigh loadMechanical engineering

A high-load retarder with a welding type piston relates to a retarder and aims at solving the problem that the existing high-load retarder is large in speed judgment overflow area and cannot conduct speed judgment gear selection. A second overflow channel is arranged on an upper piston, a plurality of first overflow channels parallel to the second overflow channel are arranged on the lateral wall of the upper piston along a circle, a groove is arranged on the upper end face of a lower piston, a Y-shaped channel is arranged at the center position of the lower piston, and the lower end face of the upper piston and the upper end face of the lower piston are mutually welded. A vertical overflow hole is arranged on the connection face of the upper piston and the lower piston, a sealing cover is connected with the lower end of a sliding oil cylinder in sealing mode, a valve plate overflow hole is arranged on a speed valve plate, a speed valve spring is arranged in the second overflow channel, a transverse oil through hole is arranged on a piston rod at the lower end of each piston, the overflow area of the upper end of the Y-shaped channel is smaller than the overflow area of the vertical overflow hole, and the overflow area of the vertical overflow hole is smaller than the overflow area of the second overflow channel. The high-load retarder is used for railway deceleration.

Owner:哈尔滨铁路减速顶调速研究有限公司

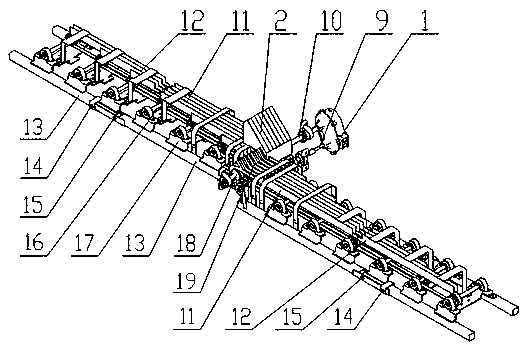

Multi-wheel scutching integrated machine of degumming and rinshing

InactiveCN101270499BHigh degree of automationSimple and fast operationMechanical fibre separationEngineeringHigh pressure water

The invention relates to a multi-gear train integral machine of scotching, degumming and washing which includes a ramie feed unit, a bone-cutting skin-scraping unit and a bone-cracking ramie-extrudingunit; wherein, the bone-cutting skin-scraping unit mainly consists of a big round roll (1) and two rollers (2) and (3); the bone-cracking ramie-extruding unit mainly consists of a first small round roll (4) and a second small round roll(5). The big round roll is fixed on a frame through a bearing seat; the two rollers and the small round rolls are respectively mounted on the dump rails of each own through a sealing seat, arranged around the big round roll (1), respectively provided with a high pressure water scraper (6) which sprays water curtain along the tangent direction and opposite to the speed direction of the ramie, and the two ends of the shafts of the two rollers and the small round rolls are all provided with a pressurizing air cylinder (12). The machine finishes from ramie stalks to semi-fine dry ramie for one time and has the advantages of high automatization degree, safe use, good fiber separating effect, good ramie output, saving water, being beneficial to popularization, etc. The method can be used for processing fresh ramie so as to obtain semi-fine dry ramie.

