An internal heating galvanized pot

A technology of internal heating and heating mechanism, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of galvanizing pot and zinc liquid loss, poor melting effect, short service life, etc. Long service life, low loss and low zinc consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and cannot limit the protection scope of the present invention.

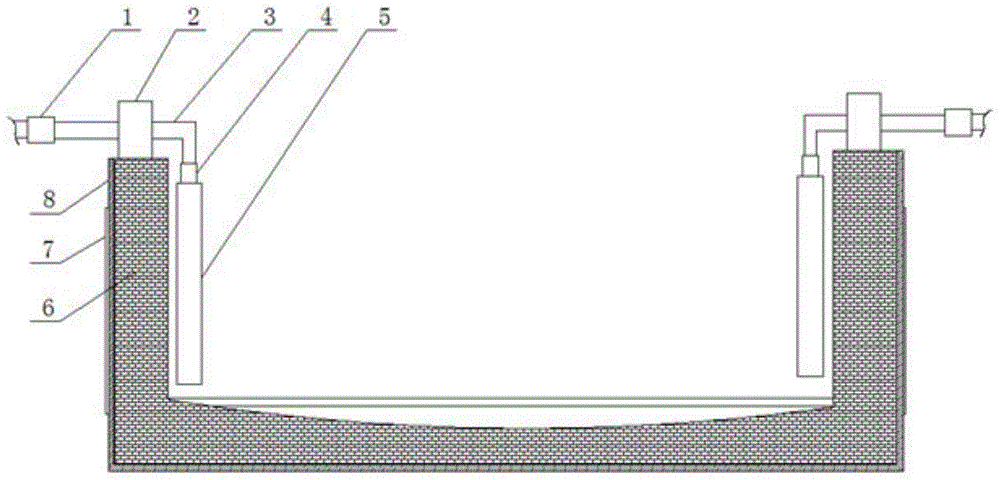

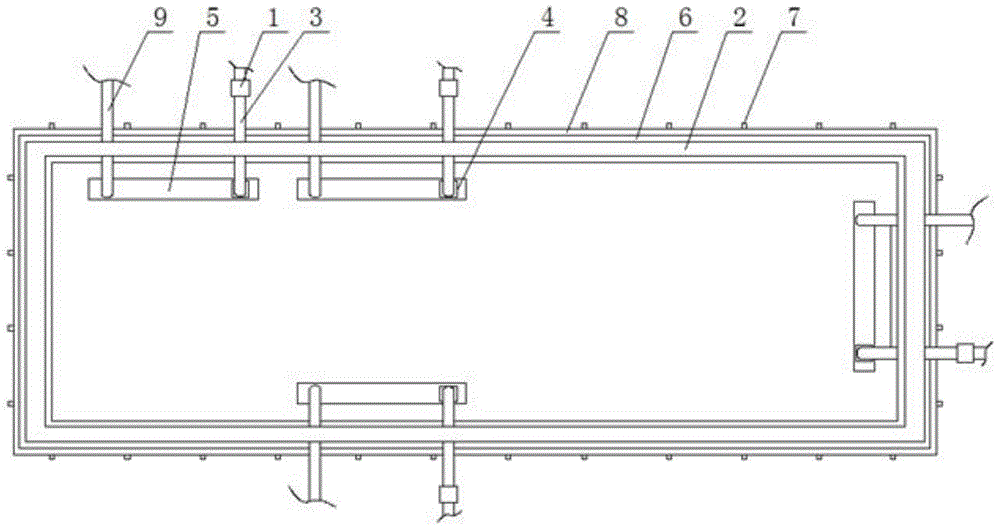

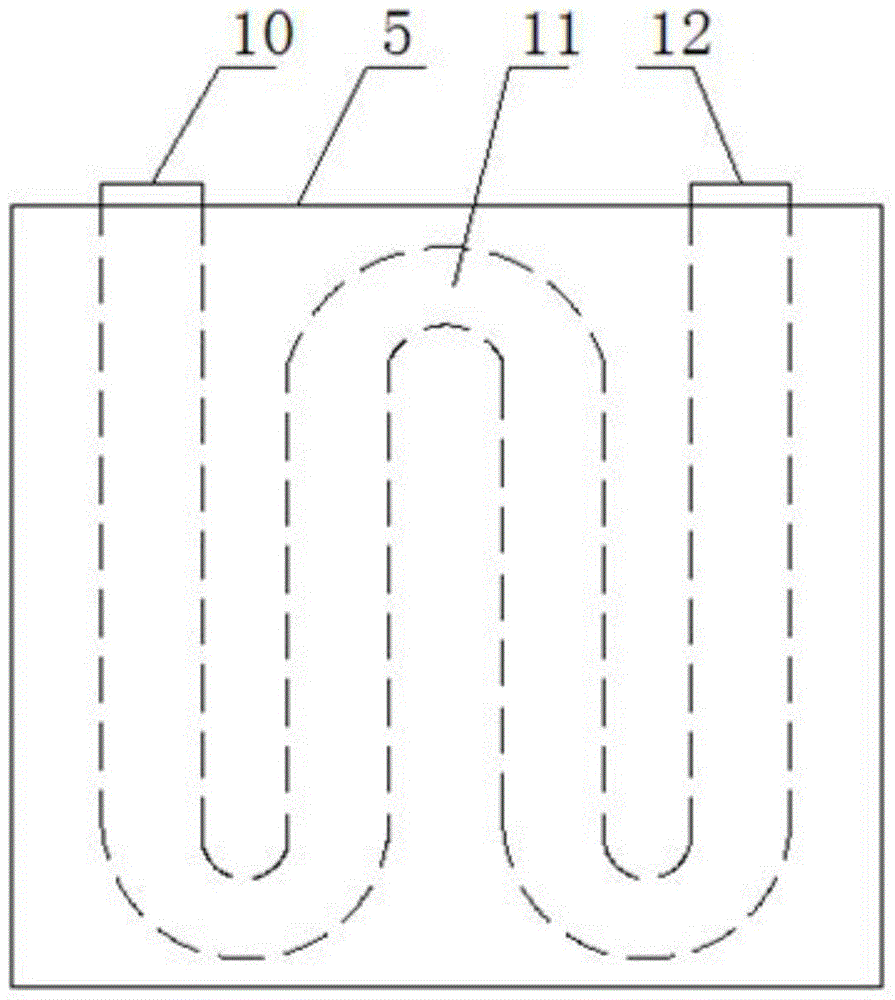

[0026] An internally heated galvanized pot includes a pot body. The innovation is that the pot body is composed of a pot body shell 8 and a pot inner core 6. The pot body shell covers the outside of the pot inner core and also includes heating The heating mechanism is arranged on the inner wall of the inner core of the pot; the heating mechanism is composed of a rectangular shell 5, an anti-corrosion layer 13, a radiant tube 11, a gas pipeline 3, a burner 4, a regulating valve 1 and an exhaust pipeline 9, An anticorrosion layer is provided on the outer surface of the rectangular housing, and a radiant tube is provided inside the rectangular housing. The inlet end of the radiant pipe is connected with the inlet 12 on the top surface of the rectangular housi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com