Patents

Literature

106results about How to "To achieve anti-corrosion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

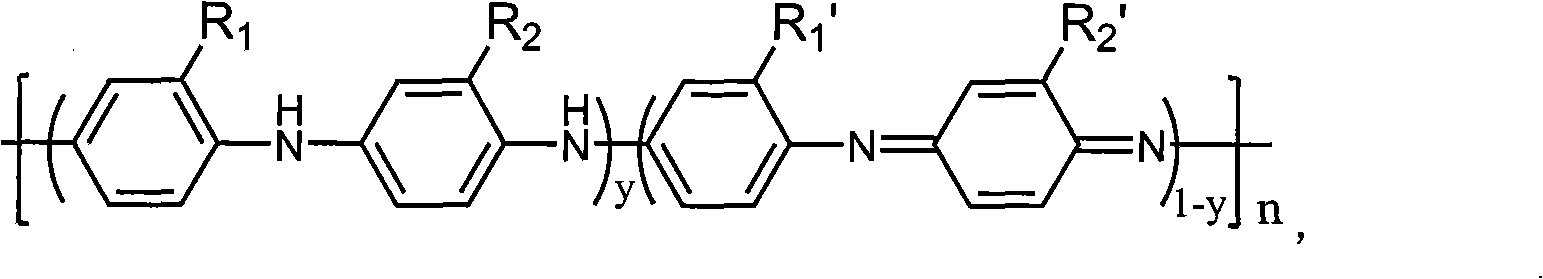

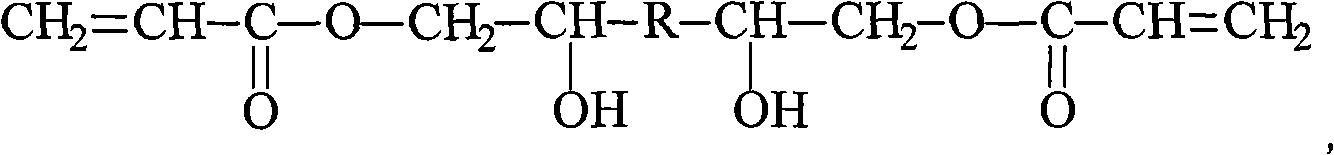

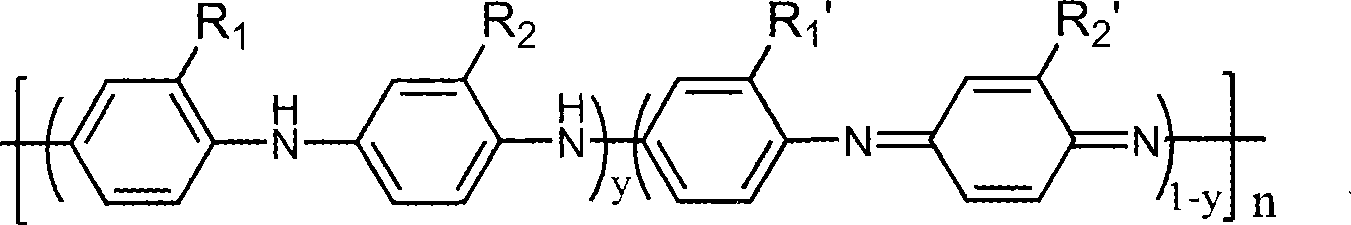

UV curing polyaniline anti-corrosive paint and preparation thereof

InactiveCN101407650AImprove anti-corrosion performanceTo achieve anti-corrosion effectAnti-corrosive paintsPhotoinitiatorChemistry

The invention provides an ultraviolet curing polyaniline anticorrosive coating and a preparation method thereof. The coating adopts polyaniline as a main anticorrosive material, an oligomer, a reactive diluent, the polyaniline, a filler, a photoinitiator and an auxiliary agent are mixed according to a formula, stirred, ground, filtered, and the like, thereby obtaining the ultraviolet curing polyaniline anticorrosive coating. The prepared anticorrosive coating has good anticorrosive effect on different metals, such as steel, copper, aluminum, etc. The coating has stronger corrosion resistance property of acid, base and other media, thereby being applicable to the use in extremely harsh environmental conditions and being particularly applicable to the corrosion resistance in marine environment. The coating does not contain Pb, Cr, Zn and other heavy metals, and the formula does not contain any organic solvents. Therefore, the coating does not have the environmental pollution problem during the production and the using processes and is a completely green environment-friendly coating.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

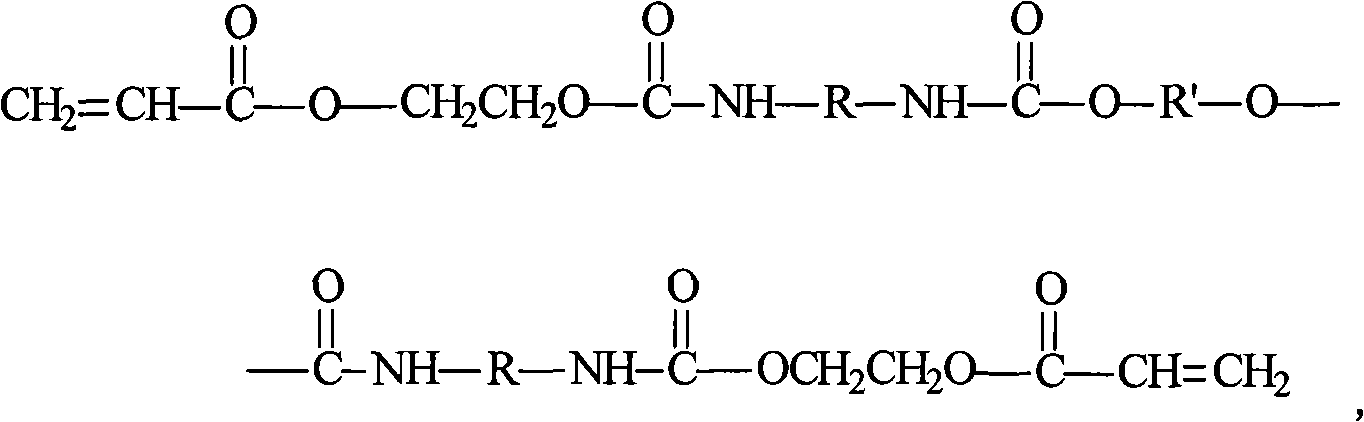

Ultraviolet-heat dual curing polyaniline anti-corrosive paint and preparation method thereof

ActiveCN101418146ANo emission issuesNo pollution problemAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletChromium

The invention provides an ultraviolet-thermal double curing polyaniline anti-corrosive coating and a preparation method thereof. In the coating, polyaniline is adopted as a main anti-corrosive material, and oligomer, a reactive diluent, polyurethane polylol, polyaniline, filler, light trigger and an auxiliary agent are used for preparing filtrate of the coating; and the filtrate and a polyurethane curing agent are stored respectively and uniformly mixed in proportion for use. The anti-corrosive paint has good anti-corrosive effect on different metals, not only can perform ultraviolet curing crosslinking but also can perform thermal curing crosslinking, well overcomes the defect of incomplete curing of an ultraviolet curing anti-corrosive paint, has the characteristics of resisting acid medium corrosion and alkali medium corrosion, is suitable to be used under the condition of a severe environment and particularly suitable for corrosion protection under the condition of a marine environment, does not contain heavy metals such as plumbum, chromium and zinc, and simultaneously does not contain any organic solvent in a formula. Therefore, the coating does not have the problem of environmental pollution during the production process and the use process, and is a completely environment-friendly coating.

Owner:中科应化(长春)科技有限公司

Preservative-free moisturizing firming cosmetic containing natural and organic ingredients

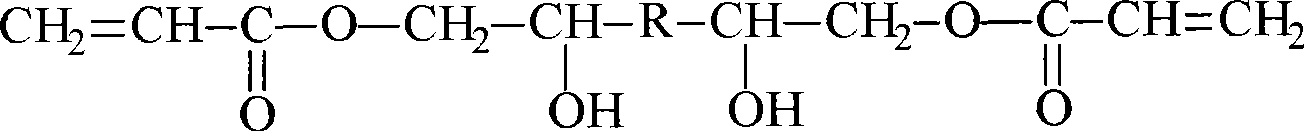

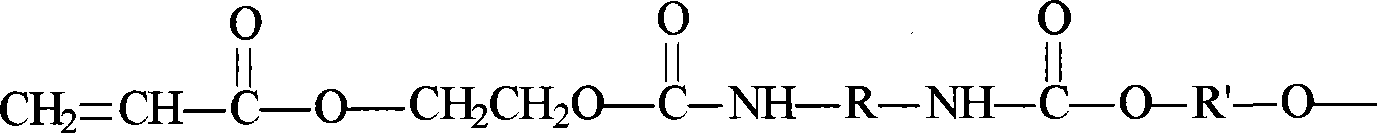

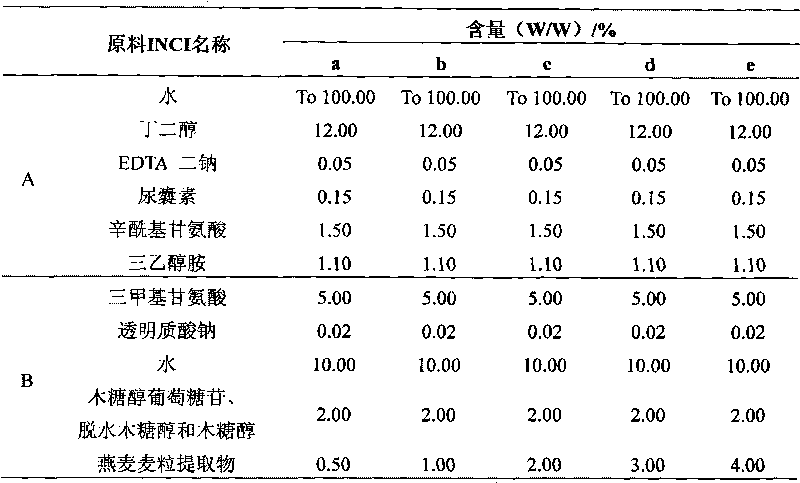

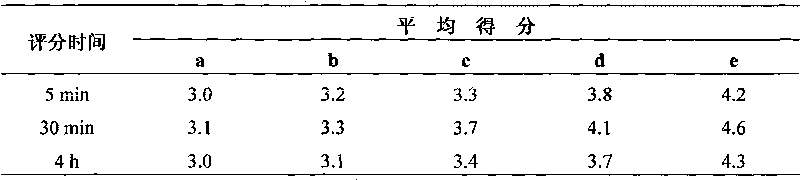

InactiveCN101744757ATo achieve anti-corrosion effectCosmetic preparationsToilet preparationsXYLITYLGLUCOSIDEAdditive ingredient

The invention relates to a group of cosmetic compositions which do not contain preservatives and have the effects of immediate firming, long-acting anti-wrinkle and moisturizing. The cosmetic compositions comprise a freshener, a moisturizer, a cream, an essence and a mask, wherein the moisturizer, the cream and the essence are emulsified products; and a surfactant is organic material coming from the natural plants. In the active ingredients, hydrolysis rhizobian gum and Arabic gum having the immediate firming effect, purified ingredients of natural polysaccharide extracted from oat grains, dipalmitoyl hydroxyproline having the long-acting anti-wrinkle effect, and xylitylglucoside, composition of anhydroxylitol and xylitol, trimethylglycine and sodium hyaluronate having the moisturizing effect are organic materials. The traditional preservatives are not contained in the product, and caprylyl glycine and caprylin substituting for the traditional preservatives come from the plants. The invention relates to an application of the organic materials and materials coming from the plants and a preparation method of the cosmetic.