Owner:WUHAN TEXTILE UNIV

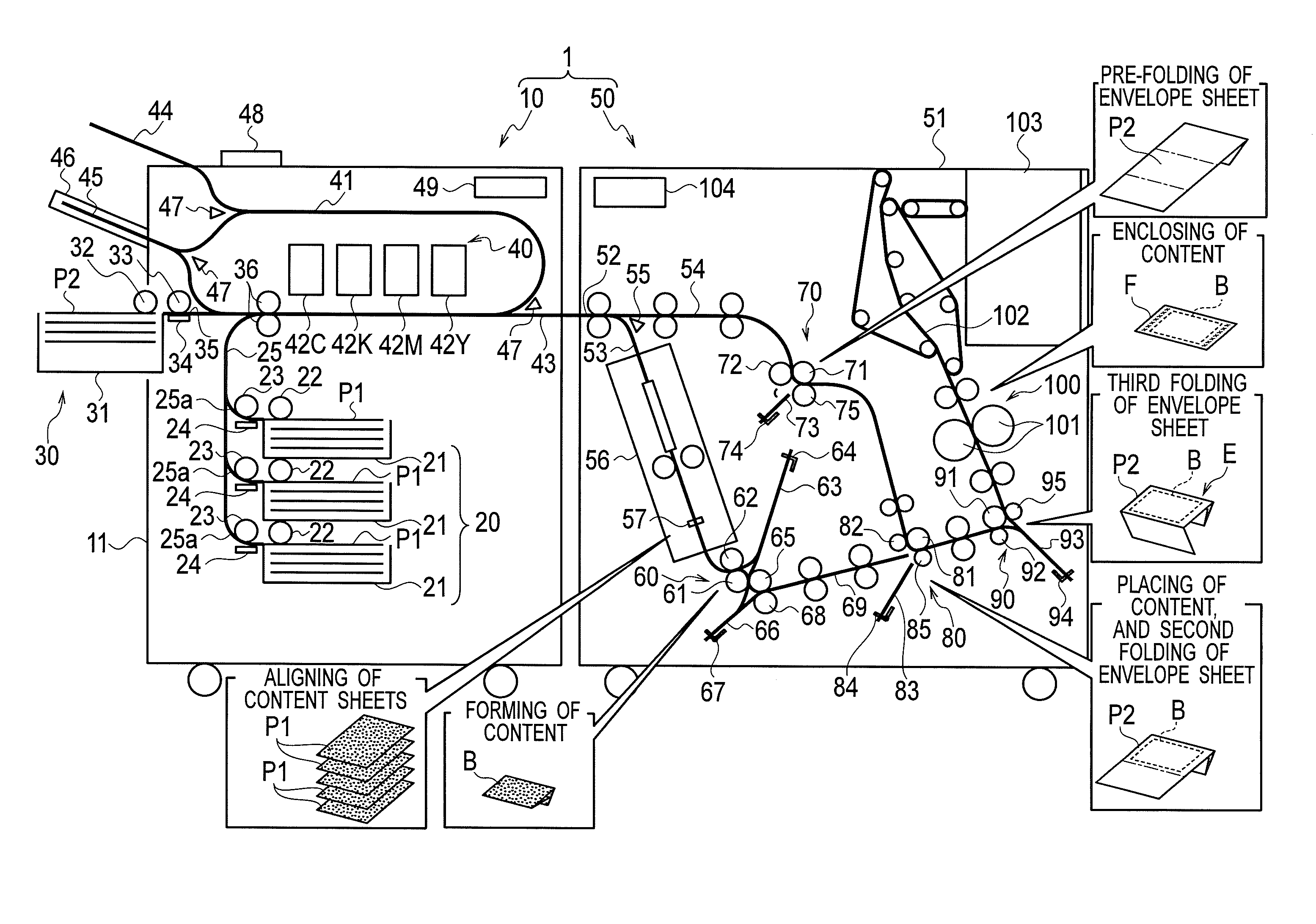

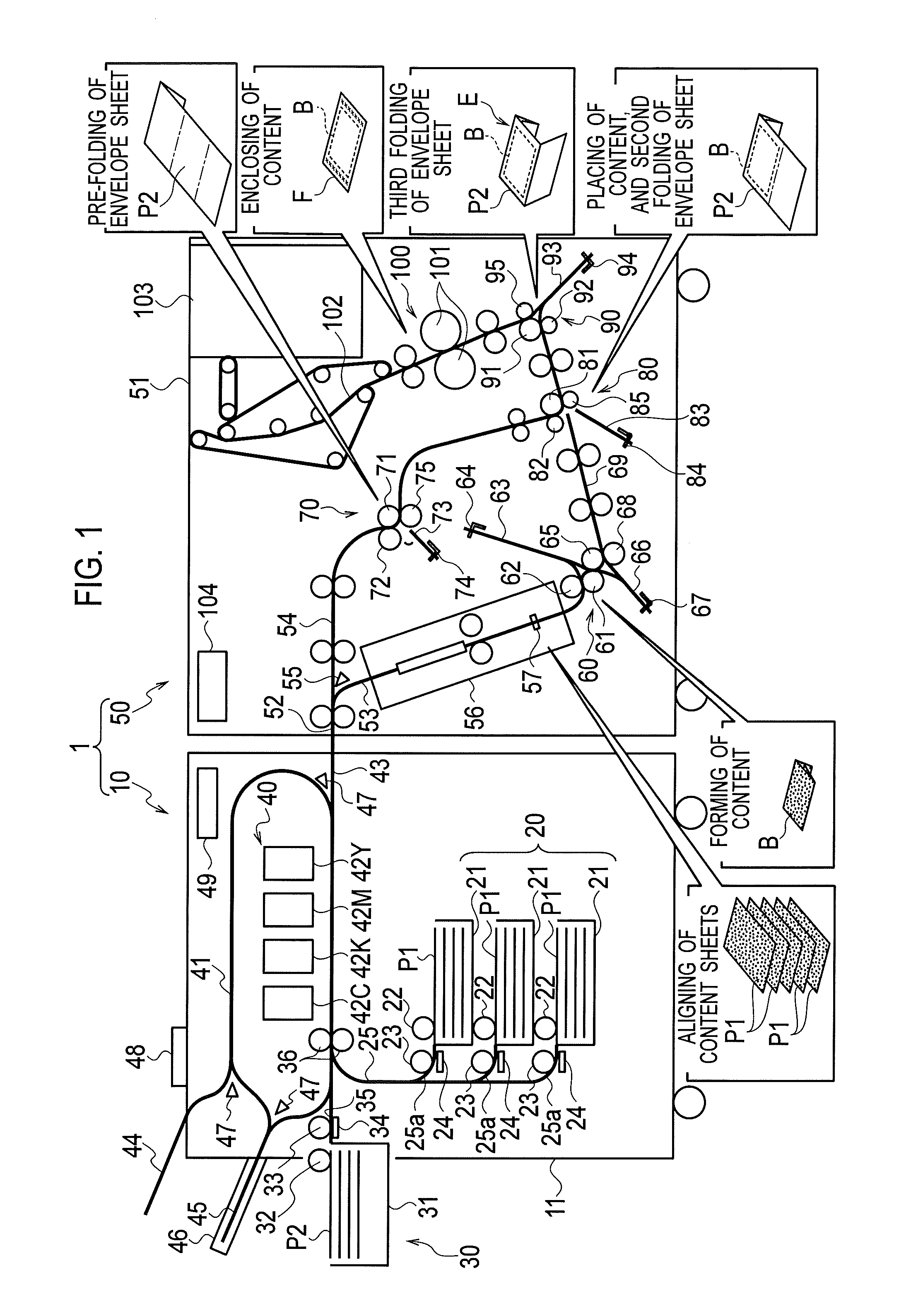

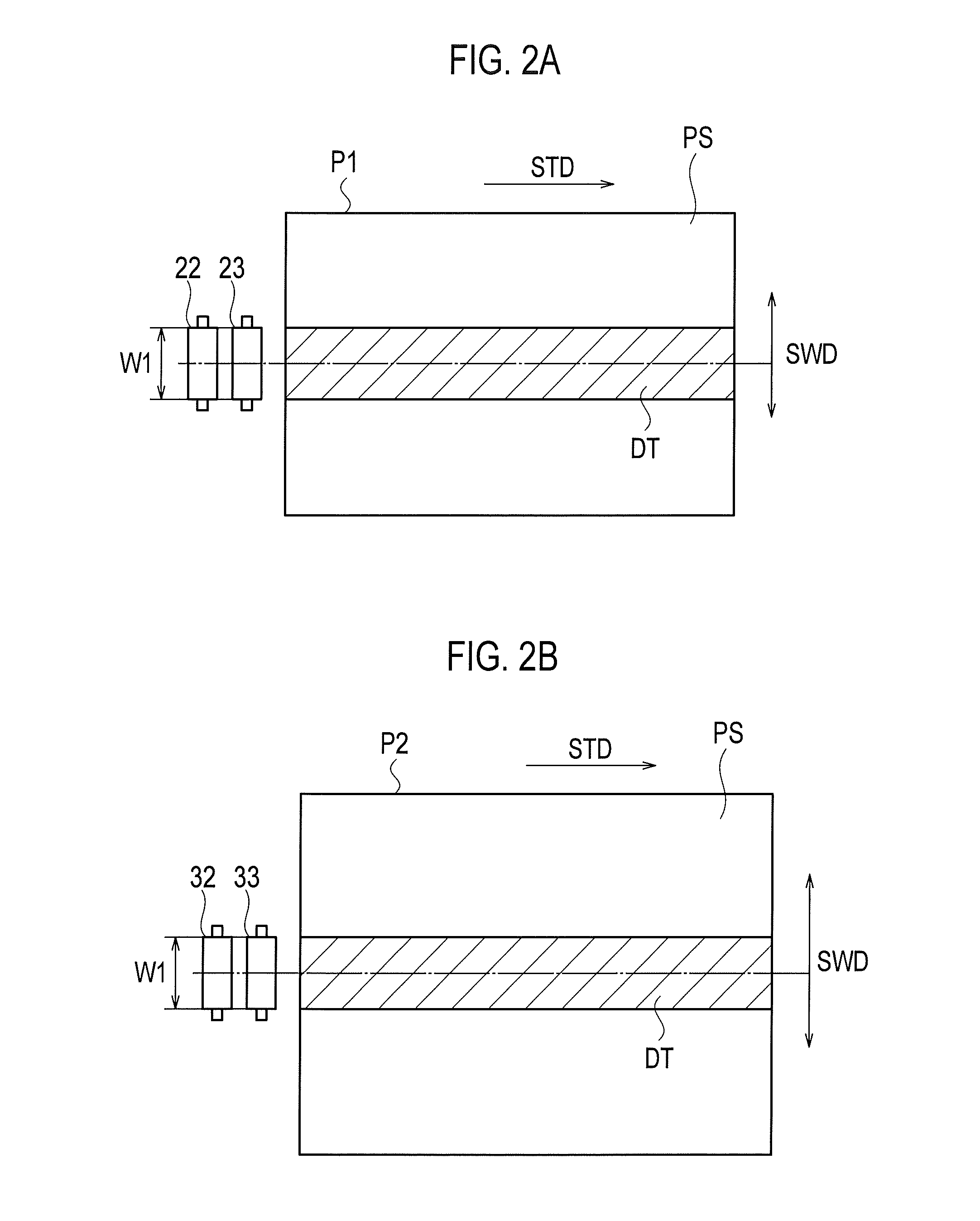

Sheet folding device

ActiveUS20150141230A1Inhibition formationInhibit transferMechanical working/deformationFolding thin materialsEngineeringElectrical and Electronics engineering

A sheet folding device includes first and second folding rollers as a pair arranged on a sheet transfer path located downstream of a printing unit and configured to form a fold on a printed sheet. At least the first folding roller includes a small-diameter portion formed at a position corresponding to a range of a width of a separating roller in the sheet width direction, and a large-diameter portion formed at a position other than the position of the small-diameter portion.

