Gear-driven hole-pricking and seed-discharging mechanism of mold-hole type seed meter

A gear-driven, seeding mechanism technology, applied to the parts of the planter, sowing, planting methods, etc., can solve the problems of difficult to guarantee the quality of hole sowing, easy to block the soil of the hole forming mechanism, and limit the promotion and application, and achieve the synchronization of hole pricking and sowing Good performance, good hole formation quality, and high hole sowing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

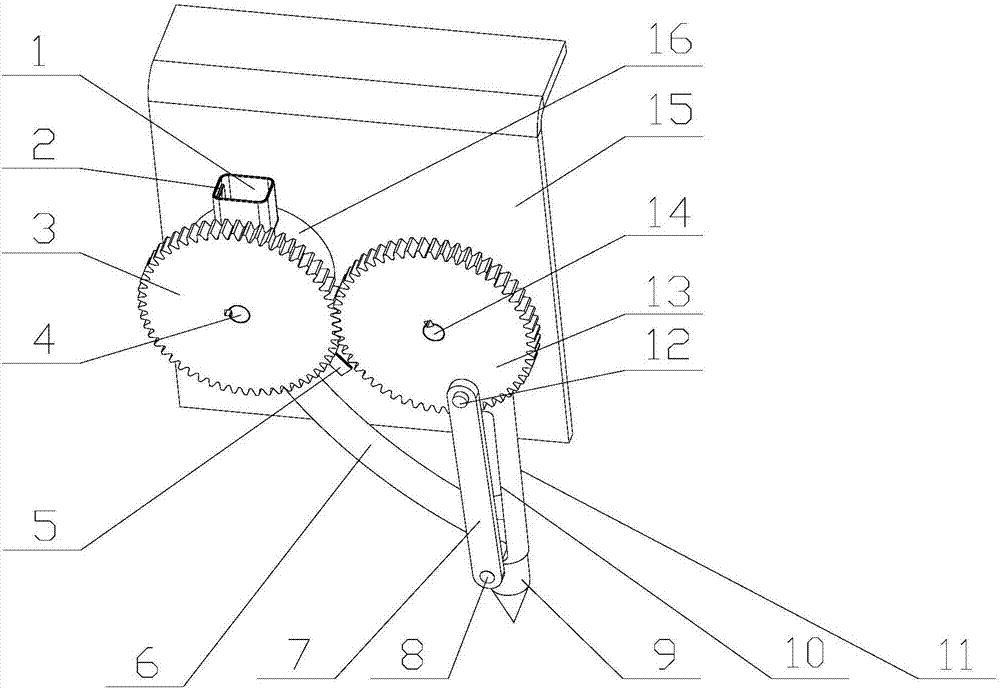

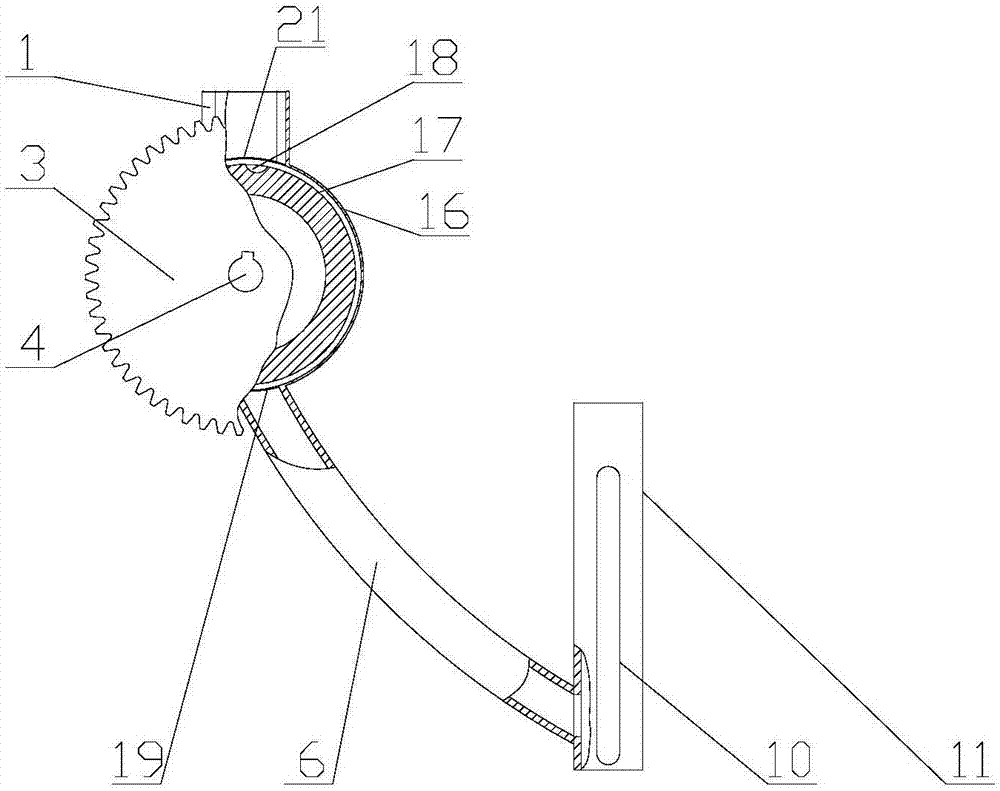

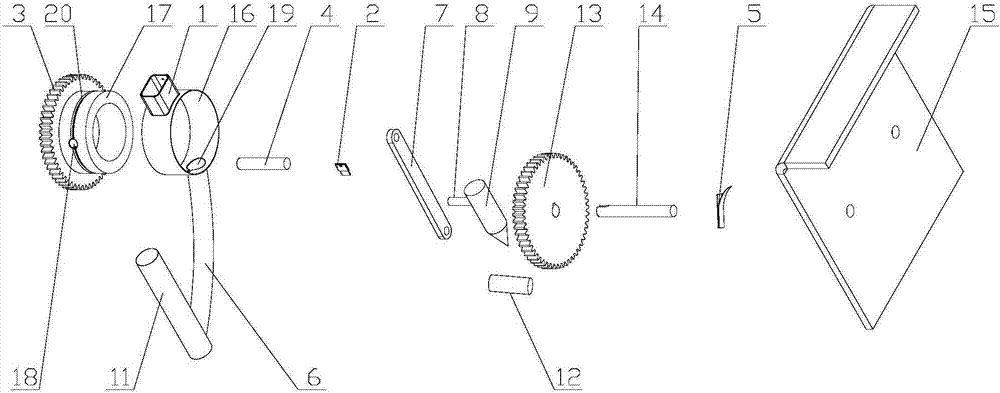

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A kind of hole-type seed meter gear-driven hole-piercing seed metering mechanism, the drive shaft 14 and the driven shaft 4 are respectively installed on the fixed frame 15 parallel to each other and rotatable, and the driving gear 13 is fixed on the drive shaft 14 , the gear pin 12 is eccentrically fitted on the driving gear 13, and the driven shaft 4 is fitted with a type hole wheel 17, and a type hole 18 and a ring-shaped clearing knife are respectively arranged on the outer surface of the type hole wheel 17. Groove 20, the ring-shaped groove 20 of the clearing knife and the type hole 18 are in a cross configuration, and the driven gear 3 is fixed on the outer end surface of the type hole wheel 17, and the driven gear 3 is fixedly connected with the driven shaft 4, The driven gear 3 meshes with the driving gear 13, and the transmission ratio between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com