Owner:GLOBAL COSMETICS HONG KONG CO LTD

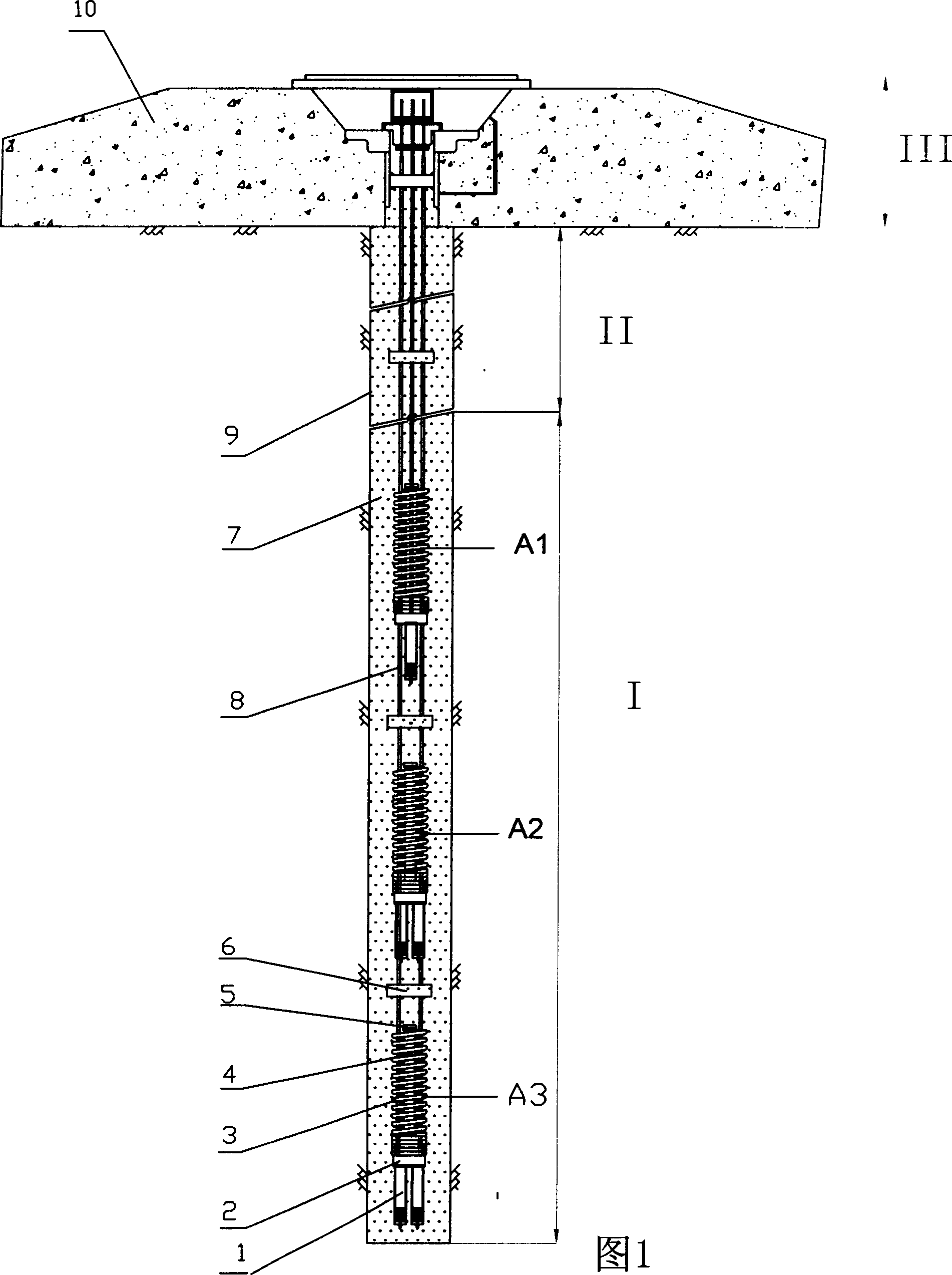

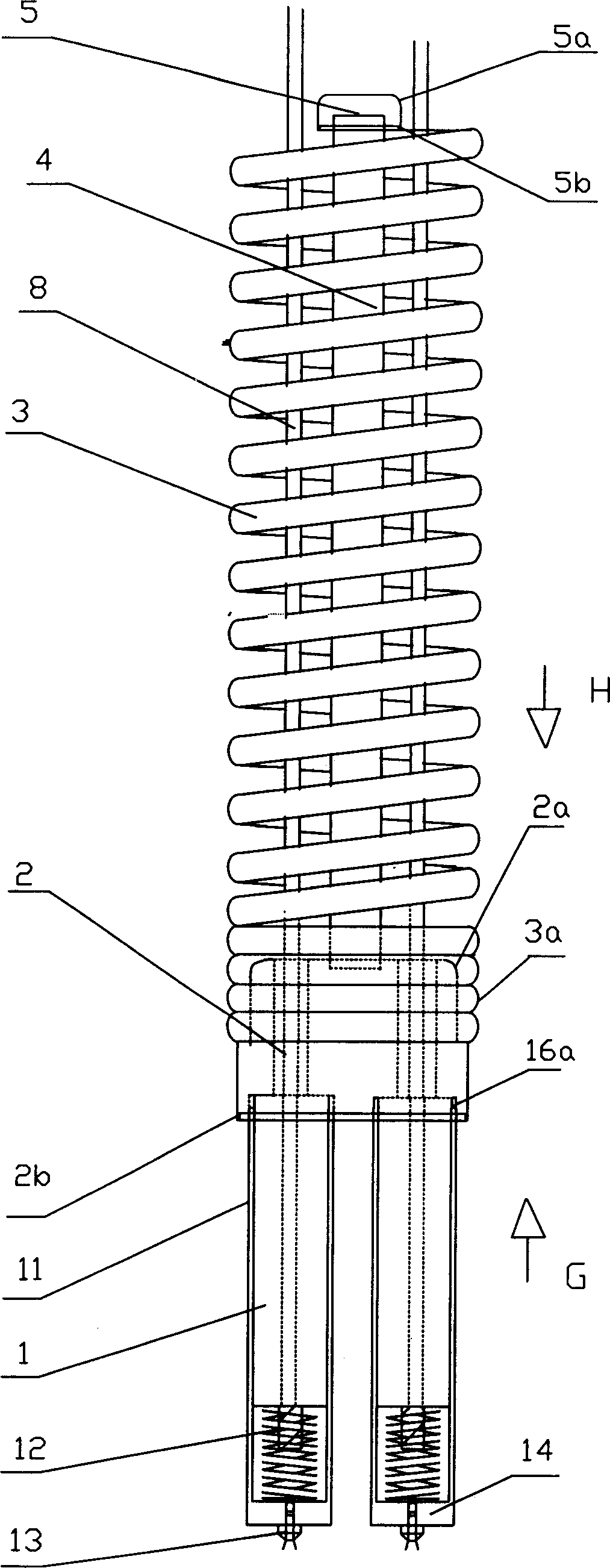

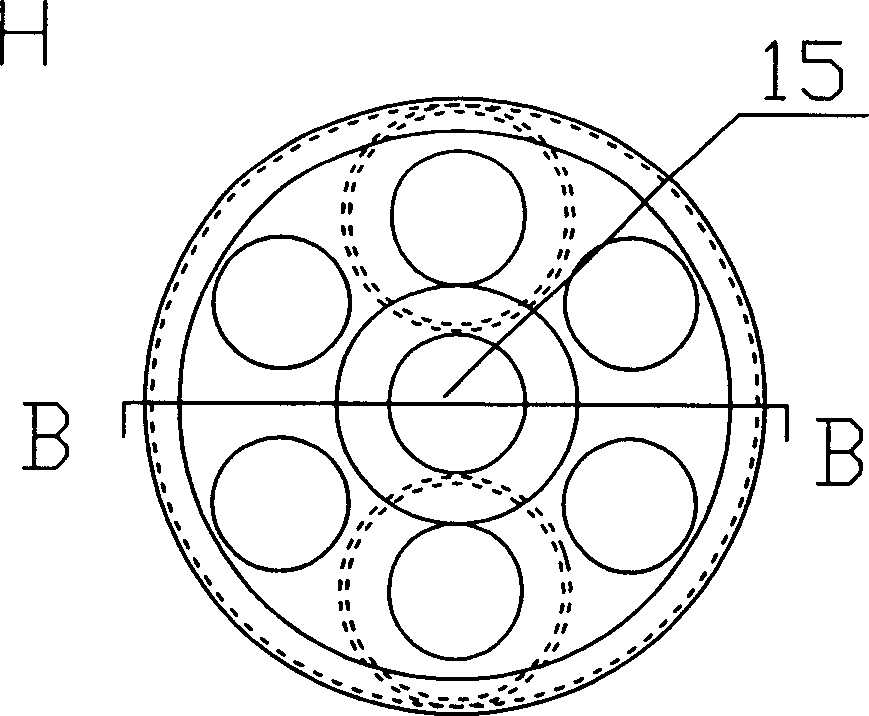

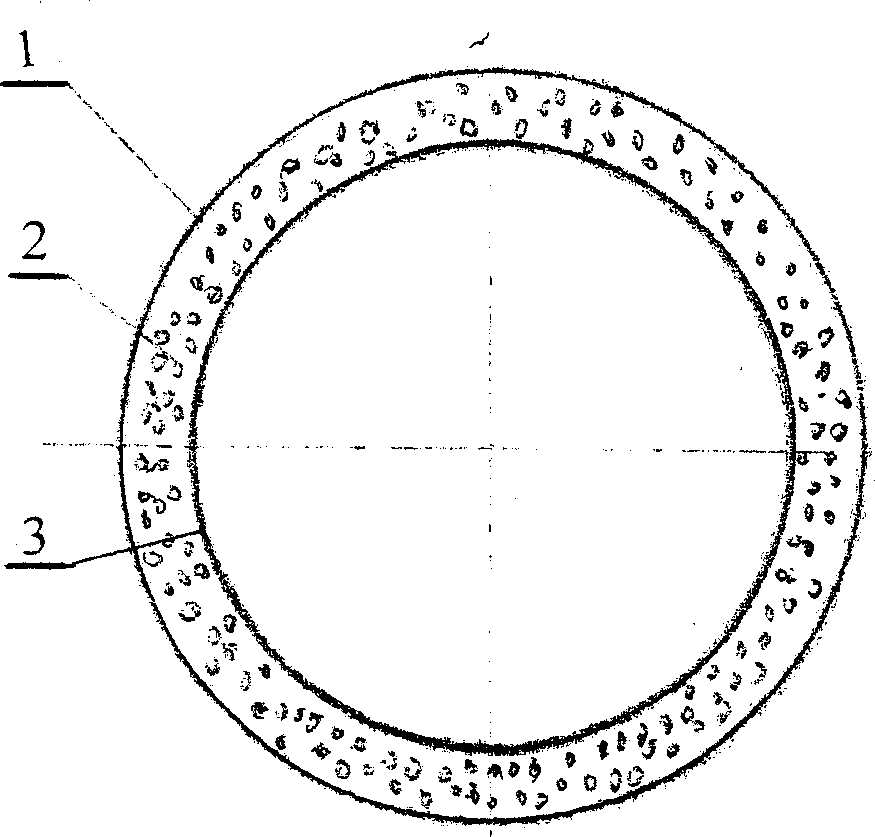

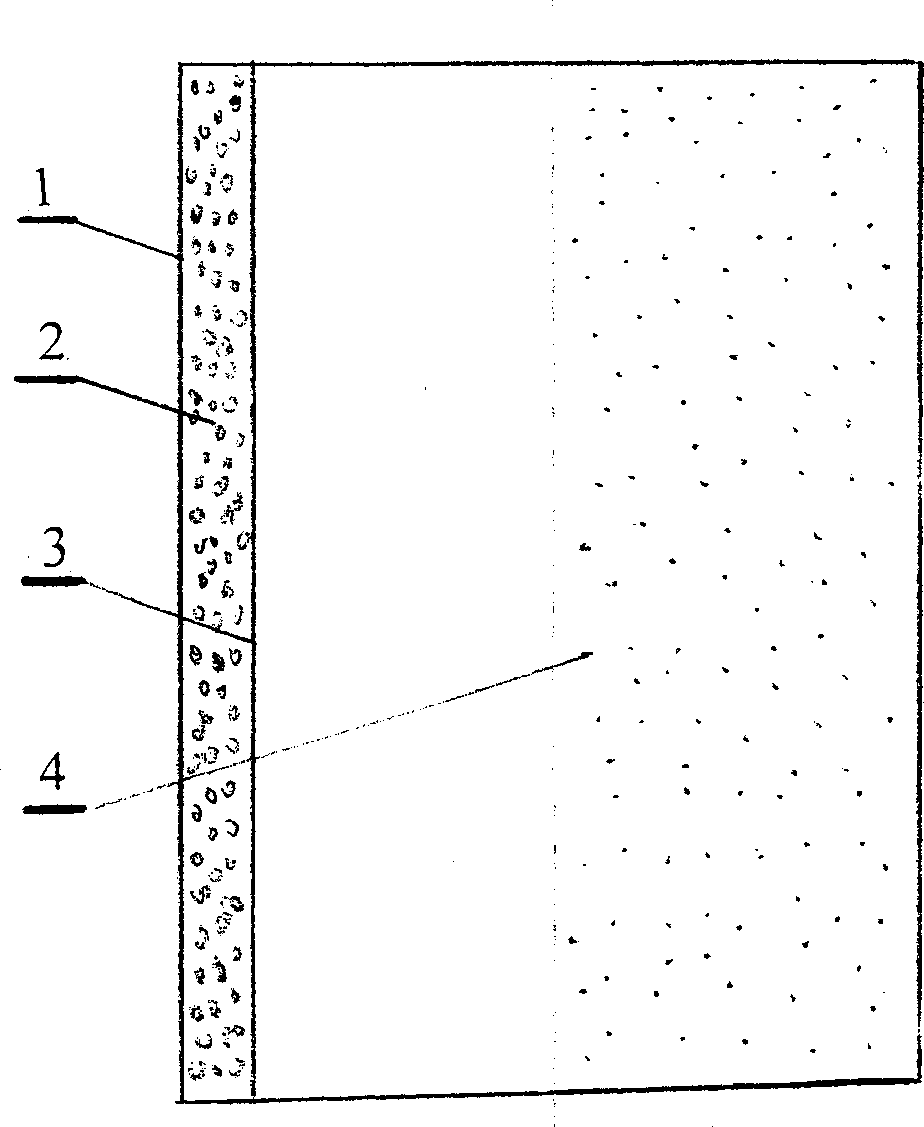

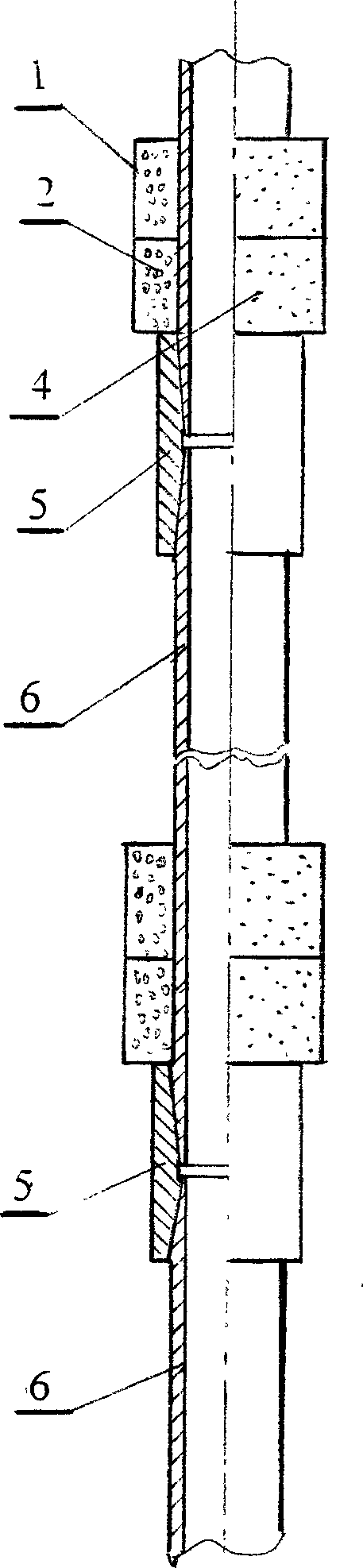

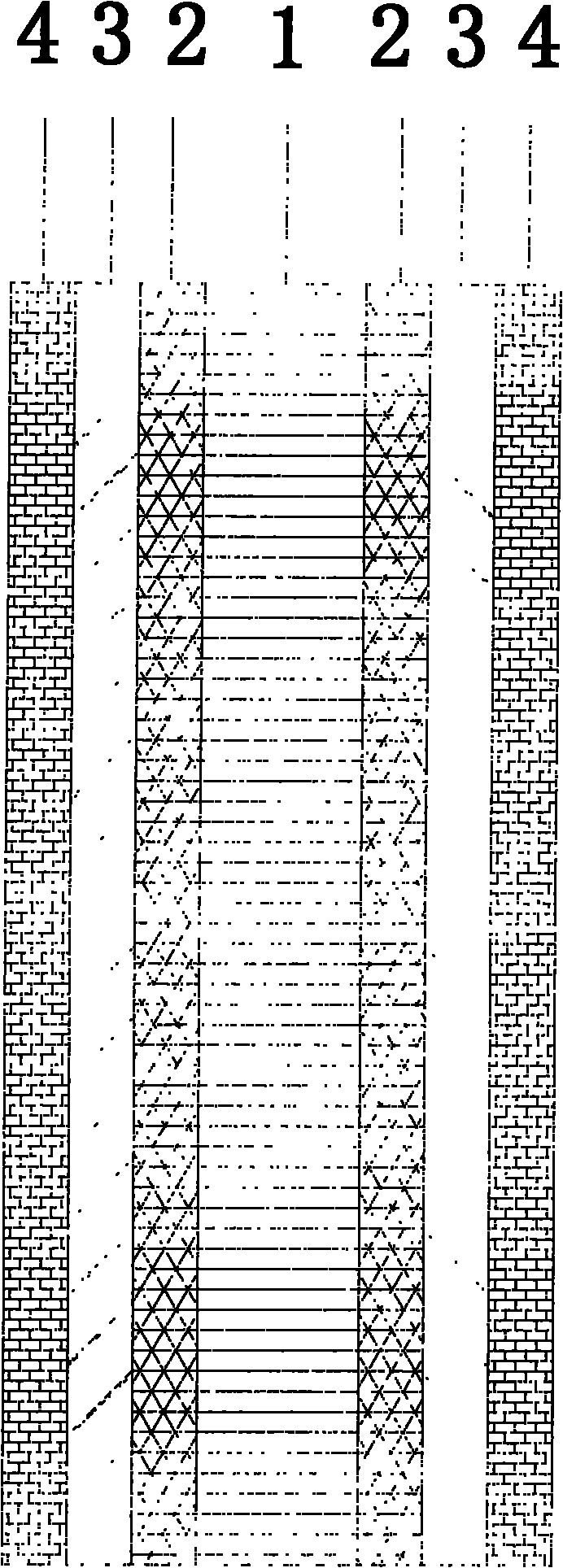

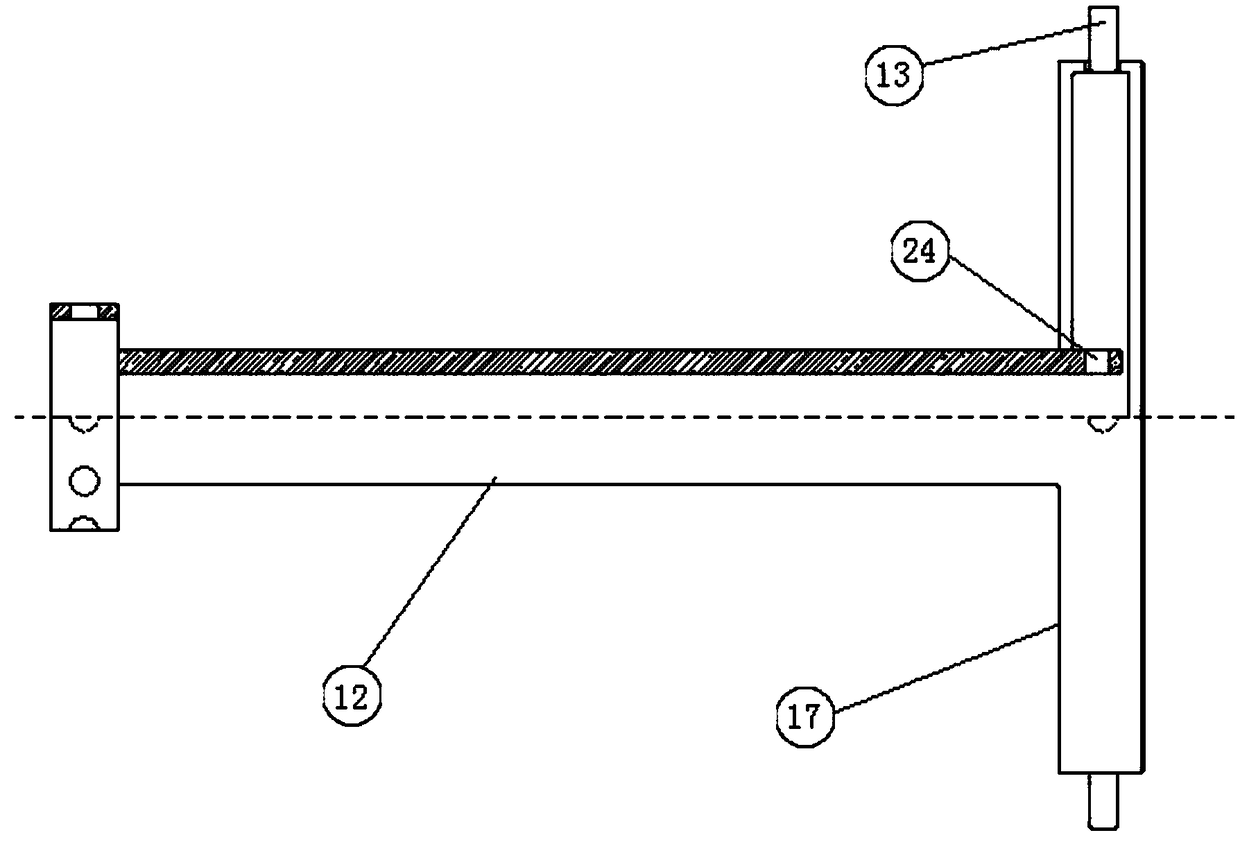

Permanent anchor rope used for side slope stabilization

ActiveCN1651660ANot easy to crackPrevent groundwater infiltrationExcavationsBulkheads/pilesRebarEngineering

The permanent anchor rope for stabilizing slope is composed of external anchoring head, internal anchoring part and free part, and said internal anchoring part is formed from guy rope and more than one group of internal anchoring end bearing components which are distributed along the vertical direction, every group of bearing components has pressure-bearing plate and vertical pressure-beaning column whose lower end is fixedly connected with pressure-bearing plate, and the upper end of the guy rope is anchored to the external anchoring head, and its lwoer end is grouped and distributed in different bearing components, and respectively fixedly connected with pressure-bearing plate of correspondent group bearing component. Said invention can make the stretching force of anchor rope obtain permanent retention.