Owner:RISO KAGAKU CORP

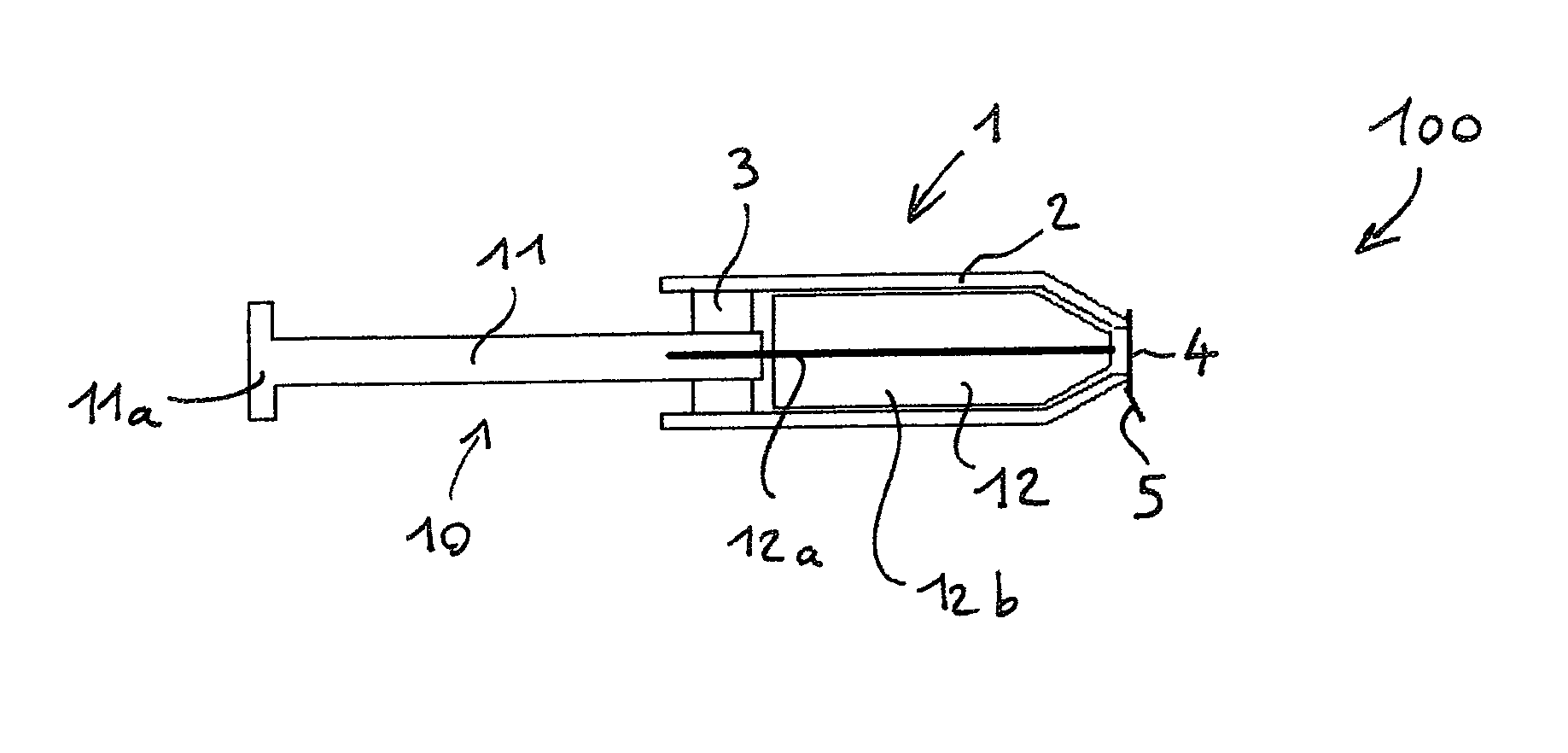

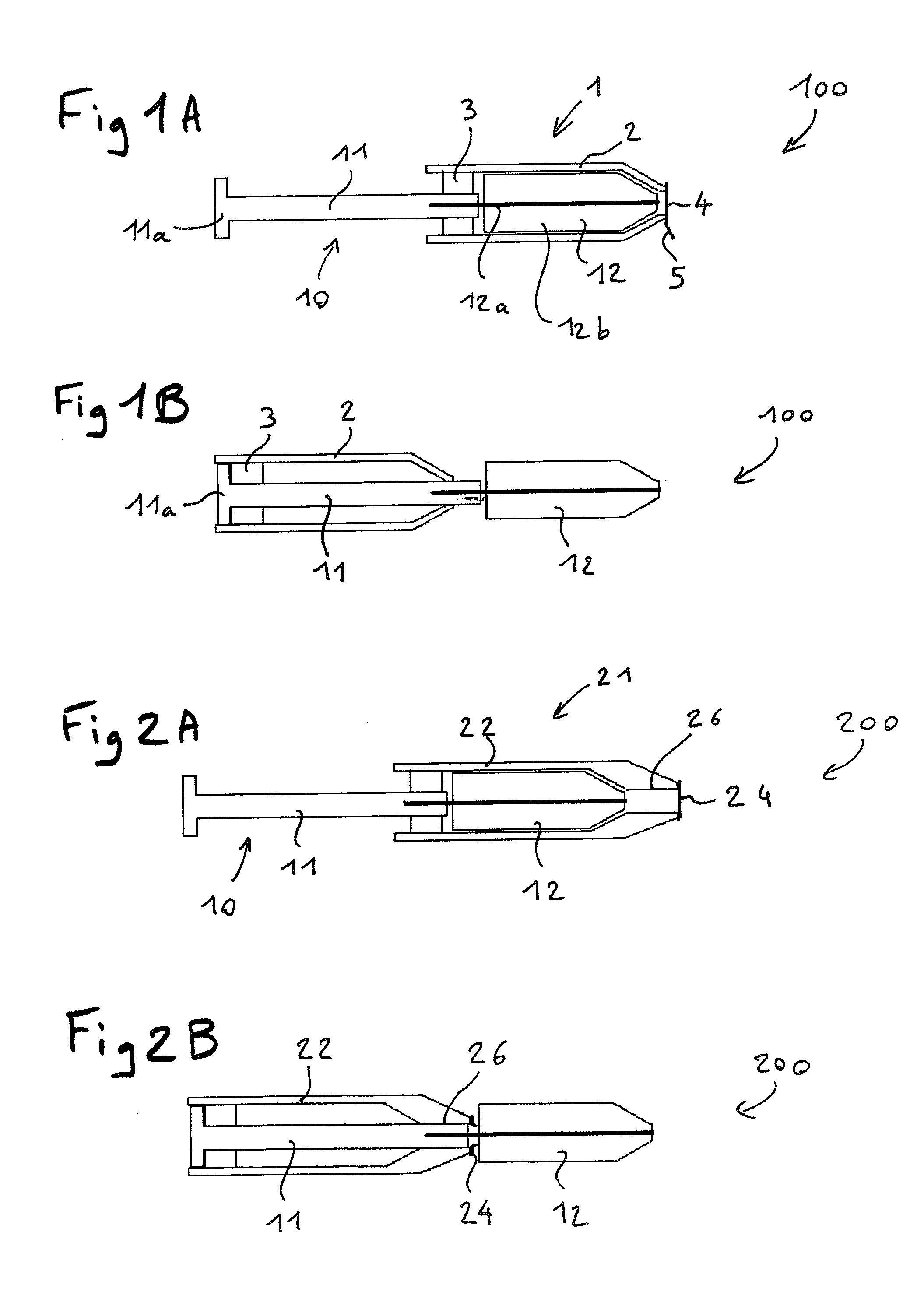

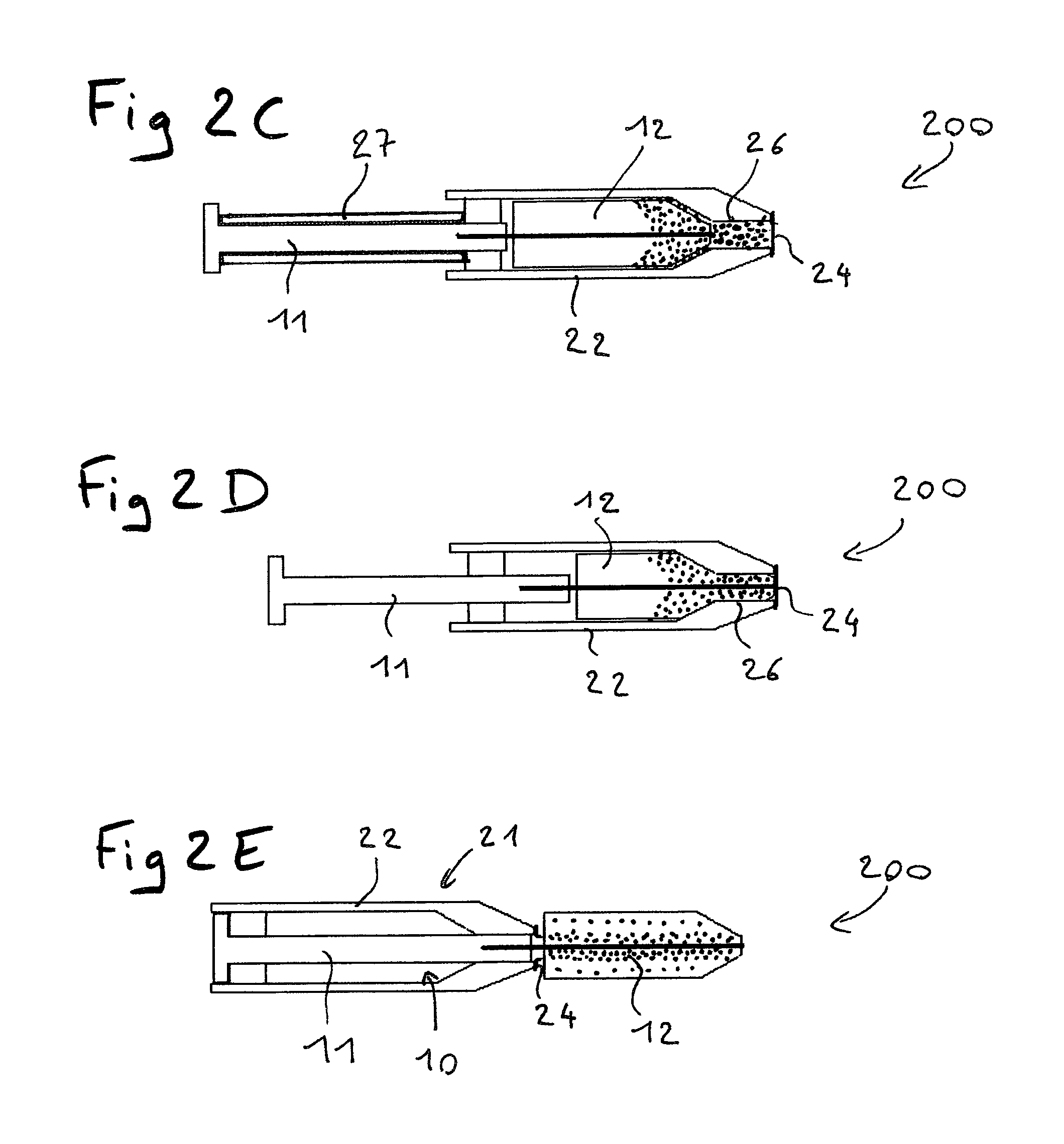

Sample dispenser applicator for mascara

Mascara sample dispenser applicators have a mascara applicator including a rod and a tip for applying the mascara to the eyelashes of the user. A receptacle contains a small amount of mascara and includes both a first opening through which the rod passes and a second opening through which the applicator tip is pushed out by translation of the rod relative to the receptacle, allowing the user to apply mascara. The second opening may be hermetically sealed by a film that cannot be returned to its original position or condition after use.

Owner:ALCAN PACKAGING BEAUTY SERVICES

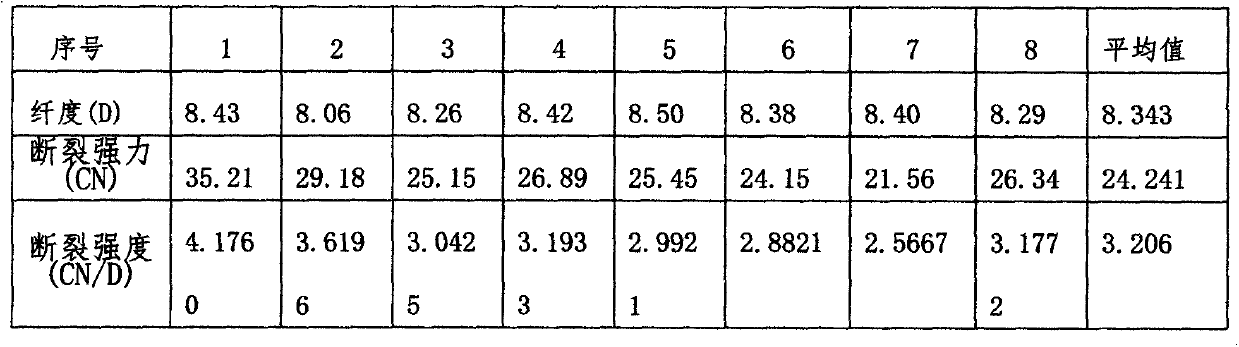

Preparation of wool lubricating oil and application of wool lubricating oil to improvement of fabric properties

The invention relates to preparation of wool lubricating oil and application of the wool lubricating oil to improvement of fabric properties. The wool lubricating oil comprises a high-molecular polymer, a softener, an emulsifier, an organic metal salt and an auxiliary agent formed by compounding of non-ionic and anionic surfactants. A preparation method for the wool lubricating oil comprises a step of subjecting the above raw materials to emulsification and stirring. A method for applying the wool lubricating oil to improvement of fabric properties comprises the following steps: in a former textile procedure, applying the wool lubricating oil onto kapok or crystal cotton fibers at 20 to 30 DEG C; then carrying out balancing in a chamber with a constant temperature and a constant humidity for 12 to 48 h; and carrying out dispersion and uniform mixing before a subsequent textile procedure. The wool lubricating oil provided by the invention is easy to remove through washing, ecological, friendly to environment, simple to apply, more energy-saving and easy for industrial production; and the wool lubricating oil allows the kapok and crystal cotton fibers to have better carding, strip forming and fabric properties and overcomes bottlenecks of application of the kapok and crystal cotton fibers to fabrics in the textile field.

Owner:如皋市西林化工有限公司

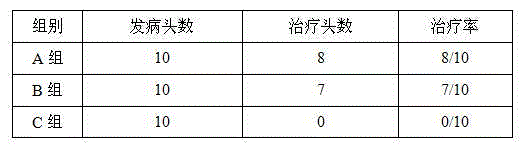

Medicine-core type feed resistant to swine viral diseases and preparation method of medicine-core type feed

The invention discloses medicine-core feed resistant to swine viral diseases. The medicine-core feed comprises traditional Chinese medicine extract, superfine powder, biological leavening and nucleotide, wherein the traditional Chinese medicine extract is prepared from the following raw materials in parts by weight: 10-30 parts of astragalus polysaccharide and 10-30 parts of codonopsis pilosula polysaccharides; the superfine powder is prepared from the following raw materials in parts by weight: 5-10 parts of coptis chinensis, 5-10 parts of flos lonicerae, 10-40 parts of organge peel,10-40 parts of Chinese angelica; the biological leavening is prepared from the following raw materials in parts by weight: 10-15 parts of probiotics and 10-15 parts of prebiotics; the nucleotide is 0.5-0.8 part of ATP. The medicine-core feed provided by the invention not only can be used for achieving the effect of preventing diseases, but also can be used for achieving a treatment effect. According to the clinical practical needs, the effect of preventing and treating can be achieved by regulating the proportion of the medicine core in the feed particles. Meanwhile, an energy factor is added in the medicine-core formula, so that not only can energy be provided to the swines, but also the immunity of the swines can be improved.

Owner:HENAN UNITED INVE FEEDSTUFF

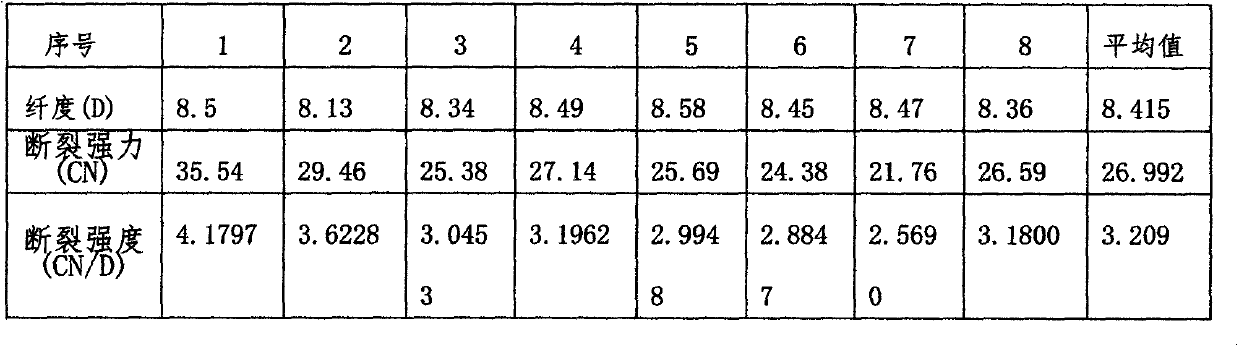

Production process of superfine mulberry silk fiber woven fabric

The invention discloses a production process of superfine mulberry silk fiber woven fabric, which comprises the following steps: the warp and weft yarns in the process specification design are all 1 / 7D / 9D mulberry silk, and the warp and weft density and plain weave of the upper machine are determined; The tension and hardness of the tube are 1.5~3CN, 22-24, 2~4CN, 24-26 respectively; 8 pieces of male and female matching steel sheet healds and one-way threading heald method, determine the reed number and the number of reed penetrations; plain weaving tension is 11CN ~ 13CN, heald frame stroke is 9 ~ 10cm; whitening finishing process conditions are: The concentration of the refining solution is 3-4g / l, the liquor ratio is 1:50, and the temperature is 95-98°C. The process of the present invention has strong productivity, the tension of each process is optimized, and they are reasonably matched with each other, greatly reducing warp flaws, and no dipping process is required. Therefore, the production process has strong productivity, thus obtaining the 2M / M of the present invention Thick thin ground woven fabrics are of good quality.