Owner:李炳奇

Method for producing microbial organic health fruit vinegar beverage by adopting microbial fermentation technology

The invention discloses a method for producing a microbial organic health fruit vinegar beverage by adopting a microbial fermentation technology. In the method, a microbial health product oral liquid production technology is adopted to produce a microbial organic health fruit vinegar beverage by using organic fruit juice as a culture substrate, and organic fruit juice, water, fermented powder (liquid) and traditional Chinese medicines are adopted to produce an organic health fruit juice vinegar beverage. The invention also discloses a preparation method of yeast, lactobacillus, lactococcus lactis and the culture substrate of organic fruit juice and traditional Chinese medicines. The method has the advantages of simpleness, low cost and production cost reduction, the health effect of a microbial health product oral liquid can be achieved by the price of a beverage, and the microbial organic health fruit vinegar beverage has the advantages of low price and good taste.

Owner:曹立江

Viable type lactobacillus fermented litchi juice beverage and preparation method thereof

InactiveCN103815483AShort half-lifeAvoid destructionFood ingredient functionsFood preparationBiotechnologyLychee fruit

The invention discloses a viable type lactobacillus fermented litchi juice beverage and a preparation method thereof, and the prepared litchi juice beverage is rich in active lactobacilli. The preparation method comprises the following steps: preparing litchi juice, adding DMDC into the litchi juice, allowing the litchi juice to stand still for 2 to 3 hours at a room temperature, adjusting the pH value to a range of 6 to 7, and adding lactobacilli to carry out fermentation so as to obtain the fermented litchi juice beverage. The preparation method utilizes DMDC to carry out a sterilization treatment on litchi juice at a room temperature, thus the flavor and nutrient destruction caused by the conventional pasteurization is avoided, and the fermentation effect of lactobacilli is not influenced either. The fermented litchi juice beverage is rich in active lactobacilli; the thickening effect can be achieved and the pulp precipitation phenomenon can be avoided without any thickening agent and stabilizing agent, because lactobacilli can generate a large amount of extracellular polysaccharide; and at the same time the beverage has a proper sweet and sour taste, a smooth and sticky mouth feel, and a rich litchi flavor, is accord with the food safety and sanitation standards, is also accord with the natural and healthy food theory, and has a very good market prospect.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

Formula, preparation method of solid corrosion inhibitor and its using method

The invention relates to a high temperature resistant solid corrosion inhibitor manufacturing and using method used in oil pipe and casing pipe. Its raw material preparation weight ratios are as follows: some dibasic acid 20-35%, diethylene triamine 5-15%, chloroacetic acid 5-15%, and sodium dodecyl benzene sulfonate, hexamethenyl tetramine, HPMA, poly epoxy succinic acid, epoxy resin, polyamide resins etc. The manufacturing method includes composing intermediate, preparing solid inhibitor, solidifying, forming, cooling to gain solid inhibitor finished product.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

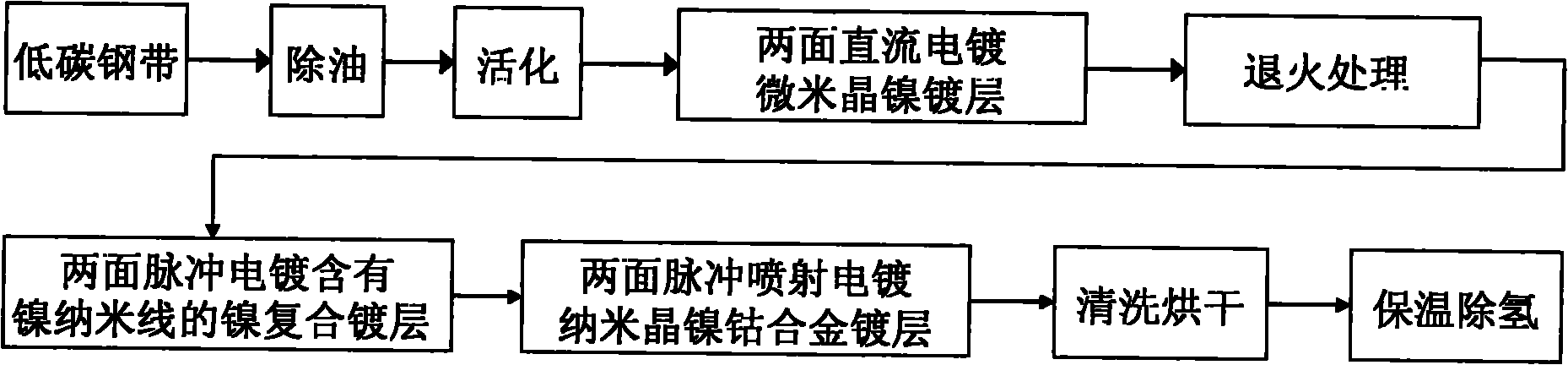

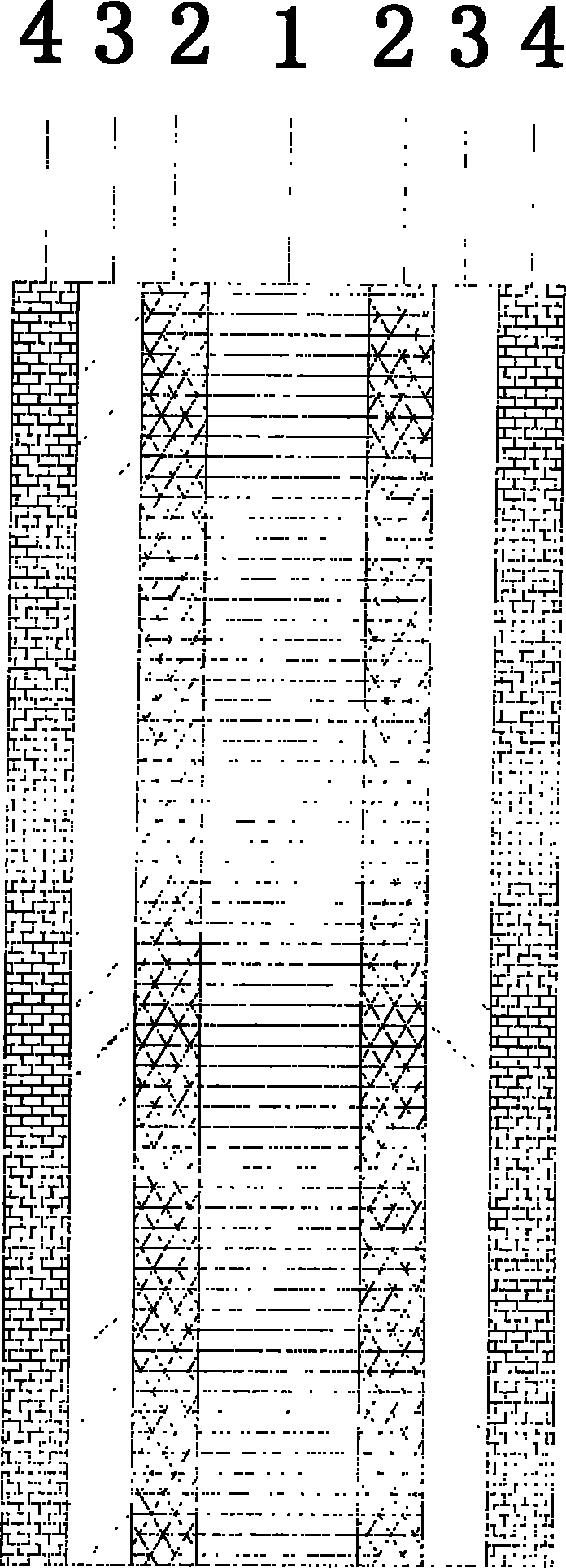

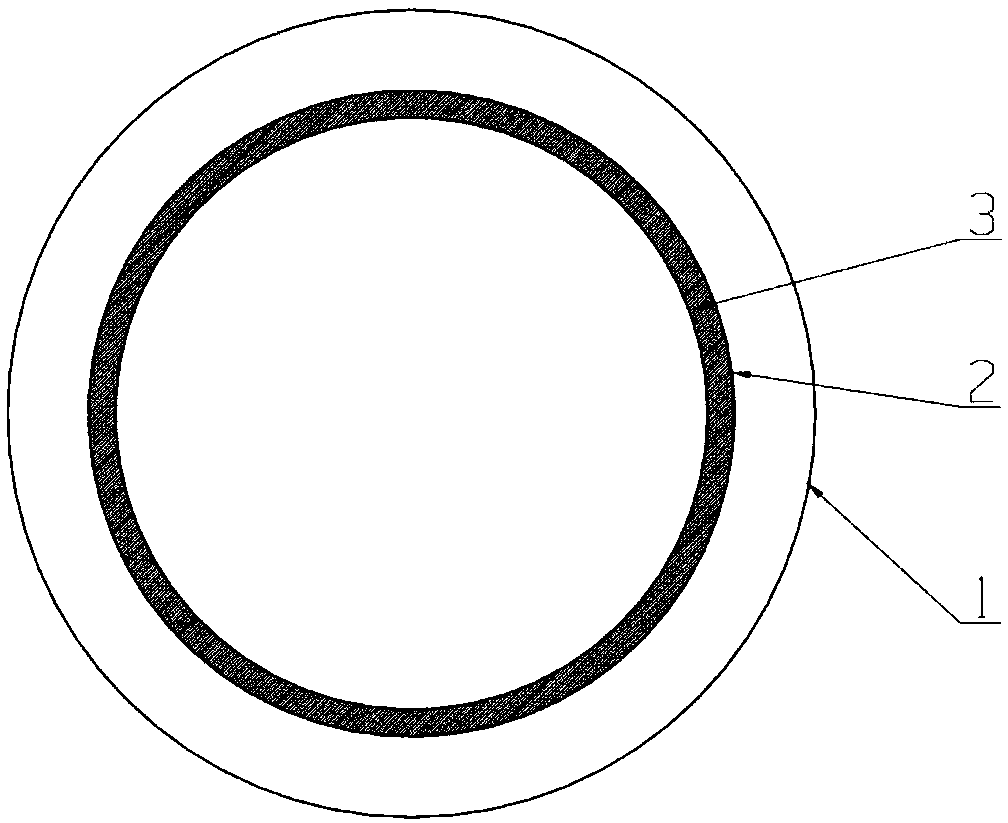

Nickeliferous nanowire laminated film plated steel belt and production method thereof

ActiveCN101954763AReduce corrosion rateHigh strengthElectrolytic coatingsCell component detailsNanowireMetallic Nickel

The invention discloses a nickeliferous nanowire laminated film plated steel belt and a production method thereof. A steel belt is used as a base, and both faces of the steel belt are respectively plated with a nickeliferous nanowire multilayer laminated film. The bottom layer of the nickeliferous nanowire multilayer laminated film is a micron-crystalline nickel plating layer, the middle layer isa nickeliferous nanowire nickel laminated plating layer, and the surface layer is a micron-crystalline nickel cobalt alloy plating layer. The invention also provides the production method of the steel belt, which comprises the following steps of: oiling and activating the base steel belt, and firstly preparing one micron-crystalline nickel plating layer on the base by using a DC electroplating mode; after annealing, preparing one nickeliferous nanowire nickel laminated plating layer on the nickel plating layer by using a pulse electroplating mode; then, preparing one micron-crystalline nickelcobalt alloy plating layer on the nickeliferous nanowire nickel laminated plating layer by using a pulse spraying mode, cleaning by using distilled water and drying; and finally, preserving temperature and removing hydrogen. The steel belt is formed by tightly combining the nickeliferous nanowire multilayer laminated film and a mild-carbon steel belt together, has good corrosion resistance, stamping performance and strong load resistance and can be applied to shell materials of lithium ion power batteries and high-performance alkaline manganese batteries.

Owner:XIANGTAN UNIV

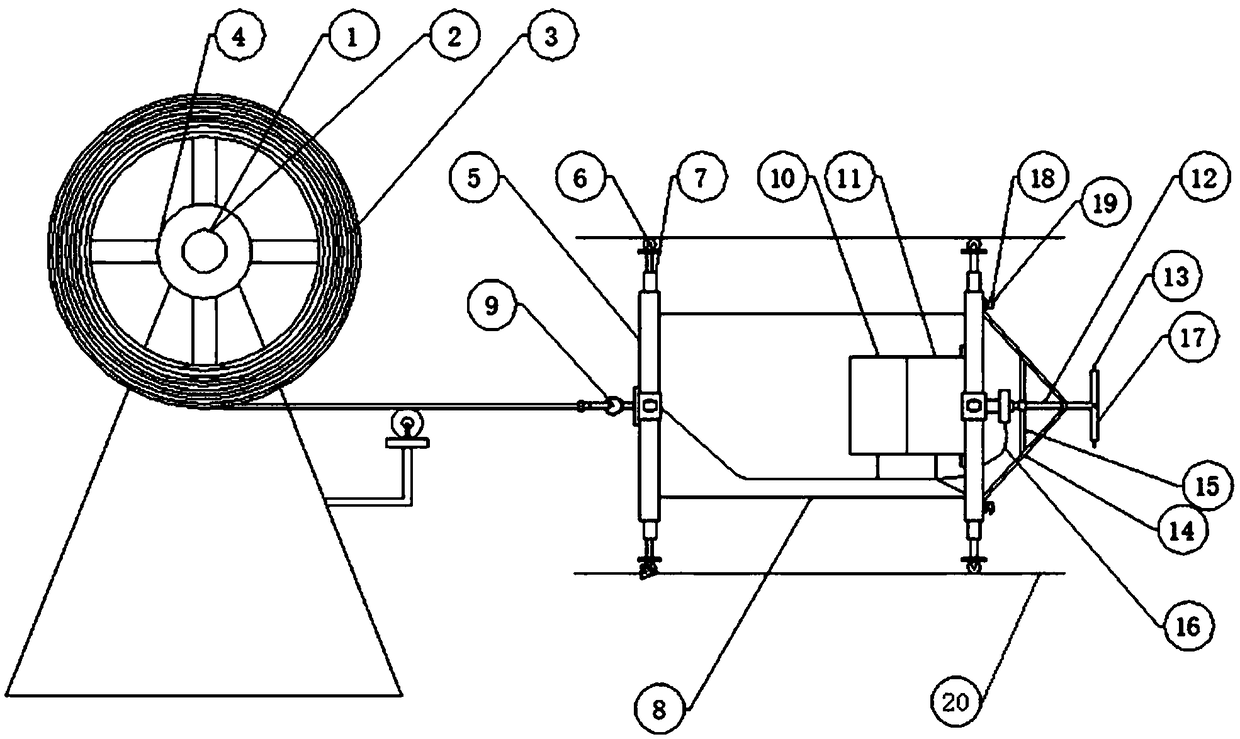

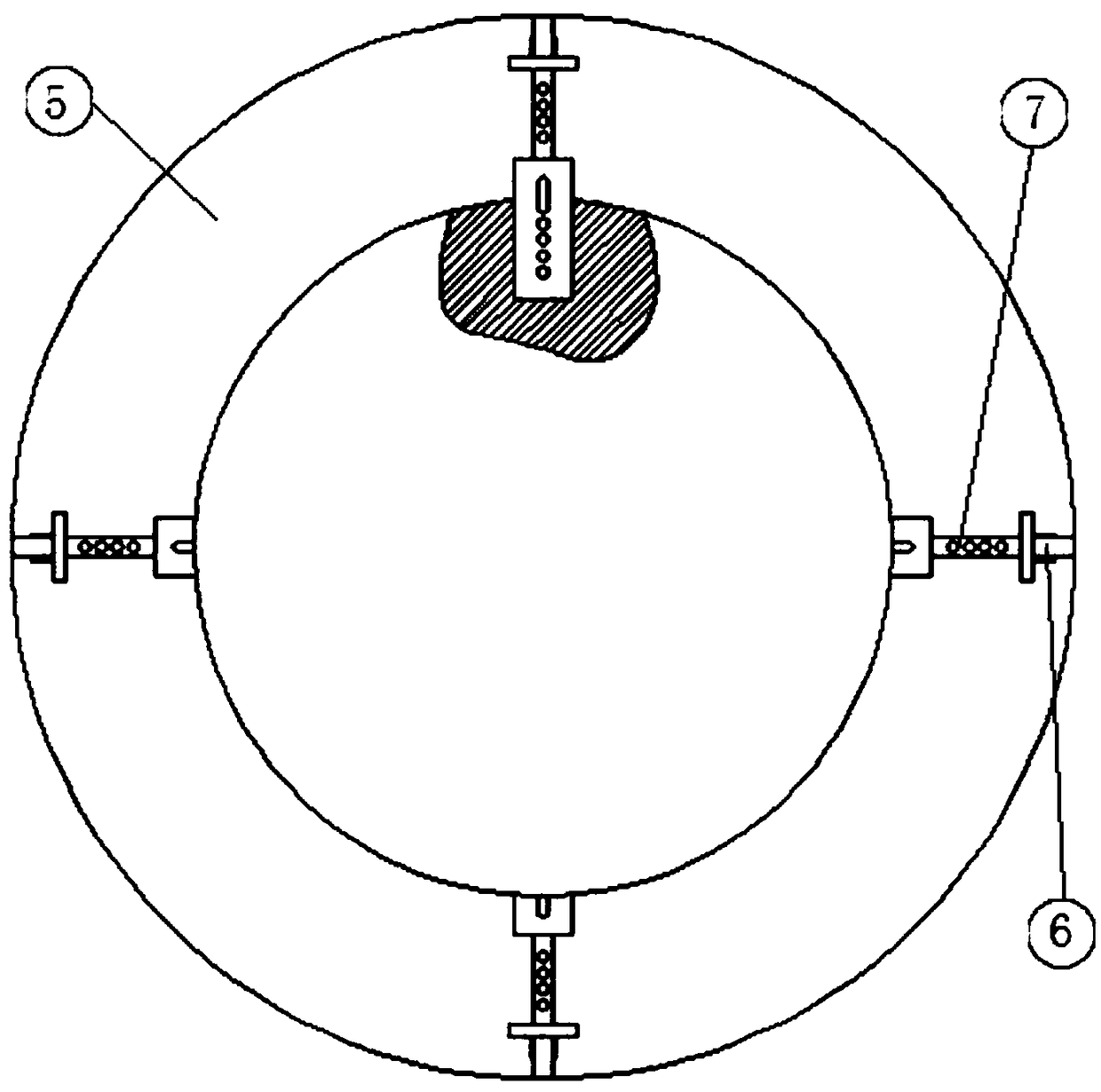

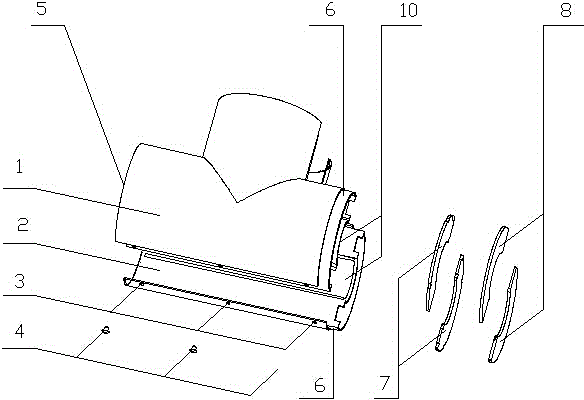

Coating spraying device for interior of thin and long pipeline

InactiveCN109277235AMeet spraying requirementsEasy to receiveLiquid spraying apparatusReducerEngineering

The invention relates to a coating spraying device for the interior of a thin and long pipeline. The coating spraying device comprises a walking mechanism, a spraying mechanism and a camera device. The walking mechanism comprises a first motor, a first speed reducer, a chain transmission mechanism, a runner and two supporting plates provided with spring control supporting wheels. Multiple connecting rods are arranged between the two supporting plates, and the spring control supporting wheels are installed on the supporting plates through spring control supporting wheel rods. A chain in the chain transmission mechanism is wound around the runner, and the chain is connected with the supporting plates through a buckle structure. The spraying mechanism comprises a coating transmission shaft, arotating nozzle, a material conveying pipe and a material disc. The coating transmission shaft is in transmission connection with an output shaft of a second speed reducer. The coating transmission shaft is of a hollow structure, and a small hole is formed in the shaft wall of the coating transmission shaft. The material disc is installed at the head portion of the coating transmission shaft, andthe rotating nozzle is installed on the material disc. The camera device comprises a camera and an illumination lamp. Compared with the prior art, the coating spraying device can be suitable for thinand long pipelines with the pipeline inner diameter being 100 mm to 600 mm, and the spraying conditions in the pipelines can be observed conveniently.

Owner:SHANGHAI INST OF TECH

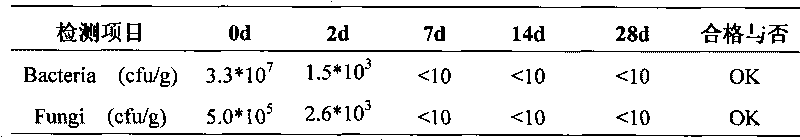

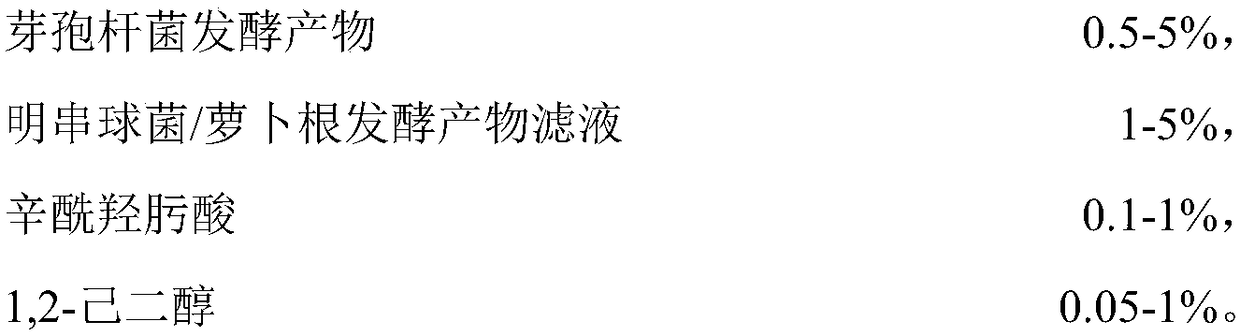

Functional composition containing plant bacterium-inhibiting polypeptide as well as preparation method and application thereof

ActiveCN108323531AMaintain healthMaintain balanceBiocideCosmetic preparationsChemical synthesisSide effect

The invention discloses a functional composition containing plant bacterium-inhibiting polypeptide as well as a preparation method and application thereof. The composition is prepared from the following components: a bacillus fermentation product, leuconostoc / radish root fermentation product filtrate, octyl hydroxamic acid and 1,2-hexanediol. Antibacterial peptide and polyol are matched accordingto different antibacterial spectrums to be used as bacterium-inhibiting components, and replace or partially replace a traditional chemically-synthesized preservative; a preservative-free system of anaddition-free preservative-free concept can be completely supported; the functional composition has moderate properties, no irritation and no toxic and side effects, and lower allergy; the functionalcomposition helps to keep ecological health and balance of skin, so that the safety of a biological preparation is improved. The bacterium-inhibiting components have good compatibility with most materials, the bacterium-inhibiting capability is not influenced by other materials and the stability of a preparation is not influenced; meanwhile, the functional composition has better experience in theaspects of moistening feeling, comfort degree and skin brightness.

Owner:SHENZHEN GENE BIOLOGICAL TECH

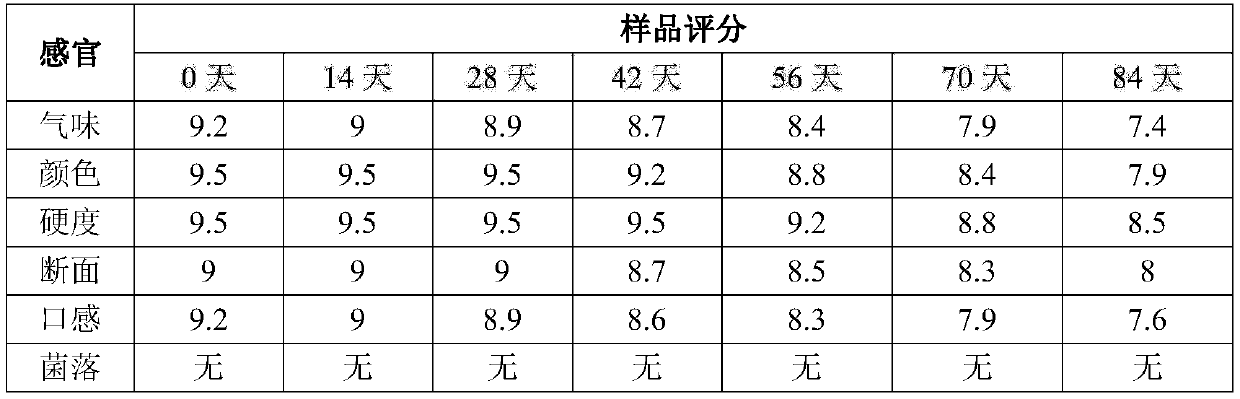

Pickled vegetables without artificial preservative and preparation method of pickled vegetables

The invention discloses pickled vegetables without an artificial preservative and a preparation method of the pickled vegetables. The pickled vegetables are prepared from, by weight, 0.01-0.5 part of lactic acid bacteria, 85-95 parts of main material, 2-10 parts of auxiliary materials and 100-300 parts of fermentation liquor. According to the pickled vegetables without the artificial preservative and the preparation method of the pickled vegetables, metabolites generated by means of fermentation of lactobacillus plantarum, leuconostoc mesenteroides, lactobacillus brevis and ethanol-tolerant pediococcocci and antibacterial ingredients in the auxiliary materials synergistically inhibit growth of sundry bacteria, the production process of the pickled vegetables is optimized and controlled, and therefore the pickled vegetables which are free of artificial preservative and long in quality guarantee period are prepared; the pickled vegetables are high in content of nutritional ingredients and unique in flavor.

Owner:四川江中源食品有限公司

Instant water-boiled minced fillet product with prolonged shelf-life and manufacturing method thereof

ActiveCN103734795AInhibition of reproductionAdd lessFood ingredient for microbe protectionFood preparationBiotechnologyMonosodium glutamate

The invention discloses an instant water-boiled minced fillet product with a prolonged shelf-life and a manufacturing method thereof. The product is composed of the following raw materials in parts by weight: 45 to 60 parts of minced fillet, 7 to 10 parts of fat, 0.05 to 0.25 part of potassium sorbate, 0.5 to 2.5 parts of salt, 0.05 to 0.25 part of phosphate, 3 to 9 parts of maltose syrup, 0.2 to 0.8 part of monosodium glutamate, 0.05 to 0.3 part of spice, 0.05 to 0.3 part of seafood essence, 7 to 11 parts of starch, and 18 to 25 parts of water. The product has the following advantages: maltose syrup is added to inhibit the microorganism breeding in the product so as to achieve an antiseptic effect, and furthermore, the white sugar can be partly or even completely displaced by maltose syrup so as to reduce the production cost; moreover, a drying technology is adopted during the production process, thus the water content in the product is reduced, so that the shelf-life of the product is prolonged, and the problem of unqualified shelf-life is solved.

Owner:SHANDONG HUIFA FOODS

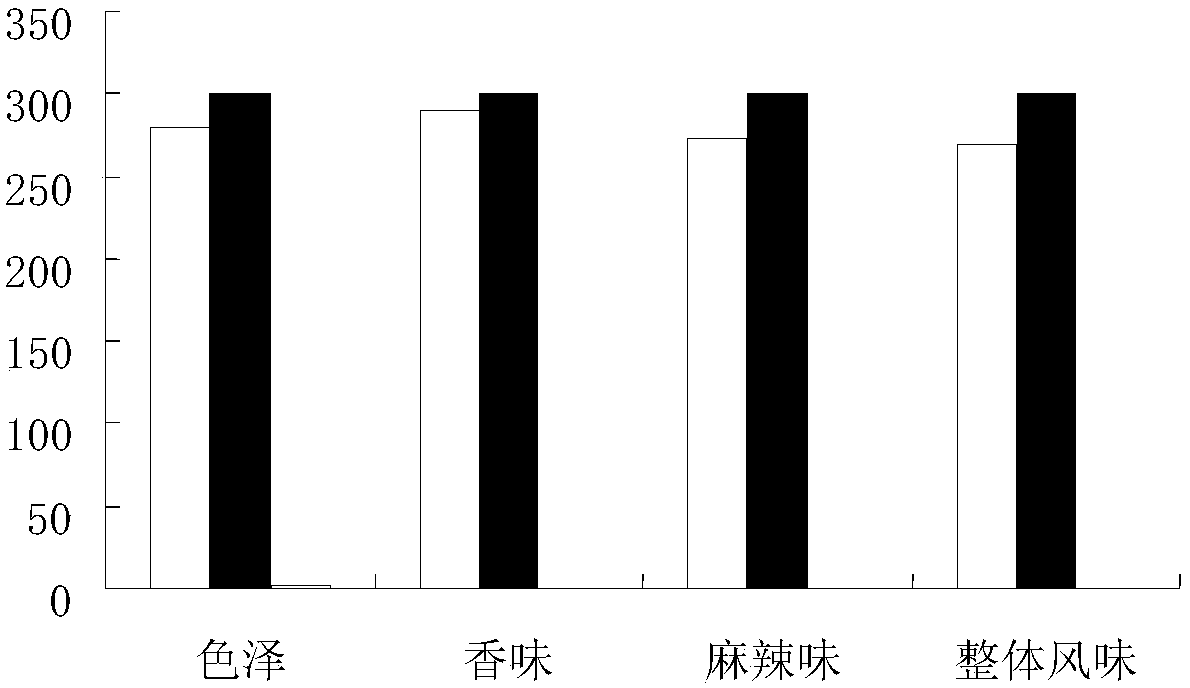

Sichuan flavor old bittern seasoning and preparation method thereof

The invention relates to the technical field of food processing, and provides Sichuan flavor old bittern seasoning and a preparation method thereof. The Sichuan flavor old bittern seasoning is prepared by the raw materials, by weight, of 25-32 parts of edible oil, 8-9 parts of dark soy sauce, 7-9 parts of bean halves, 3-5 parts of monosodium glutamate, 8-10.5 parts of white granulated sugar, 3-5 parts of ginger powder, 3-4 parts of caramel color, 6-8 parts of white wine, 0.8-0.92 part of bittern essence, 3-5 parts of red pepper seeds, 0.3-0.4 part of star anise powder, 9-10.5 parts of spice, 0.025-0.036 part of ethyl maltol, 0.1-0.2 part of capsicum oleoresin, 9-11 parts of two thorns pepper, 9-10.5 parts of edible salt and 1.2-1.5 parts of chicken essence seasoning. Bittern dishes cooked by the Sichuan flavor old bittern seasoning which is prepared by the technical scheme are golden in color and luster, rich in flavor, pleasant in aroma, smooth but not greasy and popular among consumers.

Owner:四川天味食品集团股份有限公司

Covering and sunscreen cream and preparation method thereof

InactiveCN108324626ANatural tasteGood effectCosmetic preparationsBody powdersSodium hyaluronateChemistry

The invention discloses a covering and sunscreen cream and a preparation method thereof. The covering and sunscreen cream is mainly prepared from the following components: water, glycerol, polydimethylsiloxane / vinyl polydimethylsiloxane cross-linked polymer, phenyl trimethicone, cyclopentasiloxane, trimethylsiloxysilicate, sodium hyaluronate, isononyl isononanoate, polyglycerol-2 triisostearate, methyl methacrylate cross-linked polymer, beta-glucosan, magnesium sulfate, nicotinamide, oligopeptide-1, ceramide3, panthenol, ginseng root extract, illicium verum fruit extract, scutellaria baicalensis root extract, sweet orange peel oil, aloe extract, white willow bark extract, witch hazel extract, CI 77492, and CI77491. The covering and sunscreen cream prepared by the preparation method throughscientific proportion solves the problem that a chemical preservative and a chemical conditioning agent are added into conventional cream to harm skin of people.