Owner:DALI SILK ZHEJIANG

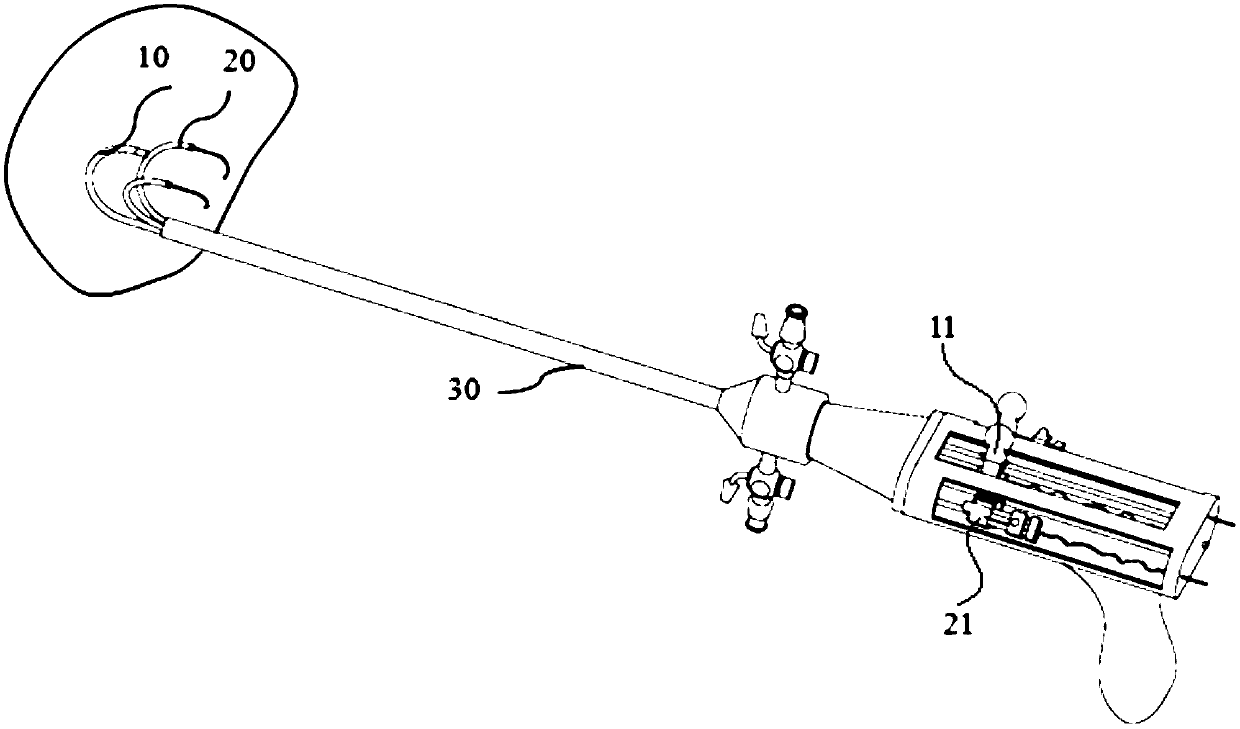

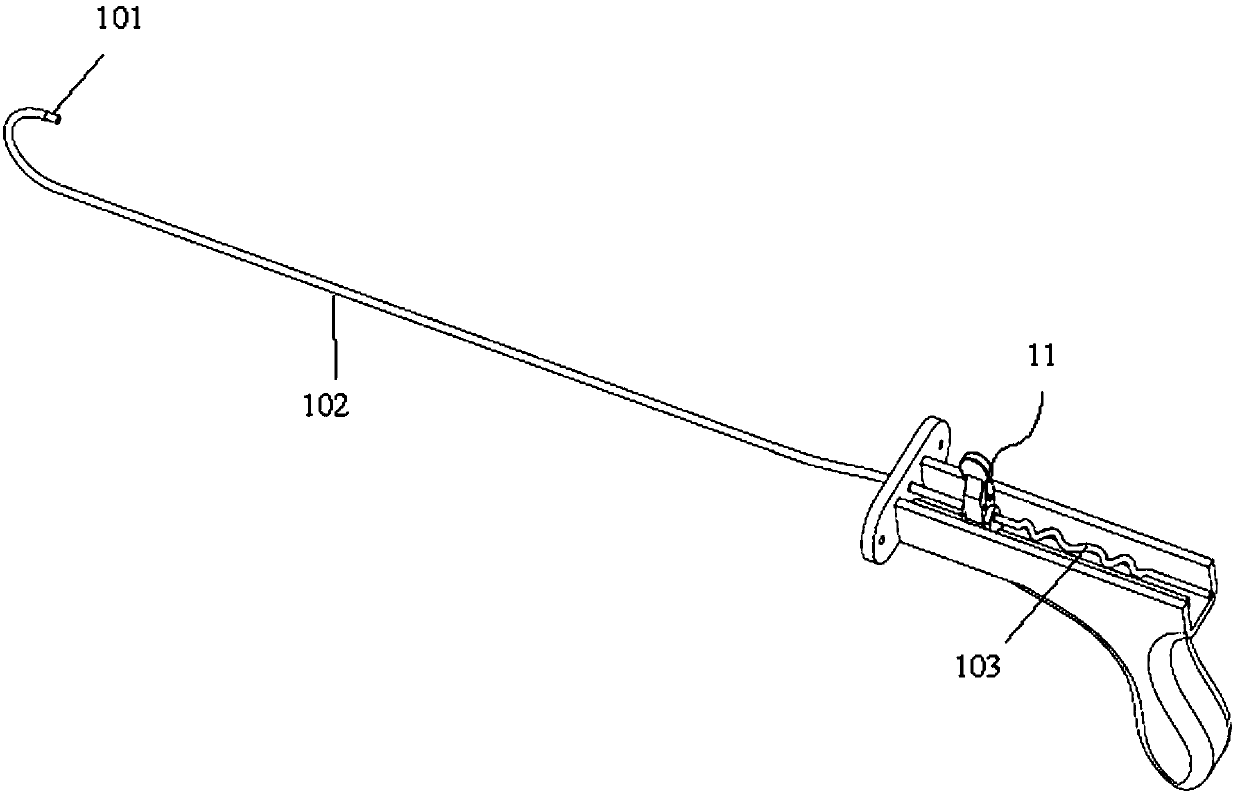

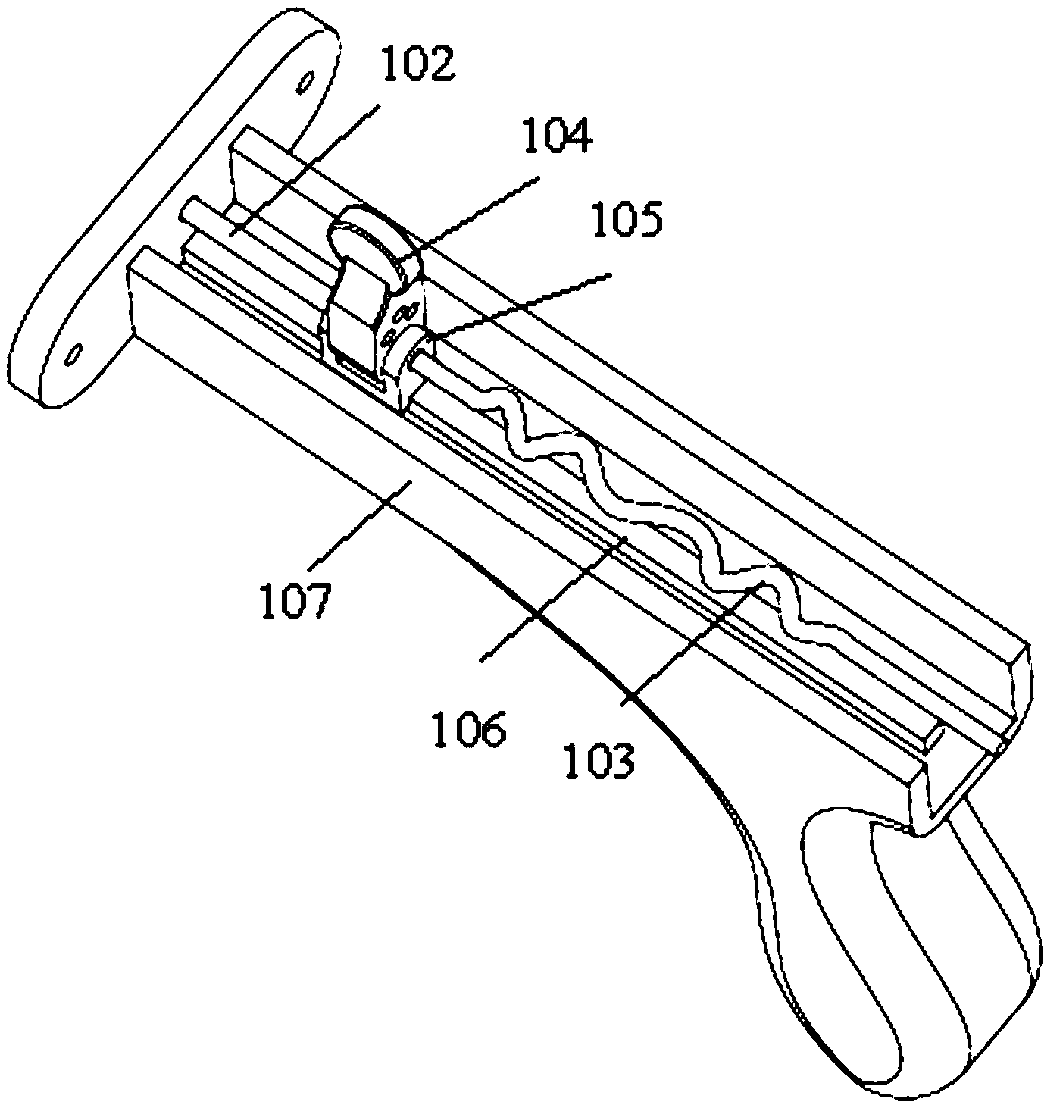

Intracavitary operation tool

InactiveCN109567927ASimple and complete structureGuaranteed implementabilitySuture equipmentsInternal osteosythesisEngineeringImaging Tool

The invention relates to a intracavitary operation tool. The intracavitary operation tool comprises an imaging tool, an operation tool, a mirror body, an imaging tool driving mechanism and an operation tool driving mechanism, wherein the imaging tool comprises a camera and an imaging tool arm body; the camera is connected to an imaging tool arm body far end; an imaging tool arm body near end is connected with the imaging tool driving mechanism; the operation tool comprises an execution mechanism and an operation tool arm body; the execution mechanism is connected to an operation tool arm bodyfar end; the execution mechanism penetrates through an inner cavity channel of the operation tool arm body and then is linked with the operation tool driving mechanism; an operation tool arm body nearend is also linked with the operation tool driving mechanism; the mirror body comprises an imaging guide pipe, an operation guide pipe and a dispersion supporting body; the imaging guide pipe and theoperation guide pipe are used for guiding and restricting the imaging tool arm body and the operation tool arm body, so that the camera and the execution mechanism reach the same region at the far ends; meanwhile, the imaging tool driving mechanism and the operation tool driving mechanism have an enough space for arrangement at the near ends.