Owner:甘永恒

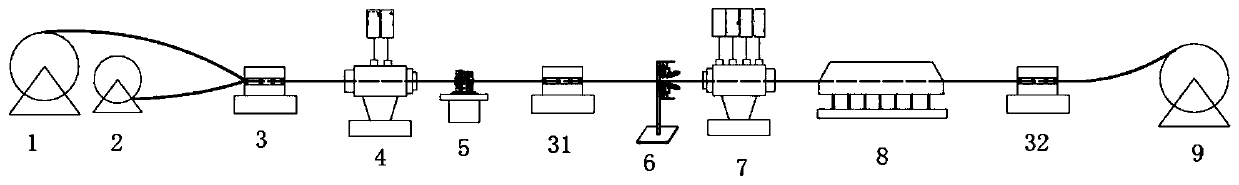

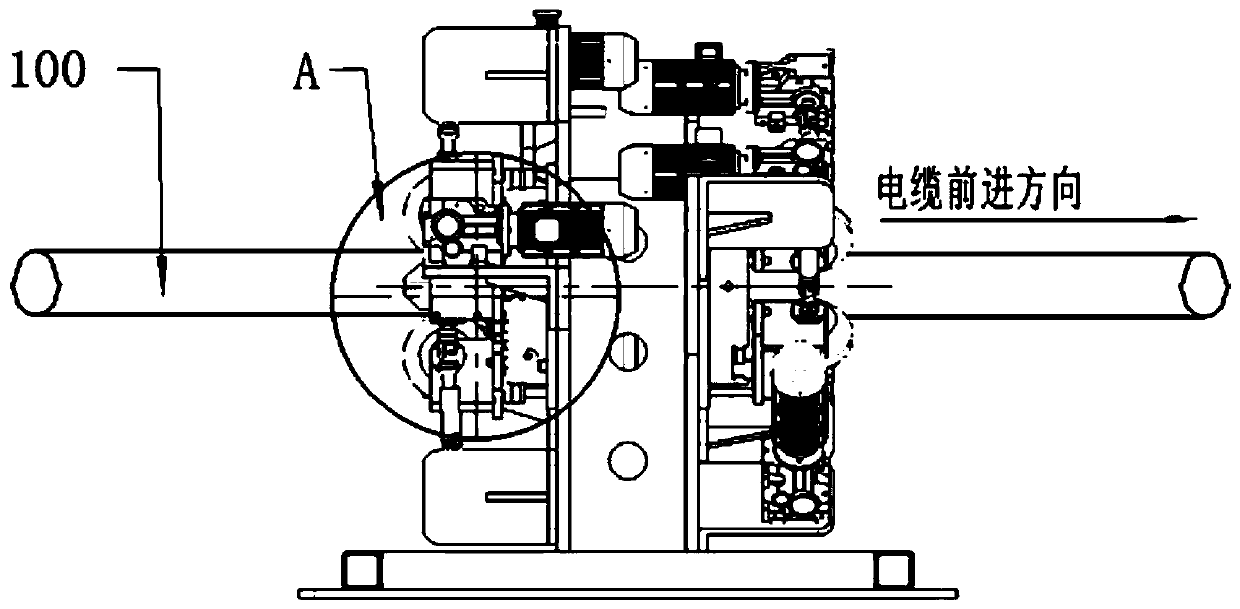

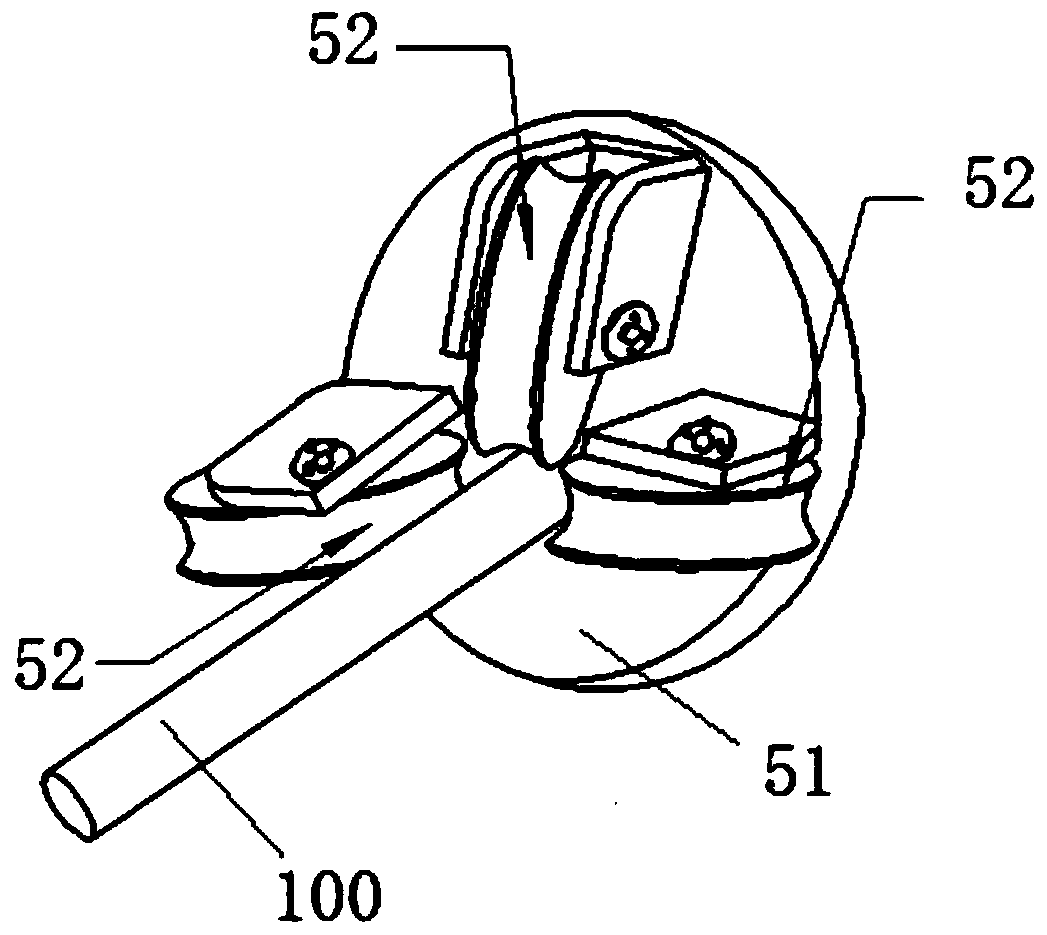

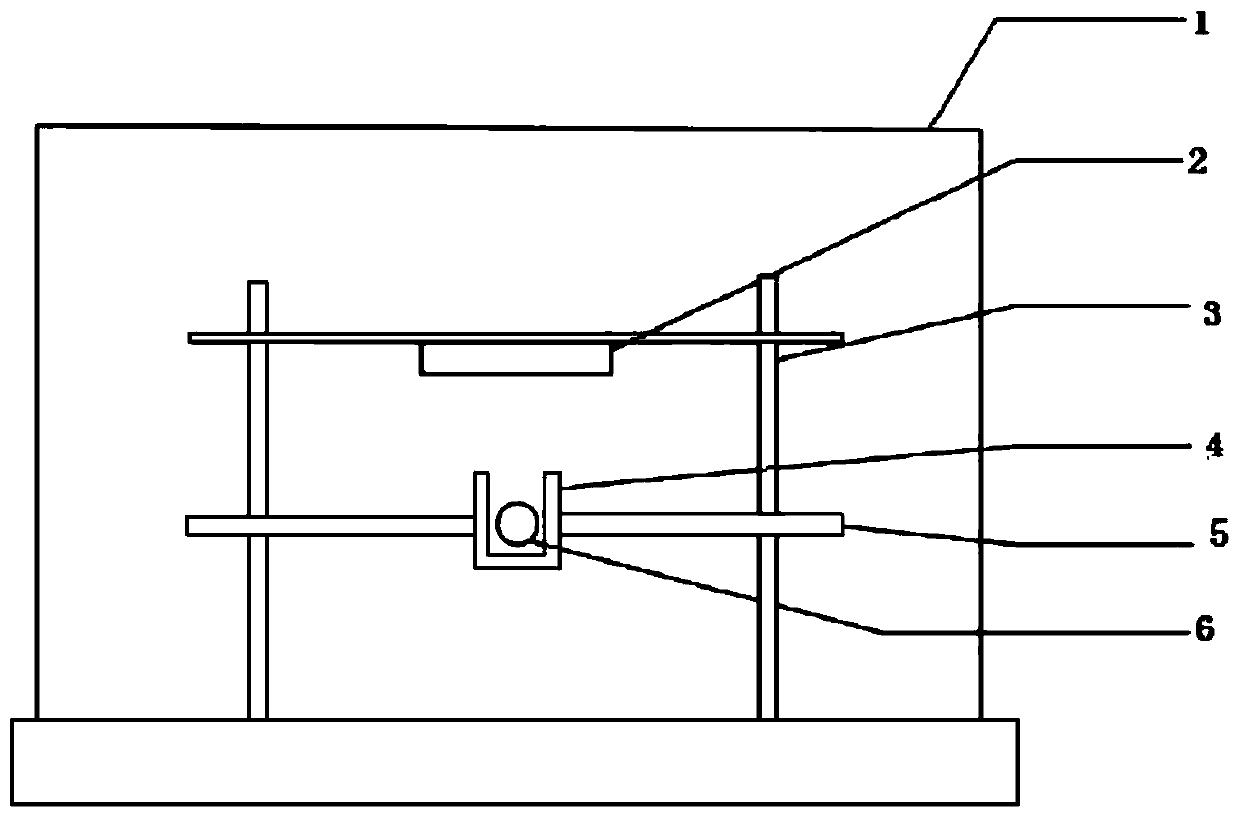

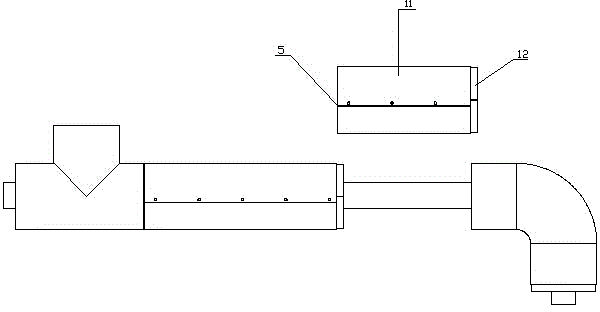

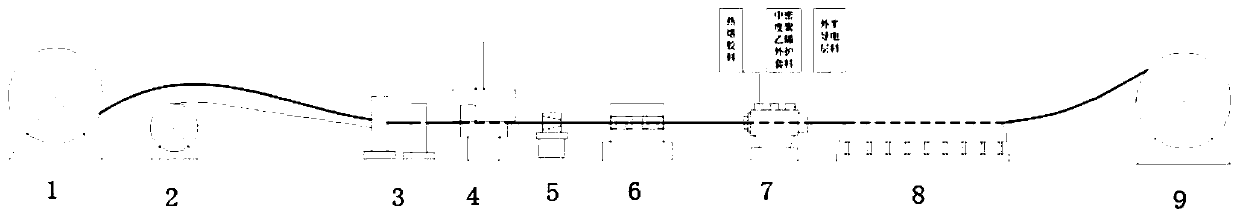

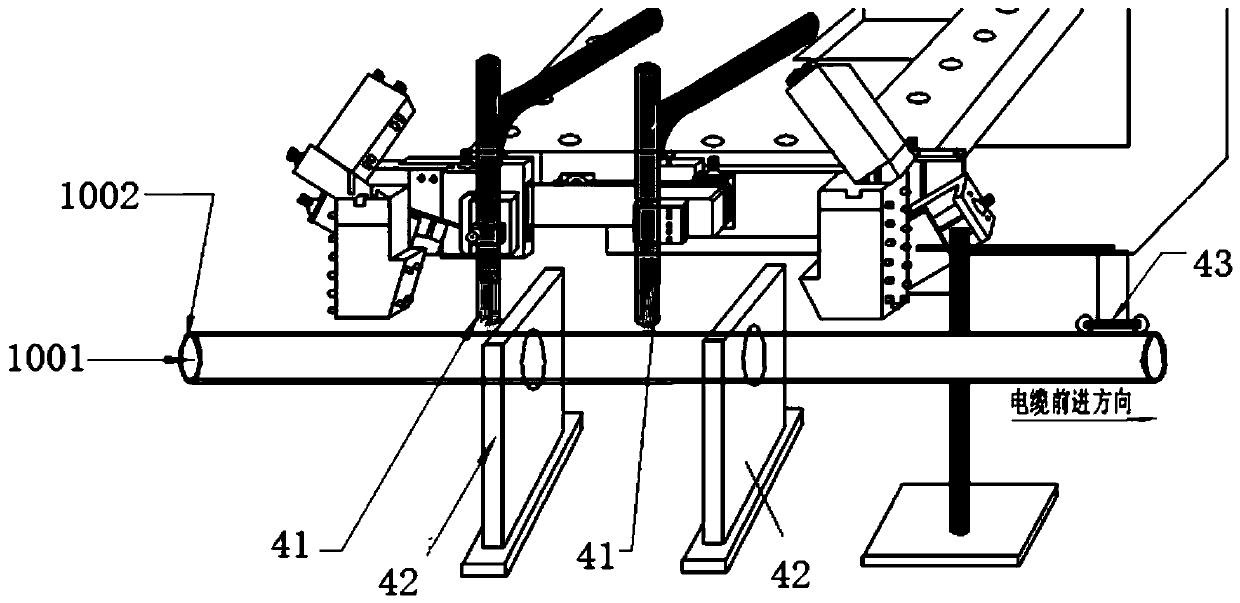

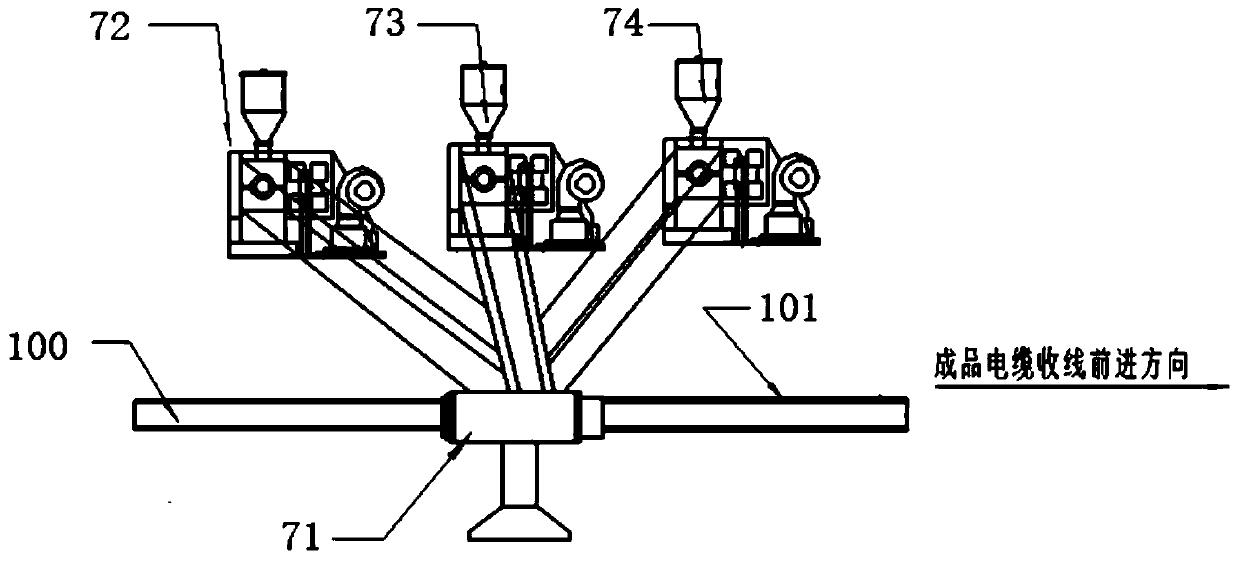

Extruded composite smooth aluminum sleeve cable production equipment and a production method

PendingCN111524657AReduce manufacturing costCompact structureInsulated cablesCable/conductor manufactureEngineeringHot melt

The invention discloses extruded composite smooth aluminum sleeve cable production equipment and a production method. The production equipment comprises an extruded aluminum sleeve device, a wheel type reducing device, a preheating device, a multi-layer co-extrusion device and a cooling water tank, and the extruded aluminum sleeve device continuously extrudes an aluminum sleeve; the cable coated with the aluminum sleeve passes through a shaft hole, and the aluminum sleeve is tightened to the outer diameter designed by the process by the wheel type reducing device, so that the whole aluminum sleeve is coated on the surface of the cable core; the preheating device is used for heating the aluminum sleeve; the multi-layer co-extrusion device is used for compounding the aluminum sleeve with thehot melt adhesive, a PE sheath, a PVC sheath and a conductive layer together and carrying out cooling molding through the cooling water tank. According to the hot melt adhesive extrusion technology designed by the invention, the hot melt adhesive not only achieves an anti-corrosion effect, but also achieves a bonding effect, so that the PE sheath, the PVC sheath, the conductive layer and the smooth aluminum sheath of the cable are firmly bonded together, and the phenomena of arching or wrinkling cannot be generated during bending, take-up and construction of the cable.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

Method for preparing MgZn2, Zn and oxide three-layer antiseptic films on surfaces of magnesium alloys

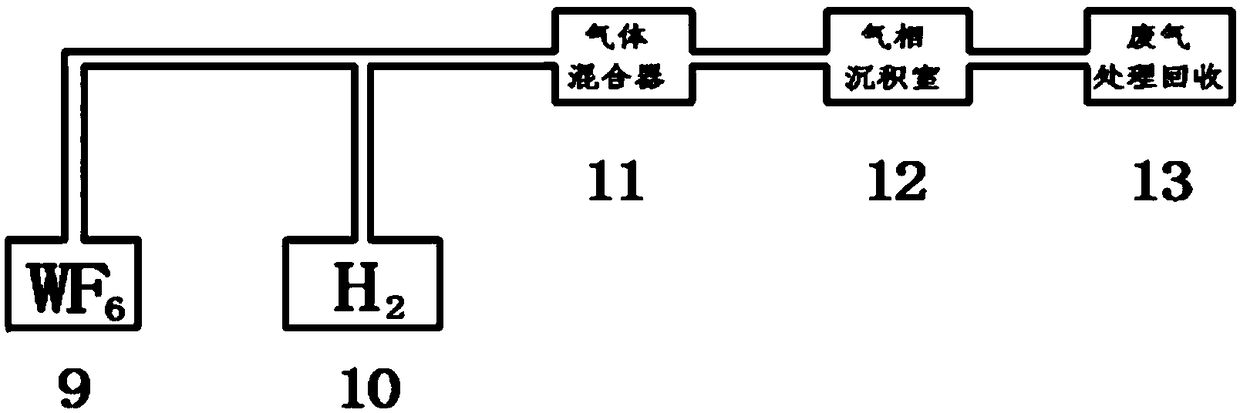

ActiveCN110512175ATo achieve anti-corrosion effectAvoid contactVacuum evaporation coatingSputtering coatingAlloy elementCorrosion

The invention discloses a method for preparing MgZn2, Zn and oxide three-layer antiseptic films on the surfaces of magnesium alloys. Zn film layers are evaporated on the surfaces of the magnesium alloys in a vacuum state; and the magnesium alloys and the zinc films are annealed to generate corrosion-resistance intermetallic compounds on interfaces. Then, the magnesium alloys are selectively oxidized; and part of alloy elements in zinc and the magnesium alloys are dispersed to the surfaces for oxidation to generate oxide films. The intermetallic compounds, the zinc films and the oxide films cover the surfaces of the magnesium alloys at the same time to effectively resist corrosion.

Owner:CHANGZHOU UNIV

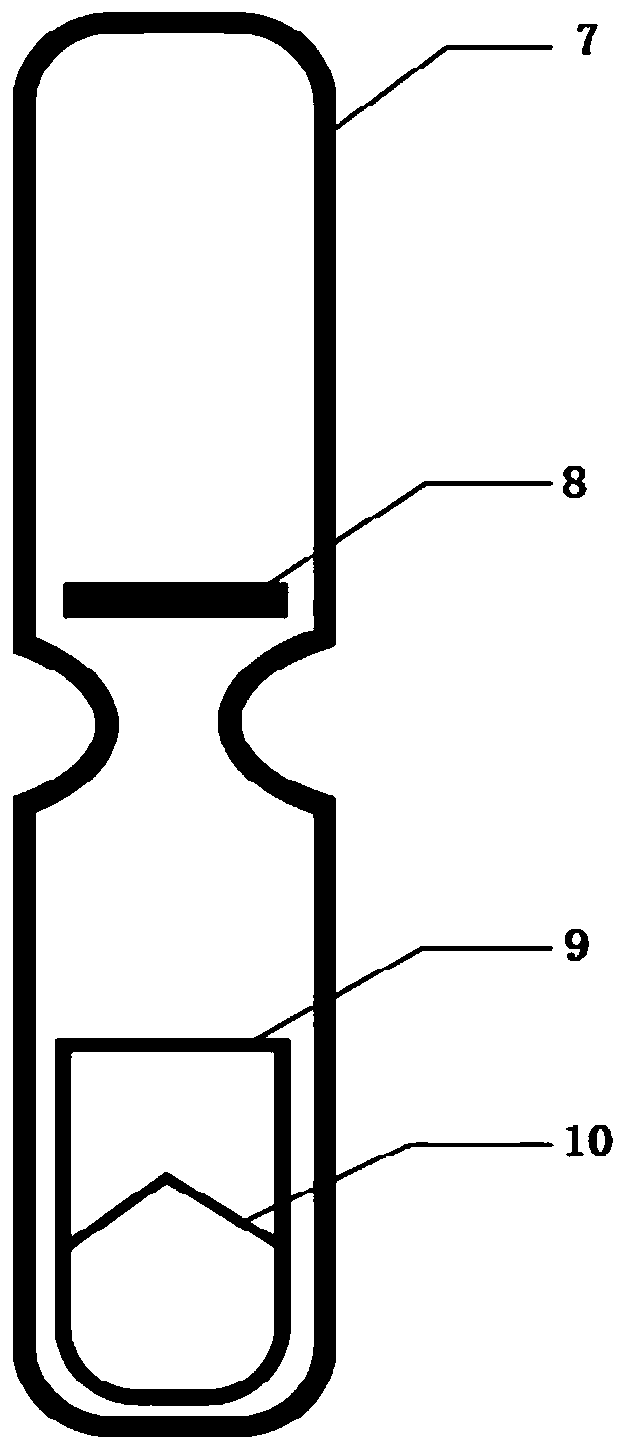

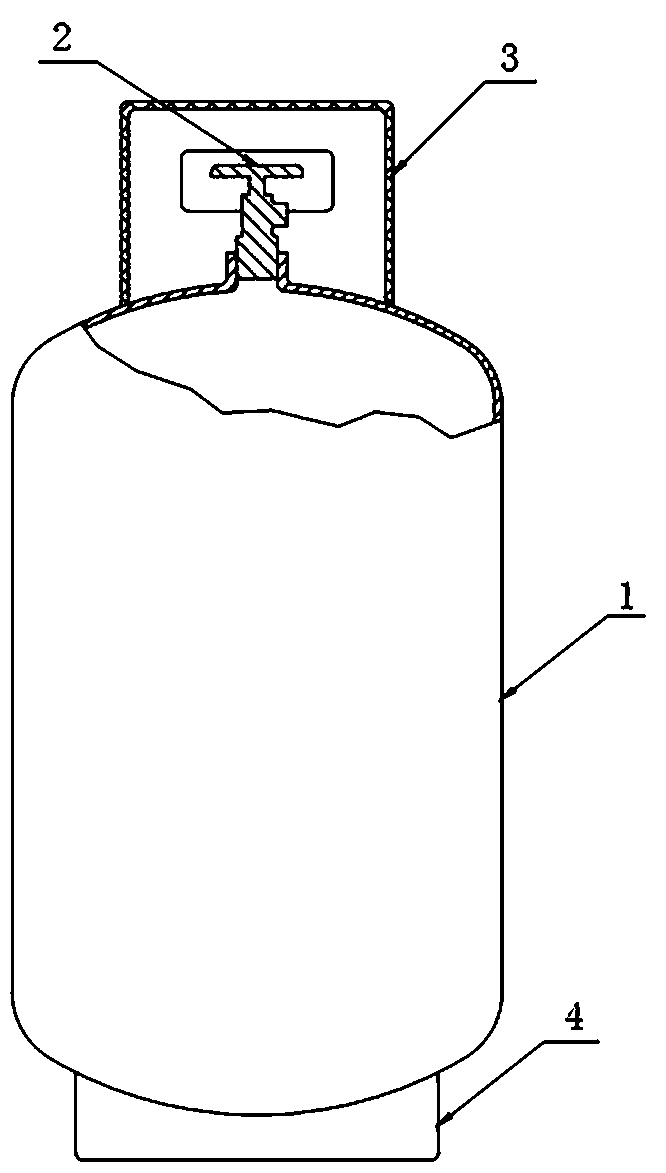

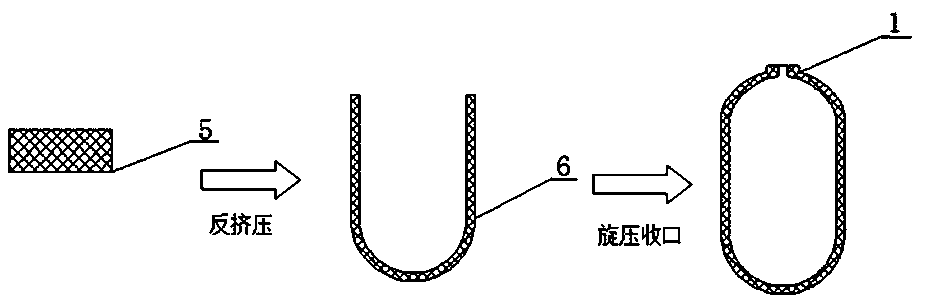

Preparation method of weldless type aluminum alloy liquefied petroleum gas cylinder

InactiveCN108723716AReasonable bottle structure designObvious weight loss effectPressure vesselsAlloy surfaceWork in process

The invention discloses a preparation method of a weldless type aluminum alloy liquefied petroleum gas cylinder. The preparation method comprises the steps of A, blank selection, B, blank extrusion, C, shell nosing on a bottle body rough blank, D, semifinished product assembly and E, finished product property detection. The weldless type aluminum alloy liquefied petroleum gas cylinder with the volume of 4.7-35.5L and the bottle body height of 190-700 mm is prepared, the weldless type aluminum alloy liquefied petroleum gas cylinder prepared by the preparation method is formed by back extrusionand thus is more compact in structure, the structural design of a bottle body is reasonable, and the weldless type aluminum alloy liquefied petroleum gas cylinder is light in weight and safe, energy-saving and environmentally friendly. Compared with a traditional liquefied petroleum gas steel cylinder, the weight reducing effect is significant, and the compression resistance is high; by use of a compact oxidation film formed on an aluminum alloy surface, a preservative effect can be achieved, and the service life is prolonged effectively; the surface does not require to be sprayed, so that theenvironmental protection effect is obvious; and the preparation method has good economic benefits and environmental benefits.

Owner:KUNMING METALLURGY INST

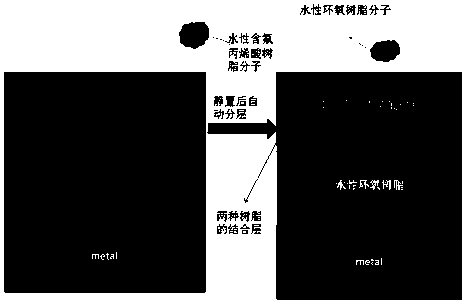

Preparation method of water-based coating integrating corrosion resistance and fireproofing

ActiveCN108373757AAvoid multiple brushingPromote charcoalFireproof paintsAnti-corrosive paintsSurface energyCoating system

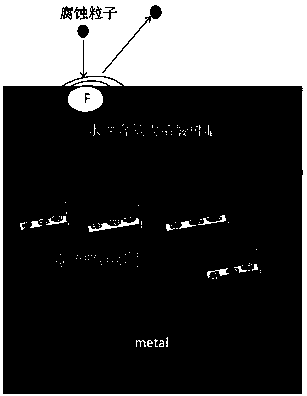

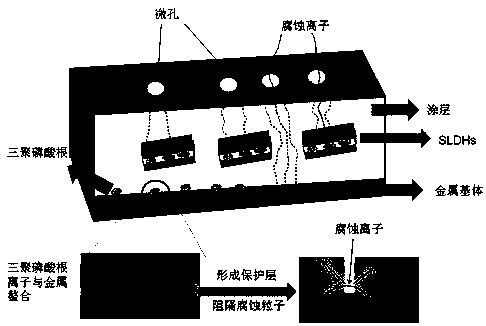

The invention relates to a preparation method of water-based coating integrating corrosion resistance and fireproofing and relates to a preparation method of building coating. The preparation method is characterized in that tripolyphosphate pillared hydrotalcites (SLDHs) is filled with water-based epoxy resin, and then the obtained mixture is physically mixed with fluorine-containing acrylic resinto obtain the water-based coating integrating corrosion resistance and fireproofing. The preparation method has the advantages that the self-stratification technology is used to allow the fluorine-containing acrylic resin with low surface energy to be distributed on the upper layer of the coating to provide corrosion resistance and allow the water-based epoxy resin with good moistening performance to be distributed on the lower layer of the coating, and the tripolyphosphate pillared hydrotalcites filled with the epoxy resin can provide flame retardance and corrosion resistance at the same time; the epoxy resin can solidify the acrylic resin and provide interlayer bonding force; the coating system can achieve both corrosion resistance and fireproofing without repeated coating, coating corrosion resistance destroying caused by the fact that a large amount of flame retardant is added is avoided, and corrosion resistance and fireproofing integration of the coating is achieved.

Owner:辽宁麦琪新材料集团有限公司

Exhaust pipe

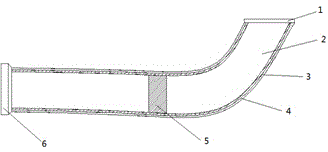

InactiveCN104481660AReduce manufacturing costAvoid burnsExhaust apparatusSilencing apparatusPhysicsExhaust gas

The invention relates to an exhaust pipe which comprises a turned edge, an exhaust pipe body, a heat-dissipating layer, an antioxidation layer, a tail gas filtering device and a connecting piece, wherein the outlet end of the exhaust pipe body is provided with the turned edge bent towards the interior of the exhaust pipe body; the other end of the exhaust pipe body is provided with the connecting piece; the exhaust pipe body is of an integral structure molded once; the tail gas filtering device is positioned in the exhaust pipe body and can purify tail gases; the heat-dissipating layer is positioned at the external surface of the exhaust pipe body and wraps the whole exhaust pipe body; the antioxidation layer is positioned at the outer side of the heat-dissipating layer. Therefore, the problems of low strength and slow cooling are solved.

Owner:CHANGSHU CITY DONGBANG COUNTY XUSHI JIAFENG MACHINERY PLANT

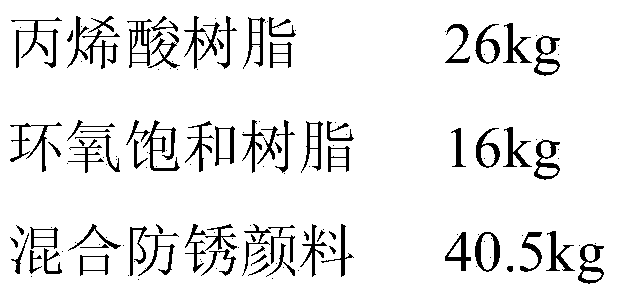

Special anticorrosive coating capable of avoiding rust removal

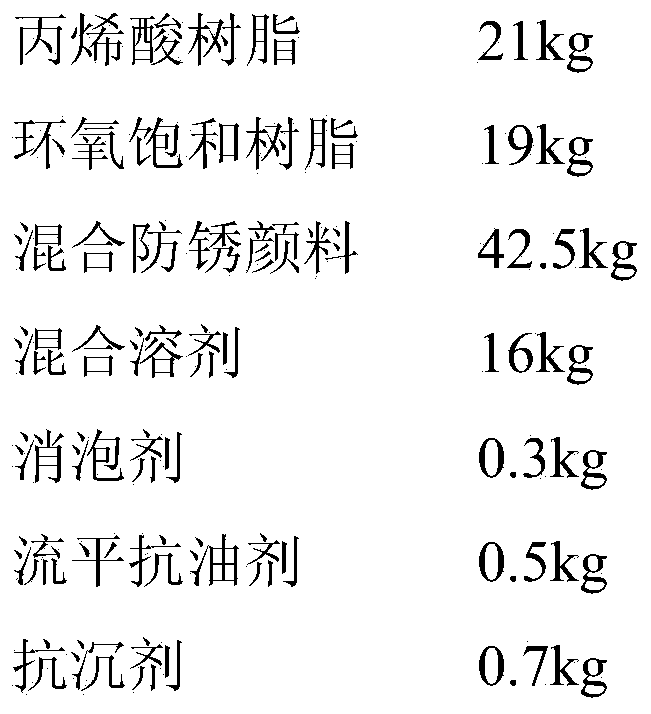

ActiveCN103805010AHigh densityHigh hardnessAnti-corrosive paintsEpoxy resin coatingsAcrylic resinSolvent

The invention discloses a special anticorrosive coating capable of avoiding rust removal. The special anticorrosive coating is prepared by mixing the following components in parts by weight: 15-35 parts of acrylic resin, 10-25 parts of epoxy saturated resin, 35-50 parts of mixed antirust pigment, 0.1-1.0 part of a defoaming agent, 10-20 parts of a mixed solvent, 0.1-1.0 part of a leveling oil resistant agent and 0.1-1.0 part of an anti-coagulating agent, wherein the mixed antirust pigment is prepared by mixing iron oxide red 190, zinc oxide, superfine zinc powder, filling material barium sulfate and zinc yellow powder. The special anticorrosive coating capable of avoiding rust removal provided by the invention has the advantages of high density, good hardness, strong wear resistance, high impact resistance and the like, also can avoid contact of new iron with outside moisture and oxygen absorption of new iron to outside moisture and oxygen, can fundamentally eliminate the phenomenon of secondary rusting, and also has the advantages of convenience in construction, good anticorrosive and antirust effects and the like concurrently.