Owner:TSINGHUA UNIV

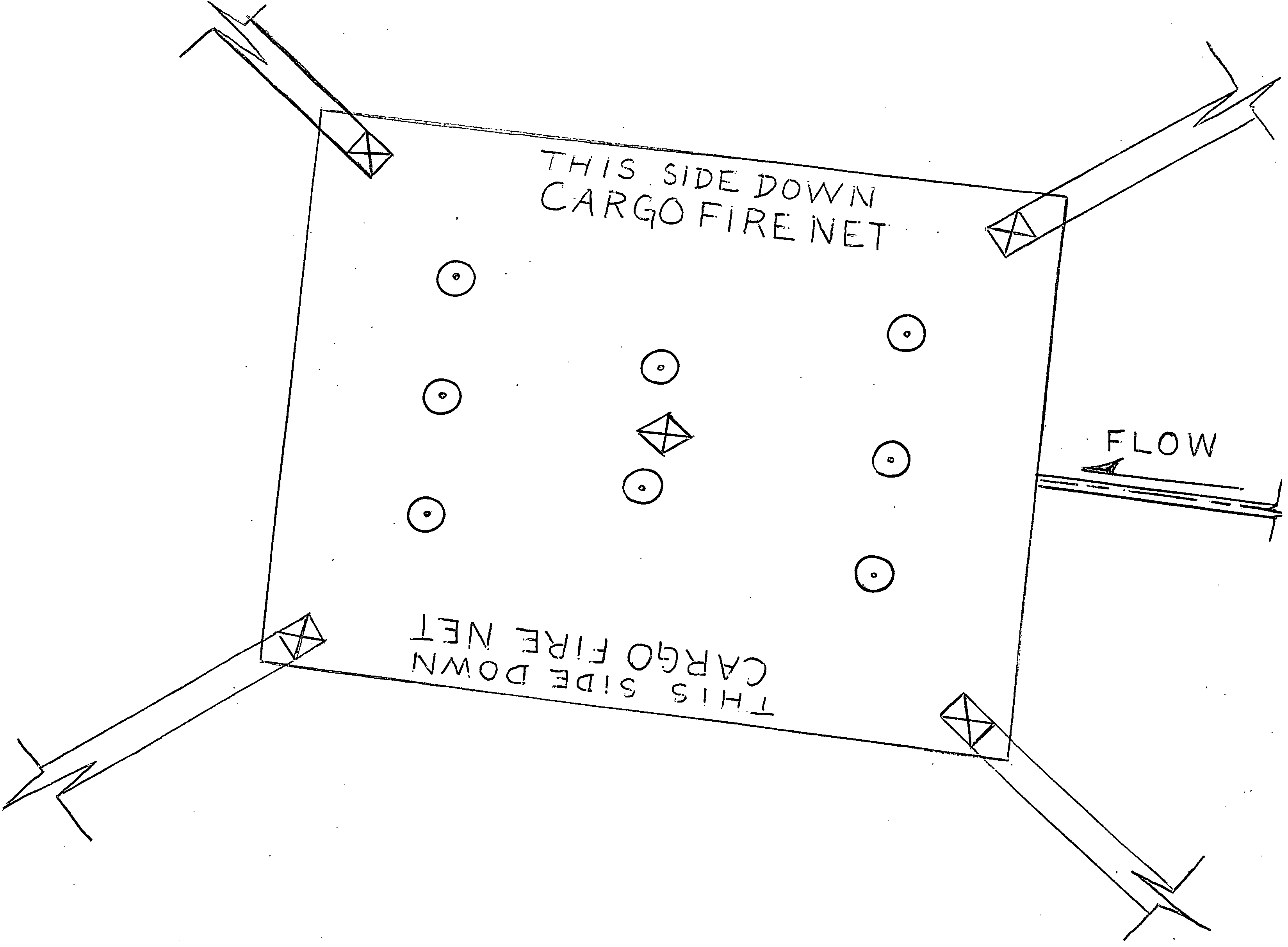

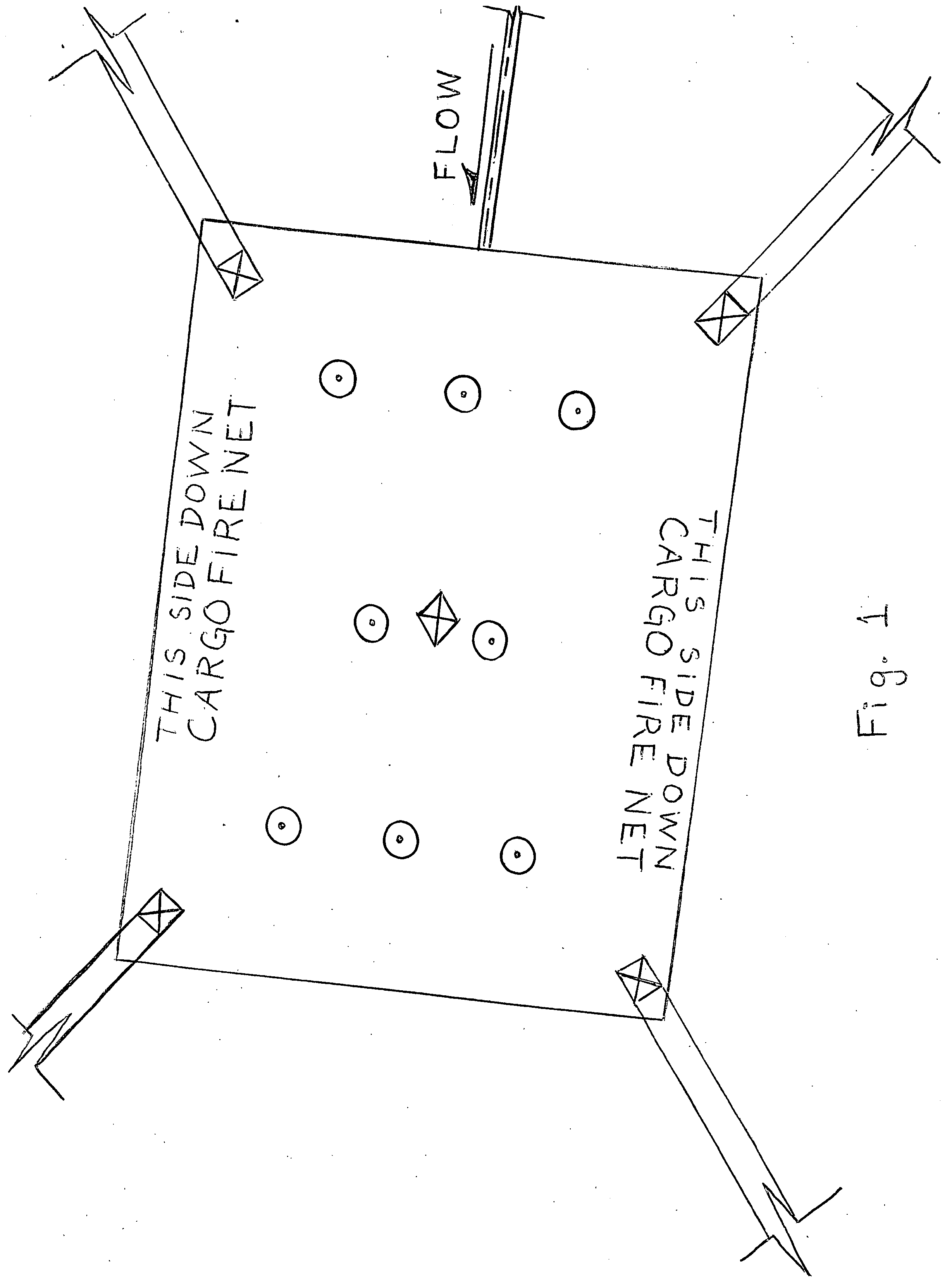

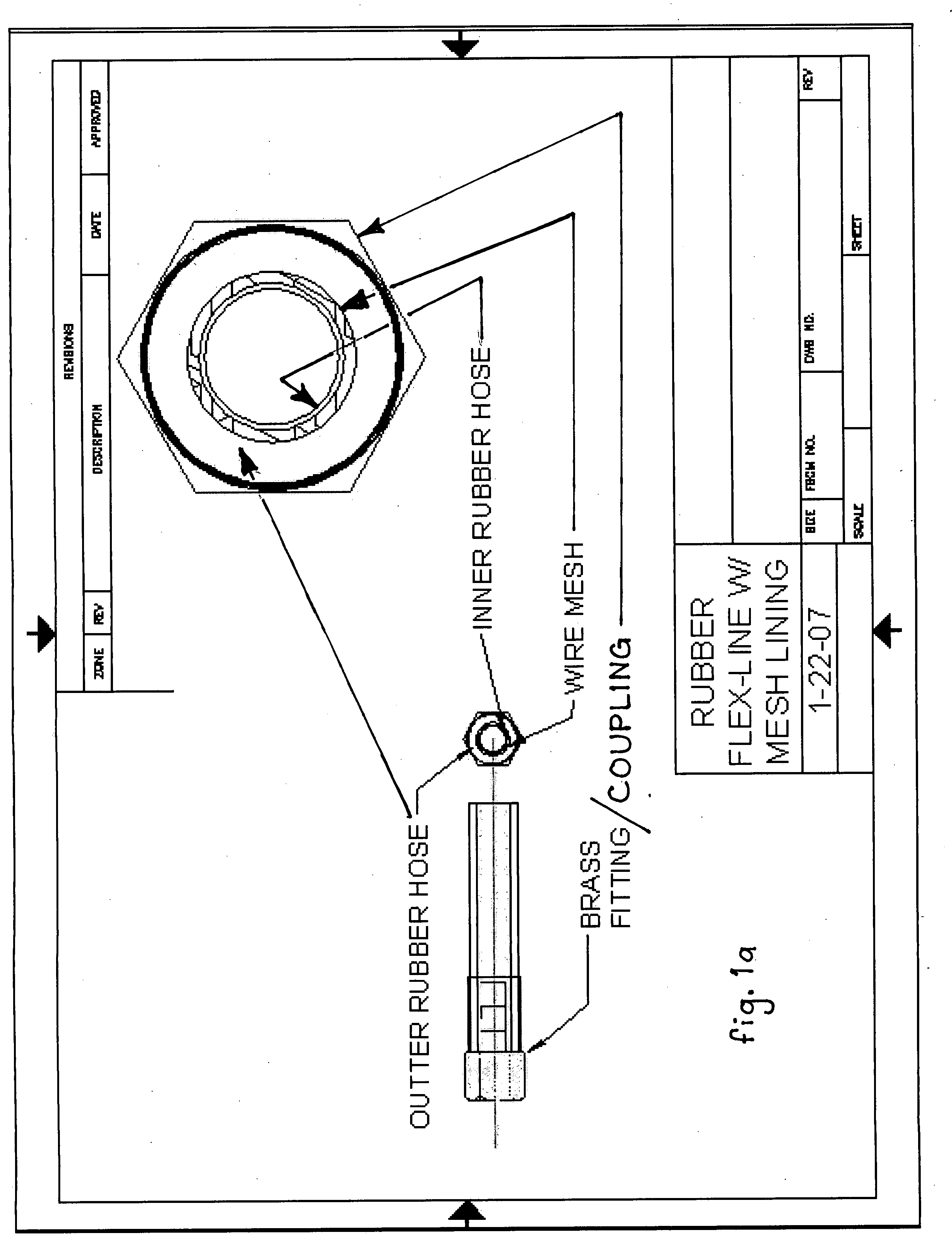

Cargo fire net

The “CARGO FIRE NET” looks much like a conventional net, the difference is that it was invented to extinguish fires in cargo settings. What makes this net different is the fact that it has several “suppression lines” inside, and throughout it, with (8) evenly spaced, exposed brass “#6540 suppression jet heads” connected to those lines, so as to spray “non-corrosive fire suppression agent” in the occurrence of fire. The “non-corrosive fire suppression agent” will be delivered by way of a centrifugal pump pulling from a 30 gal. holding tank, and into the net, so as to be sprayed. It can be used conventionally as a net, by draping it over the cargo, or non-conventional by suspending in a fixed state above the cargo. It's a net that extinguishes fires, just put it on the cargo, or hang it above the cargo, and connect it to “feed suppression line”, and walk away. When the “sensors” in the net detect an unacceptable temperature level, they will activate the system, thus starting the extinguishing process. All of this occurs with no attendant being involved, and ending the fear of “blind fires” during transport of cargo. Yes, the “CARGO FIRE NET” is the answer, a protector of Life, Property, and Merchandise. It's ready for industry, and industry is ready for it, “It's a better way”.

Owner:ADAMS CURTIS NATHANIEL

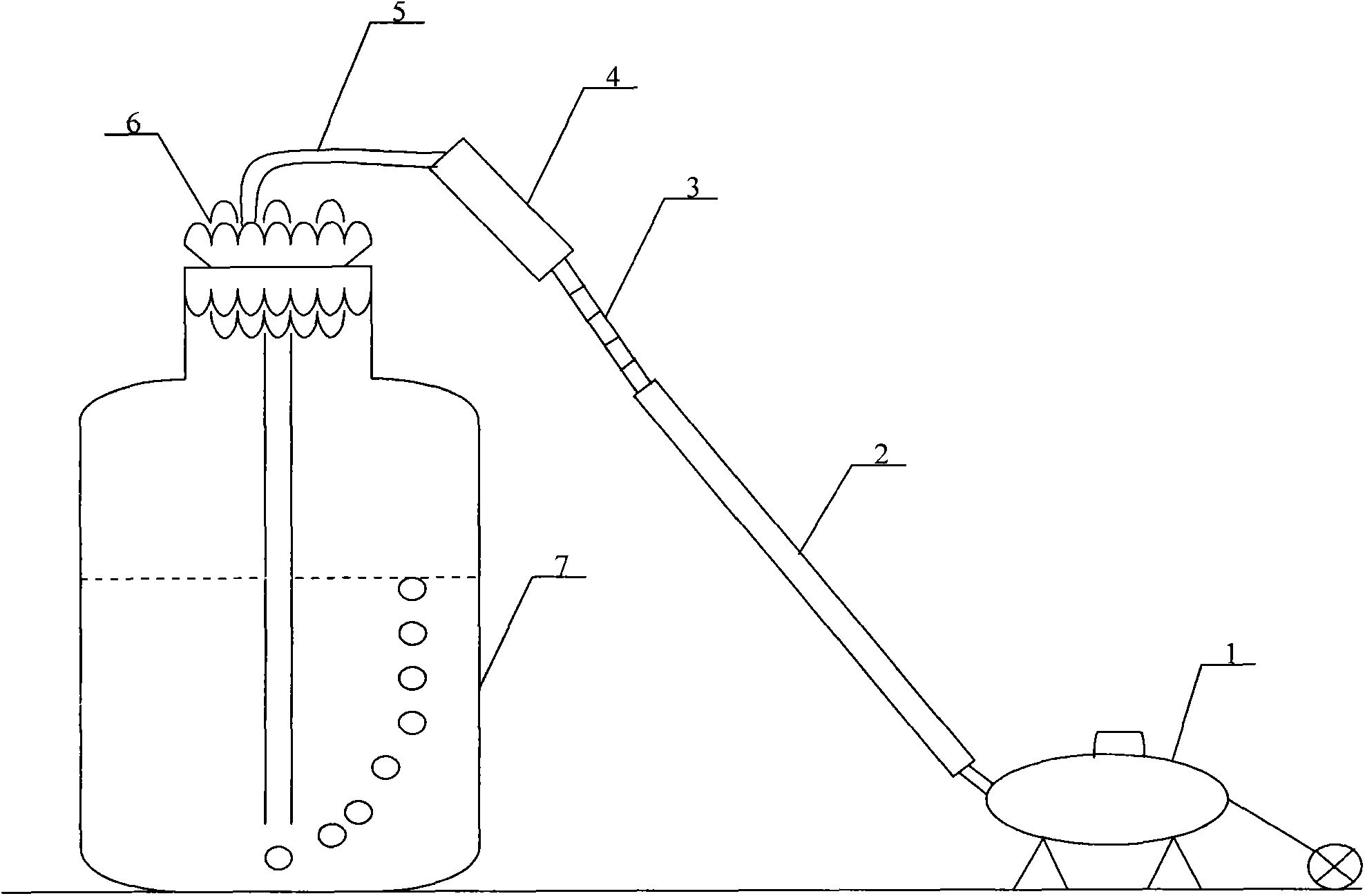

Strain manufacturing machine for culturing liquid strains

InactiveCN104285665ASmall particlesHigh densityCultivating equipmentsMushroom cultivationAdenosineAdditive ingredient

The invention relates to a strain manufacturing machine for culturing liquid strains. The strain manufacturing machine comprises a micro air compressor, a white rubber pipe, a five-section four-layer filter, a yellow rubber pipe, a glass elbow, cotton and a fermentation flask. The strain manufacturing machine is simple in structure, easy to manufacture, low in cost and wide in application range. By means of the strain manufacturing machine, the high-quality liquid strains small in particle and large in density can be cultured in a short time. The cultured high-quality liquid strains are used for inoculation culture of cordyceps militaris, the fungus fermentation, color changing and cordyceps militaris emerging are fast, the shape and the gloss of the cordyceps militaris are good, the appearance is attractive, high product value is achieved, and through the detection of the Chinese Academy of Sciences, the content of cordycepic acid, cordycepin, crude polysaccharide, adenosine, enzyme specific activity selenium and other effective ingredients of the cordyceps militaris cultured through the liquid strains cultured through the strain manufacturing device is higher than that of natural cordyceps sinensis.

Owner:李国军

Seedling separating mechanism and seedling separating method of orderly rice seedling throwing machine

PendingCN111052917AAvoid disorderImprove work efficiencyTransplantingAgricultural engineeringMechanical engineering

The invention discloses a seedling separating mechanism and seedling separating method of an orderly rice seedling throwing machine. The device comprises a gearbox, a first output shaft of the gearbox, a second output shaft of the gearbox, a left seedling separating component I, a left seedling separating component II, a right seedling separating component II and a right seedling separating component I. When rice earthen bowl seedlings are taken out in rows to fall down to seedling separating belts, driving pulleys drive all the seedling separating belts to transmit in the direction perpendicular to the advancing direction of a machine tool, so that rice seedlings on the seedling separating belts are driven to realize pinpoint seedling separation; and rice seedlings in each row are subjected to spacing movement by seedling separating spacing grids, cross is not generated between the rows, and seedling separation is guaranteed to be pinpoint. The seedling separating mechanism disclosedby the invention is simple in structure, high in operating efficiency and pinpoint in seedling separating row spacing, and can be suitable for any pinpoint separate-row transplanting of seedlings taken in rows.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

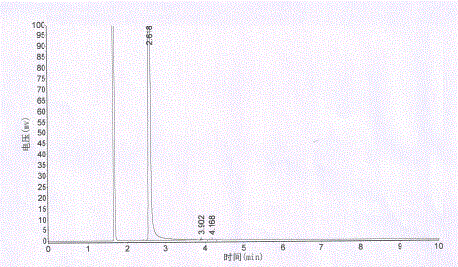

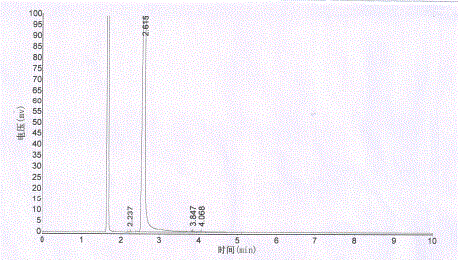

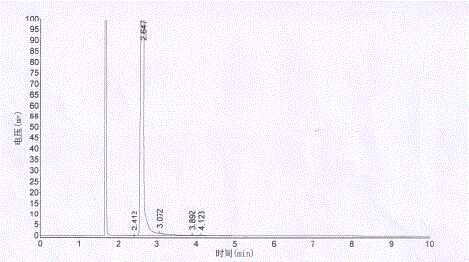

Method for detecting purity of 3-methylamino-1,2-propandiol by gas chromatography

InactiveCN105758970AImprove linearityGood repeatabilityComponent separationAnalysis dataColumn temperature

The invention provides a method for detecting the purity of 3-methylamino-1,2-propandiol by gas chromatography. The method comprises the flowing steps: preparing a sample, setting chromatographic conditions and carrying out detection; in the setting of the chromatographic conditions, the column temperature is 240 to 260 DEG C. With the adoption of the method disclosed by the invention, the content of 3-methylamino-1,2-propandiol and the contents of impurities in 3-methylamino-1,2-propandiol can be simultaneously detected and analyzed; the accuracy and precision of analysis data are improved, the repeatability is good and the sensitivity is high; the detection time is short, the operation is easy and simple, and the analysis time of an analyst is saved; the work efficiency is improved; the service life of a chromatographic column is prolonged and the cost is reduced; derivatization is not required, the sample is directly injected after being dissolved by using chromatographically pure methanol to lower the viscosity of the sample.