Owner:YIXING JUREN PAINT

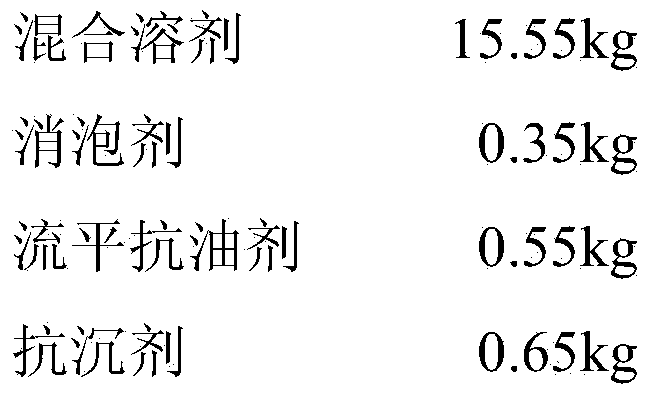

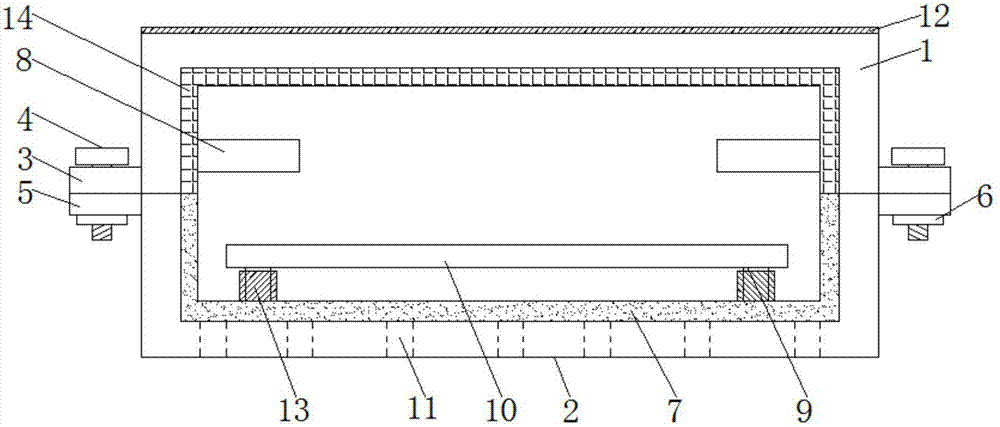

Combined waterproof and anticorrosion cable bridge

InactiveCN107394708AExtended service lifeReduce the burden onElectrical apparatusStructural engineeringCopper

The invention discloses a combined waterproof and anticorrosion cable bridge which comprises a first bridge body and a second bridge body. The first bridge body and the second bridge body form a rectangle, positioning blocks are fixedly connected on two sides of the first bridge body, threaded rods are connected on the positioning blocks in a threaded manner, connecting blocks are fixedly connected on two sides of the second bridge body, nuts are embedded on the connecting blocks and connected with the threaded rods in a threaded manner, a first anticorrosion layer is arranged on the inner wall of the first bridge body, and a water absorption sponge layer is arranged on the second bridge body. According to the combined waterproof and anticorrosion cable bridge, the first bridge body and the second bridge body are improved, anticorrosion effects are achieved under the action of a steel plate layer, a copper plate layer, a second anticorrosion layer, an abrasion-resistant layer, acrylic polyurethane finishing paint and the first anticorrosion layer, and the service life of the cable bridge is prolonged.

Owner:扬州市天海滑线电气有限公司

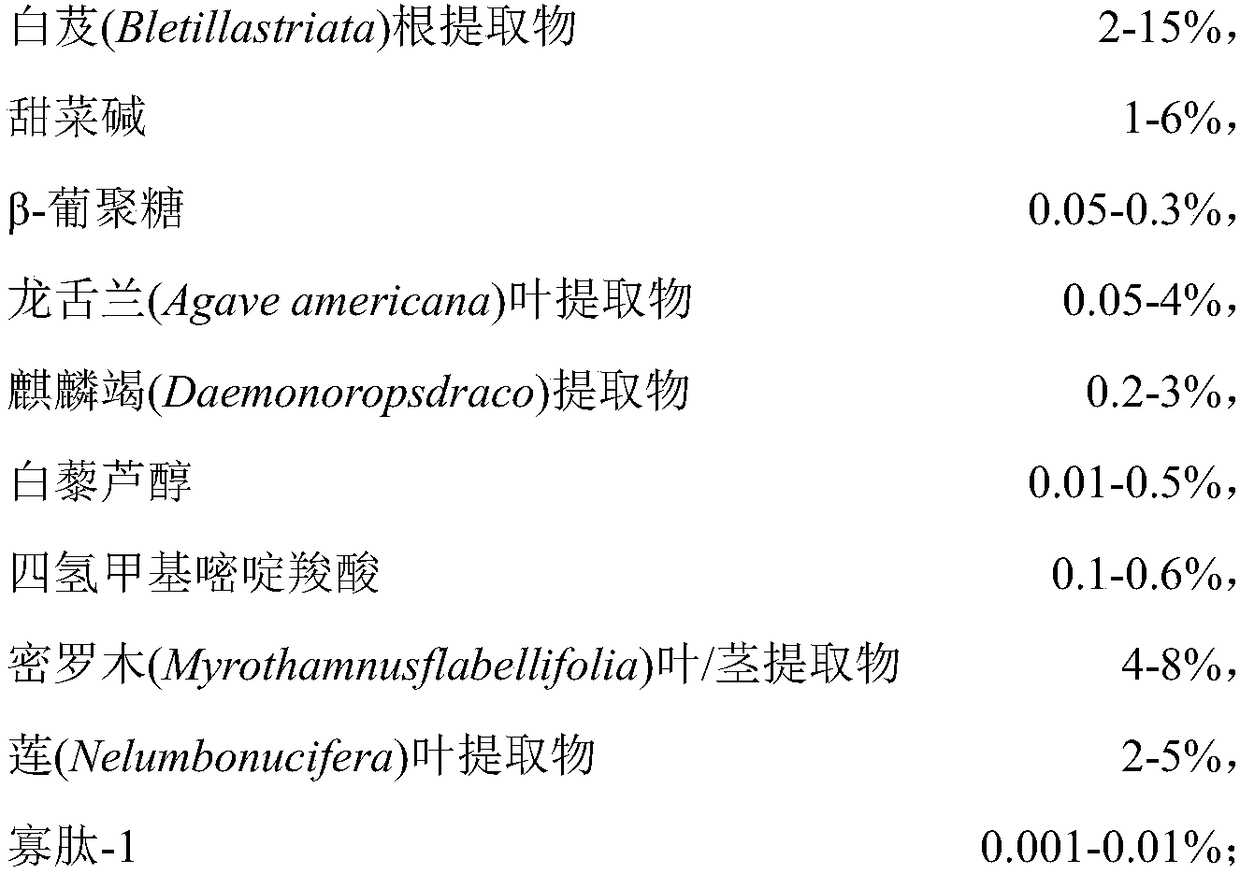

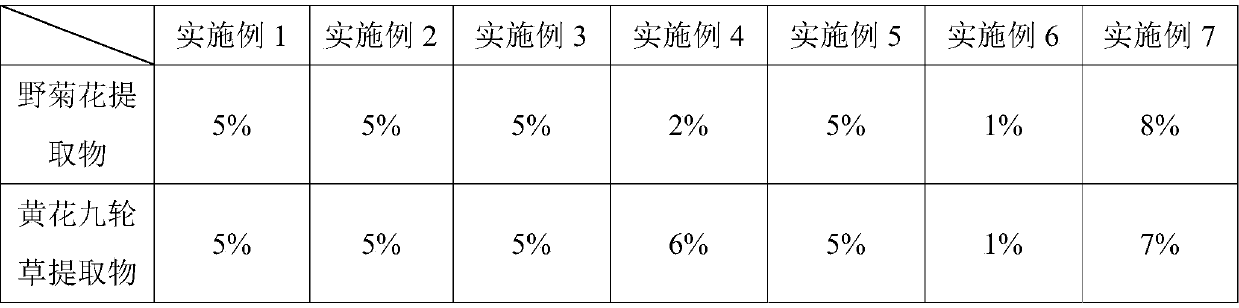

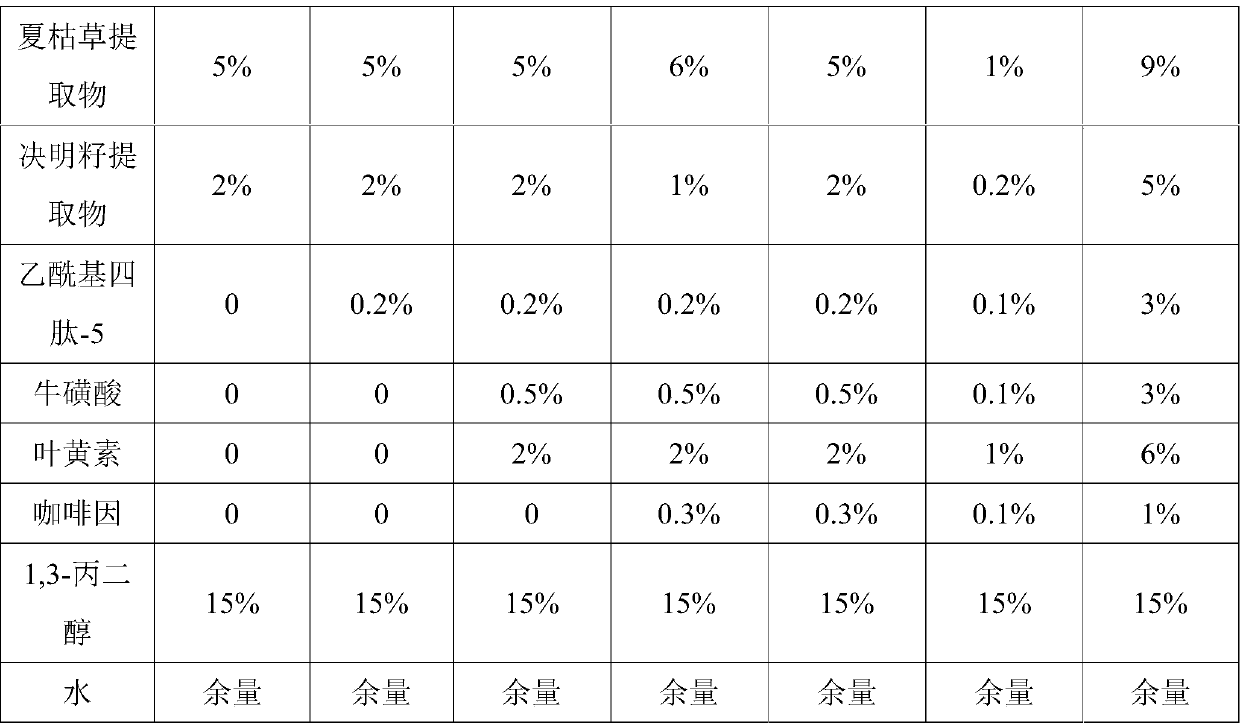

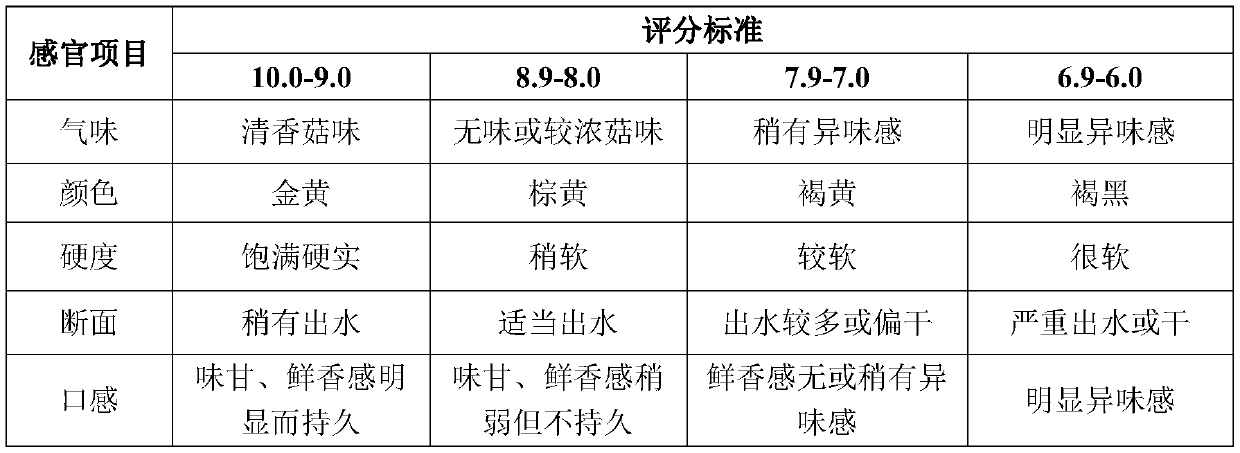

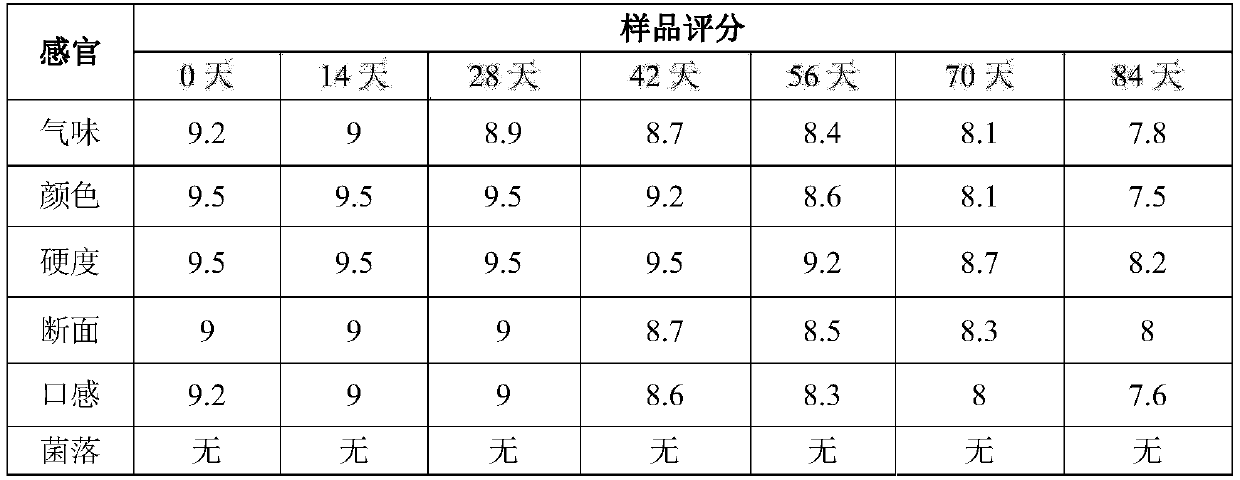

Black eye removing composition, black eye removing eye mask and preparation method of black eye removing eye mask

ActiveCN110179715ANo side effectsGood antibacterial effectCosmetic preparationsToilet preparationsWrinkle skinChrysanthemum Flower

The invention relates to a black eye removing composition, a black eye removing eye mask and a preparation method of the black eye removing eye mask. The black eye removing composition comprises the components as follows: a wild chrysanthemum flower extract, a coslip extract, a selfheal extract and a cassis seed extract. The black eye removing composition can effectively remove black eyes and recover skin vitality and also has a function of relieving thin wrinkles of eyes.

Owner:广州康蓓纳生物科技有限公司

Surface coating technique of powder metallurgical parts

InactiveCN102861915AIncrease stiffnessReduce the number of coatsPretreated surfacesSolid state diffusion coatingMetallurgyCorrosion prevention

The invention provides a surface coating technique of powder metallurgical parts, wherein the method comprises the following steps of: (1) performing gas nitriding, sulfurizing and chromizing treatment on the powder metallurgical parts; (2) polishing the powder metallurgical parts treated in step (1); (3) oxidizing the powder metallurgical parts treated in the step (2); and (4) coating dopes on the powder metallurgical parts treated in the step (3). The surface coating technique provided by the invention reduces the coating times of Dacromet dopes, and the dopes are coated once to achieve a corrosion prevention effect, so that the cost is reduced, and meanwhile, the powder metallurgical parts have excellent rigidity.