Owner:TAISHAN MEDICAL UNIV

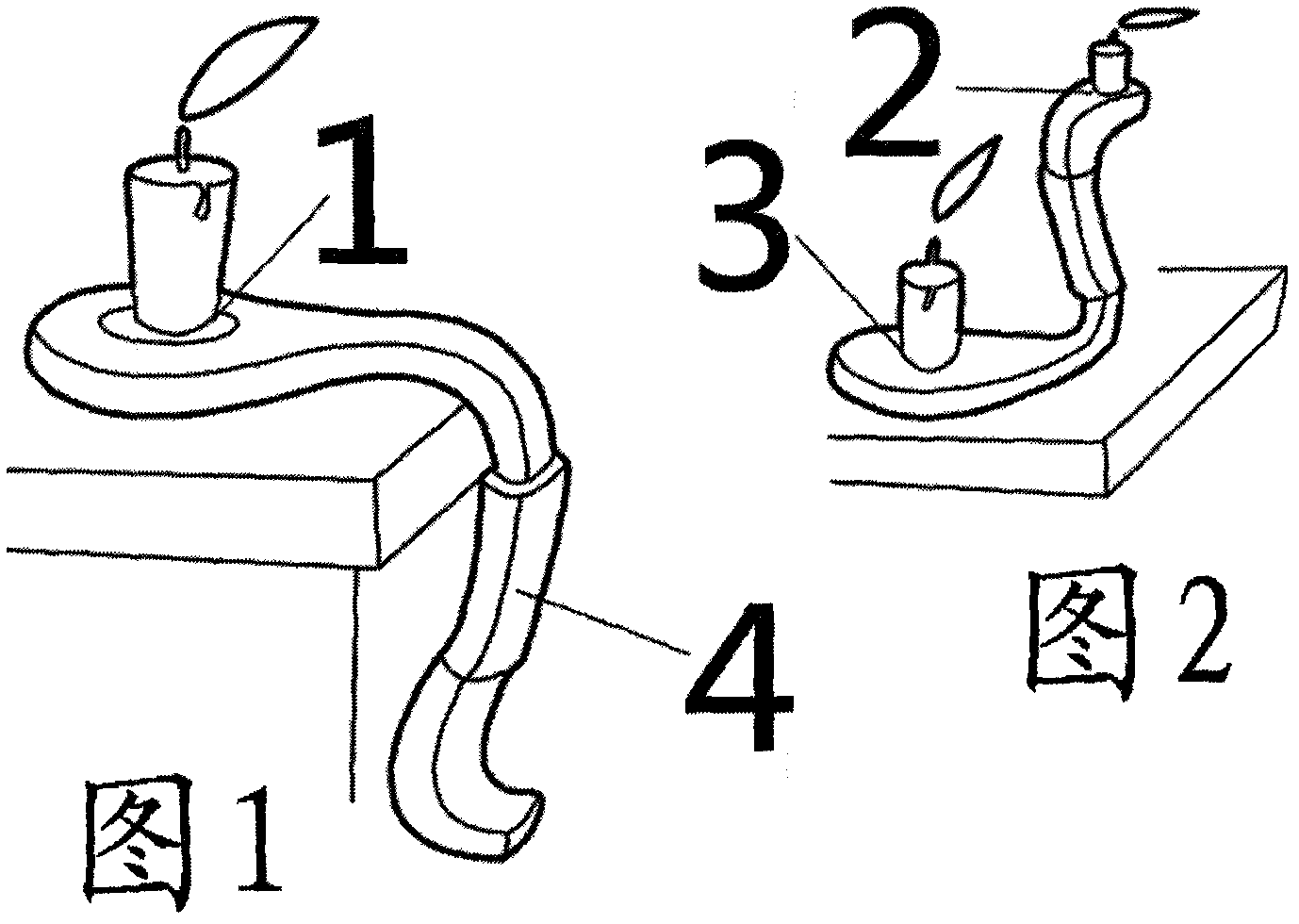

Double-end handle candle holder

The invention relates to a double-end handle candle holder, which comprises a first candle holder and a second candle holder, wherein the first candle holder is connected with the second candle holder by an L-shaped connection arm; front and reverse sides of the first candle holder and the second candle holder are provided with candle support bases for accommodating candles; and a holding part for being held is arranged on a support arm. By the double-end handle candle holder, the two candles are positioned at different heights, so that different positions can be illuminated by the candles to prevent dead angles; the first candle holder can be put on a table top, and the second candle holder hangs down, so that the candles can better illuminate the ground; and by the holding part, the double-end handle candle holder is convenient to move.

Owner:NANTONG DANDELION IND DESIGN SERVICE

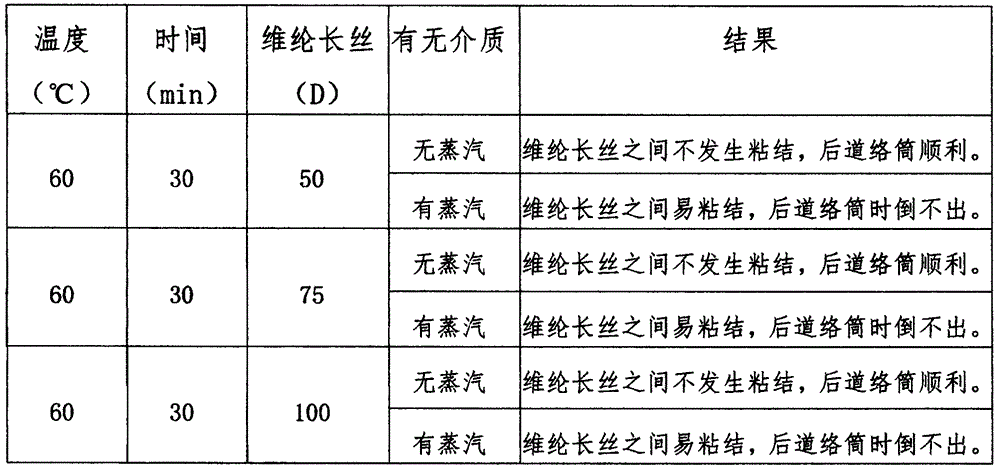

Method for manufacturing wrapped twisted yarns with spandex wrapped by silk

The invention discloses a method for manufacturing wrapped twisted yarns with spandex wrapped by silk, and belongs to the field of technologies for processing textile yarns. The method includes mulberry color yarn processing, doubling, wrapping and twisting and wrapped twisted yarn setting and precision spooling. Mulberry color yarn processing includes carrying out whitening and post-whitening dyeing on 23dtex mulberry yarns f2 S 300 and then carrying out reeling on the 23dtex mulberry yarns f2 S 300 to obtain 23dtex mulberry color yarns f2 S 300. Doubling includes doubling on the mulberry color yarns and 50D vinylon filament yarns in an untwisted manner under the condition of 19CN tension to obtain untwisted doubled yarns. Wrapping and twisting include winding the untwisted doubled yarns on the surfaces of the 20D spandex by the aid of 12CN wrapping tension, controlling drafting quantities of the 20D spandex and twisting the untwisted doubled yarns and the 20D spandex to obtain wrapped twisted yarns with the density of 1750 twists / meter. Wrapped twisted yarn setting includes setting the wrapped twisted yarns by means of dry blowing for 30 min at the dry blowing setting temperature of 60 DEG C. Precision spooling includes spooling the wrapped twisted yarns under the condition of 16CN tension after the wrapped twisted yarns are set by means of dry blowing, and returning cheese yarns after the wrapped twisted yarns are completely spooled. The method has the advantages that the method is high in feasibility and efficiency, and yarn dyeing requirements on elastic silk fabrics can be met by the wrapped twisted yarns manufactured by the aid of the method.

Owner:SHAOXING MIAOMENG SILK

American ginseng processing equipment and processing technology thereof

ActiveCN112474549AImprove overall flatnessSpeed up cleaningClimate change adaptationPharmaceutical product form changeElectric machineryAMERICAN GINSENG ROOT

The invention relates to an American ginseng processing equipment and processing technology thereof. The American ginseng processing equipment comprises a cleaning frame, a cleaning roller is rotatably connected to the cleaning frame, a plurality of cleaning holes penetrating through the outer side wall of the cleaning roller are formed in the cleaning roller, a cleaning motor is arranged on the cleaning frame, the cleaning motor is connected with the cleaning roller, a cleaning pipe is arranged in the cleaning roller in a penetrating mode, a plurality of cleaning nozzles arranged in the cleaning roller are arranged on the cleaning pipe, a placing frame is arranged at the end, close to a discharging port of the cleaning roller, of the cleaning frame, a conveying belt is arranged on the placing frame, a placing disc is arranged on the conveying belt, a moistening pipe arranged above the placing disc is arranged on the placing frame, and a plurality of moistening nozzles are arranged onthe moistening pipe. The American ginseng cleaning station and the American ginseng moistening station are connected together, automation of cleaning and moistening of the American ginseng is achieved, and the American ginseng processing equipment has the effect of improving American ginseng cleaning and moistening processing efficiency.