Owner:WUXI HUAYUE OPTICAL MIRROR BOX CO LTD

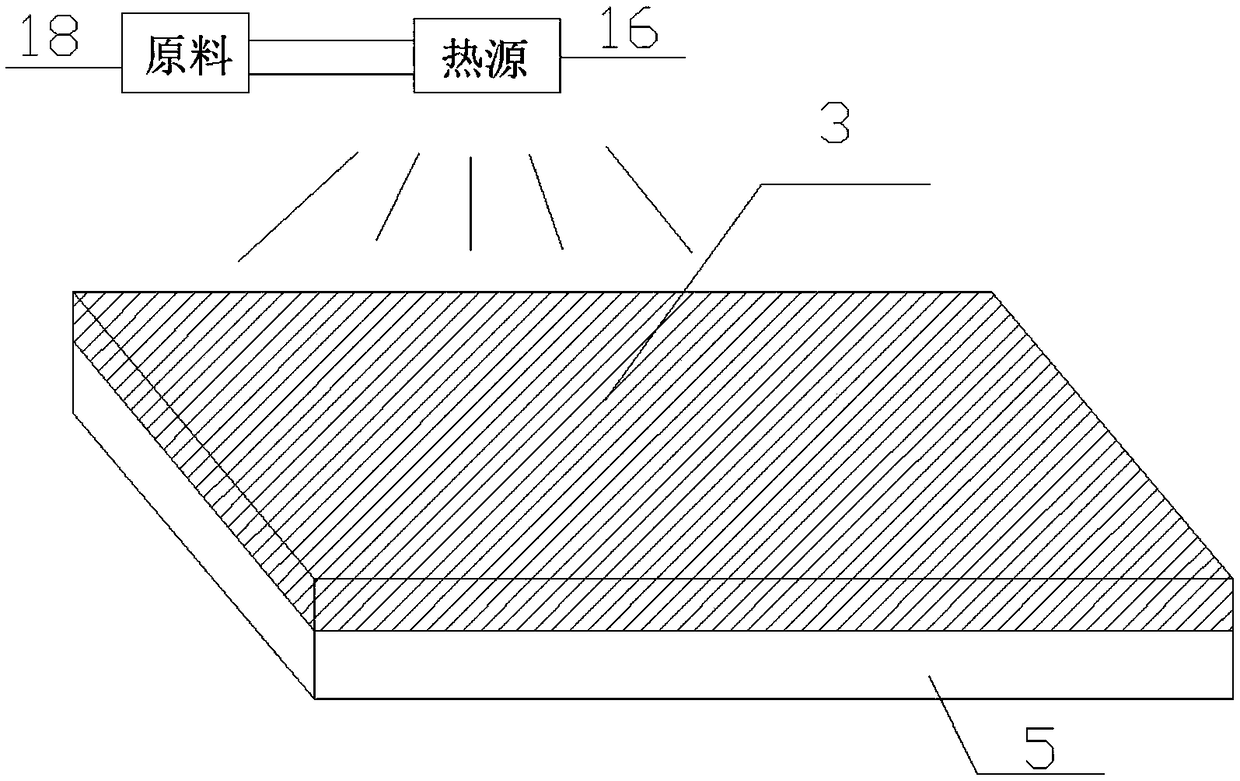

Timber high-temperature treatment method

InactiveCN103753665ATo achieve anti-corrosion effectReduce usageWood treatment detailsChemical treatmentRoom temperature

The invention discloses a timber high-temperature treatment method. The timber high-temperature treatment method comprises the following steps of 1, stacking timbers so that gaps for allowing gas flow passing are formed around each one of the timbers, 2, fixing positions of the stacked timbers to prevent timber displacement caused by gas passing, 3, putting the stacked timbers in saturated steam flows having a temperature of 85-90 DEG C for 14-16h, 4, putting the stacked timbers in dry gas flows having a temperature of 130-135 DEG C for drying, 5, putting the stacked timbers in the saturated steam flows having a temperature of 140-145 DEG C for 2-3h, and 6, putting the stacked timbers in the dry gas flows having a room temperature and carrying out drying and cooling. The timbers treated by the timber high-temperature treatment method have preservative effects the same as that of chemically-treated timbers. The timber high-temperature treatment method is free of chemical products and is conducive to environmental protection.

Owner:常熟市鑫磊木业制造厂

Fresh frozen liquid, fresh-keeping method and application thereof

ActiveCN110122730AInhibition of reproductionGuaranteed freshnessFood preservationFrozen storageWater soluble

The invention relates to the field of fresh-keeping of Chinese medicinal materials, and discloses a fresh frozen liquid, a fresh-keeping method thereof and an application thereof. The fresh frozen liquid comprises water-soluble chitosan, glycerin, trehalose and calcium chloride; the fresh-keeping method comprises the following steps: (1) pre-cooling the fresh frozen liquid under the condition of -1 DEG C to -7 DEG C; (2) placing fresh Cordyceps sinensis in the pre-cooled fresh frozen liquid in step (1) for 5 to 30 minutes; and (3) placing the fresh Cordyceps sinensis after the immersion treatment in step (2) at -1 DEG C to -7 DEG C under refrigeration. The fresh Cordyceps sinensis is treated with the fresh frozen liquid is fresher than that of a direct refrigerator frozen-storage method, and the preservation time is extended by at least 14 days.

Owner:DONGGUAN HEC CORDYCEPS R&D CO LTD +1

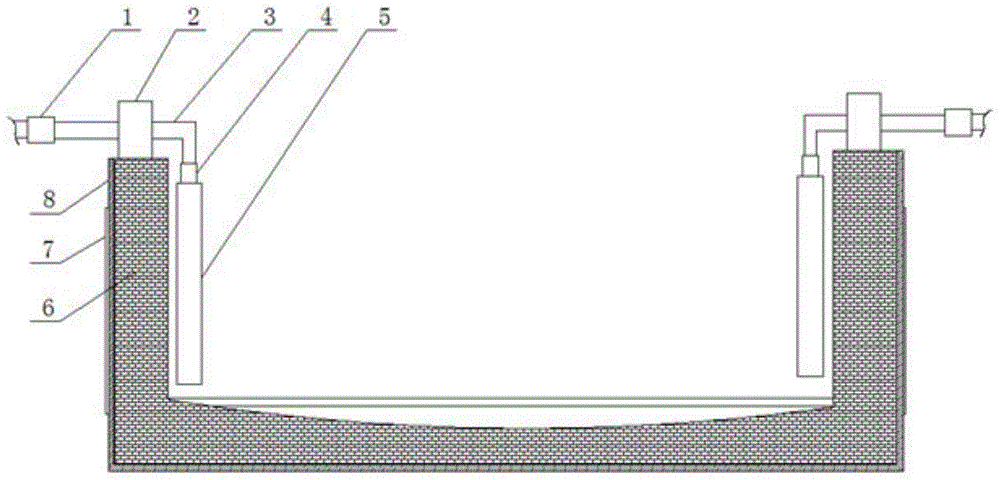

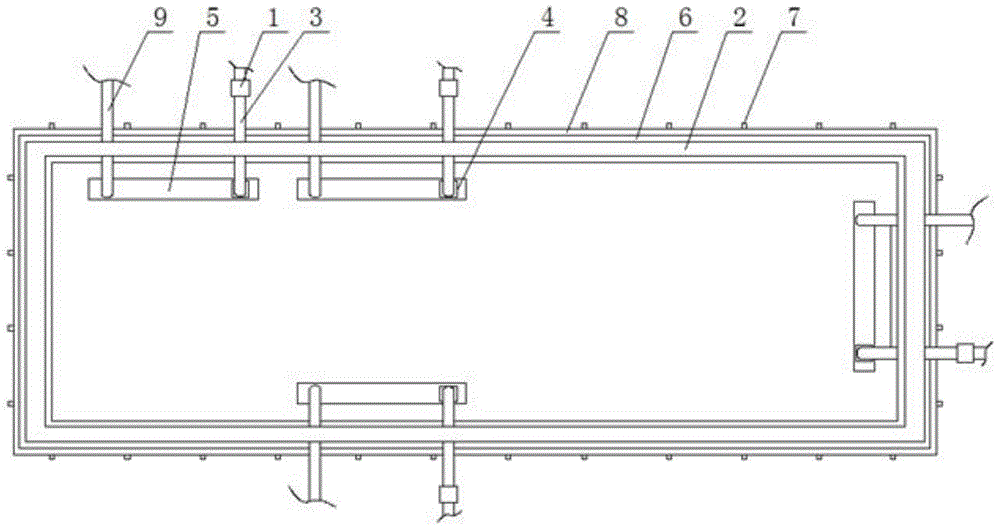

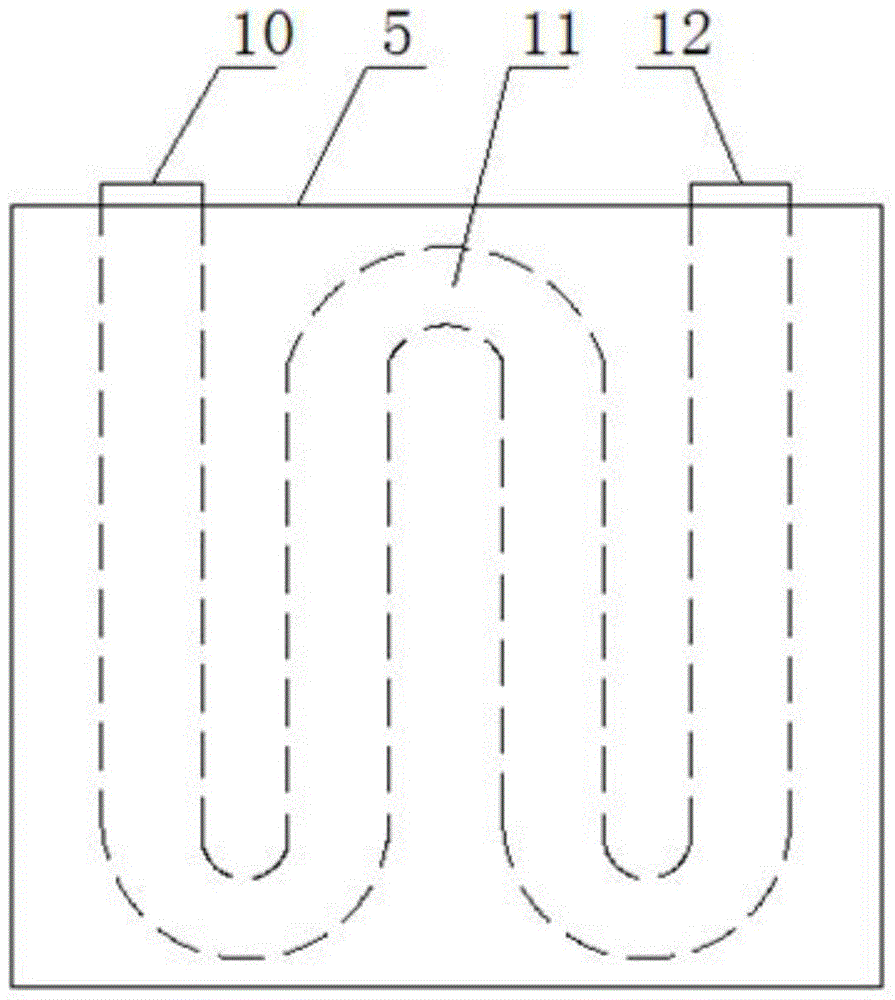

An internal heating galvanized pot

ActiveCN104233145BAvoid direct contactExtended service lifeHot-dipping/immersion processesFlue gasEngineering

The invention relates to an internal-heating galvanized pot which comprises a pot body and a heating mechanism, wherein the pot body is composed of a pot body casing and a pot body inner core, and the pot body casing covers the external part of the pot body inner core; the heating mechanism is arranged on the inner wall of the pot body inner core and composed of a rectangular casing, a corrosion prevention layer, a radiant tube, a flue gas pipeline, a burner, a regulating valve and an exhaust pipeline; the corrosion prevention layer is arranged on the outer surface of the rectangular casing, and the radiant tube is arranged in the rectangular casing; a mounting plate is arranged on the pot body inner core, and the burner is mounted at the inlet of the rectangular casing; the gas inlet end of the burner is connected with the flue gas pipeline penetrating the mounting plate, and the regulating valve is mounted on the flue gas pipeline; the exhaust pipeline communicated with the outlet of the rectangular casing penetrates the mounting plate. The internal-heating galvanized pot has the advantages of long service life, low loss, good zinc melting effect, pollution reduction, high thermal efficiency, galvanization cost reduction and the like and is easy to realize.

Owner:TIANJIN YIRUNDING METAL PROD

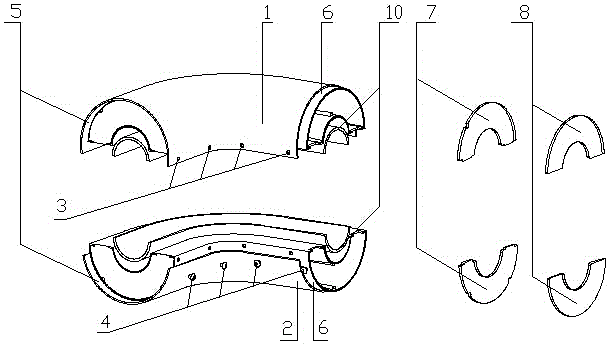

Heat-insulating pipe

InactiveCN104154345AExtend your lifeTo achieve the purpose of insulationThermal insulationPipe protection by thermal insulationEngineeringSingle section

A heat-insulating pipe comprises a straight pipe, an elbow pipe, a three-way pipe and a truncated pipe. Each of the straight pipe, the elbow pipe, the three-way pipe and the truncated pipe is a single-section pipe formed by locking an upper shell and a lower shell which are identical in structure through a locking device, a round covered edge is arranged at one end of each single-section pipe, a round contracting platform is arranged at the other end of each single-section pipe, each of the upper shells and the lower shells is arranged to be of a hollow structure, one ends of the upper shells and the lower shells are open while the other ends of the same are closed, partitions are arranged in the upper shells and the lower shells, support the same and have tension resistance and pressure resistance, heat-insulating materials are arranged in the upper shells and the lower shells, and each locking device comprises clamping holes formed in the corresponding upper shell and clamps arranged on the corresponding lower shell. The heat-insulating pipe is low in manufacturing cost, simple in structure, convenient to mount, good in heat-insulating effect, prolonged in warranty period, free of pollution, environment friendly, energy saving and convenient for popularization.

Owner:吴胜利

Method for forming anticorrosive coating on surfaces of metal parts

InactiveCN109161869AImprove corrosion resistanceImprove thermal shock resistanceMolten spray coatingSpecial surfacesPorosityNonferrous metal

The invention relates to a method for forming an anticorrosive coating on surfaces of metal parts. The anticorrosive coating comprises one or more of a rare nonferrous metal layer, an inorganic oxidelayer and a liquid coating layer, wherein the forming method of the anticorrosive coating is one or more of a chemical vapor deposition method, a dipping method and a hot spray method. The anticorrosive coating is formed on the surfaces of the metal parts, is particularly suitable for corrosion prevention of liquid metal, and can prevent the high temperature liquid metal and a metal base from direct contact, so that the corrosion prevention effect is achieved. The corrosion problem for the base material by the high temperature liquid metal during using is solved, the industrial cost is reduced, the application range of the liquid metal is enlarged, and at the using temperature, the anticorrosive coating has high corrosion resistance for the liquid metal, and has the characteristics of favorable cold and hot impact property, high adhesive force and low porosity factor.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Method for producing micro-ecological organic health fruit vinegar beverage by adopting micro-ecological fermentation technology

InactiveCN102058122ATo achieve anti-corrosion effectVinegar preparationFood preparationYeastFruit juice

The invention discloses a method for producing a micro-ecological organic health fruit vinegar beverage by adopting a micro-ecological fermentation technology. In the method, the micro-ecological organic health fruit vinegar beverage is produced by using a micro-ecological health oral liquid production technologywith organic fruit juice as culture medium, and is produced from the organic fruit juice, water, bacterial powder (liquid) and Chinese herbal medicines. The invention also discloses a preparation method of the micro-ecological organic health fruit vinegar beverage prepared from yeast, lactobacillus, lactococcus lactis, the organic fruit juice and Chinese herbal medicine culture medium. Because the method is simple and has low cost, the production cost is reduced, the health effects of the micro-ecological health oral liquid can be reached with the cost of the beverage, and different from the micro-ecological health oral liquid, the micro-ecological organic health fruit vinegar beverage has low cost and good taste.

Owner:曹业明

Production equipment for composite smooth aluminum sleeve multilayer co-extrusion cable

ActiveCN111292904AReduce manufacturing costUniform electric field distributionInsulated cablesCoatingsHot meltElectric cables

The invention discloses production equipment for a composite smooth aluminum sleeve multi-layer co-extrusion cable. The production equipment comprises an aluminum strip coating device, an aluminum strip welding device, an aluminum sleeve drawing device, a multi-layer co-extrusion device and a cooling water tank. The aluminum strip coating device is used for coating an aluminum strip outside a cable core; and the aluminum strip welding device is used for welding the aluminum strip and forming an aluminum sleeve. The multi-layer co-extrusion device comprises a multi-layer co-extrusion machine head, a hot melt adhesive extruder, an outer sheath extruder and an outer conductive layer extruder, wherein the hot melt adhesive extruder, the outer sheath extruder and the outer conductive layer extruder extrude hot melt adhesives, outer sheath melts and outer conductive layer melts and convey the hot melt adhesives, the outer sheath melts and the outer conductive layer melts to the multi-layer co-extrusion machine head respectively; and the multi-layer co-extrusion machine head composites the aluminum sleeve, the hot melt adhesives, an outer sheath and an outer conductive layer together andperforms cooling molding through a cooling water tank. The three-layer co-extrusion technology is adopted, the extruded hot melt adhesive is uniform in thickness, the smooth aluminum sleeve, the outersheath and the conductive layer are tightly integrated, and the cable quality is ensured.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com