Owner:山东文登继振西洋参产业有限公司

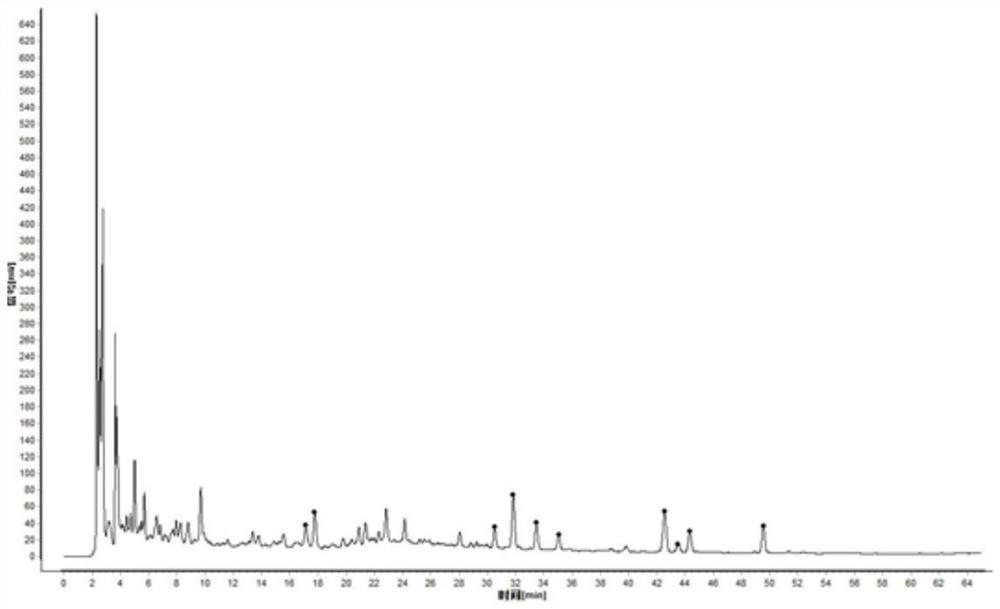

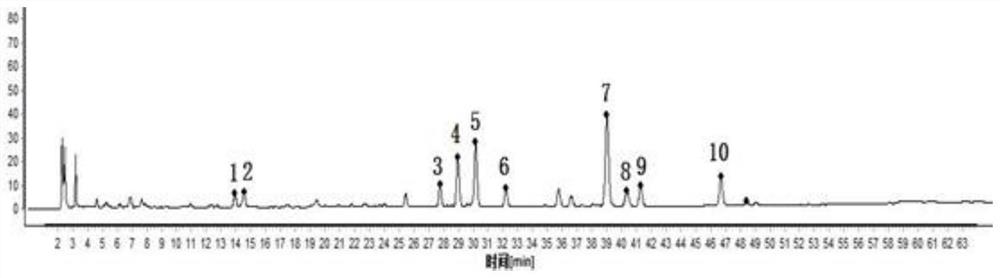

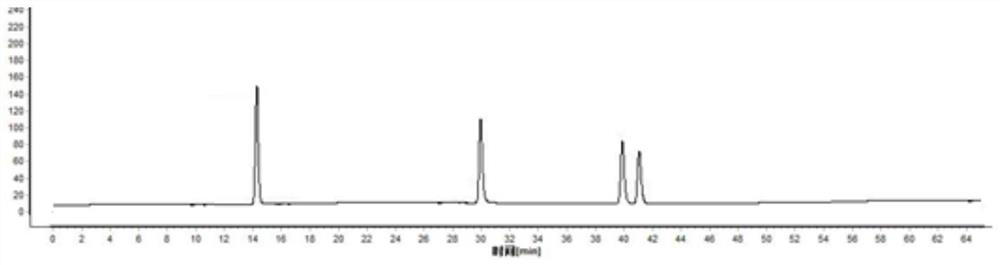

Establishment method of lindley eupatorium herb formula granule fingerprint as well as standard fingerprint and application thereof

ActiveCN114216978AFully reflect the quality statusFully extractedComponent separationMedicinal herbsPhysical chemistry

The invention provides a construction method of a lindley eupatorium herb formula granule fingerprint spectrum, a standard fingerprint spectrum of the lindley eupatorium herb formula granule and application of the standard fingerprint spectrum, and belongs to the technical field of medicine detection.The construction method comprises the steps that a test solution, a reference medicinal material solution and a reference substance solution are prepared, acetonitrile (A) and a 0.1-0.3 wt% phosphoric acid aqueous solution (B) are jointly used as mobile phases, and the standard fingerprint spectrum of the lindley eupatorium herb formula granule is obtained. Performing high performance liquid chromatography detection to obtain a fingerprint spectrum of the lindley eupatorium herb formula granules; the standard fingerprint spectrum of the lindley eupatorium herb formula granules is obtained by using the construction method, and the standard fingerprint spectrum is used for quality evaluation or control in the whole process of research / development / production / clinical application of the lindley eupatorium herb formula granules. According to the method for constructing the fingerprint spectrum of the lindley eupatorium herb formula granules, main medicinal material components in the lindley eupatorium herb formula granules can be detected only through high performance liquid chromatography, and the quality condition of the lindley eupatorium herb formula granules can be comprehensively reflected.

Owner:SHINEWAY PHARMA GRP LTD +2

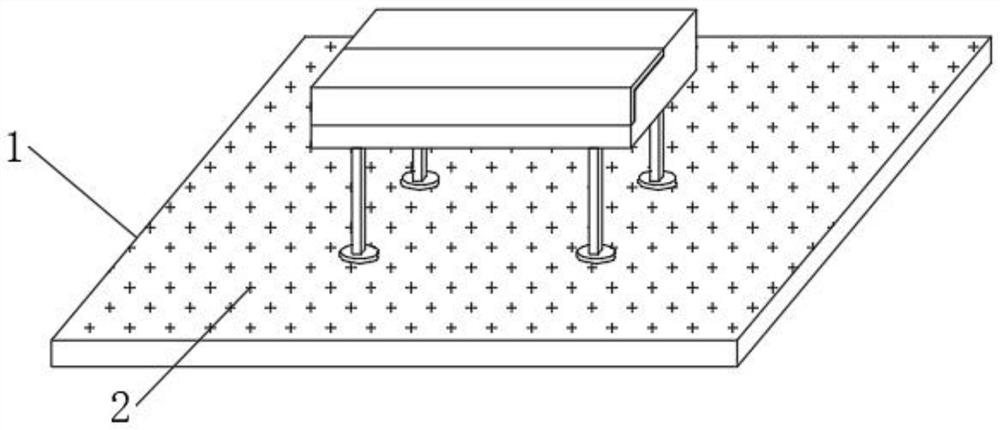

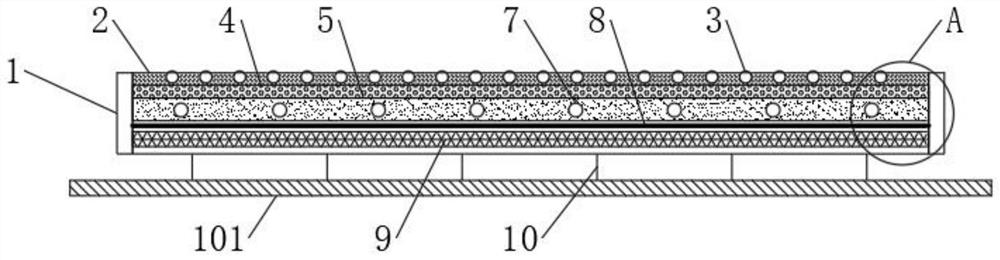

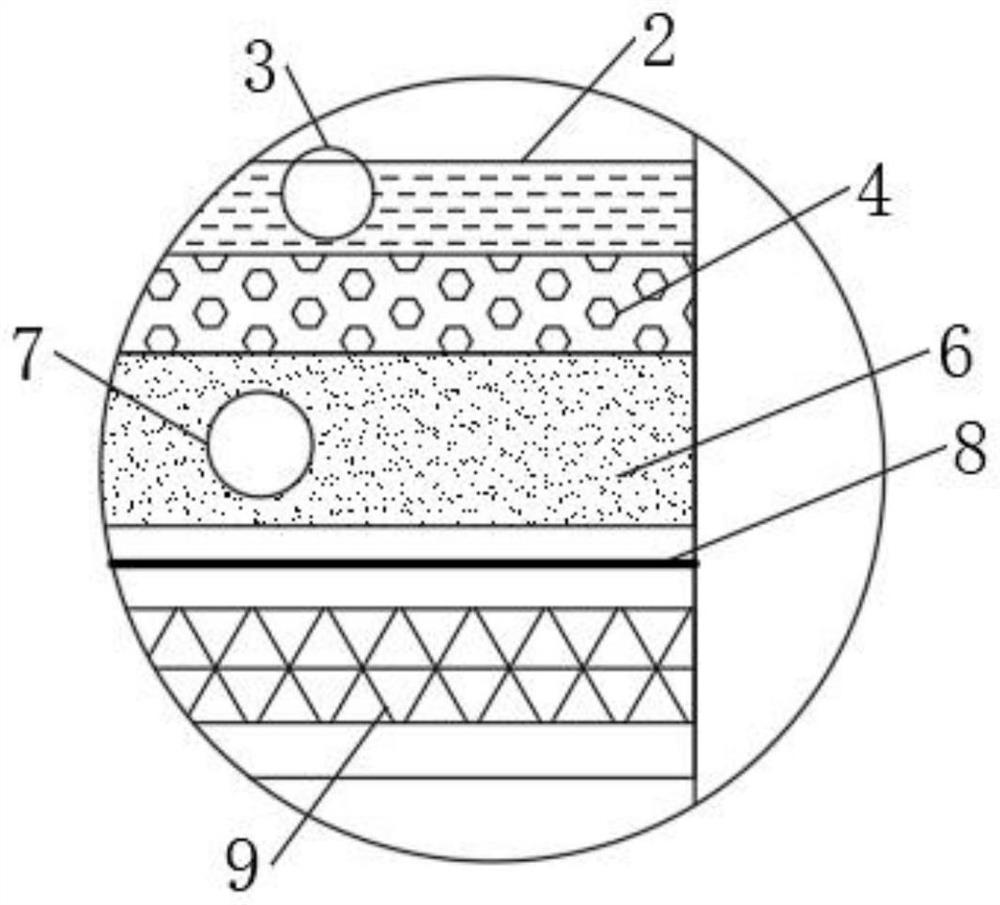

Aesthetics-based vibration noise reduction type piano training protective pad

ActiveCN112967702AReduce penetrationReduce resonanceSound producing devicesMusic aidsPianoSound wave

The invention discloses an aesthetics-based vibration noise reduction type piano training protective pad, and belongs to the field of piano training. According to the scheme, vibration between a piano and a sound wave reflecting layer is reduced through a telescopic rod when the piano makes a sound, sound waves generated by the piano are reflected to the outer side of the sound wave reflecting layer through the sound wave reflecting layer, and the continuity of the sound waves of the piano is improved. Sound waves penetrating through the sound wave reflecting layer are absorbed through a vibration silencing sponge, when part of the sound waves penetrate through the sound wave reflecting layer, the sound waves are guided into a silencing pipe through sound conducting gel, sound is consumed and absorbed through sound absorbing silica gel and protruding blocks in the silencing pipe, and penetration of the sound is reduced. Sound waves generated by the piano are reflected to the sound wave reflecting layer through the body or the indoor wall surface, most of the sound waves are reflected by the smooth surface of the sound wave reflecting layer, the penetrating sound waves are isolated through glass fibers, resonance between the piano and the ground is reduced, and the piano training effect is improved.

Owner:秦皇岛职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com